AMGS vs. Other Greenness Metrics: A Strategic Guide for Sustainable Analytical Chemistry

This article provides a comprehensive comparison of the Analytical Method Greenness Score (AMGS) with other established greenness metrics like AGREE, GAPI, and NEMI.

AMGS vs. Other Greenness Metrics: A Strategic Guide for Sustainable Analytical Chemistry

Abstract

This article provides a comprehensive comparison of the Analytical Method Greenness Score (AMGS) with other established greenness metrics like AGREE, GAPI, and NEMI. Tailored for researchers and pharmaceutical development professionals, it explores the foundational principles, practical applications, and strategic selection of these tools. By presenting real-world case studies, optimization strategies, and a critical validation of each metric's strengths and limitations, this guide empowers scientists to make informed decisions that enhance both the sustainability and efficiency of their analytical methods.

The Green Metrics Landscape: From Foundational Principles to Modern Tools

Green Analytical Chemistry (GAC) has emerged as a fundamental paradigm shift within the pharmaceutical industry and broader chemical analysis fields, driven by increased awareness of the environmental impacts associated with analytical methodologies. The foundational principles of GAC, extending from the seminal "12 principles of green chemistry" first proposed by Anastas and Warner in 1998, aim to minimize the environmental footprint of analytical processes while ensuring analytical performance and reliability [1]. The adoption of GAC principles has become increasingly urgent given the cumulative environmental burden of analytical methods. A compelling case study of rosuvastatin calcium illustrates this point: with approximately 25 liquid chromatography analyses performed per batch and an estimated 1000 batches produced globally each year, this single active pharmaceutical ingredient results in the consumption and disposal of approximately 18,000 liters of mobile phase annually solely for chromatographic analysis [1]. This example shatters the pervasive perception that analytical methods have insignificant environmental impact and underscores the critical need for standardized metrics to quantify and drive improvements in method greenness.

The Green Metrics Landscape: A Comparative Analysis

The growing recognition of analytical chemistry's environmental impact has catalyzed the development of numerous assessment tools and metrics. These tools enable researchers to systematically evaluate, compare, and improve the environmental footprint of their analytical methods. The table below provides a comprehensive comparison of the major greenness assessment metrics used in contemporary analytical practice.

Table 1: Comparison of Major Green Analytical Chemistry Assessment Metrics

| Metric Name | Type of Output | Key Assessment Criteria | Strengths | Limitations |

|---|---|---|---|---|

| Analytical Method Greenness Score (AMGS) [1] [2] | Quantitative score (%) | Solvent health/safety/environmental impact, cumulative energy demand, instrument energy usage, solvent waste | Comprehensive, specifically designed for chromatography; drives environmental awareness during method development | Currently limited to liquid chromatography and SFC; does not address additives |

| Analytical GREEnness (AGREE) [1] [3] | Pictogram (radar chart) with numerical score (0-1) | Twelve principles of GAC including energy consumption, solvent toxicity, waste generation, and safety | Comprehensive visual representation; applicable to multiple analytical techniques; online calculator available | Can involve estimations that introduce inaccuracies |

| Green Analytical Procedure Index (GAPI) [1] [4] | Qualitative pictogram (color-coded) | Five pentagrams representing different stages of analytical procedure from sample collection to waste management | Detailed breakdown of each analytical step; quick visual assessment | Limited to qualitative analysis; relatively coarse assessment model for chromatography |

| Analytical Eco-Scale [1] [5] | Quantitative score (penalty points subtracted from 100) | Reagent type/amount, energy consumption, waste generated | Simple numerical output; clear indication of greenness | Semi-quantitative; less detailed than other metrics |

| Red Analytical Performance Index (RAPI) [6] | Pictogram (star-shaped) with numerical score (0-100) | Ten analytical performance criteria (repeatability, precision, sensitivity, linearity, etc.) | Assesses analytical performance complementary to greenness metrics; aligns with validation guidelines | Does not directly assess environmental impact |

| Blue Applicability Grade Index (BAGI) [6] [5] | Pictogram (star-shaped) with numerical score (25-100) | Practicality and economic criteria (cost, time, skill requirements, etc.) | Evaluates practical applicability; complements greenness and performance metrics | Focuses only on practical/economic aspects |

| Greenness Evaluation Metric for Analytical Methods (GEMAM) [4] | Pictogram (hexagonal) with numerical score (0-10) | 21 criteria based on 12 GAC principles and 10 green sample preparation factors | Highly comprehensive; flexible weighting system; covers entire analytical workflow | Complex calculation process; newer with less established track record |

The Analytical Method Greenness Score (AMGS): A Closer Examination

Development and Core Principles

The Analytical Method Greenness Score (AMGS) represents a significant advancement in the quantification of chromatographic method sustainability. Developed by the American Chemical Society's Green Chemistry Institute in collaboration with pharmaceutical industry partners, AMGS provides a comprehensive metric that evaluates environmental impact across multiple dimensions [1] [2]. Unlike earlier tools, AMGS specifically addresses the unique environmental considerations of chromatographic techniques, incorporating solvent health, safety, and environmental impact; cumulative energy demand for solvent production and disposal; instrument energy consumption; and method solvent waste generation [2]. The metric outputs a quantitative percentage score where a lower AMGS indicates a greener method, providing researchers with a clear benchmark for comparison and improvement.

Implementation and Impact

AstraZeneca's implementation of AMGS demonstrates its practical utility in driving sustainable practices within pharmaceutical development. The organization has utilized AMGS to assess the current status of chromatographic methods across its drug project portfolio, influence standard practices, and create internal tools for trending data as a mode of continuous process verification [1]. This systematic approach has enabled the identification of method redevelopment opportunities with significant potential for environmental improvement. The AMGS calculator, available through the ACS Green Chemistry Institute, is specifically designed as a comparative metric during method development rather than an absolute measure for method rejection, emphasizing its role in fostering environmental awareness and encouraging the development of greener alternatives [2].

Table 2: AMGS Performance in Different Method Modification Scenarios

| Modification Type | Impact on AMGS Score | Key Mechanism | Environmental Benefit |

|---|---|---|---|

| Reduced Method Runtime | Decreases instrument energy contribution | Lower kWh consumption per analysis | Reduced electricity usage and carbon footprint |

| Solvent Replacement | Decreases solvent EHS and energy scores | Substitution with less hazardous, lower energy solvents | Reduced toxicity and cumulative energy demand |

| Method Miniaturization | Reduces solvent waste score | Lower mobile phase consumption per analysis | Less waste generation and solvent disposal |

| Column Technology Upgrade | Potential decrease in multiple categories | Improved efficiency allowing shorter runs or different solvent systems | Multiple environmental benefits |

Methodologies for Greenness Assessment: Experimental Protocols and Workflows

Standardized Evaluation Framework

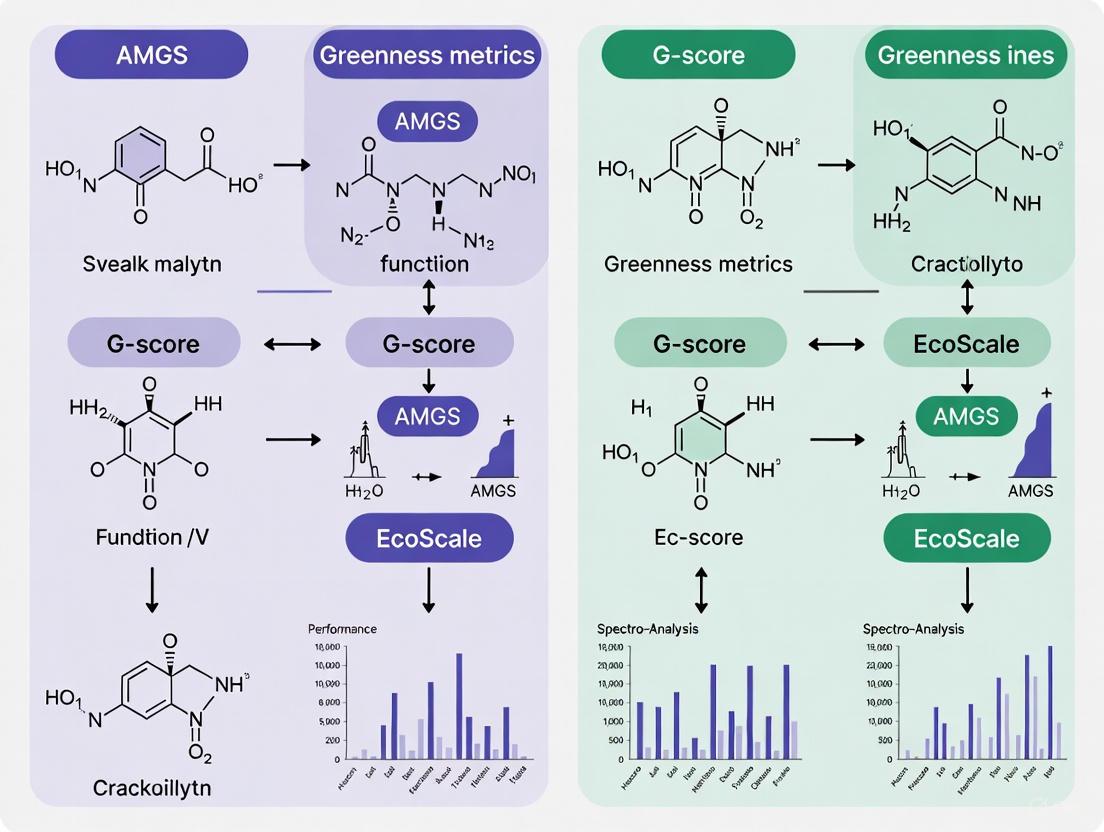

Implementing a robust greenness assessment requires a systematic approach that integrates multiple metrics to provide a comprehensive understanding of a method's environmental and functional characteristics. The workflow below illustrates the integrated evaluation process combining greenness, performance, and practicality metrics.

Detailed Experimental Protocol for Comprehensive Method Assessment

To ensure reproducible and scientifically rigorous greenness assessments, researchers should follow a standardized experimental protocol:

Method Parameter Documentation: Record all critical method parameters including instrument type (HPLC, UPLC, GC), column dimensions, flow rate, injection volume, gradient program, mobile phase composition, sample preparation steps, and analysis time [1] [4].

AMGS Calculation Procedure:

- Input solvent volumes and types into the ACS GCI AMGS calculator

- Document instrument energy consumption based on manufacturer specifications and runtime

- Calculate cumulative energy demand for solvent production using established databases

- Evaluate solvent health, safety, and environmental impact scores using implemented criteria

- Generate overall AMGS percentage and category-specific scores [2]

Complementary Metric Assessment:

Functional Performance Integration:

- Conduct RAPI assessment using open-source software to evaluate ten analytical performance criteria

- Perform BAGI evaluation to determine practical applicability and economic feasibility [6]

Data Synthesis and Interpretation:

- Compare metric outputs to identify consistent patterns and potential discrepancies

- Prioritize improvement opportunities based on metric sensitivities

- Establish baseline performance for future method comparisons [7]

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential Reagents and Materials for Green Analytical Chemistry Research

| Item/Category | Function in GAC Research | Green Alternatives & Considerations |

|---|---|---|

| Chromatographic Solvents | Mobile phase composition in LC methods | Replace acetonitrile with ethanol or methanol; minimize solvent toxicity and energy of production [1] [5] |

| Sample Preparation Materials | Extraction and preparation of analytes | Implement miniaturized systems; use less toxic extraction solvents; automate processes [3] [8] |

| Derivatization Reagents | Chemical modification for detection | Avoid derivatization where possible; use less hazardous reagents; minimize quantities [3] |

| Energy Monitoring Equipment | Quantifying instrument power consumption | Use wattmeters for direct measurement rather than estimation; enable empirical data collection [7] |

| Waste Treatment Solutions | Management of analytical waste | Implement recycling programs for solvents; utilize waste treatment protocols; minimize generation [4] |

| Alternative Column Technologies | Stationary phases for separation | Explore columns enabling faster analyses or greener mobile phases; consider high-temperature LC [1] |

| 1-Palmitoyl-sn-glycero-3-phosphocholine-d49 | 1-Palmitoyl-sn-glycero-3-phosphocholine-d49, MF:C24H50NO7P, MW:544.9 g/mol | Chemical Reagent |

| Cuprolinic Blue-d12 | Cuprolinic Blue-d12, MF:C33H27CuN12O4S+3, MW:763.3 g/mol | Chemical Reagent |

Interpreting Results: Towards Sustainable Analytical Practices

Strategic Implementation of Assessment Findings

The effective interpretation of greenness metrics requires understanding their individual strengths and limitations while recognizing their complementary nature. Research indicates that no single metric provides a complete picture of a method's sustainability profile [7]. For instance, while AMGS offers chromatographically-focused quantitative assessment of environmental impact, it should be integrated with functional metrics like RAPI and BAGI to ensure that greener methods maintain necessary analytical performance and practical applicability [6]. This integrated approach aligns with the White Analytical Chemistry concept, which seeks the optimal balance between environmental impact (green), analytical performance (red), and practical applicability (blue) [6] [5].

Beyond Greenness: The Role of Performance and Practicality

The relationship between different assessment dimensions can be visualized through their interconnectedness in method evaluation and optimization, demonstrating how comprehensive assessment leads to more sustainable analytical practices.

Recent studies demonstrate the successful application of this integrated approach. A 2025 method for simultaneous quantification of gabapentin and methylcobalamin achieved an AGREE score of 0.70 while maintaining excellent analytical performance (linearity R² > 0.9998) and practical applicability, showcasing how environmental and functional objectives can be simultaneously optimized [5]. Such examples highlight the importance of moving beyond single-dimensional greenness assessments toward holistic evaluation frameworks that consider the complete analytical profile.

The development and implementation of greenness metrics represent a critical evolution in analytical chemistry, enabling the systematic quantification and improvement of method environmental performance. Among the available tools, AMGS provides particularly valuable chromatographically-focused assessment, while complementary metrics like AGREE, GAPI, RAPI, and BAGI offer additional dimensions for comprehensive evaluation. As the field progresses toward stronger sustainability models that acknowledge ecological limits and prioritize nature conservation, these metrics will play an increasingly vital role in guiding method development and selection [8]. The ongoing refinement of assessment tools, including the planned expansion of AMGS to include gas chromatography and address methodological granularity like mobile phase additives, promises to further enhance their utility in driving the pharmaceutical industry and analytical science toward a more sustainable future [1] [2].

In recent years, the drive toward sustainability has become increasingly important across the pharmaceutical and analytical industries. The field of green analytical chemistry (GAC) has emerged as a critical discipline focused on minimizing the environmental impact of analytical processes while ensuring analytical performance. The concept extends the principles of green chemistry to analytical processes, emphasizing the reduction of hazardous substances, energy consumption, and waste generation. As the field has evolved, numerous assessment tools have been developed to evaluate and quantify the environmental impact of analytical methods.

This progression began with simpler tools like the National Environmental Method Index (NEMI) and Analytical Eco-Scale (AES) and has advanced toward more comprehensive metrics including the Green Analytical Procedure Index (GAPI) and Analytical GREEnness (AGREE). Most recently, the Analytical Method Greenness Score (AMGS) has been developed through collaboration between the American Chemical Society's Green Chemistry Institute and industry partners, offering a sophisticated approach specifically designed for chromatographic methods. This timeline of evolution represents a continuous refinement in how the scientific community quantifies and prioritizes environmental sustainability in analytical practices [1] [9].

Historical Development of Greenness Assessment Tools

First-Generation Metrics: Foundation and Limitations

The earliest green assessment tools provided foundational approaches for evaluating environmental impact but faced significant limitations in comprehensiveness and applicability.

National Environmental Method Index (NEMI) was among the pioneering tools introduced for greenness assessment. Its approach is relatively simple, representing method environmental impact through a pictogram with four quadrants that indicate whether a method meets specific criteria: (1) does not use persistent, bioaccumulative, and toxic chemicals; (2) does not use corrosive reagents; (3) does not use hazardous reagents; and (4) waste generation is minimal. While straightforward to interpret, NEMI's binary (pass/fail) assessment system lacks granularity, as it does not quantify the degree of greenness or account for energy consumption and other environmental factors [10] [9].

Analytical Eco-Scale (AES) emerged as a semi-quantitative alternative that assigns penalty points to various parameters of an analytical method, including the type and amount of reagents used, energy consumption, and waste generated. The total eco-scale score is calculated by subtracting penalty points from a base value of 100, with higher scores indicating greener methods. This tool provided a numerical assessment that enabled easier comparison between methods and identified specific areas for improvement. However, its penalty assignment system remained somewhat subjective, and it didn't comprehensively address all principles of green analytical chemistry [1] [9].

Second-Generation Metrics: Comprehensive and Visual Assessments

As the field matured, more sophisticated tools emerged that offered more comprehensive evaluations and intuitive visual representations.

Green Analytical Procedure Index (GAPI) expanded evaluation scope by incorporating a more holistic approach. GAPI uses a pictogram consisting of five pentagrams, each representing different stages of an analytical procedure from sample collection to waste management. Each pentagram is divided into sections color-coded based on environmental impact (green for low, yellow for moderate, and red for high impact). This visual representation allows for quick yet detailed assessment of method greenness across the entire analytical process, addressing a wider range of environmental concerns than earlier tools [1] [11].

Analytical GREEnness (AGREE) represents a significant advancement by comprehensively addressing all 12 principles of green analytical chemistry. The tool employs a clock-like pictogram where each of the 12 segments corresponds to one GAC principle, scored from 0-1 with weighting factors that affect segment width. The output displays a final score (0-1) in the center with a color indication (red to green) reflecting overall method greenness. AGREE's strengths include its comprehensive foundation in GAC principles, visual intuitiveness, and applicability across multiple analytical techniques. The availability of an online calculator further enhances its accessibility and standardization [11] [9].

Table 1: Evolution of Major Green Assessment Tools

| Metric | Year Introduced | Assessment Approach | Key Parameters | Output Format | Key Limitations |

|---|---|---|---|---|---|

| NEMI | Early 2000s | Binary criteria | PBT chemicals, corrosives, hazardous reagents, waste amount | Pictogram with 4 quadrants | Lacks granularity; no energy consideration |

| Analytical Eco-Scale | 2013 | Penalty point system | Reagent toxicity, energy, waste | Numerical score (0-100) | Subjective penalty assignments |

| GAPI | 2019 | Qualitative assessment | Sample collection, preparation, transportation, etc. | 5 pentagrams with color coding | Less quantitative; limited weighting flexibility |

| AGREE | 2020 | Weighted criteria based on 12 GAC principles | All 12 GAC principles | Clock-like pictogram with score | Requires detailed method knowledge |

| AMGS | Recent (post-2020) | Quantitative multi-dimensional | Solvent energy, EHS, instrument energy | Numerical score | Currently focused on chromatography |

The Emergence of Analytical Method Greenness Score (AMGS)

Development and Strategic Importance

The Analytical Method Greenness Score (AMGS) represents the latest evolution in green assessment tools, developed through collaboration between the American Chemical Society's Green Chemistry Institute and industry partners. This metric was specifically designed to address the need for a comprehensive, chromatography-focused evaluation tool that could provide strategic insight for organizations pursuing sustainability goals [1].

AMGS evaluates the environmental impact of chromatographic methods across multiple dimensions, with unique emphasis on instrument energy consumption in addition to solvent-related factors. The tool calculates three primary component scores: solvent energy (accounting for energy consumed in solvent production and disposal), solvent environment, health, and safety (EHS) factors, and instrument energy consumption. These components are integrated into an overall greenness score that enables direct comparison between methods and identification of improvement opportunities [1].

The development of AMGS responds to the substantial cumulative environmental impact of analytical methods when scaled across global manufacturing networks. As illustrated by a case study of rosuvastatin calcium, where approximately 18,000 liters of mobile phase are consumed annually for chromatographic analysis of a single active pharmaceutical ingredient, the widespread perception that analytical methods have insignificant environmental impact is both pervasive and damaging. AMGS provides the pharmaceutical industry with a tool to quantify and systematically reduce this impact [1].

Unique Characteristics and Industry Application

AMGS incorporates several distinctive features that differentiate it from earlier metrics. Unlike tools that focus primarily on solvent selection and waste generation, AMGS specifically accounts for instrument energy consumption, recognizing that analytical equipment constitutes a significant portion of laboratory energy usage. Additionally, it considers the energy consumed in the production and disposal of solvents used, providing a more complete lifecycle perspective [1].

Pharmaceutical companies like AstraZeneca have utilized AMGS to assess the current status of their analytical portfolio, influence standard practices, and create internal tools for continuous process verification. By integrating AMGS into routine analytical procedures, organizations can systematically improve their sustainability profiles, reduce hazardous waste, and promote greener alternatives while maintaining the rigorous quality standards required for pharmaceutical analysis [1].

Comparative Analysis of Major Greenness Assessment Tools

Scoring Systems and Assessment Focus

The major greenness assessment tools employ fundamentally different approaches to scoring and evaluation, each with distinct advantages and limitations.

Table 2: Scoring Characteristics of Green Assessment Tools

| Metric | Scoring System | Scope of Assessment | Weighting of Factors | Ideal Score |

|---|---|---|---|---|

| NEMI | Binary (pass/fail) for 4 criteria | Limited to reagents and waste | Equal weighting for all criteria | All quadrants green |

| Analytical Eco-Scale | Subtractive points from base of 100 | Reagents, energy, waste | Implicit through point values | >75 (excellent) |

| GAPI | Color-coded (green/yellow/red) | Entire analytical procedure | Equal across pentagrams | All green sections |

| AGREE | 0-1 with weighted segments | All 12 GAC principles | Adjustable segment weights | 1.0 |

| AMGS | Numerical component scores | Chromatography-specific factors | Defined by calculation model | Lower = greener |

The AGREE tool stands out for its comprehensive foundation in all 12 principles of green analytical chemistry, addressing factors such as miniaturization, automation, and throughput in addition to traditional solvent and energy concerns. Each principle is scored individually and contributes to an overall assessment, providing both specific and holistic feedback on method greenness [11] [9].

In contrast, AMGS employs a more specialized approach focused specifically on chromatographic applications, with quantitative assessment of solvent energy, solvent EHS factors, and instrument energy consumption. This chromatography-specific focus enables more targeted optimization of LC methods but may limit applicability to other analytical techniques [1].

Practical Applications and Performance Comparison

Recent studies have demonstrated the practical application of these tools in comparing analytical methods. A comparative study of chromatographic methods for analyzing UV filters in cosmetics evaluated ten different procedures using AGREE and AGREEprep (a complementary tool focused specifically on sample preparation). The assessment revealed that microextraction methods consistently achieved higher greenness scores, demonstrating how these tools can guide analysts toward more sustainable choices [11].

In pharmaceutical analysis, a study comparing normal-phase (NP) and reversed-phase (RP) HPTLC methods for quantifying ertugliflozin applied four greenness assessment tools: NEMI, AES, ChlorTox, and AGREE. The results consistently demonstrated that the RP-HPTLC method was greener than the NP-HPTLC approach across all assessment tools, with the AGREE tool providing the most comprehensive and nuanced evaluation [10].

When comparing AMGS with earlier metrics, several distinctions emerge. While tools like GAPI and AGREE offer visual outputs that facilitate quick assessment, AMGS provides quantitative data that supports trend analysis and portfolio-level decision-making. As noted in industry applications, "The AMGS tool has several constraints, which if addressed, would add value to the calculation, for example, additional analytical techniques, impact of chromatographic mobile phase and sample diluent additives" [1].

Experimental Protocols for Greenness Assessment

Standardized Methodology for Tool Application

To ensure consistent and comparable results when evaluating analytical methods using different greenness assessment tools, researchers should follow standardized experimental protocols:

Method Documentation: Completely document all aspects of the analytical procedure including sample preparation, reagents and solvents (type and volume), instrumentation, energy consumption parameters, and waste generation data.

Tool Selection: Based on study objectives, select appropriate assessment tools. For comprehensive evaluation, use multiple tools to leverage their complementary strengths.

Data Collection: For AGREE assessment, collect information corresponding to all 12 GAC principles. For AMGS, focus on chromatography-specific parameters including instrument type, run time, flow rate, and solvent compositions [1] [11].

Score Calculation: Utilize available software tools for score calculation when possible. AGREE offers an open-source calculator available at https://mostwiedzy.pl/AGREE, while AMGS may utilize proprietary calculators implemented within organizations [11].

Interpretation and Comparison: Compare scores across methods using the same tool, noting that absolute scores from different tools are not directly comparable due to different assessment frameworks.

Case Study Implementation Protocol

A typical experimental protocol for comparing methods, as demonstrated in the HPTLC study for ertugliflozin, includes:

Method Development: Develop and validate both NP-HPTLC and RP-HPTLC methods according to ICH Q2-R2 guidelines. For NP-HPTLC, use chloroform/methanol (85:15 v/v) mobile phase. For RP-HPTLC, use ethanol-water (80:20 v/v) mobile phase [10].

Chromatographic Conditions: Use silica gel 60 NP-18F254S plates for NP-HPTLC and 60 RP-18F254S plates for RP-HPTLC. Perform detection at 199 nm for both methods.

Greenness Assessment: Apply multiple assessment tools (NEMI, AES, AGREE, and AMGS if available) to both methods using standardized parameters.

Data Analysis: Compare scores across all tools to identify consistent trends and method superiorities.

Greenness Assessment Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential Materials for Green Analytical Chemistry Research

| Item | Function in Green Assessment | Application Example |

|---|---|---|

| AGREE Software | Open-source tool for calculating AGREE scores | Evaluating overall method greenness against 12 GAC principles |

| AGREEprep Tool | Specialized software for sample preparation assessment | Comparing greenness of microextraction techniques |

| Solvent Selection Guide | Reference for solvent environmental and safety data | Choosing greener alternatives in method development |

| Life Cycle Inventory Database | Source data for energy and environmental impact | Calculating AMGS solvent energy and EHS components |

| Chromatography Data Systems | Source of method parameters for assessment | Extracting run times, flow rates for AMGS calculations |

| Isoflupredone-d5 | Isoflupredone-d5, MF:C21H27FO5, MW:383.5 g/mol | Chemical Reagent |

| Demeton-S-d10 | Demeton-S-d10, MF:C8H19O3PS2, MW:268.4 g/mol | Chemical Reagent |

The evolution from early tools like NEMI and Eco-Scale to comprehensive metrics like AGREE, GAPI, and AMGS represents significant advancement in how the analytical community quantifies and prioritizes environmental sustainability. Each generation of tools has built upon its predecessors, addressing limitations and expanding assessment scope to provide more accurate, actionable evaluations of method greenness.

The current landscape offers analysts multiple tools with complementary strengths—from AGREE's comprehensive foundation in all 12 GAC principles to AMGS's specialized focus on chromatographic parameters and energy consumption. This progression enables more informed method selection and development, supporting the pharmaceutical industry's ambitious sustainability goals while maintaining the rigorous quality standards essential for patient safety.

As green analytical chemistry continues to evolve, future developments will likely address current tool limitations, expand assessment scope to include additional analytical techniques, and further refine the quantification of environmental impact. Through continued refinement and application of these assessment metrics, the analytical community can significantly reduce its environmental footprint while advancing scientific capabilities.

The pharmaceutical industry faces increasing pressure to minimize its environmental footprint, a challenge that extends from manufacturing to analytical testing. Green Analytical Chemistry (GAC) has emerged as a dedicated field within analytical chemistry, aiming to mitigate the detrimental effects of analytical techniques on the environment and human health [12]. While the scale of solvent use in individual analytical methods is small compared to process chemistry, its cumulative impact is substantial. A single drug compound like rosuvastatin calcium can consume approximately 18,000 liters of mobile phase annually when scaled across global production batches, highlighting the critical need for sustainable analytical practices [1].

This environmental imperative has driven the development of various assessment tools to evaluate and improve the "greenness" of analytical methods. Among these tools, the Analytical Method Greenness Score (AMGS) has emerged as a specialized metric developed specifically for chromatographic methods within the pharmaceutical industry. This guide explores the origin, development, and core philosophy of AMGS while providing a detailed comparison with other established greenness assessment tools.

Origin and Development of AMGS

Institutional Background and Leadership

The AMGS calculator was developed under the auspices of the ACS Green Chemistry Institute Pharmaceutical Roundtable (ACS GCI PR), a leading organization dedicated to catalyzing the integration of green chemistry and engineering in the pharmaceutical industry [13]. Established in 2005, the Roundtable provides a science-focused forum for member companies to collectively prioritize research needs and leverage resources toward green chemistry tools specific to the pharmaceutical industry [14].

The development team comprised industry experts from major pharmaceutical companies including:

- Michael Hicks (Merck, Rahway, NJ)

- Bill Farrell and Christine Aurigemma (Pfizer, San Diego, CA)

- Paul Ferguson (AstraZeneca, Macclesfield, UK)

- Dave Constable, Isamir Martinez, and Christiana Briddell (ACS GCI, Washington, DC) [2]

The tool evolved from a Microsoft Excel-based program originally created by Laurent Lehman at Bristol-Myers Squibb, demonstrating its origins in practical industry needs rather than purely academic research [2].

Development Timeline and Future Directions

The AMGS metric represents an ongoing commitment to sustainable analytical chemistry. The current version focuses exclusively on liquid chromatography and SFC methods, with an updated version supporting Gas Chromatography (GC) methods expected by early 2026 [2]. The ACS GCI PR continues to actively solicit feedback from users to improve the tool's functionality and application across the industry [2].

Table: Development Timeline of AMGS

| Year | Development Milestone |

|---|---|

| Pre-2020 | Original Excel-based program created by Laurent Lehman at Bristol-Myers Squibb |

| 2020-2024 | Collaborative development and refinement by ACS GCI PR Analytical Chemistry team |

| 2025 | Public launch and implementation in pharmaceutical companies (e.g., AstraZeneca case study) |

| 2026 (Expected) | Release of updated version supporting Gas Chromatography (GC) methods |

Core Philosophy and Design Principles of AMGS

The AMGS is founded on a pragmatic philosophy that balances comprehensive environmental assessment with practical applicability in pharmaceutical analytical development. Its core design principles include:

Holistic Environmental Assessment

Unlike some metrics that focus narrowly on specific aspects, AMGS employs a multi-dimensional assessment that factors in solvent health, safety, environmental impact, cumulative energy demand, instrument energy usage, and method solvent waste [2]. This comprehensive approach ensures that method improvements address the complete environmental profile rather than optimizing a single parameter at the expense of others.

Comparative, Not Absolute, Measurement

A fundamental principle of AMGS is its use as a comparative metric rather than an absolute measure of greenness. The tool is explicitly designed "to benchmark and compare one method to another" during method development [2]. The resulting score is meant to "provide environmental impact awareness and encourage analysts to develop greener methods" rather than to reject methods based on a finite threshold [2].

Actionable Feedback Through Color Coding

The tool incorporates a color-coded scoring system where yellow and red colors highlight areas where the method could be improved [2]. This provides immediate, actionable feedback to analytical chemists, directing them to specific aspects of their methods that contribute most significantly to the environmental impact, such as instrument energy consumption or solvent toxicity.

Industry-Specific Relevance

AMGS was designed specifically for chromatographic methods used in pharmaceutical analysis, ensuring relevance to the specific challenges and constraints of this application area [1]. This industry focus distinguishes it from more general-purpose green assessment tools and enhances its practical utility for pharmaceutical scientists.

Comparative Analysis: AMGS vs. Other Green Metric Tools

The landscape of green metric tools has evolved significantly, with multiple approaches developed for different assessment needs:

National Environmental Methods Index (NEMI): One of the earliest tools, using a simple pictogram with four quadrants representing different environmental criteria [15] [12]. It employs binary (yes/no) assessment with boundaries established at specific thresholds (e.g., waste generation ≤50 g per sample) [15].

Analytical Eco-Scale Assessment (ESA): A semi-quantitative tool that assigns penalty points for various parameters including reagents, energy consumption, and waste [1]. The total score is calculated by subtracting penalty points from a base value of 100, with higher scores indicating greener methods [1].

Green Analytical Procedure Index (GAPI): Employs a detailed pictogram with five pentagrams representing different stages of the analytical procedure, each color-coded (green, yellow, red) based on environmental impact [1]. It provides a more holistic visual assessment than NEMI [1].

Analytical GREEnness (AGREE): Uses a comprehensive radar chart with twelve criteria representing different green chemistry principles, each rated 0-1 [1]. An online calculator is available, and the overall score is the average of the twelve ratings [1].

Detailed Comparison of Key Metrics

Table: Comprehensive Comparison of Green Assessment Tools

| Feature | AMGS | AGREE | GAPI | Analytical Eco-Scale | NEMI |

|---|---|---|---|---|---|

| Primary Focus | Chromatographic methods in pharma | General analytical methods | General analytical procedures | General analytical methods | Environmental methods |

| Output Type | Numerical score with color coding | Numerical score (0-1) + radar chart | Pictogram (color-based) | Numerical score (0-100) | Pictogram (binary) |

| Key Assessment Criteria | Solvent EHS, solvent energy, instrument energy | 12 principles of GAC | Multiple stages from sampling to waste | Reagents, energy, waste | Toxicity, waste, corrosiveness |

| Scoring System | Lower score = greener | Higher score = greener | Color-based: green to red | Higher score = greener | Binary: filled/unfilled quadrants |

| Weighting of Criteria | Adjustable with defaults | Adjustable with defaults | Fixed | Implicit through penalty points | Fixed |

| Technical Specificity | High for chromatography | Medium | Medium | Medium | Low |

| Ease of Use | Moderate | Moderate (with calculator) | Easy | Easy | Very easy |

| Application in Pharma | High | Medium | Medium | Medium | Low |

Technical Differentiation of AMGS

AMGS distinguishes itself technically through several key features:

Integrated Energy Assessment: Unlike many other tools, AMGS specifically incorporates both solvent production energy and instrument energy consumption into its calculation [1]. This provides a more complete picture of the total energy footprint of an analytical method.

Pharmaceutical Industry Focus: While tools like AGREE and GAPI are designed for broader applicability, AMGS is optimized for the specific requirements and constraints of pharmaceutical analysis and regulatory compliance [2] [1].

Solvent-Centric Evaluation: Given that solvents represent the most significant environmental impact in liquid chromatography, AMGS provides detailed assessment of solvent environmental, health, and safety (EHS) impacts alongside the energy required for their production and disposal [2].

Experimental Application and Validation

Implementation Case Study: AstraZeneca

A comprehensive study conducted at AstraZeneca demonstrated the practical application of AMGS across their pharmaceutical development portfolio [1]. Researchers implemented AMGS to:

- Assess current status of chromatographic methods across their portfolio

- Identify improvement opportunities in method development and redevelopment

- Influence standard practices and create internal tools for data trending

- Establish continuous process verification for sustainability metrics [1]

The implementation allowed AstraZeneca to quantify their environmental impact from analytical chemistry and align with their ambition to achieve carbon zero status for analytical laboratories by 2030 [1].

Experimental Protocol for AMGS Assessment

For researchers seeking to implement AMGS in their own workflows, the following methodology provides a standardized approach:

Step 1: Data Collection

- Compile chromatographic method parameters: mobile phase composition, flow rate, runtime, injection volume, and column dimensions

- Identify instrument type (HPLC, UHPLC) and operational modes

- Quantify sample preparation requirements including dilution factors and solvent volumes [2]

Step 2: Input Parameters for AMGS Calculator

- Solvent volumes (across entire method including system suitability tests)

- Instrument energy consumption (based on runtime and instrument type)

- Solvent EHS profiles (from built-in database)

- Cumulative energy demand for solvent production [2] [1]

Step 3: Score Calculation and Interpretation

- Calculate individual scores for solvent EHS, solvent energy, and instrument energy

- Generate overall AMGS (lower scores indicate greener methods)

- Interpret color-coded results to identify primary contributors to environmental impact [2]

Step 4: Method Optimization

- Target improvements in areas highlighted by color coding (yellow/red)

- Explore alternative solvents with better EHS profiles

- Optimize method parameters to reduce runtime and solvent consumption

- Validate that changes maintain analytical performance [1]

Experimental Data from Implementation

Table: AMGS Application Data from Pharmaceutical Implementation

| Method Parameter | Before AMGS Optimization | After AMGS Optimization | Reduction Impact |

|---|---|---|---|

| Typical HPLC Flow Rate | 1.0-2.0 mL/min | 0.3-0.8 mL/min | 40-70% solvent reduction |

| Average Runtime | 30-60 minutes | 5-15 minutes | 60-80% energy reduction |

| Acetonitrile Usage | High (primary solvent) | Reduced or replaced | Lower EHS impact |

| Total Solvent Waste per Analysis | 100-500 mL | 10-100 mL | 70-90% waste reduction |

| AMGS Score | Higher (less green) | Lower (greener) | Improved sustainability |

Visualization: Relationship Among Green Assessment Tools

The following diagram illustrates the logical relationships and primary focus areas of major green assessment tools, highlighting AMGS's position within the ecosystem:

Green Metric Tools Relationship

Table: Essential Research Reagent Solutions for Green Analytical Chemistry

| Tool/Resource | Function/Purpose | Application Context |

|---|---|---|

| AMGS Calculator | Quantifies environmental impact of chromatographic methods | Pharmaceutical method development and comparison |

| AGREE Calculator | Assesses alignment with 12 GAC principles | General analytical method greenness assessment |

| GAPI Pictogram | Visual assessment across analytical process stages | Quick visual communication of method greenness |

| Alternative Solvent Database | Identifies greener solvent substitutions | Method optimization to reduce EHS impact |

| Method Scalability Calculator | Projects cumulative environmental impact | Business case development for green method adoption |

| Energy Consumption Monitor | Measures actual instrument energy usage | Empirical data collection for AMGS assessment |

The Analytical Method Greenness Score represents a significant advancement in the toolkit for sustainable analytical chemistry, particularly within the pharmaceutical industry. Its development by the ACS GCI Pharmaceutical Roundtable reflects a concerted industry effort to address the environmental impact of analytical methods through a specialized, practical metric.

While AMGS excels in its specific domain of chromatographic analysis, the diversity of available green assessment tools highlights the multifaceted nature of environmental impact assessment. Tools such as AGREE, GAPI, and Analytical Eco-Scale each offer unique strengths for different applications and contexts. The most effective approach to green analytical chemistry involves understanding the complementary nature of these tools and selecting the most appropriate metric based on specific assessment needs, analytical techniques, and industry context.

As the field continues to evolve, the ongoing development of AMGS—including the planned expansion to GC methods—demonstrates the commitment to continuous improvement in green metrics. For researchers and pharmaceutical professionals, mastering these tools is essential for advancing both environmental sustainability and analytical excellence.

In the pursuit of sustainable laboratory practices, Green Analytical Chemistry (GAC) has emerged as a critical discipline focused on minimizing the environmental impact of analytical methods [12] [16]. The evaluation of this environmental footprint revolves around three central dimensions: solvent impact, energy consumption, and waste generation [17] [2]. These core parameters form the foundation for comparing the ecological performance of different analytical techniques, particularly in pharmaceutical development and other chemical industries. Without standardized metrics, assessing and comparing the greenness of analytical methods would be subjective and inconsistent. To address this challenge, researchers have developed various assessment tools that quantify environmental impact across these key dimensions [9] [16]. This article provides a comprehensive comparison of prominent greenness metrics, with particular focus on the Analytical Method Greenness Score (AMGS) in relation to other established tools, examining their approaches to measuring solvent impact, energy consumption, and waste production.

Core Principles of Green Analytical Chemistry

Green Analytical Chemistry is built upon twelve fundamental principles that provide a framework for developing environmentally conscious analytical methods [16]. These principles, encapsulated by the mnemonic "SIGNIFICANCE," guide analysts in reducing the negative effects of analytical activities on human health and the environment [4]. The core dimensions of assessment directly address multiple GAC principles: solvent impact relates to using safer chemicals and minimizing toxicity; energy consumption connects to reducing energy requirements; and waste generation corresponds to eliminating or minimizing analytical waste [16]. More recently, these have been supplemented by ten principles of Green Sample Preparation (GSP), which further emphasize miniaturization, automation, and in-line processes to enhance environmental performance [4]. These principles collectively provide the theoretical foundation upon which all greenness assessment metrics are built, ensuring that evaluations align with established sustainability goals rather than arbitrary criteria.

Comparative Analysis of Greenness Metrics

Fifteen major greenness assessment tools have gained prominence in analytical chemistry, each with distinct approaches to evaluating environmental impact [9] [16]. The table below summarizes the core characteristics of the most widely used metrics, with particular attention to how they address the three key dimensions of solvent impact, energy consumption, and waste generation.

Table 1: Comparison of Major Greenness Assessment Metrics

| Metric Name | Assessment Approach | Solvent Impact Evaluation | Energy Consumption Evaluation | Waste Generation Evaluation | Output Type |

|---|---|---|---|---|---|

| AMGS | Quantitative scoring | Health, safety, and environmental impact of solvents | Instrument energy usage and cumulative energy demand | Method solvent waste volume | Numerical score (lower = greener) [17] [2] |

| NEMI | Qualitative pictogram | Presence on PBT and hazardous waste lists | Not considered | Total waste amount (<50g threshold) | Pictogram with four quadrants [16] |

| Analytical Eco-Scale | Penalty point system | Amount and hazard of reagents | Energy consumption (>0.1 kWh penalty) | Waste amount and hazard | Total score (100 = ideal green analysis) [16] |

| GAPI | Qualitative pictogram | Toxicity and environmental impact | Not explicitly considered | Waste generation and treatment | Pictogram with five fields [16] |

| AGREE | Quantitative scoring | Multiple solvent-related criteria | Energy consumption of instruments | Waste amount and management | Score 0-1 with pictogram [16] |

| GEMAM | Quantitative scoring | Amount and greenness score of reagents | Energy consumption per analysis | Amount and score of wastes | Score 0-10 with hexagonal pictogram [4] |

Detailed Methodology of Key Metrics

Analytical Method Greenness Score (AMGS)

The AMGS calculator, developed by the ACS Green Chemistry Institute Pharmaceutical Roundtable, employs a comprehensive quantitative approach specifically designed for chromatographic methods [17] [2]. Its algorithm integrates three core components: (1) Solvent Impact: Evaluates health, safety, and environmental factors of all solvents used, weighted by their volumes in the method; (2) Energy Consumption: Calculates cumulative energy demand based on instrument type (HPLC, UHPLC, SFC) and method duration; (3) Waste Generation: Quantifies total solvent waste produced during analysis and system suitability testing [2]. The AMGS output is a single percentage score where lower values indicate greener methods, with color-coding (yellow and red) highlighting areas for potential improvement [2]. This metric is particularly valuable for direct comparison of method iterations during development, allowing scientists to quantify environmental improvements when optimizing analytical procedures.

National Environmental Methods Index (NEMI)

As one of the oldest greenness metrics, NEMI employs a simple pictogram with four quadrants that turn green when specific criteria are met [16]. For solvent assessment, it checks that no chemicals appear on the PBT (persistent, bioaccumulative, toxic) list and that no solvents are on the D, F, P, or U hazardous waste lists. For waste, it applies a binary threshold of less than 50g per analysis. Notably, NEMI does not consider energy consumption in its evaluation [16]. While user-friendly, this binary approach lacks granularity as it doesn't differentiate between methods that just meet the criteria and those that far exceed them.

Analytical Eco-Scale

The Analytical Eco-Scale operates on a penalty point system, starting from a baseline of 100 points representing an ideal green analysis [16]. Points are deducted for: hazardous reagents (based on amount and toxicity), energy consumption exceeding 0.1 kWh per sample, and waste generation (considering both amount and hazard). Unlike the binary NEMI approach, this metric provides semi-quantitative assessment that can differentiate between methods of varying environmental performance. However, the penalty assignments can be somewhat subjective, and the output lacks a visual pictogram for quick assessment.

Green Analytical Procedure Index (GAPI)

GAPI utilizes a more detailed pictogram with five fields to evaluate analytical procedures at each stage [16]. It provides qualitative assessment of solvent toxicity and environmental impact throughout the sample collection, preparation, and analysis phases. While it considers waste treatment approaches, it does not explicitly evaluate energy consumption. The strength of GAPI lies in its ability to visually identify which specific stages of an analytical procedure have the greatest environmental impact, guiding targeted improvements.

AGREE and AGREEprep

The Analytical GREEnness Calculator (AGREE) and its sample preparation-focused counterpart AGREEprep represent advanced quantitative approaches that incorporate all twelve GAC principles [16] [4]. These tools generate a score between 0-1 accompanied by a circular pictogram with twelve sections, providing both quantitative results and visual representation. AGREE comprehensively evaluates solvent selection, energy requirements, and waste management while considering the entire analytical lifecycle. The main advantage is its alignment with all GAC principles, though the calculation process is more complex than simpler metrics.

Greenness Evaluation Metric for Analytical Methods (GEMAM)

GEMAM is a recently developed tool that evaluates six key dimensions: sample, reagent, instrument, method, waste, and operator [4]. It employs a sophisticated weighting system where reagents and waste each contribute 25% to the total score, while instrument and method account for 15% each, and sample and operator represent 10% each. The metric uses 21 specific criteria based on both the 12 GAC principles and 10 GSP factors, generating a score from 0-10 displayed in a hexagonal pictogram. This comprehensive approach specifically includes energy consumption per analysis as a key criterion with a 40% weight within the instrument dimension [4].

Experimental and Application Protocols

Implementation Workflow for Greenness Assessment

The process of evaluating analytical methods using greenness metrics follows a systematic workflow that ensures comprehensive assessment across the three key dimensions. The diagram below illustrates this standardized approach.

Diagram 1: Greenness assessment workflow for analytical methods. The process begins with method requirements definition and proceeds through systematic evaluation of the three key dimensions using selected metrics, enabling iterative improvement.

Case Study: Chromatographic Method Evaluation

To illustrate the practical application of these metrics, consider the evaluation of three analytical methods from literature: (1) A UPLC-MS/MS method with liquid-liquid extraction for determining guaifenesin and bromhexine in human plasma [16]; (2) An HPLC-UV method for oxytetracycline and bromhexine in spiked milk samples [16]; and (3) A direct UV method for simultaneous quantification of carbinoxamine maleate, paracetamol, and pseudoephedrine hydrochloride [16].

Table 2: Comparative Greenness Assessment of Three Analytical Methods

| Assessment Metric | UPLC-MS/MS Method | HPLC-UV Method | Direct UV Method |

|---|---|---|---|

| NEMI Pictogram | 2/4 green fields [16] | 2/4 green fields [16] | 4/4 green fields [16] |

| Advanced NEMI | Mixed profile (yellow/red) [16] | Mixed profile (yellow/red) [16] | Primarily green profile [16] |

| Assessment of Green Profile (AGP) | Moderate performance [16] | Moderate performance [16] | Strong performance [16] |

| Key Differentiating Factors | Higher solvent impact and energy use due to sample prep and MS detection | Moderate solvent impact from HPLC mobile phase | Minimal solvent use and energy consumption |

| Recommended Improvement | Explore alternative extraction techniques | Method transfer to UHPLC to reduce solvent volume | Already demonstrates strong green credentials |

The case study demonstrates how different metrics consistently identify the direct UV method as the greenest option due to its minimal solvent requirements, lower energy consumption (no chromatography), and reduced waste generation [16]. This alignment across multiple assessment tools reinforces the reliability of greenness evaluation when focused on the core dimensions of solvent impact, energy consumption, and waste.

Essential Research Reagents and Materials

The transition to greener analytical methods requires specific reagents, materials, and technologies that minimize environmental impact while maintaining analytical performance. The following table outlines key solutions for implementing sustainable practices in analytical laboratories.

Table 3: Research Reagent Solutions for Green Analytical Chemistry

| Reagent/Material | Function | Green Attributes | Application Examples |

|---|---|---|---|

| Bio-based Solvents | Replace traditional petroleum-derived solvents | Renewable feedstocks, reduced toxicity, biodegradable | Extraction, chromatography mobile phases |

| Water-based Mobile Phases | Chromatographic separation | Non-toxic, readily biodegradable, inexpensive | Reverse-phase HPLC with alternative columns |

| Solid-phase Microextraction (SPME) | |||

| Sample preparation and concentration | Solventless extraction, minimal waste | Environmental analysis, bioanalytical applications | |

| Microfluidic Devices | Miniaturized analytical systems | Reduced reagent consumption, lower energy requirements | Point-of-care testing, process analytical technology |

| Supercritical Fluid Chromatography (SFC) | Chromatographic separation | Uses CO2 as primary mobile phase, reduced organic solvents | Chiral separations, natural product analysis |

| Automated Sample Preparation | High-throughput sample processing | Reduced reagent volumes, improved reproducibility | Pharmaceutical quality control, clinical analysis |

The comparison of greenness assessment metrics reveals distinct approaches to evaluating the core dimensions of solvent impact, energy consumption, and waste generation. The AMGS calculator provides a specialized, quantitative tool particularly valuable for pharmaceutical method development, offering detailed assessment of solvent health/safety/environmental factors, instrument energy usage, and solvent waste [17] [2]. In contrast, broader metrics like GAPI and NEMI offer rapid visual assessment but lack the granularity for subtle differentiation between methods [16]. Emerging tools like GEMAM represent the evolution toward more comprehensive evaluations that incorporate multiple GAC and GSP principles with flexible weighting systems [4].

Future developments in greenness assessment will likely focus on integrating artificial intelligence for automated method optimization, expanding metric capabilities to encompass additional lifecycle considerations, and developing standardized reporting frameworks for regulatory submissions [2] [4]. The ongoing refinement of these tools, including planned AMGS updates for gas chromatography methods by early 2026, demonstrates the dynamic nature of this field [2]. For researchers and drug development professionals, selecting the appropriate assessment metric depends on specific needs: AMGS offers unparalleled detail for chromatographic method development, while AGREE and GEMAM provide comprehensive lifecycle assessment, and NEMI/GAPI deliver rapid screening capabilities. By understanding the strengths and limitations of each tool across the fundamental dimensions of solvent impact, energy consumption, and waste generation, scientists can make informed decisions that advance both analytical science and environmental sustainability.

The adoption of Green Analytical Chemistry (GAC) principles has transformed how researchers evaluate the environmental impact of analytical methods [12]. GAC focuses on mitigating the adverse effects of analytical activities on human safety, health, and the environment [9]. To operationalize these principles, the scientific community has developed numerous metric tools that enable objective assessment and comparison of method greenness [16]. These tools provide standardized approaches for quantifying factors such as reagent toxicity, energy consumption, and waste generation, allowing analysts to make informed decisions during method development [15]. The growing emphasis on sustainability in analytical laboratories has increased the importance of these metrics, particularly in regulated industries like pharmaceutical development where methods must balance environmental concerns with analytical performance [2] [18].

The evolution of GAC metrics has progressed from simple checklists to sophisticated algorithms that generate comprehensive scores [19]. This article classifies these tools based on three key dichotomies: general versus specific application scope, visual versus numerical output formats, and holistic versus targeted assessment approaches. Understanding these classifications helps researchers select appropriate metrics for their specific applications and correctly interpret results across different tools [15]. The Analytical Method Greenness Score (AMGS) calculator, developed by the ACS Green Chemistry Institute Pharmaceutical Roundtable, serves as a central reference point in this comparison due to its specific design for chromatographic method development in pharmaceutical applications [2] [20].

Classification Framework for Metric Tools

General vs. Specific Application Scope

Metric tools vary significantly in their scope of application, with some designed for broad use across analytical techniques and others optimized for specific methodologies [15].

General-purpose metrics provide flexible frameworks applicable to diverse analytical techniques. The Analytical Greenness Calculator (AGREE) exemplifies this category by offering a comprehensive assessment based on all 12 principles of GAC [4] [16]. Similarly, the Green Analytical Procedure Index (GAPI) creates a multi-criteria pictogram that evaluates entire analytical procedures [16] [19], while the Analytical Eco-Scale assigns penalty points based on reagent amounts, hazards, energy consumption, and waste [16].

Technique-specific metrics are optimized for particular analytical methodologies. The AMGS calculator is specifically designed for liquid chromatography and supercritical fluid chromatography methods [2]. Other specialized tools include HPLC-EAT for high-performance liquid chromatography methods and AGREEprep which focuses exclusively on the sample preparation stage of analysis [15] [4].

Table 1: Classification of Metric Tools by Application Scope

| Metric Tool | Application Scope | Target Techniques | Key Characteristics |

|---|---|---|---|

| AMGS | Specific | Liquid chromatography, SFC | Benchmarks solvent health, safety, environmental impact, energy demand [2] |

| AGREE | General | All analytical techniques | Assesses all 12 GAC principles; configurable weights [4] [16] |

| GAPI | General | All analytical techniques | Qualitative/semi-quantitative multi-criteria pictogram [16] [19] |

| AGREEprep | Specific | Sample preparation | Focuses specifically on sample preparation stage [15] |

| HPLC-EAT | Specific | HPLC-related techniques | Limited to HPLC-based methods [4] |

| NEMI | General | All analytical techniques | Simple pictogram with four criteria; qualitative only [16] [19] |

Visual vs. Numerical Output Formats

The communication of assessment results follows distinct approaches, with some tools providing primarily visual outputs and others generating numerical scores.

Visual output metrics use pictograms, symbols, and color-coding to intuitively communicate greenness assessments. The NEMI pictogram employs a circle divided into four quadrants that are filled green when criteria are met [16]. GAPI utilizes a more detailed pictogram with five pentagrams color-coded from green to red to represent environmental impact levels [16] [19]. The RGB model and its derivatives use color blending to represent different sustainability aspects [15].

Numerical output metrics generate quantitative scores that enable precise comparisons and tracking of improvements. The AMGS calculator produces a numerical score where lower values indicate greener methods [2]. The Analytical Eco-Scale starts with a perfect score of 100 and subtracts penalty points for undesirable attributes [16]. More recent tools like AGREE generate scores on a 0-1 scale while also incorporating visual elements through color-coded circular diagrams [4] [16].

Holistic vs. Targeted Assessment Approaches

Assessment tools differ in their comprehensiveness, with some evaluating multiple sustainability dimensions and others focusing on specific environmental aspects.

Holistic metrics attempt to capture a wide range of environmental and functional attributes. The emerging concept of White Analytical Chemistry (WAC) seeks to balance greenness with analytical quality and practical effectiveness [12] [15]. Tools like AGREE and the newer GEMAM incorporate numerous criteria covering samples, reagents, instrumentation, method, waste, and operator safety [4]. These comprehensive approaches aim to avoid suboptimization where environmental improvements compromise analytical performance.

Targeted metrics focus on specific environmental impact categories. The AMGS calculator specifically addresses solvent health, safety, environmental impact, cumulative energy demand, instrument energy usage, and method solvent waste [2]. The ChlorTox Scale focuses primarily on the toxicity of solvents and reagents used in analytical processes [9] [16]. Similarly, AMVI concentrates mainly on the volume of solvents consumed during analysis [4].

Diagram: Classification framework for green analytical chemistry metric tools showing the three primary classification axes and representative tools for each category.

Comparative Analysis of AMGS Against Other Metrics

Detailed Examination of AMGS Components

The AMGS calculator employs a targeted approach specifically designed for chromatographic method development in pharmaceutical applications [2]. Its calculation incorporates several distinct components: solvent health, safety, and environmental impact assessments; cumulative energy demand evaluation; instrument energy usage based on method run time; and method solvent waste volume [2]. The tool employs color-coding (yellow and red) to highlight areas where the method could be improved, such as reducing instrument energy by shortening run time [2].

A key characteristic of AMGS is its function as a comparative tool rather than an absolute measure of greenness. The ACS GCI Pharmaceutical Roundtable explicitly states it is "not meant as an absolute measure of method greenness or as a means to reject a given method based on the finite score" [2]. This positions AMGS primarily as a benchmarking tool for comparing methods during development. The calculator currently supports only liquid chromatography and SFC methods, with GC method support planned for 2026 [2].

Comparison with Other Leading Metrics

When compared to other metrics, AMGS occupies a distinctive position in the landscape of assessment tools. The following table illustrates how it compares across critical parameters:

Table 2: Comparative Analysis of AMGS with Other Greenness Assessment Metrics

| Metric Tool | Output Type | Scope | Assessment Approach | Key Strengths | Key Limitations |

|---|---|---|---|---|---|

| AMGS | Numerical | Specific | Targeted | Specific for LC/SFC; practical for pharma development [2] | Limited to chromatographic techniques [2] |

| AGREE | Both | General | Holistic | Comprehensive (12 GAC principles); configurable weights [4] [16] | Complex calculation process [4] |

| GAPI | Visual | General | Holistic | Detailed pictogram; semi-quantitative assessment [16] [19] | Qualitative nature limits precision [4] |

| NEMI | Visual | General | Targeted | Simple interpretation; historical precedence [16] [19] | Limited criteria; qualitative only [16] |

| Analytical Eco-Scale | Numerical | General | Targeted | Simple 100-point scale; penalty point system [16] | No pictogram output [4] |

| GEMAM | Both | General | Holistic | Comprehensive (21 criteria); adjustable weights [4] | Newer tool with limited track record [4] |

Experimental Protocols for Metric Application

To ensure consistent application and comparison of greenness metrics, researchers should follow standardized experimental protocols when evaluating analytical methods:

Data Collection Requirements: For AMGS application, researchers must document: (1) complete solvent inventory with volumes used per analysis; (2) instrument type (HPLC, UPLC, SFC) and method run time; (3) system suitability test preparation details including serial dilution volumes; and (4) waste collection data [2]. Similar comprehensive data collection is needed for other metrics, with AGREE requiring additional information on sample collection, preparation, and operator safety measures [4].

Calculation Methodologies: The AMGS calculation algorithm incorporates solvent health, safety, and environmental impact factors alongside cumulative energy demand and instrument energy usage [2]. Other metrics employ different calculation approaches: AGREE uses weighting factors for each of the 12 GAC principles [4], while Analytical Eco-Scale subtracts penalty points from a baseline of 100 [16]. Recent tools like GEMAM employ more complex formulas with section weights that default to specific distributions (e.g., 25% for reagents, 25% for waste, 15% for instrument) but can be adjusted based on assessment priorities [4].

Validation Procedures: Method validation should include cross-metric comparison where feasible. Researchers should apply multiple metric tools to the same method and analyze correlation between results [19]. For AMGS specifically, the ACS GCI recommends using the tool to compare method iterations during development rather than as a standalone pass/fail criterion [2].

Essential Research Reagent Solutions

Implementing greenness assessments requires both computational tools and practical laboratory solutions. The following research reagents and materials represent essential components for developing and evaluating greener analytical methods:

Table 3: Essential Research Reagents and Solutions for Green Analytical Chemistry

| Reagent/Solution | Function in Green Assessment | Application Example |

|---|---|---|

| Low-toxicity solvents | Replace hazardous solvents in sample preparation and separation | Alternative solvents with better environmental profiles in AMGS [2] |

| Natural deep eutectic solvents (NADES) | Bio-based solvents for extraction processes | Evaluate green profile in AGREEprep for sample preparation [18] |

| Miniaturized extraction devices | Reduce reagent consumption and waste generation | Implement microextraction techniques to improve GAPI and AGREE scores [4] |

| Renewable sorbents | Sustainable materials for sample preparation | Assess sustainability in Spider diagram and ComplexGAPI metrics [19] |

| Energy-efficient instrumentation | Reduce cumulative energy demand in AMGS calculation | UHPLC and SFC systems to lower instrument energy component [2] |

The classification of GAC metric tools along the axes of general versus specific scope, visual versus numerical outputs, and holistic versus targeted approaches provides researchers with a structured framework for selecting appropriate assessment methods. The AMGS calculator occupies a distinct position as a targeted, numerical tool specifically optimized for chromatographic method development in pharmaceutical applications [2]. Its design philosophy emphasizes practical benchmarking during method development rather than comprehensive sustainability assessment.

The future evolution of greenness metrics will likely address current limitations through increased standardization, integration of uncertainty estimates, and development of more objective weighting approaches [15]. Tools like AGREE and GEMAM that offer configurable weights represent a step in this direction, though consensus on default weightings remains elusive [15] [4]. For researchers in drug development, AMGS provides immediate practical value for comparing chromatographic methods, while broader sustainability assessments may benefit from complementary tools like AGREE or GAPI that address a wider range of environmental impacts [2] [16]. As the field progresses, the optimal approach may involve using multiple metrics in concert to leverage their respective strengths while mitigating their individual limitations.

Putting Metrics to Work: A Practical Guide to Calculation and Application

The push for sustainability in the pharmaceutical industry has extended into analytical laboratories, where chromatographic methods traditionally consume high volumes of solvents and energy. To quantify and minimize this environmental impact, several greenness assessment tools have been developed. Among these, the Analytical Method Greenness Score (AMGS) has emerged as a specialized metric for evaluating the environmental footprint of chromatographic separations. Developed by the American Chemical Society's Green Chemistry Institute (ACS-GCI) Pharmaceutical Roundtable, the AMGS provides a unified, quantitative approach to benchmark and improve the sustainability of analytical methods without compromising analytical performance [1] [21] [22].

The AMGS calculator is a web-based, publicly accessible tool designed specifically for liquid chromatography (HPLC/UHPLC), supercritical fluid chromatography (SFC), and, in a forthcoming update, gas chromatography (GC) methods [2] [22]. It serves as a strategic metric to raise awareness, guide method development toward more sustainable practices, and provide a systemic view of solvent and energy use throughout the analytical process. By offering a single numerical score—where a lower value indicates a greener method—it enables scientists to objectively compare different method parameters and instrument choices [2] [21] [23].

This guide provides a detailed walkthrough of the AMGS calculator, placing it within the broader context of green analytical chemistry metrics. By comparing its methodology, scope, and outputs with other available tools, researchers and drug development professionals can make informed decisions to reduce the environmental impact of their analytical operations.

Comparative Analysis of Greenness Metrics

The landscape of greenness assessment tools is diverse, with each tool offering unique perspectives and evaluation criteria. The table below summarizes how AMGS compares to other prominent metrics.

Table 1: Comparison of AMGS with Other Green Analytical Chemistry Metrics

| Metric Tool | Primary Focus | Output Type | Key Assessed Criteria | Technique Specificity |

|---|---|---|---|---|

| AMGS [2] [15] [21] | Environmental impact of chromatographic methods | Numerical score | Solvent health/safety, solvent energy, instrument energy, solvent waste | Liquid Chromatography, SFC, (GC coming in 2025) |

| NEMI [15] | Environmental impact of analytical procedures | Pictogram (4 quadrants) | Persistence, bioaccumulation, toxicity, waste generation | General |

| Analytical Eco-Scale [1] [15] | Overall environmental impact of analytical methods | Numerical score (100 - penalty points) | Reagents, instruments, waste | General |

| GAPI [1] [15] | Holistic environmental impact of analytical procedures | Pictogram (5 pentagrams) | All stages from sampling to waste management | General |

| AGREE [1] [15] | Alignment with 12 principles of Green Analytical Chemistry | Numerical score (0-1) & circular pictogram | 12 criteria including energy, toxicity, and waste | General |

A critical differentiator for AMGS is its specificity for chromatography and its incorporation of instrument energy consumption—a factor not always considered in other tools [1] [21]. While general-purpose metrics like GAPI and AGREE provide a broader, more holistic assessment applicable to various analytical techniques, AMGS offers a more granular and tailored evaluation for separation scientists. This focus allows it to capture the unique environmental drivers of chromatographic processes, such as flow rate, run time, and column geometry, and translate them into a cumulative energy demand and hazard score [15] [23].

A Step-by-Step Guide to the AMGS Calculator

Input Parameters and Data Collection

The AMGS calculation requires specific methodological and operational data. The tool's algorithm synthesizes this information across three core categories: solvent health and safety (EHS), cumulative energy demand (CED), and instrument energy usage [2] [21]. The following workflow outlines the logical relationship between your method parameters and the final AMGS score.

To use the calculator, gather the following essential data from your analytical method [2] [21] [23]:

- Solvent Information: The types and volumes of all solvents used in the mobile phase, including mixtures and additives. The calculator contains a database with pre-assigned EHS and CED values for common solvents.

- Instrumental Parameters: The chromatographic flow rate (mL/min), method run time (minutes), and the instrumental "cycle time" (the time from the end of one run to the next injection, crucial for high-throughput analysis) [23].

- Sample Preparation: The total volume of solvent used for sample dissolution and preparation, including dilutions for system suitability tests [2].

- Instrument Type: The model or type of instrument (e.g., UHPLC vs. standard HPLC) as this affects energy consumption.

Calculation Walkthrough and Formula Deconstruction

The public AMGS calculator is hosted on the ACS GCIPR website and is free to use. The step-by-step process is straightforward [2]:

- Access the Tool: Navigate to the AMGS calculator on the ACS GCIPR website.

- Input Method Details: Enter all the parameters gathered in the previous section into the corresponding fields in the web form. The interface is designed to guide you through the process.

- Calculate Score: The tool automatically computes the score upon submission. The result is a single number representing your method's environmental impact.

While the exact, full-weighted formula is proprietary, the underlying principles and some modified forms have been described in research. The score is a composite of three main components [21] [23]:

- Solvent EHS Score: Assesses the environmental, health, and safety profile of the solvents used.

- Solvent Cumulative Energy Demand (CED): Accounts for the energy required to produce and dispose of the solvents.

- Instrument Energy Score: Calculates the electricity consumed by the instrument during the analysis.

A modified AMGS formula that incorporates cycle time (t_c) to provide a more accurate assessment has been presented in recent research [23]. This is crucial because it recognizes that instrument idle time between injections contributes to the total energy footprint. The analysis time (t_a) at a given flow rate (F) can be derived from an initial run time (t_i) and flow rate (F_i):

t_a = (t_i * F_i) / F