HPLC vs. UV-Vis Spectrophotometry: A Comprehensive Guide to Advantages, Disadvantages, and Application Selection

This article provides a detailed comparative analysis of High-Performance Liquid Chromatography (HPLC) and UV-Vis Spectrophotometry for researchers and drug development professionals.

HPLC vs. UV-Vis Spectrophotometry: A Comprehensive Guide to Advantages, Disadvantages, and Application Selection

Abstract

This article provides a detailed comparative analysis of High-Performance Liquid Chromatography (HPLC) and UV-Vis Spectrophotometry for researchers and drug development professionals. It covers foundational principles, methodological applications across pharmaceutical and biomedical fields, practical troubleshooting guidance, and validation protocols. Synthesizing current research and case studies, the content delivers actionable insights for selecting the optimal analytical technique based on specific project goals, from routine quality control to complex bioanalysis, ensuring data accuracy and regulatory compliance.

Core Principles Unveiled: How HPLC and UV-Vis Spectrophotometry Work

High-Performance Liquid Chromatography (HPLC) is a pivotal analytical technique that plays a crucial role in separating, identifying, and quantifying compounds in complex mixtures across various scientific disciplines [1]. This column chromatography method involves the high-pressure injection of a sample (analyte) dissolved in a solvent (mobile phase) through a column packed with chromatographic material (stationary phase) [2]. The fundamental principle of HPLC separation revolves around the differential distribution of compounds between a stationary phase and a mobile phase, leading to separation based on chemical properties [1].

The dominance of HPLC as a premier analytical technique stems from its exceptional versatility in analyzing diverse analyte types, ranging from small organic molecules and ions to large biomolecules and polymers [3]. When coupled with mass spectrometry (MS), HPLC gains unparalleled sensitivity and specificity, creating what many consider "the perfect analytical tool" for bioanalytical testing, trace analysis, and life science research [3]. Furthermore, the exceptional precision and robustness of HPLC with ultraviolet (UV) detection make it indispensable for quality control applications in regulated industries [3].

Core Principles of Chromatographic Separation

The Chromatographic Process

The fundamental mechanism of HPLC separation operates on a simple principle: compounds within a mixture are separated based on their differential interactions with a stationary phase and a mobile phase [1]. The stationary phase typically consists of a solid adsorbent or a liquid-coated surface packed within the column, while the mobile phase is a liquid solvent or mixture of solvents that transports the sample through the system [1].

Three fundamental factors govern the separation process in HPLC: the compounds (solutes in the sample solution), the mobile phase (solution delivered using solvent delivery pumps), and the stationary phase (functional groups chemically modified onto particles packed in the column) [4]. Compounds that interact more strongly with the mobile phase elute faster from the column, while those that interact more strongly with the stationary phase are retained longer [4]. This "interaction" refers to the chemical attraction between molecules, and selecting the appropriate interaction type for the target compound's properties is essential for separation optimization [4].

Figure 1: Fundamental HPLC Separation Process

Primary Separation Modes

HPLC offers several separation modes that leverage different chemical interactions between analytes and the stationary phase. The choice of separation mode depends on the chemical properties of the target compounds and the specific analytical requirements [4].

Reversed-Phase Chromatography (RPC) is the most widely used separation mode, where separation is based on hydrophobicity [4]. Non-polar compounds interact more strongly with the hydrophobic stationary phase (typically C8 or C18 chains bonded to silica particles) and are thus retained longer, while polar compounds elute more quickly [1]. This method is particularly suitable for small molecule pharmaceuticals, vitamins, and many organic compounds [4].

Normal-Phase Chromatography (NPC) operates on the opposite principle, separating compounds based on hydrophilicity (high polarity) [4]. In this mode, polar compounds are retained longer by the polar stationary phase (such as silica with hydroxyl groups), while non-polar compounds elute first [1]. This technique is especially effective for saccharides, nucleic acids, and other highly polar compounds [4].

Ion-Exchange Chromatography (IEC) separates compounds based on electrostatic interactions between charged analytes and oppositely charged functional groups on the stationary phase [4]. This mode is particularly suitable for inorganic ions, amino acids, proteins, and other charged molecules [1] [4].

Size-Exclusion Chromatography (SEC) separates molecules based on their size, with larger molecules eluting earlier than smaller ones because they cannot enter the pores of the stationary phase and thus travel through the column more quickly [1]. This technique is valuable for analyzing synthetic polymers, biopolymers, and polysaccharides [4].

Table 1: HPLC Separation Modes and Their Applications

| Separation Mode | Basis of Separation | Primary Interactions | Typical Applications |

|---|---|---|---|

| Reversed-Phase | Hydrophobicity | Hydrophobic | Small molecule pharmaceuticals, vitamins [4] |

| Normal-Phase | Polarity | Hydrophilic, hydrogen bonding | Saccharides, nucleic acids [4] |

| Ion-Exchange | Charge | Electrostatic | Inorganic ions, amino acids, proteins [4] |

| Size-Exclusion | Molecular size | Steric hindrance | Synthetic polymers, biopolymers [1] [4] |

HPLC Instrumentation and Components

A modern HPLC system consists of several critical components that work in concert to achieve precise separations. The key modules include solvent reservoirs, high-pressure pumps, an injection system, the separation column, a detector, and data processing software [3].

The solvent delivery system comprises reservoirs for the mobile phase and high-pressure pumps that maintain a constant and pulse-free flow of solvent through the system. Modern HPLC pumps can deliver pressures up to 1000 bar or more in UHPLC systems, enabling the use of smaller particle sizes for enhanced efficiency [5] [3].

The injection system, typically an autosampler, introduces the sample into the mobile phase stream with high precision and reproducibility. Automated injectors enable the sequential analysis of numerous samples with minimal manual intervention, significantly improving throughput in analytical laboratories [3].

The chromatographic column serves as the heart of the HPLC system, where the actual separation occurs. Columns are typically stainless steel tubes packed with micron-sized particles that constitute the stationary phase. Recent innovations in column technology include superficially porous particles (also known as fused-core), monodisperse fully porous particles, and advanced bonding chemistries that enhance efficiency, peak shape, and separation speed [5].

The detection system identifies and quantifies the separated compounds as they elute from the column. Various detector types are available, with UV-Vis spectrophotometers being among the most common due to their versatility and robustness [3]. Other detection methods include fluorescence, refractive index, evaporative light scattering, and mass spectrometry, with the latter providing unparalleled sensitivity and specificity [3].

Figure 2: Simplified HPLC Instrumentation Schematic

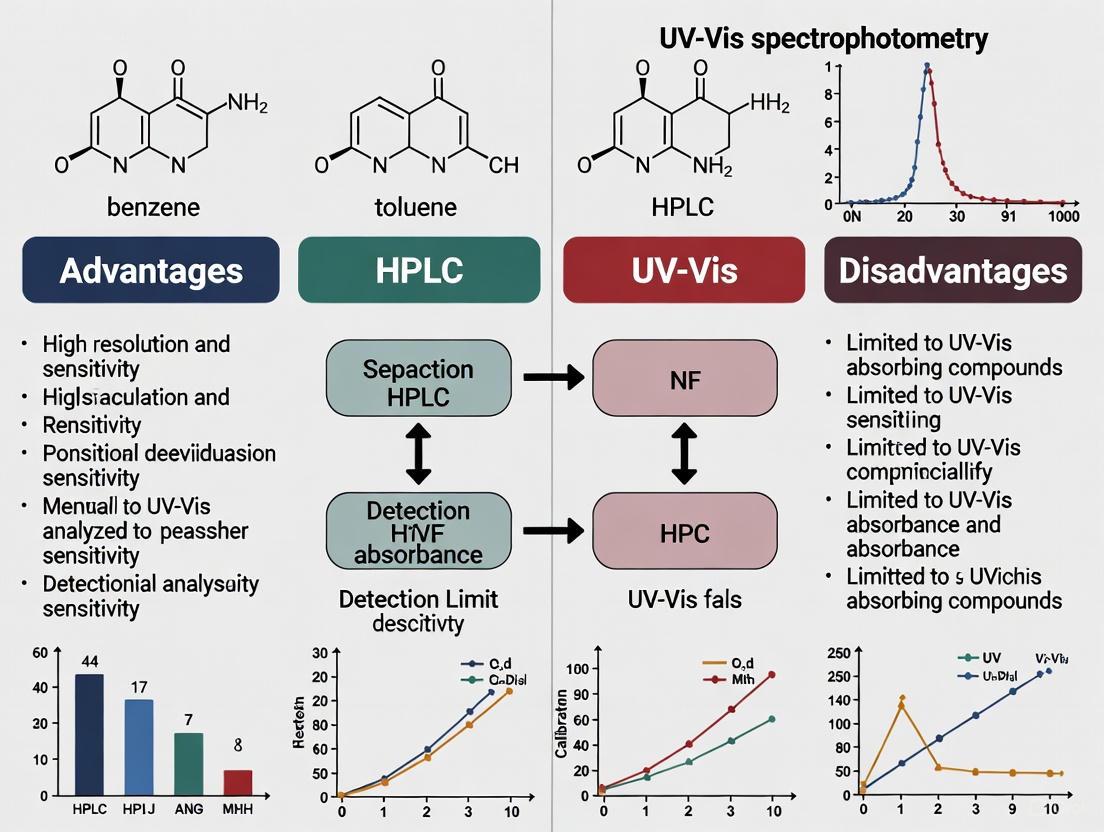

Comparative Analysis: HPLC vs. UV-Vis Spectrophotometry

Fundamental Differences in Principle and Application

While both HPLC and UV-Vis spectrophotometry are analytical techniques that utilize light absorption properties of compounds, they operate on fundamentally different principles and serve distinct purposes in analytical chemistry.

UV-Vis spectroscopy measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample in comparison to a reference or blank sample [6]. This technique provides information about electronic transitions in molecules and is primarily used for identification and quantification of chromophoric compounds in solution, but without physical separation of mixture components [6].

In contrast, HPLC is primarily a separation technique that physically resolves mixture components before detection. It utilizes differential partitioning between stationary and mobile phases to separate compounds, which are then typically detected and quantified using UV-Vis spectroscopy or other detection methods [1] [3]. This combination of separation with detection makes HPLC far more powerful for analyzing complex mixtures.

Experimental Comparison Study

A direct comparison of HPLC and UV-Vis spectrophotometry for determining Levofloxacin concentrations released from mesoporous silica microspheres/nano-hydroxyapatite composite scaffolds provides valuable insights into their relative performance characteristics [7].

Table 2: Method Comparison for Levofloxacin Analysis [7]

| Parameter | HPLC Method | UV-Vis Method |

|---|---|---|

| Regression Equation | y = 0.033x + 0.010 | y = 0.065x + 0.017 |

| Coefficient of Determination (R²) | 0.9991 | 0.9999 |

| Recovery Rate (Low Concentration) | 96.37 ± 0.50% | 96.00 ± 2.00% |

| Recovery Rate (Medium Concentration) | 110.96 ± 0.23% | 99.50 ± 0.00% |

| Recovery Rate (High Concentration) | 104.79 ± 0.06% | 98.67 ± 0.06% |

| Precision | High (low RSD) | Moderate |

The study demonstrated that while both methods showed excellent linearity, HPLC provided superior precision and more consistent recovery rates across different concentration levels, particularly for medium and high concentrations [7]. The researchers concluded that UV-Vis spectrophotometry is less accurate for measuring drug concentrations released from complex composite scaffolds, making HPLC the preferred method for evaluating sustained release characteristics in drug delivery systems [7].

Essential Research Reagent Solutions

Successful HPLC analysis requires careful selection of reagents and consumables tailored to the specific separation mode and application requirements. The following table outlines key research reagent solutions essential for HPLC operations.

Table 3: Essential HPLC Research Reagents and Materials

| Reagent/Material | Function/Description | Application Notes |

|---|---|---|

| Stationary Phases | Chromatographic media packed in columns | C18 for reversed-phase, silica for normal-phase, ion-exchange resins [5] [4] |

| Mobile Phase Solvents | Carrier for samples through the system | HPLC-grade methanol, acetonitrile, water, buffer solutions [3] |

| Reference Standards | Calibration and quantification | High-purity compounds for method development and calibration [3] |

| Inert Hardware Columns | Minimize metal-sensitive analyte interactions | Enhanced peak shape and recovery for phosphorylated compounds [5] |

| Guard Columns | Protect analytical columns from contamination | Extend column lifetime, typically 5 x 2.1 mm or 5 x 3.0 mm dimensions [5] |

Recent innovations in HPLC consumables focus on improving performance for specific applications. For instance, inert hardware columns with passivated surfaces minimize interactions with metal-sensitive analytes, particularly beneficial for phosphorylated compounds and biomolecules [5]. Similarly, advanced stationary phases like superficially porous particles (e.g., Halo, Ascentis Express) provide enhanced efficiency and peak shape for challenging separations [5].

Advantages and Limitations in Pharmaceutical Analysis

Strengths of HPLC in Drug Development

HPLC offers numerous advantages that make it indispensable in pharmaceutical research and quality control:

Exceptional Precision and Reproducibility: HPLC delivers highly reproducible assays with precision levels achieving <0.1% relative standard deviation (RSD) for UHPLC systems, which is crucial for regulatory compliance and quality control [3].

High-Sensitivity Assays: Modern HPLC systems can detect trace impurities at levels as low as 0.01%, meeting stringent regulatory requirements for pharmaceutical purity testing [3].

Comprehensive Component Analysis: HPLC can simultaneously separate, identify, and quantify multiple components in complex mixtures, including isomers and structurally related compounds [3].

Robustness Across Laboratories: Well-developed HPLC methods demonstrate excellent transferability between different laboratories, instruments, and analysts [3].

Versatile Detection Options: Compatibility with various detectors (UV, fluorescence, MS) enables method optimization for specific analytes and applications [3].

Limitations and Challenges

Despite its widespread utility, HPLC does present certain limitations:

Lack of Universal Detector: No single detector is optimal for all compound types, though UV-Vis detectors approach universality for chromophoric compounds and mass spectrometry covers many ionizable analytes [3].

High Operational Costs: HPLC systems represent significant capital investment ($35,000 or more for complete systems), with ongoing expenses for columns, solvents, and consumables [2].

Complex Method Development: The multitude of available columns, mobile phases, and operating parameters makes method development challenging, particularly for novice users [3].

Time-Consuming Regulated Testing: Analysis under Good Manufacturing Practices (GMP) requires extensive documentation, system suitability testing, and quality control measures, making the process arduous compared to spectroscopic techniques [3].

Moderate Separation Efficiency: Conventional HPLC has practical peak capacity of approximately 200, though this limitation is addressed by UHPLC (400-1000 peak capacity) and two-dimensional LC techniques [3].

Methodologies and Experimental Protocols

Standard HPLC Method Development Protocol

Developing a robust HPLC method requires systematic optimization of multiple parameters:

Sample Preparation: Dissolve sample in appropriate solvent, typically compatible with the mobile phase. Filter through 0.45 μm or 0.22 μm membrane to remove particulates.

Column Selection: Choose appropriate stationary phase based on compound properties. C18 columns are standard for reversed-phase applications [5].

Mobile Phase Preparation: Prepare HPLC-grade solvents with optional buffers or modifiers. Filter and degas to remove bubbles and particulates.

System Equilibration: Flush system with starting mobile phase composition until stable baseline is achieved, typically 10-30 column volumes.

Detection Optimization: Set detection parameters (wavelength for UV, or MS parameters) appropriate for target analytes.

Method Scouting: Perform initial runs with gradient elution to determine optimal isocratic conditions or gradient profile.

Parameter Optimization: Systematically adjust flow rate, temperature, and gradient profile to achieve resolution, efficiency, and analysis time goals.

Validation: Establish method specificity, linearity, accuracy, precision, and robustness according to regulatory requirements.

Case Study: Pharmaceutical Stability Testing

The application of HPLC in pharmaceutical stability testing illustrates its capabilities in quality control [3]. In a typical stability study for a drug tablet formulation:

- Tablets are stored under accelerated stability conditions (e.g., 40°C/75%RH or 50°C/75%RH) for designated time periods [3].

- At each time point, tablets are extracted with appropriate solvent and analyzed using a stability-indicating HPLC method [3].

- The method simultaneously quantifies the active pharmaceutical ingredient (API) and multiple impurities/degradants, including diastereomers and oxidative degradants [3].

- Data precision allows tracking of subtle changes in impurity profiles over time, enabling accurate determination of product shelf life [3].

This application highlights HPLC's ability to generate highly reliable data that can be reproduced across different laboratories - a critical requirement for regulatory submissions and quality assurance in the pharmaceutical industry [3].

The fundamental mechanism of HPLC - differential partitioning of compounds between stationary and mobile phases under high pressure - provides an exceptionally powerful foundation for separation science. While the technique demands significant expertise, instrumentation, and operational resources, its unparalleled capabilities for separating complex mixtures with high precision, sensitivity, and reproducibility ensure its continued dominance in analytical chemistry, particularly in pharmaceutical research and quality control.

The comparison with UV-Vis spectrophotometry reveals that while UV-Vis offers simplicity and speed for specific applications, HPLC provides superior analytical performance for complex mixtures and precise quantification requirements. Ongoing innovations in column technologies, instrumentation, and detection methods continue to expand HPLC capabilities, addressing current limitations and opening new applications in life sciences, environmental monitoring, and pharmaceutical development.

Ultraviolet-visible (UV-Vis) spectroscopy is a foundational analytical technique in modern laboratories, measuring the absorption of discrete wavelengths of ultraviolet or visible light by a sample. This technique operates on the principle that molecules undergo electronic transitions when they absorb light energy, providing critical insights into their composition and concentration. The widespread adoption of UV-Vis spectroscopy across pharmaceutical, biotechnology, environmental, and materials science fields is evidenced by market projections estimating the UV spectroscopy market will reach USD 27.62 billion by 2030, advancing at a 5.12% compound annual growth rate (CAGR) [8]. In the pharmaceutical sector alone, which accounts for nearly half of the UV spectroscopy market share, the technique has become indispensable for drug quality control, release testing, and bioprocess monitoring [8].

The versatility of UV-Vis spectroscopy stems from its ability to provide rapid, non-destructive analysis of samples with minimal preparation. When applied within its operational parameters, it delivers exceptional precision for quantifying analytes with characteristic chromophores. This technical guide explores the fundamental principles governing UV-Vis spectroscopy, with particular emphasis on the Beer-Lambert Law, while contextualizing its advantages and limitations within the broader analytical landscape of pharmaceutical research and development, especially when compared with complementary techniques like high-performance liquid chromatography (HPLC).

Fundamental Principles: The Interaction of Light with Matter

Light Energy and Electronic Transitions

UV-Vis spectroscopy investigates the interaction between light and matter at the electronic level. Light possesses a specific energy inversely proportional to its wavelength, meaning shorter wavelengths carry higher energy. When a photon of light with energy matching the energy gap between a molecule's ground state and excited state interacts with that molecule, the photon may be absorbed, promoting an electron to a higher energy orbital [6].

The ultraviolet region spans wavelengths from approximately 100 nm to 400 nm, while the visible region extends from 400 nm to 780 nm, corresponding to the violet-to-red spectrum detectable by the human eye [6]. Different bonding environments in molecules require specific energy amounts for electronic promotions, which is why absorption occurs at characteristic wavelengths for different substances, creating unique spectral fingerprints.

The Beer-Lambert Law

The quantitative foundation of UV-Vis spectroscopy is the Beer-Lambert Law, which establishes the relationship between light absorption and analyte properties. This law states that the absorbance (A) of a solution is directly proportional to the concentration (c) of the absorbing species and the path length (L) of light through the solution [6].

The mathematical expression of Beer-Lambert Law is: A = ε × L × c

Where:

- A is absorbance (no units)

- ε is the molar absorptivity or extinction coefficient (typically in L·molâ»Â¹Â·cmâ»Â¹)

- L is the path length of the light through the solution (usually in cm)

- c is the concentration of the absorbing species (in mol·Lâ»Â¹)

Absorbance is defined mathematically as A = -logâ‚â‚€(I/Iâ‚€), where Iâ‚€ is the intensity of incident light and I is the intensity of transmitted light [6]. The transmittance (T) is simply I/Iâ‚€, expressing the fraction of light that passes through a sample.

For accurate quantitative analysis, absorbance values should generally be maintained below 1.0, as this corresponds to 10% transmittance. Beyond this value, detector sensitivity limitations can compromise reliability [6]. The linear relationship described by Beer-Lambert Law enables researchers to determine unknown concentrations by comparing measured absorbances to standard solutions of known concentration.

Instrumentation and Measurement

Core Components of a UV-Vis Spectrophotometer

A UV-Vis spectrophotometer consists of several integrated components that work in concert to measure light absorption:

Light Source: Provides broad-spectrum illumination across UV and visible wavelengths. Common configurations include a single xenon lamp or a dual-lamp system with a deuterium lamp for UV (190-400 nm) and a tungsten/halogen lamp for visible regions (350-780 nm) [6].

Wavelength Selector: Isolates specific wavelengths from the broad emission spectrum. Modern instruments primarily use monochromators containing diffraction gratings with 300-2000 grooves per mm for wavelength selection. Higher groove frequencies provide better optical resolution, while lower frequencies offer broader usable ranges [6].

Sample Holder: Contains the sample solution during analysis. For UV measurements, quartz cuvettes are essential as quartz is transparent to most UV light, unlike glass or plastic which absorb UV radiation [6]. Standard path lengths are 1 cm, though shorter path lengths (e.g., 1 mm) accommodate limited sample availability.

Detector: Converts transmitted light intensity into an electrical signal. Photomultiplier tubes (PMT) are common for their sensitivity to very low light levels, while photodiodes and charge-coupled devices (CCD) offer alternative semiconductor-based detection [6].

The instrumental configuration significantly impacts data quality. For instance, dual-beam systems currently dominate the UV spectroscopy market share due to their superior stability during long analytical runs and high level of automation in data collection [9] [8].

Measurement Process and Workflow

The following diagram illustrates the typical workflow and component interaction within a UV-Vis spectrophotometer:

Figure 1: UV-Vis spectrophotometer component workflow

The measurement process begins when the light source emits broad-spectrum radiation. The monochromator selects a specific wavelength, which is typically split into two beams: one passing through the sample and another through a reference blank. The detector measures the intensity difference between these beams, and the data system converts this information into absorbance values. Modern instruments automatically scan across wavelength ranges to generate complete absorption spectra [6].

Experimental Protocol: Quantitative Analysis of Levofloxacin

To illustrate practical application of UV-Vis spectroscopy in pharmaceutical analysis, consider this detailed protocol for quantifying levofloxacin concentration, adapted from a published methodology comparing HPLC and UV-Vis techniques [7].

Research Reagent Solutions

Table 1: Essential materials and reagents for levofloxacin analysis

| Reagent/Material | Specifications | Function/Purpose |

|---|---|---|

| Levofloxacin Standard | National Institutes for Food and Drug Control (Ref: 130455-201106) | Primary reference standard for calibration curve |

| Simulated Body Fluid (SBF) | Aqueous buffer solution (pH ~7.4) | Dissolution medium mimicking physiological conditions |

| Volumetric Flasks | Class A, 10 mL, 100 mL | Precise preparation and dilution of standard solutions |

| Quartz Cuvettes | 1 cm path length | Sample holder transparent to UV light |

| UV-Vis Spectrophotometer | Dual-beam system with deuterium lamp | Instrument for absorbance measurements |

Methodology

Step 1: Preparation of Standard Stock Solution

- Precisely weigh 30.00 mg of levofloxacin reference standard using an analytical balance.

- Transfer the compound to a 10 mL volumetric flask and dissolve with simulated body fluid (SBF).

- Bring to volume with SBF to obtain a 3 mg/mL (3000 μg/mL) stock solution [7].

Step 2: Generation of Calibration Standards

- Serially dilute the stock solution with SBF to create 14 concentration gradients: 300, 200, 100, 50, 25, 10, 5, 2.5, 1, 0.5, 0.25, 0.1, 0.05, and 0.01 μg/mL [7].

- Each standard should be prepared in triplicate to ensure method reliability.

Step 3: Spectral Analysis and Wavelength Selection

- Using a medium concentration standard (25 μg/mL), scan from 200-400 nm against a blank of pure SBF.

- Identify the wavelength of maximum absorption (λmax) for levofloxacin, which typically occurs at ~290 nm [7].

- Set the spectrophotometer to this specific wavelength for all subsequent quantitative measurements.

Step 4: Measurement and Data Collection

- Measure the absorbance of each calibration standard at the predetermined λmax.

- For quality control, analyze prepared solutions at low, medium, and high concentrations (5, 25, and 50 μg/mL) in triplicate to assess precision [7].

- Record all absorbance values for construction of the calibration curve.

Step 5: Data Analysis

- Plot average absorbance (y-axis) versus concentration (x-axis) for all standards.

- Perform linear regression to establish the calibration equation. In comparative studies, this typically yields relationships such as y = 0.065x + 0.017 with R² = 0.9999 for UV-Vis [7].

- Determine unknown concentrations by interpolating sample absorbances using this calibration curve.

Comparative Performance in Pharmaceutical Analysis

Quantitative Comparison of HPLC and UV-Vis Techniques

UV-Vis spectroscopy serves as a rapid screening tool in pharmaceutical analysis, but understanding its performance relative to HPLC is crucial for appropriate method selection. The following table summarizes key comparative data from a study analyzing levofloxacin released from composite scaffolds [7]:

Table 2: Performance comparison of HPLC and UV-Vis for levofloxacin quantification

| Parameter | HPLC Performance | UV-Vis Performance |

|---|---|---|

| Linear Range | 0.05–300 μg/mL | 0.05–300 μg/mL |

| Regression Equation | y = 0.033x + 0.010 | y = 0.065x + 0.017 |

| Coefficient (R²) | 0.9991 | 0.9999 |

| Recovery (5 μg/mL) | 96.37 ± 0.50% | 96.00 ± 2.00% |

| Recovery (25 μg/mL) | 110.96 ± 0.23% | 99.50 ± 0.00% |

| Recovery (50 μg/mL) | 104.79 ± 0.06% | 98.67 ± 0.06% |

| Key Advantage | Superior accuracy in complex matrices; specific detection | Excellent linearity; rapid analysis; cost-effective |

The data reveals that while both techniques offer wide linear dynamic ranges and excellent correlation coefficients, HPLC demonstrates superior accuracy and precision, particularly at medium and high concentrations, with recovery rates closer to the ideal 100% value [7]. The higher specificity of HPLC reduces interference from complex matrix components in drug delivery systems.

Strategic Technique Selection Framework

The following decision diagram outlines the methodology selection process for pharmaceutical analysis:

Figure 2: Pharmaceutical analysis technique selection framework

Advantages and Limitations in Pharmaceutical Context

UV-Vis Spectroscopy Advantages:

- Operational Efficiency: Minimal sample preparation, rapid analysis, and ease of use make UV-Vis ideal for high-throughput environments [10].

- Cost-Effectiveness: Lower instrument costs, minimal consumable expenses, and reduced training requirements provide economic advantages [6] [10].

- Non-Destructive Analysis: Samples remain intact after measurement, allowing for additional testing or recovery of valuable materials [10].

- Real-Time Monitoring Capability: Particularly valuable for bioprocess monitoring, with the bioprocess monitoring segment projected to grow at 8.56% CAGR through 2030 [8].

UV-Vis Spectroscopy Limitations:

- Specificity Challenges: Limited ability to distinguish between compounds with similar chromophores, particularly problematic in complex biological matrices [7].

- Interference Susceptibility: Any component absorbing at the measurement wavelength contributes to signal, potentially leading to inaccurate quantification [7] [6].

- Structural Requirement: Dependent on presence of chromophores; compounds without suitable light-absorbing groups cannot be directly analyzed [6].

- Limited Sensitivity: For trace analysis requiring detection below 0.05%, HPLC with UV detection is often mandated by regulatory guidelines [11].

HPLC Complementary Strengths:

- Enhanced Specificity: Physical separation prior to detection eliminates most interference issues, providing accurate quantification in complex matrices like drug-loaded scaffold systems [7].

- Superior Sensitivity: HPLC-UV systems can achieve detection limits compliant with ICH Q3A guidelines requiring 0.05-0.10% sensitivity for impurity profiling [11].

- Universal Detection Compatibility: Compatibility with multiple detectors (MS, FLD, CAD) extends applicability to non-chromophoric compounds [12] [11].

HPLC Practical Constraints:

- Resource Intensity: Higher instrumentation costs, substantial solvent consumption, and need for skilled operators increase overall cost of analysis [12] [13].

- Time Investment: Longer analysis times and extensive method development requirements reduce operational efficiency compared to UV-Vis [7] [12].

UV-Vis spectroscopy remains an indispensable analytical technique in pharmaceutical research and quality control, with its utility rooted in the fundamental principles of the Beer-Lambert Law. While its simplicity, speed, and cost-effectiveness make it ideal for routine quantitative analysis of chromophoric compounds, technical limitations regarding specificity and matrix interference necessitate complementary use with separation-based techniques like HPLC.

The growing UV-Vis spectroscopy market, particularly within pharmaceutical and biotechnology sectors, reflects continued innovation in areas such as microvolume sampling, portable/hand-held devices (projected to grow at 7.46% CAGR), and bioprocess monitoring applications [9] [8]. Strategic implementation based on a thorough understanding of both UV-Vis spectroscopy and HPLC capabilities will continue to optimize analytical workflows in drug development, ensuring efficient resource utilization while maintaining rigorous quality standards.

High-Performance Liquid Chromatography (HPLC) and Ultraviolet-Visible (UV-Vis) spectrophotometry are foundational techniques in modern analytical laboratories. HPLC is renowned for its powerful separation capabilities, while UV-Vis spectroscopy offers rapid, cost-effective quantitative analysis. These techniques are indispensable in pharmaceuticals, biotechnology, environmental monitoring, and clinical research. This guide provides a detailed examination of their core components, operational principles, and practical applications, framed within a broader analysis of their comparative advantages and limitations for research and drug development professionals. The global market for HPLC is projected to grow from USD 5.01 billion in 2024 to USD 7.74 billion by 2032, reflecting its critical role in industry and research [14].

High-Performance Liquid Chromatography (HPLC) System Components

HPLC is a versatile and robust analytical technique used to separate, identify, and quantify components in a mixture. Its dominance stems from high separation efficiency, applicability to diverse analytes, and excellent precision [3] [12]. The fundamental principle involves the differential partitioning of analytes between a stationary phase (the column packing) and a mobile phase (the solvent) pumped under high pressure [13].

Core HPLC Instrumentation

A modern HPLC system consists of several integrated modules, each performing a critical function. The sequence of components and the flow of sample and data are illustrated in the workflow below:

The key components, as shown in the workflow, are:

- High-Pressure Pump: Delivers a constant, pulse-free flow of the mobile phase through the system, typically operating at pressures ranging from several hundred to over a thousand bar, especially in Ultra-High-Pressure Liquid Chromatography (UHPLC) [12] [13].

- Autosampler: Automates the introduction of the sample solution from a vial into the flowing mobile phase with high precision and reproducibility, crucial for robust quantitative analysis [12].

- Chromatographic Column: The heart of the separation process. It is a stainless-steel tube packed with micron-sized particles (the stationary phase). Recent innovations include columns with sub-2-μm fully porous or core–shell particles for higher efficiency, and those with inert hardware to prevent adsorption of metal-sensitive analytes like phosphorylated compounds and oligonucleotides [3] [5].

- Detector: Measures the eluting analytes as they exit the column. Common detectors include:

- UV-Vis Detector: Measures absorbance at specific wavelengths, providing good sensitivity for chromophoric compounds [13].

- Mass Spectrometer (MS): Provides exceptional sensitivity and selectivity, enabling structural identification and trace analysis. HPLC-MS is a standard platform for bioanalytical testing and life science research [3].

- Fluorescence (FLD) and Charged Aerosol Detectors (CAD): Offer high sensitivity for fluorescent compounds or act as a more universal detector, respectively [3] [12].

- Data System: A computer software that controls the instrument parameters, acquires the detector signal, processes the data (e.g., peak integration), and generates reports [12].

Ultraviolet-Visible (UV-Vis) Spectrophotometer System Components

UV-Vis spectroscopy is a technique that measures the absorption of light in the ultraviolet (190–400 nm) and visible (400–800 nm) regions of the electromagnetic spectrum. It is a cost-effective, simple, and non-destructive method for quantitative analysis and purity assessment [6] [15]. The principle is based on the Beer-Lambert Law, which states that the absorbance (A) of a solution is directly proportional to its concentration (c) and the path length (l) of the sample: A = εcl, where ε is the molar absorptivity [6] [15].

Core UV-Vis Instrumentation

The components of a UV-Vis spectrophotometer work in concert to select a specific wavelength, pass it through the sample, and measure its intensity. The arrangement of these components varies between single-beam and double-beam configurations, as shown below:

The key components, integral to the path shown, are:

- Light Source: Provides broad-spectrum light. Instruments often use two lamps: a deuterium lamp for UV light and a tungsten or halogen lamp for visible light [6] [15].

- Monochromator: This critical component isolates a single wavelength from the broad spectrum of the light source. It typically uses a diffraction grating with a high groove density (e.g., 1200 grooves per mm or more) to achieve a narrow band of light with high optical resolution [6].

- Sample Container: Holds the solution being analyzed. The sample is contained in a cuvette, which must be transparent to UV and/or visible light. Quartz cuvettes are required for UV measurements below 350 nm, as glass and plastic absorb strongly in this region [6] [15].

- Detector: Converts the intensity of transmitted light into an electrical signal. Modern instruments use photomultiplier tubes (PMT) for high sensitivity, photodiodes, or Charge-Coupled Devices (CCD) for rapid full-spectrum acquisition [6] [16].

Performance Data and Comparison

To objectively evaluate the two techniques, their key performance characteristics and market trends are summarized in the tables below.

Table 1: Key Quantitative Performance Metrics for HPLC and UV-Vis

| Performance Metric | HPLC / HPLC-MS | UV-Vis Spectrophotometry |

|---|---|---|

| Typical Analytical Time | Minutes to tens of minutes [3] | Seconds [16] |

| Measurement Precision (RSD) | <0.1–0.3% RSD (peak area) [3] | Varies with sample and concentration |

| Typical Detection Limits | Trace impurities ~0.01% [3] | Low nanogram (CAD) [3] |

| Sample Consumption | Microliters (injection volume) | 0.5 μL (microvolume) to mLs [16] |

| Peak Capacity (Complexity) | 200–1000 [3] | Not Applicable (non-separative) |

| Key Quantitative Law | N/A | Beer-Lambert Law [6] [15] |

Table 2: Market and Application Trends for HPLC and UV-Vis (2024-2030+)

| Aspect | HPLC Market & Trends | UV-Vis Market & Trends |

|---|---|---|

| Global Market Size (2024/2025) | USD 5.01 Billion (2024) [14] | USD 21.52 Billion (2025) [8] |

| Projected Market Size | USD 7.74 Billion by 2032 [14] | USD 27.62 Billion by 2030 [8] |

| Dominant End-User Segment | Pharmaceutical & Biotechnology Companies (58.5%) [14] | Pharmaceutical & Biotechnology Companies (48.54%) [8] |

| Fastest-Growing Application | Diagnostic Applications [14] | Bioprocess Monitoring (8.56% CAGR) [8] |

| Key Innovation Drivers | UHPLC, 2D-LC, inert columns, bioinert systems [3] [5] | Miniaturization, portability, AI-enhanced analytics [17] [8] |

Detailed Experimental Protocols

HPLC Protocol: Stability-Indicating Assay for a Pharmaceutical Product

This protocol is critical in pharmaceutical development for tracking the formation of degradants and establishing a drug's shelf life [3].

1. Objective: To separate, identify, and quantify the active pharmaceutical ingredient (API) and its related impurities/degradants in a solid dosage form after accelerated stability testing.

2. Materials and Reagents:

- Mobile Phase A: 20 mM ammonium formate, pH 3.7.

- Mobile Phase B: 0.05% formic acid in acetonitrile.

- Diluent: 20% acetonitrile in 0.1 N HCl.

- Standards: API, and available impurity standards (e.g., process impurities, degradants).

- Columns: 100 mm × 3.0 mm, 2-μm dp C18 column (e.g., ACE Excel 2 C18) [3].

3. Instrumentation and Conditions:

- System: UHPLC system capable of handling pressures up to 450 bar.

- Flow Rate: 0.8 mL/min.

- Column Temperature: 40 °C.

- Detection: UV absorbance at 280 nm.

- Injection Volume: 3 μL.

- Gradient Program: [3]

- 5–15% B in 2 min

- 15–40% B in 10 min

- 40–90% B in 1 min

4. Procedure:

- Sample Preparation: Weigh and finely powder not less than 10 tablets. Extract a portion of the powder equivalent to one tablet using the diluent. Filter the extract through a 0.45-μm membrane filter.

- Standard Preparation: Dissolve accurately weighed API and impurity standards in diluent to known concentrations.

- System Suitability: Inject the standard solution to ensure the chromatogram meets pre-defined criteria (e.g., resolution, tailing factor, repeatability).

- Analysis: Inject the blank (diluent), standard, and sample solutions. The total run time is approximately 13 minutes.

5. Data Analysis: Integrate the peaks for the API and all impurities. Calculate the percentage of each impurity relative to the API peak area. Track the increase in degradant levels (e.g., M399) in stability samples stored under accelerated conditions (e.g., 50 °C/75% relative humidity) as shown in the referenced study [3].

UV-Vis Protocol: Quantification of Nucleic Acid Concentration and Purity

This is a fundamental, rapid protocol for quality control in molecular biology.

1. Objective: To determine the concentration and assess the purity of a DNA or RNA sample.

2. Materials and Reagents:

- Sample: DNA or RNA solution.

- Blank: The buffer in which the nucleic acid is dissolved (e.g., TE buffer, nuclease-free water).

- Cuvettes: Quartz or specialized microvolume pedestals.

3. Instrumentation and Conditions:

- System: UV-Vis spectrophotometer with scanning capability.

- Path Length: 1 cm (standard) or 0.05–1 mm (for microvolume systems) [16].

- Wavelength Range: 230 nm to 350 nm.

4. Procedure:

- Blank Measurement: Pipette the blank solution into the cuvette (or onto the pedestal) and perform a background measurement.

- Sample Measurement: Carefully wipe the cuvette and load the DNA sample. Measure the absorbance.

- Data Recording: Record the absorbance values at 230 nm, 260 nm, and 280 nm.

5. Data Analysis: [15]

- Concentration (for dsDNA): ( \text{Conc. (μg/mL)} = A_{260} \times \text{Dilution Factor} \times 50 )

- Purity Ratios:

- ( A{260}/A{280} ): A ratio of ~1.8 indicates pure DNA; ~2.0 indicates pure RNA. Significant deviation suggests protein contamination.

- ( A{260}/A{230} ): A ratio in the range of 2.0-2.2 indicates minimal contamination by salts or organic compounds.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Consumables for HPLC and UV-Vis Experiments

| Item | Function / Application | Technical Notes |

|---|---|---|

| HPLC-Grade Solvents (ACN, MeOH) | Mobile phase components. | Low UV absorbance and high purity to minimize background noise and prevent system damage [12]. |

| Buffers (Ammonium Formate/Acetate) | Mobile phase additives for controlling pH and ionic strength. | Volatile buffers are preferred for LC-MS compatibility [3]. |

| Reverse-Phase C18 Column | The stationary phase for separating a wide range of non-polar to moderately polar analytes. | The "workhorse" column. Available in various particle sizes (e.g., 1.7, 3, 5 μm) and pore sizes [5]. |

| Inert HPLC Column | Stationary phase with passivated hardware. | Essential for analyzing metal-sensitive compounds like phosphorylated species, chelating PFAS, and oligonucleotides to prevent adsorption and peak tailing [5]. |

| 0.45/0.22 μm Syringe Filters | Clarification of samples and mobile phases. | Removes particulates that could clog the HPLC column or tubing [12]. |

| Quartz Cuvettes | Sample holder for UV-Vis spectroscopy in the UV range. | Transparent down to ~190 nm; required for measurements below 350 nm [6]. |

| Nucleic Acid Standards | Calibration and verification of UV-Vis spectrophotometer performance. | Used to create calibration curves and validate concentration/purity calculations. |

| Boc-D-Arg(Pbf)-OH | Boc-D-Arg(Pbf)-OH, CAS:186698-61-3, MF:C24H38N4O7S, MW:526.6 g/mol | Chemical Reagent |

| Boc-Cys(Npys)-OH | Boc-Cys(Npys)-OH, CAS:76880-29-0, MF:C13H17N3O6S2, MW:375.4 g/mol | Chemical Reagent |

Advantages and Limitations: A Comparative Analysis

High-Performance Liquid Chromatography (HPLC)

- Advantages:

- High Resolution and Peak Capacity: Can separate complex mixtures containing dozens or even hundreds of components, with modern UHPLC achieving a peak capacity of 400–1000 [3].

- Versatile Detection and Identification: Coupling with mass spectrometry (LC-MS) provides unparalleled specificity and sensitivity for identification and trace analysis, making it a "perfect analytical tool" for bioanalysis [3].

- Excellent Quantitation and Reproducibility: Delieves highly precise and robust quantitative data (<0.1% RSD), which is indispensable for quality control (QC) and regulatory compliance in industries like pharmaceuticals [3] [12].

- Limitations:

- Operational Complexity and Cost: Requires significant capital investment, expensive consumables (columns, solvents), and skilled personnel for operation, maintenance, and method development [12].

- Time-Consuming and Arduous: Analysis times are longer than UV-Vis, and procedures, especially in regulated environments, involve many steps (system suitability, lengthy data review) [3].

- High Solvent Consumption: Generates significant organic solvent waste, creating an environmental burden and requiring waste management procedures, though "green chromatography" initiatives aim to mitigate this [12].

UV-Vis Spectrophotometry

- Advantages:

- Simplicity and Speed: The technique is relatively straightforward, and modern instruments can provide results in seconds, making it ideal for high-throughput checks and routine analysis [16] [15].

- Cost-Effectiveness and Non-Destructive Nature: Lower initial and operational costs compared to HPLC. The sample is generally not consumed or destroyed, allowing for recovery and further analysis [16] [15].

- Easy Quantification: The direct relationship between absorbance and concentration via the Beer-Lambert Law makes quantification simple and rapid for a single analyte in solution [6].

- Limitations:

- Lack of Inherent Selectivity: Cannot distinguish between different compounds that absorb at the same wavelength, making it unsuitable for analyzing complex mixtures without prior separation [16].

- Lower Sensitivity and Potential for Interference: Has lower sensitivity compared to fluorescence or MS-based techniques. The accuracy of measurements can be affected by stray light, turbidity, and the presence of other chromophores [16].

- Limited Applicability: Only useful for analytes that absorb in the UV-Vis region or can be derivatized to do so. It provides no structural information on its own [3].

HPLC and UV-Vis spectrophotometry are complementary pillars of the modern analytical laboratory. HPLC is the undisputed choice for resolving complex mixtures and providing definitive identification and quantification with high precision, despite its higher operational demands. In contrast, UV-Vis spectroscopy offers unparalleled speed, simplicity, and cost-efficiency for specific quantitative and purity assessment tasks. The ongoing innovation in both fields—such as the development of more robust and inert HPLC columns and the miniaturization and integration of AI in UV-Vis systems—ensures they will remain vital tools for researchers and drug development professionals. The choice between them is not a matter of superiority, but of selecting the right tool to answer the specific scientific question at hand.

High-Performance Liquid Chromatography (HPLC) and Ultraviolet-Visible (UV-Vis) Spectrophotometry are two foundational analytical techniques in modern laboratories, each possessing a unique profile of inherent strengths and limitations. HPLC is a dominant separation technique that has been widely practiced for five decades, generating over $4 billion in annual sales of equipment and accessories [3]. The technique operates on the principle of separating compounds between a stationary phase and a mobile phase, with different chemical components separating as they move at different speeds through the column [18] [19]. UV-Vis spectroscopy, conversely, is an analytical technique that measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample in comparison to a reference or blank sample [6]. This property is influenced by the sample composition, providing information on what is in the sample and at what concentration [6].

The selection between these techniques represents a critical decision path for researchers and drug development professionals, balancing factors including analytical needs, sample complexity, and resource constraints. This technical guide provides a comprehensive examination of both techniques' operational profiles to inform these methodological choices.

Fundamental Principles and Instrumentation

HPLC Operational Framework

HPLC utilizes a pump to force a liquid solvent (mobile phase) through a column packed with solid adsorbent material (stationary phase) [18] [19]. The separation mechanism is based on the differential distribution of compounds between these two phases. As the injected sample travels through the column with the mobile phase, components migrate at different velocities based on their chemical characteristics and interaction with the stationary phase [19]. Compounds spending more time in the mobile phase elute faster, while those with stronger affinity for the stationary phase are retained longer [19]. This differential migration enables physical separation of mixture components, which are then detected as they exit the column [19]. The resulting chromatogram provides both qualitative information through retention times and quantitative data through peak areas [19].

UV-Vis Spectrophotometry Fundamentals

UV-Vis spectroscopy operates on the principle that molecules containing π-electrons or non-bonding electrons can absorb energy from ultraviolet or visible light, promoting electrons to higher anti-bonding molecular orbitals [20]. The technique measures this absorption as a function of wavelength, producing an absorption spectrum [6]. According to the Beer-Lambert Law, absorbance is directly proportional to the concentration of the absorbing species: A = εlc, where A is absorbance, ε is the molar absorptivity, l is the path length, and c is concentration [6] [20]. This relationship enables quantitative analysis when the molar absorptivity is known and operating within the instrument's linear dynamic range [6].

Advantages and Limitations: Comparative Analysis

Strengths of HPLC

Table 1: Key Advantages of HPLC

| Advantage | Technical Basis | Typical Performance Metrics |

|---|---|---|

| High Resolution & Efficiency | Uses pump-driven forced flow through columns packed with fine particles [3] [18] | Peak capacity of ~200 for conventional HPLC; 400-1000 for UHPLC in 60 minutes [3] |

| Excellent Quantitation | Automated process with precision detectors [3] | Precision <0.1% RSD for UHPLC; 0.2-0.3% RSD for HPLC [3] |

| Versatile Detection Options | Compatible with multiple detectors (UV, fluorescence, MS, CAD) [3] | UV detection sensitivity ~0.01% for trace impurities; MS provides exceptional specificity [3] |

| Broad Applicability | Suitable for diverse analyte types [3] | Handles small molecules to large biomolecules; compatible with various separation mechanisms [3] [19] |

| Automation & Robustness | Automated sample injection and solvent delivery [3] | Highly reproducible between laboratories with different instruments [3] |

HPLC's most significant strength lies in its exceptional separation capability, which allows researchers to resolve complex mixtures into individual components with high precision [3]. The technique provides excellent quantitative data, with modern systems achieving relative standard deviations below 0.1% for both retention times and peak areas [3]. This precision makes HPLC indispensable for quality control applications in pharmaceuticals and other regulated industries [3]. The coupling of HPLC with mass spectrometry (LC-MS) has created what many consider "the perfect analytical tool," combining excellent separation capability with the sensitivity and specificity of MS detection [3]. This combination is particularly powerful for bioanalytical testing, trace analysis, and life science research [3].

Limitations of HPLC

Table 2: Key Limitations of HPLC

| Limitation | Technical Basis | Practical Implications |

|---|---|---|

| Cost & Complexity | Requires sophisticated instrumentation, expensive columns, and high-purity solvents [18] | Large quantities of expensive organics needed; development of new methods requires significant expertise [18] |

| Lack of Universal Detector | No single detector identifies all compounds effectively [3] | UV detection limited to chromophoric compounds; refractive index detection has sensitivity limitations [3] |

| Method Development Challenges | Bewildering number of columns, mobile phases, and parameters [3] | Substantial experience needed to develop new methods or troubleshoot problems [3] |

| Time-Consuming Procedures | Multiple steps from sample prep to data reporting [3] | Regulated analysis under GMP can be particularly arduous despite automation [3] |

| Limited Sensitivity for Certain Compounds | Detection capability compound-dependent [18] | Some compounds show low sensitivity; volatile substances better handled by GC [18] |

The primary limitations of HPLC include its operational complexity and cost requirements [18]. The technique demands significant expertise for method development and troubleshooting, with a "bewildering number of HPLC modules, columns, mobile phases, and operating parameters" that can challenge novices [3]. While running established methods is relatively straightforward with modern automated systems, developing new methods requires substantial experience and scientific judgment [3]. The lack of a truly universal detector means that method development must carefully consider detection capabilities for target analytes [3]. Additionally, HPLC can be time-consuming and arduous for regulated testing, despite automation of many steps [3].

Strengths of UV-Vis Spectrophotometry

Table 3: Key Advantages of UV-Vis Spectrophotometry

| Advantage | Technical Basis | Typical Performance Metrics |

|---|---|---|

| Rapid Analysis | Direct measurement without separation [21] | Almost immediate results; suitable for high-throughput environments [21] |

| Cost-Effectiveness | Simpler instrumentation compared to HPLC [21] [20] | Lower initial investment and operating costs [21] |

| Non-Destructive Testing | Light absorption measurement without consuming sample [21] | Enables repeated measurements on same precious sample [21] |

| High Sensitivity | Detects minute changes in absorbance [21] | Can detect extremely low concentrations of substances [21] |

| Ease of Use | Straightforward operational principles [22] | Simple to operate with minimal training requirements [22] |

UV-Vis spectroscopy's greatest strength is its simplicity and efficiency [21] [22]. The technique provides almost immediate results, making it ideal for time-sensitive applications and high-throughput environments [21]. Its non-destructive nature allows researchers to preserve precious samples for additional analysis [21]. UV-Vis instruments are considerably more affordable than HPLC systems both in initial investment and operating costs [21] [20]. The technique also offers high sensitivity for detecting low concentrations of analytes with appropriate chromophores [21]. Operation is relatively straightforward, with minimal training requirements compared to more complex analytical techniques [22].

Limitations of UV-Vis Spectrophotometry

Table 4: Key Limitations of UV-Vis Spectrophotometry

| Limitation | Technical Basis | Practical Implications |

|---|---|---|

| Limited to Chromophores | Requires light-absorbing species [6] | Compounds without suitable chromophores cannot be detected directly [6] |

| Sample Complexity Challenges | Overlapping absorption bands in mixtures [21] | Limited utility for complex mixtures without separation [21] |

| Interference Issues | Stray light, scattering, background absorption [21] | Requires careful sample preparation; turbidity affects accuracy [21] |

| Limited Structural Information | Measures absorption/transmission only [21] | Cannot provide detailed molecular structure information [21] |

| Sensitive Experimental Conditions | Vulnerable to external interference [22] | Requires careful setup to exclude outside light and vibrations [22] |

The most significant limitation of UV-Vis spectroscopy is its requirement for analytes to contain chromophores that absorb in the ultraviolet or visible range [6]. Compounds without suitable chromophores cannot be detected directly. The technique struggles with complex mixtures where multiple absorbing components lead to overlapping absorption bands, making it difficult to discern individual substances [21]. Sample preparation is critical, as turbidity or particulate matter can scatter light and affect accuracy [21]. Unlike techniques such as IR or NMR spectroscopy, UV-Vis provides limited information about molecular structure [21]. The method is also sensitive to experimental conditions, requiring careful setup to exclude outside light and vibrations that could interfere with results [22].

Experimental Protocols and Methodologies

Representative HPLC Protocol: Pharmaceutical Stability Testing

Objective: To quantify drug components and degradants in tablet formulations to establish shelf life [3].

Materials and Reagents:

- UHPLC System: Configured with binary pump, autosampler, column oven, and UV detector [3]

- Analytical Column: 100 mm × 3.0 mm, 2-μm dp C18 stationary phase [3]

- Mobile Phase A: 20 mM ammonium formate buffer (pH 3.7) [3]

- Mobile Phase B: 0.05% formic acid in acetonitrile [3]

- Reference Standards: Active pharmaceutical ingredient (API) and known impurities/degradants [3]

- Sample Solvent: 20% acetonitrile in 0.1 N HCl [3]

Procedure:

- Mobile Phase Preparation: Prepare fresh mobile phases using high-purity solvents and filter through 0.45-μm membrane

- Standard Solution Preparation: Accurately weigh and dissolve reference standards to known concentrations

- Sample Preparation: Extract tablet formulation using sample solvent with appropriate dilution

- System Equilibration: Prime system with initial mobile phase composition (5% B) at 0.8 mL/min flow rate

- Chromatographic Conditions:

- Flow rate: 0.8 mL/min

- Column temperature: 40°C

- Injection volume: 3 μL

- Detection: UV absorbance at 280 nm

- Gradient program:

- 5-15% B in 2 minutes

- 15-40% B in 10 minutes

- 40-90% B in 1 minute

- System Suitability: Verify precision, resolution, and tailing factor using standard solution

- Sample Analysis: Inject samples and quantify components against calibrated standards

Data Analysis: Quantitate all components (API and related substances) by comparing peak areas to calibration curves. Report impurities at levels as low as 0.01% [3].

Representative UV-Vis Protocol: Concentration Determination

Objective: To determine the concentration of an analyte in solution using the Beer-Lambert Law [6] [20].

Materials and Reagents:

- UV-Vis Spectrophotometer: Equipped with deuterium and tungsten lamps [6]

- Cuvettes: Quartz for UV analysis, with 1 cm path length [6]

- Standard Solution: Precisely known concentration of target analyte

- Sample Solution: Prepared in appropriate solvent

- Blank Solution: Pure solvent used for sample preparation

Procedure:

- Instrument Preparation:

- Allow instrument to warm up for recommended time

- Select appropriate wavelength based on analyte's absorption maximum

- Ensure cuvette compartment is free from contaminants

- Blank Measurement:

- Fill cuvette with blank solution

- Place in sample holder and measure baseline

- Auto-zero instrument using blank

- Standard Curve Preparation:

- Prepare minimum of five standard solutions covering concentration range

- Ensure absorbance values remain below 1.0 for linearity

- Measure absorbance of each standard solution

- Plot absorbance versus concentration to generate calibration curve

- Sample Measurement:

- Transfer sample solution to clean cuvette

- Measure absorbance at same wavelength as standards

- Repeat for improved precision

- Validation Checks:

- Verify blank reading periodically

- Measure mid-range standard as quality control check

Data Analysis: Calculate sample concentration using the equation A = εlc, where A is measured absorbance, ε is molar absorptivity determined from standards, l is path length, and c is concentration [6] [20]. For optimal accuracy, ensure all measurements fall within the linear range of the calibration curve.

Essential Research Reagent Solutions

Table 5: Key Research Reagents and Materials

| Item | Function | Technical Considerations |

|---|---|---|

| HPLC-Grade Solvents | Mobile phase components | Low UV absorbance; minimal particulate matter [3] |

| Chromatography Columns | Stationary phase for separation | Select chemistry based on application (C18, cyano, phenyl, etc.) [3] [19] |

| Buffer Salts | Mobile phase modifiers | Volatile salts (ammonium formate/acetate) preferred for LC-MS [3] |

| Reference Standards | System calibration and identification | High-purity characterized materials for accurate quantitation [3] |

| UV Cuvettes | Sample holders for spectroscopy | Quartz for UV range; proper path length selection critical [6] |

| Standard Reference Materials | Calibration of spectrophotometers | NIST-traceable materials for accurate absorbance measurements [6] |

| Filters | Mobile phase and sample preparation | 0.45-μm or 0.22-μm membranes to remove particulates [3] |

Technique Selection Guidelines

The choice between HPLC and UV-Vis spectrophotometry depends primarily on the analytical problem's specific requirements. HPLC is the preferred technique when dealing with complex mixtures requiring component separation, when analyzing multiple analytes simultaneously, when high precision quantitation is necessary, or when working with regulated methods requiring robust validation [3] [18]. UV-Vis spectrophotometry is more appropriate for simple mixtures or pure compounds, when rapid analysis is prioritized, when working with limited budgets, when sample quantity permits non-destructive testing, or when monitoring specific chromophore-containing compounds in time-dependent studies [21] [20].

For the most challenging analytical problems, both techniques may be employed complementarily—using UV-Vis for rapid screening and HPLC for definitive separation and quantitation. Understanding the inherent strengths and limitations of each technique enables researchers to make informed decisions that optimize analytical outcomes while efficiently utilizing available resources.

Strategic Applications: Choosing the Right Technique for Your Analysis

High-Performance Liquid Chromatography (HPLC) has become an indispensable analytical technique in the pharmaceutical industry, serving as a cornerstone for drug development and quality control. Its dominance stems from exceptional separation power, precision, and versatility in analyzing diverse analyte types, from small organic molecules to large biomolecules [3]. In modern pharmaceutical analysis, HPLC applications span three critical domains: quantifying active pharmaceutical ingredients (APIs) in drug assays, identifying and characterizing impurities to ensure drug safety, and determining key pharmacokinetic properties during drug discovery [23] [24]. The technique's compatibility with various detection methods, especially mass spectrometry (LC-MS), provides an invincible edge combining excellent separation capability with unsurpassed sensitivity and specificity [3]. This technical guide examines the fundamental principles, experimental methodologies, and applications of HPLC within pharmaceutical sciences, framed against its comparative advantages and limitations with UV-Vis spectrophotometry.

Fundamental Principles and Comparative Value

Core HPLC Principles

HPLC separates complex mixtures through differential partitioning of analytes between a stationary phase (typically packed into a column) and a mobile phase (liquid solvent pumped under high pressure) [12]. Components migrate at different velocities through the column based on their chemical characteristics and interaction with the stationary phase, emerging as separated bands detected at the column outlet [3]. Key performance parameters include theoretical plate count (efficiency), peak symmetry, resolution between adjacent peaks, and analysis time [3].

Reversed-phase liquid chromatography (RPLC) dominates pharmaceutical applications due to its compatibility with most drug molecules' hydrophobic characteristics [25]. RPLC employs a non-polar stationary phase (typically C8 or C18 bonded silica) and a polar mobile phase (often water-methanol or water-acetonitrile mixtures), providing sufficient retention and mass balance for comprehensive purity assays [25].

HPLC versus UV-Vis Spectrophotometry

While both HPLC and UV-Vis spectrophotometry are essential analytical techniques, they serve complementary but distinct roles in pharmaceutical analysis. The table below summarizes their core characteristics:

Table 1: Comparison of HPLC and UV-Vis Spectrophotometry in Pharmaceutical Analysis

| Parameter | HPLC | UV-Vis Spectrophotometry |

|---|---|---|

| Selectivity | High (separates multiple components) [26] | Low (measures total absorbance) [26] |

| Analysis of Complex Mixtures | Excellent (individual component quantification) [3] | Poor (cannot resolve mixtures) [26] |

| Specificity | High (retention time + spectral data) [26] | Moderate (spectral data only) [26] |

| Precision | Excellent (RSD < 0.1-0.3%) [3] | Good (RSD < 1.5%) [26] |

| Linear Range | Wide (5 orders of magnitude with UV detection) [25] | Limited (requires dilution for concentrated samples) |

| Sample Preparation | Often complex (filtration, extraction) [25] | Simple (dissolution in solvent) [26] |

| Analysis Time | Longer (10-60 minutes) [3] | Rapid (minutes) [26] |

| Instrument Cost | High (>$100,000) [25] | Low |

| Operator Skill Required | Substantial for method development [3] | Minimal |

UV-Vis spectrophotometry provides rapid, cost-effective analysis for single-component determinations but cannot resolve mixtures without prior separation [26]. HPLC, while more complex and expensive, delivers unparalleled capability for multi-component analysis in complex matrices like pharmaceutical formulations and biological fluids [3] [27].

HPLC in Drug Assay and Content Uniformity

Experimental Protocol for Drug Assay

A validated HPLC method for drug assay must demonstrate specificity, accuracy, precision, linearity, and robustness per ICH guidelines [26]. The following protocol for repaglinide tablet assay illustrates a typical approach:

Mobile Phase Preparation: Methanol and water in 80:20 (v/v) ratio, with pH adjusted to 3.5 using orthophosphoric acid. The mixture is filtered through a 0.45 μm membrane filter and degassed by sonication [26].

Standard Solution Preparation: Accurately weigh 10 mg of repaglinide reference standard and transfer to a 10 mL volumetric flask. Dissolve and dilute to volume with methanol to obtain 1000 μg/mL stock solution. Dilute aliquots with mobile phase to obtain working standards in 5-50 μg/mL range [26].

Sample Solution Preparation: Weigh and finely powder 20 tablets. Transfer powder equivalent to 10 mg repaglinide to 100 mL volumetric flask, add 30 mL methanol, sonicate for 15 minutes, dilute to volume with methanol, and mix. Filter through 0.45 μm membrane, discard first few mL, and dilute filtrate with mobile phase to final concentration within linear range [26].

Chromatographic Conditions:

- Column: Agilent TC-C18 (250 mm × 4.6 mm i.d., 5 μm particle size)

- Mobile Phase: Methanol:water (80:20 v/v, pH 3.5)

- Flow Rate: 1.0 mL/min

- Injection Volume: 20 μL

- Detection: UV at 241 nm

- Run Time: 10-15 minutes [26]

System Suitability Testing: Before analysis, verify system performance by injecting standard solution to ensure tailing factor <1.5, theoretical plates >2000, and RSD of peak areas from replicate injections <1.0% [26].

Performance Data

Table 2: Validation Parameters for Repaglinide HPLC Assay [26]

| Validation Parameter | Result |

|---|---|

| Linearity Range | 5-50 μg/mL |

| Correlation Coefficient (r²) | >0.999 |

| Precision (Repeatability, %RSD) | <1.5% |

| Accuracy (Mean Recovery) | 99.71-100.25% |

| LOD | ~0.5 μg/mL (calculated) |

| LOQ | ~1.5 μg/mL (calculated) |

The exceptional precision of HPLC with UV detection (RSD <0.2%) makes it indispensable for quality control, enabling highly reproducible assays across different laboratories with instruments from various vendors and columns from different batches [3] [25].

Figure 1: HPLC Drug Assay Workflow

Impurity Profiling

The Critical Role of Impurity Profiling

Impurity profiling represents a systematic approach to identify, isolate, and elucidate the structure of unknown impurities in pharmaceutical substances [23]. This process is crucial for drug safety, efficacy, and stability, as impurities—even in trace amounts—can pose significant toxicological risks or reduce therapeutic activity [23]. HPLC has become the premier technique for impurity profiling due to its high resolution, sensitivity, and ability to separate diverse chemical structures [3] [23].

Impurities in pharmaceuticals originate from multiple sources:

- Process-related impurities: Starting materials, intermediates, catalysts, reagents from API synthesis [23]

- Degradation products: Formed from API decomposition under stress conditions (heat, light, pH) [3]

- Related substances: Structurally similar compounds including isomers and diastereomers [3]

- Residual solvents: Organic volatile chemicals from manufacturing [23]

Stability-Indicating Assay Methodology

Stability-indicating methods must accurately quantify API while resolving and quantifying degradation products. The following UHPLC protocol exemplifies a stability-indicating assay:

Chromatographic Conditions:

- Column: 100 mm × 3.0 mm, 2-μm dp ACE Excel 2 C18

- Mobile Phase A: 20 mM ammonium formate (pH 3.7)

- Mobile Phase B: 0.05% formic acid in acetonitrile

- Flow Rate: 0.8 mL/min

- Temperature: 40°C

- Gradient Program: 5→15% B in 2 min, 15→40% B in 10 min, 40→90% B in 1 min

- Detection: UV absorbance at 280 nm

- Injection Volume: 3 μL [3]

Forced Degradation Studies: Stress the drug substance under various conditions:

- Acidic Hydrolysis: 0.1N HCl at 60°C for 1-24 hours

- Basic Hydrolysis: 0.1N NaOH at 60°C for 1-24 hours

- Oxidative Degradation: 3% Hâ‚‚Oâ‚‚ at room temperature for 1-24 hours

- Thermal Degradation: Solid state at 105°C for 1-7 days

- Photolytic Degradation: Expose to UV and visible light [3]

Method Validation for Impurity Quantification:

- Specificity: Demonstrate resolution from all potential impurities and degradation products

- LOQ: Typically 0.05-0.10% of target concentration to meet regulatory requirements [3]

- Linearity: Establish from LOQ to 120-150% of specification level

- Accuracy: Recovery 90-110% for impurities [26]

Impurity Profiling Performance

Table 3: HPLC Capabilities in Pharmaceutical Impurity Profiling

| Parameter | Capability | Regulatory Significance |

|---|---|---|

| Detection Limit | ~0.01% relative to API [3] | Meets ICH threshold for reporting impurities |

| Quantification Limit | 0.05% (required by regulations) [3] | Enables precise impurity control |

| Precision | RSD <0.1% for UHPLC [3] | Ensures reliable trending of impurity levels |

| Isomer Separation | Excellent (diastereomers, enantiomers with chiral columns) [27] | Critical as isomers may have different toxicological properties |

| Peak Capacity | 200 (conventional HPLC) to 1000 (UHPLC) [3] | Determines capability to resolve complex mixtures |

HPLC's ability to track subtle changes in impurity profiles over time provides essential data for establishing drug shelf life and storage conditions [3]. In stability studies, HPLC can detect increased levels of specific degradants under accelerated conditions (e.g., 50°C/75%RH), informing appropriate packaging and expiration dating [3].

HPLC in Pharmacokinetic Studies

Determining Lipophilicity (log P/log D)

Lipophilicity significantly influences drug absorption, distribution, metabolism, and toxicity [24]. HPLC provides an efficient, reproducible alternative to traditional shake-flask methods for determining lipophilicity, especially for poorly water-soluble or volatile compounds [24].

Experimental Protocol for log P Determination:

- Column: C18 stationary phase (150 mm × 4.6 mm, 5 μm)

- Mobile Phase: Water-methanol or water-acetonitrile mixtures

- Standard Compounds: Minimum 6 compounds with known log P values for calibration

- Gradient Program: 5-95% organic modifier over 30 minutes

- Detection: UV at appropriate wavelength for analyte

- Temperature: 25°C maintained in column oven [24]

Calculation: Measure retention factor (k) at multiple mobile phase compositions and extrapolate to 100% aqueous conditions to obtain log k_w, which correlates with log P:

where φ is volume fraction of organic modifier and S is a constant [24].

The OECD endorses RP-HPLC as a preferred method for determining log P, particularly for compounds challenging to measure via traditional techniques [24].

Correlation with Pharmacokinetic Properties

HPLC-derived lipophilicity parameters strongly correlate with key ADME properties:

Absorption: Optimal log P values (0-3) balance solubility and membrane permeability for oral absorption [24]. Compounds with log P <0 may have good solubility but poor passive permeability, while those with log P >5 often exhibit poor aqueous solubility and excessive metabolism [24].

Distribution: Lipophilicity influences volume of distribution, plasma protein binding, and blood-brain barrier penetration. For effective CNS penetration, ideal log P is approximately 2 [24].

Metabolism and Toxicity: Higher lipophilicity generally correlates with increased metabolic clearance and potential for toxicity [24]. According to Lipinski's "Rule of Five," approximately 90% of approved drugs have log P values between 0 and 5 [24].

Figure 2: Lipophilicity Correlations with ADME Properties

Bioanalytical Method for Pharmacokinetic Studies

HPLC methods for bioanalysis require enhanced sensitivity and selectivity to quantify drugs in biological matrices:

Sample Preparation: Protein precipitation using acetonitrile or methanol, liquid-liquid extraction, or solid-phase extraction to remove interfering endogenous compounds [27].

Chromatographic Conditions: Typically UHPLC with sub-2μm particles for improved resolution and speed. Mobile phases often contain volatile additives (ammonium formate/acetate, formic acid) for MS compatibility [3].

Detection: LC-MS/MS, particularly triple quadrupole systems, provide exceptional sensitivity (ng/mL to pg/mL) and specificity for quantifying drugs and metabolites in biological fluids [3].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Reagents and Materials for Pharmaceutical HPLC Analysis

| Item | Function | Application Notes |

|---|---|---|

| C18 Columns | Reversed-phase separation of non-polar to moderately polar compounds | Workhorse for most small molecule drugs; various dimensions and particle sizes available [26] |

| Buffered Mobile Phases | Control pH to suppress ionization and modulate retention | Ammonium formate/acetate (MS-compatible); phosphate buffers (UV detection) [3] |

| Organic Modifiers | Solvent strength adjustment in reversed-phase | Acetonitrile (sharp peaks), Methanol (alternative selectivity) [26] |

| Volatile Acids | Improve peak shape for ionizable compounds | Formic acid, trifluoroacetic acid (0.05-0.1%) [3] |

| Reference Standards | Method calibration and quantification | Certified purity; required for system suitability testing [26] |

| Solid Phase Extraction Cartridges | Sample clean-up for biological matrices | Remove proteins and interfering compounds prior to analysis [27] |

| Syringe Filters | Particulate removal from samples | 0.45 μm or 0.22 μm nylon or PVDF membranes [26] |

| Boc-NH-C4-acid | Boc-NH-C4-acid, CAS:27219-07-4, MF:C10H19NO4, MW:217.26 g/mol | Chemical Reagent |

| DL-valine | DL-valine, CAS:516-06-3, MF:C5H11NO2, MW:117.15 g/mol | Chemical Reagent |

HPLC remains an indispensable analytical technique in pharmaceutical development and quality control, offering unparalleled capabilities for drug assay, impurity profiling, and pharmacokinetic property determination. Its exceptional resolving power, precision, and compatibility with diverse detection methods make it superior to UV-Vis spectrophotometry for complex analyses requiring component separation. While challenges including instrument cost, operational complexity, and regulatory burdens exist, ongoing advancements in column technology, instrumentation miniaturization, and hyphenated techniques like LC-MS continue to expand HPLC's capabilities. As pharmaceutical compounds become increasingly complex, HPLC's role in ensuring drug safety, efficacy, and quality remains fundamentally irreplaceable.