HPLC Troubleshooting Guide: Solving Separation Problems from Basics to Advanced Techniques

This comprehensive guide provides researchers, scientists, and drug development professionals with a systematic approach to diagnosing and resolving High-Performance Liquid Chromatography (HPLC) separation issues.

HPLC Troubleshooting Guide: Solving Separation Problems from Basics to Advanced Techniques

Abstract

This comprehensive guide provides researchers, scientists, and drug development professionals with a systematic approach to diagnosing and resolving High-Performance Liquid Chromatography (HPLC) separation issues. Covering foundational principles to advanced multidimensional techniques, it offers practical methodologies for troubleshooting common problems like peak tailing, pressure fluctuations, and baseline noise. The article also explores modern validation strategies and comparative approaches for assessing method limits, alongside emerging trends including machine learning and 2D-LC that are shaping the future of chromatographic analysis in biomedical research.

Understanding HPLC Fundamentals: How System Components Impact Separation Performance

Core HPLC System Components and Their Role in Separation

High-Performance Liquid Chromatography (HPLC) is a fundamental analytical technique used to separate, identify, and quantify components in a mixture. This technical guide details the core components of an HPLC system and their specific roles in the separation process, providing a foundation for effective troubleshooting within pharmaceutical research and development. Understanding these components is essential for diagnosing separation issues and ensuring data integrity.

Core HPLC System Components

An HPLC instrument is a sophisticated system comprising several key components that work in concert to perform a separation. The table below summarizes these core parts and their primary functions.

Table 1: Core Components of an HPLC System and Their Functions

| Component | Primary Function |

|---|---|

| Solvent Reservoir | Holds the mobile phase solvents [1] [2]. |

| Degasser | Removes dissolved gases from the mobile phase to prevent bubbles and baseline instability [1] [3]. |

| Pump | Drives the mobile phase through the system at a high, controlled pressure and precise flow rate [4] [2]. |

| Autosampler/Injector | Introduces the sample mixture into the mobile phase stream with accuracy and precision [4] [3]. |

| Column | Contains the stationary phase where the physical separation of analytes based on their chemical properties occurs [4] [2]. |

| Detector | Identifies and quantifies the separated compounds as they elute from the column [4] [2]. |

| Data System | Controls the instrument, acquires data from the detector, and processes the results into a chromatogram [4] [5]. |

The separation principle relies on the differential distribution of sample compounds between the mobile phase (the moving liquid solvent) and the stationary phase (the packed bed inside the column) [5]. Each analyte interacts differently with the stationary phase, causing them to elute at different times, known as retention time [6] [2].

HPLC Troubleshooting Guide

Effective troubleshooting is a systematic process. The following tables address common HPLC problems, their potential causes, and solutions.

Pressure-Related Issues

Pressure abnormalities are frequent indicators of system problems.

Table 2: Troubleshooting Pressure-Related Issues

| Symptom | Potential Causes | Solutions |

|---|---|---|

| High Pressure | • Blocked column or in-line filter• Mobile phase precipitation• Flow rate set too high | • Reverse-flush column or replace frit/column [7] [8]• Flush system with strong solvent and prepare fresh mobile phase [7]• Reduce flow rate [7] |

| Low Pressure | • System leak• Air in the pump• Flow rate set too low | • Identify and tighten or replace leaky fittings [9] [7]• Purge and prime the pump [7]• Increase flow rate [7] |

| Pressure Fluctuations | • Pump seal failure• Air bubbles in the system• Faulty check valve | • Replace pump seals [9] [7]• Degas mobile phase and purge pump [9] [7]• Replace check valves [7] |

Peak Shape and Retention Issues

The quality of the chromatographic peaks is critical for accurate integration and quantification.

Table 3: Troubleshooting Peak Anomalies and Retention Shifts

| Symptom | Potential Causes | Solutions |

|---|---|---|

| Peak Tailing | • Active sites on column (e.g., for basic compounds)• Column voiding or degradation• Incorrect mobile phase pH | • Use high-purity silica columns or add competing amines to mobile phase [8]• Replace the column [9] [8]• Adjust pH and prepare fresh mobile phase [7] |

| Peak Fronting | • Column overload• Sample dissolved in stronger solvent than mobile phase• Channels in the column | • Reduce injection volume or dilute sample [7] [8]• Dissolve sample in the mobile phase or a weaker solvent [8]• Replace the column [8] |

| Retention Time Drift | • Inconsistent mobile phase composition or temperature• Column not equilibrated• Pump flow rate inconsistency | • Prepare fresh mobile phase, use a column oven [9] [7]• Increase column equilibration time [7]• Check pump for leaks or malfunctions [9] |

Baseline and Sensitivity Issues

A stable baseline and consistent sensitivity are necessary for reliable detection.

Table 4: Troubleshooting Baseline and Sensitivity Problems

| Symptom | Potential Causes | Solutions |

|---|---|---|

| Baseline Noise | • Contaminated mobile phase or detector flow cell• Air bubbles in detector• Detector lamp failure | • Use fresh HPLC-grade solvents, flush flow cell [9] [7]• Degas mobile phase, purge system [7]• Replace detector lamp [7] |

| Baseline Drift | • Mobile phase composition change (Gradient)• Temperature fluctuations• Retained material from previous injections | • Ensure mixer is working, prepare fresh mobile phase [7]• Use a thermostat-controlled column oven [7]• Flush column with strong solvent, use a guard column [7] |

| Loss of Sensitivity | • Incorrect detector settings (wavelength, time constant)• Blocked injector needle• Contaminated column or guard column | • Optimize detector settings [8], ensure UV wavelength is at maximum absorbance [7]• Flush or replace the needle [7] [8]• Replace guard column or analytical column [7] |

Experimental Protocols for System Diagnosis

Protocol: Column Performance Verification

Purpose: To isolate and confirm whether a separation issue originates from the column. Procedure:

- Obtain a certified reference standard with known performance characteristics.

- Inject the standard using the method specified for that column.

- Compare the resulting chromatogram to the reference data. Key parameters to evaluate include:

- Theoretical Plates (N): A measure of column efficiency. A significant drop indicates degraded packing.

- Tailing Factor (Tf): A value consistently above 1.5-2.0 suggests active sites or channeling.

- Retention Factor (k): Significant changes may indicate loss of stationary phase.

- Pressure: A steady increase in backpressure suggests column blockage.

Interpretation: If the column fails to meet the reference specifications, it is likely the source of the problem and should be replaced or cleaned according to the manufacturer's instructions [9].

Protocol: Pump Flow Rate Accuracy Check

Purpose: To verify that the pump is delivering the set flow rate accurately and consistently, which is critical for retention time reproducibility. Procedure:

- Disconnect the column and connect a piece of tubing to direct the flow to a waste beaker.

- Set the pump to a specific flow rate (e.g., 1.0 mL/min).

- Using a graduated cylinder and a stopwatch, measure the volume of solvent delivered over a fixed time (e.g., 5 minutes).

- Repeat this measurement three times to ensure consistency.

- Calculate the measured flow rate (Volume/Time) and compare it to the set flow rate.

Interpretation: The measured flow rate should be within ±1-2% of the set value. Inconsistent delivery or a significant deviation points to a pump issue, such as a faulty seal, check valve, or pump piston, requiring maintenance [7].

Logical Troubleshooting Workflow

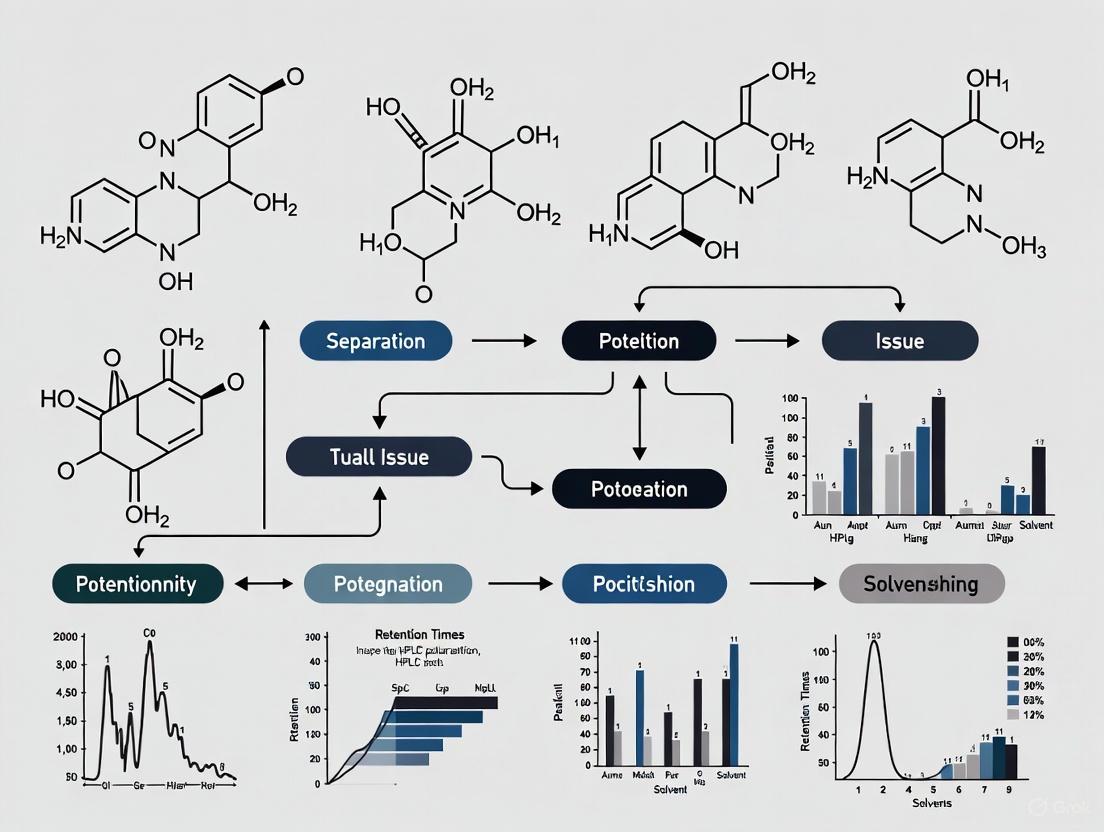

The following diagram outlines a systematic approach to diagnosing common HPLC problems.

Systematic HPLC Problem Diagnosis

The Scientist's Toolkit: Essential Research Reagents and Materials

The quality of consumables and reagents is paramount for robust and reproducible HPLC results.

Table 5: Essential HPLC Reagents and Consumables

| Item | Function & Importance |

|---|---|

| HPLC-Grade Solvents | High-purity water, acetonitrile, and methanol minimize baseline noise and prevent column contamination [9] [2]. |

| Buffers & Additives | Salts (e.g., phosphate, ammonium formate/acetate) and ion-pair agents (e.g., TFA) control pH and ionic strength to optimize separation and peak shape [6] [8]. |

| Chromatography Column | The heart of the separation; choice of chemistry (C18, C8, phenyl, etc.), particle size, and dimensions directly impact resolution, speed, and pressure [6] [2]. |

| Guard Column | A small, disposable cartridge containing the same packing as the analytical column. It protects the more expensive analytical column from particulates and strongly retained contaminants [9]. |

| Syringe Filters | Used to filter samples (typically 0.45 µm or 0.22 µm) to remove particulates that could clog the system or column [9]. |

| Certified Standards | Well-characterized compounds used for system suitability testing, calibration, and method validation to ensure data accuracy and regulatory compliance. |

| ARD-61 | ARD-61, MF:C61H71ClN8O7S, MW:1095.8 g/mol |

| L-NBDNJ | L-NBDNJ, MF:C10H21NO4, MW:219.28 g/mol |

Frequently Asked Questions (FAQs)

Q1: What is the first thing I should check if my HPLC pressure is suddenly high? A: The most common cause is a blockage. Immediately check and replace the guard column if you are using one. If the problem persists, the analytical column itself may be blocked and require flushing in the reverse direction or replacement [9] [7].

Q2: Why are my peaks tailing, and how can I fix it? A: Peak tailing can arise from multiple factors. For reversed-phase separations of basic compounds, it is often due to interactions with acidic silanol groups on the silica surface. Solutions include using a high-purity (Type B) silica column, adding a competing base like triethylamine to the mobile phase, or using a stationary phase designed to reduce these interactions [8].

Q3: My retention times are drifting later with each injection. What is the likely cause? A: This is often a symptom of a change in the mobile phase composition, typically due to evaporation of the organic solvent (e.g., acetonitrile) from an aqueous mix over time. Always use freshly prepared mobile phase and ensure the reservoir is tightly sealed. Also, ensure the column is fully equilibrated with the new mobile phase before starting a sequence [9] [7].

Q4: How can I prevent air bubbles from causing noise and pressure fluctuations in my system? A: Always degas your mobile phase thoroughly, using an online degasser or helium sparging. Regularly purge the pump modules according to the manufacturer's schedule. Using a backpressure regulator after the detector can also help prevent bubble formation in the flow cell [7] [1].

Q5: When should I attempt to fix an issue myself, and when should I call for service? A: You can typically handle issues related to consumables (columns, seals, filters), mobile phase preparation, and basic maintenance (purging, capillary connections). Contact a service technician for complex internal pump repairs, detector component replacement (like lamps in sealed units), or electronic failures, especially if the instrument is under warranty [9].

Principles of Analyte-Stationary Phase Interactions

Frequently Asked Questions (FAQs)

1. What are the fundamental principles governing analyte-stationary phase interactions? Analyte-stationary phase interactions are governed by adsorption characteristics, where the chromatographic surface is often not uniform but heterogeneous [10]. This means a stationary phase typically consists of a large number of weak, non-selective sites and only a few strong, selective sites [10]. The interaction is described by adsorption isotherms, such as the bi-Langmuir model, which accounts for molecules interacting with these two distinct types of adsorption sites [10]. The balance of these interactions determines key outcomes like retention, selectivity, and peak shape.

2. How does surface heterogeneity on a chiral stationary phase affect the separation? Surface heterogeneity on chiral stationary phases, common in protein-based phases, means the surface has multiple types of adsorption sites with different energies and selectivities [10]. It consists of many weak, non-selective sites (responsible for general retention) and a few strong, chiral-discriminating sites (essential for enantio-recognition) [10]. Under higher sample concentrations, the selective sites can become saturated, causing a loss of enantioselectivity and leading to peak tailing and distorted elution profiles [10].

3. What is the difference between kinetic and thermodynamic causes of peak tailing, and how can I diagnose them? Peak tailing can originate from two distinct sources:

- Thermodynamic heterogeneity: Tailing arises from the saturation of strong binding sites on a heterogeneous surface. It decreases at lower sample concentrations [10].

- Kinetic heterogeneity: Tailing is caused by some adsorption sites having slower rates of interaction (mass transfer). It decreases at lower flow rates [10]. A simple diagnostic test involves changing the flow rate and sample concentration to identify the root cause [10].

4. What is Adsorption Energy Distribution (AED) and how does it enhance our understanding? Adsorption Energy Distribution (AED) is a computational tool that provides a detailed "fingerprint" of a chromatographic surface by revealing the full spectrum of binding strengths present, rather than assuming a fixed number of site types [10]. It enhances understanding by moving beyond simplistic models, allowing researchers to visually identify the number and type of adsorption sites (unimodal, bimodal, etc.), which helps in selecting the most accurate physical adsorption model for predicting separation behavior, especially under overloaded conditions [10].

Troubleshooting Guides

This section connects the principles of interactions to observable problems in the chromatogram, providing diagnostics and solutions.

Problem 1: Peak Tailing

Peak tailing often indicates heterogeneous interactions between your analyte and the stationary phase.

- Primary Principle: Non-ideal peak shape frequently results from a heterogeneous stationary phase surface, where analytes interact with both high-capacity non-selective sites and low-capacity selective sites with different energies [10] [8].

- Diagnosis:

- Solutions:

- For thermodynamic tailing: Reduce the sample load to avoid saturating the strong selective sites [10].

- For basic compounds: Use high-purity silica (Type B) or shielded phases to minimize interaction with acidic silanol groups. Add a competing base like triethylamine (TEA) to the mobile phase [8].

- Change the chemistry: Switch to a different stationary phase designed to minimize unwanted interactions (e.g., a polar-embedded group or a polymeric column) [7] [8].

Problem 2: Split Peaks

Split or double peaks can stem from a single analyte taking multiple paths through the column.

- Primary Principle: This can be caused by a void or channel in the column's packing material, creating multiple, distinct flow paths for the analyte and effectively giving it different retention times [11]. A severely blocked inlet frit can cause a similar flow path disruption [11].

- Diagnosis:

- Solutions:

- Replace the column: A void or channel in the packing material is often irreversible, requiring column replacement [11].

- Replace the frit: If the column allows, replacing the inlet frit can resolve a blockage [11].

- Check method parameters: Ensure the sample is dissolved in the mobile phase or a weaker solvent. Adjust the organic concentration of the sample solvent and confirm column temperature is stable [8] [11].

Problem 3: Retention Time Drift

A gradual shift in retention time indicates a change in the equilibrium of analyte-stationary phase interactions.

- Primary Principle: The retention equilibrium is sensitive to temperature and mobile phase composition. Poor temperature control or an incorrect/drifting mobile phase composition alters the interaction energy, shifting retention [7].

- Diagnosis:

- Check if the drift is consistent across all peaks (often a system issue) or selective to certain compounds (often a chemistry-specific issue).

- Solutions:

- Stabilize temperature: Use a thermostat-controlled column oven [7].

- Prepare fresh mobile phase: Ensure consistent composition and degas to prevent bubble formation [7].

- Equilibrate the column: Allow sufficient time (e.g., 20 column volumes) for the column to reach full equilibrium with the new mobile phase, especially after a gradient or mobile phase change [7].

Problem 4: Poor Resolution

Inadequate separation of two or more compounds results from insufficient selectivity.

- Primary Principle: Resolution depends on the differential interaction of analytes with the stationary phase (selectivity). If the stationary phase chemistry does not sufficiently differentiate the compounds, or if the mobile phase does not effectively compete for interaction sites, resolution is lost [12].

- Diagnosis:

- Check if the problem is consistent or has developed over time. A gradual loss may indicate column contamination or degradation [12].

- Solutions:

- Optimize the mobile phase: Systematically adjust the pH, buffer concentration, or organic modifier ratio to fine-tune selectivity [12].

- Change the column: Switch to a stationary phase with a different chemistry (e.g., C8 instead of C18, or a phenyl column) to alter the interaction mechanism [7] [12].

- Clean or replace the column: Contamination on the column head can create active sites that degrade performance [12].

Experimental Protocols & Data

Table 1: Characterizing Adsorption Site Heterogeneity

This table summarizes the key characteristics of the two primary types of adsorption sites as described by the bi-Langmuir model [10].

| Site Type | Function | Capacity | Impact on Chromatography |

|---|---|---|---|

| Type I (Non-selective) | General retention | High | Responsible for the main retention of the analyte. |

| Type II (Selective) | Enantio-recognition or specific interaction | Low | Provides selectivity; saturates at high concentrations, leading to peak tailing and loss of resolution [10]. |

Protocol: Distinguishing Kinetic and Thermodynamic Peak Tailing

This protocol helps diagnose the root cause of peak tailing [10].

- Initial Observation: Note the peak shape and asymmetry under your current method conditions.

- Flow Rate Test: Run the sample again at a significantly lower flow rate (e.g., reduce by 50%).

- Concentration Test: Run a diluted sample (e.g., 10% of original concentration) at the original flow rate.

- Analysis:

- Solution Path:

- For kinetic issues, optimize flow rate or consider a column with smaller particles for faster mass transfer.

- For thermodynamic issues, reduce sample load or modify the mobile/stationary phase to reduce binding strength.

Workflow Diagram: Adsorption Model Identification

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Investigating Stationary Phase Interactions

| Reagent / Material | Function in Research |

|---|---|

| Type B High-Purity Silica Columns | Minimizes undesirable secondary interactions with acidic silanols, providing a more uniform surface for studying primary interactions [8]. |

| Chiral Stationary Phases (CSPs) | Used to study enantioselective interactions. Protein-based, synthetic, and polysaccharide-based CSPs are common models for investigating surface heterogeneity [10]. |

| Competitive Additives (e.g., TEA, EDTA) | Introduced in low millimolar concentrations to compete with the analyte for specific adsorption sites, helping to quantify and mask site heterogeneity [10] [8]. |

| Buffers (Various pH & Ionic Strength) | Control the ionization state of analytes and the stationary phase, modulating the strength of ionic interactions and helping to map interaction energies [7] [8]. |

| Molecular Descriptors (Computational) | Used in QSERR models to predict retention and enantioselectivity based on molecular structure, linking chemical features to interaction energy [13]. |

| KOTX1 | KOTX1, MF:C17H16FN3O2, MW:313.33 g/mol |

| FSLLRY-NH2 TFA | FSLLRY-NH2 TFA, MF:C41H61F3N10O10, MW:911.0 g/mol |

This technical support center is framed within a broader thesis on troubleshooting High-Performance Liquid Chromatography (HPLC) separation problems. For researchers, scientists, and drug development professionals, consistent and high-quality chromatographic results are paramount. This guide provides a focused overview of the three fundamental performance metrics—Resolution, Efficiency, and Peak Shape—that are critical for diagnosing and resolving common HPLC issues. Understanding these concepts allows for the systematic troubleshooting of methods, ensuring reliable and reproducible data [14] [15].

Core Concepts: The Three Pillars of HPLC Performance

Reliable HPLC analyses depend on columns that perform as expected, which can be verified by running standard mixtures [15]. The following parameters are typically determined from such an analysis.

Efficiency (Theoretical Plates)

The efficiency of an HPLC column, often expressed as the number of theoretical plates (N), describes its ability to produce narrow, sharp peaks. A higher number of theoretical plates indicates a more efficient column [15].

- Calculation: The theoretical plates for a particular component are related to its retention time (tR) and the width of the peak (W), as shown in the formula below. A high number of plates results from a high elution volume and narrow peaks [15].

- HETP: A parameter closely related to theoretical plates is the Height Equivalent to a Theoretical Plate (HETP), calculated by dividing the column length (L) by the number of theoretical plates (HETP = L/N). The HETP decreases with increasing column efficiency, providing a performance indicator independent of column length [15].

Peak Shape (Asymmetry Factor)

The asymmetry factor describes how symmetrical a peak is and indicates whether a peak is exhibiting fronting or tailing [15].

- Ideal Peak Shape: A perfectly Gaussian, symmetrical peak has an asymmetry factor of 1.0 [15].

- Tailing and Fronting: An asymmetry factor greater than 1 indicates tailing, while a value less than 1 indicates fronting [15]. These distortions can be caused by several factors, including column overload, inappropriate mobile phase composition, or active sites on the column [14] [7].

Resolution (Rs)

Resolution is a measure of how well two adjacent peaks are separated from each other. It takes into account both the distance between the peak centers and their widths [15].

- Calculation: The formula for resolution is ( Rs = \frac{2(t{R2} - t{R1})}{W1 + W2} ), where ( t{R2} ) and ( t{R1} ) are the retention times of the two peaks, and ( W1 ) and ( W2 ) are their peak widths at the baseline [14] [15].

- Interpretation: A resolution value of less than 1.5 indicates poor separation, while values greater than 2.0 indicate baseline separation and good resolution of the two peaks [15].

Table 1: Summary of Key HPLC Performance Metrics

| Metric | What It Measures | Ideal Value | Key Influencing Factors |

|---|---|---|---|

| Efficiency (N) | The sharpness of a peak; column's ability to prevent band broadening [15]. | Higher is better [15]. | Column length, particle size, flow path [14]. |

| Peak Asymmetry (As) | The symmetry of a peak; indicates potential chemical or mechanical issues [15]. | 1.0 (perfectly symmetrical) [15]. | Column overload, mobile phase composition, active sites on column, blocked frit [14] [7] [8]. |

| Resolution (Rs) | The degree of separation between two adjacent peaks [15]. | >1.5 (separation), >2.0 (baseline separation) [15]. | Column efficiency (N), selectivity (α), retention factor (k) [14]. |

HPLC Troubleshooting Guide: FAQs

Poor Peak Shape

Q: What causes peak tailing and how can I fix it?

Peak tailing (asymmetry factor >1) is a common issue that can severely impact resolution and quantification.

- Possible Causes and Solutions:

- Active Sites on Column: Silanol groups in the stationary phase can interact with basic compounds. Use high-purity silica columns, shield phases, or competing bases like triethylamine in the mobile phase [8].

- Column Void or Blockage: A voided or blocked column can cause tailing. Try reverse-flushing the column with a strong solvent or replace the column [7] [8].

- Inappropriate Mobile Phase pH: An incorrect pH can alter the ionization state of analytes. Adjust the mobile phase pH or prepare a new mobile phase with the correct pH [7].

- Sample Solvent Too Strong: If the sample is dissolved in a solvent stronger than the mobile phase, it can cause peak distortion. Always prepare or dilute the sample in the mobile phase whenever possible [7] [8].

Q: Why are my peaks fronting?

Peak fronting (asymmetry factor <1) is another distortion that affects data accuracy.

- Possible Causes and Solutions:

- Column Overload: Injecting too much sample can overload the column. Reduce the injection volume or dilute the sample [7].

- Blocked Frit or Channels in Column: A blocked inlet frit or channels in the column bed can cause fronting. Replace the pre-column frit or the analytical column itself [8].

- Temperature Mismatch: This occurs mainly with larger internal diameter columns at high temperatures. Use an eluent pre-heater to ensure the mobile phase and column are at the same temperature [8].

- Sample Solvent Incompatibility: Ensure the sample is dissolved in a solvent compatible with the mobile phase [7].

Inadequate Resolution and Efficiency

Q: How can I improve the resolution between two poorly separated peaks?

Resolution is a function of efficiency, selectivity, and retention [14].

- Possible Causes and Solutions:

- Adjust Mobile Phase Composition: Altering the ratio of solvents can improve selectivity and separation. For reversed-phase chromatography, modifying the organic-to-aqueous solvent ratio is a primary tool [14].

- Change Column Temperature: Adjusting the column temperature can enhance peak separation and reduce analysis time [14].

- Use a Different Stationary Phase: Switching to a column with different chemistry (e.g., C8, phenyl, cyano) can alter selectivity through different interactions with the analytes [14].

- Increase Column Length or Reduce Particle Size: Longer columns provide more theoretical plates for separation, and smaller particles increase efficiency. Both can improve resolution, though at the cost of potentially higher backpressure [14].

Q: Why am I seeing broad peaks, and how does this affect my analysis?

Broad peaks indicate low column efficiency and can lead to poor resolution and reduced detection sensitivity.

- Possible Causes and Solutions:

- Extra-Column Volume Too Large: Using tubing with too large an internal diameter or excessive length between the injector and detector can cause significant band broadening. Use short, narrow internal diameter capillaries [8].

- Low Flow Rate: A flow rate that is too low can broaden peaks. Increase the flow rate within the system's pressure limits [7].

- Column Temperature Too Low: Increasing the column temperature can sharpen peaks [7].

- Column Contamination or Degradation: Contaminants build up on the column over time. Flush the column with a strong solvent or replace it [7] [8].

Retention Time Instability

Q: Why are my retention times drifting?

Retention time drift complicates peak identification and quantification.

- Possible Causes and Solutions:

- Poor Temperature Control: Fluctuations in column temperature cause retention time changes. Always use a thermostat-controlled column oven [7].

- Incorrect Mobile Phase Composition: The mobile phase may have been prepared incorrectly, or its composition may be changing due to evaporation. Prepare a fresh mobile phase and ensure the mixer is working correctly for gradient methods [7].

- Poor Column Equilibration: After a change in the mobile phase, the column needs sufficient time to equilibrate. Increase the column equilibration time [7].

- Change in Flow Rate: A slight change in the pump's flow rate will directly affect retention time. Check and reset the flow rate, and test it with a flow meter if possible [7].

Experimental Protocol: Measuring Column Performance

This protocol outlines the standard procedure for evaluating the performance of a new HPLC column or for periodic monitoring of an existing column.

1. Principle A test mixture is injected onto the column under isocratic conditions. The resulting chromatogram is used to calculate the column's efficiency (theoretical plates, N), peak asymmetry (As), and resolution (Rs) between critical pairs [15].

2. Materials and Reagents

- HPLC system with UV detector

- Column to be tested

- Mobile phase: (e.g., 50:50 Acetonitrile:Water, or as specified by the column manufacturer)

- Test mixture: A solution containing one or more certified standard compounds appropriate for the column type (e.g., uracil for dead time determination, and alkylparabens or other neutral markers for C18 columns)

3. Procedure

- 3.1. Prepare the mobile phase fresh, degas it thoroughly, and set the system to the specified flow rate (e.g., 1.0 mL/min for a 4.6 mm ID column) and temperature (e.g., 25°C).

- 3.2. Allow the system to equilibrate until a stable baseline is achieved. Monitor the pressure to ensure system stability.

- 3.3. Set the UV detector to an appropriate wavelength for the test analytes.

- 3.4. Make an injection of the test mixture and record the chromatogram.

4. Data Analysis

- 4.1. Efficiency (N): For each peak of interest, calculate the number of theoretical plates using the formula: ( N = 16 \times (tR / W)^2 ), where ( tR ) is the retention time and W is the peak width at the baseline [15].

- 4.2. Peak Asymmetry (As): For each peak, calculate the asymmetry factor at 10% of the peak height: ( As = b/a ), where 'b' is the distance from the peak center to the trailing edge and 'a' is the distance to the leading edge [15].

- 4.3. Resolution (Rs): For two adjacent peaks, calculate the resolution using the formula: ( Rs = \frac{2(t{R2} - t{R1})}{W1 + W2} ) [14] [15].

5. Interpretation Compare the calculated values for N, As, and Rs against the column manufacturer's specifications or your laboratory's historical data and acceptance criteria. Significant deviations indicate a potential problem with the column or the instrument.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagents and Materials for HPLC Method Development and Troubleshooting

| Item | Function / Purpose |

|---|---|

| C18 Column | A versatile reversed-phase column using octadecylsilyl silica; ideal for separating non-polar to moderately polar compounds [14]. |

| Guard Column | A small, disposable cartridge placed before the analytical column to protect it from particulate matter and strongly adsorbed compounds, extending its lifetime [7] [8]. |

| HPLC-Grade Solvents | High-purity solvents (e.g., Acetonitrile, Methanol, Water) used for mobile phase preparation to minimize baseline noise and UV absorption [7] [8]. |

| Buffers (e.g., Phosphate, Formate) | Salts added to the mobile phase to control pH and ionic strength, which helps maintain consistent ionization states of analytes and stable retention times [14] [7]. |

| Theoretical Plate Standard | A certified reference material (e.g., alkylparaben mix) used to calculate the efficiency (N) of a column according to established protocols [15]. |

| Tailing Reference Standard | A specific compound (often basic, like amitriptyline) used to assess a column's peak asymmetry factor and identify undesirable silanol activity [8] [15]. |

| Strong Solvent (e.g., >90% ACN or MeOH) | Used for periodic column flushing to remove strongly retained contaminants and perform routine cleaning and regeneration [7]. |

| Naphthomycin B | Naphthomycin B, MF:C39H44ClNO9, MW:706.2 g/mol |

| Clozapine-d3 | Clozapine-d3, MF:C18H19ClN4, MW:329.8 g/mol |

Performance Metrics Interrelationship

The diagram below illustrates how the core HPLC performance metrics are interrelated and how they are influenced by various method parameters. This logical relationship is key to systematic troubleshooting.

Frequently Asked Questions

What are the most common symptoms of HPLC separation failure? The most common symptoms include pressure fluctuations, peak tailing or broadening, baseline noise or drift, retention time shifts, and the appearance of extra peaks [9]. These issues often point to specific component failures within the HPLC system.

My peak area and height are changing unexpectedly. What should I check first? The autosampler is the most likely culprit [16]. Begin by ensuring your rinse phase is properly degassed. Then, prime and purge the metering pump to remove any air bubbles [16].

I see an extra peak in my chromatogram. What does this mean? An extra peak can be caused by the autosampler or the column [16]. Perform blank injections to investigate. If the extra peak is wider than its neighbors, it could be a late-eluting compound from a previous run. If the peak area remains constant after several blank injections, the contamination is likely inside the needle or sample loop [16].

Why is my baseline so jagged or noisy? A jagged baseline is commonly caused by temperature fluctuations, dissolved air in the mobile phase, a dirty flow cell, or insufficient mobile phase mixing [16] [9]. Start troubleshooting by using freshly prepared, high-purity HPLC-grade solvents and ensure all mobile phase components are properly degassed [9].

Troubleshooting Guide: From Symptom to Solution

This section provides a structured approach to diagnosing and resolving common HPLC issues. Use the following guide to match the symptoms you observe with their potential causes and recommended solutions.

HPLC Symptom Diagnosis Table

| Symptom | Likely Culprit | Common Causes | Recommended Solution |

|---|---|---|---|

| Pressure Fluctuations [9] | Pump, Tubing, Leaks [9] | System leaks, blocked inlet filters, gas bubbles in the pump [9] | Check for leaks, inspect and clean filters, degas and purge pump [9] |

| Peak Tailing [9] | Column, Fittings [16] [9] | Column degradation, void volume from poorly installed fittings or improper tubing cut [16] | Flush or replace column [9]; check and re-make tubing connections [16] |

| Peak Broadening [9] | Column, Method | Thermal mismatch between column and mobile phase, high flow rates, old column [9] | Use a column oven, adjust flow rate, flush column with strong solvent or replace [9] |

| Baseline Noise [9] | Mobile Phase, Detector | Contaminated solvents, detector instability, temperature fluctuations [9] | Use fresh HPLC-grade solvents, degas mobile phase, verify detector settings (e.g., lamp intensity) [9] |

| Retention Time Shifts [9] | Pump, Mobile Phase | Mobile phase composition inconsistency, column degradation, flow rate irregularities from pump malfunctions [9] | Check pump for leaks/irregular flow, ensure consistent mobile phase preparation, equilibrate column [9] |

| Changing Peak Area/Height [16] | Autosampler | Air bubbles in metering pump, improperly degassed rinse phase [16] | Prime and purge metering pump, ensure rinse phase is degassed [16] |

| Extra Peaks [16] | Autosampler, Column | Carryover from previous injections, contamination in needle/loop, late-eluting peaks [16] | Perform blank injections, adjust needle rinse parameters, extend method run time [16] |

| Peak Splitting [16] | Tubing, Fittings | Void volume in tubing connections, scratched autosampler rotor [16] | Check all tubing connections for voids; inspect and replace autosampler rotor if damaged [16] |

Detailed Experimental Protocols for Troubleshooting

Protocol 1: Systematic Problem Isolation When a problem is identified, the first step is to isolate the cause by removing one component at a time from the flow path and repeating a test until the issue is resolved [9]. This "Rule of One" is critical—only change or modify one item at a time to correctly identify the source of the problem [16].

Protocol 2: Column Performance Verification To verify if the column is the source of an issue (such as peak tailing or retention time shifts), flush the column per the manufacturer's instructions with a stronger solvent than the current mobile phase [9]. If chromatography does not improve, replace the column. To confirm performance, test the column with a standard compound of known behavior [9].

Protocol 3: Autosampler Carryover Check To diagnose extra peaks caused by carryover, perform a series of blank injections [16]. If the extra peak's area remains the same after several blanks, the contamination is likely inside the needle or sample loop. In this case, attempt to rinse the flow line and adjust internal needle rinsing parameters [16].

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function | Application Notes |

|---|---|---|

| HPLC-Grade Solvents | High-purity mobile phase components | Minimize baseline noise and prevent column contamination; replace frequently, especially aqueous solvents and buffers [9]. |

| Guard Column | Protects the analytical column | Traps particulates and compounds that could bind strongly to the analytical column; extends analytical column life [9]. |

| In-Line Filters | Filters particulates from the mobile phase | Prevents blockages in tubing and the column, helping to avoid pressure fluctuations [9]. |

| Standard Compound | Verifies system and column performance | A compound with known retention time and peak shape; used to test the column when performance issues are suspected [9]. |

| Seals and Fittings | Maintain a leak-free flow path | Worn pump seals or improperly installed fittings can cause leaks, pressure issues, and void volumes leading to peak tailing [16] [9]. |

| Doxycycline calcium | Doxycycline calcium, MF:C22H20Ca2N2O8, MW:520.6 g/mol | Chemical Reagent |

| Docetaxel-d5 | Docetaxel-d5, MF:C43H53NO14, MW:812.9 g/mol | Chemical Reagent |

HPLC Troubleshooting Workflow

The following diagram illustrates a logical workflow for diagnosing common HPLC problems, guiding you from initial symptom observation to potential solutions.

Symptom Isolation Pathway

This diagram details the process of isolating the root cause of a chromatographic issue by testing system components individually, a key methodology for efficient troubleshooting.

Advanced Separation Techniques: Implementing 2D-LC and Method Development Strategies

Comprehensive Two-Dimensional Liquid Chromatography (LC×LC) Principles

FAQs: Core Principles and Application

Q1: What is the fundamental principle behind Comprehensive Two-Dimensional Liquid Chromatography (LC×LC)?

LC×LC is an advanced separation technique that subjects the entire sample to two distinct and independent separation mechanisms. The key principle is that the effluent from the first dimension (1D) column is continuously transferred, in small fractions, to a second dimension (2D) column. Each fraction undergoes a rapid, separate separation in the 2D column, often using a different separation mechanism (e.g., reversed-phase followed by hydrophilic interaction). This process significantly increases the peak capacity (the number of peaks that can be separated) compared to one-dimensional LC, making it ideal for complex samples like proteomic digests or natural product extracts where single-dimension separation is insufficient [17].

Q2: When should a researcher consider using LC×LC over 1D-LC?

LC×LC should be considered when analyzing highly complex samples where 1D-LC provides insufficient separation, leading to coelution of analytes. This is often the case in untargeted analyses where the goal is to characterize as many sample components as possible. For targeted methods focusing on a few specific analytes, a well-optimized 1D-LC method is usually sufficient. The main trade-off is that LC×LC method development is more resource-intensive and requires deep knowledge to manage numerous interdependent parameters [17].

Q3: What are the primary challenges in LC×LC method development?

The primary challenge is the large number of interdependent parameters that must be optimized. These include [17]:

- Kinetic Parameters: Affecting efficiency and analysis time (e.g., 1D and 2D column dimensions, particle sizes, flow rates, and gradient slopes).

- Thermodynamic Parameters: Affecting selectivity and retention (e.g., mobile phase composition, stationary phase chemistries in both dimensions, pH, and temperature). Optimizing these parameters manually is time-consuming and requires significant expertise. Furthermore, phenomena like under-sampling (incomplete transfer of 1D effluent) and 2D sample dilution can degrade the overall separation quality and must be managed during method development [17].

Troubleshooting Common LC×LC Experimental Issues

Q1: How do I resolve high backpressure in one dimension of my LC×LC system?

High pressure typically indicates a blockage. Follow a systematic, "divide and conquer" approach by isolating sections of the flow path [18] [19].

- Locate the Blockage: With the flow off, start from the detector end and disconnect components one at a time. After each disconnection, turn the flow back on and check the pressure.

- Common Blockage Points: The most common points are the 0.5-μm in-line filter located downstream of the autosampler or the frit at the head of the guard or analytical column. A significant pressure drop after removing a specific component identifies the location of the blockage [18].

- Solution: Replace the blocked in-line filter or guard column frit. If the analytical column frit is blocked, the column can sometimes be reversed and flushed according to the manufacturer's instructions, though replacement is often required [18].

Q2: My chromatogram shows peak tailing or broadening. What are the likely causes and solutions?

Poor peak shape can originate from several sources. The following table outlines common symptoms, causes, and solutions adapted from 1D-LC principles, which are also applicable to LC×LC [20] [8].

Table 1: Troubleshooting Peak Shape Problems in LC×LC

| Symptom | Common Causes | Recommended Solutions |

|---|---|---|

| Peak Tailing | - Column overloading- Worn/degraded column- Contamination- Silanol interactions (for silica-based phases) | - Dilute sample or reduce injection volume [20]- Replace or regenerate the column [20]- Prepare fresh mobile phase; flush column; replace guard column [20]- Add buffer (e.g., ammonium formate) to mobile phase to block active sites [20] |

| Peak Fronting | - Solvent incompatibility (sample solvent stronger than mobile phase)- Column degradation (e.g., void formation) | - Dilute sample in a solvent matching or weaker than the initial mobile phase [20] [8]- Replace the column [20] |

| Broad Peaks | - Excessive system volume- Low column temperature- Low flow rate- Detector cell volume too large | - Use shorter, smaller internal diameter tubing to reduce extra-column volume [20] [8]- Increase column temperature [20]- Increase mobile phase flow rate (if pressure allows) [20]- Use a detector flow cell with a smaller volume [8] |

Q3: What strategies can I use to optimize the separation efficiency and analysis time in LC×LC?

Optimization requires balancing kinetic and thermodynamic parameters. Chemometric-driven approaches, such as Pareto optimization (PO), are particularly powerful for LC×LC [17].

- Kinetic Optimization: This involves adjusting parameters that affect efficiency and speed. PO can simultaneously optimize 1D and 2D column dimensions, particle sizes, and flow rates to maximize peak capacity while minimizing analysis time and dilution factor [17].

- Thermodynamic Optimization: This focuses on improving selectivity by changing the chemistry of the separation. Strategies include [17]:

- Using mobile phase additives and different pH values.

- Employing column characterization models (e.g., the Hydrophobic Subtraction Model) to select stationary phases with complementary selectivity for the two dimensions.

- Implementing automated column screening frameworks to rapidly identify the best combination of stationary phases.

The diagram below illustrates a generalized workflow for troubleshooting and optimizing an LC×LC method, integrating both fundamental checks and advanced strategies.

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful LC×LC experimentation relies on high-quality materials and reagents to ensure reproducibility, sensitivity, and column longevity. The following table details key solutions and their functions.

Table 2: Key Research Reagent Solutions for LC×LC

| Item | Function & Importance | Application Note |

|---|---|---|

| LC-MS Grade Solvents & Additives | High-purity solvents minimize baseline noise and prevent contamination of the ion source, which is critical for maintaining sensitivity, especially when coupled with MS detection [20] [21]. | Use formic acid, acetic acid, ammonium formate, or ammonium acetate as volatile additives. Avoid non-volatile buffers like phosphates in LC-MS [21]. |

| In-line Filters & Guard Columns | Placed between the autosampler and the 1D column, these components protect expensive analytical columns from particulate matter and chemical contaminants present in samples or mobile phases [18] [20]. | Use a 0.5-μm porosity in-line filter. Replace the guard column regularly. Match the guard column's stationary phase to your analytical column [18] [20]. |

| Characterized Stationary Phases | Columns with well-understood selectivity (e.g., characterized by models like the Hydrophobic Subtraction Model) are essential for rationally selecting orthogonal separation mechanisms for the 1D and 2D, which is the foundation of a successful LC×LC separation [17]. | Build a panel of columns with different selectivities (e.g., C18, phenyl-hexyl, HILIC) for method development screening [22] [17]. |

| Benchmarking Standard | A well-characterized compound mixture (e.g., containing reserpine) used for system performance monitoring. It is the first diagnostic tool when problems occur, helping to isolate issues to the method/sample versus the instrument itself [21]. | Run the benchmarking method regularly when the system is performing well to establish a baseline. Run it at the first sign of trouble to diagnose the problem's origin [21]. |

| TH-Z827 | TH-Z827, MF:C30H38N6O, MW:498.7 g/mol | Chemical Reagent |

| BMS-200 | BMS-200, MF:C27H27F2NO6, MW:499.5 g/mol | Chemical Reagent |

Multi-second dimension comprehensive two-dimensional liquid chromatography (multi-2D LC×LC) represents a significant advancement in separation science, particularly for analyzing highly complex samples. This technique enhances traditional comprehensive 2D-LC (LC×LC) by incorporating two different second-dimension (²D) columns with orthogonal separation mechanisms, selected automatically during the analysis based on the chemical properties of the analytes eluting from the first dimension [23].

In the context of troubleshooting HPLC separation problems, this configuration is especially powerful for resolving challenges encountered when coupling normal-phase or hydrophilic interaction liquid chromatography (HILIC) with reversed-phase (RP) separations. The primary benefit is the maximum separation power, as it allows the system to direct early-eluting polar compounds to a HILIC column and later-eluting, less polar compounds to an RP column, thereby optimizing the separation for all components in a complex mixture [23].

Troubleshooting Guides

Mobile Phase Mismatch and Breakthrough Peaks

Problem: Severe peak broadening or breakthrough (elution in the void volume) in the ²D separation, particularly when transferring from a HILIC first dimension (with high organic effluent, e.g., >70% ACN) to an RP second dimension (with an aqueous-rich mobile phase) [24].

Root Cause: The large volume of ¹D effluent acts as the initial injection solvent for the ²D column. In HILIC-RP couplings, the high organic content from the ¹D drastically weakens the eluting strength for the RP column, preventing analytes from being effectively retained and focused at the head of the ²D column [24].

Solutions:

- Active Solvent Modulation (ASM): This approach uses valve technology to temporarily adjust the composition of the ¹D effluent—for instance, by reducing the acetonitrile percentage—before it is injected into the ²D column. This ensures the injection solvent is compatible with the ²D starting conditions, preventing breakthrough and improving peak shape [24].

- At-Column Dilution (ACD): A pump is used to add a diluent (e.g., aqueous buffer) directly to the ¹D effluent as it exits the column, modifying its strength before it reaches the ²D column [24].

- Optimize Injection Volume: For a 2.1 mm id ²D column, recommended injection volumes are typically 0.5-5 µL. Excessively large volumes can cause column overload and peak distortion [25].

Poor Peak Shape in the Second Dimension

Problem: Tailing or fronting peaks in the ²D chromatogram.

Root Cause: This can arise from multiple sources, including secondary interactions with active sites on the stationary phase, column overload (too much mass or volume), or a mismatch between the injection solvent and the ²D mobile phase [25] [26].

Solutions:

- Match Injection Solvent Strength: The solvent used to introduce the ¹D fraction into the ²D must closely match the initial mobile phase conditions of the ²D gradient. For RP columns, this means an aqueous-rich solvent; for HILIC columns, a high-organic solvent (>50% ACN) is required [27] [25].

- Adjust Buffer Concentration: Insufficient buffer concentration can lead to peak tailing due to unwanted ionic interactions. Increasing the buffer concentration (e.g., to 10 mM as a starting point) can mask these secondary interactions and improve peak shape. Be aware that high buffer concentrations can suppress signal in mass spectrometry [25].

- Use Inert Stationary Phases: For analytes prone to silanol interactions, use ²D columns with highly inert stationary phases, such as heavily end-capped silica or alternative base-deactivated materials [26].

Retention Time Drift and Irreproducibility

Problem: Inconsistent retention times in the ²D separation, particularly with HILIC mechanisms.

Root Cause: HILIC columns are highly sensitive to equilibration status because the separation relies on a stabilized water layer on the polar stationary phase. Insufficient equilibration between gradients is a common cause of retention time drift [27] [25].

Solutions:

- Ensure Adequate Column Equilibration: HILIC columns require longer re-equilibration times than RP columns. After a gradient, flush the column with a minimum of 10-20 column volumes of the starting mobile phase before the next injection [27] [25].

- Proper Mobile Phase Buffering: Ensure both the aqueous and organic mobile phases contain the same buffer concentration to maintain consistent ionic strength during the gradient, which is critical for stable MS response and retention [27].

- Verify Mobile Phase Preparation: Accurately prepare mobile phases with consistent pH and buffer strength, as minor changes can significantly impact the retention of ionizable analytes [26].

System Configuration and Pressure Problems

Problem: System complexity and unexpected pressure spikes when configuring multi-2D LC×LC.

Root Cause: The addition of a second ²D column, switching valves, and associated tubing increases system complexity and potential failure points. Pressure spikes often indicate a blockage, frequently at the column inlet frit [23] [26].

Solutions:

- Simplify Mobile Phase Requirements: When using a single pump for both ²D columns, select ²D chemistries (e.g., HILIC and C18) that can operate with the same mobile phase solvents, albeit in opposite gradient orders [23].

- Address Pressure Spikes: If pressure suddenly increases, start by disconnecting the column. If the pressure normalizes, the column is the culprit. Reversing and flushing the column with strong solvents can often clear the blockage [25] [26].

- Use In-Line Filters and Guard Columns: Protect expensive ²D columns from particulate matter by using in-line filters and guard columns, which are easier and cheaper to replace [26].

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of multi-2D LC×LC over standard LC×LC? Multi-2D LC×LC solves two key issues of standard LC×LC: solvent mismatch between dimensions and the lack of separation affinity of certain compounds for a single ²D column. By intelligently routing fractions to the most orthogonal ²D column (e.g., HILIC for polar compounds, RP for mid- to non-polar compounds), it maximizes the separation power for highly complex samples [23].

Q2: For which sample types is this technique most suitable? This technique is ideal for samples containing analytes with a very wide range of polarities. It has been successfully applied to natural product profiling (e.g., phenolic compounds in foods, cannabinoids, triterpene saponins), the analysis of biological molecules like monoclonal antibodies, and in fields like environmental analysis (pesticides, PAHs) and clinical research [24] [23].

Q3: Is multi-2D LC×LC substantially more complex than traditional 2D-LC? While the initial instrumentation and method development are undeniably more complex, the fundamental principles are the same. The setup requires an additional automatic switching valve to select between the two ²D columns. Method development involves optimizing conditions for each ²D column individually before combining them in the multi-2D setup [23].

Q4: How can I minimize the risk of breakthrough peaks when coupling HILIC and RP? The most effective strategy is to use an active modulation technique like Active Solvent Modulation (ASM) or At-Column Dilution (ACD). These technologies actively modify the strength of the ¹D effluent before it enters the ²D column, ensuring optimal focusing and retention [24].

Q5: Why am I seeing ghost peaks in my blank injections? Ghost peaks are typically caused by carryover from previous samples, contaminants in the mobile phases or vials, or column bleed. To troubleshoot, run a series of blank injections, thoroughly clean the autosampler (including the needle and loop), use fresh high-purity mobile phases, and consider replacing the column if it is old or degraded [26].

Essential Experimental Parameters and Data

Key Operational Parameters for HILIC and RP in Multi-2D LC×LC

The table below summarizes critical parameters to consider during method development for a multi-2D LC×LC system incorporating HILIC and RP phases.

Table 1: Key Operational Parameters for HILIC and RP Phases

| Parameter | HILIC Mode | Reversed-Phase (RP) Mode |

|---|---|---|

| Strong Solvent | Water (high % aqueous) [27] | Organic solvent (e.g., ACN, MeOH) [24] |

| Weak Solvent | Organic solvent (e.g., >60% ACN) [24] [27] | Water (high % aqueous) [24] |

| Injection Solvent | High organic content (>50% ACN) [25] | High aqueous content [25] |

| Buffer Concentration | Start at 10 mM; monitor for precipitation [27] [25] | Start at 10 mM; compatible with MS [25] |

| Equilibration Volume | 10-20 column volumes (longer than RP) [25] | Typically fewer column volumes than HILIC [25] |

| Common Buffers | Volatile (Ammonium formate/acetate) [27] | Volatile (Ammonium formate/acetate) [27] |

Research Reagent Solutions

This table lists essential materials and their functions for establishing a robust multi-2D LC×LC method.

Table 2: Essential Research Reagents and Materials

| Item | Function in Multi-2D LC×LC |

|---|---|

| PFP (Pentafluorophenyl) Column | Often used as the ¹D column for its unique selectivity and ability to separate a wide range of compound classes, providing a good foundation for the second-dimension separation [23]. |

| HILIC Column (e.g., bare silica) | Used as one ²D column to retain and separate highly polar compounds that are poorly retained in RP mode [23]. |

| C18 Column | Used as a ²D column for the separation of mid- to non-polar compounds, providing complementary selectivity to HILIC [23]. |

| Volatile Buffers (Ammonium Formate/Acetate) | Essential for maintaining pH and ionic strength in both dimensions while being compatible with mass spectrometry detection [27]. |

| Active Solvent Modulator (ASM) | Interface technology used to adjust the composition of the ¹D effluent before injection onto the ²D column, preventing breakthrough and peak distortion caused by mobile phase mismatch [24]. |

| Two-Position Six-Port Switching Valve | The core hardware that enables the automatic selection between the two ²D columns based on the elution time from the ¹D column [23]. |

System Workflow and Configuration

The following diagram illustrates the instrumental setup and logical workflow of a multi-2D LC×LC system, showing how fractions are directed to the most appropriate second-dimension column.

Multi-2D LC×LC System Workflow: This diagram shows the instrumental configuration. The ¹D separation (e.g., on a PFP column) occurs first. The modulator collects effluent fractions and, with the ²D pump, prepares them for the second dimension. A switching valve automatically directs each fraction to the most orthogonal ²D column—HILIC for early-eluting polar compounds or RP-C18 for later-eluting non-polar compounds—before detection and data analysis [23].

Method Development Workflow for Challenging Separations

High Performance Liquid Chromatography (HPLC) method development is a systematic, multi-stage process essential for achieving robust and reproducible separations, particularly for complex samples in pharmaceutical research and drug development. A well-developed method ensures accurate quantification of active ingredients, identification of impurities, and reliable quality control. This guide provides a structured workflow and troubleshooting resources to help scientists navigate challenging separations, framed within the broader context of troubleshooting HPLC separation problems.

Core Method Development Workflow

The development of a robust HPLC method follows a logical progression from initial scouting to final validation. The workflow below outlines the key stages involved in this process.

Figure 1: The systematic workflow for HPLC method development, from initial sample preparation to final validation.

Step 1: Sample Preparation and Matrix Analysis

Objective: To prepare a representative sample solution while mitigating matrix effects that can interfere with analysis [28].

Sample preparation is critical for successful HPLC and UHPLC analyses. The goals include converting samples into a suitable liquid form, simplifying complex mixtures, removing interfering matrix components, and concentrating or diluting analytes [28]. The table below summarizes common sample preparation techniques.

Table 1: Common Sample Preparation Techniques and Their Applications [28]

| Technique | Analytical Principle | Primary Application |

|---|---|---|

| Dilution | Decreases analyte, solvent, or matrix concentration | Prevents column/detector overloading; reduces sample solvent elution strength |

| Centrifugation | Sedimentation based on density | Removes large cellular components from solution |

| Filtration | Removes particulates from sample | Extends column lifetime; prevents clogging of fluidics |

| Protein Precipitation | Desolubilizes proteins by adding salt, solvent, or altering pH | Removal of protein from solution |

| Solid Phase Extraction (SPE) | Selective separation/purification using a sorbent | Isolating small molecules from biological matrices; desalting large biomolecules |

| Derivatization | Chemical reaction to alter analyte properties | Improves analyte retention, stability, or detectability |

Matrix Effects: The sample matrix encompasses everything in the sample except the analytes of interest. Matrix effects can cause bias in analyte quantification and manifest as co-elution of interfering compounds, pH altering retention, or ion suppression in mass spectrometry [28]. Mitigation strategies include sample dilution, extraction, using 2D-LC, or switching to a more selective detection method [28].

Step 2: Selection of HPLC Method and Initial System

Objective: To choose the most appropriate chromatographic mode and initial hardware based on analyte and sample properties [29] [30].

Chromatography Mode Selection:

- Reversed-Phase (RP-HPLC): The choice for the majority of samples [29]. Use C18-bonded phases as a starting point [29] [30].

- Ion Suppression RP-HPLC: For weak acids or bases [29] [30].

- Ion-Pairing RP-HPLC: For strong acids or bases [29] [30].

- Normal-Phase (NP-HPLC): For low/medium polarity analytes or separation of isomers. Cyano-bonded phases are recommended over plain silica [29].

- Hydrophilic Interaction Liquid Chromatography (HILIC): A powerful alternative for separating polar compounds [31].

- Ion Exchange (IEC): Best for inorganic anion/cation analysis [29] [30].

- Size Exclusion (SEC): For high molecular weight compounds (>2000) [29] [30].

Gradient vs. Isocratic Elution:

Initial Column and Detector Selection:

- Column: Start with short columns (10-15 cm) packed with 3 or 5 µm particles to reduce method development time [29]. A flow rate of 1-1.5 mL/min is recommended initially [29] [30].

- Detector: A UV/Visible detector is standard [29]. For the greatest sensitivity, use the analyte's λmax, but avoid wavelengths below 200 nm where noise increases [29]. Use Photodiode Array (PDA) detection for peak purity assessment [32]. For trace analysis or non-chromophoric compounds, consider fluorescence or mass spectrometric detectors [29] [32].

Step 3: Selection of Initial Chromatographic Conditions

Objective: To find conditions where all analytes are adequately retained, with capacity factors (k') typically between 0.5 and 10-15 [29].

- Mobile Phase Solvent Strength: Adjust the concentration of the strong solvent (e.g., organic modifier in RP-HPLC) to bring all peaks within the desired retention window [29].

- Determination of Initial Conditions: A recommended approach involves performing two gradient runs with different run times using a binary system like acetonitrile/water or methanol/water [29].

Step 4: Selectivity Optimization

Objective: To achieve adequate selectivity (α), or peak spacing, for critical pairs [29].

Selectivity is the most significant parameter for improving resolution. Optimization should focus on parameters with the greatest impact [29]. The table below guides parameter selection based on analyte type.

Table 2: Selectivity Optimization Parameters Based on Analyte Type [29]

| Analyte Type | Primary Parameters to Optimize | Secondary Parameters |

|---|---|---|

| Neutral / Non-ionizable | Organic modifier type (e.g., Acetonitrile vs. Methanol) | Column temperature; Stationary phase |

| Acidic (pKa 3-5) | Mobile phase pH; Organic modifier type | Buffer concentration; Stationary phase |

| Basic (pKa 5-8) | Mobile phase pH; Organic modifier type | Buffer concentration; Stationary phase |

| Ions (Acids/Bases) | Ion-pair reagent concentration; Mobile phase pH | Buffer concentration; Organic modifier type |

- Mobile Phase pH: Operate at least 1.0 pH unit away from the analyte pKa to ensure analytes are fully ionized or non-ionized, which improves peak shape and reproducibility [32]. Use buffers in the aqueous portion to control the retention of ionic analytes and increase method ruggedness [32].

- Buffer Concentration: A concentration between 5-100 mM is usually sufficient [32].

- Organic Additives: Additives like triethylamine (TEA) for basic analytes or acetic acid for acidic analytes can help control peak tailing by interacting with residual silanols on the stationary phase [32].

- Stationary Phase: If mobile phase optimization fails, scout different column chemistries (e.g., C8, phenyl, cyano) [28] [32].

Step 5: System Parameter Optimization

Objective: To fine-tune the balance between resolution and analysis time after satisfactory selectivity is achieved [29].

Parameters like column dimensions, particle size, and flow rate can be changed without affecting capacity factors or selectivity [29]. For instance, using a shorter column or increasing the flow rate can reduce analysis time, potentially at the cost of some resolution.

Step 6: Robustness Testing

Objective: To determine the impact of small, deliberate variations in method parameters (e.g., pH, temperature, flow rate, mobile phase composition) on the separation [28].

This step is critical for identifying which parameters require tight control to ensure the method performs reliably during routine use. Modern software like ChromSword AutoRobust can streamline this multivariate testing [28].

Step 7: Method Validation

Objective: To formally verify that the HPLC method is fit for its intended purpose [28] [29].

Method validation is an industry-specific, systematic process [28]. For pharmaceutical quality control, methods must be validated according to regulatory guidelines (ICH, USP, FDA) [29]. The most widely applied validation characteristics include [29]:

- Accuracy

- Precision (Repeatability, Intermediate Precision)

- Specificity

- Detection Limit (LOD)

- Quantitation Limit (LOQ)

- Linearity

- Range

- Robustness

Troubleshooting Common HPLC Separation Problems

Even well-developed methods can encounter issues. The following guide addresses common problems, their causes, and solutions.

Pressure Anomalies

Table 3: Troubleshooting Guide for HPLC Pressure Issues [12] [33] [7]

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| High Pressure | - Clogged column or guard column- Salt precipitation- Blocked inlet frit or tubing- Flow rate too high | - Flush column with water (40-50°C), followed by strong solvent [12]- Backflush column (if permitted) [33]- Reduce flow rate temporarily [12] [7]- Replace clogged frits, guard column, or tubing |

| Low Pressure | - System leak- Flow rate too low- Air in pump- Check valve failure | - Inspect and tighten fittings; replace damaged seals [12] [7]- Increase flow rate [7]- Purge pump to remove air [12]- Clean or replace check valves [33] |

| Pressure Fluctuations | - Air bubbles in system- Leak- Failing pump seal- Malfunctioning check valve- Incomplete mixing (gradients) | - Degas mobile phase thoroughly [12] [7]- Identify and fix leak [7]- Replace pump seal [7]- Clean or replace check valve [12] [33] |

Peak Shape Problems

Table 4: Troubleshooting Guide for Abnormal Peak Shapes [12] [33] [7]

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Peak Tailing(As > 1.2) | - Secondary interactions with residual silanols (most common)- Column bed deformation (void)- Partially blocked frit- Inappropriate mobile phase pH | - Use a highly deactivated, end-capped column [33]- Operate at a lower pH to suppress silanol ionization [33]- Reverse the column and flush [33]- Use mobile phase additives (e.g., TEA) [32] |

| Peak Fronting | - Column overload- Sample solvent too strong- Column stationary phase depleted | - Reduce injection volume; dilute sample [33] [7]- Ensure sample is dissolved in mobile phase or weaker solvent [33] [7]- Replace column [7] |

| Broad Peaks | - Mobile phase composition changed- Flow rate too low- Leak between column and detector- Column contamination- Extra-column volume (long, wide tubing) | - Prepare fresh mobile phase [7]- Increase flow rate [7]- Check for and fix leaks [7]- Flush or replace column [7]- Use shorter, narrower internal diameter tubing [7] |

Retention Time and Baseline Issues

Table 5: Troubleshooting Guide for Retention Time and Baseline Problems [12] [33] [7]

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Retention Time Drift | - Poor temperature control- Incorrect mobile phase composition- Insufficient column equilibration (gradient)- Change in flow rate- Column aging | - Use a thermostat column oven [7]- Prepare fresh mobile phase consistently [12] [7]- Increase equilibration time (≥10 column volumes) [33]- Reset flow rate; check pump performance [7]- Flush column with strong solvent or replace [33] |

| Baseline Noise & Drift | - Air bubbles in detector- Contaminated mobile phase or detector cell- Leak- Old or defective detector lamp- UV-absorbing mobile phase- Temperature instability | - Degas mobile phase; purge system [12] [7]- Use high-purity solvents; clean flow cell [12] [7]- Identify and fix leak [7]- Replace lamp [7]- Use HPLC-grade solvents without UV absorption [7]- Maintain stable lab temperature [12] |

| Ghost Peaks | - Contamination in injector or column- Contaminated mobile phase- Late-eluting compounds from previous runs | - Flush injector and column with strong solvent [33] [7]- Prepare fresh mobile phase [7]- Include a final wash step in gradient methods [33] |

Frequently Asked Questions (FAQs)

Q1: What are the four main steps in HPLC method development? A1: The four main steps are: 1) Method Scouting (screening columns and eluents), 2) Method Optimization (iterative testing for best resolution and speed), 3) Robustness Testing (determining the impact of parameter changes), and 4) Method Validation (formal process to prove the method is fit for purpose) [28].

Q2: How can I reduce peak tailing for a basic compound? A2: Peak tailing for basic compounds is often due to interactions with acidic residual silanols on the silica stationary phase. To mitigate this: a) Use a highly deactivated, end-capped column designed for basic compounds; b) Operate at a lower pH (e.g., pH 3) to suppress silanol ionization; c) Add a competing base like triethylamine (TEA) to the mobile phase to block silanol sites; and d) Ensure adequate buffer concentration [33] [32].

Q3: My retention times are inconsistent from run to run. What should I check? A3: First, ensure the system is fully equilibrated, especially after a gradient or mobile phase change—this may require 10-20 column volumes [33]. Second, check that the mobile phase is prepared consistently and accurately. Third, verify that the column temperature is controlled using an oven. Fourth, inspect the system for leaks or pump malfunctions that could cause flow rate variations [12] [7].

Q4: When should I use HILIC chromatography? A4: Use Hydrophilic Interaction Liquid Chromatography (HILIC) for separating polar and hydrophilic compounds that are poorly retained in reversed-phase HPLC. This includes compounds like sugars, amino acids, organic acids, and metabolites. HILIC requires careful attention to mobile phase preparation, buffer selection, and longer column equilibration times [31].

Q5: What is the simplest way to mitigate matrix effects? A5: If analyte sensitivity is adequate, the most straightforward approach is to dilute the sample with a suitable injection solvent. A more dilute sample presents a smaller amount of matrix to the system, thereby reducing the matrix effect. Other solutions include implementing a sample extraction or clean-up procedure (e.g., Solid Phase Extraction) or switching to a more selective detection method [28].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 6: Essential Materials and Reagents for HPLC Method Development [28] [29] [32]

| Item | Typical Function / Purpose | Examples & Notes |

|---|---|---|

| C18 Bonded Silica Column | The default reversed-phase stationary phase for most applications. | Various particle sizes (3, 5 µm) and dimensions (e.g., 150 x 4.6 mm). The workhorse of HPLC [29] [30]. |

| Buffers (e.g., Phosphate, Acetate) | Controls mobile phase pH to ensure consistent ionization state of analytes, crucial for reproducibility. | Use 5-100 mM concentration. Prepare fresh and filter. Flush system thoroughly after use [32]. |

| Ion-Pair Reagents | Imparts retention to ionic analytes (strong acids/bases) on reversed-phase columns. | Alkyl sulfonates for bases; alkyl ammonium salts for acids. Use with caution as they can contaminate the system [29] [30]. |

| Triethylamine (TEA) | Mobile phase additive used to passivate acidic silanol sites on the stationary phase, reducing tailing of basic peaks. | Typically used at 0.1-0.5% v/v. An alternative to TEA for basic compounds [32]. |

| Guard Column | Protects the expensive analytical column from particulate matter and strongly retained contaminants. | Contains the same or similar packing as the analytical column. Extends column life and is cost-effective [12] [7]. |

| HPLC-Grade Solvents | Ensures high purity, low UV background, and minimal contaminants for reliable baselines and consistent results. | Acetonitrile and Methanol are common organic modifiers. Water must be ultra-pure (18.2 MΩ·cm) [29] [32]. |

| Inosine-13C5 | Inosine-13C5, MF:C10H12N4O5, MW:273.19 g/mol | Chemical Reagent |

| Cabergoline-d5 | Cabergoline-d5, MF:C26H37N5O2, MW:456.6 g/mol | Chemical Reagent |

Active Solvent Modulation and Other Modern LC×LC Innovations

In the evolving landscape of liquid chromatography, comprehensive two-dimensional liquid chromatography (LC×LC) represents a significant advancement for analyzing complex mixtures. Active Solvent Modulation (ASM) stands as a pivotal innovation within this domain, addressing fundamental challenges associated with solvent incompatibility between the first and second dimensions. This technical support center provides a structured troubleshooting framework for researchers implementing these sophisticated separations, framed within the broader thesis of improving HPLC problem-solving methodologies. The guidance herein addresses specific issues scientists encounter during method development and routine operation, enabling more robust and reproducible analyses in pharmaceutical development and other research applications.

Systematic Troubleshooting Methodology

Effective troubleshooting requires a logical, step-by-step approach to isolate variables and identify root causes efficiently. Following a systematic protocol prevents unnecessary part replacement and minimizes instrument downtime.

The Troubleshooting Control Cycle

A systematic approach to troubleshooting follows a defined control cycle: recognition, analysis, correction, and control [34]. The most challenging step is often connecting an observed symptom to the operator's recognition that a problem exists, which requires deep chromatographic knowledge and system familiarity.

The accompanying workflow, "Systematic Troubleshooting Process," illustrates this iterative cycle. When problems persist after correction, the process returns to the recognition phase for re-evaluation rather than proceeding with unsystematic component replacement.

Problem Classification Framework

Chromatographic problems can originate from multiple sources, and effective troubleshooting requires categorizing these sources to narrow diagnostic focus [34]:

- Chromatographic Problems: Related to eluent composition, buffer selection, column chemistry, or void volumes

- Mechanical Problems: Involving pump malfunctions, injector issues, fitting failures, or tubing defects

- Electrical/Electronic Problems: Affecting pump control, detector electronics, thermostat regulation, or data systems

- Chemical Problems: Stemming from sample composition, eluent purity, or column chemistry interactions

- Human Factors: Including injection technique, data interpretation, or mobile phase preparation errors

A critical rule during correction is to check only one system component at a time [34]. If multiple components are replaced simultaneously, it becomes impossible to determine which action actually resolved the problem.

HPLC Symptom Troubleshooting Guide

The following section addresses specific HPLC symptoms, their common causes, and validated solutions organized for efficient problem-solving.

Pressure-Related Problems

Pressure abnormalities are among the most frequent issues in HPLC operation and often indicate underlying problems requiring immediate attention.

Table 1: Pressure-Related Problems and Solutions

| Pressure Symptom | Possible Causes | Recommended Solutions |

|---|---|---|