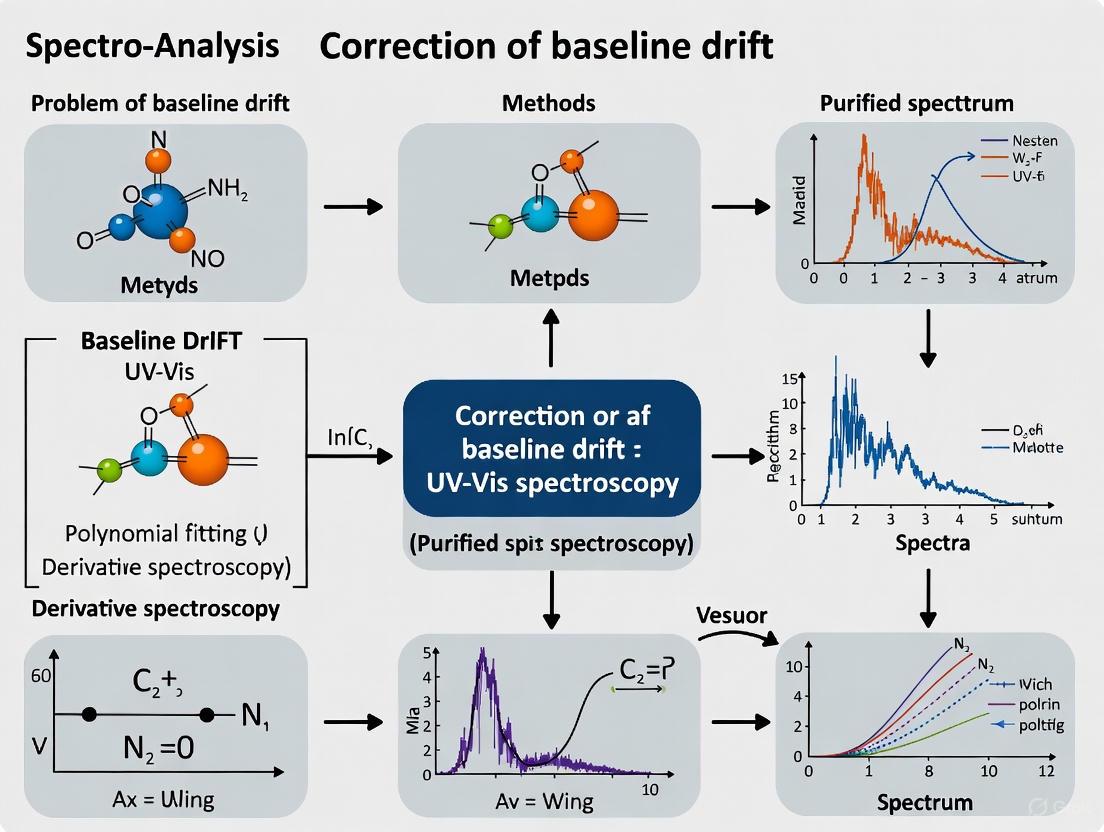

Correcting Baseline Drift in UV-Vis Spectroscopy: A Complete Guide for Accurate Analysis

This article provides a comprehensive guide for researchers and scientists on addressing baseline drift in UV-Vis spectroscopy.

Correcting Baseline Drift in UV-Vis Spectroscopy: A Complete Guide for Accurate Analysis

Abstract

This article provides a comprehensive guide for researchers and scientists on addressing baseline drift in UV-Vis spectroscopy. Covering foundational concepts to advanced applications, it explores the common causes of baseline artifacts—from mobile phase impurities and temperature effects to instrumental misalignment. The content details proven correction methodologies, including polynomial fitting, wavelet transforms, and instrument-specific protocols, alongside practical troubleshooting strategies for laboratory settings. A comparative analysis of validation techniques and correction approaches equips professionals in drug development and biomedical research with the knowledge to select optimal methods, ensuring data integrity and enhancing the reliability of quantitative analyses in critical applications.

Understanding Baseline Drift: Causes, Impacts, and Detection in UV-Vis Spectra

What is Baseline Drift? Defining Short-Term Noise vs. Long-Term Drift

Defining the Problem: Noise vs. Drift

In analytical chemistry, a stable baseline is the foundation for accurate data. Baseline drift is a gradual, unidirectional shift in the baseline signal over time. In contrast, noise refers to random, high-frequency fluctuations in the detector's output. Distinguishing between them is the first critical step in troubleshooting.

The table below summarizes their core differences.

| Feature | Short-Term Noise | Long-Term Noise | Baseline Drift |

|---|---|---|---|

| Definition | Random, high-frequency signal fluctuations [1] | Slow, wave-like baseline undulations [1] | Gradual, unidirectional baseline shift over time [1] [2] |

| Appearance | Fine, hair-like "spikes" on the baseline [1] | Irregular, low-frequency undulations [1] | A steady rise or fall in the baseline position [3] [1] |

| Primary Causes | Pump pulsations; Electronic interference [1] | Detector instability; Temperature & flow rate fluctuations [1] | Mobile phase absorbance mismatch; Temperature changes; Column contamination [1] [2] [4] |

| Impact on Data | Affects detection limits; Does not blur peak resolution [1] | Can obscure peaks due to similar frequency [1] | Induces errors in peak height and area quantification [3] |

Troubleshooting Guide & FAQs

Why is my baseline drifting during a gradient run in HPLC or UHPLC?

This is most commonly caused by a difference in the UV absorbance of your mobile phase components.

- Cause: In gradient runs, the proportion of solvents (e.g., water and organic solvent like methanol or acetonitrile) changes. If the "A" and "B" solvents have different UV absorbance at your detection wavelength, the baseline will drift as the composition changes [2].

- Solutions:

- Match Absorbance: Use a UV-absorbing buffer (like phosphate) in the aqueous solvent to better match the absorbance of the organic solvent [2].

- Change Wavelength: Increase the detection wavelength (e.g., to >250 nm) where most solvents have minimal absorbance [2].

- Change Solvent: Switch to an organic solvent with lower UV absorbance, such as using acetonitrile instead of methanol for low-wavelength work [2].

- Blank Gradient: Run a blank gradient to characterize the drift, which can sometimes be subtracted during data processing [4].

How can I tell if my issue is noise or drift, and what are the common fixes?

Identify the pattern using the definitions above, then investigate these common culprits.

- For Short-Term Noise:

- For Long-Term Noise:

- Control temperature: Ensure the mobile phase and detector cell temperature are stable. Use a heat exchanger if available [1] [4].

- Degas mobile phase: Use an inline degasser or helium sparging to prevent bubbles, which cause low-frequency noise [4].

- Check for contamination: Contamination in the mobile phase, sample, or system can cause drifting and noise. Clean the system regularly and use high-purity solvents [4] [5].

- For Baseline Drift:

- Allow for equilibration: After a solvent change or at the start of a sequence, ensure the system has sufficient time to equilibrate thermally and chemically [4].

- Stabilize temperature: Ensure the laboratory environment and instrument are free from drafts and temperature fluctuations [6] [5].

- Maintain the instrument: Regular maintenance, including cleaning optical components and checking for worn parts (e.g., lamps), is crucial [5].

My UV-Vis spectrophotometer baseline is drifting. What should I do?

- Cause: Instrumental factors (degrading light source, dirty optics), environmental influences (temperature, humidity), or sample effects (bubbles, particulates) can all cause drift [5].

- Solutions:

- Perform Baseline Correction: Use the instrument's software to perform a baseline correction with a blank (solvent or buffer) before measuring samples [7] [8].

- Control the Environment: House the instrument in a stable environment with minimal temperature fluctuations and vibrations [5].

- Proper Sample Handling: Ensure samples are free of bubbles and particulates. Use matched cuvettes to avoid artifacts [5].

- Regular Maintenance: Follow the manufacturer's schedule for calibration and maintenance, including cleaning optics and replacing old lamps [5].

Experimental Protocol: Baseline Correction in UV-Vis Spectroscopy

This protocol outlines a standard baseline correction procedure to eliminate background absorbance and instrumental drift.

Workflow: Baseline Correction

Procedure

- Preparation: Prepare a blank solution containing only the solvent or buffer used to dissolve your sample, with no analyte present [7] [8].

- Loading: Carefully load the blank solution into a clean, matched cuvette. Ensure the cuvette is free of fingerprints, scratches, and bubbles [5].

- Placement: Place the cuvette into the spectrophotometer's sample holder and close the lid.

- Correction: Initiate the baseline correction (sometimes called "zero" or "auto-zero") function on your instrument. This command instructs the spectrophotometer to measure the absorbance of the blank across the desired wavelength range and store it as the background reference [7]. The instrument will subsequently subtract this baseline from all sample measurements.

- Measurement: Replace the blank cuvette with your sample cuvette and run the measurement. The resulting spectrum will be automatically corrected for the baseline absorbance contributed by the solvent and instrument [8].

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function |

|---|---|

| HPLC-Grade Solvents | High-purity solvents minimize UV-absorbing contaminants that cause baseline drift and noise [4]. |

| Trifluoroacetic Acid (TFA) | A common ion-pairing reagent and acidifier for biomolecule separations. It has low UV absorbance at ~214 nm, making it suitable for peptide analysis [2]. |

| Potassium Phosphate Buffer | A UV-absorbing buffer used to balance the absorbance of the aqueous and organic mobile phases, reducing drift in gradients [2]. |

| In-line Degasser | Removes dissolved gases from the mobile phase to prevent bubble formation, a common cause of long-term noise and drift [4]. |

| Matched Cuvettes | A pair of cuettes with identical optical properties, essential for accurately subtracting background in UV-Vis sample and blank measurements [5]. |

| Tubulysin B | Tubulysin B, CAS:205304-87-6, MF:C42H63N5O10S, MW:830.0 g/mol |

| Edratide | Edratide, CAS:433922-67-9, MF:C111H149N27O28, MW:2309.5 g/mol |

A stable baseline is the foundation of reliable UV-Vis data.

For researchers and scientists in drug development, baseline drift can compromise data integrity and hinder analytical accuracy. This guide provides targeted troubleshooting strategies to identify and correct the common causes of baseline disturbances in your UV-Vis spectroscopy and HPLC experiments.

Troubleshooting FAQs

Q1: Why does my baseline drift upwards during a gradient HPLC run with UV detection?

This is frequently caused by a difference in the UV absorbance of your mobile phase solvents. In reversed-phase chromatography, the weak solvent (A, often aqueous) typically has lower UV absorbance than the strong solvent (B, organic like acetonitrile or methanol). As the proportion of solvent B increases during the gradient, the overall absorbance of the mobile phase stream also increases, causing an upward drift [9] [10].

- Solution A: Modify the mobile phase. Add a UV-absorbing compound to solvent A so that its absorbance matches that of solvent B. This balances the background absorption throughout the gradient [9].

- Solution B: Change the detection wavelength. Move to a higher wavelength where the organic solvents have lower and more similar absorbance [9]. Acetonitrile is often preferred over methanol or THF for low-wavelength methods due to its lower UV absorbance [9].

- Solution C: Use a blank gradient for baseline subtraction in the data processing software.

Q2: My baseline is noisy and shows "ghost peaks" even with no sample injection. What is the cause?

This is a classic sign of mobile phase impurities. Contaminants in the water, organic solvents, or buffers can be concentrated on the column head during the initial part of the run and then eluted as sharp peaks later in the gradient, appearing as "ghost peaks" [11]. These impurities can also contribute to a generally elevated and noisy baseline [11].

- Solution A: Use high-purity solvents and additives. Specifically, use HPLC-grade or LC-MS grade solvents, which are certified for low UV absorbance [11] [12].

- Solution B: Always use high-purity water (e.g., 18 MΩ-cm resistivity) and prepare mobile phases fresh daily.

- Solution C: Filter all mobile phases through 0.45 µm or 0.22 µm filters to remove particulate contaminants [12].

Q3: How do temperature fluctuations affect my UV-Vis baseline, and how can I stabilize it?

Temperature fluctuations can cause baseline drift in several ways. For refractive index (RI) detectors, the signal is notoriously sensitive to temperature changes. UV detectors are also affected, as temperature changes can alter the density of the mobile phase and the detector's electronic components, leading to signal drift [11] [12]. Inconsistent laboratory temperatures can cause a "wavy" baseline pattern [12].

- Solution A: Use a column oven. Maintaining a constant temperature for the column and mobile phase is crucial for baseline stability [9] [12].

- Solution B: Control the laboratory environment. Place the instrument in a draft-free area away from air conditioning vents and ensure room temperature is stable [5] [12].

- Solution C: Allow sufficient warm-up time. Let the instrument and lamp stabilize for 30-60 minutes before starting critical measurements [13].

Q4: I've ruled out the mobile phase and temperature. What instrumental issues could be causing the drift?

Instrumental factors are a common culprit. An aging UV lamp is a primary source of baseline fluctuation and drift; deuterium lamps typically last 1,000–3,000 hours [14] [12]. Pump problems in an HPLC system, such as a sticky check valve or trapped air bubble, can cause inconsistent mobile phase delivery, leading to a saw-tooth pattern in the baseline [11]. Dirty flow cells or cuvettes can also scatter light and cause instability [15].

- Solution A: Check and replace the lamp. Log lamp usage hours and replace lamps proactively based on the manufacturer's specifications or if performance degrades [14] [12].

- Solution B: Perform regular pump maintenance. Purge the pump to remove trapped air, and clean or replace malfunctioning check valves [11] [12].

- Solution C: Ensure proper cuvette care. Use clean, matched cuvettes without scratches or fingerprints, as these can scatter light and cause errors [15] [16].

The table below summarizes the common causes of baseline drift and immediate corrective actions.

| Cause Category | Specific Cause | Symptoms | Corrective Actions |

|---|---|---|---|

| Mobile Phase Impurities | Contaminants in water, solvents, or buffers [11] | Ghost peaks, elevated baseline, high noise [11] | Use HPLC/LC-MS grade solvents, fresh high-purity water, and filter mobile phases [11] [12]. |

| Solvent Effects | Differing UV absorbance of mobile phase components [9] [10] | Smooth, upward or downward drift during a gradient [9] | Add UV absorber to A solvent, change wavelength, or use acetonitrile over methanol/THF [9]. |

| Temperature Fluctuations | Unstable lab temperature or lack of column oven [12] | Wavy baseline drift, most severe in RI detectors [12] | Use a column oven, thermostat the detector flow cell, and stabilize the room environment [5] [12]. |

| Instrumental Issues | Aging/degrading UV lamp [14] [12] | High noise, random spikes, or general drift [12] | Replace lamp per manufacturer's recommended hours or if intensity fails [14] [15]. |

| HPLC pump malfunctions (e.g., sticky check valve, air bubble) [11] | Saw-tooth or cyclic baseline pattern [11] | Purge pump to remove air, clean or replace check valves [11] [12]. | |

| Dirty optics or cuvette [15] [13] | Increased noise and baseline shifts [13] | Clean optics and cuvettes with lint-free cloth and suitable solvent (e.g., ethanol) [15]. |

Experimental Protocol for Systematic Diagnosis

Follow this step-by-step methodology to diagnose the source of baseline drift.

1. Visual Inspection of Baseline Pattern

- Objective: Form a initial hypothesis based on the baseline's appearance.

- Procedure: Observe the chromatogram or spectrum. A smooth, continuous drift suggests solvent effects [9]. A saw-tooth or cyclic pattern points to pump issues [11]. Random spikes or high-frequency noise suggests a failing lamp or electrical interference [12].

2. Execute a Blank Run

- Objective: Isolate the problem to the instrument or mobile phase.

- Procedure: Run a gradient or spectrum using only the mobile phase (no sample injection) [11]. If ghost peaks or drift persist, the issue is with the mobile phase, column, or instrument—not the sample.

3. Method Modification Tests

- Objective: Confirm the role of solvent effects.

- Procedure:

- Isocratic Test: Switch to an isocratic method with a fixed mobile phase composition. If the drift disappears, the gradient itself is the cause [11] [9].

- Wavelength Change: Increase the detection wavelength. A significant reduction in drift confirms differing solvent absorbance as the primary cause [9].

4. Instrumental Checks

- Objective: Rule out hardware failures.

- Procedure:

- Lamp Hours Check: Review the instrument's log for lamp usage. If near or beyond the rated lifespan (e.g., 2,000 hours for a deuterium lamp), replacement is the first step [14].

- Pump Purge: Open the purge valve and run a high flow rate (e.g., 5 mL/min) for 10-15 minutes to remove trapped air bubbles from the pump [12].

- Cuvette Inspection: Ensure the cuvette is clean, scratch-free, and properly aligned [15].

The Scientist's Toolkit: Essential Research Reagents and Materials

The table lists key materials for preventing and correcting baseline issues.

| Item | Function & Importance |

|---|---|

| HPLC/LC-MS Grade Solvents | Guarantee low UV absorbance and minimal particulate impurities, directly reducing baseline noise and ghost peaks [11] [15]. |

| High-Purity Water (18 MΩ-cm) | Preents ionic and organic contaminants from water from accumulating on the column and causing baseline artifacts [11]. |

| 0.22 µm Nylon Membrane Filters | Removes particulate matter from mobile phases during preparation, protecting the column and detector flow cell from clogs and noise [12]. |

| Certified Reference Materials (CRMs) | Validates instrument performance, wavelength accuracy, and photometric accuracy, confirming that observed drift is not due to calibration error [15]. |

| Matched Quartz Cuvettes | Provides optimal UV transmission and consistent pathlength, critical for accurate and reproducible absorbance measurements without artifact signals [15] [16]. |

| Column Oven | Maintains a constant temperature for the HPLC column and mobile phase, eliminating drift caused by thermal fluctuations [9] [12]. |

| Avilamycin C | Avilamycin C, CAS:69787-80-0, MF:C61H90Cl2O32, MW:1406.2 g/mol |

| 3,5-Dimethoxybenzylzinc chloride | 3,5-Dimethoxybenzylzinc chloride, CAS:352530-33-7, MF:C9H11ClO2Zn, MW:252 g/mol |

Troubleshooting Workflow and Cause Relationships

The diagram below outlines a logical workflow for diagnosing baseline drift problems.

Troubleshooting Baseline Drift Workflow

This guide provides a foundation for resolving baseline instability. For persistent issues, consult your instrument's service manual or contact technical support, as problems may relate to detector electronics or other internal components requiring professional repair.

Troubleshooting FAQs

FAQ 1: My spectrophotometer's baseline is noisy and unstable, or it fails self-tests with energy-related error codes (e.g., NG9, E3093, Energy Error). What should I check?

This is typically the first sign of a failing or aged light source.

- Primary Cause: The deuterium or tungsten lamp is nearing the end of its operational life, leading to insufficient energy output [17] [14]. Lamps have a finite lifespan; deuterium lamps generally last 1,000–3,000 hours, while xenon flash lamps last about 500 hours [14].

- Solution:

- Check the logged usage hours for the lamp in the instrument's software [14].

- Visually inspect the lamps (if safe and possible) through the ventilation grille. A deuterium lamp should emit a steady blue glow, and the tungsten lamp should be lit [17].

- Replace the lamp if it is near or beyond its rated hours, or if visual inspection reveals it is not lighting [17] [14].

FAQ 2: After replacing the lamp, my absorbance readings are still erratic and won't zero. What could be wrong?

When a new lamp doesn't resolve the issue, the problem often lies with the sample or its container.

- Primary Cause: Dirty, scratched, or contaminated cuvettes are a very common source of light scattering and erratic readings [18] [19]. Fingerprints, dust, or residue on the cuvette windows can significantly scatter light.

- Solution:

FAQ 3: I have confirmed my cuvettes are clean and my lamp is new, but my signal is low and the baseline is drifting. What else should I investigate?

This points to potential physical or optical issues within the instrument or setup.

- Primary Cause: For modular systems, optical misalignment or damaged fiber optic cables can cause signal loss and drift [18]. For all systems, dirty optics or unstable environmental conditions can be the culprit [5].

- Solution:

- Alignment: Ensure all modular components are correctly aligned. The sample should be perpendicular to the light source and detector. Use optical fibers to guide light and maintain a stable path [18].

- Cables: Check fiber optic cables for sharp bends, twists, or damage, and replace them if necessary [18].

- Environment: Ensure the instrument is on a stable surface, away from vibrations, and in a room with stable temperature and low humidity [17] [5].

Detailed Troubleshooting Protocols

Protocol 1: Diagnosing and Replacing an Aging Lamp

An aging lamp is a leading cause of photometric inaccuracy, baseline noise, and failed instrument self-checks [17] [14].

Diagnostic Steps:

- Check for Error Codes: Note any specific codes like "NG9" (insufficient deuterium lamp energy) or "Energy Error" [17].

- Inspect Lamp Hours: Access the lamp hour counter from the instrument's software menu. Compare the logged hours against the manufacturer's rated lifespan [14].

- Visual Inspection: With the instrument powered on, check if the lamps are illuminated. A failing deuterium lamp may flicker, fail to ignite, or appear dim [17].

- Run a Baseline Scan: Observe the baseline for excessive noise or drift, particularly in the wavelength range you use most frequently.

Resolution: If diagnostics confirm a lamp issue, proceed with replacement according to the manufacturer's instructions. After installing a new lamp, allow it to warm up for the recommended time (typically 20 minutes for tungsten halogen or arc lamps, a few minutes for LEDs) before taking measurements [18]. Log the replacement date and reset the lamp hour counter.

Protocol 2: Identifying and Resolving Cuvette-Related Issues

Cuvette problems directly cause light scattering and path length inconsistencies, leading to inaccurate absorbance values and an unstable baseline [18] [19].

Diagnostic Steps:

- Visual Inspection: Hold the cuvette up to the light and check for scratches, chips, or cloudiness.

- Blank Measurement: Use a perfectly clean cuvette filled with pure solvent (your blank). An absorbance reading that is noisy, won't zero, or shows unexpected peaks indicates a dirty or defective cuvette [18].

- Comparative Test: Measure the same sample using different cuvettes. Significant variation in absorbance readings between cuvettes suggests one or more are defective or contaminated.

Resolution:

- Cleaning: Clean cuvettes meticulously with a compatible solvent immediately after use [19].

- Handling: Always use gloves and handle cuvettes by the opaque sides only.

- Selection: Ensure you are using the correct cuvette type for your application. Use quartz cuvettes for UV measurements and ensure the path length is correct and consistent [18]. Replace any cuvettes that are scratched or damaged.

Protocol 3: Correcting Optical Misalignment

Misalignment in a modular spectrophotometer setup can drastically reduce light throughput to the detector, causing low signal-to-noise ratios and baseline drift [18].

Diagnostic Steps:

- Check Signal Strength: Observe the reported signal strength or %T. A consistently low value may indicate misalignment.

- Inspect Physical Setup: Verify that all components (lamp, sample holder, detector) are securely fastened and that the optical path is unobstructed.

- Inspect Fiber Optics: If used, check fiber optic cables for sharp bends, broken jackets, or loose connectors [18].

Resolution:

- Realign Components: Follow the manufacturer's alignment procedure. Generally, this involves adjusting the position and angle of each component (light source, sample holder, detector) to maximize the detected signal [18].

- Use Alignment Tools: Utilize holders designed to position samples at a perfect 90° angle to the beam [18].

- Replace Damaged Cables: Replace any damaged optical fibers, ensuring the new cable has the same connector type (e.g., SMA) and length [18].

Troubleshooting Data Tables

Table 1: Common Instrument Error Codes and Solutions

| Error Code / Message | Instrument Model | Likely Cause | Recommended Action |

|---|---|---|---|

| NG9 / Error Code 24 | Various | Insufficient deuterium lamp energy; lamp aging [17] | Check and replace deuterium lamp [17]. |

| E3093 dark signal too large | Thermo Helios α | Sample compartment lid open or detector issue [17] | Ensure compartment lid is fully closed. |

| D2-failure / WL-Calibrate fail | Model 6010 | Deuterium lamp failure or ignition issue [17] | Confirm nothing blocks the light path; replace lamp [17]. |

| ENERGY ERROR | Shimadzu UV-260 | Faulty deuterium lamp or its power supply [17] | Replace lamp; if persistent, check ignition circuit and relays [17]. |

| Tungsten lamp energy high | TU1901 | Light source switching motor or sensor fault [17] | Service required to check motor and control circuit [17]. |

| RAM INITIALIZED... FAIL | Shimadzu UV2201 | Faulty memory (RAM) chip [17] | Service required to replace the internal 62256 RAM chip [17]. |

Table 2: Research Reagent and Material Solutions

| Item | Function | Best Practice Guidance |

|---|---|---|

| Quartz Cuvettes | Hold liquid samples for analysis; transparent in UV-Vis range. | Use for high-accuracy work; clean thoroughly and inspect for scratches [18] [19]. |

| Deuterium Lamp | Provides high-intensity UV light. | Log usage hours; replace proactively after 1,000–2,000 hours [14]. |

| Tungsten Halogen Lamp | Provides visible and NIR light. | Log usage hours; allow 20-minute warm-up for stable output [18]. |

| Optical Fibers | Guide light in modular setups, reducing alignment issues. | Avoid sharp bends; ensure compatible SMA connectors for a tight seal [18]. |

| Standard Reference Materials | (e.g., Potassium Dichromate) for instrument calibration [19]. | Use for regular calibration to ensure photometric and wavelength accuracy [19]. |

Logical Troubleshooting Workflow

The diagram below outlines a systematic decision-making process for diagnosing and resolving issues related to lamp aging, cuvettes, and optical alignment.

Why is baseline drift a critical issue in UV-Vis spectroscopy?

Baseline drift refers to an unsteady, shifting baseline in UV-Vis spectroscopy, which can directly lead to significant inaccuracies in peak quantification and concentration measurements. An unstable baseline affects the fundamental absorbance reading, causing errors in the application of the Beer-Lambert law for concentration determination [5]. For example, a single offset can cause reported absorbance values at key wavelengths (e.g., 260 nm for nucleic acids) to be about 20% higher than the true value, directly translating to a 20% overestimation of concentration [7].

This guide outlines the common sources of this problem and provides methodologies for its identification and correction.

Troubleshooting Guides

Baseline anomalies and drift can originate from instrumental issues, sample characteristics, or operational factors. The table below summarizes the primary sources and their manifestations.

Table 1: Common Sources of Baseline Errors and Their Impact on Quantification

| Source Category | Specific Cause | Effect on Baseline & Quantification |

|---|---|---|

| Instrumental Factors | Unstable light source or detector sensitivity [5] | Causes baseline drift (slow shift up or down), affecting all absorbance readings [5]. |

| Stray light [20] [21] [22] | Leads to non-linearity at high absorbance, flattening peaks and underestimating high concentrations [22]. | |

| Mobile phase impurities (in LC-UV) [11] | Creates a sloping baseline, ghost peaks, or a rising baseline during a gradient, interfering with peak integration [11]. | |

| Sample-Related Factors | Light-scattering particulates or aggregates [7] [23] | Causes a significant upward offset across the spectrum, overestimating concentration [7]. |

| Bubbles, contaminants, or inappropriate cuvettes [5] [18] | Introduces noise, sharp spikes, or an overall shift, leading to inaccurate peak identification and quantification [18]. | |

| Solvent absorption [22] [11] | Creates a strongly sloping baseline, which can distort the apparent shape and height of analyte peaks [11]. | |

| Operational & Environmental Factors | Temperature and humidity fluctuations [5] [22] | Induces slow baseline drift as the instrument's components are affected [5]. |

| Improper calibration or blank measurement [5] [24] | Results in a consistent offset or slope, making all sample measurements systematically inaccurate [5]. |

The following diagram illustrates the logical workflow for diagnosing the root cause of a baseline issue.

Experimental Protocol: Baseline Correction and Validation

Implementing a proper baseline correction is essential for data integrity. The following provides a detailed methodology.

Objective: To acquire a UV-Vis spectrum with a flat, stable baseline for accurate peak quantification and concentration calculation.

Materials:

- UV-Vis spectrophotometer

- Matched quartz cuvettes (e.g., 1 cm path length)

- High-purity solvent for blank (identical to the sample solvent)

- Sample solution

- Syringe filter (0.22 µm or 0.45 µm, if needed)

Procedure:

- Instrument Warm-up and Stabilization: Turn on the instrument and allow the lamp to warm up for the recommended time (typically 20-30 minutes). This ensures stable light output and minimizes initial drift [18].

- Blank Measurement:

- Thoroughly clean the cuvette.

- Fill it with the pure solvent used to prepare your sample.

- Place the cuvette in the holder, ensuring it is clean and positioned correctly.

- Run the blank measurement to set the 0.000 absorbance (100% transmittance) baseline for the system [24].

- Assess Blank Baseline:

- Scan the blank solvent over your intended wavelength range. A proper baseline should be flat and noise-free.

- If the blank baseline shows significant drift, noise, or absorption features, the solvent may be impure, the cuvette dirty, or there may be an instrument issue. Do not proceed until this is resolved.

- Sample Measurement:

- Replace the blank cuvette with your sample cuvette.

- Ensure the sample is clear and free of bubbles.

- Collect the sample spectrum.

- Apply Baseline Correction:

- Single-Point Correction: For simple offsets, subtract the absorbance value at a non-absorbing wavelength (e.g., 340 nm for UV assays, 750 nm for Vis assays) from the entire spectrum [7].

- Software-Assisted Fitting: For sloping baselines, use the instrument's software to fit a baseline to regions where the analyte does not absorb and subtract this fitted curve. Advanced corrections based on light-scattering equations (e.g., Rayleigh-Mie correction) can be used for particulate-rich samples [23].

Validation: After correction, the baseline regions of your sample spectrum should be close to zero absorbance. Quantification should be performed using peaks that are well-resolved from the baseline.

Frequently Asked Questions (FAQs)

Q1: My sample is turbid. How does this affect my concentration measurement, and how can I correct it? Turbid samples contain light-scattering particles that cause an offset in the absorbance baseline, leading to overestimation of concentration [7] [23]. Simple filtration can often resolve this. For samples where filtration is not possible (e.g., protein aggregates), advanced baseline subtraction techniques that use fundamental Rayleigh and Mie scattering equations are recommended to correct the spectrum mathematically [23].

Q2: What is the optimal absorbance range for accurate concentration measurements, and why? The optimal range is between 0.2 and 1.0 Absorbance Units (AU). The Beer-Lambert law assumes a linear relationship, which deviates at high concentrations due to instrumental effects like stray light and chemical factors [22] [24]. Below 0.2 AU, the signal-to-noise ratio may be too low. If your sample absorbance exceeds 1.0 AU, dilute the sample or use a cuvette with a shorter path length [18] [24].

Q3: How do I select the correct wavelength for baseline correction? The baseline correction wavelength must be a region where your analyte and buffer do not absorb [7].

- For standard UV nucleic acid/protein assays, 340 nm is a common default [7].

- For assays extending into the visible range, 750 nm is often used [7].

- The optimal wavelength should be empirically determined for your specific sample type and method [7].

Q4: After baseline correction, my sample shows negative absorbance in some regions. What does this mean? Negative absorbance is generally non-physical and indicates a problem with the blank measurement or sample handling [20]. The blank absorbance was likely higher than the sample's absorbance at those wavelengths. Ensure the blank and sample are in matched cuvettes, the blank is truly a representative solvent, and that the cuvettes are clean and properly positioned [18].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Reliable UV-Vis Quantification

| Item | Function & Importance | Considerations |

|---|---|---|

| High-Purity Solvents | Forms the blank baseline; impurities absorb light and cause sloping baselines or ghost peaks [22] [11]. | Use "HPLC" or "spectroscopic" grade solvents. Check the solvent's UV cutoff wavelength to ensure transparency in your measurement range [24]. |

| Matched Quartz Cuvettes | Hold the sample and blank. Quartz is transparent down to ~190 nm [24]. | Use a matched pair for blank and sample. Cuvettes must be scrupulously clean; handle with gloves to avoid fingerprints [18]. |

| Certified Reference Materials | Calibrate the spectrophotometer for wavelength accuracy and photometric linearity [21] [22]. | Holmium oxide solution is standard for wavelength verification. Neutral density filters or potassium dichromate solutions can test photometric accuracy [21] [22]. |

| Syringe Filters | Remove particulates and micro-bubbles from samples, eliminating a major source of light scattering and baseline offset [5]. | Use 0.22 µm or 0.45 µm pore size. Ensure the filter membrane is compatible with your solvent (e.g., Nylon for aqueous, PTFE for organic) [5]. |

| Stable Light Source | Provides consistent illumination; a degrading source is a primary cause of baseline drift and noise [5] [24]. | Follow manufacturer guidelines for lamp lifetime and warm-up procedures (typically 20 min) [18]. |

| Globomycin | Globomycin|LspA Inhibitor|For Research Use | Globomycin is a lipopeptide antibiotic that inhibits signal peptidase II (LspA). For research use only. Not for human or veterinary diagnostic or therapeutic use. |

| Casuarictin | Casuarictin, CAS:79786-00-8, MF:C41H28O26, MW:936.6 g/mol | Chemical Reagent |

FAQ: Understanding Spectral Artifacts

Q1: What are the key visual differences between baseline drift, a rising baseline, and a ghost peak?

- Baseline Drift: Appears as a slow, gradual upward or downward shift of the entire baseline over the course of a measurement or between sample runs. It is a broad, low-frequency change affecting the entire spectral range rather than a specific wavelength [5].

- Rising Baseline: Manifests as a steady, consistent increase in the baseline signal, often with a specific slope. It is frequently caused by the accumulation of contaminants in the flow path or temperature fluctuations [22].

- Ghost Peaks: Are sharp, peak-like features that appear in blank runs or sample analyses at retention times where no known analyte is expected. They can be positive or negative and often have irregular shapes compared to analyte peaks [25] [26].

Q2: I've identified a ghost peak. What are its most common sources?

Ghost peaks are system-related artifacts. Their origins can be systematically investigated [25] [27]:

- Mobile Phase Contamination: Trace impurities in solvents or buffers are a primary cause. This is especially problematic in high-sensitivity analyses and gradient elution methods [27].

- System Contamination: Carryover from previous injections or contaminated components (e.g., autosampler needles, injection valves, pump seals) can elute as ghost peaks [27].

- Column-Related Issues: Aging columns, contaminated guard columns, or column fouling can generate extraneous signals [27].

- Sample Preparation: Contaminated vials, caps, or glassware can introduce impurities that manifest as ghost peaks [27].

Q3: What immediate steps should I take if my baseline is unstable or drifting?

First, perform a blank run with your mobile phase to establish a baseline profile [25]. Then, check the following:

- Solvent Quality: Ensure high-purity, freshly prepared, and properly degassed solvents are used [25] [27].

- Temperature Control: Verify that the instrument environment is stable, as temperature fluctuations are a common cause of baseline instability [25] [5].

- Instrument Warm-up: Allow the light source (e.g., tungsten halogen or arc lamps) to warm up for at least 20 minutes before measurement for stable output [18].

- Cuvette/Sample Holder: Inspect for cleanliness, scratches, or fingerprints that can cause light scattering [18].

Troubleshooting Guide: A Systematic Workflow

Follow this logical pathway to diagnose and correct common spectral artifacts.

Protocol 1: Identification and Elimination of Ghost Peaks

- Run a Gradient Blank: Perform a blank injection (mobile phase only) using the same method as your sample analysis. Any peaks that appear are ghost peaks originating from the system or mobile phase [25] [27].

- Compare Retention Times and Shapes: Analyze the retention times and shapes of suspected ghost peaks. Ghost peaks often elute at times not matching any known analyte and may have broader or more diffuse shapes [25].

- Isolate the Source:

- Remove the Column: Replace the column with a zero-dead-volume union and run the blank. If ghost peaks disappear, the issue is with the column [27].

- Test Solvents and Vials: Run a clean solvent in a new vial, then rinse the vial and test again. This helps determine if contamination is from the solvent or the vial itself [27].

- Implement Corrective Actions:

- Mobile Phase: Use fresh, high-purity solvents from different lots or brands. Always use clean glassware for preparation [27].

- System Maintenance: Perform regular cleaning and maintenance of the autosampler (needle, seat), replace worn pump seals, and use in-line filters [25] [27].

- Column Care: Use a guard column, and follow proper column storage and regeneration procedures [27].

Protocol 2: Correcting Baseline Drift and Rise

- Assess Environmental Conditions: Ensure the instrument is housed in a stable environment, free from temperature fluctuations, humidity changes, and vibrations [5].

- Verify Instrument Status:

- Inspect the Sample:

- Apply Software Correction: Use the instrument's built-in baseline correction functions. For example, many systems can subtract a baseline measured at a specific wavelength (e.g., 340 nm for UV, 750 nm for Vis-NIR) from the entire spectrum [7].

Essential Research Reagent Solutions

The following materials are crucial for preventing and troubleshooting spectral artifacts.

| Item | Function & Rationale |

|---|---|

| HPLC-Grade Solvents | High-purity solvents minimize mobile phase contaminants that cause ghost peaks and baseline rise [27]. |

| Certified Reference Materials | Used for regular instrument calibration to ensure wavelength accuracy and photometric linearity, critical for identifying true baseline drift [22]. |

| In-Line Filters & Guard Columns | Protect the analytical column and system from particulate matter and contaminants that can cause ghost peaks and baseline instability [27]. |

| Matched Quartz Cuvettes | Provide consistent light paths and high UV transmission, reducing baseline noise and drift caused by poor-quality or mismatched cell materials [18]. |

| Ghost Trap Cartridges | Specialized cartridges that bind tightly to impurities in the mobile phase, preventing them from eluting and appearing as ghost peaks [27]. |

Data Interpretation Tables

Table 1: Visual Characteristics of Spectral Artifacts

| Artifact Type | Visual Description | Common Causes | Quick Diagnostic Test |

|---|---|---|---|

| Baseline Drift | Slow, continuous upward or downward shift across the spectral range. | Temperature/humidity fluctuations [5], degrading lamp [22], unstable electronics [5]. | Monitor baseline over time without injecting a sample. |

| Rising Baseline | Steady, directional increase in signal, often with a definable slope. | Contaminant accumulation in the flow path [27], solvent evaporation changing concentration [18]. | Run a blank to see if the rise is system-related. |

| Ghost Peaks | Sharp, unexpected peaks in blank runs or sample chromatograms. | Contaminated mobile phase or system components [25] [27], carryover from previous samples [27]. | Inject a pure solvent blank using the sample method. |

Table 2: Recommended Baseline Correction Wavelengths

This table summarizes empirical guidance for selecting baseline correction wavelengths in different applications, which is critical for stabilizing the baseline during data processing [7].

| Application / Method Type | Recommended Baseline Wavelength | Rationale & Notes |

|---|---|---|

| Nucleic Acids/Protein A280 | 340 nm | Standard for UV-only ranges; away from analyte absorbance [7]. |

| UV-Vis App (General Use) | 340 nm (UV), 750 nm (Vis) | 340 nm for UV ranges; 750 nm for methods extending into visible range [7]. |

| Microarray/Labeled Proteins | 750 nm - 840 nm | Anchors the visual spectrum; use >800 nm for dyes with maxima >700 nm [7]. |

| Custom Methods (Vis-NIR) | Empirically determined | Must be determined for each method, considering sample and reagents [7]. |

Proven Correction Methods: From Instrument Setup to Computational Algorithms

In UV-Vis spectroscopy, the absorbance baseline is the reference signal measured when only the solvent or blank is present in the light path. This baseline, also referred to as the baseline OD spectrum or optical density baseline, represents the background contribution from the solvent, cuvette, and instrument optics [28]. Accurate baseline correction is fundamental because it separates these background effects from the genuine sample absorbance, ensuring that the final spectrum accurately represents the analyte of interest. Without proper correction, baseline artifacts can lead to significant errors in concentration calculations, with inaccuracies potentially reaching 5-30% [28]. This process is therefore not merely cosmetic but is essential for data integrity, particularly in regulated environments like pharmaceutical quality control [28].

This guide details the implementation of two common baseline correction protocols—single-point and wavelength-specific methods—within the context of a research thesis. It provides actionable troubleshooting advice and technical FAQs to support researchers, scientists, and drug development professionals in obtaining reliable spectroscopic data.

Core Principles and Protocols

Understanding Single-Point Baseline Correction

The single-point baseline correction method is one of the most straightforward and commonly used techniques. It works by subtracting the absorbance value measured at a single, user-defined wavelength from the absorbance values across the entire sample spectrum [7]. This corrects for uniform vertical offsets in the baseline caused by instrument noise or general light scattering from particulates in the sample.

The critical step in this method is selecting an appropriate baseline correction wavelength. This must be a wavelength where neither the molecule of interest nor the sample buffer exhibits any absorbance [7]. The table below summarizes the standard wavelength recommendations for different types of assays.

Table 1: Standard Baseline Correction Wavelengths for Single-Point Correction

| Application Type | Recommended Baseline Wavelength | Rationale |

|---|---|---|

| Nucleic Acids & Proteins (UV range) | 340 nm | Traditional 320 nm correction has been superseded by 340 nm in modern microvolume instruments [7]. |

| General UV-Vis (Methods extending into visible range) | 750 nm | A wavelength in the high visible range where most analytes do not absorb [7]. |

| Custom Dyes (Absorbance >700 nm) | 800 nm or greater | Ensures the correction wavelength is outside the dye's absorption band [7]. |

Implementing a Wavelength-Specific and Curve-Fitting Approach

For more complex samples, a simple single-point subtraction may be insufficient. A wavelength-specific baseline involves using a multi-point or curve-fitting approach to model and subtract a non-uniform baseline. This is particularly important when dealing with artifacts like Rayleigh and Mie light scattering from particulates, soluble protein aggregates, or large proteins, which can create a sloping baseline [23].

One advanced method is the Rayleigh-Mie correction, a curve-fitting baseline subtraction approach based on fundamental scattering equations. This technique factors in instrument baseline artifacts to accurately distinguish between light absorption and light scattering, which is crucial for accurate concentration measurements of samples like proteins or nanoparticles using Beer's Law [23].

Another powerful algorithm is Asymmetric Least Squares (ALS). The core idea of ALS is to iteratively fit a smooth curve that follows the baseline. It applies a much higher penalty to positive deviations (the sample's real peaks) than to negative deviations (the baseline), forcing the fitted curve to neglect the peaks and adapt closely to the baseline points [29].

Table 2: Comparison of Baseline Correction Methods

| Method | Complexity | Best For | Key Consideration |

|---|---|---|---|

| Single-Point | Low | Clear solutions with a flat, uniform baseline offset. | Highly dependent on choosing a correct, non-absorbing wavelength [7]. |

| Multi-Point/Linear Fit | Medium | Simple, linear baseline drift across wavelengths. | Requires selecting multiple wavelengths known to be free of analyte absorption. |

| ALS/Curve-Fitting | High | Complex samples with non-linear baselines, scattering effects, or overlapping peaks [29]. | Computationally intensive; requires iterative fitting and parameter tuning (e.g., lam=1e6, niter=5) [29]. |

| Rayleigh-Mie Scattering Fit | High | Samples with significant light scattering from particulates or aggregates, such as protein solutions or nanoparticles [23]. | Based on physical scattering models; requires validation with controls. |

Experimental Workflow for Baseline Correction

The following diagram illustrates a generalized workflow for implementing baseline correction in a UV-Vis experiment, integrating both single-point and advanced fitting methods.

Diagram 1: Baseline correction workflow for UV-Vis experiments.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table lists key materials required for reliable baseline correction in UV-Vis spectroscopy.

Table 3: Essential Research Reagents and Materials for Baseline Correction

| Item | Function & Importance in Baseline Correction |

|---|---|

| High-Purity Solvent | Used to prepare the blank. Must be the same batch and grade as the sample solvent to accurately match its absorption profile [28]. |

| Spectrophotometric Cuvettes | Sample containers. Quartz is essential for UV work (200-400 nm) as glass and plastic absorb UV light. Consistency in cuvette quality and path length is critical [24] [30]. |

| Certified Reference Materials | Used for instrument calibration and validation (e.g., Holmium oxide for wavelength accuracy). Ensures the instrument itself is not introducing baseline artifacts [22]. |

| Sample Filtration Units | Used to clarify cloudy or particulate-laden samples via filtration or centrifugation. Removes light-scattering particles that cause a sloping baseline [22]. |

| S-Isopropylisothiourea hydrobromide | [Amino(propan-2-ylsulfanyl)methylidene]azanium |

| 3-Octanol | 3-Octanol, CAS:22658-92-0, MF:C8H18O, MW:130.23 g/mol |

Troubleshooting Guides and FAQs

Troubleshooting Guide: Common Baseline Problems and Solutions

| Problem | Potential Causes | Corrective Actions |

|---|---|---|

| Negative Absorbance (Baseline drops below zero) | The blank has a higher absorbance than the sample at certain wavelengths [31]. Mismatched cuvettes between blank and sample measurement. A scratch on the cuvette was rotated into the beam path [31]. | 1. Ensure the blank is chemically identical to the sample solvent. 2. Use perfectly matched cuvettes and ensure their orientation is consistent. 3. Use high-quality, scratch-free cuvettes. |

| Non-Flat or Noisy Baseline | Stray light. Unstable light source (lamp needs warm-up or replacement). Dirty cuvettes or contaminants in the solvent [22] [18]. | 1. Allow the lamp to warm up for 20-30 minutes before use [18]. 2. Thoroughly clean cuvettes and use high-purity solvents. 3. Check instrument manual for stray light tests. |

| Sloping Baseline in Sample | Light scattering from turbid samples or large particles (e.g., proteins, aggregates) [23]. | 1. Filter or centrifuge the sample to remove particulates. 2. If scattering is inherent (e.g., from large proteins), apply an advanced scattering correction method like Rayleigh-Mie fitting [23]. |

| Incorrect Concentration (after correction) | Wrong baseline wavelength selected (e.g., chosen in an area where the analyte absorbs). Significant baseline drift during a long measurement sequence [7]. | 1. Empirically determine the optimal baseline wavelength where the analyte and buffer do not absorb. 2. Run periodic baseline checks during long sequences to correct for drift. |

Frequently Asked Questions (FAQs)

Q1: Can I skip baseline correction if my solvent is "clear" and my cuvettes look clean? No. Even the purest solvents and cleanest cuvettes contribute to the baseline signal. Skipping correction risks significant errors in quantification, as instrument noise and inherent solvent absorption are always present. In one documented case, a baseline drift of just 0.02 AU led to a 15% error in concentration calculation [28].

Q2: How do I empirically determine the best baseline correction wavelength for a new dye? Scan the dye and its solvent buffer across your wavelength range of interest. Identify a region where the solvent buffer is flat and the dye itself shows no absorbance. This "quiet" region, often at the higher end of the visible spectrum (e.g., 750 nm) or beyond for NIR dyes, is your ideal baseline correction wavelength [7].

Q3: Why does my baseline keep drifting over time, and how can I prevent it? Baseline drift can be caused by temperature fluctuations in the lab or within the instrument, instability of the light source (especially if it hasn't warmed up sufficiently), or evaporation from the blank solution in an uncapped cuvette over time. To prevent drift, ensure the instrument is in a temperature-stable environment, allow lamps to warm up for at least 20 minutes, and use capped cuvettes for long sequences [28] [18].

Q4: What should I do if single-point baseline correction doesn't fix my sloping baseline? A persistent slope often indicates light scattering. For mildly sloping baselines, a multi-point or linear fit baseline correction may suffice. For significant scattering from particulates or large biomolecules, you will need to use advanced baseline correction algorithms such as asymmetric least squares (ALS) or a Rayleigh-Mie scattering correction, which are designed to model and subtract these complex backgrounds [23] [29].

FAQs on Baseline Correction Methods

What is the primary goal of baseline correction in UV-Vis spectroscopy?

The primary goal is to adjust the baseline level of a spectrum to remove background noise and other non-chemical artifacts, thereby improving the clarity of the analytical signal. This process eliminates unwanted interference from factors like instrumental drift, light-scattering from particulates, or sample matrix effects, ensuring that the resulting absorbance data accurately reflects the analyte of interest for reliable quantification [8] [7].

When should I use polynomial fitting versus least squares regression for baseline correction?

The choice depends on the complexity of your baseline and the required robustness.

- Polynomial Fitting is best for simple, smooth baseline shapes. It is a straightforward method where a polynomial (linear, quadratic, or cubic) is fitted to points in the spectrum identified as baseline. However, it may not adequately address complex, nonlinear baselines and risks overfitting if a polynomial of too high a degree is used [32] [8].

- Least Squares Regression methods, particularly the family of Penalized Least Squares (PLS) algorithms like Asymmetric Least Squares (AsLS), are more flexible and powerful for handling nonlinear baselines and spectra with multiple peaks. These methods are considered a standard in classical chemometrics as they use a smoothing parameter to control the trade-off between fit and background smoothness, preventing intense analytical signals from distorting the baseline estimate [33] [32].

A common issue I encounter is the baseline correction distorting my analyte's peaks. How can I prevent this?

Peak distortion often occurs when the correction algorithm mistakenly identifies small peaks as part of the background. To mitigate this:

- Use Asymmetric Methods: Employ asymmetric least squares (AsLS) techniques. These methods apply different weights to positive (peaks) and negative (baseline) residuals, preventing the baseline from being "pulled up" by the analyte's absorption signals [33] [32].

- Leverage Modern Algorithms: Explore data-driven methods like Convolutional Autoencoders (ConvAuto). These deep learning models are trained to recognize and separate the baseline from the analyte signal, which can be particularly effective for complex signals with multiple peaks and a nonlinear background, reducing the need for manual parameter tuning that can lead to errors [32].

Troubleshooting Guides

Problem: Persistent Baseline Drift After Standard Correction

Possible Causes and Solutions:

- Cause: Incorrect baseline wavelength selection.

- Solution: Empirically determine the optimal baseline correction wavelength. A general recommendation is 340 nm for UV-only ranges (190-350 nm) and 750 nm for methods that include the visible range. Ensure the selected wavelength is one where neither your sample buffer nor the analyte absorbs [7].

- Cause: Severe light scattering from particulates or aggregates in the sample.

- Solution: For complex samples like proteins, consider advanced scatter correction models. One approach is a curve-fitting baseline subtraction based on fundamental Rayleigh and Mie scattering equations, which specifically accounts for these physical phenomena [23].

- Cause: The baseline is highly complex and nonlinear.

- Solution: Move beyond simple polynomial fitting. Implement an adaptive iteratively reweighted Penalized Least Squares (airPLS) method or a deep learning-based ConvAuto model. These are designed to handle irregular, nonlinear baselines more effectively [32].

Problem: Poor Performance of Quantitative Model After Baseline Correction

Diagnosis and Resolution:

- Diagnosis: The preprocessing method may have removed or distorted chemically relevant variance, or it may be overfitting the calibration set.

- Resolution:

- Compare Preprocessing Methods: Test multiple techniques on your dataset. A study on UV-Vis spectroscopy for coffee adulteration found that the performance of Partial Least Squares Regression (PLSR) models varied with different preprocessing methods, with Savitzky-Golay smoothing yielding the best results in that specific case [34].

- Validate Robustly: Ensure your model is validated using an independent prediction set, not just cross-validation. Monitor metrics like the Root Mean Square Error of Cross-Validation (RMSECV) and the Ratio of Prediction to Deviation (RPD) to assess real-world performance [34].

- Apply Signal Filtering: High-frequency noise can impair models. Before baseline correction, apply a noise filter, such as one based on Discrete Wavelet Transforms (DWT), to improve the signal-to-noise ratio [35].

Comparison of Correction Methods and Performance

The table below summarizes key mathematical approaches for baseline correction, helping you select an appropriate method.

| Method | Principle | Typical Application Context | Advantages | Limitations |

|---|---|---|---|---|

| Polynomial Fitting [32] [8] | Fits a polynomial function (e.g., linear, quadratic) to user-selected baseline points. | Simple, smooth baselines with minimal drift. | Simple implementation, intuitively understandable parameters, low computational cost. | Requires manual point selection, ineffective for complex/nonlinear baselines, risks overfitting. |

| Asymmetric Least Squares (AsLS) [33] [32] | Penalized Least Squares regression with asymmetric weighting, so peaks do not pull baseline upward. | Spectra with multiple peaks and a moderately nonlinear baseline. | Automatic, handles nonlinear baselines, standard in chemometrics. | Requires selection of smoothing & asymmetry parameters. |

| Adaptive iteratively reweighted PLS (airPLS) [32] | An advanced PLS method that iteratively reweights residuals to automatically adjust the baseline. | Complex baselines common in chromatographic or Raman data. | Fully automatic, no user intervention after algorithm starts. | Higher computational complexity than basic AsLS. |

| Convolutional Autoencoder (ConvAuto) [32] | A deep learning model that learns to separate baseline from signal using trained neural networks. | Complex signals with multiple peaks and highly nonlinear background. | Fully automatic, parameter-free, handles signals of various lengths. | Requires a database of signals for training, complex model setup. |

Performance Metrics from Experimental Data:

A comparative study on complex signals with multiple peaks and a nonlinear background reported the following Root Mean Square Error (RMSE) values, where a lower value indicates better baseline estimation [32]:

- ConvAuto Model: 0.0263

- ResUNet Model: 1.7957

In a quantitative determination of Pb(II) in a certified reference material, the ConvAuto model achieved a recovery of 89.6%, which was 1% higher than the ResUNet model [32]. This demonstrates the potential of modern, data-driven approaches for high-precision analytical work.

Experimental Protocol: Applying AsLS Baseline Correction

This protocol provides a detailed methodology for implementing an Asymmetric Least Squares (AsLS) baseline correction on a set of UV-Vis spectra, based on established chemometric practices [33] [32].

Principle: The AsLS method estimates the baseline, ( z ), by minimizing the following cost function: ( Q = \sum_{i} w_i (y_i - z_i)^2 + \lambda \sum_{i} (\Delta^2 z_i)^2 ) where ( y ) is the measured spectrum, ( w_i ) are asymmetric weights, ( \lambda ) is a smoothness parameter, and ( \Delta^2 z_i ) is the second difference of the baseline. The weights ( w_i ) are set to be small for data points identified as peaks (positive residuals) and large for points identified as baseline (negative residuals).

Workflow:

Materials and Reagents:

- UV-Vis Spectrophotometer (e.g., DeNovix DS-11 Series, Thermo Scientific GENESYS 10S) [7] [34].

- Quartz Cuvettes (path length typically 10 mm), as plastic and glass absorb UV light [24].

- Sample and Reference Solutions: The sample containing the analyte and a matched blank/reference solvent (e.g., distilled water, aqueous buffer) [24].

- Software: Data analysis software capable of running custom scripts (e.g., Python with SciPy, MATLAB, R) or specialized chemometrics software that implements the AsLS or airPLS algorithm.

Step-by-Step Procedure:

Data Acquisition:

Initial Preprocessing (Optional but Recommended):

Algorithm Initialization:

- Set the initial parameters for the AsLS algorithm. A typical starting point is a smoothness parameter (( \lambda )) of ( 10^5 ) and an asymmetry parameter (p) of 0.001 [32]. These will likely need optimization for your specific data.

Iterative Baseline Estimation:

- The algorithm will iteratively: a. Fit a smooth baseline to the current weighted spectrum. b. Update the weights: decrease weights for points where the spectrum is above the current baseline (potential peaks) and increase weights for points below the baseline. c. Repeat until the weights converge and the baseline estimate stabilizes.

Baseline Subtraction and Validation:

- Subtract the final estimated baseline from the original raw spectrum to obtain the corrected spectrum.

- Visually inspect the corrected spectra to ensure the baseline is flat and no analyte peaks have been distorted. Validate the correction by checking the performance of subsequent quantitative analysis (e.g., improved R² in a calibration model) [34].

The Scientist's Toolkit

| Reagent / Material | Function in Experiment |

|---|---|

| Quartz Cuvette | Sample holder; transparent to UV and visible light, unlike plastic or glass which absorb UV [24]. |

| Reference Blank (e.g., Distilled Water, Buffer) | Accounts for solvent absorbance and instrument noise; used to establish the 0 absorbance baseline [24] [34]. |

| Certified Reference Material (CRM) | Validates the accuracy of the entire analytical method, including baseline correction, by comparing measured values to known true values [32]. |

| Enecadin | Enecadin, CAS:259525-01-4, MF:C21H28FN3O, MW:357.5 g/mol |

| Barusiban | Barusiban, CAS:285571-64-4, MF:C40H63N9O8S, MW:830.1 g/mol |

FAQs on Baseline Correction Techniques

FAQ 1: What is baseline drift in UV-Vis spectroscopy and why is it a problem? Baseline drift is an unwanted low-frequency distortion that shifts the entire spectrum up or down, often due to instrumental instabilities, environmental changes, or sample matrix effects like scattering particles or solvent absorption [5]. This drift obscures the true analyte signal, leading to inaccurate absorbance readings and concentration calculations; an uncorrected baseline can cause concentration overestimation by as much as 20% [7].

FAQ 2: When should I use a Wavelet Transform over Savitzky-Golay smoothing for baseline correction? Wavelet Transform is superior for isolating and removing complex, non-linear baselines, especially when the baseline has a slowly varying, broad shape [29]. Savitzky-Golay is a filtering technique better suited for high-frequency noise reduction while preserving the original shape and height of spectral peaks [36]. Use Wavelets when the background is the main issue, and Savitzky-Golay when high-frequency random noise is the primary concern.

FAQ 3: My baseline-corrected spectrum shows negative absorbance values. What went wrong?

This is a common issue with over-aggressive baseline subtraction. In the Wavelet Transform method, this can happen if too many decomposition levels are set to zero, causing the corrected baseline to dip below zero [29]. In iterative methods like Asymmetric Least Squares (ALS), it can result from the smoothing parameter (lam) being set too low, allowing the fitted baseline to follow chemical peaks too closely. Re-run the correction with a higher lam value or fewer wavelet decomposition levels.

FAQ 4: Are there automated methods for baseline correction in high-throughput screening? Yes, modern approaches like Asymmetric Least Squares (ALS) and its variants (e.g., AirPLS) are designed for automation. These methods iteratively fit a smooth baseline without requiring manual peak selection, making them suitable for processing large batches of spectra [29]. Data-driven methods, including PCA-based modeling and CNN-based correction, are also emerging for automated, nonlinear correction [33].

Troubleshooting Guides

Issue 1: Poor Baseline Fit with Wavelet Transform

Symptoms: The corrected baseline is not flat, dips below zero, or overshoots in the vicinity of peaks [29].

| Possible Cause | Solution | Technical Parameters to Adjust |

|---|---|---|

| Incorrect wavelet type selected. | Experiment with different wavelet families. Daubechies (db) wavelets are a common starting point. |

Wavelet type (e.g., db4, db6, db8) [29]. |

| Too many decomposition levels set to zero. | Reduce the number of approximation coefficients (low-order components) that are zeroed out. | The level parameter in the decomposition [29]. |

| Crude coefficient removal strategy. | Instead of setting coefficients to zero, smoothly decrease their amplitude. | Apply a scaling factor < 1 to approximation coefficients. |

Issue 2: Savitzky-Golay Filter Distorts Peak Shapes

Symptoms: Peaks become broadened, shoulder peaks are lost, or spectral resolution is reduced.

| Possible Cause | Solution | Technical Parameters to Adjust |

|---|---|---|

| Filter window size is too large. | Choose a smaller window size that preserves the full width at half maximum (FWHM) of the narrowest peak. | Window size (number of data points), must be an odd number. |

| Polynomial order is too high or too low. | A low order over-smoothers; a high order can fit to noise. Typically, orders 2 or 3 are used for spectra. | Polynomial order [36]. |

Issue 3: Inconsistent Correction Across Multiple Samples

Symptoms: The same correction method and parameters yield variable results across a sample set.

| Possible Cause | Solution | Technical Parameters to Adjust |

|---|---|---|

| Varying baseline shapes and intensities between samples. | Use a robust, parameter-insensitive method like Asymmetric Least Squares (ALS) with auto-tuning. | For ALS, increase the lam (smoothness) and niter parameters for stability [29]. |

| High sample heterogeneity. | Apply scatter correction methods like Multiplicative Scatter Correction (MSC) or Standard Normal Variate (SNV) before baseline correction [33]. | Reference spectrum for MSC. |

Comparative Analysis of Techniques

The table below summarizes the core characteristics, advantages, and disadvantages of the featured signal processing techniques.

| Method | Core Mechanism | Key Advantages | Key Disadvantages & Common Pitfalls |

|---|---|---|---|

| Wavelet Transform | Decomposes a spectrum into different frequency components (wavelet coefficients). The baseline is removed by suppressing the low-frequency components [29]. | Models local spectral features; explains results based on decomposition; effective for non-linear baselines [33] [29]. | Can produce a non-flat baseline (dipping or overshooting); highly sensitive to the choice of wavelet type and decomposition level [29]. |

| Savitzky-Golay | A simplified least-squares convolution filter for smoothing and derivative calculation. Fits a low-order polynomial to a moving window of data points [36]. | Excellent at preserving the original shape and height of spectral peaks; simple and computationally fast [36]. | Can broaden peaks and obscure shoulder peaks if the window size is too large; primarily for noise removal, not direct baseline correction. |

| Asymmetric Least Squares (ALS) | Iteratively fits a smooth baseline by applying a much higher penalty to positive deviations (peaks) than to negative deviations (baseline) [29]. | Highly effective for complex baselines; automatic and requires no peak detection; robust for high-throughput processing [33] [29]. | Sensitive to the smoothness (lam) and asymmetry (p) parameters; can leave broad peaks in the baseline if lam is too high [29]. |

Detailed Experimental Protocols

Protocol 1: Baseline Correction using Wavelet Transform

This protocol outlines the steps for implementing a Wavelet Transform baseline correction in Python, using a PyWavelets library [29].

Research Reagent Solutions & Computational Tools

| Item | Function/Specification |

|---|---|

PyWavelets (pywt) Library |

A comprehensive Python library for performing Discrete and Continuous Wavelet Transforms. |

| NumPy and SciPy | Foundational Python libraries for numerical computation and handling spectral data arrays. |

Daubechies (db) Wavelet |

A family of orthogonal wavelets often recommended as a starting point for spectral data [29]. |

| Decomposition Level | The number of times the signal is decomposed. A level of 5-7 is often used for spectra [29]. |

Methodology:

- Import Libraries: Import necessary Python libraries (

pywt,numpy,matplotlib). - Select Wavelet and Level: Choose a wavelet type (e.g.,

'db6') and the level of decomposition (e.g.,level=7). - Perform Wavelet Decomposition: Use

pywt.wavedec()to decompose the raw spectrum, which returns a list of wavelet coefficients[cA_n, cD_n, cD_{n-1}, ..., cD1], wherecA_nis the highest-level (lowest frequency) approximation coefficient. - Modify Coefficients: Create a copy of the coefficients and set the first approximation coefficient array to zero:

new_coeffs[0] = 0 * new_coeffs[0]. This removes the lowest-frequency baseline component. - Reconstruct the Signal: Use

pywt.waverec()with the modified coefficients to generate the baseline-corrected spectrum. - Visualize: Plot the original spectrum, the calculated baseline, and the corrected spectrum to assess the result [29].

Protocol 2: Savitzky-Golay Smoothing and Differentiation

This protocol details the application of the Savitzky-Golay filter for smoothing spectra and calculating derivatives to enhance spectral features.

Research Reagent Solutions & Computational Tools

| Item | Function/Specification |

|---|---|

| SciPy Library | Provides the scipy.signal.savgol_filter function for applying the Savitzky-Golay filter. |

| Window Length | The number of data points in the moving window (must be a positive odd integer). |

| Polynomial Order | The order of the polynomial to fit to the data within the window (e.g., 2 or 3). |

Methodology:

- Define Parameters: Select the window length and polynomial order. The window length should be smaller than the width of the narrowest peak.

- Apply Smoothing: Use

scipy.signal.savgol_filter(spectrum, window_length, polyorder)to smooth the spectrum. - Calculate Derivatives: To compute the first or second derivative, use the same function with the

derivargument:scipy.signal.savgol_filter(spectrum, window_length, polyorder, deriv=1)[36]. - Validation: Compare the smoothed spectrum to the original to ensure critical features have not been distorted.

Workflow Diagrams

Signal Processing Workflow for UV-Vis Spectra

Wavelet Transform Baseline Correction Process

Troubleshooting Guide: Baseline Correction and Wavelength Selection

This guide addresses common challenges researchers face when selecting baseline correction wavelengths for different sample types in UV-Vis spectroscopy.

1. Problem: Inconsistent or inaccurate concentration readings for nucleic acids and proteins.

- Cause: Using an incorrect baseline correction wavelength can cause a significant offset in the overall sample absorbance, leading to inaccurate concentration calculations. For instance, an uncorrected baseline can result in a reported absorbance at 260 nm that is about 20% higher than expected [7].

- Solution: For nucleic acid and protein applications (e.g., dsDNA, RNA, Protein A280), use a baseline correction wavelength of 340 nm. This is the default in modern microvolume spectrophotometers [7].

2. Problem: High background interference in measurements of labeled proteins or custom dyes.

- Cause: The buffer, solvent, or the dye itself may absorb light, contributing to a sloping or elevated baseline. This is particularly problematic for dyes with absorbance maxima in the visible or near-infrared range [7].

- Solution:

- For labeled proteins and microarray applications, the software often uses 750 nm to anchor the visual spectrum. For dyes absorbing above 700 nm, empirically determine a baseline correction wavelength of 800 nm or greater [7].

- In the UV-Vis app, the default is 750 nm, but the optimal wavelength should be determined for each sample type [7].

3. Problem: Significant baseline drift during kinetic studies or long measurement sessions.

- Cause: Instrument drift over time can cause gradual inaccuracies in absorbance measurements. This can be due to changes in lamp intensity or temperature fluctuations in the instrument's components [22] [37].

- Solution: A baseline correction wavelength is required for all Kinetics app methods. Utilize the instrument's software to perform a baseline correction at the empirically determined optimal wavelength before starting the experiment [7] [37].

4. Problem: Poor linearity and deviation from the Beer-Lambert law at high sample concentrations.

- Cause: At high analyte concentrations, molecular interactions or the effects of stray light can cause a non-linear relationship between absorbance and concentration [22].

- Solution: Dilute samples to an optimal absorbance range (ideally between 0.2 and 1.0 AU) to restore linearity. Using baseline correction can also help account for offsets that contribute to inaccuracies in this range [22] [37].

Baseline Wavelength Selection Guide by Sample Type

The table below summarizes recommended baseline correction wavelengths for various applications to prevent inaccurate readings [7].

| Sample Type / Application | Recommended Baseline Wavelength | Notes |

|---|---|---|

| Nucleic Acids (dsDNA, ssDNA, RNA) | 340 nm | Default for modern microvolume spectrophotometers; replaces traditional 320 nm [7]. |

| Proteins (A280, Peptide assays) | 340 nm | Standard default for unlabeled protein quantification [7]. |

| Labeled Proteins / Microarrays | 750 nm (default), 800 nm or greater for dyes >700 nm | Uses a sloping baseline between 400-750 nm for dye calculations [7]. |

| UV-Vis General Analysis | 750 nm (default) | The optimal wavelength should be empirically determined for each sample type [7]. |

| Kinetics Studies | Empirically determined | A baseline correction wavelength is required and must be established for the specific method [7]. |

| Colorimetric Assays | Pre-configured per assay | User modification is typically not allowed [7]. |

| OD600 (Microbial Culture) | Not typically applied | Measurement of light scattering; no baseline normalization unless specified by user [7]. |

Frequently Asked Questions (FAQs)

Q1: What is the principle behind baseline correction in UV-Vis spectroscopy? Baseline correction accounts for the effect of instrument noise and light-scattering particulates in the sample that can cause an offset in the overall sample absorbance. It works by subtracting the absorbance value at a specific, non-absorbing wavelength from all wavelengths across the sample spectrum [7].

Q2: How do I empirically determine the best baseline correction wavelength for a new dye or sample type? The optimal baseline correction wavelength is a wavelength at which there is no absorbance from the sample buffer or the molecule of interest. This is typically done by running a full wavelength scan of your sample and its buffer blank. The ideal correction wavelength is a region of the spectrum where the sample itself shows minimal absorbance, but where any background offset or slope is apparent [7].

Q3: My sample is turbid or cloudy. How does this affect my baseline and measurement? Cloudy or particle-filled samples scatter light instead of absorbing it evenly, which violates the assumptions of the Beer-Lambert Law and leads to inaccurate results. If possible, filter the sample to remove particulates. Baseline correction can help mitigate some of these effects, but it may not fully compensate for significant light scattering [22].

Q4: How often should I perform a baseline correction on my spectrophotometer? The frequency depends on your instrument's stability and the requirements of your experiment. For high-precision work or long-term kinetic studies, a baseline correction should be performed at the start of each session or even between samples if instrument drift is suspected. Consult your instrument's manual for specific recommendations [37].

Experimental Protocol: Empirical Determination of Baseline Wavelength

Objective: To identify the optimal baseline correction wavelength for a novel fluorescently labeled protein.

Materials:

- Purified protein, labeled and unlabeled.

- Storage buffer.

- UV-Vis spectrophotometer (e.g., DeNovix DS-11 Series or equivalent).

- Quartz cuvettes.

Method:

- Prepare Samples: Dilute the labeled protein and the unlabeled protein (as a control) in the storage buffer to an appropriate concentration (absorbance < 1.0 at the peak wavelength).

- Blank the Instrument: Use the storage buffer as a blank to zero the instrument.

- Run Spectral Scan: Obtain a full absorbance spectrum (e.g., 250 nm to 800 nm) for both the labeled protein sample and the unlabeled protein control.

- Analyze Spectra: Overlay the spectra. The optimal baseline correction wavelength is a region where:

- The unlabeled protein and buffer show minimal absorbance.

- The labeled protein spectrum is flat and shows no apparent absorbance features from the protein or buffer components. For dyes absorbing in the visible range, this is often in the near-infrared region (e.g., 750 nm to 840 nm) [7].

- Validate Selection: Apply the selected baseline wavelength and measure the sample again to confirm that it produces a flat, stable baseline in the regions away from the analyte's peak absorbances.

Flowchart for Empirical Wavelength Determination

The Scientist's Toolkit: Key Research Reagent Solutions

The table below lists essential materials and their functions for successful baseline correction and sample analysis [7] [22] [37].

| Item | Function / Application |

|---|---|

| High-Quality Quartz Cuvettes | Ensuring minimal light scattering and accurate path length, especially in the UV range. |

| Optically Clear, Low-Absorbance Buffers | Used for sample dilution and as a blank to minimize solvent background interference. |