A Comprehensive Comparison of Spectroscopic Techniques for Heavy Metal Detection in Biomedical Research

This article provides a systematic evaluation of spectroscopic techniques for heavy metal detection, addressing critical needs for pharmaceutical and clinical researchers.

A Comprehensive Comparison of Spectroscopic Techniques for Heavy Metal Detection in Biomedical Research

Abstract

This article provides a systematic evaluation of spectroscopic techniques for heavy metal detection, addressing critical needs for pharmaceutical and clinical researchers. We explore fundamental principles of major techniques including AAS, ICP-OES, ICP-MS, and emerging methods, with specific application guidance for drug development compliance. The content covers methodological optimization strategies, troubleshooting for common interference challenges, and rigorous validation protocols. By presenting comparative performance data and selection criteria tailored to pharmaceutical impurity testing, this review serves as an essential resource for professionals making informed analytical decisions in regulated environments.

Understanding Spectroscopic Fundamentals: Principles and Techniques for Heavy Metal Analysis

The Critical Need for Heavy Metal Detection in Pharmaceutical and Clinical Settings

In pharmaceutical and clinical settings, the accurate detection of heavy metals is not merely an analytical procedure but a fundamental requirement for ensuring patient safety and product quality. Heavy metals such as lead (Pb), mercury (Hg), cadmium (Cd), and arsenic (As) pose significant health risks even at trace concentrations, potentially causing neurological damage, renal dysfunction, and other serious health complications [1]. The presence of these contaminants in pharmaceutical products can originate from raw materials, manufacturing processes, or environmental sources, making rigorous testing an indispensable component of quality control and regulatory compliance [2]. This guide provides an objective comparison of current analytical techniques, evaluating their performance characteristics, applications, and limitations to inform method selection for researchers and drug development professionals.

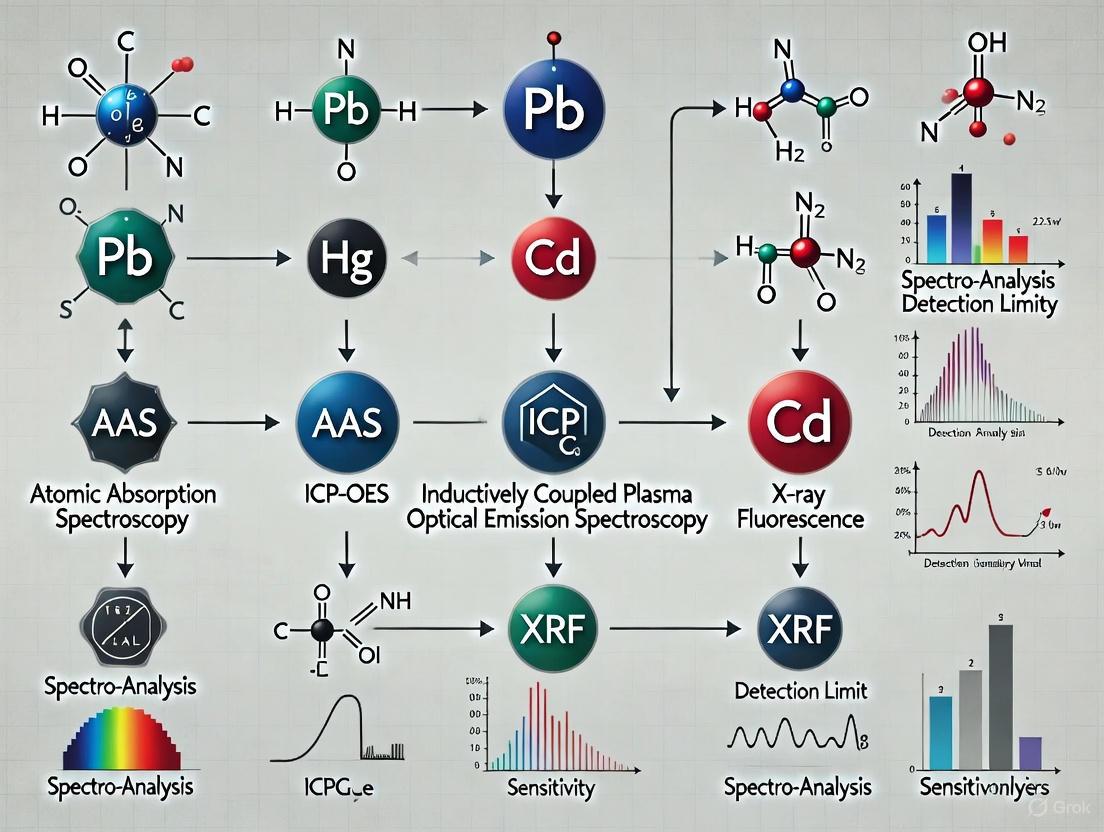

Comparative Analysis of Spectroscopic Techniques

The selection of an appropriate analytical technique depends on multiple factors including detection limits, sample throughput, operational complexity, and cost. The following sections and comparative tables provide a detailed evaluation of predominant methods.

Established Core Techniques

Table 1: Performance Comparison of Primary Detection Techniques

| Technique | Detection Limits | Multi-Element Capability | Sample Throughput | Operational Complexity | Best Use Cases |

|---|---|---|---|---|---|

| ICP-MS | Parts per trillion (ppt) [3] | Simultaneous multi-element [3] | High [3] | High; requires skilled operators [3] | Ultra-trace analysis, regulatory compliance for toxic elements [2] [3] |

| ICP-OES | Parts per billion (ppb) [4] | Simultaneous multi-element [5] | High [3] | Moderate to High [3] | Determination of major, minor, and trace elements except chlorine [5] |

| AAS | Parts per million (ppm) [3] | Single-element [3] | Low [3] | Low; straightforward operation [3] | Routine analysis of simple matrices, cost-sensitive labs [3] |

| TXRF | Information not in search results | Provides information on most elements except light elements (P, S, Cl) [5] | Information not in search results | Information not in search results | Rapid, non-destructive determination of light elements at high concentrations [5] |

| EDXRF | Information not in search results | Suited for light elements (S, Cl, K, Ca) [5] | Rapid [5] | Non-destructive; minimal sample prep [6] | Non-destructive analysis of light elements at relatively high concentrations [5] [6] |

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is recognized for its exceptional sensitivity, capable of detecting metal concentrations in the parts per trillion (ppt) range, making it the gold standard for applications requiring ultra-trace analysis [3]. Its ability to simultaneously measure dozens of elements from a single sample and handle complex matrices is invaluable for comprehensive impurity profiling in pharmaceuticals [3]. However, this technique involves high initial investment, significant operational costs, and requires skilled personnel, which can be a constraint for some laboratories [3].

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES / ICP-AES) offers robust multi-element capability with detection limits in the parts per billion (ppb) range, bridging the gap between sensitivity and operational practicality [4]. It is highly effective for the determination of major, minor, and trace elements, though it is not suitable for chlorine detection [5]. While less sensitive than ICP-MS, its broader dynamic range and relatively lower operational complexity make it a workhorse for many quality control laboratories.

Atomic Absorption Spectroscopy (AAS) remains a widely used technique, particularly in laboratories with lower sample volumes or budget constraints [3]. It provides good sensitivity for many metals at parts per million (ppm) levels and is well-suited for simple matrices like purified water or standard pharmaceutical formulations [3]. Its primary limitations are single-element analysis, which reduces throughput for multi-analyte panels, and a narrower analytical range compared to ICP techniques [3].

Emerging and Complementary Techniques

Table 2: Comparison of Emerging and Specialized Techniques

| Technique | Key Feature | Application in Pharmaceutical/Clinical Context |

|---|---|---|

| Laser-Induced Plasma Spectroscopy (LIPS) | Calibration-free analysis, minimal sample prep, on-site potential [4] | Rapid screening of solid samples, spatial contamination mapping [4] |

| Electrochemical Sensors | Portable, low-cost, real-time analysis [7] | Point-of-care testing, decentralized water quality monitoring [7] |

| FTIR Spectroscopy | Identifies functional groups and metal-binding interactions [8] | Probing molecular mechanisms of metal-binding in biological systems [8] |

| Quantum Dots (QDs) | High photoluminescence, sensitivity to environmental changes [9] | Fluorescent sensing platforms for multiplexed heavy metal detection [9] |

Laser-Induced Plasma Spectroscopy (LIPS), particularly with picosecond pulses (Ps-LIPS), enables calibration-free quantification of heavy metals in solid samples with minimal preparation, offering a pathway for rapid, on-site analysis [4]. This methodology is groundbreaking for its ability to provide spatial contamination gradients, which is valuable for investigating heterogeneous samples [4].

Electrochemical Sensors, especially when integrated with IoT and deep learning algorithms, represent a growing field for decentralized testing. These sensors, such as those using gold nanoparticle-modified electrodes, can simultaneously detect multiple heavy metals like Cd²âº, Pb²âº, Cu²âº, and Hg²⺠in water samples with low detection limits (µM range) [7]. The integration of convolutional neural networks (CNN) enhances the interpretation of complex signals, improving classification accuracy for metal ion types and concentrations [7].

Fourier Transform Infrared (FTIR) Spectroscopy does not directly quantify metal concentrations but is a powerful tool for identifying functional groups involved in metal binding and understanding metal-induced biochemical alterations [8]. This provides critical insights into contamination mechanisms and toxicity profiles, often in conjunction with quantitative techniques like AAS or ICP-MS [8].

Detailed Experimental Protocols

To ensure reproducibility and provide clear methodological insights, detailed protocols for two distinct approaches are outlined below.

Protocol: ICP-MS for Multi-Element Trace Analysis

This protocol is adapted for the determination of elemental impurities in pharmaceutical-grade water.

1. Sample Preparation:

- Acquire appropriate Certified Reference Materials (CRMs) for calibration and quality control [5].

- If analyzing solid samples (e.g., plant tissues, clinical specimens), a digestion step is mandatory. Typically, 0.5 g of sample is digested with 5-10 mL of high-purity nitric acid using a microwave digestion system [10].

- After digestion, dilute the sample to a final volume with ultrapure water, ensuring the acid concentration is compatible with the ICP-MS instrument (usually 1-2% v/v nitric acid) [10].

2. Instrument Calibration and Operation:

- Calibrate the ICP-MS using a series of multi-element standard solutions prepared in the same acid matrix as the samples.

- Internal standards (e.g., Indium [In], Germanium [Ge], Rhodium [Rh]) should be added online to all samples, standards, and blanks to correct for instrumental drift and matrix effects.

- Instrument Parameters: Set the RF power, plasma gas flow, nebulizer flow, and ion lens voltages according to the manufacturer's specifications for the target elements. Data is acquired in a multi-element method, monitoring specific isotopes for each heavy metal (e.g., Pb²â°â¸, Cd¹¹¹, Asâ·âµ).

3. Data Analysis:

- Quantify elemental concentrations based on the calibration curve.

- Verify method accuracy by analyzing the CRM and ensuring recovered values fall within the certified range [5].

Protocol: Fabrication of an AuNP-Modified Electrochemical Sensor

This protocol details the creation of a low-cost sensor for multiplexed heavy metal sensing in water [7].

1. Electrode Fabrication:

- Use a discarded plastic bottle as the substrate for a three-electrode system.

- Attach a carbon thread as the working electrode, a platinum wire as the counter electrode, and a silver/silver chloride (Ag/AgCl) wire as the reference electrode.

2. Electrode Modification:

- Electrochemically deposit gold nanoparticles (AuNPs) on the surface of the carbon thread working electrode by performing electrodeposition in a solution of chloroauric acid (HAuClâ‚„).

- Characterize the modified electrode using Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDX) to confirm the presence and distribution of spherical AuNP structures [7].

3. Heavy Metal Detection via Differential Pulse Voltammetry (DPV):

- Prepare standard solutions of Cd²âº, Pb²âº, Cu²âº, and Hg²⺠in an HCl-KCl buffer solution (pH 2) across a concentration range of 1–100 µM.

- Perform DPV with the fabricated sensor using a voltage range of -1 V to +1 V, a scan rate of 15 mV/s, a pulse amplitude of 90 mV, and a pulse time of 25 ms.

- The peak potentials for each metal will appear at approximately -0.85 V (Cd), -0.60 V (Pb), -0.20 V (Cu), and +0.20 V (Hg). The peak current is proportional to the metal concentration [7].

4. Data Processing with Deep Learning:

- Process the complex DPV signals using a pre-trained Convolutional Neural Network (CNN) model to classify the type and concentration of heavy metal ions, enhancing the accuracy of quantification [7].

Workflow and Pathway Visualizations

ICP-MS Analysis Workflow

Sensor Development and Deployment

Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for Heavy Metal Analysis

| Item | Function | Example Application |

|---|---|---|

| Certified Reference Materials (CRMs) | Method validation and quality assurance; ensures analytical accuracy [5]. | Used to assess the performance of ICP-MS, ICP-OES, and AAS methods [5]. |

| High-Purity Acids & Reagents | Sample digestion and dilution; minimizes background contamination. | Nitric acid for digesting organic matrices (e.g., plant tissues, clinical samples) [10]. |

| Multi-Element Standard Solutions | Instrument calibration for quantitative analysis. | Preparing calibration curves for ICP-OES/ICP-MS and AAS. |

| Hollow Cathode Lamps | Element-specific light source for AAS. | Required for detecting specific metals like Pb, Cd, or Hg using AAS [3]. |

| Functionalized Nanomaterials | Enhance sensitivity and selectivity of sensors. | Gold nanoparticles (AuNPs) for modifying electrochemical electrodes [7]. Quantum Dots (QDs) for fluorescent-based detection [9]. |

| Buffer Solutions | Control pH during analysis to optimize detection. | HCl-KCl buffer (pH 2) for electrochemical sensing using DPV [7]. |

The landscape of heavy metal detection in pharmaceutical and clinical environments is diverse, encompassing both well-established spectroscopic methods and promising emerging technologies. The choice between techniques like ICP-MS, ICP-OES, and AAS involves a careful balance of sensitivity, throughput, and cost. Meanwhile, advancements in electrochemical sensors, LIPS, and FTIR are continuously expanding the toolbox available to scientists, enabling faster, cheaper, and more specialized analyses. As regulatory standards tighten and the need for on-site monitoring grows, the integration of these advanced technologies with data science approaches like machine learning and IoT will play a pivotal role in safeguarding public health by ensuring the purity and safety of pharmaceutical products and clinical environments.

Atomic spectroscopy stands as a cornerstone analytical technique for the detection and quantification of heavy metals, playing a critical role in ensuring public health, environmental protection, and pharmaceutical safety. These techniques operate on the fundamental principle that atoms of metallic elements can absorb or emit light at specific characteristic wavelengths when energy is applied, allowing for precise identification and measurement. In the context of a broader thesis comparing spectroscopic techniques for heavy metal detection, this guide provides an objective analysis of the core principles, performance, and experimental protocols of key atomic spectroscopy methods. The global heavy metal testing market, which relies heavily on these techniques, is projected to grow from $4.0 billion in 2024 to $7.4 billion by 2034, driven by increasing regulatory scrutiny and technological advancements [11]. This growth underscores the importance of understanding the operational principles and comparative strengths of these indispensable analytical tools.

Core Principles of Atomic Spectroscopy

Fundamental Physical Processes

Atomic spectroscopy techniques share a common foundational process: the conversion of a sample from its natural state into free atoms (atomization), followed by the measurement of how these atoms interact with electromagnetic radiation. The process begins when a sample solution is introduced into the instrument and converted into an aerosol. This aerosol is then transported into the source region where high thermal energy (from a flame, graphite furnace, or plasma) desolvates, vaporizes, and atomizes the sample, breaking molecular bonds to create a cloud of free ground-state atoms. These ground-state atoms can then absorb light at characteristic wavelengths (Atomic Absorption Spectroscopy - AAS) or become excited to higher energy levels and subsequently emit light upon returning to lower energy states (Atomic Emission Spectroscopy - AES) [12].

The wavelength of the absorbed or emitted light is specific to each element, serving as a qualitative fingerprint, while the intensity of the absorption or emission is directly proportional to the concentration of the element in the sample, enabling quantitative analysis. The precise measurement of these interactions forms the basis for all atomic spectroscopy techniques, though the methods for atomization and signal detection vary significantly between different instrumental approaches.

From Atomization to Detection: A Unified Workflow

The following diagram illustrates the generalized workflow common to most atomic spectroscopy techniques, from sample introduction through to signal detection and data interpretation.

Key Atomic Spectroscopy Techniques

Atomic Absorption Spectroscopy (AAS)

Atomic Absorption Spectroscopy operates on the principle that ground-state atoms can absorb light of specific wavelengths corresponding to electronic transitions. A hollow cathode lamp made of the element to be analyzed provides the characteristic wavelength light, which passes through the atomized sample. The amount of light absorbed is measured by a detector and is proportional to the concentration of the element in the sample [12]. AAS is particularly valued for its significant accuracy, greater sensitivity and detection limits, as well as relatively short duration for analysis [13]. The technique typically uses either a flame or graphite furnace for atomization, with graphite furnace AAS offering lower detection limits due to more efficient atomization and longer residence time of atoms in the light path.

Inductively Coupled Plasma Techniques

Inductively Coupled Plasma (ICP) serves as a high-temperature atomization and excitation source that can be coupled with different detection systems:

ICP-Optical Emission Spectroscopy (ICP-OES): Uses a plasma (approximately 6000-10000 K) to excite atoms, which then emit light at characteristic wavelengths as they return to lower energy states. The intensity of the emitted light is measured for quantification [12]. ICP-OES can detect multiple elements simultaneously and offers a wide linear dynamic range.

ICP-Mass Spectrometry (ICP-MS): The plasma serves to generate ions rather than excited atoms. These ions are then separated and quantified based on their mass-to-charge ratio using a mass spectrometer. ICP-MS offers exceptional sensitivity, allowing for detection of metals at extremely low concentrations, ranging from sub part per billion (ppb) to sub part per trillion (ppt) for most elements [14]. It has become a preferred method in clinical laboratories for heavy metal analysis due to its low detection limit and ability to detect multiple elements simultaneously [15].

Comparative Performance Analysis

Technical Specifications and Performance Metrics

The following table provides a systematic comparison of key performance characteristics for major atomic spectroscopy techniques used in heavy metal detection:

| Parameter | AAS | ICP-OES | ICP-MS |

|---|---|---|---|

| Detection Limits | ppm to ppb range | ppb range | ppt to ppb range [14] |

| Multi-element Capability | Limited (typically single element) | Excellent | Excellent [15] |

| Sample Throughput | Moderate | High | High |

| Linear Dynamic Range | 2-3 orders of magnitude | 4-6 orders of magnitude | 7-9 orders of magnitude |

| Precision | 0.1-1% RSD | 0.2-2% RSD | 1-3% RSD |

| Capital Cost | Low | Moderate | High |

| Operational Cost | Low | Moderate | High |

| Interference Effects | Significant chemical & spectral | Moderate spectral | Minimal, but polyatomic interferences possible |

| Sample Consumption | Moderate | Low | Very low |

Experimental Validation Data

A 2019 study validating AAS for heavy metal analysis in river sediments demonstrates typical experimental protocols and performance characteristics. Researchers used an aqua regia extraction procedure (3:1 HCl/HNO3) to digest sediment samples, which were then analyzed using a Perkin Elmer AAS Model Optima 8300 [13]. The method successfully determined 12 metals of interest (Al, Mn, Ca, Cd, Cu, Fe, Cr, Ni, Co, Zn, and Pb) with appropriate accuracy and precision, confirmed through analysis of Certified Reference Material (CRM) Number 142Q (sewage sludge amended soil) [13].

For ICP-MS, experimental protocols typically involve sample dilution with acidified solutions and the use of internal standards (e.g., Indium, Germanium) to correct for matrix effects and instrument drift. In clinical settings for heavy metal testing, blood samples must be collected using specialized "trace element free" vials with royal blue caps, while lead testing requires tan top, lead-free tubes [15]. Proper sample handling is critical as metal concentrations are normally in the nano and microgram range, requiring careful consideration to prevent contamination [15].

Experimental Protocols and Methodologies

Sample Preparation Workflow

Proper sample preparation is critical across all atomic spectroscopy techniques to avoid interferences and ensure accurate results. The following diagram illustrates a generalized sample preparation workflow for heavy metal analysis in different matrices:

Specific preparation methods vary by sample type:

- Sediment/Soil Samples: Typically involve aqua regia digestion (3:1 HCl/HNO3) at approximately 80°C for 2 hours, followed by filtration and dilution to volume with 1% v/v HNO3 [13].

- Biological Samples (blood, urine): Often require direct dilution with dilute nitric acid or tetramethylammonium hydroxide, though some applications may need complete digestion with nitric acid and hydrogen peroxide [15].

- Water Samples: May be analyzed directly after acidification, though preconcentration might be necessary for ultratrace analysis.

The Scientist's Toolkit: Essential Research Reagents

| Reagent/Material | Function | Application Examples |

|---|---|---|

| Aqua Regia (3:1 HCl/HNO3) | Digest organic matrices and dissolve heavy metals | Sediment, soil, and biological sample preparation [13] |

| Trace Metal-Free Vials | Prevent sample contamination during collection and storage | Blood collection (royal blue top), urine collection [15] |

| Certified Reference Materials | Method validation and quality control | Verification of analytical accuracy [13] |

| Hollow Cathode Lamps | Source of element-specific wavelengths | AAS analysis [13] |

| Internal Standards | Correction for matrix effects and instrument drift | ICP-MS analysis (e.g., Sc, Y, In, Bi) |

| High-Purity Acids & Water | Minimize background contamination | Sample dilution and preparation for all techniques |

| 12,14-Dichlorodehydroabietic acid | 12,14-Dichlorodehydroabietic acid, CAS:65281-77-8, MF:C20H26Cl2O2, MW:369.3 g/mol | Chemical Reagent |

| Sulfogaiacol | Sulfogaiacol, CAS:7134-11-4, MF:C7H8O5S, MW:204.20 g/mol | Chemical Reagent |

Emerging Innovations and Future Directions

The field of atomic spectroscopy continues to evolve with several emerging trends. There is a growing shift towards portable testing devices that enable real-time analysis in field applications such as water and soil testing [16]. The integration of artificial intelligence and machine learning with spectroscopic data is enhancing efficiency and accuracy, with algorithms like random forest and support vector machines being applied to improve detection limits and handle complex spectral interferences [14] [17].

Additionally, nover detection techniques such as femtosecond Laser-Induced Breakdown Spectroscopy (fs-LIBS) are showing promise for environmental monitoring, with demonstrated detection limits as low as 0.0179 μg/mL for Chromium and 0.1301 μg/mL for Lead in flowing aqueous solutions [18]. These innovations are expanding the applications of atomic spectroscopy while addressing traditional limitations related to cost, complexity, and field deployment.

Atomic spectroscopy techniques remain indispensable tools for heavy metal detection across environmental, clinical, and pharmaceutical applications. While AAS provides a robust and cost-effective solution for routine single-element analysis, ICP-based techniques offer superior sensitivity, multi-element capability, and wider dynamic ranges. The choice of technique depends on specific application requirements, including detection limits needed, sample throughput, budget constraints, and expertise available. As technological advancements continue to enhance the capabilities and accessibility of these techniques, atomic spectroscopy will maintain its critical role in safeguarding public health and environmental quality through precise heavy metal monitoring.

The accurate detection and quantification of heavy metals is a critical requirement across diverse scientific fields, including environmental monitoring, pharmaceutical quality control, and biomedical research. Atomic Absorption Spectrometry (AAS), Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), and X-ray Fluorescence (XRF) Spectroscopy represent four principal analytical techniques for elemental analysis [6] [19]. Each method possesses distinct operational principles, advantages, and limitations, making them uniquely suited for specific applications and concentration ranges. This guide provides an objective, data-driven comparison of these techniques, framing their performance within the context of heavy metal detection research. By synthesizing experimental data and comparative studies, we aim to equip researchers, scientists, and drug development professionals with the information necessary to select the most appropriate analytical tool for their specific needs.

Atomic Absorption Spectrometry (AAS)

AAS is a well-established technique that quantifies elements by measuring the absorption of specific wavelengths of light by free ground-state atoms in a sample. The sample is typically atomized in a flame or graphite furnace. The instrument measures the amount of light absorbed at a characteristic wavelength for the target element, which is directly proportional to the concentration of that element in the sample. A primary limitation is its sequential nature, typically analyzing only one element at a time, which can hinder comprehensive multi-elemental analysis [20].

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

ICP-OES utilizes a high-temperature argon plasma (approximately 6,000–10,000 K) to atomize and excite elemental species in a sample. The excited atoms or ions emit light at characteristic wavelengths as they return to lower energy states. The intensity of this emitted light is measured and correlated to the element's concentration. ICP-OES allows for simultaneous or rapid sequential multi-element analysis and offers a broader dynamic range and better tolerance for complex sample matrices compared to AAS [21] [20].

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

ICP-MS also uses a high-temperature argon plasma to generate positively charged ions from the sample. However, instead of measuring light emission, these ions are separated and quantified based on their mass-to-charge ratio by a mass spectrometer. This process provides extremely low detection limits, the ability to measure isotopes, and rapid multi-element analysis capabilities. It is, however, more susceptible to certain spectral interferences, such as polyatomic and isobaric interferences, than ICP-OES [21] [22].

X-Ray Fluorescence (XRF) Spectroscopy

XRF is a non-destructive technique where a sample is irradiated with high-energy X-rays. This excitation causes elements in the sample to emit characteristic secondary (or "fluorescent") X-rays. The energy of these emitted X-rays identifies the element, while their intensity quantifies its concentration [19] [23]. Minimal sample preparation is required for solids, making it ideal for rapid screening and field analysis using portable units [19].

Table 1: Fundamental Principles of Analytical Techniques

| Technique | Atomization/Excitation Source | Detection Principle | Sample State |

|---|---|---|---|

| AAS | Flame or Graphite Furnace | Absorption of light by atoms | Liquid |

| ICP-OES | Inductively Coupled Plasma | Emission of light by excited atoms/ions | Liquid |

| ICP-MS | Inductively Coupled Plasma | Separation and detection of ions by mass | Liquid |

| XRF | X-ray Tube or Radioisotope | Emission of characteristic X-rays | Solid or Liquid |

The following diagram illustrates the fundamental workflows for each spectroscopic technique, highlighting the key stages from sample introduction to detection.

Performance Comparison and Experimental Data

Detection Limits and Sensitivity

The detection limit is a paramount performance criterion, especially for regulatory compliance and trace analysis.

- ICP-MS offers the highest sensitivity, with detection limits typically in the parts per trillion (ppt) range [21] [19]. This makes it the gold standard for ultra-trace analysis, such as measuring toxic metals like lead and arsenic in drinking water or biological samples to meet stringent safety standards [21] [24].

- ICP-OES provides detection limits in the parts per billion (ppb) range, making it suitable for applications requiring robust multi-element analysis at higher concentrations, such as in industrial quality control and environmental monitoring of contaminated soils [21] [23].

- AAS generally has detection limits comparable to or slightly higher than ICP-OES (ppb to low ppm), though this can vary significantly with the element and the specific atomization technique (flame vs. graphite furnace) [20].

- XRF typically has the highest detection limits among the four, usually in the parts per million (ppm) range [19] [23]. While not suited for ultra-trace work, this is often sufficient for screening contaminated soils, analyzing alloys, and quality control of materials like cement and ceramics [6] [23].

Table 2: Comparison of Detection Capabilities and Key Features

| Technique | Typical Detection Limits | Multi-Element Capability | Dynamic Range |

|---|---|---|---|

| AAS | ppb - low ppm | Sequential (single element) | Limited |

| ICP-OES | ppb | Simultaneous | Broad (up to 5 orders of magnitude) |

| ICP-MS | ppt | Simultaneous | Very Broad (up to 8-9 orders of magnitude) |

| XRF | ppm | Simultaneous | Moderate |

Sample Preparation and Analysis Workflow

Sample handling protocols vary dramatically and directly impact analysis time, cost, and risk of error.

- ICP-MS and ICP-OES generally require liquid samples. Solid samples must undergo acid digestion using microwave digesters (e.g., MARS6) with reagents like nitric acid and hydrogen peroxide [22] [25]. This process is time-consuming, requires skilled personnel, and risks sample contamination or loss of volatile elements [22] [23].

- AAS also requires liquid samples, necessitating similar digestion procedures for solid materials [25].

- XRF requires minimal sample preparation. Solid samples can often be analyzed directly, sometimes simply pressed into pellets with a boric acid binder [25] [23]. This non-destructive approach allows for rapid analysis, preserves sample integrity, and enables on-site testing with portable instruments [19] [23].

Experimental Protocols from Comparative Studies

Study 1: Soil Contamination Analysis [22]

- Objective: Compare the effectiveness of XRF and ICP-MS for determining Potentially Toxic Elements (PTEs) in soil samples.

- Methodology: 50 soil samples were collected. For ICP-MS analysis, samples were digested with acid. XRF analysis was performed directly on solid samples. Statistical analyses (including correlation and Bland-Altman plots) were used to compare results.

- Key Findings: Significant differences were found for several elements (Sr, Ni, Cr, V, As, Zn). XRF consistently underestimated V compared to ICP-MS, highlighting a systematic bias. However, strong linear correlations for Ni and Cr indicated good agreement for some elements.

Study 2: Heavy Fuel Oil (HFO) Ash Analysis [6]

- Objective: Determine concentrations of V, Ni, Fe, Pb, and Zn in oil ashes and compare the performance of AAS, EDXRF, ICP-MS, and INAA.

- Methodology: Ash samples from Egyptian and Saudi Arabian power plants were collected and analyzed. Internal reference materials (IRMs) were prepared for validation.

- Key Findings: ICP-MS and EDXRF were deemed suitable for determining major elements. The study concluded that EDXRF offers advantages as a multielemental technique that is faster and requires no pretreatment.

Study 3: Analysis of Traditional Mongolian Medicines [25]

- Objective: Compare XRF and ICP-MS for analyzing heavy metals (Pb, Hg, As, Cr, etc.) in medicinal powders.

- Methodology: For XRF, powder samples were pressed into tablets with a boric acid edge. For ICP-MS, samples were digested with nitric acid and hydrogen peroxide via microwave digestion.

- Key Findings: XRF demonstrated good stability and speed with no pretreatment. The recovery rates for most elements were within 85-130%, except for Hg, which suffered from volatility issues. The method was validated as fast, accurate, and simple for quality control.

Operational Considerations and Application Suitability

Cost, Throughput, and Maintenance

The total cost of ownership and operational efficiency are critical factors in technique selection.

- Initial and Operational Cost: XRF and AAS generally have the lowest initial investment and operating costs. XRF uses minimal consumables, while AAS may require specific lamps and gases. ICP-OES is moderately expensive, and ICP-MS is the most costly both in terms of purchase price and ongoing operation, which includes high-purity gases and more frequent maintenance [19] [20].

- Sample Throughput: XRF and ICP-OES/ICP-MS offer high throughput but for different reasons. XRF provides rapid results due to minimal sample preparation [23]. ICP-OES and ICP-MS provide high analytical throughput once samples are in liquid form, analyzing multiple elements simultaneously in minutes [21]. AAS has the lowest throughput due to its sequential element-by-element analysis [20].

- Maintenance and Skill Requirements: ICP-MS systems are the most complex, requiring highly skilled operators for maintenance and troubleshooting. XRF is relatively user-friendly and suitable for use by non-expert operators, especially in field settings [19].

Table 3: Operational and Application-Based Comparison

| Technique | Initial Instrument Cost | Best-Suited Applications | Key Limitation |

|---|---|---|---|

| AAS | Low | Single-element analysis in food/water; limited scope QC | Slow sequential analysis |

| ICP-OES | Moderate | Multi-element analysis in environmental, industrial, and geological samples (ppb level) | Liquid sample requirement |

| ICP-MS | High | Ultra-trace analysis in food safety, clinical, environmental, and pharmaceutical research | High cost; complex interferences |

| XRF | Low (Portable) to Moderate (Benchtop) | Rapid screening of soils, sediments, alloys; quality control in construction materials | Higher detection limits |

Application-Specific Recommendations

- Environmental Monitoring: For ultra-trace level detection in water to meet strict regulatory limits, ICP-MS is the preferred choice [21] [24]. For rapid, on-site screening of contaminated soils and sediments to identify "hot spots," portable XRF is invaluable [22] [23].

- Pharmaceutical and Food Safety: ICP-MS is ideal for enforcing stringent regulatory limits on toxic impurities like Cd, Pb, and As in drugs and food products due to its exceptional sensitivity [21] [19].

- Industrial Quality Control and Geochemistry: ICP-OES offers a cost-effective and robust solution for analyzing materials with higher elemental concentrations, such as ores, metals, and process chemicals [21]. XRF is extensively used in mining, metal recycling, and analysis of construction materials [19].

- Clinical and Biological Research: ICP-MS is the gold standard for measuring trace metals in tissues and bodily fluids due to its low detection limits and ability to handle complex matrices [26] [24].

Essential Research Reagent Solutions

The following table details key reagents and consumables essential for implementing these analytical techniques, particularly for sample preparation.

Table 4: Key Research Reagents and Consumables

| Item | Primary Function | Common Application / Technique |

|---|---|---|

| High-Purity Nitric Acid (HNO₃) | Primary digesting agent for organic and inorganic matrices | Sample digestion for ICP-MS, ICP-OES, AAS [22] [25] |

| Hydrogen Peroxide (H₂O₂) | Oxidizing agent, aids in breaking down organic matter | Used in combination with HNO₃ in microwave digestion [25] |

| Boric Acid (H₃BO₃) | Binder and edge-forming agent for powder samples | Preparing pressed pellets for XRF analysis [25] |

| Certified Reference Materials (CRMs) | Quality control, calibration, and method validation | Essential for all quantitative techniques (AAS, ICP-OES, ICP-MS, XRF) [23] [5] |

| High-Purity Argon Gas | Sustains the plasma and acts as a carrier gas | Essential for plasma generation and operation in ICP-MS and ICP-OES [21] |

| Element-Specific Hollow Cathode Lamps | Source of characteristic wavelength light | Required for the detection of specific elements in AAS [20] |

The selection of an appropriate analytical technique for heavy metal detection is a nuanced decision that balances sensitivity, speed, cost, and specific application requirements.

- ICP-MS is the undisputed leader for ultra-trace level quantification where the highest sensitivity is required, despite its higher operational complexity and cost.

- ICP-OES serves as a powerful and robust workhorse for laboratories needing reliable multi-element data at ppb levels across diverse sample types.

- AAS remains a cost-effective option for labs with a focused need to analyze one or a few elements at a time, though its use is declining in favor of plasma-based techniques.

- XRF is unmatched for rapid, non-destructive screening of solid samples, offering exceptional efficiency for field use and quality control in industrial settings.

A complementary approach, using XRF for rapid initial screening followed by confirmatory analysis with ICP-MS or ICP-OES, often provides an optimal strategy, leveraging the strengths of each technique to achieve both high throughput and definitive, accurate results [19] [23].

In the critical field of environmental monitoring and industrial safety, the accurate detection of heavy metals is a cornerstone of protecting ecosystem and human health. The quest for rapid, precise, and field-deployable analytical techniques has driven the adoption of advanced spectroscopic methods. Among these, Laser-Induced Breakdown Spectroscopy (LIBS) and Portable X-Ray Fluorescence (pXRF) have emerged as two leading handheld technologies, each with distinct operational principles and analytical capabilities. Framed within a broader thesis on spectroscopic techniques for heavy metal detection, this guide provides an objective, data-driven comparison of LIBS and pXRF. It is structured to assist researchers, scientists, and development professionals in selecting the appropriate technology based on rigorous experimental data, detailed methodologies, and a clear understanding of performance trade-offs, particularly in the context of analyzing complex matrices like soils and aerosols.

At their core, both LIBS and XRF are techniques used to determine the elemental composition of materials. However, they achieve this through fundamentally different physical processes, which in turn dictate their applications, strengths, and limitations.

X-Ray Fluorescence (XRF) is a non-destructive analytical technique that uses a primary X-ray beam to excite atoms within a sample. When these X-rays strike an atom, they displace inner-shell electrons, creating vacancies. As the atom returns to a stable state, electrons from higher energy levels fill these vacancies, emitting secondary (fluorescent) X-rays in the process. The energy of these emitted X-rays is unique to each element, allowing for their identification, while the intensity of the signal correlates to the element's concentration [27] [28]. Portable XRF (pXRF) brings this laboratory technique into the field, enabling rapid, on-site analysis.

Laser-Induced Breakdown Spectroscopy (LIBS) operates on a different principle. It uses a highly focused, short-pulse laser to ablate a microscopic amount of material from the sample surface, creating a transient plasma. As this plasma cools, the excited atoms and ions within it emit light at characteristic wavelengths. This emitted light is then collected and dispersed by a spectrometer, and the resulting spectrum is analyzed to identify the elemental composition of the sample based on the unique wavelengths of light emitted by each element [27] [29] [28].

The following diagram illustrates the fundamental operational workflows of both techniques, highlighting the key steps from sample interaction to data analysis:

Performance Comparison: Experimental Data and Analytical Capabilities

Direct comparative studies and application-specific evaluations provide the most robust basis for understanding the performance of LIBS and pXRF. The following tables summarize key quantitative data and analytical parameters from published research.

Table 1: Quantitative Analytical Performance from Direct Technology Comparisons

| Performance Metric | LIBS Performance | pXRF Performance | Experimental Context |

|---|---|---|---|

| Limit of Detection (LoD) for Ga | 0.1% Ga (≈1000 ppm) [30] | "Low tens of ppm" (e.g., 10-30 ppm) [30] | Analysis of gallium in a plutonium surrogate matrix (Ce) [30] |

| Speed of Analysis | 1-3 seconds per analysis [28] | Several seconds to minutes per analysis [30] [28] | Varies with required precision and element; LIBS offers near-instant results [27] [28] |

| Light Element Analysis (e.g., Li, Be, B, Mg, Al, Si) | Excels; capable of detecting and quantifying [27] [28] [31] | Limited to poor performance [27] [28] | Critical for alloys in aerospace, automotive; LIBS is clearly best [27] [31] |

| Heavy Element & Trace Analysis | Struggles with some refractory metals (Cr, Zr, Mo); less sensitive for traces [28] [31] | Excellent for heavy metals and trace elements (<0.1%) [27] [28] | Preferred for stainless steel, high-temp alloys, and precise PMI [27] [31] |

Table 2: Application-Based Performance in Environmental Analysis

| Analysis Context | LIBS Application & Performance | pXRF Application & Performance | Key Study Findings |

|---|---|---|---|

| Heavy Metals in Liquid Aerosols | Quantitative analysis of Cu and Zn using RFE-PLSR model (R2 > 0.98) [32] | Not typically applied for aerosol analysis | LIBS combined with machine learning algorithms enables rapid, accurate detection in aerosols [32] |

| Metals in Contaminated Soils | Less commonly reported for field soil analysis | Strong correlation with lab-based ICP-MS for Pb, Zn; requires correction for moisture/organic matter [33] [34] [35] | pXRF provides a rapid, cost-effective screening tool; correlation coefficients of 0.8-0.93 for Pb, Zn reported [35] |

| Alloy Sorting & Scrap Metal Identification | Ideal for rapid sorting of Al, Mg, and Ti alloys based on light elements [31] | Best for stainless steel, heavy metals, and applications requiring high precision [27] [31] | LIBS is best for fast light-element sorting; XRF for precision and heavy alloys [31] |

Detailed Experimental Protocols

To ensure the reproducibility of results and a deeper understanding of the practical considerations for each technique, this section outlines standard experimental protocols cited in the literature.

Protocol for Soil Analysis using pXRF

The following methodology is adapted from studies monitoring metal pollution in soils, which involve correlating pXRF data with laboratory-standard techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) [33] [34] [35].

- Sample Collection: Soil samples are collected from the field using a sanitized hand trowel. A common approach involves taking sub-samples from multiple points within a defined area (e.g., a residential yard) and combining them into a single, representative composite sample [33].

- Sample Preparation (Field-Moist): For rapid screening, samples can be analyzed with minimal preparation. Vegetation and large debris are removed. The soil is often loosely homogenized and placed in a polyethylene sample bag, ensuring a consistent thickness for measurement. The pXRF analyzer is pressed directly against the outside of the bag [35].

- Sample Preparation (Lab-Based): For higher accuracy, samples are air-dried at room temperature without heat for 24 hours. The dried soil is then sieved (e.g., to pass a 2 mm mesh) to remove stones and homogenize particle size, which reduces analytical error. The prepared soil is typically presented to the analyzer in a dedicated sample cup with a thin, X-ray transparent film window [33] [34].

- Instrument Operation: The analyzer is calibrated according to the manufacturer's instructions. The probe window is placed in direct contact with the soil sample. The measurement is initiated, with a typical counting time of 30-90 seconds per spot to achieve sufficient counting statistics for heavy metals. Multiple readings per sample are recommended to account for soil heterogeneity [35].

- Data Correction: Measurements on moist or organic-rich soils require correction. A common procedure involves developing site-specific calibration models that integrate parameters like soil moisture content and organic matter content, which are measured separately, to improve the agreement between pXRF and ICP-MS results [33] [35].

Protocol for Aerosol Analysis using LIBS

This protocol is based on a recent study that developed a method for the quantitative analysis of heavy metals in liquid aerosols using LIBS combined with machine learning [32].

- Sample Collection & Chamber Setup: A custom-designed chamber is used to generate and contain a stable liquid aerosol. This chamber is critical for improving the hit efficiency and reproducibility of the LIBS plasma generation on aerosol particles compared to open-air measurements [32].

- Laser Ablation & Plasma Generation: A pulsed laser beam (e.g., a Nd:YAG laser at 1064 nm) is focused through a lens into the custom chamber, where it interacts with the aerosol particles. The high-energy laser pulse ablates the particles, generating a transient plasma [29] [32].

- Spectral Acquisition: The light emitted from the cooling plasma is collected by optical lenses or fiber optics and transmitted to a spectrometer. The spectrometer resolves the light into its constituent wavelengths, creating a characteristic emission spectrum for the elements present [29] [32].

- Spectral Screening & Data Processing: The acquired spectra are screened using advanced algorithms, such as the Light Gradient Boosting Machine (LGBM), to select the highest quality data and reduce noise [32].

- Quantification via Calibration Model: Univariate (single wavelength) or multivariate models like Partial Least Squares Regression (PLSR) are developed. The model is optimized using feature selection algorithms (e.g., Recursive Feature Elimination - RFE) to produce a final calibration model (RFE-PLSR) that converts the spectral data into quantitative elemental concentrations for metals like Cu and Zn [32].

The logical flow of this advanced LIBS protocol is visualized below:

Research Reagent and Essential Materials

Successful implementation of LIBS and pXRF methods, particularly for method development and validation, relies on a set of essential materials and reference standards.

Table 3: Essential Research Reagents and Materials for Method Validation

| Item | Function | Example in Context |

|---|---|---|

| Certified Reference Materials (CRMs) | Calibration and validation of analytical accuracy; used to check instrument performance and develop quantification models. | NIST soil standards (e.g., 2709 San Joaquin soil, 2710 Montana Soil) are used for pXRF calibration [33] [35]. |

| Custom Calibration Samples | Creating matrix-matched calibration curves for specific applications, especially when CRMs are not available. | Cerium-Gallium samples were used as a surrogate matrix for LIBS and XRF calibration in a nuclear research context [30]. |

| Microwave Digestion System & Acids | Sample preparation for benchmark laboratory analysis (e.g., ICP-MS) to which portable data is compared. | Used in soil studies with aqua regia (HCl/HNO₃) or multi-acid digestion including HF for "total" digestion [34] [35]. |

| Sample Preparation Tools | Ensuring consistent and representative presentation of samples to the analyzer, minimizing particle size and heterogeneity effects. | Sieves (e.g., 250 μm, 2 mm), sample bags, powder presses, and polyethylene film for XRF cups [33] [34]. |

| Specialized Gases & Chambers | For LIBS, controlling the atmosphere (e.g., using argon) can enhance signal; custom chambers are needed for specific sample types like aerosols. | The custom chamber for aerosol LIBS analysis significantly improved spectral hit efficiency and reproducibility [32]. |

The choice between LIBS and pXRF is not a matter of declaring one technology universally superior, but rather of selecting the right tool for a specific analytical question within heavy metal detection research. The experimental data and protocols presented herein demonstrate a clear trade-off: pXRF offers superior detection limits for heavy metals and trace elements, making it the more precise and established tool for quantitative soil analysis and heavy alloy identification. LIBS, conversely, provides unparalleled speed and a unique capability for light element analysis, positioning it as the ideal technology for rapid sorting of aluminum and magnesium alloys, and for innovative applications in challenging matrices like aerosols. Factors such as cost of ownership, safety regulations concerning X-ray radiation, and the required sample throughput further inform this decision. As both technologies continue to evolve, their integration with sophisticated data processing algorithms and their complementary use in field investigations will undoubtedly enhance our ability to conduct rapid, accurate, and high-resolution characterization of heavy metal contamination.

The analysis of elemental impurities in pharmaceuticals has undergone a fundamental transformation, moving from a nonspecific, century-old test to a modern, risk-based approach grounded in advanced spectroscopic techniques. This shift is encapsulated in the implementation of the ICH Q3D guideline and the replacement of the United States Pharmacopeia (USP) General Chapter <231> with new chapters <232> (Elemental Impurities – Limits) and <233> (Elemental Impurities – Procedures) [36] [37]. The outdated USP <231> "heavy metals" test, a colorimetric method, lacked the specificity, sensitivity, and accuracy required for modern pharmaceutical quality control [38] [37]. It could not distinguish between individual elements, suffered from volatile analyte loss (e.g., mercury) during sample preparation, and did not cover many elements of concern, such as catalyst metals [38].

The contemporary framework mandates a risk-based assessment of 24 elemental impurities across the entire product lifecycle, from raw materials and manufacturing equipment to the final container closure system [36] [37]. This requires analytical techniques capable of precise quantification at very low concentrations. This guide objectively compares the primary spectroscopic techniques—Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), and Atomic Absorption Spectrometry (AAS)—for compliance with these new standards, providing experimental data and protocols to inform researchers and drug development professionals.

The selection of an appropriate analytical technique is critical for successfully implementing ICH Q3D and USP <232>/<233>. The following section compares the fundamental principles, capabilities, and limitations of the three major techniques.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

- Principle: Samples are introduced into an argon plasma that ionizes the constituent elements. The resulting ions are then separated and quantified based on their mass-to-charge ratio in a mass spectrometer [36] [38].

- Key Strengths: ICP-MS offers the lowest detection limits (parts per trillion) among the techniques discussed, making it indispensable for elements with very low Permitted Daily Exposure (PDE) limits, especially for parenteral and inhalational routes [36] [38] [39]. It enables simultaneous multi-element analysis and can handle complex sample matrices effectively when equipped with collision/reaction cell technology to remove polyatomic interferences [38].

- Regulatory Applicability: It is the preferred technique for most ICH Q3D analyses due to its superior sensitivity and is highly recommended for validating methods according to USP <233> [36] [38] [39].

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

- Principle: Similar to ICP-MS, a sample is introduced into an argon plasma. However, instead of ion separation by mass, this technique measures the characteristic light emitted by excited atoms or ions at specific wavelengths [36].

- Key Strengths: ICP-OES provides good sensitivity (parts per million to parts per billion) and a wide dynamic range. It is more robust than ICP-MS for samples with high dissolved solids or complex matrices [36].

- Regulatory Applicability: It serves as a suitable and robust alternative for elements with higher PDE limits or when ICP-MS is not available. It is explicitly referenced as a valid procedure in USP <233> [36] [38].

Atomic Absorption Spectrometry (AAS)

- Principle: This technique measures the absorption of light by free atoms in a vaporized sample. Different variants include Flame AAS (FAAS) and the more sensitive Graphite Furnace AAS (GFAAS) [36].

- Key Strengths: AAS instrumentation is relatively inexpensive and simple to operate. GFAAS offers excellent sensitivity for specific trace elements [36] [8].

- Limitations: AAS is typically a single-element technique, making multi-element analysis time-consuming. It is generally less sensitive and has a narrower dynamic range than ICP-MS for most elements. Its use in modern pharmaceutical control is declining in favor of plasma-based techniques [36].

Table 1: Comparative Analysis of Spectroscopic Techniques for Elemental Impurities

| Feature | ICP-MS | ICP-OES | AAS (GFAAS) |

|---|---|---|---|

| Detection Limit | Parts per trillion (ppt) | Parts per billion (ppb) | Parts per billion (ppb) |

| Multi-element Capability | Yes, simultaneous | Yes, simultaneous | No, sequential |

| Dynamic Range | Very wide (up to 9 orders) | Wide (up to 6 orders) | Narrow (2-3 orders) |

| Sample Throughput | High | High | Low |

| Tolerance to Matrix | Moderate (with dilution/cell tech) | High | Low to Moderate |

| Capital & Operational Cost | High | Medium | Low to Medium |

| Primary Regulatory Use | Full compliance, low PDE elements | Elements with higher PDEs | Targeted analysis, limited use |

Table 2: Suitability for Detecting Key Elemental Impurities (Based on PDE Requirements)

| Element | Class (ICH Q3D) | PDE (Oral, μg/day) | ICP-MS | ICP-OES | AAS |

|---|---|---|---|---|---|

| Cadmium (Cd) | 1 | 5 | Excellent | Good | Good (GFAAS) |

| Lead (Pb) | 1 | 5 | Excellent | Good | Good (GFAAS) |

| Arsenic (As) | 1 | 15 | Excellent | Fair | Good (HGAAS)* |

| Mercury (Hg) | 1 | 5 | Excellent | Poor | Good (HGAAS)* |

| Nickel (Ni) | 2A | 230 | Excellent | Excellent | Good |

| Copper (Cu) | 3 | 3400 | Excellent | Excellent | Good |

| Palladium (Pd) | 2B | 100 | Excellent | Fair | Poor |

Note: HGAAS = Hydride Generation AAS, a specialized technique for specific elements like As and Hg.

Experimental Protocols for Method Validation

Validation according to USP <233> is required to ensure the analytical procedure is "specific, accurate, and precise" [38]. The following protocol outlines a typical validation workflow for ICP-MS, which can be adapted for ICP-OES.

Sample Preparation

For solid pharmaceutical samples (e.g., tablets, capsules, powders), closed-vessel microwave digestion is the preferred technique [38]. This approach prevents the loss of volatile elements like mercury, a known shortcoming of the old USP <231> method [38] [37].

- Procedure: Accurately weigh a representative sample (e.g., 100-500 mg) into a dedicated microwave digestion vessel. Add a mixture of high-purity nitric acid (HNO₃) and hydrochloric acid (HCl), typically resulting in a final digestate with 1% HNO₃ and 0.5% HCl [38]. The HCl is critical for stabilizing mercury and platinum group elements (PGEs) in solution [38]. Seal the vessels and digest using a controlled temperature and pressure ramp program. After cooling, quantitatively transfer the digestate to a volumetric flask and dilute to volume with high-purity water.

- Note: For liquid samples or APIs soluble in organic solvents, dilution in a suitable aqueous or organic solvent (e.g., water, dilute acid, DMSO) may be sufficient, though analyte stabilization must be verified [38].

Instrumental Analysis and Validation

- Instrumentation: An ICP-MS system equipped with a collision/reaction cell (CRC) is used. Operating the CRC in helium (He) gas mode is highly effective for eliminating widespread polyatomic interferences (e.g., ArCl⺠on Asâº) without requiring analyte-specific optimization [38].

- Validation Steps: [38]

- Specificity/Selectivity: Demonstrate that the method can unequivocally assess each target element in the presence of other sample components. The use of ICP-MS in He mode allows for the monitoring of secondary isotopes as qualifier ions for confirmation.

- Accuracy (Spike Recovery): Spike sample matrices with known concentrations of analytes at levels such as 0.5J, J, and 1.5J (where J is the target concentration limit corrected for dilution). Recovery should typically be within 70-150%, demonstrating the method's accuracy.

- Precision: Analyze multiple replicates (n≥6) of a homogenized sample spiked at the J level. The relative standard deviation (RSD) should not exceed 20% for the results to be considered precise.

- System Suitability (Drift Check): A standardization solution at a concentration of 2J is measured at the beginning and end of an analytical batch. The drift between these two measurements must not exceed 20% [38].

USP <233> Compliant Workflow: This diagram outlines the sample preparation and analysis workflow for elemental impurities, emphasizing closed-vessel digestion and interference-resistant ICP-MS analysis.

Essential Research Reagents and Materials

A successful elemental impurities testing program relies on high-purity materials and well-characterized reagents to avoid contamination and ensure accuracy.

Table 3: Essential Research Reagent Solutions for Elemental Impurities Testing

| Reagent/Material | Function/Application | Critical Notes |

|---|---|---|

| High-Purity Acids (HNO₃, HCl) | Sample digestion and dilution. | Essential for minimizing background contamination. Must be trace metal grade. |

| Single-Element ICP-MS Stock Solutions (1000 ppm) | Preparation of calibration standards and spiking solutions. | Used to create multi-element calibration curves in the same acid matrix as samples [38]. |

| Internal Standard Solution | Correction for instrument drift and matrix effects. | Elements like Scandium (Sc), Germanium (Ge), Rhodium (Rh) are added online to all samples and standards [38]. |

| Tuning Solution | Optimization of ICP-MS instrument performance. | Contains elements (e.g., Li, Y, Ce, Tl) across the mass range to ensure sensitivity and stability. |

| Certified Reference Material (CRM) | Method validation and verification of accuracy. | A material with known concentrations of elemental impurities, used for recovery studies. |

| High-Purity Water (18.2 MΩ·cm) | Preparation of all solutions and dilutions. | Required to maintain low procedural blanks. |

The modern regulatory landscape for elemental impurities, defined by ICH Q3D and USP <232>/<233>, demands highly specific, sensitive, and reliable analytical techniques. The comparative data and protocols presented in this guide demonstrate that ICP-MS is the most capable technique for comprehensive compliance, particularly for elements with stringent PDEs and for novel drugs with limited sample availability. ICP-OES serves as a robust alternative for higher-concentration impurities and routine quality control. While AAS has specific uses, its sequential nature and generally higher detection limits limit its application in broad-spectrum pharmaceutical testing. The choice of technique ultimately depends on the specific elements of concern, their PDEs, the product's route of administration, and the required throughput, all within the framework of a science-based risk assessment.

Practical Implementation: Method Selection and Application-Specific Protocols

The accurate detection of heavy metals is a critical requirement in environmental monitoring, industrial safety, and public health protection. Spectroscopic techniques form the backbone of analytical capabilities in this domain, offering varied approaches with distinct strengths and limitations for different analytical scenarios. The selection of an appropriate method depends on multiple factors including required sensitivity, sample matrix complexity, available resources, and desired throughput. This guide provides a systematic framework for matching analytical needs with suitable spectroscopic techniques, supported by experimental data and procedural details.

Heavy metal pollution represents a significant environmental challenge due to its persistence, bioaccumulation potential, and associated health risks. Metals such as lead (Pb), mercury (Hg), cadmium (Cd), arsenic (As), and chromium (Cr) can cause severe physiological damage even at low concentrations, including neurological disorders, kidney damage, and increased cancer risk [14] [10]. The detection of these metals in complex matrices like wastewater, soil, and biological tissues requires sophisticated instrumentation capable of delivering precise quantitative data amid potential interferents.

Comparative Analysis of Spectroscopic Techniques

Technical Specifications and Performance Metrics

The selection of an appropriate spectroscopic technique requires careful consideration of performance characteristics relative to analytical requirements. The following table summarizes key specifications for major heavy metal detection techniques:

Table 1: Performance Comparison of Heavy Metal Detection Techniques

| Technique | Detection Limits | Sample Throughput | Multi-element Capability | Operational Complexity | Equipment Cost |

|---|---|---|---|---|---|

| ICP-MS | sub-ppb to sub-ppt [14] | Moderate | Excellent | High | Very High |

| ICP-OES | ppb range [14] | High | Excellent | High | High |

| AAS | ppb range [10] | Low | Limited | Moderate | Moderate |

| AFS | ppb range [10] | Moderate | Limited | Moderate | Moderate |

| LA-ICP-MS | ppm-ppb range [10] | Low | Excellent | Very High | Very High |

| XRF | ppm range [10] | High | Good | Low | Moderate to High |

| UV-Vis | ppm range [40] | High | Good | Low | Low |

Applicability to Different Analytical Scenarios

Each technique offers distinct advantages for specific application contexts:

- Regulatory compliance and trace analysis: ICP-MS provides the sensitivity required for stringent regulatory limits in drinking water and food products, with detection capabilities reaching sub-part per trillion levels for many elements [14].

- High-throughput screening: XRF and UV-Vis spectroscopy offer rapid analysis with minimal sample preparation, making them suitable for initial screening and field applications [10] [40].

- Spatial distribution mapping: LA-ICP-MS and XRF enable direct elemental mapping in solid samples without destructive preparation, preserving sample integrity for additional analyses [10].

- Cost-effective routine analysis: AAS remains a reliable choice for laboratories with budget constraints that require accurate quantification of specific metals at moderate sensitivity [10].

Experimental Protocols and Methodologies

Standardized Workflow for Method Validation

Regardless of the selected technique, proper method validation ensures reliable results. The following workflow outlines essential steps for establishing robust analytical methods:

Experimental Workflow for Heavy Metal Analysis

Detailed Methodological Protocols

ICP-MS Procedure for Trace Metal Analysis

Sample Preparation:

- Digest 0.5 g solid sample or 10 mL liquid sample with 5 mL concentrated nitric acid (HNO₃) using microwave-assisted digestion at 180°C for 15 minutes [14].

- Dilute digested sample to 50 mL with deionized water (18.2 MΩ·cm).

- Add internal standards (e.g., Sc, Ge, In, Bi) to correct for instrumental drift and matrix effects.

Instrumental Parameters:

- RF Power: 1550 W

- Plasma gas flow: 15 L/min Argon

- Auxiliary gas flow: 0.9 L/min Argon

- Nebulizer gas flow: 1.05 L/min Argon

- Data acquisition: 3 points per peak, 10 sweeps per reading, 3 replicates

- Dwell time: 50 ms per isotope

Quality Control:

- Analyze method blanks with each batch to monitor contamination.

- Include certified reference materials (NIST 1640a) every 10 samples to verify accuracy.

- Spike recovery tests (85-115% acceptance) for each sample matrix type.

UV-Vis Spectrophotometry with Deep Learning Integration

Chemical Probe Preparation:

- Prepare combinatorial chemical probes specifically designed to enhance specificity for target heavy metals [40].

- Optimize probe concentration to maximize colorimetric response while minimizing background interference.

Spectral Acquisition:

- Use high-throughput automated systems to collect UV-Vis spectra (200-800 nm range).

- Generate superimposed spectra for multi-component analysis.

- Maintain consistent measurement parameters: 1 cm pathlength, 1 nm spectral resolution.

Deep Learning Processing:

- Train Transformer model on extensive spectral library of known concentrations.

- Implement end-to-end qualitative and quantitative information extraction.

- Validate model performance with independent test sets (average R² = 0.936 reported) [40].

Advanced Integration Approaches

Electrode Modification for Enhanced Electrochemical Detection

Electrochemical techniques often serve as complementary approaches to spectroscopic methods, particularly for field applications. Performance enhancements through electrode modification have shown significant promise:

Table 2: Electrode Modification Materials for Enhanced Heavy Metal Detection

| Modification Material | Target Metals | Enhancement Mechanism | Improvement Factor |

|---|---|---|---|

| Metal Oxides (TiOâ‚‚, CuO) | Pb, Cd, Hg | Increased surface area and electrocatalytic activity | 3-5x sensitivity [14] |

| Metal-Organic Frameworks (ZIF-8) | Cu, Zn, Cd | Highly porous structure with specific binding sites | 5-8x selectivity [14] |

| MXenes | Various | Excellent conductivity and surface functionalization | 4-6x response time [14] |

| Metal Nanomaterials | Multiple | High surface area-to-volume ratio | 2-3x detection limits [14] |

Sample Pretreatment Methods for Complex Matrices

Complex sample matrices often require pretreatment to minimize interference and improve detection accuracy:

- Fenton Oxidation: Uses hydrogen peroxide and iron catalysts to degrade organic interferents through generation of hydroxyl radicals [14].

- Microwave-Assisted Digestion: Rapid, controlled digestion of organic matrices using microwave energy with acid mixtures [14].

- Non-thermal Plasma Oxidation: Employ high-energy plasma to break down interfering compounds without thermal degradation of target analytes [14].

Computational Approaches and Data Analysis

Machine Learning Integration for Spectral Analysis

Advanced algorithms have become increasingly important for processing complex spectral data and mitigating interference effects:

Machine Learning Workflow for Spectral Data

Performance Metrics of Computational Models

Table 3: Performance of Algorithms in Heavy Metal Detection

| Algorithm | Application | Key Advantages | Reported Accuracy |

|---|---|---|---|

| BPNN | Hg, Cu, Pb detection [14] | Handles non-linear relationships effectively | R² > 0.90 for most metals [14] |

| SVM | Classification of pollution sources [14] | Effective with sparse or noisy data | >85% classification accuracy [14] |

| Random Forest | Complex environmental datasets [14] | Reduces overfitting, handles multiple features | R² = 0.82-0.94 [14] |

| Transformer Model | UV-Vis superimposed spectra [40] | End-to-end qualitative and quantitative analysis | Average R² = 0.936 [40] |

Essential Research Reagents and Materials

The experimental work in spectroscopic heavy metal detection relies on several critical reagents and materials:

Table 4: Essential Research Reagents for Heavy Metal Detection

| Reagent/Material | Specification | Primary Function | Application Context |

|---|---|---|---|

| High-Purity Acids | Trace metal grade HNO₃, HCl | Sample digestion and preservation | ICP-MS, ICP-OES, AAS |

| Certified Reference Materials | NIST 1640a, 1643e | Method validation and quality control | All quantitative techniques |

| Chemical Probes | Combinatorial libraries | Selective complexation with target metals | UV-Vis spectrophotometry [40] |

| Modified Electrodes | Nanomaterial-enhanced | Signal amplification and selectivity | Electrochemical sensors [14] |

| Internal Standards | Sc, Ge, Y, In, Bi | Correction for instrumental drift | ICP-MS, ICP-OES |

| Calibration Standards | Multi-element mixtures | Instrument calibration | All techniques |

The selection of appropriate spectroscopic techniques for heavy metal detection requires careful consideration of analytical needs, sample characteristics, and available resources. While traditional laboratory-based methods like ICP-MS offer exceptional sensitivity for regulatory compliance, emerging approaches combining UV-Vis spectroscopy with machine learning present promising alternatives for rapid screening and field deployment. The integration of advanced materials for electrode modification and sophisticated algorithms for data processing further expands the capabilities of these analytical platforms. By applying the framework presented in this guide, researchers can systematically match their specific analytical requirements with the most suitable methodological approach, optimizing resource allocation while ensuring data quality and reliability.

ICP-MS Protocols for Ultra-Trace Elemental Impurities in Pharmaceuticals

In modern pharmaceuticals, ensuring patient safety extends beyond a drug's biological activity to include strict control of elemental impurities. These contaminants, such as arsenic (As), cadmium (Cd), lead (Pb), and mercury (Hg), can originate from catalysts, raw materials, manufacturing equipment, or packaging. Strict global regulations, including ICH Q3D and USP 〈232〉/〈233〉, mandate the monitoring and control of these impurities at ultra-trace levels, often in the parts-per-trillion (ppt) range. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has emerged as the dominant analytical technique for this task, offering the requisite sensitivity, multi-element capability, and high throughput. This guide provides a detailed comparison of ICP-MS against other spectroscopic techniques and outlines established protocols for its application in pharmaceutical quality control, framing this within the broader context of spectroscopic techniques for heavy metal detection.

Technique Comparison: ICP-MS Versus Alternatives

The selection of an analytical technique for elemental impurities is a critical decision for any pharmaceutical laboratory. The following sections and comparison table provide an objective evaluation of the primary methods available.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

ICP-MS combines a high-temperature argon plasma (~6000-10000 K), which atomizes and ionizes the sample, with a mass spectrometer that separates and quantifies these ions based on their mass-to-charge ratio [41]. Its key advantages for pharmaceutical analysis include ultra-trace sensitivity with detection limits extending to ppt levels, simultaneous multi-element analysis of over 70 elements in a single run, and a wide dynamic range that allows for the measurement of major and trace elements in the same sequence [41] [42]. It is the globally accepted technique for compliance with ICH Q3D [41].

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

ICP-OES utilizes the same plasma source as ICP-MS but detects the characteristic light emitted by excited atoms and ions [43]. While it is a robust, multi-element technique, its detection limits are typically in the parts-per-billion (ppb) range, which may be insufficient for some ultra-trace level regulatory limits [43] [42]. It is generally considered more tolerant of samples with high total dissolved solids (TDS) compared to ICP-MS [43].

Graphite Furnace Atomic Absorption Spectrometry (GF-AAS)

GF-AAS is a single-element technique that measures the absorption of light by ground-state atoms in a heated graphite tube [42]. It offers excellent sensitivity for a single element, often at ppb to sub-ppb levels, but its lack of multi-element capability makes it time-consuming for screening multiple impurities [44] [42]. One study noted its particular suitability for analyzing samples with very high or very low concentrations of specific elements, such as cadmium [44].

Comparative Performance Table

Table 1: Comparison of Key Techniques for Elemental Impurity Analysis

| Technique | Typical Detection Limits | Multi-Element Capability | Sample Throughput | Best For |

|---|---|---|---|---|

| ICP-MS | Sub-ppt to low ppb [42] | Yes, >70 elements simultaneously [41] | High (~1-3 min/sample) [42] | Ultra-trace, multi-element regulatory testing (e.g., ICH Q3D) [41] |

| ICP-OES | ~0.1–10 ppb [42] | Yes, typically 10-20 elements [42] | High (~1-3 min/sample) [42] | Samples with high matrix content or elements with higher regulatory limits [43] |

| GF-AAS | Sub-ppb (for a single element) [42] | No | Slow | Targeted, single-element analysis where cost is a primary concern [42] |

Experimental Protocols for ICP-MS in Pharmaceuticals

A robust ICP-MS protocol is built on meticulous sample preparation, optimized instrument operation, and rigorous data validation. The following workflow and detailed methodology are compiled from established practices in the field.

Diagram 1: ICP-MS Experimental Workflow for Pharmaceutical Samples

Sample Preparation and Digestion

Proper sample preparation is the most critical step for accurate results. For solid pharmaceutical samples like Active Pharmaceutical Ingredients (APIs) or finished dosage forms, microwave-assisted acid digestion is the gold standard.

- Materials: The sample is accurately weighed (typically 0.1-0.5 g) into a digestion vessel. High-purity nitric acid (HNO₃) is the primary digestant, often with an added oxidant like hydrogen peroxide (H₂O₂) for complex matrices [25].

- Protocol: The sample and acid mixture is allowed to pre-digest at room temperature for several hours or overnight. It is then subjected to a controlled, temperature-ramped microwave digestion program. An example program involves heating to various plateaus (e.g., 110°C, 140°C, 180°C, and 210°C) with hold times at each step to ensure complete dissolution of organic material without loss of volatile analytes [25].

- Post-Digestion: After cooling, the digestate is transferred to a volumetric flask and diluted to volume with ultra-pure water. A further dilution (e.g., 10-fold or 100-fold) is often required to match the total dissolved solid content to the ICP-MS's tolerance (typically <0.2%) and to bring analyte concentrations within the instrument's linear range [43].

ICP-MS Instrumental Analysis

The prepared sample solution is introduced into the ICP-MS via a peristaltic pump.

- Nebulization & Plasma: The solution is converted into a fine aerosol by a nebulizer and transported into the argon plasma, where it is desolvated, atomized, and ionized.

- Interference Management: Polyatomic interferences (e.g., ArCl⺠on Asâº) are a significant challenge. The use of a collision/reaction cell (CRC) with helium gas is a common and effective method to control these interferences, making the method more universal and reliable [45] [41].

- Quantification: Analysis is typically performed against a calibration curve created from certified multi-element standard solutions. An Internal Standard (ISTD), such as a mixture of Scandium (Sc), Indium (In), and Bismuth (Bi), is added online to both samples and standards to correct for instrument drift and matrix suppression/enhancement effects [25].

Key Reagent Solutions

Table 2: Essential Research Reagents for ICP-MS Pharmaceutical Analysis

| Reagent/Solution | Function | Critical Notes |

|---|---|---|

| High-Purity Nitric Acid (HNO₃) | Primary digestant for organic matrices. | Must be trace metal grade to minimize background contamination. |

| Hydrogen Peroxide (Hâ‚‚Oâ‚‚) | Oxidizing agent to aid complete digestion. | Adds to digestion efficiency for complex samples. |

| Multi-Element Calibration Standards | Used to create the quantitative calibration curve. | Certified Reference Materials (CRMs) from a national body are essential for accuracy. |

| Internal Standard (ISTD) Mix | Corrects for signal drift and matrix effects. | Added in-line to all samples and standards; elements (e.g., Sc, In, Bi) should not be present in the sample. |

| Tune Solution | Optimizes instrument performance (sensitivity, resolution). | Contains elements like Li, Y, Ce, Tl at known concentrations. |

Analytical Challenges and Best Practices