Implementing AMGS: A Practical Guide to Sustainable Chromatographic Method Development

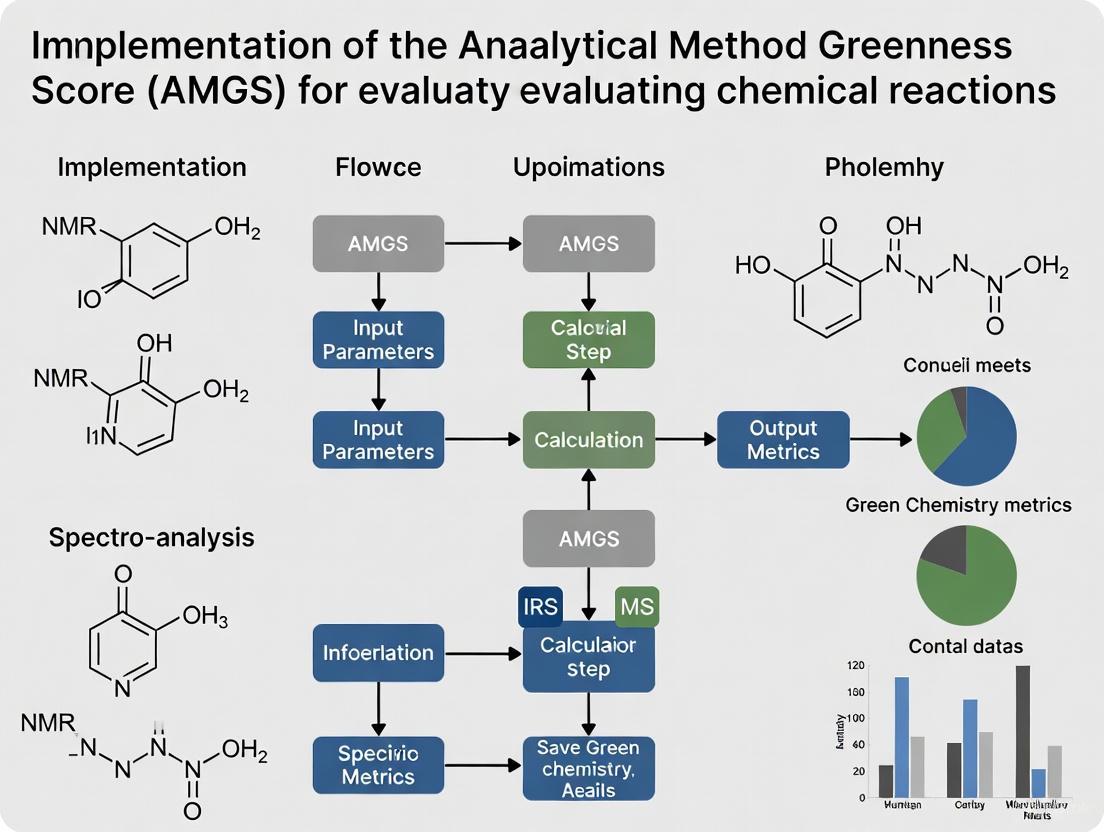

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on implementing the Analytical Method Greenness Score (AMGS).

Implementing AMGS: A Practical Guide to Sustainable Chromatographic Method Development

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on implementing the Analytical Method Greenness Score (AMGS). Developed by the ACS Green Chemistry Institute Pharmaceutical Roundtable, AMGS is a comprehensive metric that benchmarks the environmental impact of chromatographic methods by evaluating solvent health, safety, environmental impact, cumulative energy demand, instrument energy usage, and solvent waste. We explore the foundational principles of AMGS, detail its methodological application with practical examples from industry leaders like AstraZeneca, provide troubleshooting and optimization strategies for improving method scores, and position AMGS within the broader landscape of green analytical chemistry tools. This guide empowers laboratories to systematically enhance their sustainability profiles while maintaining analytical quality, supporting the pharmaceutical industry's ambitious environmental goals.

Understanding AMGS: The Foundation of Sustainable Analytical Chemistry

The Critical Need for Green Metrics in Pharmaceutical Analysis

Pharmaceutical analysis, vital for ensuring drug safety and efficacy, traditionally relies on resource-intensive processes that generate substantial waste. The global production of active pharmaceutical ingredients (APIs), estimated at 65–100 million kilograms annually, generates approximately 10 billion kilograms of waste, with disposal costs reaching $20 billion [1]. Analytical chemistry's success in determining composition plays a crucial role in addressing environmental challenges, yet its dependence on energy-intensive processes, non-renewable resources, and waste generation raises significant sustainability concerns [2]. This application note establishes the critical need for standardized green metrics, particularly the Analytical Method Greenness Score (AMGS), within pharmaceutical analysis workflows to quantify and reduce this environmental impact while maintaining analytical integrity.

Green Metrics: A Comparative Toolkit for Researchers

The principles of Green Analytical Chemistry (GAC) aim to mitigate the adverse effects of analytical activities on human health and the environment [3]. Numerous metrics have been developed to assess the greenness of analytical methods, each with distinct characteristics, merits, and limitations [4]. The table below summarizes the most widely used GAC tools relevant to pharmaceutical analysis.

Table 1: Comparison of Key Green Analytical Chemistry (GAC) Metrics

| Metric Name | Type of Output | Key Assessment Criteria | Primary Advantages | Primary Limitations |

|---|---|---|---|---|

| AMGS (Analytical Method Greenness Score) [5] | Numerical Score (%) | Solvent health/safety/environmental impact, cumulative energy demand, instrument energy, solvent waste. | Quantitative, covers multiple environmental facets, specific for LC/SFC methods. | Currently limited to LC/SFC (GC version expected 2026). |

| NEMI (National Environmental Methods Index) [3] | Pictogram (4-quadrant circle) | PBT chemicals, hazardous waste, corrosivity (pH 2-12), waste amount (<50 g). | Simple, immediate visual interpretation. | Qualitative only, provides general information. |

| Analytical Eco-Scale [3] | Numerical Score (100=ideal) | Reagent toxicity, energy consumption, waste generation. | Semi-quantitative, penalty point system is intuitive. | Requires detailed method data for accurate scoring. |

| GAPI (Green Analytical Procedure Index) [3] | Pictogram (multi-step) | Multiple stages from sample collection to waste treatment. | Comprehensive, covers entire analytical procedure. | Complex pictogram can be difficult to interpret. |

| AGREEprep (Analytical GREEnness Metric for Sample Preparation) [6] | Numerical Score (0-1) | 10 criteria for sample preparation including waste, energy, and reagent toxicity. | Specific, quantitative focus on sample preparation. | Does not cover the entire analytical process. |

| BAGI (Blue Applicability Grade Index) [3] | Pictogram | Applicability and practicality of the method. | Assesses practical implementation potential. | Does not directly focus on environmental impact. |

| Diethyltoluamide-d7 | Diethyltoluamide-d7, CAS:1219799-37-7, MF:C12H17NO, MW:198.31 g/mol | Chemical Reagent | Bench Chemicals | |

| PI3K-IN-22 | PI3K-IN-22, CAS:1202884-94-3, MF:C31H35F3N8O3, MW:624.7 g/mol | Chemical Reagent | Bench Chemicals |

A recent comprehensive assessment of 174 standard methods from CEN, ISO, and Pharmacopoeias using the AGREEprep metric revealed that 67% of methods scored below 0.2 (on a 0-1 scale), highlighting that most official methods still rely on resource-intensive, outdated techniques [6]. The performance was poorest in environmental analysis of organic compounds (86% scoring below 0.2), though pharmaceutical methods also showed significant room for improvement (45% scoring below 0.2) [6]. This demonstrates the urgent need for tools like AMGS to drive methodological improvements.

AMGS Protocol: A Step-by-Step Guide for Implementation

Principles of the AMGS Calculator

The AMGS calculator, developed from an initiative by the ACS Green Chemistry Institute Pharmaceutical Roundtable, is designed as a comparative metric for method development rather than an absolute measure for method rejection [5]. It functions by evaluating four primary components:

- Solvent Impact: Factors in health, safety, and environmental impact of all solvents used.

- Cumulative Energy Demand (CED): Accounts for the energy required to produce the solvents.

- Instrument Energy Usage: Based on the power consumption of the instrument over the method runtime.

- Method Solvent Waste: Calculated from the total volume of solvent waste generated.

The metric produces a score where a lower AMGS percentage indicates a greener method. The calculator also employs color-coding (green, yellow, red) to highlight which category contributes most significantly to the score, guiding scientists toward areas for potential improvement [5].

Detailed Experimental Protocol for AMGS Assessment

Table 2: Research Reagent Solutions for Green Pharmaceutical Analysis

| Item/Category | Function | Green Alternatives & Considerations |

|---|---|---|

| Extraction Sorbents (SPE) [7] | Isolate and concentrate analytes from complex matrices. | Use of selective sorbents (e.g., MIPs) to reduce solvent consumption and improve efficiency. |

| Primary Secondary Amine (PSA) [7] | Clean-up agent in QuEChERS to remove polar interferences. | Enables efficient sample clean-up with minimal solvent use compared to traditional methods. |

| Solid Phase Microextraction (SPME) Fiber [7] | Solvent-less extraction and concentration of analytes. | Eliminates the need for organic solvents, significantly reducing waste and toxicity. |

| Green Solvents (e.g., Ethanol, Water) [7] | Mobile phase or extraction solvent. | Replace hazardous solvents like acetonitrile or methanol to reduce environmental and health impacts. |

| UHPLC Systems [7] | Chromatographic separation. | Reduces solvent consumption and analysis time via smaller particle sizes and higher pressures. |

| Automated Sample Preparation [2] | Handle sample preparation steps. | Reduces reagent consumption, waste generation, and operator exposure to hazards. |

Protocol: Implementing AMGS to Evaluate a Liquid Chromatography Method for Drug Analysis

I. Scope This protocol provides a standardized procedure for calculating the Analytical Method Greenness Score (AMGS) for a liquid chromatography (HPLC or UPLC) method used in pharmaceutical analysis. It guides the user through data collection, input, and interpretation of results to compare the greenness of different methodological approaches.

II. Safety

- Standard laboratory safety procedures must be followed.

- Consult safety data sheets (SDS) for all chemicals and solvents used in the analytical method.

- Proper personal protective equipment (PPE) is required when handling chemical standards and solvents.

III. Materials and Equipment

- Computer with internet access.

- AMGS Calculator (online tool from ACS GCI PR website).

- Detailed parameters of the chromatographic method to be assessed.

- Solvent volumes and types used in sample preparation and mobile phase.

- Instrumental energy specifications (if available) or default values from the calculator.

IV. Step-by-Step Procedure

Step 1: Define Method Scope and Boundaries

- Clearly define the start and end points of the analysis (e.g., from sample weighing to final detection).

- Decide if system suitability testing (SST) will be included in the assessment. If so, collect data on solvent volumes used for all dilution steps of the SST [5].

Step 2: Gather Method Parameters for the Chromatographic Run Collect the following data for a single injection:

- Mobile Phase Composition: List all solvents (e.g., Water, Acetonitrile, Methanol) and their respective percentages in the mobile phase (A and B).

- Flow Rate: Record in mL/min.

- Injection Volume: Record in µL.

- Run Time: Record in minutes.

- Column Dimensions: Column length, internal diameter, and particle size.

Step 3: Quantify Sample Preparation Solvents

- List all solvents and volumes used in sample preparation steps (e.g., extraction, dilution, reconstitution). If a method like QuEChERS or SPME is used, which minimizes solvent, this should be accurately recorded [7].

Step 4: Access and Input Data into the AMGS Calculator

- Navigate to the official AMGS calculator tool [5].

- Input the data gathered in Steps 2 and 3 into the corresponding fields of the calculator.

- For instrument energy, use default values provided by the calculator unless specific instrument power data is available.

Step 5: Calculate and Record the Score

- Execute the calculation. The tool will generate an overall AMGS percentage and a color-coded breakdown showing the contribution of each category (solvent, energy, waste).

- Record the overall score and the category-specific scores.

Step 6: Interpret Results and Identify Areas for Improvement

- A lower AMGS score indicates a greener method.

- Use the color-coding to identify the largest contributor to the environmental footprint (e.g., a red "Instrument Energy" score suggests shortening the run time could significantly improve greenness) [5].

- Compare scores for different method variants (e.g., different run times, solvents, or sample prep techniques) to guide optimization toward greener practices.

V. Troubleshooting

- Inconsistent Comparisons: Ensure all methods being compared are assessed using the same system boundaries (e.g., with or without SST).

- Missing Solvent Data: The calculator requires complete solvent information for an accurate score. Estimate volumes carefully if exact measurements are not available.

- High Score in One Category: Focus method improvement efforts on the category (solvent, energy, waste) flagged with a yellow or red color.

Application in Pharmaceutical Analysis: From Theory to Practice

Implementing green metrics like AMGS facilitates the transition from a linear "take-make-dispose" model toward a Circular Analytical Chemistry (CAC) framework [2]. Practical applications in pharmaceutical analysis include:

4.1 Green Sample Preparation

- Solid-Phase Microextraction (SPME): This technique combines extraction and enrichment into a single, solvent-free step, directly reducing solvent waste generation [7].

- QuEChERS: Originally developed for pesticide analysis, this method is recognized as a green extraction technique due to its minimal solvent consumption compared to traditional means [7].

- Automation and Integration: Automated systems save time, lower reagent consumption, and reduce waste generation while minimizing human exposure to hazardous chemicals [2]. Integrating multiple preparation steps into a single workflow cuts down on resource use [2].

4.2 Direct Chromatographic Analysis Where possible, direct analytical techniques that require no sample preparation are ideal from a GAC perspective. While many pharmaceutical matrices are complex, some APIs or formulations may be amenable to direct injection after simple filtration or dilution, dramatically reducing the method's environmental footprint [7].

4.3 Instrumental Method Optimization A key strategy revealed by AMGS is maximizing sample throughput, which reduces the environmental cost per sample. This can be achieved by [2]:

- Accelerating the analysis (e.g., transferring from HPLC to UHPLC to reduce run time and solvent use [7]).

- Treating samples in parallel where instrumentation allows.

- Automating the analytical process.

4.4 Mitigating the Rebound Effect A critical consideration in green analytical chemistry is the "rebound effect," where efficiency gains are offset by increased usage [2]. For example, a cheap, fast microextraction method might lead laboratories to perform significantly more analyses, negating the per-analysis environmental benefit. Laboratories should implement strategies like optimized testing protocols and predictive analytics to ensure that greener methods do not inadvertently lead to over-testing [2].

The adoption of green metrics, particularly the AMGS, is not merely an environmental consideration but a strategic imperative for the modern pharmaceutical industry [1]. It provides a quantitative framework to benchmark and drive the development of analytical methods that align with the principles of Green Analytical Chemistry. This application note demonstrates that by integrating the AMGS protocol into routine method development and optimization, researchers and drug development professionals can significantly reduce the environmental footprint of pharmaceutical analysis while maintaining high analytical standards, ultimately contributing to a more sustainable and responsible industry.

What is AMGS? Origins and Development by ACS Green Chemistry Institute

The Analytical Method Greenness Score (AMGS) is a dedicated metric developed to evaluate and benchmark the environmental sustainability of analytical methods, particularly in chromatography [4]. This calculator serves as a general metric guideline to compare methods during development, providing researchers with a quantitative means to assess the environmental impact of their analytical procedures [5]. The fundamental principle behind AMGS is straightforward: the lower the numerical AMGS value, the greener the analytical method [5]. This inverse relationship encourages scientists to continuously refine their methods to minimize environmental impact while maintaining analytical validity.

The AMGS framework specifically factors in multiple dimensions of environmental impact, including solvent health, safety, and environmental impact, cumulative energy demand, instrument energy usage, and method solvent waste [5]. By integrating these diverse factors into a single calculable score, AMGS provides a holistic view of a method's environmental footprint, enabling analysts to make more informed decisions during method development and optimization. The metric employs a color-coding system as a visual guideline to indicate if a specific energy score category contributes disproportionately to the total AMGS value, highlighting areas where the method could be improved [5].

Historical Development and Institutional Background

The development of AMGS represents a collaborative effort spearheaded by the American Chemical Society Green Chemistry Institute (ACS GCI) Pharmaceutical Roundtable. This initiative emerged from the pharmaceutical industry's growing recognition that approximately 50% of materials used to manufacture bulk active pharmaceutical ingredients are solvents, creating significant environmental implications that needed addressing [8]. The AMGS calculator originated from a Microsoft Excel-based program first developed by Laurent Lehman at Bristol-Myers Squibb, New Brunswick, and was subsequently improved through development by members of the ACS GCI Pharmaceutical Roundtable's Analytical Chemistry team [5].

The institutional development of green chemistry, which provided the foundation for tools like AMGS, can be traced through several key historical phases. The political and scientific momentum began building with the Pollution Prevention Act of 1990, which marked a formal shift from end-of-pipeline control toward pollution prevention as a primary strategy [9]. This legislative foundation was further strengthened by the establishment of the ACS Green Chemistry Institute (ACS GCI), which has led the American Chemical Society's efforts to catalyze the implementation of sustainable approaches to chemistry and engineering across the globe [10]. The historical growth of green chemistry demonstrates how contextual influences and the user-friendliness of the term became drivers for its explosive development [9] [11].

Table: Historical Development of Green Chemistry and AMGS

| Time Period | Key Developments | Institutional Drivers |

|---|---|---|

| Pre-1990 | Informal origins of green chemistry concepts | US EPA, academic researchers |

| 1990-1998 | Pollution Prevention Act of 1990; Early green chemistry symposiums | US Congress, US EPA, NSF |

| 1999-2008 | Rapid growth of green chemistry; Institutionalization | ACS Green Chemistry Institute, pharmaceutical industry |

| 2008-Present | Development of specialized metrics including AMGS | ACS GCI Pharmaceutical Roundtable, industry-academia collaborations |

The current version of the AMGS calculator is specifically designed for determining liquid chromatography and SFC greenness scores, with the ACS GCIPR Analytical Focus Team actively working on improvements and an updated version that will support Gas Chromatography (GC) methods by early 2026 [5]. This ongoing development reflects the commitment to continuous improvement and expansion of the tool's applicability across different analytical techniques.

The AMGS Calculation Framework

Core Calculation Components

The AMGS calculation incorporates multiple environmental factors into a comprehensive assessment framework. The metric systematically evaluates three primary categories that contribute to the overall environmental impact of analytical methods. The color-coding system implemented in AMGS results helps identify which category disproportionately contributes to the total score, guiding researchers toward targeted improvements [5].

Table: AMGS Assessment Categories and Improvement Strategies

| Assessment Category | Key Components Evaluated | Common Improvement Strategies |

|---|---|---|

| Solvent Impact | Health, safety, and environmental factors of solvents used | Substitute hazardous solvents with greener alternatives; reduce solvent volumes |

| Energy Consumption | Cumulative energy demand; instrument energy usage | Shorten method run time; optimize temperature parameters; implement energy-efficient equipment |

| Waste Generation | Method solvent waste; by-products | Miniaturize methods; implement solvent recycling; reduce sample preparation steps |

The AMGS framework encourages environmental impact awareness and provides analysts with concrete data to support the development of greener methods [5]. The calculation specifically accounts for the system suitability test (SST), typically representing 0.05% (v/v) relative to the API reference standard, and includes the total volume of dilutions used when preparations involve serial dilution [5]. This comprehensive approach ensures that even ancillary aspects of analytical methods are incorporated into the environmental assessment.

Implementation Protocol

Protocol: Calculating AMGS for Liquid Chromatography Methods

Purpose: To quantitatively assess the environmental sustainability of liquid chromatography methods using the standardized AMGS calculator.

Materials and Equipment:

- AMGS calculator (digital tool)

- Complete method parameters including runtime, flow rates, and column dimensions

- Solvent types and volumes for mobile phase preparation

- Sample preparation details including solvents and consumables

- System suitability test parameters and dilution schemes

Procedure:

Method Parameter Documentation

- Record all method duration parameters including equilibration time, injection cycle time, and total analytical run time

- Document column oven temperature and any temperature gradient programs

- Note detector-specific energy requirements (e.g., PDA, MS, CAD)

Solvent Inventory Assessment

- Identify all solvents used in mobile phase preparations with exact volumes

- Document solvent volumes used for sample preparation including extraction, dilution, and reconstitution

- Record solvent volumes used for system suitability tests and standard preparations

Waste Stream Quantification

- Calculate total waste generation during analytical runs including purge volumes and needle wash solvents

- Account for waste generated during sample preparation including used vials, filters, and solid-phase extraction cartridges

- Include solvent waste from system suitability tests and quality control samples

Data Input and Calculation

- Access the AMGS calculator through the ACS GCI platform

- Input all documented parameters in the appropriate calculator fields

- Review color-coded results to identify areas with highest environmental impact

- Iteratively adjust method parameters to optimize the AMGS value

Interpretation and Optimization

- Analyze which category (solvent health/safety, energy demand, or waste) contributes most significantly to the score

- Develop optimization strategy targeting the highest impact category first

- Validate that method performance remains acceptable after greenness improvements

Troubleshooting Notes:

- If the AMGS calculator returns unexpectedly high values, verify that all solvent volumes include preparatory and purification steps

- When method modifications are implemented to improve greenness, ensure system suitability criteria are still met

- For methods requiring exceptional sensitivity, focus optimization efforts on waste reduction and energy consumption rather than solvent selection

AMGS Within the Green Analytical Chemistry Landscape

The AMGS represents one of several metrics developed to assess method greenness within the broader context of Green Analytical Chemistry (GAC). GAC focuses on mitigating the adverse effects of analytical activities on human safety, human health, and the environment [4]. Currently, there are 15 widely used GAC metrics, including the National Environmental Methods Index (NEMI), Analytical Eco-Scale, Green Analytical Procedure Index (GAPI), Analytical GREEnness Calculator (AGREE), and AMGS, each with distinct characteristics, merits, and demerits [4].

A recent comparative analysis highlights that while numerous GAC metrics exist, many have specific limitations. Some metrics are restricted to particular analytical techniques, while others provide only qualitative assessment or require complex calculation processes [12]. The AMGS distinguishes itself by focusing specifically on chromatographic methods and incorporating both solvent impact and energy consumption into a single calculable score [5]. However, it should be noted that unlike some newer metrics, AMGS does not generate a pictogram to visually represent method greenness [12].

The development of green chemistry evaluation tools continues to evolve, with recent introductions like the Greenness Evaluation Metric for Analytical Methods (GEMAM) aiming to address limitations of existing tools by providing both qualitative and quantitative information through a pictogram display [12]. These ongoing developments in assessment methodologies reflect the scientific community's continued commitment to enhancing environmental sustainability in analytical practices.

AMGS Assessment Workflow

Essential Research Reagent Solutions for Green Method Development

Implementing AMGS principles requires careful selection of reagents and materials that minimize environmental impact while maintaining analytical performance. The following table details key research reagent solutions aligned with green chemistry principles.

Table: Research Reagent Solutions for Green Analytical Methods

| Reagent Category | Green Alternatives | Function | AMGS Impact |

|---|---|---|---|

| Extraction Solvents | Ethyl acetate, ethanol, cyclopentyl methyl ether | Sample preparation and compound extraction | Reduces health and environmental hazard scores |

| Chromatographic Solvents | Acetonitrile/ethanol blends, methanol/water | Mobile phase composition | Lowers environmental impact and safety concerns |

| Derivatization Agents | Water-soluble reagents, microwave-assisted | Analyte modification for detection | Minimizes hazardous waste generation |

| Precipitation Inhibitors | HPMCAS, HPMC polymers | Maintains supersaturation in SEDDS | Reduces organic solvent consumption |

| Calibration Standards | Aqueous-based formulations | Method calibration and quantification | Eliminates organic solvent waste from standards |

The ongoing development of AMGS reflects the dynamic nature of green chemistry metrics and their increasing importance in sustainable science. The ACS GCI Pharmaceutical Roundtable continues to enhance the AMGS calculator, with planned updates including expansion to Gas Chromatography methods by early 2026 [5]. This directional development highlights the commitment to broadening the applicability of green chemistry assessment tools across analytical techniques.

The AMGS represents a practical implementation of green chemistry principles that aligns with the broader historical development of sustainable science. From its origins in the Pollution Prevention Act of 1990 to its current institutionalization through the ACS GCI, green chemistry has evolved from a conceptual framework to a practical toolkit that includes metrics like AMGS [9]. The continued refinement of these tools addresses the growing need for standardized, quantifiable approaches to environmental assessment in analytical chemistry.

For researchers implementing AMGS, the metric provides both an assessment framework and an optimization pathway for developing more sustainable analytical methods. By integrating AMGS evaluation early in method development, scientists can make environmentally conscious decisions that reduce hazardous waste, decrease energy consumption, and minimize overall environmental impact while maintaining the analytical integrity required for pharmaceutical research and quality control.

The Analytical Method Greenness Score (AMGS) is a comprehensive metric developed to evaluate and minimize the environmental impact of analytical methods, with a particular focus on chromatographic techniques used in pharmaceutical development. Conceived by the American Chemical Society's Green Chemistry Institute (ACS GCI) Pharmaceutical Roundtable, the AMGS provides researchers with a standardized tool to benchmark and compare the sustainability of their analytical procedures [13] [5]. The primary objective of this metric is to raise awareness of environmental impacts and encourage the development of greener methods by providing a clear, quantifiable score where a lower AMGS value indicates a greener method [5].

The AMGS framework is particularly valuable in the pharmaceutical industry, where analytical chemistry plays a critical role in drug development and quality control. By integrating sustainability considerations early in the method development process, organizations can systematically reduce their environmental footprint while maintaining analytical integrity. The metric achieves this by evaluating three core components: the Environmental, Health, and Safety (EHS) profile of solvents, the cumulative energy demand of the method, and the volume of solvent waste generated [5] [14]. This application note provides detailed protocols for implementing the AMGS metric, enabling researchers to quantitatively assess and improve the greenness of their analytical methods.

Core Components of the AMGS Metric

The AMGS calculation integrates three fundamental components that collectively determine the environmental impact of an analytical method. Each component is quantified and weighted to produce a comprehensive score.

Table 1: Core Components of the AMGS Metric

| Component | Description | Key Input Parameters | Measurement Approach |

|---|---|---|---|

| Solvent EHS Impact | Evaluates solvent toxicity and environmental hazards [15] | Health, Safety, and Environmental (HSE) scores; GHS hazard statements [15] | CHEM21 Solvent Selection Guide or similar systems; scores derived from GHS data and physical properties [15] [16] |

| Cumulative Energy Demand (CED) | Total energy for solvent production and disposal [13] | CED values (MJ/kg solvent) [13] | Lifecycle inventory data; accounts for energy from raw material extraction to solvent disposal |

| Instrument Energy Usage | Electricity consumed by analytical instrument [13] | Method runtime, instrument power consumption | Calculated from instrument power rating (kW) multiplied by analysis time (hours) |

| Solvent Waste | Volume of waste solvent generated per analysis [5] | Total solvent volume used per sample | Sum of mobile phase and sample preparation solvent volumes; incorporates system suitability test (SST) dilutions [5] |

Solvent Environmental, Health, and Safety (EHS) Profile

The solvent EHS assessment is a critical element of the AMGS, evaluating the impact of the solvents used throughout the analytical method. The CHEM21 Solvent Selection Guide is a widely adopted tool for this purpose, providing a standardized ranking system based on safety, health, and environmental criteria aligned with the Globally Harmonized System (GHS) [15] [16]. The CHEM21 scoring system assigns a separate score from 1 (lowest hazard) to 10 (highest hazard) for each of the three categories:

- Safety Score: Derived primarily from the solvent's flash point, with additional points for low auto-ignition temperature (<200°C), high resistivity (>10⸠ohm.m), and the ability to form explosive peroxides [15].

- Health Score: Based predominantly on the most stringent GHS H3xx statements (e.g., H330: fatal if inhaled, H341: suspected of causing genetic defects), with an additional point added if the boiling point is below 85°C (increased inhalation risk) [15].

- Environmental Score: Considers the solvent's volatility (boiling point) and associated GHS H4xx statements (e.g., H400: very toxic to aquatic life) [15].

These three scores are then combined to assign an overall solvent ranking of "Recommended," "Problematic," or "Hazardous" [15]. For the AMGS calculation, these categorical rankings or the underlying numerical scores are integrated to reflect the solvent's relative environmental and safety impact.

Energy Demand and Consumption

The AMGS metric incorporates energy consumption from two distinct sources: the energy embedded in the solvents used and the direct electrical energy consumed by the instrument during operation.

- Cumulative Energy Demand (CED): This represents the total energy required to produce and eventually dispose of a unit of solvent (typically in MJ/kg) [13]. It is a lifecycle-based concept that accounts for energy consumption from raw material extraction through manufacturing, transportation, and end-of-life treatment. Utilizing solvents with lower CED values directly contributes to a greener AMGS.

- Instrument Energy Usage: This component quantifies the direct electricity consumption of the chromatographic system (e.g., HPLC, UHPLC) during a single analytical run. It is a function of the instrument's power draw (in kW) and the method runtime (in hours). Shorter method times and energy-efficient instruments significantly reduce this component of the score [5].

Solvent Waste Generation

The volume of solvent waste generated per analysis is a straightforward but critical component. This includes all solvents used in the mobile phase and during sample preparation, such as dilution and extraction solvents [5]. The AMGS calculator specifically notes that the total volume should account for serial dilutions used in preparing system suitability test (SST) solutions [5]. Minimizing waste volume through method miniaturization, solvent recycling, or reducing scale is a direct and effective strategy for improving the AMGS.

AMGS Calculation Workflow

The process of calculating the Analytical Method Greenness Score follows a logical sequence where data from the analytical method is collected and processed through the AMGS algorithm. The workflow below visualizes this process from method parameters to the final score and its interpretation.

Protocol for AMGS Calculation

This protocol provides a step-by-step methodology for calculating the AMGS for a liquid chromatography method.

Materials and Software:

- AMGS Calculator (Web-based tool from ACS GCI PR)

- Chromatographic method details (solvents, flow rate, runtime, etc.)

- CHEM21 Solvent Selection Guide

Procedure:

Gather Method Parameters:

- Record the names and volumes of all solvents used in the mobile phase and for sample preparation/dilution.

- Note the method runtime (in minutes).

- Identify the instrument type (e.g., HPLC, UHPLC) and its typical power consumption, if known.

- Calculate the total solvent waste volume per sample, including the mobile phase volume consumed during the run and any sample preparation solvents.

Determine Solvent EHS Scores:

Input Data into AMGS Calculator:

- Access the AMGS calculator via the ACS GCI PR website [5] [14].

- Enter the required data into the designated fields:

- Solvent Section: Input solvent types and volumes.

- Energy Section: Input method runtime and instrument type.

- Waste Section: Input the total waste volume calculated in Step 1.

- System Suitability: Include the total volume of dilutions if a serial dilution was performed for the SST [5].

Execute Calculation and Interpret Results:

- Run the calculation to generate the AMGS score. A lower percentage score indicates a greener method [5].

- Analyze the color-coded output, which highlights which component (solvent EHS, energy, or waste) contributes most significantly to the score. Yellow and red indicators pinpoint areas with the greatest potential for improvement [5].

Case Study and Experimental Data

A recent study by AstraZeneca demonstrates the practical application of the AMGS in a industrial drug development context. The researchers utilized the AMGS to assess the current state of their analytical methods, influence standard practices, and create internal tools for trending data as a mode of continuous process verification [13]. This systematic approach allowed them to quantify the environmental benefits of method optimization and drive a cultural shift towards sustainable analytical practices within the organization.

Table 2: Exemplary AMGS Comparison for Chromatographic Methods

| Method Parameter | Traditional HPLC Method | Optimized UHPLC Method | Notes and Impact |

|---|---|---|---|

| Column Dimensions | 4.6 x 150 mm, 5 µm | 2.1 x 50 mm, 1.7 µm | Miniaturization reduces solvent consumption and waste. |

| Flow Rate | 1.0 mL/min | 0.4 mL/min | Directly lowers solvent usage per unit time. |

| Primary Solvent | Acetonitrile (Problematic) [15] | Ethanol (Recommended) [15] | Switching to a CHEM21 "Recommended" solvent improves EHS profile. |

| Method Runtime | 20 minutes | 5 minutes | 75% reduction significantly cuts instrument energy consumption. |

| Total Solvent Waste/Sample | 20 mL | 2 mL | 90% reduction in waste volume due to smaller column and shorter runtime. |

| Calculated AMGS | Higher (Less Green) | Lower (Greener) | The optimized method achieves a superior sustainability profile. |

The data in Table 2 illustrates how strategic modifications to an analytical method directly influence the core components of the AMGS. The transition from a traditional HPLC setup to an optimized UHPLC method results in substantial improvements across all evaluated domains: a better EHS profile via solvent substitution, reduced energy demand from a shorter runtime, and a drastic reduction in solvent waste generation through miniaturization [13].

The Scientist's Toolkit: Research Reagent Solutions

Selecting appropriate reagents, particularly solvents, is fundamental to designing green analytical methods. The following table details key reagents and their roles within the AMGS framework.

Table 3: Essential Reagents and Materials for Green Analytical Methods

| Reagent/Material | Function in Analytical Method | Greenness Considerations (CHEM21 Guide) | Example Substitutions for Greener Profile |

|---|---|---|---|

| Acetonitrile | Common HPLC strong solvent. | Often ranked "Problematic" due to health (H312, H332) and environmental concerns [15] [16]. | Substitute with Ethanol or Isopropanol, which are often "Recommended" and bio-derived [15] [16]. |

| Methanol | HPLC solvent, extraction solvent. | Can be "Problematic" (H301, H311, H331) but often revised to "Recommended" with proper handling [15]. | Ethanol is a less toxic alternative for some applications [15]. |

| n-Hexane | Extraction solvent. | Typically "Hazardous" due to safety (H224) and health (H304, H361, H373) risks [16]. | Heptane or Cyclopentyl methyl ether (CPME) may offer safer profiles [16]. |

| Dichloromethane | Strong extraction solvent. | "Hazardous" due to health concerns (H351 - suspected carcinogen) [16]. | Ethyl Acetate ("Recommended") is a commonly explored greener alternative [15]. |

| Diethyl Ether | Extraction solvent. | "Hazardous" due to extreme flammability (H224) and peroxide formation risk [15]. | Methyl tert-butyl ether (MTBE) or Ethyl Acetate are generally safer options [15]. |

| Ethyl Acetate | Extraction solvent, HPLC mobile phase. | Widely "Recommended" with noted flammability (H225) requiring standard precautions [15]. | A versatile, greener solvent for multiple applications. |

| Water | HPLC weak solvent, extraction solvent. | The greenest solvent, with perfect SHE scores (1,1,1) [15]. | Use as a primary solvent where method performance allows. |

| 3,7-DMF | 3,7-DMF, CAS:20950-52-1, MF:C17H14O4, MW:282.29 g/mol | Chemical Reagent | Bench Chemicals |

| LEQ506 | LEQ506, CAS:1204975-42-7, MF:C25H32N6O, MW:432.6 g/mol | Chemical Reagent | Bench Chemicals |

The Analytical Method Greenness Score (AMGS) provides a robust, quantitative framework for assessing and improving the environmental sustainability of analytical methods in pharmaceutical research and development. By systematically evaluating the three core components of solvent EHS impact, energy demand, and waste generation, researchers can make informed decisions that significantly reduce the ecological footprint of their work. The provided protocols, data tables, and the standardized CHEM21 guide offer a practical toolkit for scientists to implement this metric effectively. As the industry moves towards greater sustainability, adopting tools like the AMGS is no longer optional but essential for driving innovation in green chemistry and minimizing the environmental impact of drug development.

How AMGS Complements Traditional Analytical Performance Metrics

The pharmaceutical industry is increasingly prioritizing sustainability, driven by awareness of environmental impacts associated with drug development and manufacturing [17]. Within this framework, Green Analytical Chemistry (GAC) has emerged as a disciplined approach to minimize the environmental footprint of analytical techniques while maintaining data quality and reliability [18]. The fundamental challenge lies in balancing conventional method performance criteria—such as specificity, accuracy, and precision—with emerging environmental considerations [3].

The Analytical Method Greenness Score (AMGS) represents a significant advancement in quantifying this balance. Developed by the American Chemical Society's Green Chemistry Institute in collaboration with industry partners, AMGS provides a comprehensive, quantitative assessment of environmental impact across multiple dimensions [17]. Unlike traditional metrics that focus solely on technical performance, AMGS evaluates solvent energy consumption, environmental health and safety (EHS) characteristics, and instrument energy usage, providing a holistic sustainability profile for chromatographic and other analytical methods [17].

The Analytical Method Greenness Score (AMGS): Principles and Calculation

Fundamental Components

AMGS operates on a multi-factor assessment model that quantifies the environmental impact of analytical methods based on several key parameters. The score incorporates three primary components: solvent EHS considerations, solvent energy footprint, and instrument energy consumption [17]. This tripartite structure enables a balanced evaluation that accounts for both chemical and operational sustainability factors.

The solvent EHS score assesses environmental, health, and safety impacts of solvents used in analytical methods, penalizing hazardous substances while rewarding safer alternatives. The solvent energy score calculates energy consumed during solvent production and disposal, emphasizing lifecycle thinking. Meanwhile, the instrument energy score quantifies direct power consumption of analytical equipment during method operation, encouraging energy-efficient technologies and practices [17].

Calculation Methodology

AMGS employs a structured calculation framework that transforms raw method parameters into a comprehensive greenness score. The formula integrates the three component scores through weighted aggregation:

AMGS = (Solvent EHS Score + Solvent Energy Score + Instrument Energy Score) / 3

Each component score is calculated separately based on method-specific parameters. The solvent EHS score incorporates toxicity, flammability, and environmental impact data. The solvent energy score considers the energy intensity of solvent production and waste processing. The instrument energy score factors in power consumption rates, run times, and throughput efficiency [17]. This calculation yields a single numerical score that facilitates straightforward comparison between different analytical methods and their environmental performance.

Comparative Analysis: AMGS Versus Traditional Performance Metrics

Complementary Roles in Method Assessment

Traditional analytical performance metrics and AMGS serve distinct but complementary roles in comprehensive method evaluation. While conventional parameters ensure technical reliability and data quality, AMGS addresses environmental sustainability, together enabling more informed method selection and development decisions.

Table 1: Comparison of AMGS and Traditional Analytical Performance Metrics

| Assessment Dimension | Traditional Metrics | AMGS | Complementary Relationship |

|---|---|---|---|

| Primary Focus | Data quality, reliability, regulatory compliance | Environmental impact, safety, sustainability | Ensures methods are both technically valid and environmentally responsible |

| Key Parameters | Accuracy, precision, specificity, linearity, robustness | Solvent EHS, solvent energy, instrument energy consumption | Broadens assessment beyond technical performance to environmental footprint |

| Assessment Approach | Method validation protocols, system suitability testing | Multi-factor scoring of environmental parameters | Provides complementary perspective for holistic method characterization |

| Decision Support | Method capability for intended purpose | Environmental impact reduction opportunities | Balances technical and sustainability considerations in method selection |

| Regulatory Significance | Required for method approval | Emerging importance in environmental compliance | Addresses both product quality and corporate sustainability mandates |

Integration in Pharmaceutical Development

The pharmaceutical industry presents a compelling case for AMGS implementation, where analytical methods are fundamental to quality control and regulatory compliance throughout drug development [17]. A case study of rosuvastatin calcium manufacturing illustrates the cumulative environmental impact of analytical methods when scaled across global production networks. With approximately 25 liquid chromatography analyses per batch and an estimated 1,000 batches produced annually, this single API consumes approximately 18,000 liters of mobile phase each year solely for chromatographic analysis [17].

This example underscores how AMGS complements traditional performance metrics by revealing environmental cost factors that remain invisible in conventional assessments. While system suitability tests and validation protocols ensure method reliability, AMGS quantifies the sustainability profile, enabling organizations to make more environmentally responsible choices without compromising data quality [17].

Experimental Protocols for AMGS Assessment

Protocol: Comprehensive AMGS Calculation for HPLC Methods

Principle: This protocol provides a standardized methodology for calculating the Analytical Method Greenness Score for High Performance Liquid Chromatography (HPLC) methods, enabling objective comparison of environmental performance across different analytical procedures.

Materials and Reagents:

- HPLC system with documented power consumption specifications

- Analytical columns specified in method documentation

- HPLC-grade solvents and reagents

- Method validation documentation

- Power consumption meter (optional)

Procedure:

- Solvent Inventory and Volumes

- Record all solvents used in mobile phase preparation, including compositions and proportions

- Calculate total solvent consumption per analysis based on flow rate and run time

- Account for solvent usage in sample preparation and dilution steps

- Document waste generation volumes, including column equilibration and shutdown steps

Solvent EHS Assessment

- Consult solvent safety data sheets for hazard classifications

- Assign EHS penalties based on environmental impact, health effects, and safety hazards

- Apply weighting factors for solvent volume used in the method

- Calculate composite EHS score using established penalty point systems

Solvent Energy Calculation

- Determine energy intensity factors for each solvent (production and disposal)

- Multiply solvent volumes by respective energy intensity factors

- Sum energy components across all solvents used in the method

- Normalize to energy per analysis basis

Instrument Energy Consumption

- Document HPLC system power rating from manufacturer specifications

- Record actual method run time, including equilibration and re-equilibration

- Calculate energy consumption per analysis (kWh)

- For multi-sample sequences, factor in standby energy consumption

AMGS Computation

- Normalize each component score to a common scale (0-100)

- Apply weighting factors if specified by organizational guidelines

- Calculate final AMGS using the formula: (Solvent EHS + Solvent Energy + Instrument Energy) / 3

- Document all assumptions and calculation parameters

Notes: For methods requiring sample derivation, include derivative reagent volumes and energies. For automated sequences, calculate average energy per sample based on full sequence runtime.

Workflow Visualization

Comparative Evaluation of Green Metrics

AMGS in Context with Other Assessment Tools

Multiple green assessment tools have emerged alongside AMGS, each with distinct approaches, advantages, and limitations. Understanding how AMGS complements these tools provides valuable context for its application in analytical method development.

Table 2: Comparison of AMGS with Other Green Assessment Metrics

| Metric | Assessment Approach | Key Strengths | Key Limitations | Relationship to AMGS |

|---|---|---|---|---|

| AMGS | Multi-factor quantitative scoring of solvent EHS, solvent energy, instrument energy | Comprehensive, quantitative, specifically designed for chromatography | Limited to chromatographic methods, does not address sample preparation in detail | Reference standard for chromatographic methods |

| NEMI | Pictogram with four criteria (PBT, hazardous waste, corrosivity, waste volume) | Simple, visual representation | Qualitative only, limited discrimination between methods | AMGS provides quantitative refinement of NEMI concepts |

| Analytical Eco-Scale | Penalty point system subtracted from ideal score of 100 | Semi-quantitative, incorporates reagent toxicity and energy | Does not specifically address instrument energy consumption | AMGS offers more specific focus on chromatographic parameters |

| GAPI | Multi-criteria pictogram with color-coded impact assessment | Comprehensive visual assessment of entire method | Qualitative assessment, limited numerical comparison | AMGS provides quantitative alternative with specific chromatography focus |

| AGREE | Radar chart visualization of 12 GAC principles | Comprehensive, visual, applicable to multiple techniques | Less specific to chromatographic method parameters | AMGS offers chromatography-specific complement to general AGREE assessment |

| GEMAM | Hexagonal pictogram scoring 21 criteria across 6 dimensions | Comprehensive, incorporates sample preparation and operator safety | Complex calculation process, newer with less established track record | AMGS provides simpler, chromatography-focused alternative |

Research Reagent Solutions for Green Analytical Chemistry

Implementing AMGS and improving analytical method greenness requires specific reagents and materials designed to reduce environmental impact while maintaining analytical performance.

Table 3: Essential Research Reagents and Materials for Green Method Development

| Reagent/Material | Function | Green Chemistry Application |

|---|---|---|

| Water-Miscible Organic Solvents (e.g., ethanol, acetone) | Mobile phase component | Replace hazardous solvents like acetonitrile, reduce waste treatment complexity |

| Supercritical COâ‚‚ | Extraction and chromatography solvent | Eliminate organic solvent use, easily recycled after use |

| Ionic Liquids | Alternative solvents for extraction | Low volatility reduces atmospheric emissions, tunable properties |

| Molecularly Imprinted Polymers | Selective extraction sorbents | Enable miniaturized extraction, reduce solvent consumption |

| Switchable Hydrophilicity Solvents | Extraction media | Solvents that can be switched between hydrophobic and hydrophilic forms for easy recovery and reuse |

| Bioprocessed Solvents (e.g., bioethanol, biodiesel) | Mobile phase components | Renewable sourcing reduces lifecycle environmental impact |

| Monolithic Columns | Chromatographic separation | Reduce backpressure, enable lower flow rates and faster separations |

| Core-Shell Particle Columns | Chromatographic separation | Enable high efficiency at lower pressures, reducing energy consumption |

| Green Derivatization Agents | Sample derivation for detection | Less toxic alternatives to hazardous derivatization reagents |

Implementation Strategy: Integrating AMGS in Method Development and Validation

Organizational Adoption Framework

Successfully integrating AMGS into established analytical workflows requires a systematic implementation approach. Organizations should develop a phased adoption strategy that introduces AMGS assessment alongside traditional method validation protocols without disrupting existing quality systems.

The initial phase should focus on assessment and benchmarking of current method portfolio using AMGS criteria. This establishes baseline environmental performance and identifies priority areas for improvement. AstraZeneca's approach demonstrates this principle, where they "utilised this readily available tool to assess the current status, influence standard practices and create internal tools that trend data as a mode of continuous process verification" [17].

The second phase involves method redesign and optimization targeting the lowest-scoring AMGS components. This may include solvent substitution, method miniaturization, or instrument parameter optimization. The case study from AstraZeneca highlights how general methods with "poor sustainability credentials" can be identified and systematically improved [17].

The final phase establishes ongoing monitoring and continuous improvement, integrating AMGS tracking into routine method management. This ensures that environmental considerations remain central to analytical method lifecycle management alongside traditional performance metrics.

Decision Framework Visualization

The Analytical Method Greenness Score represents a critical evolution in analytical science, complementing traditional performance metrics by quantifying environmental sustainability. As the pharmaceutical industry advances toward ambitious goals like AstraZeneca's target of "carbon zero status for analytical laboratories by 2030," tools like AMGS provide the measurement framework necessary to track progress and guide improvement efforts [17].

By integrating AMGS assessment alongside traditional validation parameters, organizations can make more informed decisions that balance technical requirements with environmental responsibility. This integrated approach ensures that analytical methods support not only product quality and regulatory compliance but also corporate sustainability objectives and the broader imperative of environmental stewardship.

The Analytical Method Greenness Score (AMGS) is a comparative metric designed to benchmark and evaluate the environmental sustainability of analytical methods, particularly in pharmaceutical development and drug discovery [5]. This calculator provides researchers with a straightforward, quantitative means to assess the greenness of their analytical processes, enabling informed decisions that reduce environmental impact while maintaining scientific rigor [14].

The AMGS was developed from a Microsoft Excel-based program initially created at Bristol-Myers Squibb and subsequently refined through collaboration by members of the American Chemical Society (ACS) Green Chemistry Institute (GCI) Pharmaceutical Roundtable's Analytical Chemistry team [5]. This pedigree ensures the tool is both practically grounded and scientifically validated for use within the pharmaceutical industry. The primary purpose of the AMGS is to raise environmental impact awareness during method development and encourage analysts to create greener methods by providing a clear, comparative score [5].

A fundamental principle of the AMGS is that a lower score indicates a greener method [5]. The metric synthesizes multiple environmental factors into a single value, including solvent health and safety profiles, cumulative energy demand, instrument energy consumption, and method solvent waste generation [4] [14]. This multi-factorial approach prevents the optimization of one environmental aspect at the expense of others, promoting truly sustainable method development.

Quantitative Environmental Benefits of AMGS Implementation

Core Environmental Metrics and Comparative Data

Implementation of AMGS enables organizations to quantify and manage the environmental footprint of their analytical operations. The table below summarizes key environmental metrics that can be optimized through AMGS-guided method development:

Table 1: Environmental Impact Metrics for Analytical Method Assessment

| Metric Category | Specific Parameters | Measurement Approach | Impact of Greener Methods |

|---|---|---|---|

| Solvent Waste | Total solvent volume consumed; Waste generated per analysis | Volume accounting per method; Solvent recycling rates | Reduction in hazardous waste generation and disposal [5] |

| Energy Consumption | Instrument energy usage; Cumulative energy demand | kWh per analysis; Energy source (grid vs. renewable) | Lower power consumption through shortened run times and efficient instrumentation [5] [14] |

| Greenhouse Gas Emissions | COâ‚‚e emissions from solvent production and energy use | Lifecycle assessment calculations | Reduced carbon footprint through minimized energy and resource consumption [19] |

| Toxicity & Safety | Solvent health, safety, and environmental impact scores | Standardized solvent assessment tools | Improved workplace safety and reduced environmental toxicity [5] |

Organizations that systematically track these metrics can demonstrate tangible environmental improvements. For instance, transitioning from traditional High-Performance Liquid Chromatography (HPLC) to Ultra-High-Performance Liquid Chromatography (UHPLC) or Supercritical Fluid Chromatography (SFC) typically reduces solvent consumption by 50-90% and decreases analysis time by 60-80% while maintaining or improving analytical performance [14]. These methodological improvements directly translate to reduced environmental impact across all metrics captured by the AMGS calculation.

Economic Advantages of Green Method Implementation

The business case for AMGS implementation extends beyond environmental benefits to deliver substantial economic value through multiple pathways:

Table 2: Economic Benefits of AMGS Implementation

| Economic Benefit Category | Specific Financial Impacts | Implementation Example |

|---|---|---|

| Operational Cost Reduction | Lower solvent purchase costs; Reduced waste disposal expenses; Decreased energy bills | SFC methods typically use <10% of the solvent required by normal-phase HPLC, directly cutting material and waste management costs [14] |

| Regulatory Compliance | Minimized regulatory burden; Simplified permitting; Reduced compliance monitoring | Methods with greener solvent selections may fall under higher thresholds for hazardous waste reporting [19] |

| Productivity Gains | Higher sample throughput; Reduced analyst time per sample; Faster method development | UHPLC methods with shorter run times enable more analyses per instrument per day, delaying capital equipment investments [14] |

| Innovation & Reputation | Enhanced corporate sustainability profile; Stronger green credentials; Competitive advantage | Public commitment to green chemistry principles can strengthen brand position and attract sustainability-conscious partners [20] |

The economic argument is strengthened by recognizing that the "grow now, clean up later" approach has been widely discredited by experience across multiple industries, often resulting in rapidly escalating external costs from accumulated pollution damage and substantial investments in remediation [20]. Proactive environmental management through tools like AMGS helps organizations avoid these downstream costs while capturing immediate operational efficiencies.

AMGS Calculation Protocol and Methodology

Step-by-Step Calculation Procedure

The AMGS calculator provides a systematic approach to evaluating analytical methods. Follow this standardized protocol to ensure consistent, comparable results:

- Method Documentation: Record all relevant method parameters including instrument type, flow rate, run time, column dimensions, and injection volume [5].

- Solvent System Identification: Document the complete mobile phase composition, including all solvents and their percentages throughout the chromatographic run. Note any solvent recycling or recovery practices [5].

- Sample Preparation Accounting: Include all solvents and materials used in sample preparation, standard solutions, and system suitability testing. For serial dilutions, provide the total volume of all dilutions used to make the final solution [5].

- Energy Consumption Assessment: Calculate instrument energy usage based on run time and instrument power specifications. Shorter run times generally reduce energy consumption [5].

- Data Input and Calculation: Enter all collected data into the AMGS calculator. The tool will factor solvent health, safety, environmental impact, cumulative energy demand, instrument energy usage, and method solvent waste to generate the composite score [5] [4].

- Results Interpretation: Review the color-coded output, which highlights areas for potential improvement. Yellow and red indicators signal opportunities to optimize specific method parameters [5].

Diagram: AMGS Calculation Workflow

Experimental Design for Method Comparison

When evaluating multiple analytical methods for the same application, employ this standardized experimental protocol to ensure valid AMGS comparisons:

- Define Analytical Requirements: Establish fixed method performance criteria including resolution, sensitivity, precision, and accuracy that all methods must meet.

- Develop Parallel Methods: Create multiple method options that all meet the analytical requirements but employ different approaches (e.g., varied instrumentation, solvent systems, or run times).

- Calculate Individual AMGS Values: Apply the AMGS calculation procedure to each qualified method.

- Compare Scores: Rank methods by their AMGS values, recognizing that lower scores indicate greener methods while ensuring all maintained the required analytical performance [5].

- Optimize Leading Candidates: Use the color-coded AMGS feedback to further refine the most promising methods, focusing on parameters indicated as high-impact (yellow or red indicators).

This systematic comparison enables evidence-based selection of the greenest viable method while maintaining analytical integrity.

Implementation Framework for AMGS in Research Organizations

Organizational Integration Strategy

Successful AMGS implementation requires both technical adoption and organizational commitment. The following workflow outlines a structured approach for integrating AMGS into existing research and development processes:

Diagram: AMGS Organizational Implementation Process

Effective implementation mirrors environmental management approaches used in other industrial sectors, where dedicated committees focus on associated legal liabilities, discrete remediation projects, and addressing environmental risks from business units [19]. Similar governance structures can support AMGS integration within research organizations.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key materials and their optimized selections for reducing AMGS in analytical method development:

Table 3: Research Reagent Solutions for Greener Analytical Methods

| Material Category | Green Alternatives | Function | Environmental Advantage |

|---|---|---|---|

| Chromatographic Solvents | Ethanol, acetone, ethyl acetate, supercritical COâ‚‚ | Mobile phase composition; Sample preparation | Lower toxicity, improved biodegradability, reduced environmental persistence [5] |

| Extraction Solvents | Water (at elevated temperatures), bio-based solvents, solvent-free extraction | Sample preparation and analyte extraction | Reduced hazardous waste generation, safer workplace environment [5] |

| Derivatization Reagents | Water-compatible reagents, reduced toxicity catalysts | Analyte chemical modification for detection | Minimized generation of hazardous byproducts [4] |

| Separation Columns | UHPLC columns (sub-2μm particles), core-shell technology | Chromatographic separation | Enables faster separations with lower solvent consumption [14] |

| Evogliptin tartrate | Evogliptin tartrate, CAS:1222102-51-3, MF:C23H32F3N3O9, MW:551.5 g/mol | Chemical Reagent | Bench Chemicals |

| Clozapine-d4 | Clozapine-d4, CAS:204395-52-8, MF:C18H19ClN4, MW:330.8 g/mol | Chemical Reagent | Bench Chemicals |

Environmental and Economic Impact Assessment

Comprehensive Benefit Analysis

Systematic implementation of AMGS-guided methods generates compounding environmental and economic benefits:

- Accumulated Resource Savings: The cumulative impact of multiple method optimizations across an organization can yield substantial reductions in solvent purchasing, waste disposal costs, and energy consumption. One study found that using greener alternatives could result in 25% or more GHG emissions mitigation benefit when compared with standard approaches [19].

- Risk Mitigation: By reducing reliance on hazardous solvents and minimizing waste generation, organizations decrease their environmental liability and potential regulatory exposure [19] [20].

- Innovation Acceleration: The discipline of method greening often stimulates procedural innovations that deliver both environmental and operational benefits. One company reported designing processes that achieve over 99% conversion of materials to saleable finished goods while generating no process wastewater [19].

- Strategic Alignment: AMGS implementation supports corporate sustainability commitments and Environmental, Social, and Governance (ESG) reporting requirements, increasingly important for market positioning and stakeholder relations [19].

Limitations and Future Developments

The current version of the AMGS calculator is designed for determining liquid chromatography and SFC greenness scores only [5]. The ACS GCI Pharmaceutical Roundtable's Analytical Focus Team is actively working on improvements to the tool, with an updated version supporting Gas Chromatography (GC) methods expected by early 2026 [5].

Researchers should recognize that AMGS is intended as a comparative metric to guide method selection during development, not as an absolute measure of method greenness or as a means to reject a given method based solely on the finite score [5]. The tool should be used in conjunction with traditional method validation criteria to ensure both analytical and environmental performance.

Forward-looking organizations will benefit from establishing AMGS baselines for their current methods and tracking improvements over time as they implement greener alternatives. This approach demonstrates continuous improvement and contributes to broader corporate sustainability objectives while delivering measurable economic benefits through more efficient resource utilization.

The field of analytical chemistry has undergone a significant paradigm shift with the emergence of Green Analytical Chemistry (GAC), which aims to mitigate the environmental impacts of analytical processes. This evolution addresses the paradox that while analytical chemistry plays a crucial role in environmental monitoring, its own practices—characterized by toxic solvents, high energy consumption, and substantial waste generation—contribute to environmental degradation [21] [22]. Within this context, the Analytical Method Greenness Score (AMGS) has emerged as a specialized metric to benchmark and compare the environmental performance of analytical methods, particularly in chromatography [5].

The development of AMGS represents a practical implementation of broader green chemistry principles into analytical practice. Originally developed from a Microsoft Excel-based program at Bristol-Myers Squibb and further refined by the American Chemical Society Green Chemistry Institute Pharmaceutical Roundtable (ACS GCI PR), AMGS provides a quantitative framework for assessing method greenness [5]. This metric specifically factors solvent health, safety, environmental impact, cumulative energy demand, instrument energy usage, and method solvent waste to provide a comprehensive environmental profile [5]. The calculated score serves as a comparative tool, where a lower AMGS value indicates a greener method, enabling scientists to make informed decisions during method development that align with sustainability goals.

The Theoretical Evolution: From Green to White Analytical Chemistry

Historical Development of Green Chemistry in Analysis

The conceptual foundation for GAC was established with Paul Anastas and John Warner's formulation of the twelve principles of green chemistry in 1998 [22]. These principles provided the basis for what would later become the twelve principles of Green Analytical Chemistry, which aim to avoid adverse environmental impacts without compromising analytical quality and efficiency [22]. The movement gained institutional support with the launch of the American Chemical Society-Green Chemistry Institute Pharmaceutical Roundtable (ACS-GCIPR) in 2005, followed by the first seminal publication specifically addressing Green Analytical Chemistry in 2006 [22].

Early green chemistry metrics focused primarily on waste reduction, with Sheldon's E-Factor being one of the most prominent examples. This simple metric calculates the total weight of waste generated per kilogram of product [23]. As shown in Table 1, E-Factor values vary significantly across industry sectors, with pharmaceutical manufacturing typically generating 25-100+ kg of waste per kg of product due to multi-stage syntheses and high-purity requirements [23].

Table 1: E-Factor Values Across Chemical Industry Sectors [23]

| Industry Sector | Product Tonnage | E-Factor (kg Waste/kg Product) |

|---|---|---|

| Oil refining | 10â¶-10⸠| <0.1 |

| Bulk chemicals | 10â´-10ⶠ| <1.0 to 5.0 |

| Fine chemicals | 10²-10ⴠ| 5.0 to >50 |

| Pharmaceutical industry | 10-10³ | 25 to >100 |

Expansion to White Analytical Chemistry (WAC)

While GAC focused primarily on environmental aspects, a more comprehensive approach has emerged called White Analytical Chemistry (WAC), which addresses observed limitations in practically applying GAC principles [22]. A primary concern was the potential trade-off between environmental sustainability and analytical performance, where strict adherence to GAC principles could sometimes lead to compromised sensitivity, precision, or accuracy [22].

WAC introduces an integrated approach incorporating three complementary dimensions, visualized using an RGB color model:

- Red Criteria: Represents analytical performance parameters, including accuracy, precision, sensitivity, and reproducibility [22].

- Green Criteria: Encompasses environmental sustainability factors, including waste generation, energy consumption, and reagent toxicity [22].

- Blue Criteria: Addresses practical and economic considerations, such as cost-efficiency, operational simplicity, and time requirements [22].

The combination of these three dimensions aims to achieve "method whiteness" - an indicator of how well an approach satisfies sustainability, analytical capability, and practical applicability criteria simultaneously [22]. This holistic framework aligns analytical method development with the broader concept of sustainable development, where environmental responsibility coexists with technical excellence and practical feasibility.

Figure 1: Evolution from Green Chemistry to White Analytical Chemistry and the positioning of AMGS within this framework.

AMGS Fundamentals and Calculation Methodology

Core Components of the AMGS Metric

The Analytical Method Greenness Score provides a structured approach to evaluate the environmental impact of chromatographic methods. According to the ACS GCI Pharmaceutical Roundtable, AMGS calculation incorporates three primary categories [5]:

- Solvent Impact: Evaluates solvent health, safety, and environmental factors, along with cumulative energy demand.

- Instrument Energy: Assesses energy consumption based on instrument type and method runtime.

- Method Solvent Waste: Calculates waste generation considering flow rate, collection time, and solvent composition.

The AMGS calculator employs color coding (yellow and red) to highlight areas contributing most significantly to the overall score, providing clear indicators for potential methodological improvements [5]. For instance, a red indicator for instrument energy would suggest that reducing method runtime could enhance greenness.

Practical Implementation Protocol

Protocol: Calculating AMGS for Liquid Chromatography Methods

Objective: To determine the Analytical Method Greenness Score for HPLC or UPLC methods to enable environmental impact assessment and comparison.

Materials:

- AMGS calculator (available through ACS GCI PR)

- Chromatographic method parameters

- Solvent consumption data

- Instrument specifications

Procedure:

Data Collection:

- Record mobile phase composition including all solvents and additives

- Document flow rate (mL/min) and method runtime (minutes)

- Note injection volume and any needle wash compositions

- Identify instrument type (HPLC, UPLC, or SFC)

System Suitability Solution Preparation:

- Include total volume of all dilutions when preparing serial dilutions

- For methods using both resolution and sensitivity solutions, include total volume for both in the sensitivity solution entry [5]

Calculator Input:

- Enter solvent volumes and compositions in appropriate fields

- Input instrument type and method duration

- Specify collection time for waste calculation

- Include all system suitability testing parameters

Score Interpretation:

- Review total AMGS (lower scores indicate greener methods)

- Identify category-specific color codes to pinpoint improvement areas

- Compare with alternative method configurations

Method Optimization:

- Implement changes to address high-impact categories

- Recalculate AMGS for modified methods

- Balance environmental improvements with analytical performance

Notes: The current AMGS calculator version supports liquid chromatography and SFC methods only, with GC compatibility planned for 2026 [5]. The tool is intended as a comparative metric during method development rather than an absolute measure of greenness.

Case Studies: AMGS in Pharmaceutical Analysis

Application in Chromatographic Method Greening

Recent research demonstrates the practical application of AMGS in developing greener chromatographic methods. In one study, researchers utilized in silico modeling to significantly improve method greenness while maintaining analytical performance [24]. By mapping AMGS across the entire separation landscape, scientists could simultaneously develop methods based on both performance and greenness criteria.

A key application involved replacing fluorinated mobile phase additives with chlorinated alternatives, which reduced the AMGS from 9.46 to 4.49 while improving resolution from fully overlapped peaks to a resolution of 1.40 [24]. In another example, researchers replaced acetonitrile with environmentally friendlier methanol, reducing the AMGS from 7.79 to 5.09 while preserving critical resolution [24]. These examples demonstrate how AMGS provides quantitative guidance for solvent selection in method development.

Table 2: AMGS Improvement Through Method Modifications [24]

| Modification Type | Original AMGS | Improved AMGS | Performance Impact |

|---|---|---|---|

| Fluorinated to chlorinated mobile phase additive | 9.46 | 4.49 | Resolution improved from overlapped to 1.40 |

| Acetonitrile to methanol replacement | 7.79 | 5.09 | Critical resolution preserved |

| Preparative chromatography optimization | Not specified | Not specified | 2.5× increased loading capacity |

Comprehensive Sustainability Assessment Protocol

Protocol: Greenness and Whiteness Assessment of Analytical Methods

Objective: To comprehensively evaluate the environmental, functional, and practical characteristics of analytical methods using multiple metrics including AMGS, AGREE, and White Analytical Chemistry principles.

Materials:

- Fully developed analytical method

- Complete method parameters and validation data

- AGREE and AGREEprep calculators

- WAC assessment template

Procedure:

Method Characterization:

- Document all reagents, volumes, and energy requirements

- Record waste generation and disposal methods

- Compile analytical performance data (accuracy, precision, sensitivity, linearity)

- Document practical considerations (cost, time, operational complexity)

AMGS Assessment:

- Calculate AMGS per Protocol 3.2

- Identify primary contributors to environmental impact

- Note opportunities for improvement

Complementary Greenness Metrics:

White Analytical Chemistry Assessment:

- Evaluate Red (Analytical) Criteria: Score method performance on accuracy, precision, sensitivity, selectivity, linearity, and robustness

- Evaluate Green (Environmental) Criteria: Assess energy consumption, waste generation, reagent toxicity, and operator safety

- Evaluate Blue (Practical) Criteria: Rate cost-effectiveness, time efficiency, operational simplicity, and equipment availability [22]

- Calculate overall whiteness score based on RGB balance

Interpretation and Optimization:

- Compare scores across multiple metrics

- Identify consistent strengths and weaknesses

- Implement iterative improvements targeting deficient areas

- Validate that optimizations maintain analytical performance