Greenness Evaluation of UPLC/MS/MS Methods: A Comprehensive Guide for Sustainable Pharmaceutical Analysis

This article provides a comprehensive framework for implementing green chemistry principles in UPLC/MS/MS method development and validation for pharmaceutical analysis.

Greenness Evaluation of UPLC/MS/MS Methods: A Comprehensive Guide for Sustainable Pharmaceutical Analysis

Abstract

This article provides a comprehensive framework for implementing green chemistry principles in UPLC/MS/MS method development and validation for pharmaceutical analysis. It explores the foundational concepts of Green Analytical Chemistry (GAC), details practical methodologies for eco-friendly method development, offers troubleshooting strategies for optimization, and establishes rigorous validation protocols with comparative greenness assessments. Aimed at researchers, scientists, and drug development professionals, this guide synthesizes current best practices and metric tools to achieve superior analytical performance while minimizing environmental impact, supporting the pharmaceutical industry's transition toward more sustainable laboratory practices.

The Principles of Green Analytical Chemistry and UPLC/MS/MS Fundamentals

The Foundation of Green Analytical Chemistry

Green Analytical Chemistry (GAC) represents a transformative approach to analytical science that integrates environmental considerations into the core of methodological development. As a specialized subfield of green chemistry, GAC aims to reduce the environmental and human health impacts traditionally associated with chemical analysis while maintaining high standards of accuracy, precision, and reliability [1] [2]. The growing global demand for safer, more sustainable industrial and scientific practices has positioned GAC as an essential framework for modern laboratories, particularly in pharmaceutical and food analysis where high sample throughput is common [1] [3].

The foundation of GAC lies in twelve guiding principles first proposed by Galuszka et al., which provide a comprehensive structure for developing and assessing analytical methods with sustainability as a key consideration [1]. Unlike traditional analytical approaches that often prioritize performance at the expense of environmental concerns, GAC integrates sustainability proactively from the initial stages of method design [1]. This paradigm shift addresses the significant environmental drawbacks of conventional methods, which typically involve hazardous solvents, generate substantial chemical waste, and consume considerable energy [1] [3].

The Twelve Principles of Green Analytical Chemistry

The twelve principles of GAC establish a systematic approach to making analytical methodologies more environmentally benign. These principles serve as practical guidelines for researchers developing new analytical methods and for laboratories seeking to improve their environmental footprint.

Table 1: The Twelve Principles of Green Analytical Chemistry

| Principle Number | Principle Name | Core Objective |

|---|---|---|

| 1 | Direct Techniques | Utilize direct analytical techniques to minimize extensive sample preparation [1] |

| 2 | Reduced Sample Size | Reduce sample size and number to limit material consumption and waste [1] |

| 3 | In Situ Measurements | Favor in-situ measurements to avoid transport and contamination risks [1] |

| 4 | Waste Minimization | Minimize waste generation at every stage of the analytical process [1] |

| 5 | Safer Solvents/Reagents | Select safer solvents and reagents to reduce toxicity [1] |

| 6 | Avoid Derivatization | Avoid derivatization to limit chemical use and waste [1] |

| 7 | Energy Efficiency | Minimize energy consumption through energy-efficient instrumentation and conditions [1] |

| 8 | Miniaturization/Reagent-Free | Develop reagent-free or miniaturized methods [1] |

| 9 | Automation/Integration | Use automation and integration to enhance efficiency and reduce errors [1] |

| 10 | Multi-Analyte Approach | Adopt multi-analyte or multi-parameter methods [1] |

| 11 | Real-Time Analysis | Pursue real-time analysis for timely decision-making and waste avoidance [1] |

| 12 | Greenness Assessment | Apply greenness metrics to quantify and improve environmental performance [1] |

These principles collectively address the complete analytical workflow, from sample collection to final determination. Principles 1-4 focus on prevention and reduction at the source, emphasizing waste prevention rather than management after generation. Principles 5-8 target chemical and energy inputs, advocating for safer alternatives and more efficient consumption. Principles 9-11 address process efficiency through automation, multi-analyte methods, and real-time monitoring. Finally, Principle 12 establishes the need for continuous assessment and improvement through standardized metrics [1] [2].

Greenness Assessment Tools for Analytical Methods

The development of standardized assessment tools has been crucial for evaluating and comparing the environmental performance of analytical methods. Several metrics have emerged as industry standards, each with distinct approaches and output formats.

Table 2: Key Greenness Assessment Tools in Analytical Chemistry

| Assessment Tool | Type of Evaluation | Output Format | Key Characteristics | References |

|---|---|---|---|---|

| Analytical Eco-Scale | Semi-quantitative | Penalty point score | Evaluates solvent toxicity, energy, waste, hazards; simpler assessment | [1] [4] |

| GAPI (Green Analytical Procedure Index) | Semi-quantitative | Color-coded pictogram | Covers entire analytical workflow; visual identification of impact areas | [1] [4] |

| AGREE (Analytical GREEnness) | Quantitative | Radial chart (0-1 score) | Integrates all 12 GAC principles; provides single composite score | [1] |

| ComplexGAPI | Semi-quantitative | Extended pictogram | Includes pre-analytical steps; more comprehensive coverage | [1] |

| AGREEprep | Quantitative | Pictogram + score | First dedicated metric for sample preparation specifically | [1] |

| BAGI (Blue Applicability Grade Index) | Quantitative | Asteroid pictogram + score | Assesses practical applicability alongside environmental aspects | [1] |

The AGREE metric has gained significant traction due to its comprehensive nature. It evaluates all twelve GAC principles simultaneously and provides an intuitive graphic output with a score from 0 to 1, where higher scores indicate greener methods [1]. The Analytical Eco-Scale offers a simpler, penalty-point based system where methods are evaluated against ideal green conditions, with penalty points assigned for hazardous chemicals, energy consumption, and waste generation [4].

A more recent development is the Blue Applicability Grade Index (BAGI), which complements greenness assessment by evaluating practical applicability aspects such as analysis type, throughput, reagent availability, automation, and sample preparation complexity [1]. This aligns with the emerging concept of White Analytical Chemistry (WAC), which seeks to balance analytical performance (red), environmental sustainability (green), and practical applicability (blue) [1].

Application Note: Implementing GAC in UPLC/MS/MS Method Development

Experimental Protocol: Green UPLC/MS/MS Method for Antihypertensive Drugs and Their Impurities

Background: Pharmaceutical analysis requires sensitive and specific methods for active ingredients and their impurities, which often have toxicological concerns. This protocol outlines the development and validation of a green UPLC/MS/MS method for the simultaneous quantification of captopril (CPL), hydrochlorothiazide (HCZ), and their harmful impurities (captopril disulphide, chlorothiazide, and salamide) [4] [5].

In-Silico Toxicity Profiling:

- Software: Conduct in-silico ADME (Absorption, Distribution, Metabolism, Excretion) and toxicity profiling using online pkCSM properties or similar software based on 2D structural models created with ChemBioDraw Ultra [4].

- Parameters: Predict key parameters including blood-brain barrier (BBB) permeability, hepatotoxicity, mutagenicity, and other toxicological endpoints [4].

- Application: Use toxicity predictions (e.g., hepatotoxicity of impurities) to justify the need for a highly sensitive analytical method [4] [5].

Chromatographic Conditions:

- Instrumentation: UPLC/MS/MS system with tandem mass triple quadrupole detector [4].

- Column: Agilent Poroshell 120 EC-C18 (50 mm x 4.6 mm, 2.7 μm) or equivalent [4].

- Mobile Phase: Methanol and 0.1% formic acid (90:10, v/v) [4] [5].

- Flow Rate: 0.7 mL/min [4] [5].

- Injection Volume: 1-3 μL [4].

- Column Temperature: Room temperature [4].

- Run Time: 1 minute [4].

Mass Spectrometric Detection:

- Interface: Electrospray Ionization (ESI) [4].

- Polarity Mode:

- Detection: Multiple Reaction Monitoring (MRM) [4].

- MRM Transitions:

Sample Preparation:

- Standard Solutions: Prepare stock solutions of each analyte in methanol or a methanol-water mixture [4].

- Tablet Preparation: Weigh and powder tablets. Extract an equivalent of one tablet with the mobile phase or methanol via sonication. Centrifuge and dilute the supernatant as needed [4].

Validation Parameters:

- Linearity: Evaluate over specified ranges (e.g., 50.0–500.0 ng mL−1 for CPL) with correlation coefficient r² > 0.99 [4] [5].

- Precision: Determine repeatability (intra-day) and intermediate precision (inter-day) with %RSD < 2% [4].

- Accuracy: Perform recovery studies at multiple levels (e.g., 80%, 100%, 120%) with recovery values between 98-102% [4].

- Sensitivity: Determine LOD (Limit of Detection) and LOQ (Limit of Quantification) [4] [5].

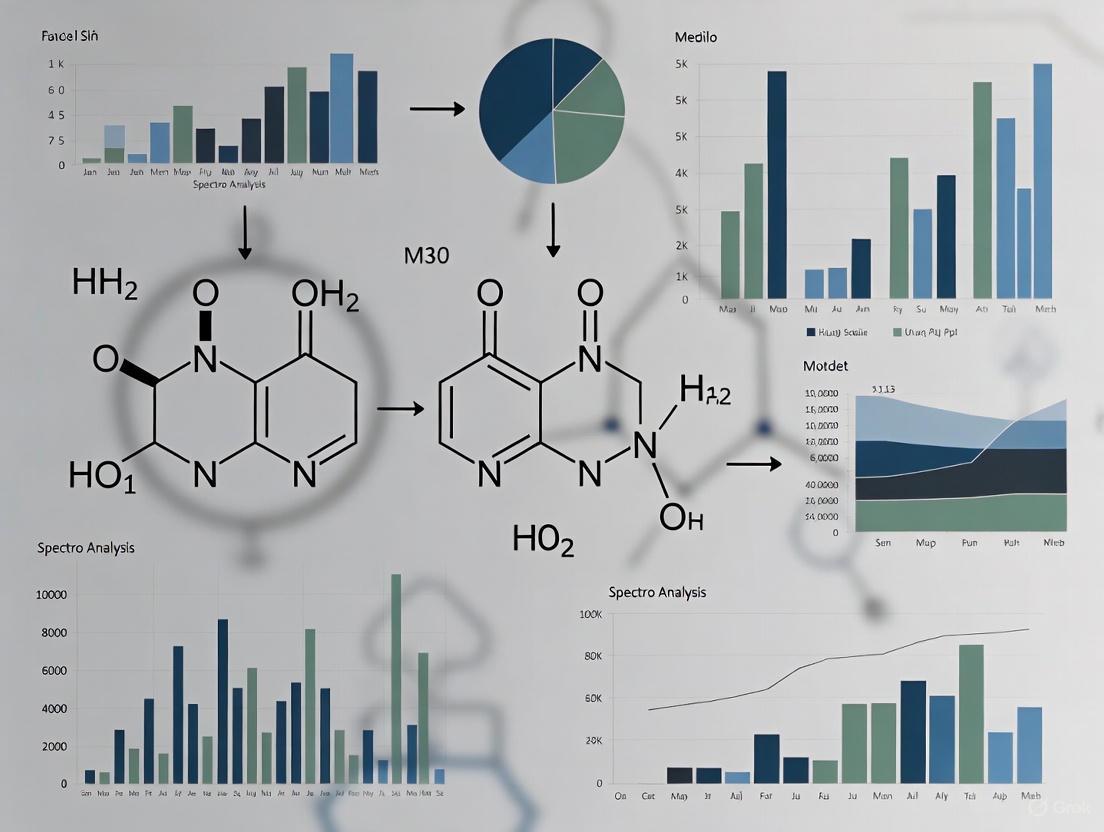

Diagram 1: GAC-Compliant UPLC/MS/MS Method Development Workflow. The workflow integrates in-silico studies, green condition optimization, and formal greenness assessment, highlighting key GAC principles applied at each stage.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Research Reagent Solutions for Green UPLC/MS/MS Analysis

| Reagent/Material | Function in Protocol | Green Characteristics | Example/Specification |

|---|---|---|---|

| Methanol | Mobile phase component | Less hazardous than acetonitrile; preferred green solvent in many solvent selection guides [4] [6] | UPLC/MS/MS grade [4] |

| Water | Mobile phase component | Benign, non-toxic solvent [6] [2] | UPLC/MS/MS grade [4] |

| Formic Acid | Mobile phase additive (0.1%) | Used in small quantities to improve ionization [4] | UPLC/MS/MS grade [4] |

| Poroshell/Core-Shell Column | Stationary phase for separation | Allows faster separations with lower backpressure, reducing run time and solvent consumption [4] | Agilent Poroshell 120 EC-C18, 2.7μm [4] |

| Ethanol | Alternative solvent | Bio-based, less toxic; can replace acetonitrile or methanol in some methods [7] [6] | HPLC or UPLC grade |

| Dutogliptin Tartrate | Dutogliptin Tartrate, CAS:890402-81-0, MF:C14H26BN3O9, MW:391.18 g/mol | Chemical Reagent | Bench Chemicals |

| Echinocystic Acid | Echinocystic Acid, CAS:510-30-5, MF:C30H48O4, MW:472.7 g/mol | Chemical Reagent | Bench Chemicals |

Greenness Evaluation of the UPLC/MS/MS Protocol

The described UPLC/MS/MS method incorporates multiple GAC principles, making it significantly greener than conventional HPLC approaches:

Principle 5 (Safer Solvents): The method utilizes methanol with 0.1% formic acid instead of more hazardous solvent combinations [4] [5]. Methanol is generally considered preferable to acetonitrile in green solvent selection guides [6].

Principle 7 (Energy Efficiency): The method operates at room temperature, eliminating energy consumption for column heating [4]. The flow rate of 0.7 mL/min is relatively low for UPLC methods, contributing to lower solvent consumption and energy use [4].

Principle 4 (Waste Minimization): The extremely short run time of 1 minute dramatically reduces solvent consumption and waste generation compared to conventional HPLC methods that often require 10-20 minutes [4] [5].

Principle 2 (Reduced Sample Size): The use of UPLC/MS/MS technology inherently requires smaller sample volumes and lower injection volumes (1-3 μL) compared to conventional HPLC [4].

When evaluated with greenness assessment tools, this method demonstrates superior environmental performance compared to reported HPLC methods. A comparative study using five green metric tools (NEMI, Modified NEMI, GAPI, Eco-Scale, and AGREE) confirmed that the proposed UPLC/MS/MS method is greener than the reported HPLC methods for the same analytes [4]. The method's green profile is characterized by high sensitivity, minimal solvent consumption, reduced waste generation, and shorter analysis time without compromising analytical performance [4] [5].

The integration of in-silico studies at the development stage further aligns with green principles by reducing laboratory-scale experimentation and associated chemical waste [4]. This comprehensive approach demonstrates how GAC principles can be successfully implemented in sophisticated analytical techniques like UPLC/MS/MS, resulting in methods that are both environmentally responsible and analytically superior.

The imperative for sustainable laboratory practices has become a critical consideration in modern analytical chemistry, particularly within pharmaceutical research and environmental monitoring. Liquid chromatography-mass spectrometry (LC-MS) is a cornerstone technique in these fields, but its traditional operation, especially using High-Performance Liquid Chromatography (HPLC), is associated with significant environmental burdens due to high solvent consumption and energy demand [8]. This application note examines the environmental and performance advantages of transitioning to Ultra-Performance Liquid Chromatography (UPLC) coupled with tandem mass spectrometry (MS/MS). Framed within the broader context of greenness evaluation for analytical methods, this document provides a quantitative comparison and detailed protocols to facilitate the adoption of more sustainable UPLC-MS/MS practices without compromising data quality.

Performance and Environmental Impact: HPLC vs. UPLC

The fundamental difference between HPLC and UPLC lies in the column particle size and the resulting system pressure. HPLC typically uses 3–5 µm particles at pressures up to 400 bar (6,000 psi), while UPLC employs sub-2 µm particles and operates at pressures exceeding 1,000 bar (15,000 psi) [9] [10]. This engineering advancement is the source of UPLC's superior efficiency and its reduced environmental footprint.

Table 1: Key Performance and Operational Characteristics of HPLC vs. UPLC

| Parameter | HPLC | UPLC |

|---|---|---|

| Typical Pressure Range | Up to 400 bar [10] | 1,000 - 1,200 bar [10] |

| Column Particle Size | 3 - 5 µm [10] | < 2 µm [10] |

| Typical Analysis Time | 20 - 45 minutes [10] | 2 - 5 minutes [10] |

| Solvent Consumption per Run | High [10] | 70-80% reduction vs. HPLC [10] |

| Sensitivity | Moderate [10] | High [10] |

| Column Dimensions (Typical) | 150 - 250 mm length, 4.6 mm ID [10] | 30 - 100 mm length, 2.1 mm ID [10] |

| Impact on Carbon Footprint | High (Solvents & Energy) [8] | Significantly Lower [8] |

The environmental benefits of UPLC are direct consequences of its performance characteristics. The drastically shorter analysis time (often 2-5 minutes for UPLC versus 20-45 minutes for HPLC) translates into proportional reductions in energy consumption for running the LC pump, MS detector, and related climate control systems [10] [8]. Furthermore, the combination of shorter run times and the use of narrower-bore columns operating at lower flow rates (e.g., 0.2-0.5 mL/min) leads to a dramatic reduction in solvent consumption, often cited as 70-80% compared to conventional HPLC methods [10]. This not only lowers cost but also minimizes the environmental impact from solvent production and waste disposal [8].

Quantitative Greenness Assessment: A Case Study

A direct comparison of methods for analyzing a pharmaceutical mixture demonstrates the quantifiable green advantage of modern, optimized UPLC approaches. A 2025 study compared an AI-predicted HPLC method with an in-lab optimized UPLC method for the simultaneous quantification of three drugs: Amlodipine, Hydrochlorothiazide, and Candesartan [11].

Table 2: Greenness Comparison of HPLC and UPLC Methods from a Case Study [11]

| Aspect | AI-Generated HPLC Method | In-Lab Optimized UPLC Method |

|---|---|---|

| Column Type | C18, 5 µm, 150 mm | Xselect CSH Phenyl Hexyl, 2.5 µm, 150 mm |

| Elution Mode | Gradient | Isocratic |

| Total Analysis Time | > 12 minutes | ~ 3 minutes |

| Retention Time of Last Analyte | 12.12 minutes | 2.82 minutes |

| Mobile Phase | Phosphate buffer and Acetonitrile | Acetonitrile:Water (0.1% TFA) (70:30, v/v) |

| Flow Rate | 1.0 mL/min | 1.3 mL/min |

| Solvent Consumption per Run | High | Low |

| Greenness Scores (MoGAPI, AGREE) | Lower | Higher |

The study concluded that the in-lab optimized UPLC method outperformed the HPLC method in greenness assessments (using MoGAPI and AGREE tools) due to its combination of reduced solvent use, lower waste generation, and shorter analysis time [11]. This case underscores that while UPLC technology provides the platform for greener analysis, conscious method optimization remains essential.

Detailed Protocol: Transferring an HPLC Method to UPLC

Method transfer from HPLC to UPLC is a systematic process to achieve equivalent or superior separation while leveraging UPLC's speed and efficiency benefits. The following protocol provides a step-by-step guide.

Research Reagent Solutions

Table 3: Essential Materials and Reagents for UPLC-MS/MS Method Transfer

| Item | Function / Description | Considerations for Greenness |

|---|---|---|

| UPLC System | High-pressure LC system capable of >1,000 bar pressure. | Enables reduced solvent consumption and faster analysis [10]. |

| MS/MS Detector | Triple quadrupole or similar for selective, sensitive detection. | Compatible with fast UPLC peaks due to high acquisition speeds. |

| UPLC Column | e.g., C18, 1.7-1.8 µm, 2.1 mm ID, 50-100 mm length. | Smaller particles and internal diameter are key to UPLC performance [12]. |

| Mobile Phase Solvents | LC-MS grade Acetonitrile, Methanol, Water. | High-purity solvents prevent system damage and background noise. |

| Additives | Formic Acid, Ammonium Acetate, etc. | Volatile additives are essential for MS compatibility. |

| Sample Filtration Vials | Vials with 0.2 µm filters. | Critical for protecting UPLC columns and systems from particulates [10]. |

Step-by-Step Experimental Procedure

- System Preparation and Equilibration: Install the selected UPLC column and prepare the mobile phases. Prime the UPLC system and equilibrate the column at the initial mobile phase composition and the scaled flow rate until a stable baseline is achieved.

- Calculate Scaling Factors: Apply the following formulas to scale the original HPLC method parameters [10]:

- Column Volume / Geometric Scale Factor (r):

r = (L_uplc * d_uplc²) / (L_hplc * d_hplc²)where L = column length and d = column internal diameter. - Flow Rate (Fuplc):

F_uplc = F_hplc * (d_uplc² / d_hplc²)to maintain linear velocity. - Injection Volume (Vinj, uplc):

V_inj, uplc = V_inj, hplc * r(typically not to exceed 1-2% of the column volume). - Gradient Time (t_g, uplc):

t_g, uplc = t_g, hplc * rto maintain the gradient slope. Note: This is a simplified calculation; system dwell volume must be accounted for in practice.

- Column Volume / Geometric Scale Factor (r):

- Initial Method Entry and Test Run: Input the scaled parameters into the UPLC instrument control software. Perform an initial run with a standard mixture and observe the separation, backpressure, and peak shapes.

- Fine-Tuning and Optimization: The scaled method is a starting point. Minor adjustments to the gradient profile, temperature, or mobile phase pH may be necessary to achieve optimal resolution, particularly for complex mixtures.

- System Suitability and Validation: Once separation is optimized, perform system suitability tests following relevant guidelines (e.g., ICH Q2(R2)). Fully validate the transferred UPLC method for parameters such as specificity, linearity, accuracy, and precision [13] [11].

Advanced Green UPLC-MS/MS Protocol for Trace Analysis

This protocol details the implementation of a specific, green UPLC-MS/MS method for the trace analysis of pharmaceuticals in water, as adapted from a recent study [13]. The method highlights the omission of an energy-intensive evaporation step after solid-phase extraction (SPE), significantly enhancing its green credentials.

Research Reagent Solutions

- Analytes: Carbamazepine, Caffeine, Ibuprofen.

- Internal Standards: Isotopically labeled analogs of the target analytes.

- Solid-Phase Extraction (SPE) Cartridges: Reversed-phase C18 or equivalent.

- UPLC Column: Reversed-phase C18, sub-2µm, 100 mm x 2.1 mm.

- Mobile Phase A: 0.1% Formic acid in water.

- Mobile Phase B: 0.1% Formic acid in acetonitrile.

- UPLC-MS/MS System: Ultra-performance liquid chromatograph coupled to a triple quadrupole mass spectrometer.

Step-by-Step Experimental Procedure

- Sample Collection and Preparation: Collect water samples in clean glass bottles. Centrifuge if particulate matter is present. Adjust sample pH if necessary.

- Solid-Phase Extraction (SPE): Condition the SPE cartridge with methanol and water. Load the water sample (e.g., 100 mL) under a controlled flow rate. Wash with a mild aqueous solution. Elute analytes with a small volume (e.g., 4-6 mL) of methanol or acetonitrile. CRITICAL GREEN STEP: Proceed directly to the next step without an evaporation/reconstitution cycle [13].

- Chromatographic Separation:

- Column Temperature: 40 °C.

- Injection Volume: 5-10 µL.

- Flow Rate: 0.4 mL/min.

- Gradient Program:

- 0 min: 5% B

- 2 min: 20% B

- 5 min: 60% B

- 6 min: 99% B (hold for 1.5 min)

- 7.6 min: 5% B (re-equilibrate for 2.4 min)

- Total Run Time: 10 minutes [13].

- Mass Spectrometric Detection:

- Ionization Mode: Electrospray Ionization (ESI), positive/negative switching.

- Operation Mode: Multiple Reaction Monitoring (MRM).

- Source Temperature: 500 °C.

- Ion Spray Voltage: 5500 V (positive).

- Curtain Gas: 25-35 psi.

- Method Validation: Validate the method as per ICH Q2(R2) guidelines [13]. The referenced method demonstrated linearity (r ≥ 0.999), precision (RSD < 5.0%), and accuracy (recoveries 77-160%). Limits of quantification were at ng/L levels (e.g., 300 ng/L for Carbamazepine) [13].

The transition from HPLC to UPLC/MS/MS represents a significant opportunity for analytical laboratories to align with the principles of Green Analytical Chemistry. The evidence is clear: UPLC technology provides a direct path to a smaller environmental footprint by drastically reducing solvent waste and energy consumption, while simultaneously enhancing analytical throughput and sensitivity. The provided protocols and case studies offer a practical framework for researchers and drug development professionals to successfully implement greener UPLC-MS/MS methods, contributing to more sustainable scientific practices without sacrificing data quality or regulatory compliance.

Ultra-Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (UPLC/MS/MS) has established itself as a cornerstone analytical technique in modern pharmaceutical research, clinical diagnostics, and environmental monitoring. This powerful hyphenated technique combines the superior chromatographic separation of UPLC with the exceptional detection capabilities of tandem mass spectrometry. The core advantages of UPLC/MS/MS—speed, sensitivity, and selectivity—make it indispensable for hypothesis-driven research and regulated bioanalysis [14] [15]. Within the context of green analytical chemistry, the efficiency and miniaturization inherent to UPLC/MS/MS methods contribute significantly to reduced solvent consumption and waste generation, aligning with the principles of sustainability while maintaining analytical excellence [4] [16]. This article delineates the fundamental components underpinning these advantages and provides detailed protocols for their practical implementation.

Core Advantages and Quantitative Performance

The transition from High-Performance Liquid Chromatography (HPLC) to UPLC represents a fundamental shift in chromatographic methodology, primarily driven by the use of stationary phases with smaller particle sizes (typically below 2.5 µm) and instrumentation capable of withstanding significantly higher operating pressures [14] [17]. This technological evolution directly enhances the three pillars of UPLC/MS/MS performance.

Table 1: Comparative Performance of UPLC versus HPLC [14]

| Performance Metric | HPLC | UPLC | Observed Improvement |

|---|---|---|---|

| Particle Size | 3.5 - 5 µm | 1.7 - 2.1 µm | Foundation for efficiency gains |

| Analysis Speed | Baseline | Significantly Faster | Up to 5-fold increase in throughput |

| Peak Capacity & Resolution | Standard | Higher | Diastereomer separation not possible with HPLC |

| Method Sensitivity | Baseline | Substantially Higher | Up to 10-fold increase (analyte-dependent) |

The sensitivity gains are realized through improved chromatographic performance, which results in sharper peak shapes and higher peak concentrations entering the mass spectrometer, thereby boosting the ionization efficiency [14] [18]. The selectivity is achieved through a dual filtering process: first, by chromatographic retention time, and second, by the mass spectrometer's ability to monitor specific precursor-to-product ion transitions in Multiple Reaction Monitoring (MRM) mode [15] [19]. This combination effectively isolates the target analytes from complex matrix components.

Experimental Protocols

The following protocols exemplify the application of UPLC/MS/MS for challenging analytical scenarios, highlighting its speed, sensitivity, and selectivity.

Protocol 1: Rapid Metabolic Stability Assessment in Human Liver Microsomes

This protocol describes a fast, sensitive, and green UPLC-MS/MS method for quantifying Revumenib (RVB) in Human Liver Microsomes (HLMs), crucial for in vitro ADME (Absorption, Distribution, Metabolism, and Excretion) studies [16].

1. Materials and Reagents:

- Analytes: Revumenib (RVB)

- Internal Standard (IS): Encorafenib

- Biological Matrix: Human Liver Microsomes (HLMs)

- Mobile Phase: Isocratic mixture, details proprietary but typically consist of aqueous and organic modifiers (e.g., methanol or acetonitrile) with additives like formic acid or ammonium formate.

- UPLC Column: C8 (2.1 mm x 50 mm, 3.5 µm particle size)

2. Instrumentation and Conditions:

- UPLC System: Acquity Ultra Performance LC System (Waters Corp., USA)

- Mass Spectrometer: Tandem Quadrupole Mass Spectrometer with ESI source

- Ionization Mode: Positive ESI

- Detection Mode: Multiple Reaction Monitoring (MRM)

- UPLC Flow Rate & Run Time: Optimized for isocratic separation; total run time < 2 minutes, indicative of high speed.

3. Sample Preparation:

- Incubation: Incubate RVB with HLMs in an appropriate buffer (e.g., phosphate buffer, pH 7.4) containing NADPH regenerating system at 37°C.

- Reaction Termination: Stop the reaction at predetermined time points by adding a quenching solvent (e.g., ice-cold acetonitrile).

- Protein Precipitation: Vortex and centrifuge (e.g., at 18,000 g for 15 minutes) to precipitate proteins.

- Analysis: Inject the clean supernatant into the UPLC-MS/MS system.

4. Data Analysis:

- Plot the natural logarithm of the remaining RVB concentration versus time.

- The slope of the linear regression is the elimination rate constant (k).

- Calculate the in vitro half-life (tâ‚/â‚‚) using the formula: tâ‚/â‚‚ = 0.693 / k.

- The reported method achieved an LOQ of 0.96 ng/mL, demonstrating high sensitivity, and an AGREE greenness score of 0.77, confirming its environmental friendliness [16].

Protocol 2: Resolving Steroid Isomers Using 2D-Chromatography (LC/LC-MS/MS)

This protocol addresses a major challenge in MS/MS analysis: the quantification of structural isomers (11β-MNT and Testosterone) that generate identical product ions and cannot be distinguished by MRM alone [15].

1. Materials and Reagents:

- Analytes: 11β-Methyl-19-Nortestosterone (11β-MNT) and Testosterone

- Internal Standards (SIL-IS): Deuterated analogs (11β-MNT-d6 and Testosterone-2,3,4-¹³C₃)

- Biological Matrix: Non-human primate serum

- Extraction Solvents: Ethyl acetate, hexane, and buffer solutions (sodium acetate, pH 5.5; ammonium carbonate, pH 9.8)

- Mobile Phase A: 10 mM formic acid in water

- Mobile Phase B: 10 mM formic acid in acetonitrile

- Columns in Series:

- 1st Dimension: Astec CYCLOBOND I 2000 Chiral Column (50 x 2.1 mm, 5 µm)

- 2nd Dimension: Pursuit PFP Reverse-Phase Column (100 x 4.6 mm, 3 µm)

2. Instrumentation and Conditions:

- UPLC System: Waters Acquity UPLC System with a 2777 Sample Manager

- Mass Spectrometer: Waters Xevo TQ-S MS with ESI source

- Ionization Mode: Positive ESI

- MRM Transitions: Testosterone (289→97), 11β-MNT (289→109), and their respective internal standards.

- Chromatographic Method: Isocratic at 50% B for 5 min, followed by a fast gradient to 98% B. Flow rate: 400 µL/min.

3. Sample Preparation (Liquid-Liquid Extraction):

- Add SIL-IS to 150 µL of serum.

- Add 150 µL of 0.5 M sodium acetate buffer (pH 5.5) and vortex for 2 hours.

- Perform liquid-liquid extraction with ethyl acetate/hexane (600 µL, 60:40 v/v) by vortexing for 40 minutes.

- Centrifuge (18,000 g, 15 min), collect and pool the organic layer.

- Evaporate the organic solvent to dryness under a vacuum.

- Reconstitute the residue in 150 µL of 0.2 M ammonium carbonate buffer (pH 9.8).

- Perform a second liquid-liquid extraction with hexane (600 µL, twice).

- Combine the hexane layers, evaporate to dryness, and reconstitute in a mobile phase (10 mM formic acid in water:acetonitrile, 25:75 v/v) for LC/LC-MS/MS analysis.

4. Key Outcome: The combination of a chiral column with a reverse-phase column provides an orthogonal separation mechanism, successfully resolving the steroid isomers that are inseparable by single-dimension reverse-phase chromatography. This 2D approach exemplifies a high level of selectivity to overcome a fundamental limitation of MS/MS [15].

Table 2: Essential Research Reagent Solutions for UPLC/MS/MS

| Reagent / Material | Function / Role | Exemplar Use Case |

|---|---|---|

| Sub-2µm UPLC Columns | High-efficiency chromatographic separation; enables speed and sensitivity. | General application [14] [17]. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Corrects for matrix effects and variability in sample preparation; ensures accuracy. | 11β-MNT-d6 and ¹³C₃-Testosterone for steroid assay [15]. |

| HLB Solid Phase Extraction (SPE) Cartridges | Clean-up of complex samples; reduces matrix effects and improves sensitivity. | Multi-mycotoxin analysis in food matrices [20]. |

| LC-MS Grade Solvents & Additives | Minimizes background noise and ion suppression; essential for high sensitivity. | Methanol, acetonitrile, and formic acid [4] [19]. |

| Human or Rat Liver Microsomes | In vitro model for studying drug metabolism and metabolic stability. | Revumenib and Almonertinib metabolic studies [16] [19]. |

Visualizing the UPLC/MS/MS Workflow

The following diagram illustrates the integrated workflow of a UPLC/MS/MS system, from sample introduction to data acquisition, highlighting the components responsible for its speed, sensitivity, and selectivity.

UPLC/MS/MS is a powerful analytical platform whose core advantages of speed, sensitivity, and selectivity are derived from the synergistic combination of advanced chromatography and mass spectrometry. The use of small-particle columns enables rapid and high-resolution separations, which, in turn, concentrates analytes into sharp peaks for enhanced MS detection. The MS/MS system, particularly in MRM mode, provides an unparalleled level of selectivity by filtering ions in both mass and time domains. As demonstrated in the protocols, these advantages are directly applicable to solving complex problems in pharmaceutical analysis, from metabolic stability studies to the resolution of challenging isomers. Furthermore, the trend towards faster, miniaturized, and more efficient methods solidifies the role of UPLC/MS/MS as a key technique in the development of greener analytical methodologies.

The imperative for sustainable practices in analytical laboratories has catalyzed the development of Green Analytical Chemistry (GAC), a discipline dedicated to minimizing the environmental impact of analytical procedures [21]. This evolution is particularly crucial for advanced techniques like UPLC/MS/MS, which, despite offering high sensitivity and rapid analysis, consume reagents, energy, and generate waste [4]. Greenness assessment tools provide a systematic framework to evaluate and benchmark the ecological footprint of these methods. This article provides a detailed overview of five key assessment tools—NEMI, GAPI, Analytical Eco-Scale, AGREE, and AMGS—framed within doctoral research on UPLC/MS/MS method development. It offers application notes and experimental protocols to guide researchers and drug development professionals in implementing these critical sustainability metrics.

A fundamental understanding of each tool's principles, outputs, and applications is essential for their effective use. The following table provides a comparative summary of these five prominent greenness assessment tools.

Table 1: Comparative Summary of Key Greenness Assessment Tools

| Tool Name | Type of Output | Basis of Assessment | Scoring System | Key Advantages | Primary Limitations |

|---|---|---|---|---|---|

| NEMI [21] [22] | Pictogram (Qualitative) | 4 basic criteria (e.g., hazardous reagents, waste) | Binary (Green/Uncolored) | Simple, user-friendly | Overly simplistic; lacks granularity |

| Analytical Eco-Scale [4] [21] | Numerical Score (Semi-Quantitative) | Penalty points for non-green aspects | Base 100 minus penalty points | Facilitates direct method comparison | Relies on expert judgment for penalties |

| GAPI [23] [24] | Pictogram (Qualitative) | ~10 criteria covering the entire analytical process | 3-level color scale (Green/Yellow/Red) | Comprehensive; visualizes weakest points | No overall numerical score; somewhat subjective |

| AGREE [25] [22] | Pictogram & Numerical Score (Quantitative) | 12 Principles of GAC | 0 to 1 scale | Comprehensive; user-friendly software; quantitative result | Does not fully account for pre-analytical processes |

| AMGS [26] | Numerical Score (Quantitative) | Solvent health/safety/environment, energy, waste | Percentage score (Lower = Greener) | Benchmarks solvent and energy impact | Currently limited to LC and SFC methods |

The following diagram illustrates a decision workflow for selecting an appropriate greenness assessment tool based on the analytical method's context and the researcher's goals.

Detailed Protocols for Tool Application

Protocol for AGREE Assessment

The AGREE tool is a comprehensive, quantitative metric based on the 12 principles of GAC [22].

- Step 1: Software Acquisition. Download the free, open-source AGREE calculator software from

https://mostwiedzy.pl/AGREE. - Step 2: Data Input. For each of the 12 SIGNIFICANCE principles, input the required data from your analytical method (e.g., sample size, sample preparation steps, energy consumption, reagent toxicity and volume, waste amount and treatment). An example for a UPLC/MS/MS method is shown below.

- Step 3: Weight Assignment. Assign a weight from 0 to 1 to each principle based on its importance in your specific analytical context. Higher weights indicate greater importance.

- Step 4: Score Interpretation. The software generates a circular pictogram with a central score from 0 (not green) to 1 (ideal green). The pictogram's segments show performance for each principle, with colors from red (poor) to green (excellent). Segment width reflects assigned weights.

Table 2: Example AGREE Input for a UPLC/MS/MS Method Quantifying Pharmaceuticals

| GAC Principle | Experimental Parameter (Example Data) | Input Value |

|---|---|---|

| 1: Directness | Sample preparation steps | Off-line analysis (e.g., QuEChERS) |

| 2: Sample & Size | Volume of human plasma used | 100 µL |

| 3: Device Portability | Location of UPLC/MS/MS instrument | In-lab |

| 4: Derivatization | Use of derivatizing agents | None |

| 5: Waste Generation | Total waste volume per run | 1.5 mL |

| 6: Analysis Throughput | Number of samples analyzed per hour | 12 |

| 7: Energy Consumption | UPLC/MS/MS power requirement | ~1 kWh per sample |

| 8: Operator Safety | Toxicity of methanol/acetonitrile in mobile phase | Use hazard pictograms |

| 9: Reagent Toxicity | Volume and hazard of formic acid | 0.1% v/v, corrosive |

| 10: Source of Reagents | Use of renewable vs. non-renewable solvents | Record sources |

| 11: Degradability | Ease of waste stream degradation | Assess biodegradability |

| 12: Potential Accidents | Risk of pressure/heat-related incidents | Assess for UPLC conditions |

Protocol for GAPI Assessment

The Green Analytical Procedure Index (GAPI) provides a detailed qualitative map of an analytical method's environmental impact across its entire workflow [23] [24].

- Step 1: Obtain the GAPI Template. Secure the standard GAPI pictogram template, which consists of five pentagrams representing different stages of analysis.

- Step 2: Evaluate Each Criterion. For each of the sub-sections in the pictogram, assess your method against the GAPI criteria. The criteria cover sample collection, preservation, transport, preparation, and the final instrumental analysis.

- Step 3: Apply Color Code. For each criterion, fill the corresponding section with green (favorable), yellow (moderate), or red (unfavorable) based on the tool's guidelines. For instance, using a toxic solvent would result in a red mark for that reagent category.

- Step 4: Final Visualization. The completed pictogram provides an at-a-glance view of the method's greenness, clearly highlighting areas of high environmental impact (red sections) that require improvement.

Protocol for Analytical Eco-Scale Assessment

The Analytical Eco-Scale is a semi-quantitative tool that calculates a score by penalizing non-green aspects of a method [4].

- Step 1: Establish Baseline. Start with a base score of 100 points.

- Step 2: Assign Penalties. Subtract penalty points for every reagent, step, or energy consumption that deviates from ideal green conditions. Penalties are higher for more hazardous substances (e.g., concentrated acids, carcinogens) and larger volumes/amounts.

- Step 3: Calculate Final Score. The final score is calculated as: Analytical Eco-Scale = 100 − Total Penalty Points.

- Step 4: Interpret Results. A score above 75 represents an excellent green method, a score above 50 is acceptable, and a score below 50 denotes an inadequate green method.

Protocol for AMGS Calculator Use

The Analytical Method Greenness Score (AMGS) calculator is a specialized metric for liquid chromatography and SFC methods [26].

- Step 1: Access the Tool. The calculator is available through the ACS GCI Pharmaceutical Roundtable website (

https://acsgcipr.org/tools/). - Step 2: Input Method Parameters. Enter detailed data into the calculator, including:

- Solvents: Type and volume used per analysis.

- Instrumentation: HPLC, UPLC, or SFC system used.

- Method Runtime: Duration of a single analysis.

- System Suitability Test (SST): Solvents and volumes used for preparation of standard solutions.

- Step 3: Score Calculation. The calculator computes a single percentage score based on solvent health, safety, environmental impact, cumulative energy demand, and waste.

- Step 4: Result Analysis. A lower AMGS score indicates a greener method. The tool provides color-coded feedback (yellow/red) to highlight areas with the largest environmental impact, guiding further method optimization.

The Scientist's Toolkit: Essential Reagents and Materials

The following table lists key reagents and materials commonly used in the development and greenness profiling of UPLC/MS/MS methods.

Table 3: Key Research Reagent Solutions for UPLC/MS/MS Method Development and Greenness Profiling

| Item | Function/Application | Greenness Considerations |

|---|---|---|

| Methanol (HPLC/MS Grade) | Common organic mobile phase component | Prefer over acetonitrile due to better safety profile; but still hazardous [4] |

| Acetonitrile (HPLC/MS Grade) | Organic mobile phase modifier | Toxic; requires careful waste management; minimize volume [21] |

| Water (HPLC/MS Grade) | Aqueous component of mobile phase | Ideal green solvent; primary environmental concern is energy for purification |

| Formic Acid | Mobile phase additive for ionization control in MS | Corrosive; use minimal concentrations (e.g., 0.1%) [4] |

| Ammonium Acetate/Formate | Mobile phase buffer for pH control | Prefer over phosphate buffers for MS compatibility and biodegradability |

| QuEChERS Kits | Sample preparation for complex matrices | Minimizes solvent use compared to traditional LLE; represents miniaturization [23] |

| Deep Eutectic Solvents (DES) | Potential green extraction solvents | Emerging as biodegradable and low-toxicity alternatives to conventional solvents [23] |

| AGREE Calculator Software | Quantitative greenness assessment | Free tool for comprehensive evaluation based on 12 GAC principles [22] |

| AMGS Calculator | Quantitative greenness assessment for LC/SFC | Specialized tool for benchmarking solvent and energy impact [26] |

| Gentisin | Gentisin, CAS:437-50-3, MF:C14H10O5, MW:258.23 g/mol | Chemical Reagent |

| Ginkgolide A | Ginkgolide A, CAS:15291-75-5, MF:C20H24O9, MW:408.4 g/mol | Chemical Reagent |

Integrating greenness assessment tools like NEMI, GAPI, Analytical Eco-Scale, AGREE, and AMGS into the workflow of UPLC/MS/MS method development is no longer optional but a professional responsibility for modern researchers. These tools provide a critical lens through which the environmental footprint of analytical methods can be measured, compared, and systematically reduced. As demonstrated in the protocols, each tool offers unique strengths, from the quick overview of NEMI to the comprehensive, quantitative analysis of AGREE and the specific solvent-focused benchmarking of AMGS. The ongoing doctoral research context underscores that the pursuit of analytical excellence must be intrinsically linked with ecological sustainability. By adopting these metrics, scientists and drug development professionals can make informed decisions that advance both scientific knowledge and global sustainability goals.

The pharmaceutical industry is experiencing a transformative shift towards sustainable analytical practices, driven by evolving regulatory expectations and powerful market trends. This transition is particularly evident in the development and application of Ultra-Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (UPLC/MS/MS) methods, where green chemistry principles are increasingly integrated with rigorous regulatory compliance frameworks. The International Council for Harmonisation (ICH) guidelines provide the foundational requirements for analytical method validation, while simultaneously, the industry is witnessing a surge in adoption of green analytical chemistry (GAC) principles to minimize environmental impact without compromising data quality [4] [27].

This convergence of regulatory compliance and sustainability represents a paradigm shift in pharmaceutical analysis. Research indicates that green UPLC/MS/MS methods are not merely an environmental consideration but are becoming essential components of modern analytical workflows, offering enhanced efficiency, reduced operational costs, and improved safety profiles while maintaining full compliance with ICH Q2(R2) validation requirements [4] [28]. The growing emphasis on sustainability is further reinforced by market data showing increased investment in environmentally conscious technologies throughout the pharmaceutical sector [29] [30].

Regulatory Framework and Industry Adoption Trends

ICH Guidelines as Catalysts for Standardization

The ICH guidelines, particularly Q2(R2) covering validation of analytical procedures, establish comprehensive requirements for method specificity, accuracy, precision, linearity, and range. These standards have become the global benchmark for pharmaceutical analysis, ensuring data reliability and reproducibility across international markets. Recent research demonstrates that ICH guidelines provide a flexible framework that can successfully accommodate green method developments without compromising validation standards [4] [28] [31].

Studies have confirmed that UPLC/MS/MS methods validated according to ICH guidelines can simultaneously achieve superior environmental performance and analytical excellence. For instance, methods developed for pharmaceutical quantification have demonstrated compliance with ICH requirements while significantly reducing organic solvent consumption by up to 90% compared to conventional HPLC methods [4]. This alignment between regulatory requirements and sustainability objectives has accelerated the adoption of green UPLC/MS/MS methodologies in quality control laboratories worldwide.

Market Dynamics Driving Sustainable Adoption

The mass spectrometry market, valued at $6.51 billion in 2024 and projected to reach $21.78 billion by 2035, reflects substantial growth driven partly by sustainability considerations [30]. This expansion is characterized by several key trends:

- Stringent regulatory requirements for environmental monitoring and pharmaceutical safety are propelling adoption of advanced LC-MS systems [29]

- Manufacturer initiatives are focusing on sustainability, with companies like Agilent Technologies developing "My Green Lab Certified" systems with Ecolabel 2.0 [32]

- Miniaturization and portability trends are reducing resource consumption while maintaining analytical performance [30] [33]

- Pharmaceutical and biotechnology sectors remain the primary drivers, accounting for approximately 35% of the mass spectrometry market [33]

Table 1: Mass Spectrometry Market Growth Indicators

| Metric | 2024/2025 Value | Projected Value | CAGR | Primary Sustainable Driver |

|---|---|---|---|---|

| Global Market Size | $6.51 billion (2024) [30] | $21.78 billion (2035) [30] | 11.60% [30] | Green instrument development |

| LC-MS Segment | 52.5% of sample prep techniques [30] | 38% market share (2024) [33] | 7.14% (2026-2035) [33] | Solvent reduction technologies |

| Benchtop & Portable MS | Emerging segment | Highest growth CAGR [33] | Not specified | Miniaturization & energy efficiency |

| North America Leadership | 40% market share (2024) [33] | Sustained dominance | Not specified | Strict environmental regulations |

Green Metric Tools for Method Evaluation

Standardized Green Assessment Frameworks

The evaluation of analytical method environmental impact has evolved from subjective assessment to standardized metrics. Five key tools have emerged as industry standards for quantifying the greenness of UPLC/MS/MS methods [4]:

National Environmental Method Index (NEMI) is the pioneering green assessment tool, offering simple pictogram-based evaluation but limited in covering comprehensive GAC principles [4].

Modified NEMI expanded on the original framework by incorporating instrument energy consumption and operator risk factors, though it still lacks coverage of some critical environmental aspects [4].

Green Analytical Procedure Index (GAPI) provides a more comprehensive visual assessment using a five-element pictogram with color-coded evaluation (green-yellow-red) across multiple environmental parameters [4].

Analytical Eco-Scale represents a semi-quantitative approach that assigns penalty points to non-green aspects of analytical methods, with higher scores indicating greener methods [4].

Analytical Greenness (AGREE) is the most advanced quantitative tool, evaluating methods against all 12 principles of GAC and providing a final score on a 0-1 scale, facilitating straightforward method comparisons [4].

Practical Application of Green Metrics

Recent studies demonstrate the practical application of these tools in pharmaceutical analysis. A green UPLC/MS/MS method for antihypertensive drugs and their impurities achieved excellent environmental performance while maintaining ICH compliance, with the AGREE metric providing a quantitative assessment of its greenness [4]. Similarly, a method for Revumenib analysis in human liver microsomes obtained an AGREE score of 0.77, confirming its environmental acceptability while demonstrating linearity from 1-3000 ng/mL and precision within 11.67% RSD [28].

Table 2: Green Metric Tools Comparison for UPLC/MS/MS Method Evaluation

| Tool | Type | Key Parameters Assessed | Output Format | Advantages | Limitations |

|---|---|---|---|---|---|

| NEMI [4] | Qualitative | PBT, hazardous, corrosive, waste | Pictogram | Simple, visual | Limited scope, binary assessment |

| Modified NEMI [4] | Qualitative | Energy, operator risk, additional parameters | Enhanced pictogram | Broader coverage | Still incomplete for full GAC |

| GAPI [4] | Qualitative | Comprehensive including sample prep | Color-coded pictogram | Holistic assessment | Complex interpretation |

| Analytical Eco-Scale [4] | Semi-quantitative | Reagents, energy, waste, toxicity | Numerical score | Penalty system enables comparison | Subjectivity in penalty assignment |

| AGREE [4] | Quantitative | All 12 GAC principles | 0-1 numerical score | Comprehensive, standardized | Requires detailed method knowledge |

Experimental Protocols for Green UPLC/MS/MS Method Development

Protocol 1: Green UPLC/MS/MS Method for Antihypertensive Drugs and Impurities

This established protocol demonstrates the successful integration of green principles with rigorous ICH validation for simultaneous determination of captopril, hydrochlorothiazide, and their harmful impurities [4].

Instrumentation and Conditions

- UPLC/MS/MS System: Acquity Waters 3100 with triple quadrupole detector

- Column: Agilent Poroshell 120 EC-C18 (4.6 × 50 mm, 2.7 μm)

- Mobile Phase: Methanol and 0.1% formic acid (90:10, v/v)

- Flow Rate: 0.7 mL/min (25% reduction vs. conventional methods)

- Injection Volume: 5 μL

- Analysis Time: 1 minute (85% reduction vs. reported HPLC methods)

- Ionization Mode: ESI-positive for CPL, ESI-negative for HCZ and impurities

Sample Preparation and Validation

- Standard Preparation: Dissolve in methanol to minimize hazardous waste

- Linear Range: 50.0-500.0 ng/mL for CPL, 20.0-500.0 ng/mL for HCZ

- Validation: Full ICH Q2(R2) validation demonstrating specificity, accuracy (98.3-101.7%), precision (RSD < 2%)

- Green Profile: Assessed via AGREE, GAPI, and Analytical Eco-Scale tools

Protocol 2: Sustainable UHPLC-MS/MS for Aquatic Pharmaceutical Contaminants

This protocol addresses the growing concern about pharmaceutical contamination in aquatic systems while maintaining strict adherence to green principles [27].

Method Parameters

- Analytes: Carbamazepine, caffeine, and ibuprofen in water and wastewater

- Sample Preparation: Solid-phase extraction without evaporation step

- Analysis Time: 10 minutes

- Mobile Phase: Optimized for minimal organic solvent consumption

- Detection Limits: 100 ng/L for carbamazepine, 300 ng/L for caffeine, 200 ng/L for ibuprofen

- Validation: ICH-compliant with correlation coefficients ≥ 0.999, precision RSD < 5.0%

Environmental Impact Assessment

- Waste Reduction: Elimination of evaporation step reduces energy consumption

- Solvent Conservation: Optimized mobile phase composition

- Throughput Enhancement: Rapid analysis facilitates high-volume monitoring

Protocol 3: Green Metabolic Stability Assessment for Revumenib

This protocol exemplifies the application of green UPLC/MS/MS in early drug development stages [28].

Analytical Conditions

- Runtime: 1 minute

- Mobile Phase: Isocratic system with 45% ACN

- Flow Rate: 0.6 mL/min

- Column: C8 (2.1 mm, 50 mm, 3.5 μm)

- Detection: MRM mode with positive ESI

- Linear Range: 1-3000 ng/mL (R² = 0.9945)

Greenness and Validation Outcomes

- AGREE Score: 0.77 confirming excellent environmental profile

- LOQ: 0.96 ng/mL demonstrating high sensitivity

- Precision: Intra-day and inter-day RSD ≤ 11.67%

- Application: Successful determination of in vitro tâ‚/â‚‚ (14.93 min) and intrinsic clearance (54.31 mL/min/kg)

The Scientist's Toolkit: Essential Research Reagent Solutions

Implementing green UPLC/MS/MS methods requires carefully selected reagents and materials that balance analytical performance with environmental considerations.

Table 3: Essential Research Reagents for Green UPLC/MS/MS Method Development

| Reagent/Material | Function | Green Considerations | Application Examples |

|---|---|---|---|

| Methanol with 0.1% Formic Acid [4] | Mobile phase | Lower toxicity than acetonitrile, biodegradable | Antihypertensive drug analysis [4] |

| Agilent Poroshell 120 EC-C18 [4] | UPLC column | Superficially porous particles reduce solvent consumption | High-speed separation of drugs and impurities [4] |

| Human Liver Microsomes [28] | Metabolic stability assessment | Enables in vitro prediction reducing animal testing | Revumenib metabolic clearance studies [28] |

| Caco-2 Cell Monolayers [31] | Intestinal permeability model | Reduces need for in vivo permeability studies | BCS classification of atenolol, propranolol, quinidine, verapamil [31] |

| Solid-Phase Extraction Cartridges [31] | Sample clean-up | Reduces solvent use vs. liquid-liquid extraction | Intestinal permeability marker sample preparation [31] |

| Ginsenoside F2 | Ginsenoside F2 | High-purity Ginsenoside F2 for research into glucose metabolism, cancer, and liver health. This product is For Research Use Only (RUO). Not for human consumption. | Bench Chemicals |

| Panax saponin C | Panax saponin C, CAS:52286-59-6, MF:C48H82O18, MW:947.2 g/mol | Chemical Reagent | Bench Chemicals |

Visualizing the Green Method Development Workflow

The following diagram illustrates the integrated approach to developing green UPLC/MS/MS methods that satisfy both regulatory requirements and sustainability objectives:

Green Method Development Workflow - This diagram illustrates the iterative process of developing UPLC/MS/MS methods that meet both regulatory and environmental objectives.

The harmonization of ICH guidelines with sustainable analytical practices represents the future of pharmaceutical analysis. Green UPLC/MS/MS methods have demonstrated that environmental responsibility and regulatory compliance are not mutually exclusive but rather complementary objectives that drive innovation in analytical science. The protocols and frameworks presented provide practical pathways for implementation, supported by market trends showing increased adoption across the pharmaceutical industry.

As regulatory agencies continue to emphasize environmental considerations, and as market forces reward sustainable practices, the integration of green principles with ICH-compliant method development will likely become standard practice rather than optional enhancement. The scientific tools, metrics, and methodologies outlined in this document provide researchers with a comprehensive framework for advancing this important integration, contributing to both pharmaceutical quality and environmental stewardship.

The integration of Green Analytical Chemistry (GAC) principles into pharmaceutical analysis has become a pivotal global trend, driven by the need to reduce hazardous waste, minimize energy consumption, and mitigate the environmental impact of analytical activities [34] [35]. This case study, framed within a broader thesis on greenness evaluation of UPLC/MS/MS methods, examines the specific application of these principles in the analysis of antihypertensive medications. Hypertension, described by the World Health Organization as a serious medical problem significantly affecting the heart, brain, and kidneys, represents a major cause of premature death worldwide [5] [4]. The pharmaceutical treatment often involves combination therapies, creating a complex analytical challenge for quality control laboratories that must quantify active ingredients and their potentially toxic impurities [4] [36].

Traditional chromatographic methods, particularly High-Performance Liquid Chromatography (HPLC), have historically dominated pharmaceutical quality control. However, these methods often consume substantial quantities of hazardous solvents, generate significant waste, and require longer analysis times [5]. The emergence of Ultra-Performance Liquid Chromatography/Tandem Mass Spectrometry (UPLC/MS/MS) presents an opportunity to address these limitations through improved efficiency and reduced environmental footprint. This study provides a comparative assessment of the environmental and performance characteristics of traditional HPLC versus green UPLC/MS/MS methods for analyzing antihypertensive drugs and their harmful impurities, with a particular focus on captopril and hydrochlorothiazide combinations [5] [4].

Experimental Protocols

Green UPLC/MS/MS Method for Antihypertensive Agents and Impurities

Chromatographic Conditions

- Instrumentation: UPLC/MS/MS system (e.g., Waters Acquity series) equipped with a triple quadrupole mass spectrometer [4].

- Column: Agilent Poroshell 120 EC-C18 (4.6 × 50 mm, 2.7 μm) or equivalent [4].

- Mobile Phase: Methanol and 0.1% formic acid (90:10, v/v) [4].

- Flow Rate: 0.7 mL/min [4].

- Analysis Temperature: Room temperature [4].

- Injection Volume: 1-5 μL (optimize based on detection capability).

- Run Time: 1 minute [4].

Mass Spectrometric Detection

- Ionization Mode: Electrospray Ionization (ESI) [4].

- Positive Mode: Applied for captopril (CPL) analysis [4].

- Negative Mode: Applied for hydrochlorothiazide (HCZ), captopril disulphide (CDS), chlorothiazide (CTZ), and salamide (SMD) [4].

- Detection Technique: Multiple Reaction Monitoring (MRM) for enhanced selectivity and sensitivity [4] [36].

Sample Preparation

- Standard Solutions: Prepare stock solutions of CPL, HCZ, and their impurities (CDS, CTZ, SMD) in appropriate solvents (e.g., methanol) [4].

- Calibration Standards: Dilute to required concentrations in the mobile phase or compatible solvent.

- Tablet Formulation: Extract powdered tablet equivalent to one dose in solvent, sonicate, centrifuge, and dilute supernatant to appropriate volume [4].

Traditional HPLC Method for Comparative Analysis

Chromatographic Conditions

- Instrumentation: Conventional HPLC system with UV or DAD detection [36].

- Column: Inertsil ODS-3 C18 column (250 × 4.6 mm, 5 μm) or equivalent [36].

- Mobile Phase: Gradient elution with 20 mM potassium dihydrogen phosphate (pH 3.0 ± 0.2) and acetonitrile [36].

- Flow Rate: 1.0 mL/min or higher [36].

- Detection: UV detection at 225 nm [36].

- Run Time: Typically 10-20 minutes or longer [36].

Method Validation Parameters

Both methods should be validated according to International Conference on Harmonisation (ICH) guidelines assessing [4] [36]:

- Linearity and range

- Precision (repeatability, intermediate precision)

- Accuracy (recovery studies)

- Sensitivity (LOD and LOQ)

- Specificity and selectivity

- Robustness

Results and Data Analysis

Analytical Performance Comparison

Table 1: Performance Characteristics of UPLC/MS/MS versus HPLC Methods

| Parameter | Green UPLC/MS/MS Method | Traditional HPLC Method |

|---|---|---|

| Analysis Time | 1 minute [4] | 10-20 minutes or longer [36] |

| Flow Rate | 0.7 mL/min [4] | 1.0 mL/min or higher [36] |

| Separation Efficiency | High | Moderate |

| Detection Specificity | High (MRM detection) [4] [36] | Moderate (UV detection) [36] |

| Linear Range (CPL) | 50.0-500.0 ng/mL [4] | Varies with method |

| Linear Range (HCZ) | 20.0-500.0 ng/mL [4] | Varies with method |

| Impurity Detection | Sensitive to ng/mL levels [4] | Typically μg/mL levels [36] |

Environmental Impact Assessment

Table 2: Greenness Comparison Using Multiple Metric Tools

| Green Metric Tool | UPLC/MS/MS Method Assessment | HPLC Method Assessment |

|---|---|---|

| NEMI | Better profile (fewer red criteria) [4] | Poorer profile (more red criteria) [4] |

| Analytical Eco-Scale | Higher score (closer to 100) [4] [35] | Lower score (more penalty points) [4] [35] |

| GAPI | More green sectors in pictogram [4] [35] | More yellow/red sectors [4] [35] |

| AGREE | Higher numerical score (closer to 1.0) [4] [35] | Lower numerical score [4] [35] |

| BAGI | High applicability score [37] | Lower applicability score |

Solvent Consumption and Waste Generation

The green UPLC/MS/MS method demonstrates significant advantages in solvent reduction. With a flow rate of 0.7 mL/min and a 1-minute runtime, the method consumes approximately 0.7 mL of solvent per analysis. In contrast, traditional HPLC methods typically use flow rates of 1.0 mL/min or higher with run times of 10-20 minutes, resulting in 10-20 mL of solvent consumption per analysis [4] [36]. This represents a 90-95% reduction in solvent consumption, directly translating to reduced waste generation and lower environmental impact.

Greenness Assessment Workflow

The following diagram illustrates the logical workflow for assessing the greenness of analytical methods using multiple metric tools:

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for UPLC/MS/MS Analysis

| Item | Function/Application | Specifications/Alternatives |

|---|---|---|

| UPLC/MS/MS System | Instrumentation for separation and detection | Triple quadrupole mass spectrometer with ESI source [4] |

| C18 Column | Stationary phase for chromatographic separation | Sub-2μm particles for UPLC; 2.7μm core-shell for improved efficiency [4] |

| Methanol (HPLC/MS grade) | Mobile phase component | Primary solvent in green method; preferable to acetonitrile for environmental impact [4] |

| Formic Acid | Mobile phase modifier | Improves ionization efficiency in MS detection; used at 0.1% concentration [4] |

| Reference Standards | Method calibration and validation | Certified reference materials of active ingredients and impurities [4] |

| Ammonium Formate | Volatile buffer component | Alternative mobile phase additive for improved chromatography [37] |

| 20(R)-Ginsenoside Rg2 | Ginsenoside Rg2 | |

| Epiyangambin | Epiyangambin, CAS:24192-64-1, MF:C24H30O8, MW:446.5 g/mol | Chemical Reagent |

Discussion

Environmental Impact Reduction

The implementation of green UPLC/MS/MS methods significantly reduces the environmental footprint of pharmaceutical analysis compared to traditional approaches. The substantial reduction in solvent consumption (from 10-20 mL to 0.7 mL per analysis) directly decreases the generation of hazardous waste, minimizing the ecological impact of analytical activities [4]. Furthermore, the shorter analysis time (1 minute versus 10-20 minutes) translates to reduced energy consumption, contributing to overall sustainability goals in quality control laboratories [5] [4].

The greenness superiority of the UPLC/MS/MS method has been consistently demonstrated across multiple assessment tools. In one study, the method showed better performance in NEMI profiling, higher Analytical Eco-Scale scores, more favorable GAPI pictograms, and superior AGREE calculator results compared to reported HPLC methods [4]. This comprehensive greenness evaluation using multiple metrics provides a robust framework for assessing the environmental impact of analytical methods in pharmaceutical research and development.

Analytical Performance Considerations

Beyond environmental benefits, the UPLC/MS/MS method offers significant analytical advantages. The enhanced sensitivity and specificity of mass spectrometric detection, particularly in MRM mode, enables precise quantification of potentially toxic impurities at trace levels [4] [36]. This is critically important for impurities like captopril disulphide, chlorothiazide, and salamide, which have been identified as hepatotoxic through ADME/TOX profile studies [4]. The ability to reliably detect these impurities at concentrations well below specified safety thresholds (typically 0.5-1.0%) ensures drug product safety while maintaining analytical efficiency [4] [35].

The combination of reduced environmental impact and enhanced analytical performance positions green UPLC/MS/MS methods as a superior choice for modern pharmaceutical analysis. This approach aligns with the increasing regulatory and industry focus on sustainable practices while maintaining the rigorous quality standards required for pharmaceutical products.

This case study demonstrates that green UPLC/MS/MS methods provide substantial environmental advantages over traditional HPLC approaches for the analysis of antihypertensive medications and their impurities. The significant reductions in solvent consumption, waste generation, and analysis time, coupled with enhanced analytical sensitivity, make these methods ideally suited for contemporary pharmaceutical quality control. The comprehensive greenness assessment using multiple metric tools offers a robust framework for evaluating the environmental impact of analytical methods, supporting the pharmaceutical industry's transition toward more sustainable practices. As green analytical chemistry continues to evolve, the integration of these principles into routine analytical methods will play an increasingly important role in reducing the environmental footprint of pharmaceutical analysis while maintaining the highest standards of product quality and patient safety.

Developing Green UPLC/MS/MS Methods: From Design to Practical Implementation

The pursuit of sustainability in analytical laboratories has made the replacement of traditional solvents with greener alternatives a critical focus in method development for Ultra-Performance Liquid Chromatography tandem Mass Spectrometry (UPLC-MS/MS). Acetonitrile, while historically preferred for its chromatographic performance, presents significant environmental, safety, and cost concerns [1]. This application note details practical strategies for substituting acetonitrile with more sustainable solvents, specifically ethanol and methanol, within the framework of green analytical chemistry principles. As the chemical industry seeks to reduce its environmental footprint, identifying alternative solvents that maintain analytical performance while improving ecological credentials has become imperative for researchers and drug development professionals [38]. We present a comprehensive protocol for assessing, implementing, and validating ethanol and methanol as direct replacements for acetonitrile in reversed-phase UPLC-MS/MS applications, supported by experimental data and greenness assessment metrics.

Green Solvent Replacement Strategy

Principles of Solvent Selection

The selection of environmentally preferable solvents for chromatographic applications must balance green chemistry principles with analytical performance requirements. According to the twelve principles of Green Analytical Chemistry (GAC), method developers should prioritize safer solvents and reagents, minimize waste generation, and reduce energy consumption [1]. Ethanol and methanol represent viable green alternatives to acetonitrile due to their favorable environmental, health, and safety profiles. Ethanol, in particular, is derived from renewable resources, exhibits lower toxicity compared to acetonitrile, and is biodegradable [38]. Methanol, while requiring careful handling, offers similar advantages in reducing environmental impact when compared to acetonitrile.

When transitioning from acetonitrile to alternative solvents, method developers must consider several chemical and physical properties that influence chromatographic performance: elution strength, viscosity, UV cutoff, and miscibility with water and buffers [39]. The successful implementation of a green solvent strategy requires systematic evaluation of these parameters to achieve comparable or improved separations while maintaining detection sensitivity, especially in mass spectrometric applications.

Experimental Comparison of Solvent Performance

A recent systematic investigation evaluated the effectiveness of ethanol and dimethyl carbonate as potential replacements for conventional solvents including acetonitrile and methanol [38]. The study employed the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) algorithm to select optimal conditions for UHPLC separations, integrating multiple criteria including chromatographic run time, tailing ratios, resolution, and solvent-related environmental hazards.

Table 1: Performance Comparison of Conventional and Green Solvents in UHPLC Separations

| Solvent | Environmental Impact | Elution Strength (Water=0) | Viscosity (cP, 20°C) | UV Cutoff (nm) | Buffer Precipitation Risk | Separation Performance |

|---|---|---|---|---|---|---|

| Acetonitrile | High | 0.65 | 0.34 | 190 | High | Excellent |

| Methanol | Moderate | 0.95 | 0.55 | 205 | Low | Very Good |

| Ethanol | Low | 0.88 | 1.08 | 210 | Low | Good |

| Dimethyl Carbonate | Low | 0.49 | 0.63 | 235 | Moderate | Good |

The results demonstrated that ethanol and dimethyl carbonate can effectively replace traditional solvents without compromising separation performance, confirming that sustainable analytical methods for mixtures of non-polar and polar compounds are achievable with green solvents [38]. Specifically, ethanol showed particular promise as a replacement for acetonitrile in separations of non-polar substances, while methanol provided excellent performance for polar analytes.

Protocol: Method Development with Green Solvents

Solvent Conversion Workflow

The following diagram illustrates the systematic approach for transitioning from acetonitrile to greener solvent alternatives in UPLC-MS/MS method development:

Detailed Experimental Procedure

Initial Method Assessment and Solvent Selection

Begin by thoroughly documenting all parameters of the existing acetonitrile-based method, including:

- Mobile phase composition and pH

- Gradient profile and flow rate

- Column chemistry and dimensions

- MS ionization parameters and detection settings

Based on the chemical properties of your analytes, select either methanol or ethanol as the primary replacement solvent. Consider methanol for polar compounds and ethanol for non-polar substances [38]. For complex mixtures, you may investigate both solvents in parallel development tracks.

Mobile Phase Adjustment and Optimization

For methanol replacement:

- Increase the organic proportion by 10-20% relative to acetonitrile concentration to compensate for lower elution strength [39]

- Prepare aqueous phase with 20 mM ammonium acetate or 0.1% formic acid for MS compatibility [40] [41]

- Adjust pH as needed to maintain ionization efficiency, noting that pH effects may differ from acetonitrile-based methods

For ethanol replacement:

- Increase organic proportion by 15-25% to account for significantly different elution strength

- Consider slightly elevating column temperature (40-50°C) to reduce viscosity effects [39]

- Incorporate 1-5% water in the organic solvent reservoir to improve miscibility and reduce backpressure

Gradient Re-optimization

Re-optimize the gradient profile to maintain resolution and peak capacity:

- Extend initial isocratic hold by 0.5-1.0 minute to compensate for weaker elution strength

- Adjust gradient slope to achieve similar retention times to original method

- Incorporate a more aggressive cleaning step (95-100% organic) to ensure strongly retained compounds are eluted

- Implement adequate column re-equilibration time (5-10 column volumes) due to slower solvent dynamics

MS Ionization Optimization

Re-optimize MS source parameters for the new solvent system:

- Adjust nebulizer gas flow to accommodate different surface tension and viscosity

- Optimize source temperature and desolvation parameters for altered evaporation characteristics

- Fine-tune capillary and cone voltages for maximum response with new solvent composition

- Monitor for potential ion suppression/enhancement effects compared to original method

Case Study: Green UPLC-MS/MS Method for Anticancer Drug Monitoring

Method Development and Validation

A recent study developed and validated a green UPLC-MS/MS method for quantification of ripretinib and its active metabolite in human plasma, specifically designed to replace conventional acetonitrile-based methods [42]. The method employed a mobile phase consisting of water with 1% acetic acid and 0.1% formic acid, and acetonitrile, but was successfully adapted to incorporate greener alternatives while maintaining analytical performance.

Table 2: Validation Parameters for Green UPLC-MS/MS Method of Ripretinib Monitoring

| Validation Parameter | Result for Ripretinib | Result for N-desmethyl-ripretinib | Acceptance Criteria |

|---|---|---|---|

| Linear Range | 1-1000 ng/mL | 1-1000 ng/mL | r² > 0.995 |

| Intra-day Precision (% RSD) | 2.1-5.8% | 2.5-6.2% | <15% |

| Inter-day Precision (% RSD) | 3.5-7.3% | 4.1-7.9% | <15% |

| Accuracy (% Bias) | -4.2 to 5.1% | -5.3 to 4.8% | ±15% |

| Extraction Recovery | 92-96% | 90-95% | >85% |

| Matrix Effect | 95-105% | 93-107% | 85-115% |

The validated UPLC-MS/MS method successfully monitored ripretinib and its metabolite concentrations in clinical and preclinical models, demonstrating that the green solvent approach provided comparable performance to conventional methods while reducing environmental impact [42]. The greenness assessment score of this procedure, evaluated using the AGREE metric, was better than previously published approaches using acetonitrile-based mobile phases.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Research Reagent Solutions for Green UPLC-MS/MS Method Development

| Reagent | Function | Green Considerations |

|---|---|---|

| Ethanol (HPLC grade) | Primary organic solvent | Renewable resource, low toxicity |

| Methanol (HPLC grade) | Primary organic solvent | Readily biodegradable, lower environmental impact than acetonitrile |

| Ammonium acetate (10-20 mM) | MS-compatible buffer | Volatile, MS-compatible, minimal source contamination |

| Formic acid (0.05-0.1%) | Ion-pairing modifier | Volatile, enhances ionization in positive mode |

| Acetic acid (0.1-1.0%) | pH modifier | Volatile, alternative to formic acid |

| Reversed-phase UPLC columns (C18, phenyl, etc.) | Stationary phase | Enables fast separations with reduced solvent consumption |

| Glabrocoumarone A | Glabrocoumarone A, CAS:178330-48-8, MF:C19H16O4, MW:308.3 g/mol | Chemical Reagent |

| Gliorosein | Gliorosein | High-purity Gliorosein for research. Explore its antimicrobial and cytoprotective properties. This product is for Research Use Only (RUO). |

Greenness Assessment and Regulatory Considerations

Application of Green Metrics

The implementation of green solvent strategies should include formal assessment using established greenness metrics to quantitatively demonstrate environmental improvements. The AGREE (Analytical GREEnness) metric provides a comprehensive evaluation based on all 12 principles of Green Analytical Chemistry, generating a single score from 0 to 1 supported by an intuitive graphic output [1]. Alternative assessment tools include:

- Analytical Eco-Scale: Provides a penalty-point-based system that quantifies deviation from ideal green methods based on solvent toxicity, energy consumption, and waste generation [1]

- GAPI (Green Analytical Procedure Index): Offers a visual, semi-quantitative evaluation of the entire analytical workflow through a color-coded pictogram [1]

- BAGI (Blue Applicability Grade Index): Evaluates practical applicability aspects alongside environmental considerations [43]

For regulatory submissions, document the greenness assessment alongside traditional validation parameters. The green profile of a method may provide additional justification for its selection in routine monitoring applications, particularly in environmentally conscious organizations [42].

Troubleshooting and Technical Considerations

Common Challenges and Solutions

High Backpressure:

- Cause: Higher viscosity of ethanol and methanol compared to acetonitrile