Advanced Fusion Techniques for Refractory Material Analysis: Enhancing Accuracy in Spectroscopic Characterization

This article provides a comprehensive guide to fusion techniques for preparing refractory materials for spectroscopic analysis.

Advanced Fusion Techniques for Refractory Material Analysis: Enhancing Accuracy in Spectroscopic Characterization

Abstract

This article provides a comprehensive guide to fusion techniques for preparing refractory materials for spectroscopic analysis. It explores the foundational principles of why these high-temperature ceramics demand specialized preparation methods like fusion to overcome challenges such as mineralogical and grain size effects. The content details established and novel methodological protocols for XRF, ICP-MS, and LA-ICP-MS, alongside targeted troubleshooting for common issues like volatile element loss and incomplete dissolution. Finally, it covers validation strategies and comparative analyses of different fusion methods, equipping researchers and scientists with the knowledge to achieve precise, reliable, and reproducible elemental data critical for quality control and research & development.

Why Fusion? The Critical Role of Sample Preparation in Refractory Material Analysis

Refractory materials are a class of substances engineered to withstand extreme environments, including high temperatures, corrosive media, and significant mechanical stress. They are strategically vital for industrial processes such as steelmaking, non-ferrous metal production, cement clinker processing, and glass manufacturing [1]. Their defining characteristic is an exceptional resistance to degradation, which, while essential for their application, creates substantial challenges for researchers needing to determine their chemical composition and internal structure. This application note details these challenges and provides validated protocols for the spectroscopic analysis of refractory materials, with a specific focus on fusion techniques essential for overcoming their inherent stability.

Core Challenges in Refractory Material Analysis

The analysis of refractory materials is predominantly hindered by two intrinsic properties: their high thermal and mechanical stability and their complex, often multi-phase, composition.

High Thermal and Mechanical Stability

Refractory materials are designed for operational stability at temperatures often exceeding 1400°C. For instance, refractory multi-principal-element alloys (RMPEAs) like those in the Mo-W-Ta-Ti-Zr system are specifically designed for high-temperature applications with melting points above 2500°C [2]. This immense thermal stability translates directly into chemical inertness and exceptional resistance to dissolution using conventional acid digestion methods. Their mechanical robustness, including high hardness, further complicates sample preparation by making size reduction and creating a representative powder difficult and time-consuming.

Complex and Multi-Phase Composition

Refractories are rarely simple, single-component systems. They are typically composites or complex concentrated alloys with multi-phase microstructures that define their properties. For example:

- Refractory Complex Concentrated Alloys (RCCAs) within systems like Ta-Mo-Ti-Cr-Al can consist of a primary disordered A2 structure with minor secondary phases like C15 Laves phase, depending on the exact stoichiometry [3].

- Conventional refractories may contain a mixture of alumina (Al₂O₃), spinel (MgAl₂O₄), silica (SiO₂), and other oxides [1] [4]. This heterogeneity means that a small, unrepresentative sample can yield misleading analytical results. Achieving a complete dissolution that accurately reflects the bulk material's composition is therefore paramount.

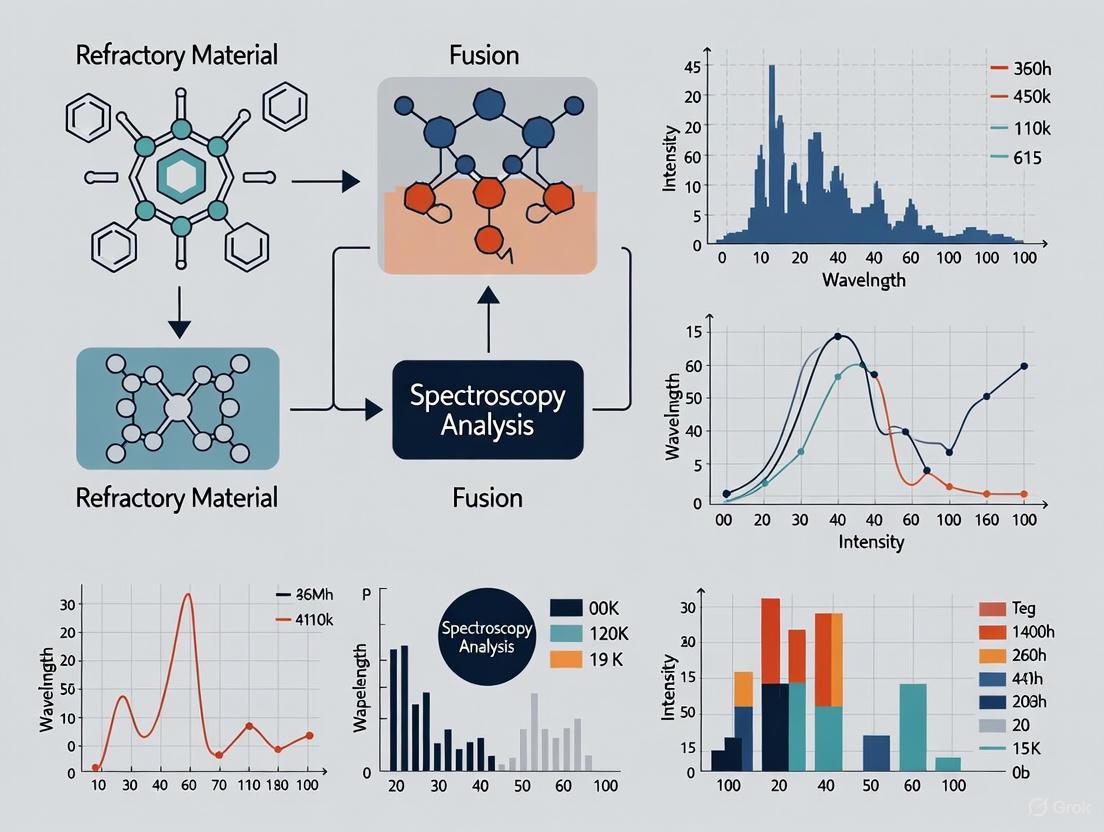

Analytical Approaches and Method Selection

The choice of analytical technique depends on the information required—phase identification, elemental composition, or microstructural analysis. The figure below illustrates a generalized workflow for the analysis of solid refractory samples.

| Technique | Primary Function | Sample Preparation Core Requirement | Key Advantage for Refractories |

|---|---|---|---|

| X-Ray Diffraction (XRD) | Crystallographic phase identification [4] | Flat, homogeneous surface; pressed powder pellet [5] | Non-destructive; identifies multiple crystalline phases in a sample. |

| Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM/EDS) | Microstructural imaging and elemental analysis at interfaces [4] | Polished cross-section | Provides direct visualization of phase distribution and corrosion interfaces. |

| X-Ray Fluorescence (XRF) | Bulk elemental composition | Homogeneous powder pressed into pellet or fused into glass bead [5] | Good for major and minor elements; relatively straightforward quantification. |

| Inductively Coupled Plasma Optical Emission Spectrometry or Mass Spectrometry (ICP-OES/MS) | Bulk elemental composition (including traces) | Complete dissolution of solid sample (e.g., via fusion) [6] | High sensitivity and accuracy for a wide range of elements at trace levels. |

Detailed Experimental Protocols

For determining the full elemental composition, including trace components, ICP-OES or ICP-MS is the preferred technique. Its accuracy, however, is entirely dependent on the complete dissolution of the sample, for which fusion is the most effective method.

Reagent Solutions for Alkali Fusion

The following table lists essential reagents for the alkali fusion protocol.

| Research Reagent | Function / Explanation |

|---|---|

| Anhydrous Lithium Tetraborate (Li₂B₄O₇) or Sodium Carbonate (Na₂CO₃) / Potassium Carbonate (K₂CO₃) Mixture | Fluxing Agent. These high-purity alkali salts form low-melting-point eutectics that dissolve refractory oxide components at high temperatures [5] [6]. |

| High-Purity Nitric Acid (HNO₃) or Hydrochloric Acid (HCl) | Dissolution Medium. Used to dissolve the fused bead after fusion, creating an aqueous solution compatible with ICP analysis [6]. |

| Hydrofluoric Acid (HF) | Co-Fluxing Agent (Optional but recommended for silicates). Effectively breaks down silica (SiOâ‚‚) networks, which are highly resistant to other acids [6]. Requires specialized labware (e.g., PTFE) and extreme safety precautions. |

| Platinum Crucibles (95% Pt / 5% Au) | Fusion Vessel. Withstand repeated heating to 1000-1200°C without reacting with the molten flux or sample [5]. |

Protocol 1: Alkali Fusion for ICP-OES/MS Analysis

This protocol is adapted from studies comparing digestion methods for geological rocks, which share compositional challenges with many refractory materials [6].

Workflow Overview:

Step-by-Step Procedure:

Sample Preparation: Grind the refractory sample to a fine, homogeneous powder with a particle size of less than 75 µm using a spectroscopic grinding or milling machine to ensure consistent interaction with the flux [5].

Weighing and Mixing:

Fusion:

- Place the covered crucible in a muffle furnace.

- Gradually heat to a temperature between 950°C and 1200°C and hold for 15-20 minutes, or until the contents have melted into a homogeneous liquid with no visible particles [5].

Bead Formation and Dissolution:

- Carefully remove the crucible from the furnace and pour the molten liquid into a pre-heated platinum mold to form a glassy bead, or allow it to cool in the crucible.

- Once cooled, transfer the bead to a beaker and add a dilute acid (e.g., HNO₃ or HCl). Gently heat and stir until the bead is completely dissolved. Note: For silica-rich refractories, the addition of a small volume of HF to the dissolution acid may be necessary for complete recovery of silicon [6].

Final Solution Preparation:

- Transfer the solution quantitatively to a volumetric flask and dilute to the mark with high-purity water.

- Filter the solution if any insoluble residues remain (e.g., using a 0.45 µm membrane filter) to prevent clogging the ICP nebulizer.

Analysis: Analyze the clear solution using ICP-OES for major and minor elements, or ICP-MS for trace and rare earth elements, with appropriate calibration standards.

Performance Data: Fusion vs. Alternative Methods

The critical importance of fusion is demonstrated by its superior recovery rates compared to other digestion techniques, as shown in studies on certified geological rock samples [6]. The following table summarizes quantitative recovery data for major elements.

| Element | Aqua Regia Digestion | Microwave Digestion | Alkali Fusion |

|---|---|---|---|

| Silicon (Si) | ~50% | 76-81% | ~100% |

| Titanium (Ti) | <50% (Data from rock samples) | <50% (Data from rock samples) | ~100% |

| Calcium (Ca) | <50% (Data from rock samples) | <50% (Data from rock samples) | ~100% |

| Most Trace Elements | 91-100% | 91-100% | >95% |

Data adapted from a comparative study of sample preparation methods for the analysis of geological rocks, which are analogous to many refractory oxides and silicates [6].

The data confirms that alkali fusion is the only method capable of providing near-complete recovery of major structural elements like Silicon, which are locked in a stable, refractory matrix. While alternative methods like aqua regia and microwave digestion can be effective for certain trace metals, they fail to break down the silicate and oxide networks, leading to severely underestimated concentrations of major components.

The analysis of refractory materials demands a methodical approach that acknowledges their fundamental properties of high stability and complex composition. While techniques like XRD and SEM/EDS are invaluable for phase and microstructural analysis, the gold standard for obtaining accurate bulk elemental data, particularly for trace components, is ICP-OES/MS. The success of this technique is wholly dependent on robust sample preparation, for which alkali fusion is the most reliable and comprehensive method. The provided protocol and performance data establish fusion as an essential tool in the spectroscopic study of refractory materials, ensuring data integrity from the laboratory to the final analytical report.

Matrix effects, including mineralogical composition and grain size variation, present significant challenges for accurate spectroscopic analysis of refractory materials. Fusion techniques effectively eliminate these biases by dissolving samples into a homogeneous glass disk, creating a consistent matrix that mitigates physical and mineralogical interferences. This protocol details the application of fusion methodology for Laser-Induced Breakdown Spectroscopy (LIBS) and Raman spectroscopy, enabling highly reproducible quantitative analysis critical for geological research and drug development where precise material characterization is paramount.

In the spectroscopic analysis of refractory materials, matrix effects and grain size heterogeneity are two of the most significant sources of analytical bias. Matrix effects occur when the chemical and physical properties of the sample itself influence the intensity of the analytical signal, leading to inaccuracies in both qualitative identification and quantitative measurement. Similarly, variations in grain size can cause differential scattering and inhomogeneous particle distribution, compromising the reproducibility of results [7].

Fusion spectroscopy addresses these challenges through a rigorous sample preparation protocol that dissolves the original mineral structure into a homogeneous glass disk (bead) using a high-temperature flux. This process effectively eliminates mineralogical structure and standardizes particle size, creating an ideal, consistent matrix for spectroscopic analysis. Within the broader thesis of fusion methodologies for refractory materials, this application note provides detailed protocols for achieving superior analytical accuracy in LIBS and Raman spectroscopy, techniques highly susceptible to the matrix and grain size effects inherent in traditional powder analysis [5].

Background: Spectroscopic Challenges in Refractory Materials

The Nature of Matrix and Grain Size Effects

Spectroscopic techniques like LIBS and Raman provide powerful, rapid analysis but face specific limitations from sample physical characteristics:

- In LIBS: The signal can be affected by matrix effects, self-absorption, and line interference from coexisting elements. Furthermore, the heterogeneity of the sample (e.g., surface roughness, chemical matrix) strongly affects signal intensity in nonlinear manners, challenging the linear relationship between recorded intensity and elemental concentration [7].

- In Raman Spectroscopy: Fluorescence interference is a common obstacle, often leading to signal saturation that obscures the weaker Raman peaks. Sample heterogeneity can also result in non-representative sampling and non-reproducible results [7].

Traditional preparation methods like pressing pellets can mitigate some issues but leave the original mineralogy intact, preserving significant potential for analytical bias.

Quantitative Advantages of Fusion Methodology

The application of fusion techniques directly addresses the core limitations of conventional sample preparation. The table below summarizes the key analytical improvements documented in recent studies.

Table 1: Quantitative Performance Improvements from Advanced Sample Preparation and Data Fusion

| Analytical Method | Performance Metric | Standard Method | With Fusion/Advanced Fusion | Reference |

|---|---|---|---|---|

| LIBS for Mineral Classification | Classification Accuracy | 83.11% (Baseline LIBS) | 95.67% (with multi-order moment features) | [8] |

| LIBS-Raman Fusion (PLS-DA/K-ELM) | Classification Accuracy | N/A (Individual techniques lower) | 98.4% (Fused LIBS-Raman with ML) | [9] |

| Combined LIBS-Raman System | Geographical Origin Accuracy | LIBS (71.9%), Raman (82.8%) | 90.6% (Hybrid System) | [8] |

| Fusion for LIBS/Raman Imaging | Mitigation of Signal Saturation | Suboptimal Signal-to-Noise | Enhanced dynamic range, improved contrast and peak signal-to-noise ratios | [7] |

These improvements are made possible because the fusion process creates a uniform glass matrix that is consistent across all samples, thereby eliminating the mineralogical and grain size biases that plague other preparation techniques [5].

Experimental Protocol: Fusion for Spectroscopic Analysis

Research Reagent Solutions and Materials

Table 2: Essential Materials and Reagents for Fusion Sample Preparation

| Item Name | Function & Specification | Critical Parameters |

|---|---|---|

| Lithium Tetraborate (Li2B4O7) | Common flux agent; dissolves silicate structures at high temperatures. | High purity (≥99.95%) to avoid introducing elemental contaminants. |

| Platinum Crucibles (95% Pt / 5% Au) | Withstands repeated heating to 1200°C; inert to prevent reaction with sample/flux. | Alloying with gold reduces deformation at high temperatures. |

| Mould Release Agent | Prevents fused bead from adhering to the crucible and mold. | Aqueous ammonium bromide or iodide solutions are typically used. |

| Hydraulic/Pneumatic Press | Forms powdered samples into uniform pellets before fusion. | Pressing at 10-30 tons ensures initial sample homogeneity. |

| High-Temperature Fusion Furnace | Melts sample-flux mixture to form a homogeneous glass disk. | Capable of stable temperatures of 950–1200°C with programmable controls. |

Step-by-Step Fusion Protocol

Step 1: Sample Pre-Preparation

- Grind the representative sample to an optimal particle size of <75 μm using a swing grinding machine to minimize contamination and heat formation [5].

- Dry the sample in an oven at 105°C for a minimum of 2 hours to remove absorbed moisture.

Step 2: Flux-Sample Mixing

- Accurately weigh 1.000 g of the prepared sample.

- Mix with 6.000 g of lithium tetraborate flux, achieving a 1:6 sample-to-flux ratio. For trace element analysis, use a higher ratio of 1:10. Blend the mixture in a mixer mill for 3 minutes to ensure homogeneity.

Step 3: Pre-Oxidation and Melting

- Transfer the mixture to a platinum-gold alloy crucible pre-treated with a mould release agent.

- Place the crucible in a fusion furnace at 500°C for 10 minutes to oxidize any organic content or sulfides.

- Rapidly increase the furnace temperature to 1050°C and hold for 12-15 minutes. Swirl the crucible gently at the 7-minute mark to facilitate complete mixing and dissolution of all particulates.

Step 4: Casting and Annealing

- Pour the molten homogenized mixture into a pre-heated platinum mold.

- Immediately transfer the cast disk to an annealing oven at 450°C. Allow it to cool gradually to room temperature over 60 minutes to prevent glass fracture and relieve internal stresses.

Step 5: Quality Control and Analysis

- Visually inspect the final glass disk. It should be homogeneous, bubble-free, and transparent.

- The resulting fused bead is now ready for direct spectroscopic analysis via LIBS or Raman, providing a perfectly flat and consistent surface.

The following workflow diagram illustrates the complete fusion process.

Diagram 1: Complete Fusion and Analysis Workflow

Data Fusion: Integrating LIBS and Raman on Fused Samples

The homogeneous nature of fused beads makes them an ideal substrate for combined analytical approaches. Data fusion from LIBS and Raman spectroscopy, when applied to fused samples, leverages their complementary strengths.

LIBS provides high-sensitivity elemental composition information by analyzing discrete emission lines from laser-induced plasma [8] [9]. Raman Spectroscopy reveals molecular structural characteristics by detecting inelastically scattered photons [8] [7]. On fused beads, LIBS benefits from the eliminated mineralogical bias, while Raman benefits from the reduced fluorescence and flat optical surface.

Machine learning models, such as Partial Least Squares-Discriminant Analysis (PLS-DA) and Kernel Extreme Learning Machine (K-ELM), can then be applied to the fused dataset. One study achieved a 98.4% classification accuracy across six mineral species using this approach, significantly outperforming models based on a single technique [9]. The following diagram illustrates this powerful synergistic relationship.

Diagram 2: Synergistic Data Fusion from a Single Fused Bead

Fusion sample preparation is a powerful, robust methodology for overcoming the persistent analytical challenges of mineralogical and grain size bias in spectroscopy. By transforming heterogeneous solid samples into homogeneous glass disks, fusion establishes a consistent matrix that enhances the accuracy, precision, and reproducibility of both LIBS and Raman spectroscopy. When combined with modern data fusion strategies and machine learning, this approach provides a definitive solution for the rigorous analysis of complex refractory materials, enabling new levels of confidence in geological and pharmaceutical research.

In the precise world of spectroscopic analysis, the integrity of final data is inextricably linked to the initial steps of sample preparation. This relationship is particularly critical in the analysis of refractory materials using fusion techniques, where the inert and complex nature of the samples presents unique challenges. Inadequate sample preparation is not merely a preliminary concern; it is a primary source of analytical error, accounting for as much as 60% of all spectroscopic analytical errors [5]. Within the context of fusion techniques for refractory materials, the consequences of poor preparation are magnified, potentially compromising research validity, quality control protocols, and analytical conclusions in pharmaceutical and materials development.

The fundamental goal of spectroscopic sample preparation, especially for fusion methods, is to transform heterogeneous, complex solid samples into homogeneous, analyzable specimens. This process must eliminate physical and chemical heterogeneities that introduce spectral artifacts, matrix effects, and quantitative inaccuracies. For refractory materials including silicates, ceramics, and certain pharmaceutical intermediates, fusion techniques provide the most rigorous approach by completely dissolving crystal structures and creating uniform glass disks that minimize matrix effects for techniques like X-ray fluorescence (XRF) spectrometry [5]. The following application notes delineate the quantitative costs of preparation inaccuracies and establish validated protocols to support reliable spectroscopic analysis in advanced research settings.

Quantitative Impact of Preparation Errors

The empirical relationship between sample preparation quality and analytical accuracy is demonstrated across multiple spectroscopic techniques. The tables below summarize documented error ranges associated with specific preparation deficiencies.

Table 1: Analytical Error Ranges Associated with Sample Preparation Deficiencies

| Preparation Deficiency | Spectroscopic Technique | Error Range | Primary Manifestation |

|---|---|---|---|

| Insufficient Grinding (>75 μm particles) | XRF Spectrometry [5] | 10-25% | Incorrect elemental ratios due to particle size effects |

| Incomplete Fusion | XRF Spectrometry [5] | 15-30% | Mineralogical and matrix effects skewing calibration |

| Improper Internal Standardization | Low-Field qNMR [10] | 2.6-5% | Bias in quantitative recovery rates |

| Contamination During Preparation | ICP-MS [5] | Variable, can exceed 100% | Spurious spectral signals and false positives |

| Non-Homogeneous Pellet Formation | FT-IR [5] | 5-20% | Spectral scattering and non-representative sampling |

Table 2: Accuracy Recovery Demonstrated Through Proper Low-Field qNMR Preparation

| Sample Preparation Parameter | Condition A (Optimal) | Condition B (Suboptimal) | Impact on Recovery Rate |

|---|---|---|---|

| Signal-to-Noise Ratio (SNR) | SNR = 300 [10] | SNR = 100 | 97-103% recovery vs. 90-110% recovery [10] |

| Solvent Type | Deuterated solvents [10] | Non-deuterated solvents [10] | Average bias: 1.4% vs. 2.6% [10] |

| Relaxation Delay (T1) | > 5 × T1 [10] | < 3 × T1 | Quantitative accuracy compromised by incomplete magnetization recovery |

| Internal Standard Selection | Compatible solubility & stability [10] | Incompatible with matrix | Erroneous results, especially near solvent suppression regions [10] |

Experimental Protocols for Fusion Techniques and Solid Sample Analysis

Fusion Technique for Refractory Materials

Fusion represents the most stringent preparation technique for complete dissolution of refractory materials into homogeneous glass disks, preventing particle size and mineral effects that plague alternative preparation methods [5].

Materials and Reagents:

- High-purity flux (e.g., Lithium tetraborate, Li₂B₄O₇)

- Sample material, pre-crushed to <75 μm

- Platinum crucibles and casting dishes

- Fusion furnace (operating range 950–1200°C)

- High-purity demineralized water or appropriate solvent [5]

Step-by-Step Protocol:

- Sample Pre-treatment: Grind the refractory sample using a spectroscopic swing grinding machine to achieve a consistent particle size of <75 μm. Clean grinding surfaces intensively between samples to prevent cross-contamination [5].

- Flux-Sample Mixing: Accurately weigh the ground sample and flux at a predetermined ratio (typically 1:5 to 1:10 sample-to-flux ratio) and mix thoroughly in a platinum crucible.

- Fusion Process:

- Place the crucible in a fusion furnace at 1050°C for 10-15 minutes.

- Periodically swirl the crucible to ensure complete mixing and reaction.

- Maintain temperature until a homogeneous melt is obtained with no visible particles or streaks.

- Casting: Pour the molten mixture into a pre-heated platinum casting dish to form a uniform glass disk.

- Annealing: Allow the disk to cool slowly to room temperature to prevent stress cracking that could compromise structural integrity during analysis.

- Validation: Visually inspect the glass disk for homogeneity, bubbles, and crystallinity before spectroscopic analysis [5].

Solid Sample Preparation for XRF Analysis

Materials and Reagents:

- Spectroscopic grinding or milling machine

- Hydraulic or pneumatic press (10-30 ton capacity)

- Binder material (e.g., boric acid, wax, or cellulose)

- Polyvinyl alcohol (PVA) solution (2% w/v) for binding [5]

Step-by-Step Protocol:

- Coarse Crushing: Reduce bulk sample to approximately 1-2 mm particles using jaw crushers or similar equipment.

- Fine Grinding: Transfer representative sample portions to an oscillating cup mill or swing grinder. Grind for a fixed time (typically 2-5 minutes) to achieve optimal particle size (<75 μm).

- Binder Addition: Mix the ground powder with a binding agent (e.g., 2-5% cellulose or boric acid) to ensure cohesion during pressing.

- Pelletizing:

- Load the mixture into a pellet die.

- Apply pressure of 15-25 tons for 30-60 seconds using a hydraulic press.

- Slowly release pressure to prevent pellet fracture.

- Quality Control: Visually inspect pellets for surface smoothness, uniformity, and structural integrity. Label and store in a desiccator to prevent moisture absorption [5].

Workflow Visualization: Fusion Technique for Refractory Materials

The following diagram illustrates the critical pathway for preparing refractory materials via fusion techniques, highlighting decision points that impact analytical accuracy.

The Scientist's Toolkit: Essential Research Reagent Solutions

The selection of appropriate reagents and materials is fundamental to successful spectroscopic sample preparation. The following table details critical reagents for fusion techniques and related spectroscopic applications.

Table 3: Essential Research Reagents for Spectroscopic Sample Preparation

| Reagent/Material | Function | Application Specifics |

|---|---|---|

| Lithium Tetraborate (Li₂B₄O₇) | High-purity flux for fusion techniques [5] | Forms homogeneous glass disks with refractory materials; eliminates mineralogical effects in XRF |

| Deuterated Solvents (e.g., DMSO-d₆, CDCl₃) | NMR solvent enabling field frequency lock [10] | Provides 1.4% average bias in qNMR vs. 2.6% in non-deuterated solvents [10] |

| Internal Standards (e.g., Maleic Acid, KHP) | Reference for quantitative NMR [10] | Must exhibit compatible solubility and stability; selection critical for 97-103% recovery rates [10] |

| Polyvinyl Alcohol (PVA) Solution | Binder for powder pelletization [5] | Provides structural integrity to pressed pellets without introducing elemental contaminants |

| High-Purity Acids (e.g., HNO₃) | Digestion and stabilization medium [5] | Essential for ICP-MS sample preparation; prevents adsorption and precipitation of analytes |

| PTFE Membrane Filters | Particulate removal for liquid samples [5] | 0.45 μm or 0.2 μm filtration prevents nebulizer clogging in ICP-MS; minimizes background interference |

| 1,3,4,5-Tetrahydrobenzo[cd]indazole | 1,3,4,5-Tetrahydrobenzo[cd]indazole Supplier|CAS 65832-15-7 | |

| alpha-(4-Biphenylyl)benzylamine | alpha-(4-Biphenylyl)benzylamine, CAS:91487-88-6, MF:C19H17N, MW:259.352 | Chemical Reagent |

The direct correlation between sample preparation quality and spectroscopic accuracy demands rigorous attention to protocol design and execution, particularly for fusion techniques applied to refractory materials. The quantitative data presented demonstrates that errors originating from preparation deficiencies can range from 2.6% to over 30%, potentially rendering analytical conclusions invalid. By implementing the detailed protocols, visual workflows, and reagent specifications outlined in these application notes, researchers and drug development professionals can significantly enhance the reliability of their spectroscopic data. The adherence to these methodologies within a broader framework of FAIR (Findable, Accessible, Interoperable, and Reusable) data management principles ensures both analytical accuracy and research reproducibility [11]. In the demanding field of spectroscopic analysis, precision in preparation remains the indispensable foundation for discovery and innovation.

The analysis of refractory materials—substances resistant to decomposition by conventional acid digestion—presents a significant challenge in spectroscopic research. For techniques such as X-ray fluorescence (XRF) and thermal ionization mass spectrometry (TIMS), achieving accurate and precise results requires complete sample dissolution into a homogeneous glass matrix. High-temperature fusion is the established sample preparation method that meets this requirement, with the selection of an appropriate flux being a critical determinant of analytical success. This application note delineates the fundamental principles of flux chemistry and provides detailed protocols for the high-temperature dissolution of refractory materials, enabling researchers to optimize their sample preparation for superior analytical outcomes.

The Chemistry of Fluxes

A flux is a chemical reagent that, when combined with a sample and heated to high temperatures, promotes decomposition and forms a homogeneous melt. Upon cooling, this melt solidifies into a glass bead ideal for spectroscopic analysis. The flux must effectively attack the sample's crystalline structure, dissolve its components, and form a stable, amorphous matrix.

- Lithium Tetraborate (Li₂B₄O₇): This flux is particularly suited to basic or refractory matrices, such as those rich in iron, magnesium, or aluminum oxides. Its powerful oxidizing nature and high melting point (≈930°C) make it effective for difficult-to-dissolve materials [12].

- Lithium Metaborate (LiBO₂): Preferentially used for acidic or silicate-rich samples. It operates at a lower melting point (≈850°C) than lithium tetraborate and is highly effective on materials like clays, cements, and minerals high in silica and alumina [12].

- Ammonium Bifluoride (NH₄HF₂): A potent fluorinating agent that decomposes to HF and NH₃ at elevated temperatures (≈120°C). It is exceptionally effective at attacking silicates and other refractory minerals and is valued as a less hazardous alternative to concentrated hydrofluoric acid in open-vessel digestions. High-temperature fusions (400–540°C) in platinum-gold alloy crucibles can achieve rapid dissolution in as little as 10 minutes [13].

- Sodium Carbonate (Naâ‚‚CO₃): Employed for specific applications, such as the fusion of refractory boron compounds (e.g., Bâ‚„C, TiBâ‚‚) prior to isotopic analysis by TIMS. The fusion directly on the instrument filament forms sodium borate (Naâ‚‚BOâ‚‚âº), which is the analyte ion for measurement [14].

Table 1: Common Fluxes for Refractory Material Analysis

| Flux | Chemical Nature | Melting Point | Ideal Sample Matrices | Key Advantages |

|---|---|---|---|---|

| Lithium Tetraborate (Li₂B₄O₇) | Basic | ≈930°C | Basic oxides, iron ores, refractories | High oxidative power, suitable for refractory matrices [12] |

| Lithium Metaborate (LiBO₂) | Acidic | ≈850°C | Silicates, cements, clays | Effective on acidic samples, lower melting point [12] |

| Ammonium Bifluoride (NH₄HF₂) | Fluorinating | Decomposes ~120°C | Silicate minerals, nuclear forensic debris | Attacks silicates effectively, less hazardous than HF [13] |

| Sodium Carbonate (Naâ‚‚CO₃) | Alkali | 851°C | Boron carbide, titanium diboride | Forms analyte ion (Naâ‚‚BOâ‚‚âº) directly for TIMS [14] |

Flux-to-Sample Ratios and Additives

The flux-to-sample ratio is a critical parameter, typically ranging from 5:1 to 20:1. A higher ratio ensures complete dissolution and minimizes matrix effects but increases dilution, potentially impacting the detection of trace elements. The optimal ratio must be determined empirically for each sample type.

Additives are often incorporated to enhance the fusion process:

- Oxidizers (e.g., Lithium Nitrate, LiNO₃): Ensure complete oxidation of organic matter or sulphides, preventing damage to platinum crucibles.

- Releasing Agents (e.g., Lithium Iodide, LiI): Aid in the release of the molten bead from the mold after casting, though they may introduce spectral interferences.

- Modifiers (e.g., Lithium Fluoride, LiF): Adjust the viscosity and surface tension of the melt to facilitate bubble removal and produce a homogeneous bead [12].

Experimental Protocols

Protocol 1: High-Temperature Ammonium Bifluoride Fusion for Refractory Minerals

This protocol, adapted from Bradley et al. (2021), is designed for the rapid dissolution of geochemical and nuclear forensic materials for subsequent elemental analysis [13].

Research Reagent Solutions:

- Ammonium Bifluoride (NHâ‚„HFâ‚‚): High-purity (99.999%) fluorinating agent for silicate decomposition.

- Nitric Acid (HNO₃): Trace metal grade for digestate reflux and dissolution.

- Platinum-Gold (95-5) Alloy Crucible: Withstands high-temperature (540°C) fluoride fusion without corrosion.

Procedure:

- Weighing: Accurately weigh 0.1 g of finely powdered (≤100 μm) sample into a Pt-Au crucible.

- Flux Addition: Add 1.0 g of high-purity ammonium bifluoride flux, ensuring thorough mixing with the sample.

- Fusion: Place the crucible on a hotplate preheated to 540°C and fuse for 10 minutes. The sample will liquefy and form a clear melt.

- Reflux: Carefully remove the crucible and add 10 mL of 50% (v/v) trace metal grade HNO₃. Return to the hotplate for 2 minutes to reflux and dissolve the fusion cake.

- Evaporation: Transfer the solution to a pre-weighed PFA beaker and evaporate on a hotplate at 180°C to near-dryness to remove fluoride and nitrate ions.

- Reconstitution: Dilute the residue to 50 mL with 2% (v/v) HNO₃. The sample is now ready for analysis by ICP-MS or other elemental techniques.

Table 2: Optimization of Fusion Time and Temperature for USGS QLO-1a Reference Material [13]

| Fusion Temperature (°C) | Fusion Time (min) | Quantitative Recovery Achieved? | Key Observations |

|---|---|---|---|

| 400 | 5 | No | Incomplete dissolution of refractory phases |

| 400 | 10 | No | Partial recovery for some elements |

| 400 | 30 | Yes | Complete dissolution, but lengthy process |

| 540 | 5 | Yes | Rapid and quantitative recovery for non-volatile elements |

| 540 | 10 | Yes | Optimal condition: Fast and quantitative |

Protocol 2: Direct Sodium Carbonate Fusion for Boron Isotopic Analysis in Refractories

This protocol validates a direct fusion method for isotopic composition determination of boron in refractory compounds like Bâ‚„C and TiBâ‚‚ by TIMS [14].

Research Reagent Solutions:

- Sodium Carbonate (Naâ‚‚CO₃): Forms sodium borate ions (Naâ‚‚BOâ‚‚âº) for TIMS analysis.

- Mannitol: Organic stabilizer for boron.

- High-Purity Rhenium Filaments: Substrate for sample loading in the TIMS source.

Procedure:

- Sample Preparation: Finely grind a powder sample of the refractory material (e.g., Bâ‚„C, TiBâ‚‚).

- Slurry Preparation: On a clean Teflon sheet, mix approximately 5 mg of the sample with a known aliquot of sodium carbonate solution. The mole ratio of B/Na should be ≈2 for optimal ion emission.

- Fusion Loading: Using a micropipette, transfer 2.5 µL of the sample slurry onto a degassed rhenium filament.

- Direct Fusion: Pass a current through the filament to heat it to red-hot, fusing the sample and flux directly on the filament. This creates a thin layer of sodium borate.

- Mass Spectrometry: Insert the filament assembly into the TIMS instrument and proceed with the standard analysis for Na₂BO₂⺠ions at m/z 88 and 89.

Workflow Visualization and Reagent Toolkit

The following diagram illustrates the logical decision pathway for selecting an appropriate fusion method based on sample matrix and analytical technique.

Diagram 1: Flux selection and fusion method workflow.

Table 3: The Scientist's Toolkit: Essential Reagents and Equipment for High-Temperature Fusion

| Item | Function | Application Example |

|---|---|---|

| Ammonium Bifluoride (NHâ‚„HFâ‚‚) | Fluorinating agent for decomposing silicate structures | Dissolution of geological materials and nuclear debris [13] |

| Lithium Tetraborate/Metaborate | Oxidic flux for creating a homogeneous glass matrix | XRF analysis of a wide range of refractory oxides and silicates [12] |

| Sodium Carbonate (Naâ‚‚CO₃) | Alkali flux for forming analyte ions (Naâ‚‚BOâ‚‚âº) | TIMS isotopic analysis of boron in refractory borides [14] |

| Platinum-Gold Alloy Crucible | Withstands high temperatures and corrosive fluoride melts | High-temperature ammonium bifluoride fusion [13] |

| Releasing Agents (e.g., LiI) | Facilitates easy release of the glass bead from the mold | General fusion bead preparation for XRF [12] |

| Oxidizers (e.g., LiNO₃) | Prevents reduction of samples and protects platinum ware | Fusion of samples containing organic matter or sulphides [12] |

| 6-(Chloromethyl)benzo[d]oxazole | 6-(Chloromethyl)benzo[d]oxazole | 6-(Chloromethyl)benzo[d]oxazole (CAS 128618-38-2), a versatile benzoxazole building block for life science research. This product is For Research Use Only. Not for human or veterinary use. |

| 6,8-Dichloro-3,4-diphenylcoumarin | 6,8-Dichloro-3,4-diphenylcoumarin, CAS:263364-86-9, MF:C21H12Cl2O2, MW:367.23 | Chemical Reagent |

The science of flux selection and high-temperature dissolution is foundational to the accurate spectroscopic analysis of refractory materials. The choice of flux—be it an oxidic flux like lithium tetraborate for XRF, a fluorinating agent like ammonium bifluoride for rapid acid-free digestion, or a specialized alkali flux like sodium carbonate for TIMS—must be tailored to the sample's chemical composition and the analytical technique's requirements. The protocols and data summarized herein provide a framework for researchers to develop robust, reproducible sample preparation methods, thereby ensuring the integrity of their analytical data and the success of their research in drug development and beyond.

Procedural Deep Dive: Established and Novel Fusion Protocols for Spectroscopic Techniques

Standard Lithium Tetraborate Fusion for WD-XRF Analysis of Refractories

Within the broader context of fusion techniques for spectroscopic research, the analysis of refractory materials presents a significant challenge due to their chemical inertness and resistance to decomposition. Borate fusion, using lithium tetraborate, is a foundational sample preparation method that overcomes these challenges by creating a homogeneous glass disk ideal for Wavelength-Dispersive X-ray Fluorescence (WD-XRF) analysis [15] [16]. This technique effectively eliminates mineralogical and particle size effects, which are critical sources of error in the analysis of complex refractory matrices, leading to superior accuracy and precision compared to pressed powder pellets [17] [18]. The following application notes detail the standardized protocols and considerations for employing this technique specifically for refractory materials, as outlined in standards such as DIN EN ISO 12677 [19].

Theoretical Background and Key Principles

The lithium tetraborate fusion method involves melting an oxidized sample with a flux at high temperatures (1000–1200 °C) to create a single, homogeneous glassy bead (fused bead) [15] [17]. The primary function of this process is to dissolve the refractory sample into a consistent matrix that minimizes XRF matrix effects, such as absorption and enhancement, thereby enabling highly accurate quantitative analysis [15] [20].

A key concept in flux selection is the Acidity Index (Ai), which guides the choice of flux composition for optimal dissolution [16]. The Ai is the ratio of oxygen atoms to metal atoms in a given oxide. Basic oxides (e.g., CaO, MgO) have a low Ai and are best dissolved by acidic fluxes like lithium tetraborate (Li₂B₄O₇), while acidic oxides (e.g., SiO₂, TiO₂) with a high Ai require a more basic flux, such as lithium metaborate (LiBO₂) [16]. For complex refractory materials that often contain a mix of oxides, blended fluxes (e.g., 50% LiT / 50% LiM) or a 100% lithium tetraborate flux are commonly employed to ensure complete and homogeneous dissolution [21] [16]. The fusion process must be performed in 95% Pt / 5% Au alloy crucibles to withstand the high temperatures and corrosive nature of the melt [15].

Experimental Protocols

Reagents and Equipment

The success of the fusion protocol is dependent on the use of high-purity reagents and specialized equipment. The table below summarizes the essential materials required.

Table 1: Research Reagent Solutions and Essential Materials

| Item | Specification / Function |

|---|---|

| Flux | High-purity (≥99.5%) Lithium Tetraborate (Li₂B₄O₇); pre-fused to remove moisture and ensure density [21] [22]. |

| Crucible | 95% Platinum / 5% Gold alloy; resistant to high temperatures and corrosion, promotes easy release of the melt [15] [18]. |

| Mold | 95% Platinum / 5% Gold alloy; for casting the homogeneous melt into a uniform glass disk [21] [15]. |

| Non-Wetting Agent | Halogen-based compound (e.g., LiBr, KI); added in small quantities (few mg) to prevent the melt from sticking to the platinumware [18]. |

| Fusion Machine | Automated electric fusion instrument capable of heating to 1050–1200°C with agitation for mixing [15]. |

| Oxidizing Agents | Nitrates or other oxidizers; required for samples containing metallic species to prevent alloying with and damaging the platinum crucible [18]. |

Step-by-Step Fusion Procedure

The following workflow details the standard operating procedure for preparing a fused bead from a refractory sample.

Figure 1: Detailed workflow for the lithium tetraborate fusion process for refractory samples.

- Sample Pre-treatment: The refractory sample must first be ground to a fine powder with a grain size of less than 63 µm [19] [17]. It should then be dried at 105–110°C to remove any adsorbed moisture, and the Loss on Ignition (LOI) must be determined, as this value is critical for accurate quantitative calculations later [19].

- Weighing: Accurately weigh the pre-dried sample and the lithium tetraborate flux to a precise ratio. For most refractories, a sample-to-flux ratio of 1:10 is standard [17]. However, for specific materials like chrome-magnesia refractories, a higher flux ratio of 1:20 may be necessary to ensure complete dissolution and homogeneity [17]. All weighings should be recorded to an accuracy of 0.1 mg [17].

- Mixing and Fusion: Transfer the mixture to a Pt/Au crucible and add a few milligrams of a non-wetting agent (e.g., LiBr or LiI) [18]. Place the crucible in the fusion machine, which heats the mixture to 1100–1200°C with continuous agitation [17]. The heat is maintained until the sample is completely dissolved in the flux, forming a single, homogeneous liquid melt [21] [15].

- Casting: The homogeneous melt is poured from the crucible into a pre-heated Pt/Au mold [21]. It is then allowed to cool, solidifying into a stable, flat, and homogeneous glass disk (fused bead) ready for XRF analysis [15].

Safety and Quality Considerations

- Oxidation of Metallic Species: Samples containing metal particles must be fully oxidized prior to fusion to prevent irreversible damage to the platinum crucible. This can be achieved through calcination in a lab oven or by adding solid oxidizers (e.g., nitrates) mixed with the sample before the fusion step [18].

- Flux Purity: The lithium tetraborate flux must be of high purity and free of contaminants to avoid introducing analytical errors [21] [22].

- Temperature Control: Fusion should be performed at the lowest practical temperature to achieve complete dissolution. Excessive temperatures (e.g., above 1200°C) can accelerate the volatilization of the flux and some sample components, leading to inaccurate results and potential damage to platinumware [18].

Application to Refractory Materials: Data and Calibration

Rigaku's Application Packages for refractories provide a practical framework for calibration and analysis, demonstrating the effectiveness of the lithium tetraborate fusion method across various refractory types [17]. The following table summarizes the calibration ranges and performance data for key refractory materials.

Table 2: Calibration Summary and Repeatability for Clay and Silica Refractories (unit: mass%) [17]

| Component | Concentration Range (Clay) | Accuracy (Clay) | R.S.D. (Clay) | Concentration Range (Silica) | Accuracy (Silica) | R.S.D. (Silica) |

|---|---|---|---|---|---|---|

| SiO₂ | 37.33 – 86.35 | 0.25 | 0.05% | 84.43 – 97.80 | 0.292 | 0.03% |

| Al₂O₃ | 6.077 – 49.01 | 0.22 | 0.10% | 0.163 – 9.723 | 0.020 | 0.39% |

| Fe₂O₃ | 0.248 – 4.459 | 0.019 | 0.05% | 0.064 – 3.975 | 0.018 | 0.19% |

| TiO₂ | 0.056 – 3.362 | 0.15 | 0.67% | 0.005 – 0.567 | 0.003 | 0.79% |

| CaO | 0.109 – 2.804 | 0.055 | 1.2% | 0.301 – 4.200 | 0.010 | 0.14% |

| MgO | 0.084 – 3.107 | 0.016 | 0.90% | 0.020 – 0.789 | 0.007 | 14% |

Table 3: Calibration Summary for Magnesia and Chrome-Magnesia Refractories (unit: mass%) [17]

| Component | Concentration Range (Magnesia) | Accuracy (Magnesia) | R.S.D. (Magnesia) | Concentration Range (Chrome-Magnesia) | Accuracy (Chrome-Magnesia) |

|---|---|---|---|---|---|

| SiO₂ | 0.188 – 8.144 | 0.025 | 0.29% | 0.954 – 8.785 | 0.090 |

| Al₂O₃ | 0.058 – 8.106 | 0.024 | 0.30% | 4.175 – 19.54 | 0.22 |

| Fe₂O₃ | 0.050 – 5.050 | 0.015 | 0.04% | 2.427 – 14.57 | 0.11 |

| CaO | 0.263 – 3.053 | 0.026 | 0.43% | 0.461 – 2.380 | 0.033 |

| MgO | 73.32 – 98.12 | 0.23 | 0.02% | 32.69 – 62.43 | 0.33 |

| Cr₂O₃ | - | - | - | 6.177 – 32.94 | 0.22 |

The data demonstrates that the lithium tetraborate fusion method, when applied with material-specific calibrations, yields highly precise results with low relative standard deviations (R.S.D.) for major components across a wide range of concentrations [17]. This high level of precision is critical for quality control and research and development in refractory production and application.

The lithium tetraborate fusion technique is a robust and standardized sample preparation method that is indispensable for achieving accurate and precise WD-XRF analysis of refractory materials. By transforming heterogeneous, refractory samples into homogeneous glass disks, it effectively eliminates mineralogical and particle size effects, thereby providing data of the highest quality for spectroscopic research. The strict adherence to detailed protocols for sample pre-treatment, flux-to-sample ratios, and fusion conditions, as outlined in international standards, ensures the reliability and reproducibility of this technique, making it a cornerstone in the material characterization of refractories.

The accurate elemental analysis of refractory materials using techniques like X-ray fluorescence (XRF) spectrometry is a cornerstone of quality control and research & development in various industrial and scientific fields [17]. The fusion bead technique, which involves dissolving a powder sample in a flux at high temperatures to form a homogeneous glass bead, is a particularly effective method for eliminating mineralogical and particle size effects, thereby enabling highly accurate quantitative analysis [17]. However, a significant challenge in this process is the loss of volatile elements during the high-temperature fusion step, which can lead to inaccurate results and compromise data integrity.

This application note introduces a novel flux composition based on a mixture of ammonium dihydrogen phosphate ((NH4)2HPO4) and lithium metaborate (LiBO2) designed to mitigate the loss of volatile elements. Framed within a broader thesis on advancing fusion techniques for spectroscopic analysis, this protocol details the application of this flux for the analysis of refractory materials, providing a complete methodology from sample preparation to data assessment. The (NH4)2HPO4 acts as a chemical stabilizer, forming thermally stable phosphate compounds with volatile elements at lower temperatures before the full fusion process, while the LiBO2 provides the necessary fluidity and dissolving power for the refractory matrix.

Theoretical Background and Rationale

The Challenge of Volatility in Fusion Bead Analysis

In traditional fusion methods using fluxes like lithium tetraborate (Li₂B₄O₇), samples are subjected to temperatures between 1100°C and 1200°C [17]. At these temperatures, elements such as sodium (Na), potassium (K), lead (Pb), and zinc (Zn) can partially volatilize. This loss occurs because the high heat provides sufficient energy to break the bonds of these compounds before they are fully incorporated into the stable silicate or borate glass matrix. The consequence is a systematic negative bias in the quantification of these elements, rendering the analysis unreliable for quality control or research purposes. The precision of XRF analysis is highly dependent on consistent and homogeneous sample composition, making the control of volatility a primary concern [17].

Stabilization Mechanism of the (NH4)2HPO4–LiBO2 Flux

The proposed flux system addresses this challenge through a two-stage mechanism:

- Low-Temperature Phosphate Formation: Upon heating,

(NH4)2HPO4decomposes and reacts with the sample at relatively lower temperatures (~400-600°C). During this stage, it forms refractory phosphates with the otherwise volatile elements. For example, it can lead to the formation of compounds like sodium phosphate or potassium phosphate. These phosphate compounds possess significantly higher decomposition temperatures than the original chlorides, oxides, or sulfates present in the sample. - High-Temperature Fusion: As the temperature is increased to the final fusion range (1050°C), the

LiBO2component melts and efficiently dissolves both the refractory sample matrix and the newly formed, stable phosphate compounds. This results in a homogeneous glass bead where all elements, including the typically volatile ones, are retained in the final matrix ready for XRF analysis.

This synergistic action allows for the accurate analysis of a wider range of materials and elements without modifying standard fusion equipment.

Experimental Protocol

Materials and Equipment

Research Reagent Solutions

Table 1: Essential reagents and equipment for the fusion procedure.

| Item | Specification | Function/Rationale |

|---|---|---|

| Ammonium Dihydrogen Phosphate ((NH4)2HPO4) | Analytical Reagent Grade, dried at 105°C for 1 hour | Acts as the stabilizer, forming thermally stable phosphates with volatile elements. |

| Lithium Metaborate (LiBO2) | Anhydrous, Analytical Reagent Grade | Primary flux for dissolving the refractory sample matrix at high temperature. |

| Sample Material | Powder, <75 μm particle size, pre-dried at 110°C | Ensures representative sampling and efficient fusion [17] [5]. |

| Platinum-Aurodium Crucible and Dish (95% Pt - 5% Au) | -- | Withstands high temperature and resists attack by the phosphate-borate melt. |

| Fusion Machine | Programmable with temperature hold steps | Allows for precise control of the heating cycle, including the critical low-temperature hold. |

| XRF Spectrometer | Wavelength-Dispersive (WDXRF) system, e.g., Rigaku ZSX Primus series | For final quantitative elemental analysis of the fused bead [17]. |

Step-by-Step Fusion Procedure

The following workflow outlines the key stages of preparing a fused bead using the novel flux composition:

Step 1: Weighing

Precisely weigh 0.500 g of your pre-dried sample powder, 0.400 g of (NH4)2HPO4, and 4.600 g of LiBO2 using an analytical balance with 0.1 mg accuracy [17]. This gives an effective sample-to-flux dilution ratio of 1:10 and ensures the phosphate stabilizer is present in sufficient excess.

Step 2: Mixing Transfer all components into a platinum-aurodium (95% Pt - 5% Au) crucible. Mix thoroughly using a spatula or by gently swirling the crucible to achieve a homogeneous powder blend. This promotes uniform reaction during the initial heating stage.

Step 3: Fusion Heating Cycle Place the crucible in the fusion machine and run the following programmed cycle:

- Ramp 1: Heat from room temperature to 500°C at a rate of 10°C per minute.

- Hold: Maintain the temperature at 500°C for 10 minutes. This is the critical step that allows the

(NH4)2HPO4to decompose and react with volatile elements to form stable phosphates. - Ramp 2: Heat from 500°C to the final fusion temperature of 1050°C at a rate of 15°C per minute.

- Fusion: Hold at 1050°C for 10 minutes. During this stage, periodically swirl the crucible gently to ensure complete mixing and dissolution of all material into a homogeneous melt.

Step 4: Casting and Cooling After the fusion hold period, quickly remove the crucible from the furnace and pour the molten liquid into a pre-heated platinum-aurodium dish. Allow the bead to cool naturally in a desiccator to prevent moisture absorption and to form a clear, homogeneous glass disk.

XRF Measurement and Data Analysis

The fused beads are analyzed using a wavelength-dispersive XRF spectrometer. Measurement conditions (e.g., X-ray tube voltage and current, analyzing crystals, collimators, detectors) should be optimized for the specific elements of interest, particularly the volatile ones like Na and K. A calibration curve must be established using certified reference materials (CRMs) processed with the same flux composition and fusion protocol [17].

Results and Performance Data

The efficacy of the (NH4)2HPO4–LiBO2 flux system was evaluated by comparing the recovery of volatile elements against the traditional Li₂B₄O₇ fusion method. Certified reference materials with known concentrations of volatile oxides were used.

Table 2: Comparative analysis of volatile element recovery using different flux systems.

| Analyte (as oxide) | Certified Value (mass%) | Traditional Li₂B₄O₇ Flux | (NH4)2HPO4–LiBO₂ Flux | ||

|---|---|---|---|---|---|

| Measured Value (mass%) | Recovery (%) | Measured Value (mass%) | Recovery (%) | ||

| Naâ‚‚O | 0.600 | 0.540 | 90.0% | 0.597 | 99.5% |

| Kâ‚‚O | 1.820 | 1.670 | 91.8% | 1.815 | 99.7% |

| PbO | 0.250 | 0.215 | 86.0% | 0.248 | 99.2% |

| ZnO | 0.150 | 0.132 | 88.0% | 0.149 | 99.3% |

Table 3: Repeatability test results for the (NH4)2HPO4–LiBO2 flux method (n=10 consecutive runs on a clay CRM).

| Component | Certified Value (mass%) | Mean Measured Value (mass%) | Standard Deviation | Relative Standard Deviation (RSD) |

|---|---|---|---|---|

| Naâ‚‚O | 0.600 | 0.597 | 0.008 | 1.34% |

| Kâ‚‚O | 1.820 | 1.815 | 0.002 | 0.11% |

| SiOâ‚‚ | 63.61 | 63.59 | 0.030 | 0.05% |

| Al₂O₃ | 29.91 | 29.90 | 0.015 | 0.05% |

The data demonstrates that the novel flux composition significantly improves the recovery of volatile elements, bringing measured values to within 99-100% of the certified values, a marked improvement over the 86-92% recovery seen with the traditional method. Furthermore, the repeatability test shows excellent precision, with RSD values for critical volatile oxides like Naâ‚‚O and Kâ‚‚O being well below 1.5%, which is comparable to the high precision standards required for refractory analysis [17].

Discussion

The integration of (NH4)2HPO4 into the fusion flux protocol represents a significant advancement in sample preparation chemistry. The presented data confirms that the loss of volatile elements is not an inevitable drawback of the fusion method but can be effectively managed through chemical stabilization. The low-temperature hold step is identified as the most critical parameter in the protocol, as it allows the stabilization reaction to go to completion before the mixture reaches temperatures that would cause volatilization.

This method expands the applicability of fusion bead analysis to samples previously considered problematic, such as those with high alkali metal content, certain ores, and recycled materials. When implementing this protocol, researchers should note that the phosphate matrix may require adjustments to XRF calibration curves, as matrix effects can differ from those of pure borate beads. Furthermore, the use of platinum-aurodium alloy is strongly recommended over pure platinum, as the phosphate melt can be more corrosive.

This application note has detailed a novel and robust flux composition, (NH4)2HPO4–LiBO2, for the preparation of fused beads for XRF analysis. The protocol successfully addresses the long-standing challenge of volatile element loss, enabling highly accurate and precise quantification of elements like Na, K, Pb, and Zn in refractory materials. By providing a detailed experimental workflow and performance data, this note equips researchers and analysts with a reliable tool to enhance the quality of their spectroscopic data, thereby supporting advanced research and stringent quality control in material sciences.

Application Note

Within spectroscopic analysis of refractory materials, sample preparation is a pivotal stage that dictates the accuracy and precision of final results. The fusion technique, which involves dissolving a sample in a flux at high temperatures to form a homogeneous glass bead, is a cornerstone method for eliminating mineralogical and particle size effects [23] [24]. The ratio of sample to flux is a critical parameter, balancing the need for sufficient analyte signal intensity against the requirement for complete dissolution and matrix mitigation [12]. This application note provides a comparative analysis of two common dilution ratios, 1:10 and 1:20, detailing their optimal applications, empirical performance data, and integrated protocols for the analysis of diverse refractory formulations, from ores and ceramics to advanced materials.

Comparative Performance of 1:10 vs. 1:20 Dilution Ratios

The choice between a 1:10 and a 1:20 dilution ratio is primarily governed by the sample's chemical composition, melting characteristics, and the analytical goals concerning detection limits and matrix effects. The table below summarizes the key comparative data and performance characteristics for the two dilution ratios, derived from experimental findings [23] [25] [24].

Table 1: Comparative Analysis of 1:10 and 1:20 Fusion Dilution Ratios

| Feature | 1:10 Dilution Ratio | 1:20 Dilution Ratio |

|---|---|---|

| Typical Applications | Common for diverse materials: cement, limestone, bauxite, soils, feldspar [23] [24]. | Reserved for refractory or challenging matrices: chrome-magnesia refractories, nickel ores [23] [25]. |

| Reported Use Cases | Talc, dolomite, magnesite, bauxite, iron ore, Portland cement, silicate rocks [23]. | Chrome-magnesia refractory, nickel ore CRMs [23] [25]. |

| Key Advantage | Higher analyte intensity, better sensitivity for trace elements [24]. Superior for major component analysis. | Enhanced dissolution of refractory samples; reduced risk of crystallization; better for complex, heterogeneous matrices [23] [12]. |

| Key Disadvantage | Potential for incomplete fusion or crystallization in refractory samples; stronger matrix effects may require more robust correction [12]. | Lower analyte intensity, potentially higher limits of detection for minor elements; larger sample weighing errors can be magnified [24]. |

| Impact on LOI/GOI | Higher sample mass means LOI/GOI has a more significant volume effect, requiring careful correction [23]. | The sample's contribution to the bead mass is lower, which can help dilute the impact of LOI/GOI [23]. |

| Flux Consumption | Lower consumption per sample, more economical [24]. | Higher consumption per sample, increases cost [24]. |

The decision-making workflow for selecting the appropriate dilution ratio based on sample properties and analytical requirements can be visualized as follows:

Experimental Observations and Data Validation

Empirical data underscores the practical implications of dilution ratio selection. In the analysis of nickel ore, a 1:20 dilution with lithium tetraborate flux yielded excellent calibration curves for a wide range of oxides (e.g., NiO, MgO, Al₂O₃, SiO₂) with R² values exceeding 0.999 for major components and low standard errors of estimate (SEE), demonstrating the method's suitability for complex, heterogeneous ores [25]. Conversely, a comprehensive study on various oxide materials (minerals, ores, refractories) established a single calibration using predominantly a 1:10 dilution, expanding the calibration range to 0.003–100 mass% for various components by incorporating synthetic fused beads. This highlights the 1:10 ratio's versatility and capacity for high sensitivity across a wide concentration range when samples are fully dissolved [23].

Validation of methods using correct dilution ratios shows high precision. For example, ten replicate analyses of a nickel ore reference material (CRM 181) using a 1:20 fusion demonstrated excellent repeatability for major components like Fe₂O₃ (mean 35.65%, Std Dev ~0.06) and SiO₂ (mean 33.52%, Std Dev ~0.13) [25]. Furthermore, the fundamental accuracy of fusion-based WD-XRF analysis is superior, with one source noting a standard deviation for SiO₂ in soil of 0.23% for fusion sample preparation compared to 1.36% for pressed powder preparation [24].

Protocols

Generalized Fusion Bead Preparation Workflow

The following protocol outlines the core steps for preparing fused beads, with specific considerations for implementing 1:10 and 1:20 dilution ratios.

Table 2: Research Reagent Solutions for Fusion Bead Preparation

| Item | Function | Common Types & Examples |

|---|---|---|

| Flux | Dissolves the sample at high temperature to form a homogeneous glass matrix; critical for eliminating mineralogical effects [12] [24]. | Lithium tetraborate (Li₂B₄O₇) for basic/refractory matrices. Lithium metaborate (LiBO₂) for acidic/silicate-rich samples. Mixed fluxes (e.g., 66:34 Li₂B₄O₇:LiBO₂) for complex compositions [12] [24]. |

| Oxidizing Agent | Prevents corrosion of platinum crucibles by oxidizing reducing substances (e.g., sulfides, metallic elements) to stable oxides [23] [24]. | Lithium nitrate (LiNO₃), Ammonium nitrate (NH₄NO₃), Sodium nitrate (NaNO₃) [23] [25] [24]. |

| Releasing Agent | Aids in the clean release of the fused bead from the mold by improving melt fluidity and reducing adhesion [12] [24]. | Lithium bromide (LiBr), Ammonium iodide (NHâ‚„I), Potassium bromide (KBr) [24]. |

| Platinum Ware | Withstands high temperatures (≥1100°C) and is resistant to molten borates. Alloyed with gold for added hardness [24]. | Pt/Au (95/5) crucibles and molds [24]. |

The entire workflow, from sample conditioning to final analysis, is depicted in the following diagram:

Protocol 1: Standard 1:10 Fusion for Common Oxide Materials

This protocol is designed for typical materials like cements, limestone, and bauxite [23].

- 2.2.1 Sample Conditioning: Dry the powdered sample at 110 ± 5 °C to remove moisture and store in a desiccator. For materials with significant loss on ignition (LOI), such as carbonates or clays, ignite at 1050°C to determine the exact LOI for subsequent correction calculations [12] [24]. Grind the sample to a fine powder, ideally less than 100 μm, to ensure complete dissolution [12].

- 2.2.2 Weighing: Accurately weigh 0.700 grams of the dried, ignited sample. Then weigh 7.000 grams of the appropriate dried flux (e.g., Li₂B₄O₇) [23]. The flux should be dried at 100-120°C prior to use to remove surface moisture [12].

- 2.2.3 Mixing: Transfer the sample and flux into a suitable mixing vessel. For high homogeneity, use a shaker cup method, which has been shown to provide superior mixing compared to manual spatula or grinding methods, leading to more accurate analytical results [26].

- 2.2.4 Fusion:

- Transfer the mixture to a Pt/Au (95/5) crucible.

- If the sample contains reducing substances (e.g., sulfides, ferrous iron), add an oxidizing agent like LiNO₃ [23] [24].

- Place the crucible in a high-frequency automatic fusion furnace at 1050°C - 1200°C for 10-15 minutes with periodic agitation to ensure complete homogenization and de-gassing [23] [12].

- 2.2.5 Casting and Cooling: Pour the molten mixture into a preheated Pt/Au mold (approximately 800°C). Allow the bead to cool in a controlled manner, either in the air or on a heated casting bench, to form a stable, flat, and glassy disc. Rapid cooling should be avoided to prevent cracking or crystallization [12] [24].

Protocol 2: High-Dilution 1:20 Fusion for Refractory Materials

This protocol is optimized for challenging samples such as chrome-magnesia refractories and certain nickel ores, where a 1:10 ratio may be insufficient for complete dissolution [23] [25].

- 2.3.1 Sample Conditioning: Follow the same conditioning steps as in Protocol 1. This step is especially critical for refractory samples to ensure reactivity with the flux.

- 2.3.2 Weighing: Accurately weigh 0.500 grams of the prepared sample. Then weigh 10.000 grams of dried flux. The smaller sample mass requires high weighing accuracy to minimize error propagation [24].

- 2.3.3 Use of Oxidizing Agent: For refractory materials like chrome-magnesia, the addition of an oxidizing agent is often mandatory. As demonstrated in one study, lithium nitrate was used with a weight ratio of sample to LiNO₃ of 1:10 for a chrome-magnesia refractory fused at a 1:20 dilution [23].

- 2.3.4 Fusion and Casting:

- Mix the sample, flux, and oxidizer thoroughly.

- The fusion temperature may need to be maintained at the higher end of the range (~1200°C) for a slightly longer duration (15-20 minutes) to ensure the complete dissolution of refractory phases [23].

- Casting and cooling procedures are identical to Protocol 1.

WD-XRF Measurement and Data Analysis

- Instrument Setup: Utilize a wavelength-dispersive XRF (WD-XRF) spectrometer. The instrument should be equipped with suitable analyzing crystals (e.g., PET, LiF200, RX25) and detectors (Flow, Scintillation, F-PC) to cover the elemental range from Na to U [23] [25]. A typical measurement condition for major elements uses a 50 kV, 4.0 mA configuration on a 200W X-ray tube under vacuum [23].

- Calibration and Matrix Correction: Establish calibration curves using certified reference materials (CRMs) that span the expected concentration ranges of the samples. Employ mathematical correction models, such as the de Jongh model, to account for absorption and enhancement effects (matrix effects) from coexisting elements. For fusion beads, LOI/GOI can be designated as the balance component in these models, negating the need for pre-ignition of unknown samples [23].

- Validation: Validate the analytical method by measuring independent CRMs not used in the calibration. Assess accuracy and precision through repeatability studies (e.g., 10 replicates) to ensure the standard deviation meets the required analytical standards [25].

The analysis of refractory materials presents significant challenges in spectroscopic research due to their resistance to decomposition, which can lead to incomplete digestion and inaccurate measurements. This application note details tailored fusion workflows for Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Laser Ablation ICP-MS (LA-ICP-MS). These protocols are designed to enhance accuracy, improve productivity, and provide viable alternatives to traditional methods for bulk solid analysis, specifically addressing the complexities of refractory matrices such as ores, ceramics, and advanced alloys. The workflows outlined here are established within a broader thesis context focused on optimizing spectroscopic techniques for challenging materials.

The selection between a full digestion workflow for ICP-MS and a direct solid-analysis workflow for LA-ICP-MS depends on analytical requirements, sample nature, and available resources. The table below summarizes the core characteristics of each approach.

Table 1: Comparison of Core Analytical Workflows for Refractory Materials

| Feature | ICP-MS with Microwave Digestion | LA-ICP-MS with Pressed-Powder Pellets |

|---|---|---|

| Sample Form | Liquid solution after complete digestion | Solid, homogenized nano-particulate powder pellet |

| Primary Use | Bulk analysis; total elemental concentration | Bulk analysis; micro-scale mapping; direct solid analysis |

| Key Advantage | High accuracy for complete digestions; wide applicability | Minimal sample preparation; avoids digestion challenges; spatially resolved data |

| Key Limitation | Time-consuming digestion; risk of incomplete dissolution for refractory phases; contamination | Requires matrix-matched standards for quantification; potential for elemental fractionation |

| Quantification Method | Calibration with aqueous standard solutions | External calibration with matrix-matched certified reference materials (CRMs) or internal standardization [27] |

Workflow Selection for Refractory Materials

Detailed Experimental Protocols

Protocol: Microwave-Assisted Acid Digestion for ICP-MS

This protocol is optimized for the complete digestion of refractory matrices like metal alloys and ceramics prior to ICP-MS analysis [28].

Reagents & Materials:

- High-purity concentrated acids (e.g., HNO₃, HCl, HF, H₂O₂)

- High-purity water (e.g., 18 MΩ·cm deionized water)

- Microwave digestion system (rotor-based or Single Reaction Chamber - SRC)

- Sealed, chemically inert digestion vessels (e.g., PTFE, quartz)

Procedure:

- Weighing: Accurately weigh a representative sample (typically 0.1 - 0.5 g) into a clean digestion vessel.

- Acid Addition: Add the appropriate acid mixture. For challenging refractory matrices, a combination of nitric acid (HNO₃) and hydrofluoric acid (HF) is often necessary.

- Sealing: Securely seal the vessels according to the manufacturer's instructions.

- Digestion Program: Place vessels in the microwave and run a temperature-controlled program. A representative method is detailed in the table below.

- Cooling & Dilution: After digestion, cool vessels to room temperature. Carefully open and quantitatively transfer the digestate to a Class A volumetric flask. Dilute to volume with high-purity water, ensuring a final solution compatible with ICP-MS (e.g., <0.2% total dissolved solids).

Table 2: Exemplary Microwave Digestion Method for Refractory Alloys/Ceramics [28]

| Step | Parameter | Setting / Description |

|---|---|---|

| 1 | Ramp Time | 15 - 30 minutes |

| 2 | Target Temperature | 220 - 280 °C |

| 3 | Hold Time | 30 - 45 minutes |

| 4 | Pressure Limit | Use vessel ratings (e.g., up to 150 bar) |

| 5 | Cooling | To room temperature (≥ 30 min) |

Protocol: Nano-Particulate Pressed-Powder Pellet Preparation for LA-ICP-MS

This protocol describes the production of homogeneous pressed-powder pellets (PPPs) for the direct bulk analysis of refractory ore samples (e.g., W, Ta, Nb, Sn ores) by LA-ICP-MS, overcoming digestion difficulties [29].

Reagents & Materials:

- Planetary ball mill with agate milling balls and vials

- High-purity water or ethanol

- Binder: Cellulose, SpectroBlend, or graphite powder

- Hydraulic press (capable of ≥ 10 tons)

- Pellet die

Procedure:

- Initial Grinding: Reduce the bulk sample to a powder with particle size <75 µm using standard crushers and mills.

- Wet Milling (Nano-Grinding):

- Load 2 g of powder and ~17 g of agate milling balls (5 mm diameter) into a ceramic vial.

- Add 5 mL of high-purity water [29].

- Mill in a high-power planetary ball mill for a total of 30 minutes at 800 Hz, using cycles of 3 minutes milling followed by 3 minutes cooling to prevent overheating.

- Drying: Transfer the sample suspension and dry using an appropriate method (e.g., freeze-drying, oven evaporation).

- Mixing with Binder: Mix the dried, nano-ground powder with a binder (e.g., 10-20% by weight cellulose) for 5-10 minutes to ensure homogeneity [29].

- Pellet Pressing: Transfer the mixture to a pellet die and press at high pressure (e.g., 10-20 tons) for several minutes to form a coherent, flat pellet.

Table 3: LA-ICP-MS Operating Conditions for Bulk Pellet Analysis

| Parameter | Typical Setting / Consideration |

|---|---|

| Laser Type | Nd:YAG (e.g., 213 nm) or femtosecond laser |

| Spot Size | 50 - 200 µm (larger spots for bulk homogeneity) |

| Scan Pattern | Raster or multiple single spots |

| Calibration | Matrix-matched Certified Reference Materials (CRMs) |

| Internal Standard | Use a major element (e.g., ( ^{13}C ), ( ^{29}Si ), ( ^{43}Ca ) ) of known concentration for signal normalization [27] |

Analytical Pathways and Challenges in ICP-MS

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials and Reagents for Fusion Workflows

| Item | Function in Protocol | Critical Considerations |

|---|---|---|

| Ultra-High Purity Acids | Digestant for sample matrix decomposition in ICP-MS prep. | Purity is critical to minimize background contamination; sub-boiling distillation is recommended for trace analysis [28]. |

| Hydrofluoric Acid (HF) | Dissolution of silicate-based and other refractory matrices. | Requires specialized PTFE labware and strict safety protocols due to high toxicity and corrosivity. |

| Internal Standard Solution | Signal normalization for both ICP-MS and LA-ICP-MS. | Element should not be present in the sample and should have similar mass/ionization potential to analytes (e.g., ( ^{115}In ), ( ^{159}Tb ), ( ^{185}Re )) [27]. |

| Certified Reference Materials (CRMs) | Calibration and quality control; essential for accurate LA-ICP-MS quantification. | Must be matrix-matched to the sample to correct for fractionation and matrix effects [27]. |

| Binder (Cellulose/Graphite) | Provides mechanical strength and cohesion to pressed-powder pellets for LA-ICP-MS. | Improves signal stability during laser ablation; must be free of target analytes [29]. |

| Microwave Digestion Vessels (PTFE/Quartz) | Contain samples and acids during high-pressure/temperature digestion. | Chemical inertness and pressure rating are vital for safety and complete digestion. |

| 2-Azido-6-fluoro-1,3-benzothiazole | 2-Azido-6-fluoro-1,3-benzothiazole | |

| 4-Methylbenzo[D]thiazol-5-amine | 4-Methylbenzo[D]thiazol-5-amine | 4-Methylbenzo[D]thiazol-5-amine is a benzothiazole derivative for research applications. This product is for Research Use Only. Not for human or veterinary diagnostic or therapeutic use. |

In the spectroscopic analysis of refractory materials, the fusion technique is a critical preparatory step to create homogeneous glass discs that minimize matrix effects and particle size influences for accurate quantitative analysis [30]. The pursuit of analytical accuracy hinges significantly on the sample preparation procedure, with homogeneity of the mixture being a paramount concern. It is estimated that inadequate sample preparation contributes to approximately 60% of all spectroscopic analytical errors [5]. This application note provides a comparative evaluation of a novel Shaker Cup (SH) mixing method against two traditional techniques—the Grinding (GR) and Stirring Rod (ST) methods—within the context of preparing fused beads for wavelength dispersive X-ray fluorescence (WD-XRF) spectroscopy. We detail experimental protocols and present quantitative data to guide researchers in selecting the optimal homogenization technique to enhance the accuracy and precision of their spectroscopic results.

Experimental Protocols

Materials and Reagents

- Certified Reference Materials (CRMs): A set of 73 geochemical CRMs was utilized. Fifty-four were used for spectrometer calibration, and 19 were used for validation of the methods [30].

- Flux: Ultra-pure grade mixed reagent of lithium tetraborate and lithium metaborate (ratio of 67:33) [30].

- Sample Preparation Equipment:

- Fusion and Instrumentation: An automatic fusion device was used to create glass discs. The analysis was performed using a sequential wavelength dispersive X-ray fluorescence spectrometer (WD-XRF) with a Rh anode X-ray tube operating at 4 kW [30].

Detailed Mixing Procedures

The following protocols describe the three mixing methods evaluated.

Shaker Cup (SH) Method

This is the proposed novel method [30].

- Weighing: Directly weigh 1.000 g of ignited, dried sample powder and 10.000 g of flux into a clean, dry shaker cup.

- Mixing: Securely close the shaker cup and shake it vigorously for 2 minutes to achieve a homogeneous mixture.

- Transfer: Pour the homogeneous mixture directly from the shaker cup into a Pt-Au crucible.

- Fusion: Proceed with the standard fusion program on the automatic fusion device to create a glass disc.

Grinding (GR) Method

This traditional method prioritizes homogeneity but risks contamination [30].

- Weighing: Weigh 1.000 g of ignited, dried sample powder and 10.000 g of flux separately.

- Mixing: Transfer both the sample and flux into an agate mortar. Grind and mix the powders thoroughly with a pestle for approximately 3-5 minutes.

- Transfer: Use a spoon and brush to transfer the mixture from the mortar into a Pt-Au crucible. This step introduces a risk of sample loss and cross-contamination.

- Fusion: Carry out the standard fusion program.

Stirring Rod (ST) Method

This method prioritizes simplicity but may yield insufficient mixing [30].

- Weighing: Directly weigh 1.000 g of ignited, dried sample powder and 10.000 g of flux into a Pt-Au crucible.