Mastering UV-Vis Calibration: A Pharmaceutical Scientist's Guide to Compliance, Accuracy, and Troubleshooting

This comprehensive guide addresses the critical challenge of UV-Vis spectrophotometer calibration and performance in pharmaceutical quality control and research.

Mastering UV-Vis Calibration: A Pharmaceutical Scientist's Guide to Compliance, Accuracy, and Troubleshooting

Abstract

This comprehensive guide addresses the critical challenge of UV-Vis spectrophotometer calibration and performance in pharmaceutical quality control and research. Tailored for drug development professionals, it covers foundational principles, regulatory-compliant methodologies, advanced troubleshooting for common issues like photometric fluctuations and lamp degradation, and validation strategies aligned with current FDA, USP, and ICH guidelines. The article also explores emerging trends, including AI-assisted analysis and in-line UV-Vis for real-time monitoring, providing a complete resource for ensuring data integrity, regulatory compliance, and analytical accuracy in pharmaceutical applications from raw material testing to dissolution profiling.

UV-Vis Calibration Fundamentals: Ensuring Pharma Data Integrity and Regulatory Compliance

Troubleshooting Guide: Common UV-Vis Issues and Solutions

Q: Our UV-Vis measurements are inconsistent between replicates. What could be causing this?

A: Inconsistent replicates often stem from sample preparation errors or instrumental factors.

- Probable Causes & Solutions:

- Incorrect Dilutions: Use calibrated pipettes and volumetric glassware. Prepare fresh standard solutions daily for quantitative work [1].

- Air Bubbles in Cuvette: Gently tap the cuvette or briefly centrifuge the sample before measurement to remove bubbles [1].

- Cuvette Issues: Use matched quartz cuvettes for UV measurements. Ensure they are clean and free from scratches. Always orient the cuvette the same way in the holder [2].

- Sample Turbidity: Clarify samples by filtration or centrifugation. Particulates scatter light and violate the Beer-Lambert law, leading to inaccurate absorbance readings [1] [2].

Q: The baseline of my instrument is unstable or drifting. How can I fix this?

A: Baseline instability is a common instrumental issue.

- Probable Causes & Solutions:

- Insufficient Warm-up Time: Allow the instrument to warm up for at least 30 minutes before use to stabilize the light source and electronics [1].

- Stray Light: Ensure the sample compartment is clean and the lid is fully closed during measurement. Stray light is a common cause of non-linearity at high absorbance [1].

- Contaminated Cuvette Compartment: Clean the sample compartment with a soft brush or air duster to remove any debris or sample residue.

- Solvent Absorption: Ensure the solvent in the reference cuvette is optically clear and does not absorb strongly at the analytical wavelength. For example, ethanol absorbs strongly below 210 nm [1].

Q: Our calibration curve shows poor linearity (low R² value). What should we do?

A: Deviation from the Beer-Lambert law indicates a problem with the calibration standards or the analyte itself.

- Probable Causes & Solutions:

- Absorbance Out of Range: Prepare standards so that the measured absorbance falls within the ideal linear range of 0.2 to 1.0 AU. Absorbance values above 1.2 AU often become non-linear due to stray light effects [1] [2].

- Chemical Interactions: At high concentrations, analyte molecules may interact, affecting absorbance. Dilute the sample to an appropriate concentration [1].

- Improper Standard Preparation: Serially dilute stock solutions from a single, accurately prepared source to minimize cumulative errors. Use high-purity solvents and compounds [1].

Q: How do we ensure our UV-Vis system is compliant with pharmacopeial regulations (USP, EP, JP)?

A: Regulatory compliance is built on regular instrument qualification and performance verification.

- Key Steps:

- Regular Performance Verification: Perform tests for wavelength accuracy, photometric accuracy, stray light, and resolution at installation and at set intervals thereafter, as required by USP <857> and other pharmacopeias [3] [1].

- Use Certified Reference Materials: Use certified materials like Holmium Oxide for wavelength checks and potassium dichromate or neutral density filters for photometric accuracy, traceable to national standards (e.g., NIST) [1].

- Software Compliance: For regulated laboratories, use software like Thermo Scientific Insight Pro Security Software that enables 21 CFR Part 11 compliance with features like audit trails and electronic signatures [3].

Key Performance Parameters for UV-Vis Spectrophotometers in Pharma QC

The following table summarizes critical verification parameters as per pharmacopeial standards [3] [1].

| Parameter | Acceptance Criteria (Typical) | Common Test Material | Purpose |

|---|---|---|---|

| Wavelength Accuracy | ± 1 nm | Holmium Oxide filter or solution | Verifies that the instrument reports the correct wavelength. |

| Photometric Accuracy | ± 0.5% Abs (e.g., at 0.5 AU) | Neutral Density Filters or Potassium Dichromate | Confirms the accuracy of the absorbance measurement. |

| Stray Light | < 0.1% (e.g., at 220 nm) | Aqueous Potassium Chloride (KCl) solution | Ensures no unwanted light reaches the detector, critical for high-absorbance samples. |

| Resolution | Resolve sharp peaks (e.g., in Toluene spectrum) | Toluene in Hexane | Assesses the instrument's ability to distinguish closely spaced peaks. |

| Baseline Flatness | ± 0.001 AU over specified range | Air vs. Air scan | Checks the stability and noise of the instrument across the wavelength range. |

Experimental Protocol: Dissolution Testing of Solid Oral Dosage Forms

UV-Vis spectroscopy is a standard method for analyzing dissolution samples due to its speed, cost-effectiveness, and ability to provide immediate data for trending [4].

1. Principle: The dosage form is placed in a dissolution apparatus containing a specified medium at a controlled temperature. As the drug dissolves, samples are withdrawn and analyzed by UV-Vis to determine the percentage of Active Pharmaceutical Ingredient (API) released over time [3] [4].

2. Materials:

- Dissolution apparatus (paddles or baskets)

- Dissolution medium (e.g., buffer at pH 1.2, 4.5, or 6.8)

- Thermostatted UV-Vis spectrophotometer with sipper system (optional)

- Quartz cuvettes (for UV wavelengths) or disposable cuvettes (for Vis)

- Syringe filters (0.45 µm)

3. Procedure:

- Sample Withdrawal: At predetermined time intervals (e.g., 10, 20, 30, 45 minutes), withdraw a specified volume (e.g., 5-10 mL) from each vessel of the dissolution apparatus.

- Filtration: Immediately filter the samples using a syringe filter to remove any undissolved particles that could cause light scattering.

- Dilution (if necessary): Dilute the filtered sample with dissolution medium to bring the absorbance within the linear range of the method (ideally 0.2-1.0 AU).

- Measurement: Measure the absorbance of the sample at the validated wavelength (λ~max~ of the API) against a blank of the dissolution medium.

- Calculation: Calculate the concentration of the API using a pre-established calibration curve. Report the cumulative percentage of API released versus time.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in UV-Vis Analysis |

|---|---|

| Matched Quartz Cuvettes | Provide a consistent pathlength and are transparent in the UV and visible range, essential for accurate and reproducible absorbance measurements [2]. |

| High-Purity Solvents | Used to dissolve samples and prepare standards. Must be optically clear and not absorb significantly at the analytical wavelength to avoid interference [2]. |

| Certified Reference Materials (CRMs) | Holmium oxide, potassium dichromate, and neutral density filters are used for performance verification and calibration of the spectrophotometer to ensure pharmacopeial compliance [1]. |

| Syringe Filters (0.45 µm or 0.22 µm) | Used to clarify dissolution samples or any turbid solutions by removing particulates that scatter light and cause erroneous absorbance readings [2]. |

| Methyl 5-bromo-2-methylbenzoate | Methyl 5-bromo-2-methylbenzoate, CAS:79669-50-4, MF:C9H9BrO2, MW:229.07 g/mol |

| Anamorelin Hydrochloride | Anamorelin Hydrochloride, CAS:861998-00-7, MF:C31H43ClN6O3, MW:583.2 g/mol |

Troubleshooting Workflow for UV-Vis in a Regulated Lab

The following diagram outlines a systematic approach to diagnosing and resolving UV-Vis issues.

Frequently Asked Questions (FAQs)

Q: Can UV-Vis spectroscopy be used for impurity quantification? A: Yes, UV-Vis is commonly used for quantifying known impurities as specified in pharmaceutical monographs. It can detect unwanted absorption peaks that may indicate the presence of impurities or degradation products. However, for complex mixtures with overlapping peaks, separation techniques like HPLC may be required [3] [2].

Q: What is the advantage of using a sipper system with a UV-Vis for dissolution testing? A: A sipper system automates the sampling process from the dissolution vessels. It allows for quick, sequential analysis of multiple samples immediately following the dissolution experiment, increasing throughput, reducing analyst error, and providing immediate data for trending [4].

Q: How often should we calibrate our UV-Vis spectrophotometer in a QA/QC lab? A: The frequency should be determined by your use, performance history, and SOPs. Performance verification is typically required at installation and at regular intervals thereafter (e.g., every 6-12 months). However, critical checks like wavelength and photometric accuracy may be performed more frequently, such as weekly or before a critical set of analyses, to ensure data integrity [3] [1].

Q: Why is my absorbance reading above 1.5 not reliable for quantification? A: At high absorbance levels, the relationship between absorbance and concentration (Beer-Lambert Law) often becomes non-linear. This is primarily due to the effects of stray light within the instrument, where a small amount of light outside the nominal wavelength reaches the detector, skewing the measurement. For accurate quantification, samples should be diluted to an absorbance below 1.2 AU, and ideally between 0.2 and 1.0 AU [1].

This guide provides technical support for researchers and scientists in pharmaceutical laboratories on the core calibration parameters of UV-Vis spectrophotometers. Proper calibration is essential for generating reliable and compliant analytical data for drug development and quality control.

Core Calibration Parameters & Acceptance Criteria

Regular calibration ensures your instrument's measurements are accurate and reliable. The following parameters are critical for quantitative analysis and must be checked periodically.

Table 1: Core Calibration Parameters and Acceptance Criteria

| Calibration Parameter | Standard/Reagent Used | Key Experimental Protocol | Acceptance Criteria |

|---|---|---|---|

| Wavelength Accuracy [5] | Holmium Oxide filters or solution (in-built test) | Instrument's self-test or scan a standard and measure peak wavelengths. | Observed wavelength must be within ±0.3 nm of the known standard (e.g., 656.1 nm, 486.0 nm) [5]. |

| Photometric Accuracy [5] | Potassium Dichromate in 0.005M Hâ‚‚SOâ‚„ (57-63 mg/L) | Measure absorbance at specific wavelengths (e.g., 235, 257, 313, 350 nm). Calculate A(1%, 1cm). | Calculated A(1%, 1cm) values must fall within specified limits (e.g., 142.8 - 145.7 at 257 nm) [5]. |

| Stray Light [6] [5] | Potassium Chloride (1.2% w/v in water) | Measure absorbance of the KCl solution at 198-202 nm using water as a blank. | Absorbance must be greater than 2 at the specified wavelengths [5]. |

| Resolution Power [5] | Toluene in Hexane (0.02% v/v) | Scan the solution from 260 nm to 420 nm. Identify the absorbance maximum at ~269 nm and minimum at ~266 nm. | The ratio of absorbance at 269 nm to that at 266 nm must not be less than 1.5 [5]. |

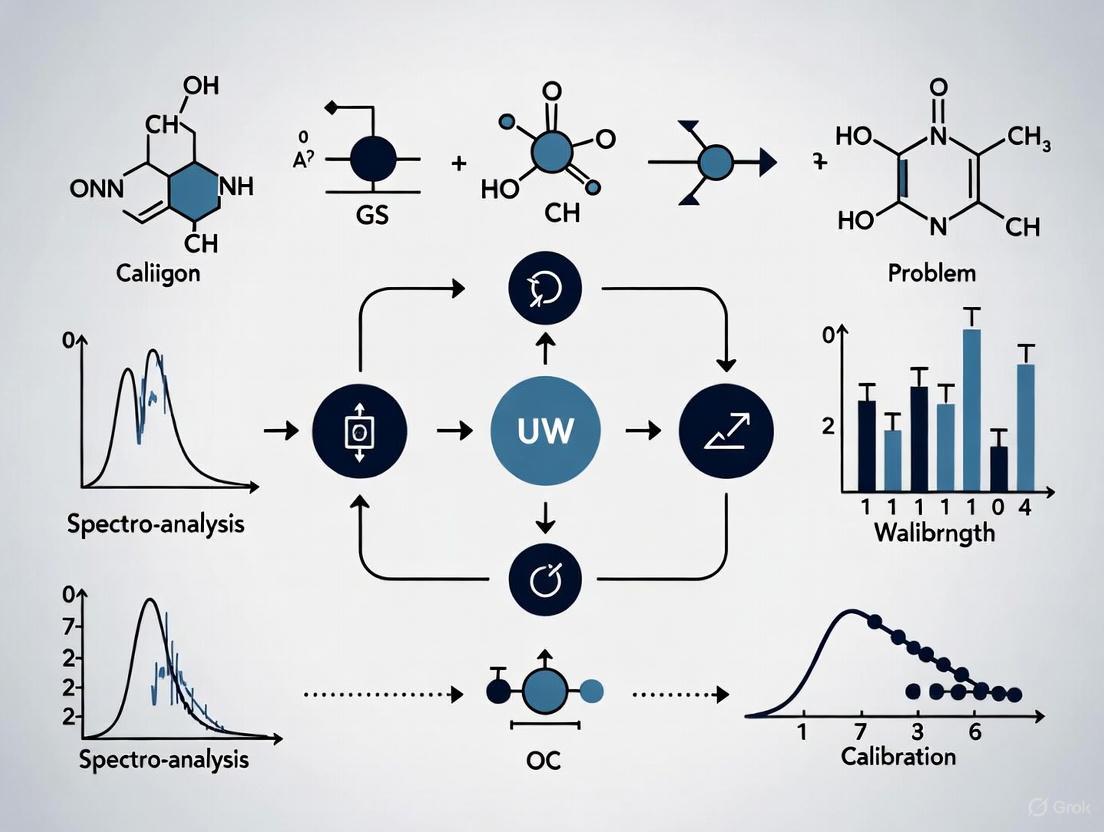

Figure 1: Logical workflow for the sequential calibration of core UV-Vis parameters.

Troubleshooting Common Calibration Issues

Wavelength Accuracy Failures

- Problem: Observed wavelengths deviate from standards by more than ±0.3 nm.

- Solution: Ensure the instrument is warm. Re-run the in-built wavelength accuracy test. If it fails again, the instrument may require professional service for optical alignment [5].

Photometric Accuracy Deviations

- Problem: Potassium dichromate absorbance values are outside specified limits.

- Solution:

Stray Light Detected

- Problem: Absorbance of 1.2% KCl is less than 2 at 200 nm [5].

- Causes & Solutions:

- Dirty Optics: Dust, scratches, or residues on lenses, mirrors, or the lamp housing can scatter light [7] [6]. Clean optical components according to the manufacturer's instructions.

- Aging Light Source: A deuterium lamp nearing the end of its life often shows increased stray light, especially in the UV region [8] [9]. Replace the lamp.

- Stray Light Test: Use a high absorbance filter or solution; if the reading is lower than expected, stray light is likely present [7].

Poor Resolution

- Problem: The absorbance ratio of toluene in hexane is less than 1.5.

- Solution: This can indicate a problem with the monochromator's slit width or optical alignment [5]. Verify that the instrument's bandwidth is set correctly. This issue typically requires service by a qualified technician.

Research Reagent Solutions

Table 2: Essential Reagents for UV-Vis Spectrophotometer Calibration

| Reagent/Standard | Function | Critical Protocol Note |

|---|---|---|

| Potassium Dichromate (K₂Cr₂O₇) [5] | Photometric Accuracy Standard | Must be dried to constant weight at 130°C before use to ensure accurate purity. |

| Potassium Chloride (KCl) [5] | Stray Light Validation | A 1.2% w/v solution in water is used to check for stray light in the far-UV region. |

| Holmium Oxide Filter (Ho₂O₃) [1] | Wavelength Accuracy Standard | Provides sharp, known absorption peaks for verifying wavelength scale accuracy. |

| Toluene in Hexane [5] | Resolution Power Check | A 0.02% v/v solution must be prepared fresh with hexane that has a transmittance ≥97% in the scan range. |

| Sodium Iodide / Nitrite [6] | Alternative Stray Light Tests | Used per ASTM procedures to measure stray light transmittance at 220 nm and 340/370 nm, respectively. |

Frequently Asked Questions (FAQs)

Q1: Our spectrophotometer failed stray light checks after a power surge. What should we check? Start by inspecting the optical compartment for any visible damage or misalignment. Run a full instrument self-test, which often includes checks for stray light and wavelength repeatability. Error codes like "NG9" can indicate insufficient deuterium lamp energy, a common culprit after electrical events [8]. If the self-test fails, the lamp or its power supply may need replacement.

Q2: How often should we perform a full calibration with these chemical standards? A full calibration using chemical standards should be performed once a month to ensure ongoing accuracy and compliance with good laboratory practices (GLP) [5]. Additionally, critical parameters like photometric accuracy should be verified whenever the instrument is moved, after a lamp change, or if service is performed.

Q3: Can we use any brand of potassium dichromate for photometric calibration? While potassium dichromate is a common standard, it is crucial to use a high-purity, analytical-grade material. More importantly, the preparation protocol must be followed exactly as specified in pharmacopoeial methods (e.g., drying, precise weighing, using 0.005M Hâ‚‚SOâ‚„ as solvent) to ensure the certified absorbance values are valid [5].

Q4: Why do we test resolution with toluene in hexane specifically? Toluene in hexane has a characteristic fine structure in its spectrum with closely spaced peaks and valleys (e.g., at 269 nm and 266 nm). The ability of the spectrophotometer to distinguish these closely spaced spectral features is a direct measure of its resolution power. A ratio of less than 1.5 indicates the instrument cannot resolve fine spectral details, which is critical for identifying compounds or analyzing mixtures [5].

Q5: The baseline is unstable during resolution scans. What could be wrong? Baseline instability can be caused by several factors:

- Contaminated Solvent: Ensure the hexane is of spectroscopic grade and the cuvettes are meticulously clean [1].

- Electrical Fluctuations: Connect the instrument to a voltage stabilizer to prevent fluctuations [8].

- Environmental Factors: High humidity can affect electronic components and optical surfaces. Ensure the lab environment is controlled [1] [8].

Frequently Asked Questions (FAQs)

Q1: What is the key difference between the wavelength accuracy requirements in USP <857> and Ph. Eur. 2.2.25? A1: USP <857> specifies verification using holmium oxide filter maxima at 241.15 nm, 287.15 nm, and 536.30 nm, with a tolerance of ± 1 nm. Ph. Eur. 2.2.25 uses a holmium oxide solution, checking bands at 241.5 nm, 287.5 nm, and 536.0 nm, with a stricter tolerance of ± 0.5 nm for UV and ± 1.0 nm for Vis. The primary difference lies in the tolerance and the specific reference wavelengths used.

Q2: How does ICH Q2(R2) guide the validation of a UV-Vis method for assay determination? A2: ICH Q2(R2) provides a framework for method validation, requiring the demonstration of specificity, accuracy, precision (repeatability and intermediate precision), linearity, and range. For a UV-Vis assay, this involves spiking the drug substance with excipients to prove specificity, recovery studies for accuracy, and a minimum of 5 concentrations across the specified range (e.g., 80-120% of the target concentration) for linearity assessment.

Q3: My instrument passes the stray light test with a 1.2% transmittance cutoff, but my low-concentration sample results are still erratic. What could be the issue? A3: While your instrument may meet the general pharmacopoeial stipulation (e.g., < 0.5% T at 220 nm with KCl), the specific wavelength of analysis is critical. Stray light effects are more pronounced at the spectral extremes where the source intensity and detector sensitivity are low. You should perform a stray light test at or very near your analytical wavelength. Furthermore, consider sample-based issues such as fluorescence or non-specific scattering from particulates.

Q4: Do I need to perform a full instrument qualification (IQ/OQ/PQ) for every method validation? A4: No, a full Instrument Qualification (IQ/OQ) is performed upon installation and after major repairs or relocations. However, before any method validation or use in GxP testing, you must perform Performance Qualification (PQ) or Performance Verification (PV). This involves running the specific tests mandated by the relevant pharmacopoeia (e.g., wavelength accuracy, stray light, photometric accuracy) to ensure the instrument is suitable for its intended use at that time.

Troubleshooting Guides

Issue: Repeated Wavelength Accuracy Failures

Symptoms:

- Consistent deviation (> ±1 nm) when verifying with holmium oxide filters or solutions.

- Shifted or distorted absorption spectra compared to reference data.

Potential Causes & Solutions:

| Symptom | Potential Root Cause | Investigative Action | Corrective Action |

|---|---|---|---|

| Consistent positive or negative shift across all wavelengths | Instrument misalignment due to temperature fluctuation or physical shock. | Check laboratory logs for recent temperature extremes or instrument movement. | Execute the instrument's internal wavelength calibration routine as per the manufacturer's instructions. Contact service if the issue persists. |

| Failure at specific wavelengths only | Defective or contaminated verification filter/cell. | Visually inspect the holmium oxide filter for scratches or the solution cell for cracks/contamination. | Replace the verification artifact (filter or solution). Ensure the solution is within its expiry date. |

| Erratic, non-reproducible values | Wavelength drive mechanism wear or a failing deuterium lamp. | Review the instrument's usage history and lamp hours. Check for error logs. | Replace the deuterium lamp if it is near or beyond its rated lifetime. If the problem continues, a service visit is required. |

Validation Protocol: Wavelength Accuracy (Per USP <857> and Ph. Eur. 2.2.25)

- Materials: Certified holmium oxide glass filter or 4% w/v holmium oxide in perchloric acid solution.

- Instrument Setup: Allow the spectrophotometer to warm up for at least 30 minutes. Use a slow scan speed and narrow slit width.

- Procedure:

- Scan the holmium oxide reference from 240 nm to 650 nm.

- Identify the observed peak maxima for the specified wavelengths (e.g., 241.15 nm, 287.15 nm, 536.30 nm for USP).

- Record the measured wavelength for each peak.

- Acceptance Criteria:

- USP <857>: Measured wavelengths must be within ± 1.0 nm of the certified values.

- Ph. Eur. 2.2.25: Measured wavelengths must be within ± 0.5 nm (UV range) and ± 1.0 nm (Vis range) of the certified values.

Issue: High Stray Light Leading to Non-Linear Calibration Curves

Symptoms:

- Negative deviation from Beer-Lambert law at high absorbances.

- Poor linearity (R² < 0.999) in the calibration curve, especially at the upper end of the range.

- Inaccurate results for high-concentration samples.

Potential Causes & Solutions:

| Symptom | Potential Root Cause | Investigative Action | Corrective Action |

|---|---|---|---|

| Negative deviation at high absorbance | Stray light, aging source lamp, or dirty optics. | Perform a stray light test at the analytical wavelength and at the spectral extremes (e.g., 220 nm with KCl, 340 nm with NaNOâ‚‚). | Replace the deuterium or tungsten lamp. Thoroughly clean the sample compartment, cuvette holders, and external optics. Use a cuvette with a matched lid. |

| Non-linearity across the entire range | Improper calibration standard preparation or photometric accuracy issue. | Verify the preparation of calibration standards gravimetrically. Check photometric accuracy using a neutral density filter. | Re-prepare calibration standards. If photometric accuracy fails, a full instrument service is required. |

Validation Protocol: Stray Light Verification (Per USP <857>)

- Materials: Aqueous solutions of Potassium Chloride (1.2% w/v for 200 nm cutoff) and Sodium Nitrite (0.5% w/v for 340 nm cutoff).

- Instrument Setup: Use a matched pair of high-quality quartz cuvettes.

- Procedure:

- Fill one cuvette with the appropriate stray light solution (e.g., KCl for 200 nm check) and the other with high-purity water as a blank.

- Set the spectrophotometer to the test wavelength (e.g., 220 nm for KCl).

- Measure the transmittance (%T) of the solution against the water blank.

- Acceptance Criteria: The measured transmittance must be less than the specified limit, typically < 1.0% T (or > 2.0 AU) at the designated wavelength.

UV-Vis Method Validation and Calibration Workflow

Title: UV-Vis Method Validation Workflow

Stray Light Investigation Pathway

Title: Stray Light Troubleshooting Path

The Scientist's Toolkit: Key Reagent Solutions

| Item | Function | Critical Note |

|---|---|---|

| Holmium Oxide Filter/Solution | For wavelength accuracy verification. Provides sharp, well-characterized absorption peaks. | Ensure certification traceable to a national metrology institute. Solutions have a limited shelf life. |

| Potassium Chloride (KCl) | Used for stray light verification in the UV region (e.g., at 200-220 nm). A 1.2% w/v solution should show near-zero transmittance. | Must be of high spectroscopic purity to avoid introducing absorbance from impurities. |

| Neutral Density Filters | For verifying photometric (absorbance/transmittance) accuracy. These are stable, calibrated glass filters. | Certified values are provided at specific wavelengths. Handle with care to avoid scratches. |

| Matched Quartz Cuvettes | To hold liquid samples for analysis. Must have a known pathlength and be perfectly matched. | Mismatched cuvettes are a common source of error. Clean meticulously with suitable solvents. |

| Potassium Dichromate | A classic standard for resolution and photometric accuracy checks, often used in Ph. Eur. | Prepare solutions accurately in perchloric acid or water as specified. |

| Mitiglinide Calcium Hydrate | Mitiglinide Calcium Hydrate, CAS:207844-01-7, MF:C38H52CaN2O8, MW:704.9 g/mol | Chemical Reagent |

| Atropine oxide hydrochloride | Atropine oxide hydrochloride, CAS:4574-60-1, MF:C17H24ClNO4, MW:341.8 g/mol | Chemical Reagent |

Troubleshooting Guide: UV-Vis Calibration Issues

Q1: My spectrophotometer is failing the photometric accuracy test. What could be wrong?

Problem: The measured absorbance values of potassium dichromate standard solutions do not fall within the specified tolerances [10] [11].

Investigation & Solutions:

- Primary Cause (Stray Light): A failing photometric accuracy test, particularly at higher absorbance values, is very often caused by excessive stray light [12]. Stray light introduces a systematic error that makes measured absorbance appear lower than the true value, violating the Beer-Lambert Law.

- Corrective Actions:

- Perform Stray Light Verification: Check the instrument's stray light level using a potassium chloride (KCl) solution [10] [13]. The absorbance of a 1.2% w/v KCl solution at 198 nm must be greater than 2.0 [10] [11].

- Inspect & Clean Optics: If stray light is high, check for and clean any contaminated or fogged optical components, such as the detector or lenses. Ensure the sample compartment is free of dust and the cuvettes are clean and matched [11] [13].

- Verify Lamp Life: Check the usage hours of the instrument's deuterium or tungsten lamp. An aging or failing lamp is a common source of photometric inaccuracy and increased stray light [12].

Q2: The wavelength accuracy of my instrument is out of specification. What steps should I take?

Problem: The absorption maxima of a holmium oxide filter or solution do not align with certified wavelengths within the permitted tolerance (e.g., ±1 nm for UV range) [10] [11].

Investigation & Solutions:

- Primary Cause (Mechanical/Optical Drift): Wavelength inaccuracy typically stems from mechanical shock, vibrations, or gradual misalignment of the monochromator's diffraction grating or mirrors over time [12].

- Corrective Actions:

- Allow Warm-up: Ensure the instrument has been allowed to warm up for the manufacturer's specified time (typically 30-60 minutes) before performing the test [10].

- Run Internal Calibration: If available, execute the instrument's internal self-calibration routine, which may use an internal holmium oxide filter or a mercury/deuterium lamp emission line for wavelength standardization [11] [13].

- Seek Service: If the internal calibration does not resolve the issue, the misalignment may be significant. Contact qualified service engineers for a comprehensive optical alignment, as this is not typically a user-serviceable task [12].

Frequently Asked Questions (FAQs)

Q1: How often should I calibrate my UV-Vis spectrophotometer?

Calibration should be performed on a quarterly basis (every three months) as a routine schedule [14] [11]. Furthermore, calibration is mandatory in these specific situations:

- After initial installation of a new instrument [15].

- Following any maintenance or repair work [14] [15].

- After relocating the instrument [14].

- Whenever you observe questionable or inconsistent readings during routine use [15].

Q2: What are the critical performance parameters checked during a full calibration?

A comprehensive calibration verifies four key parameters [10]:

- Control of Wavelength: Verifies the instrument selects the correct wavelength.

- Control of Absorbance: Confirms the instrument reports accurate absorbance values.

- Limit of Stray Light: Ensures no unwanted light reaches the detector.

- Resolution Power: Checks the instrument's ability to distinguish between closely spaced peaks.

Q3: Why is post-maintenance calibration verification non-negotiable?

Any maintenance or repair, even a simple lamp replacement, can potentially disturb the instrument's optical alignment or electronic calibration [15]. Verification ensures that the instrument still performs to its specifications and that the data it generates remains accurate and reliable, which is a fundamental requirement under GMP/GLP guidelines [12].

Q4: My instrument passed its internal self-test. Do I still need to perform a chemical calibration?

Yes. The internal self-test (using built-in filters or lamps) is a useful preliminary check for gross errors [11]. However, a full external calibration using certified chemical standards like holmium oxide and potassium dichromate is essential because it independently validates the entire analytical pathway, including the sample compartment and any potential issues related to the liquid sample interface [13] [12].

Calibration Frequency and Triggers

The following workflow outlines the decision process for scheduling UV-Vis spectrophotometer calibration, integrating both routine and event-based triggers.

Research Reagent Solutions for Calibration

This table details the essential materials and standards required for a complete UV-Vis spectrophotometer calibration.

| Reagent / Standard | Function / Purpose | Key Application Details |

|---|---|---|

| Holmium Oxide (Ho₂O₃) [10] [11] | Validates wavelength accuracy by providing sharp, known absorption peaks. | Dissolved in 1.4 M Perchloric Acid; peaks checked at, e.g., 241.15 nm, 361.5 nm [10]. |

| Potassium Dichromate (K₂Cr₂O₇) [10] [13] | Verifies photometric (absorbance) accuracy across different wavelengths. | Dissolved in 0.005 M Sulfuric Acid; absorbance checked at 235, 257, 313, 350, and 430 nm [10]. |

| Potassium Chloride (KCl) [10] [11] | Determines the limit of stray light at the low-wavelength end. | A 1.2% w/v solution must have an absorbance >2.0 at 198 nm when measured against water [10]. |

| Toluene in Hexane [10] [13] | Tests resolution power by assessing the instrument's ability to distinguish close peaks. | A 0.02% v/v solution; the ratio of absorbance at 269 nm (max) to 266 nm (min) must be ≥1.5 [10]. |

| NIST-Traceable Certified Reference Materials (CRMs) [12] | Provides the highest assurance of accuracy and data integrity for all calibration parameters. | Used in place of lab-prepared solutions to ensure traceability to national/international standards [12]. |

The following table consolidates the key tests, their acceptance criteria, and procedures for a standardized calibration protocol.

| Calibration Parameter | Standard Used | Acceptance Criteria | Procedure Summary |

|---|---|---|---|

| Wavelength Accuracy [10] [11] | Holmium Oxide Perchlorate Solution | ±1 nm (200-400 nm)±3 nm (400-800 nm) | Scan solution from 200-600 nm against a 1.4 M Perchloric acid blank. Verify peak maxima. |

| Photometric Accuracy [10] [11] | Potassium Dichromate in 0.005 M H₂SO₄ | Specific Absorbance (E1%1cm) within tolerances (e.g., 144.0 ± 1.5 at 257 nm) | Measure absorbance at specified wavelengths. Calculate specific absorbance and compare. |

| Stray Light [10] [13] | Potassium Chloride (1.2% w/v) | Absorbance > 2.0 at 198 nm | Measure absorbance of KCl solution against water blank at 198 nm. |

| Resolution Power [10] [13] | Toluene in Hexane (0.02% v/v) | A₂₆₉/A₂₆₆ ≥ 1.5 | Scan solution from 255-275 nm against hexane blank. Check ratio of peak to trough. |

ALCOA+ Principles: The Foundation of Data Integrity

In pharmaceutical research, ALCOA+ is the internationally recognized framework for ensuring data integrity in regulatory submissions and daily laboratory operations. It provides the criteria against which regulatory agencies like the FDA and EMA assess the reliability of data [16] [17].

Adherence to ALCOA+ principles is not optional; it is a fundamental regulatory expectation for all GxP data. Failure to comply can lead to serious regulatory actions, including warning letters and consent decrees [16] [18].

The table below details the core components of the ALCOA+ framework.

| ALCOA+ Principle | Core Requirement | Practical Application in UV-Vis Analysis |

|---|---|---|

| Attributable | Data must be linked to the person or system that created or modified it [16]. | Use unique login IDs for analysts; systems should record user identity in metadata [16]. |

| Legible | Data must be readable and permanently durable [18]. | Ensure electronic data is secure; avoid thermal paper prints; data encoding must be reversible [16] [17]. |

| Contemporaneous | Data must be recorded at the time of the activity [17]. | Use automated, network-synchronized timestamps for measurements; avoid manual entries [16]. |

| Original | The first capture of data or a certified copy must be preserved [16]. | Preserve the source spectral file; printouts or exported data are not considered original [16]. |

| Accurate | Data must be error-free, with amendments not obscuring the original record [18]. | Use calibrated instruments; document any changes with a reason without hiding the original value [16] [17]. |

| Complete | All data, including repeats and reanalysis, must be present [17]. | All data, including invalid runs, metadata, and audit trails, must be retained [16] [18]. |

| Consistent | Data should be chronologically ordered with sequential timestamps [17]. | Ensure all processes are documented; audit trails should show a logical sequence of events [18]. |

| Enduring | Data must be long-lasting and durable for the entire retention period [18]. | Archive data in a secure, non-rewritable format with verified backup and recovery processes [16]. |

| Available | Data must be readily retrievable for review and inspection over its lifetime [16]. | Ensure data is indexed and stored in a searchable repository for timely retrieval during audits [16] [17]. |

Troubleshooting Guide: Common UV-Vis Calibration and Data Integrity Issues

This section addresses frequent problems encountered in pharmaceutical labs, linking technical failures to data integrity risks.

Fluctuating Absorbance Readings During Calibration

- Problem: Inconsistent or fluctuating absorbance readings during UV-Vis calibration or method validation.

- Data Integrity Principle Impacted: Accurate, Complete.

- Root Cause: The most common cause is lamp degradation. UV-Vis spectrophotometers use deuterium or xenon lamps with finite lifespans (typically 1,000-3,000 hours for deuterium) [19]. An aging lamp leads to instability, noise, and photometric inaccuracy, compromising the reliability of all subsequent data.

- Solution:

- Check Lamp Hours: Proactively log all lamp usage hours. Replace lamps approaching their end-of-life as per manufacturer specifications [19].

- Use a Calibration Kit: Employ a UV-Vis calibration kit to diagnostically check for wavelength accuracy drift and photometric instability [19].

- Additional Checks: If the issue persists after lamp replacement, inspect the detector optics for dust or contamination and verify baseline stability with a blank [19].

Failure in Method Validation Parameters

- Problem: Failure to meet validation parameters like linearity, precision, or accuracy during a UV-Vis method validation, as required by ICH Q2(R1) [20].

- Data Integrity Principle Impacted: Accurate, Consistent, Complete.

- Root Cause: Often traced to improper preparation of reference standards, miscalibrated equipment, or uncontrolled environmental conditions (e.g., temperature fluctuations). For example, an uncalibrated balance or volumetric flask introduces Measurement Uncertainty (MU) that can invalidate the results [20].

- Solution:

- Error Budget Analysis: Identify all sources of error (e.g., reference standard purity, weighing, volumetric operations) and quantify their uncertainty [20].

- System Suitability: Ensure all equipment (balances, pipettes, glassware) is within its calibration period and is qualified for its intended use.

- Controlled Environment: Conduct analyses in a temperature-controlled environment to minimize volumetric error due to thermal expansion [20].

Incomplete or Unreliable Audit Trails

- Problem: The laboratory's data system has an inactive, unreviewed, or incomplete audit trail.

- Data Integrity Principle Impacted: Attributable, Complete, Consistent.

- Root Cause: Lack of configured audit trails in the software, shared user accounts, or failure to implement a procedure for regular audit trail review by the Quality Unit [17].

- Solution:

- System Configuration: Validate computerized systems to ensure audit trails are automatically enabled for all data creation, modification, and deletion [16] [18].

- Unique Logins: Enforce a policy of unique user IDs with role-based access controls; shared accounts are strictly prohibited [16].

- Proactive Review: Establish a procedure for a risk-based, ongoing review of audit trails for critical data, documenting the scope, frequency, and responsibilities [16].

Experimental Protocol: Validating a UV-Vis Method for Ascorbic Acid Assay

This protocol outlines a detailed methodology for validating a UV-Vis spectrophotometric method to determine ascorbic acid content in a beverage, ensuring alignment with ALCOA+ principles [21].

Research Reagent Solutions

| Reagent/Material | Function in the Experiment |

|---|---|

| Ascorbic Acid Reference Standard | Serves as the primary benchmark for quantifying the unknown analyte (vitamin C) in the sample [21]. |

| Solvent (e.g., Distilled Water) | Used to dissolve the standard and dilute the sample to a concentration within the instrument's linear range. |

| UV-Vis Spectrophotometer | The instrument used to measure the absorbance of the standard and sample solutions at the determined maximum wavelength (λmax) [21]. |

| Volumetric Flasks & Pipettes | For accurate preparation and dilution of standard and sample solutions. Must be of appropriate grade and calibrated [20]. |

Step-by-Step Workflow

The following diagram maps the experimental workflow for the UV-Vis method validation, highlighting key steps where ALCOA+ principles must be demonstrated.

Detailed Methodology

Preparation of Standard Solutions: Accurately weigh an appropriate amount of ascorbic acid reference standard. Dissolve and dilute with a suitable solvent (e.g., distilled water) to prepare a series of standard solutions covering a concentration range of 10-18 ppm [21].

- ALCOA+ Focus: Attributable (analyst logs preparation), Accurate (use calibrated balance and glassware), Original (record weight and volume data directly in lab notebook/ELS).

Determination of Maximum Wavelength (λmax): Scan one of the standard solutions (e.g., 14 ppm) over the UV-Vis spectrum (e.g., 200-300 nm) to identify the wavelength of maximum absorbance (λmax) for ascorbic acid [21].

- ALCOA+ Focus: Contemporaneous (instrument software automatically timestamps the spectral scan).

Generation of Standard Calibration Curve: Measure the absorbance of each standard solution at the predetermined λmax. Plot a graph of absorbance (Y-axis) versus concentration (X-axis). Generate a linear regression equation for the line [21].

- ALCOA+ Focus: Accurate (the regression coefficient (r²) should be ≥0.995), Complete (save the entire curve and data points within the software).

Sample Preparation and Analysis: Process the sample beverage as needed (e.g., dilution, filtration) and measure its absorbance at the same λmax. Use the regression equation from the standard curve to calculate the concentration of ascorbic acid in the sample [21].

- ALCOA+ Focus: Consistent (apply the exact same method and conditions as used for standards).

Method Validation Parameters: Execute the following validation experiments [21]:

- Linearity: Demonstrated by the coefficient of determination (r²) of the standard curve. A value of 0.995 or higher is typically required [21].

- Accuracy: Conduct a spike-and-recovery study. Report the percentage recovery (% Recovery); 100% ± 5% is often acceptable [21].

- Precision: Perform repeatability analysis (n=6) on a homogeneous sample. Calculate the Relative Standard Deviation (%RSD); a value of <2% is generally acceptable [21].

- LOD & LOQ: Calculate the Limit of Detection (LOD) and Limit of Quantitation (LOQ) based on the standard deviation of the response and the slope of the calibration curve [21].

Frequently Asked Questions (FAQs)

Q1: Our UV-Vis is a standalone instrument without network connectivity. How can we ensure timestamps are "Contemporaneous"?

- A: Use an instrument with an internal clock that is synchronized to a reliable external time standard (e.g., UTC via NTP) and subject to formal procedures for periodic time checks. Manual time zone conversions are not sufficient for compliance [16]. The procedure for time-checking must be documented.

Q2: What is the single most common data integrity failure observed by regulators in labs?

- A: A recurring theme is incomplete data and unreliable audit trails. This includes deleted data files, lack of controls to prevent data deletion, shared user accounts making data non-attributable, and the Quality Unit's failure to review audit trails [17].

Q3: How does the concept of "Measurement Uncertainty" (MU) relate to the ALCOA+ principle of "Accurate"?

- A: "Accurate" means the data must be correct. Measurement Uncertainty quantifies the doubt associated with a measurement result. For a result to be truly "Accurate," its uncertainty budget must be understood and shown to be sufficiently small for its intended purpose, as per ISO/IEC 17025 requirements [22] [20]. It provides the scientific evidence for accuracy.

Q4: Who is ultimately responsible for data integrity in a pharmaceutical laboratory?

- A: Data integrity is a shared responsibility. Management is responsible for creating a culture of quality and allocating resources. Individual scientists are responsible for following procedures and documenting data in real-time. The Quality Unit is responsible for oversight and audit trail review. Ultimately, "Personnel should be aware and responsible for data and its integrity" [18] [17].

Pharmaceutical Calibration Protocols: Step-by-Step Methods for USP Compliance

Troubleshooting Guides

Guide 1: Resolving Fluctuating Absorbance Readings During Calibration

Problem: Inconsistent or fluctuating absorbance readings when using holmium oxide or didymium filters for wavelength verification.

Solution: Follow this systematic troubleshooting guide to identify and resolve the root cause.

Detailed Steps:

Check Lamp Usage Hours: Review the instrument's logged usage hours.

Verify Baseline Stability: After addressing the lamp, run a blank baseline to check for excessive noise or drift, which can indicate underlying instrument instability [19].

Inspect Instrument Components:

Escalate to Service: If the above steps do not resolve fluctuations, the issue may be related to internal electronics or detector performance, requiring a qualified service technician [19].

Guide 2: Addressing Wavelength Scale Inaccuracy

Problem: Measured peak wavelengths from holmium oxide or didymium standards do not match certified values within the instrument's specified tolerance.

Solution: Follow this guide to diagnose and correct wavelength inaccuracies.

Detailed Steps:

Confirm Testing Parameters:

Compare with Tolerance:

Check Multiple Peaks: Verify the inaccuracy across several characteristic peaks to determine if the error is consistent across the spectral range [25].

Take Action:

Frequently Asked Questions (FAQs)

Q1: What is the primary difference between holmium oxide liquid and didymium glass filters?

A1: The primary differences lie in their physical state, composition, and spectral range.

- HoDi Liquid Filter: A solution of holmium oxide and didymium in perchloric acid. It is ideally suited for checking wavelength accuracy in both the UV and visible range (240-870 nm) and can present up to 22 characteristic peaks [23]. Specific versions are available for compliance with pharmacopoeial methods (Ph. Eur. and USP) [23].

- Didymium Glass Filter: A solid glass filter containing didymium (a mixture of praseodymium and neodymium). It is typically used to verify the wavelength scale in the visible to near-IR region (430 nm to 890 nm) and is valued for being more robust than liquid cells [24].

Q2: Why are holmium oxide and didymium used for wavelength verification?

A2: These materials are used because they produce spectra with multiple, characteristic, and very well-defined absorption peaks across a broad wavelength range [23] [25]. The exact wavelengths of these peaks are known with high certainty and are stable over time, making them ideal reference materials for verifying that a spectrophotometer's wavelength scale is reporting accurate values [25] [24].

Q3: My spectrophotometer is passing verification with a didymium glass filter but failing with a holmium oxide liquid filter in the UV region. What could be wrong?

A3: This is a common scenario that points to an issue specific to the UV range.

- Stray Light: The instrument may have a high level of stray light at shorter UV wavelengths, which can distort absorption spectra and shift the apparent peak positions [25].

- Lamp Performance: The UV source (deuterium lamp) may be nearing the end of its life or be faulty, leading to reduced output and instability in the UV region, which the liquid test is sensitive enough to detect [19].

- Spectral Range: Since didymium glass is primarily for the visible region, it would not detect problems occurring in the UV. The holmium oxide liquid filter is therefore a more comprehensive test for instruments used in UV spectroscopy [23] [24].

Data Presentation

Certified Wavelengths for Verification

Table 1: Certified Wavelength Peaks of Holmium Oxide and Didymium (HoDi) Liquid Filter Measurement conditions: Slit width: 1 nm. Source: Hellma Analytics [23]

| Wavelength (nm) | Wavelength (nm) | Wavelength (nm) | Wavelength (nm) |

|---|---|---|---|

| 241.0 | 347.0 | 451.0 | 641.0 |

| 278.0 | 354.0 | 468.0 | 732.0 |

| 287.0 | 361.0 | 482.0 | 740.0 |

| 333.0 | 416.0 | 512.0 | 794.0 |

| 341.5 | 444.0 | 537.0 | 864.0 |

Table 2: Example of Certified Wavelength Peaks of a Didymium Glass Filter Peak positions can vary slightly with spectral bandwidth (SBW). Source: Starna Cells [24]

| SBW 0.5 nm | SBW 1.0 nm | SBW 2.0 nm | SBW 3.0 nm |

|---|---|---|---|

| 879.30 nm | 879.36 nm | 879.44 nm | 879.36 nm |

| 805.74 nm | 805.48 nm | 805.46 nm | 805.48 nm |

| 748.62 nm | 748.54 nm | 748.59 nm | 748.54 nm |

| 741.15 nm | 741.07 nm | 740.46 nm | 741.07 nm |

| 684.47 nm | 684.53 nm | 684.55 nm | 684.53 nm |

| 587.01 nm | 587.39 nm | 587.34 nm | 587.39 nm |

The Scientist's Toolkit

Table 3: Essential Materials for Wavelength Accuracy Verification

| Item | Function | Key Considerations |

|---|---|---|

| HoDi Liquid Filter | Verifies wavelength accuracy in UV/Vis range (240-870 nm) [23]. | Contains holmium oxide & didymium in perchloric acid. Requires correct cuvette and handling. Pharmacopoeial versions available (USP, Ph. Eur.) [23]. |

| Didymium Glass Filter | Verifies wavelength accuracy in Visible/NIR range (430-890 nm) [24]. | Solid, robust reference material. Mounted in a housing. Ensure certificate is NIST-traceable and notes uncertainty (±0.2 nm is typical) [24]. |

| Deuterium & Tungsten Lamps | Provides UV and Vis/NIR light sources for the spectrophotometer. | Log usage hours. Deuterium lamps last 1,000-3,000 hrs; tungsten lasts longer. Replace if output is low or unstable [19]. |

| Certified Calibration Certificate | Provides the accepted, traceable peak wavelength values for the standard. | Must be specific to the individual filter (liquid or glass) you are using. Essential for comparing against your measured values [23] [24]. |

| Acetyl tetrapeptide-15 | Acetyl tetrapeptide-15, CAS:928007-64-1, MF:C34H39N5O6, MW:613.7 g/mol | Chemical Reagent |

| BGC-20-1531 free base | BGC-20-1531 free base, CAS:1186532-61-5, MF:C26H24N2O6S, MW:492.5 g/mol | Chemical Reagent |

Photometric accuracy is a fundamental specification for UV-Vis spectrophotometers, defined as the difference between a measured absorbance value and an established standard value [26] [27]. In pharmaceutical quality control and research, verifying this accuracy is not just a best practice but often a regulatory requirement dictated by pharmacopoeias such as the USP, Ph. Eur., and IP [28] [5].

Potassium dichromate in acidic solution serves as a primary photometric standard for this critical verification. Its spectrum provides characteristic maxima and minima at specific wavelengths in the UV range, making it exceptionally suitable for checking the performance of spectrophotometers [28] [29]. The National Institute of Standards and Technology (NIST) provides a Standard Reference Material (SRM 935a) for this compound, underlining its importance as a traceable standard [28] [27]. This guide details the use of potassium dichromate for testing photometric accuracy, providing researchers with clear protocols, acceptance criteria, and troubleshooting advice.

Key Reagents and Equipment

The following table summarizes the essential materials required for performing photometric accuracy testing.

Table 1: Research Reagent Solutions and Essential Materials

| Item | Specification / Function |

|---|---|

| Potassium Dichromate (K₂Cr₂O₇) | High-purity, analytical reagent grade. Must be dried to constant weight at 130°C prior to use [5] [11]. |

| Diluent (Acidic Solvent) | Option 1: 0.005 M Sulfuric Acid (Hâ‚‚SOâ‚„) [5] [11]. Option 2: 0.001 M Perchloric Acid (HClOâ‚„) [28] [29]. |

| Volumetric Flasks | Class A, for precise preparation of standard solutions (e.g., 100 ml, 1000 ml) [5]. |

| Quartz Cuvettes | Matched pair, with a defined path length (typically 10 mm). Must be clean and free of scratches [30]. |

| UV-Vis Spectrophotometer | Instrument to be calibrated. Should have a narrow spectral bandwidth (e.g., 2 nm or less) [28] [29]. |

Detailed Experimental Protocol

Solution Preparation

- Dry the standard: Heat potassium dichromate crystals to a constant weight at 130°C and allow them to cool in a desiccator [5] [11].

- Prepare stock solution: Accurately weigh between 57.0 mg and 63.0 mg of the dried potassium dichromate [5]. Transfer this quantity to a 1000 ml volumetric flask, dissolve, and dilute to volume with 0.005 M Sulfuric Acid [5] [11]. This yields a nominal 60 mg/L solution.

- For visible range check (430 nm): A higher concentration solution is needed. Accurately prepare a solution of approximately 600 mg/L of potassium dichromate in the acidic diluent [11].

Measurement Procedure

- Instrument Setup: Allow the spectrophotometer to warm up sufficiently. Set the slit width to 2 nm or as per manufacturer's recommendation [28].

- Blank Measurement: Fill a quartz cuvette with the acidic diluent (0.005 M Hâ‚‚SOâ‚„ or 0.001 M HClOâ‚„) and use it to zero the instrument's absorbance across the relevant wavelength range [30] [11].

- Sample Measurement:

- Replace the blank with the prepared potassium dichromate solution (nominal 60 mg/L).

- Scan the solution between 200 nm and 400 nm, or specifically measure the absorbance at the four critical wavelengths: 235 nm, 257 nm, 313 nm, and 350 nm [28] [5] [11].

- For the visible range check, measure the absorbance of the 600 mg/L solution at 430 nm [28] [11].

The workflow for the calibration procedure is systematic and follows these key stages:

Data Calculation and Acceptance Criteria

Calculate the specific absorbance (A(1%, 1cm)) for each wavelength using the formula below. This standardizes the absorbance value to a 1 g/100ml solution in a 1 cm pathlength cuvette [5].

Formula:

A(1%, 1cm) = (Measured Absorbance × 10000) / Weight of potassium dichromate (in mg) [5] [11]

Compare your calculated specific absorbance values against the pharmacopoeial acceptance criteria provided in the table below.

Table 2: Acceptance Criteria for Potassium Dichromate Photometric Accuracy Control

| Wavelength (nm) | Feature in Spectrum | Specific Absorbance A(1%, 1cm) Limit [5] |

|---|---|---|

| 235 nm | Minimum (Valley) | 122.9 - 126.2 |

| 257 nm | Maximum (Peak) | 142.8 - 145.7 |

| 313 nm | Minimum (Valley) | 47.0 - 50.3 |

| 350 nm | Maximum (Peak) | 105.6 - 108.2 |

| 430 nm * | Plateau | Verify absorbance is as expected for the concentration used [28] [11] |

Note: For the 430 nm measurement, the acceptance is typically a direct comparison of the measured absorbance against the value stated on the certificate for a certified filter, or against an internally defined specification for a lab-made solution [28] [11].

Troubleshooting and FAQs

Q1: Our absorbance readings for the potassium dichromate standard are unstable and fluctuating. What is the most likely cause? A: Fluctuating readings are most commonly attributed to a degraded light source.

- Primary Cause: UV lamps (deuterium or xenon) have a finite lifespan. A lamp approaching or exceeding its rated hours (e.g., 1,000–2,000 hours for deuterium) often causes instability and noise [19].

- Action: Check the logged usage hours of your lamp. If unknown or high, replacing the lamp is the first recommended step [19]. Also, ensure the cuvette is clean and free of scratches, as this can also cause light scatter and inconsistent readings [30].

Q2: The calculated specific absorbance values are outside the acceptance range. What does this indicate? A: This is a clear sign of a potential error in the instrument's photometric accuracy. The source of the error could be:

- Instrument-Related: Photometric scale misalignment, a failing detector, or excessive electronic drift [30] [25].

- Preparation-Related: Use of impure potassium dichromate, incorrect dilution, use of non-dried material, or using dirty or mismatched cuvettes [30] [5].

- Diagnosis: First, repeat the measurement with a freshly prepared solution and a clean cuvette. If the problem persists, use a commercially available, certified potassium dichromate filter to rule out solution preparation errors. If the certified filter also fails, a service visit to calibrate the instrument's photometric axis is required [28] [19].

Q3: How often should we perform photometric accuracy testing with potassium dichromate? A: The frequency should be based on risk assessment, usage patterns, and regulatory requirements. A common schedule in pharmaceutical labs is quarterly [11]. However, it is also considered a best practice to perform this check whenever you notice performance issues, after instrument repair or maintenance, or as mandated by your internal quality procedures [30] [5].

Q4: Why is an acidic diluent like sulfuric acid required for preparing the solution? A: Potassium dichromate in aqueous solution establishes an equilibrium between the chromate (CrO₄²â») and dichromate (Crâ‚‚O₇²â») ions, which is pH-dependent. Using an acidic diluent stabilizes the dichromate ion, providing a reproducible and stable absorbance spectrum necessary for a reliable calibration standard [29].

The following diagram outlines a logical troubleshooting workflow to diagnose and resolve common calibration failures:

Stray light is a critical parameter in UV-Vis spectrophotometry that can significantly compromise the accuracy of your measurements. It is defined as any light that reaches the detector outside the wavelength band selected for analysis by the monochromator [6]. In pharmaceutical development, controlling stray light is not just good practice—it is a regulatory requirement. Recent updates to the US Pharmacopeia (USP) Chapter <857> and European Pharmacopoeia (EP) Chapter 2.2.25 mandate rigorous qualification of spectrophotometer performance using specific protocols and certified materials [31]. This guide provides detailed methodologies for measuring stray light using Potassium Chloride and Sodium Nitrite solutions, ensuring your laboratory remains compliant and your analytical results reliable.

Key Reagent Solutions for Stray Light Testing

The following table details the essential materials required for pharmacopeial-compliant stray light measurement.

Table 1: Key Research Reagent Solutions for Stray Light Qualification

| Reagent Solution | Recommended Wavelength | Primary Pharmacopeial Application | Function in Stray Light Testing |

|---|---|---|---|

| Potassium Chloride (12 g/L) | 198 nm / 200 nm [32] | EP & USP [31] | Cut-off filter for far-UV stray light detection; sensitive indicator of optics deterioration [31]. |

| Sodium Nitrite (50 g/L) | 340 nm & 370 nm [32] | EP & USP [31] | Cut-off filter for assessing stray light in the near-UV region [32]. |

| Holmium Oxide Filter | 240–650 nm [31] | EP & USP [31] | Certifies wavelength accuracy, a prerequisite for reliable stray light measurement. |

| Certified Quartz Cuvettes (10 mm path length) | N/A | EP & USP (by procedure) | Provides a precise, spectrally neutral light path. Essential for measurement accuracy [32]. |

Experimental Protocols

The procedures for stray light verification differ between the major pharmacopoeias. The following workflows and tables outline the specific steps and acceptance criteria for each.

Stray Light Measurement Workflow

The following diagram illustrates the logical decision process for performing stray light measurement according to pharmacopeial standards.

Detailed Pharmacopeial Protocols

A. European Pharmacopoeia (Ph. Eur. 2.2.25) Procedure

This method directly measures the absorbance of a certified stray light filter at a specified wavelength [32].

- Sample Preparation: Fill a certified quartz cuvette (typically 10 mm path length) with the Potassium Chloride or Sodium Nitrite solution. Fill a matched reference cuvette with pure water [32].

- Instrument Setup: Place the reference cuvette (water) in the spectrophotometer's sample compartment and perform a baseline correction.

- Measurement: Replace the reference cuvette with the sample cuvette (stray light solution). Measure the absorbance at the recommended wavelength (e.g., 198 nm for Potassium Chloride, 340 nm or 370 nm for Sodium Nitrite) [32].

- Acceptance Criterion: The measured absorbance value must be equal to or greater than the value specified in the pharmacopoeia (e.g., ≥ 2.0 A for Potassium Chloride at 198 nm) [32].

B. United States Pharmacopeia (USP <857>) Procedure B

USP Procedure B is similar to the EP method and is commonly used for its simplicity [32].

- Sample Preparation: Fill a 10 mm path length quartz cuvette with the stray light solution (e.g., Potassium Chloride). For the reference, use a 10 mm cuvette filled with pure water. The exception is Acetone, which is measured against air [32].

- Instrument Setup: Perform a baseline correction with the reference cuvette (water) in place.

- Measurement: Measure the absorbance of the sample solution at the pharmacopoeia-recommended wavelength.

- Acceptance Criterion: The measured absorbance must be greater than 2.0 at the specified wavelength [32].

Table 2: Summary of Stray Light Protocols and Acceptance Criteria

| Reagent | Pharmacopeia | Procedure | Wavelength | Acceptance Criterion |

|---|---|---|---|---|

| Potassium Chloride (12 g/L) | EP 2.2.25 [32] | Measure vs. Water | 198 nm | Absorbance ≥ 2.0 |

| USP <857> (Proc. B) [32] | Measure vs. Water | 198 nm | Absorbance > 2.0 | |

| Sodium Nitrite (50 g/L) | EP 2.2.25 [32] | Measure vs. Water | 340 nm & 370 nm | Absorbance ≥ 3.0 |

| USP <857> (Proc. B) [32] | Measure vs. Water | 340 nm | Absorbance > 2.0 |

Frequently Asked Questions (FAQs)

Q1: Why is Potassium Chloride solution no longer considered a universal stray light reference? Recent updates to the USP and EP require that qualification measurements match or 'bracket' the parameters used in your actual analysis. This means a single reference material is often insufficient. While Potassium Chloride remains essential for the far-UV region (200 nm), other materials like Sodium Iodide (220 nm) or Potassium Iodide (250 nm) are now required to qualify performance across the entire UV range you use [31].

Q2: My stray light measurement failed the acceptance criteria. What is the most common cause? The most common cause of instability and failing performance qualifications, including stray light tests, is a degraded or aging lamp. UV-Vis spectrophotometer lamps (deuterium or xenon) have a finite lifespan (1,000–3,000 hours for deuterium). If your lamp is approaching or has exceeded its rated hours, replacement should be your first troubleshooting step [19].

Q3: Can I use plastic cuvettes for stray light measurements in the UV range? No. The majority of plastic cuvettes absorb UV light and are inappropriate for UV absorption studies, including stray light verification. You must use high-quality quartz cuvettes, as quartz is transparent to most UV light and will not introduce erroneous absorbance readings [33].

Troubleshooting Guide

Use this guide to diagnose and resolve common issues that lead to stray light test failures.

Table 3: Stray Light Measurement Troubleshooting Guide

| Problem | Potential Causes | Corrective Actions |

|---|---|---|

| Low Absorbance Reading | 1. Degraded light source (lamp) [19].2. Contaminated cuvette (dust, fingerprints) [34].3. Contaminated or improperly prepared reagent solution. | 1. Check and replace the lamp if usage hours exceed manufacturer specs [19].2. Clean cuvettes with lint-free cloth and spectrometric-grade solvent [34].3. Use fresh, certified reference materials and high-purity solvents. |

| Erratic or Noisy Signal | 1. Instrument instability due to failing lamp or electronics [19].2. Dust or contamination on optical components [19].3. Environmental fluctuations (temperature, stray light in room). | 1. Check lamp hours and schedule a service call to evaluate electronics if needed [19].2. Ensure sample compartment is clean and sealed properly [6].3. Keep the instrument in a stable, low-light environment [34]. |

| Consistent Test Failure After Lamp Replacement | 1. Detector optics may be dirty or damaged [19].2. Misalignment of optical components.3. Use of non-certified or damaged cuvettes. | 1. Schedule qualified service maintenance to inspect and clean detector optics [19].2. Verify cuvette path length consistency and ensure they are not scratched or damaged. |

Rigorous and routine stray light measurement using Potassium Chloride and Sodium Nitrite is a cornerstone of robust UV-Vis spectrophotometer qualification in pharmaceutical laboratories. By adhering to the detailed EP and USP protocols outlined in this guide, researchers can ensure their instruments perform within specified parameters, thereby guaranteeing the accuracy and linearity of absorbance data. This commitment to proper calibration is not only a technical necessity but also a fundamental component of data integrity, regulatory compliance, and ultimately, patient safety.

Frequently Asked Questions

1. What does the "resolution power" of a UV-Vis spectrophotometer mean? Resolution power, or spectral bandwidth, is a fundamental instrumental parameter that describes the spectrophotometer's ability to distinguish between two closely spaced wavelengths in an absorption spectrum. It is the most misunderstood and often unchecked parameter, yet it critically impacts the quality of both wavelength and absorbance measurement results. Proper resolution ensures that sharp absorption peaks are correctly distinguished and measured, which is essential for both qualitative identification and quantitative analysis [35].

2. Why is a solution of toluene in hexane specified for testing resolution? A 0.02% (v/v) solution of toluene in n-hexane is specified by pharmacopeial standards (such as USP and EP) because it produces a spectrum with fine, closely spaced structural features. The specific ratio of the absorbance at the peak (269 nm) to the absorbance at the trough (~266 nm) provides a sensitive measure of the instrument's spectral bandwidth. This test directly verifies whether the instrument can resolve these closely adjacent spectral features, which is a key indicator of its optical performance [36] [37].

3. My resolution test failed. What is the most common cause of instability or fluctuations in UV-Vis readings? The most common cause of general instrument instability, fluctuating readings, and qualification failures is lamp degradation. UV-Vis spectrophotometers use either deuterium lamps (typically lasting 1,000–3,000 hours) or xenon lamps (~500 hours). If the lamp is approaching or has exceeded its rated lifespan, it can lead to significant instability, noise, and inaccurate results. Lamp replacement should be the first step in troubleshooting such issues [19].

4. What are the acceptance criteria for a passing resolution test? When using the 0.02% toluene in hexane solution, the test is passed if the ratio of the absorbance at the maximum (269 nm) to the absorbance at the minimum (approximately 266 nm) is ≥ 1.5. This specific criterion is designed to validate the instrument's performance within the nominal spectral bandwidth range of 0.5 to 2.0 nm [35] [36].

5. Are there alternatives to the toluene/hexane solution for resolution testing? Yes. Newer measurement artifacts are available that offer key advantages, such as the ability to validate resolution in real-time simultaneously with wavelength accuracy using a certified holmium oxide solution. These alternatives are easier to use as they do not require a reference blank solution cuvette and provide better discrimination between spectral bandwidths [35].

Troubleshooting Guide

Problem: Unstable Baseline or Noisy Spectrum During Resolution Test

| Possible Cause | Investigation Steps | Corrective Action |

|---|---|---|

| Degraded Light Source [19] | Check the instrument's lamp usage hours log. | If the lamp is near or beyond its rated lifespan (1,000-3,000 hours for deuterium), replace the lamp. |

| Contaminated Optics [19] | Visually inspect the sample compartment and detector window for dust or residue. | Gently clean the optics according to the manufacturer's instructions using approved materials. |

| Improper Cuvette Handling | Check cuvettes for fingerprints, scratches, or residue. Ensure they are properly matched. | Thoroughly clean and dry cuvettes. Use a lens tissue to handle them, and always use a matched set. |

| Stray Light or Temperature Fluctuations [19] | Run a baseline with empty compartment or blank solvent. Monitor lab temperature. | Ensure the sample compartment door is fully closed. Relocate the instrument away from air vents or direct sunlight. |

Problem: Failed Resolution Test (Peak-to-Trough Ratio < 1.5)

| Possible Cause | Investigation Steps | Corrective Action |

|---|---|---|

| Incorrect Solution Preparation | Verify the concentration of the toluene in hexane is exactly 0.02% (v/v). | Prepare a fresh solution using a certified standard or a volumetric flask for accuracy [37]. |

| Deteriorated Solution | Check the age of the solution. Toluene in hexane can degrade over time, especially if improperly stored. | Always use a freshly prepared solution or one that has been stored according to guidelines in a sealed, dark container. |

| Incorrect Spectral Bandwidth (SBW) Setting | Check the instrument method setting for the SBW. | Ensure the SBW is set to the manufacturer's specification for the test (often 1 nm). Using too wide a bandwidth will fail the test. |

| Misaligned Optical System | This may be suspected if other performance tests (wavelength, photometric accuracy) also fail. | Contact qualified service personnel for a full instrument performance check and optical realignment. |

Problem: Absorbance Values are Inaccurate or Non-Linear

| Possible Cause | Investigation Steps | Corrective Action |

|---|---|---|

| High Stray Light [12] | Perform a stray light test using Potassium Chloride (for ~200 nm) or Sodium Nitrite (for ~340 nm). | If stray light is high (absorbance reading < 2.0 A), the optical path may need cleaning or the source may need replacement [36] [37]. |

| Faulty Detector | Suspected if lamp is new, optics are clean, and multiple photometric tests fail. | A service call is required to evaluate the detector and internal electronics [19]. |

Experimental Protocol: Executing the Toluene in Hexane Resolution Test

Principle and Purpose

This test establishes the resolution of the spectrophotometer in the UV region by verifying its ability to resolve the fine structure of a toluene in hexane spectrum. The pass/fail criterion is based on the ratio of absorbances at specific wavelengths [36] [37].

Materials and Equipment

The following toolkit is essential for correctly performing this test.

Research Reagent Solutions

| Item | Function | Specification / Note |

|---|---|---|

| Toluene in n-Hexane | The analyte whose fine spectral structure tests the instrument's resolution. | Concentration must be 0.02% (v/v) [36] [37]. |

| n-Hexane | Serves as the reference blank solution. | Must be of high spectral purity [37]. |

| Matched Quartz Cuvettes | Hold the sample and reference blank. | A matched pair is critical for accurate baseline correction. |

| Certified Reference Material (CRM) | Ensures traceability and accuracy. | Use a NIST-traceable, certified toluene in hexane solution for defensible results [12]. |

Step-by-Step Methodology

- Solution Preparation: Obtain a certified 0.02% (v/v) solution of toluene in n-hexane. Alternatively, prepare it carefully using volumetric glassware and high-purity reagents [37].

- Blank Preparation: Fill a quartz cuvette with spectral-grade n-hexane as the reference blank.

- Sample Preparation: Fill a matched quartz cuvette with the prepared 0.02% toluene in hexane solution.

- Instrument Setup: Allow the spectrophotometer to warm up for the manufacturer-specified time (typically 30 minutes). Set the spectral bandwidth (SBW) as per the instrument's SOP, often to 1 nm.

- Baseline Correction: Place the n-hexane blank in the sample compartment and perform a baseline correction or record a background spectrum over the range of 260 nm to 280 nm.

- Sample Scanning: Replace the blank with the sample cuvette and scan the absorption spectrum from 260 nm to 280 nm.

- Data Analysis: From the recorded spectrum, identify the absorption maximum at 269 nm (A₂₆₉) and the absorption minimum (trough) at approximately 266 nm (A₂₆₆).

- Calculation and Acceptance: Calculate the ratio A₂₆₉ / A₂₆₆. The instrument passes the resolution test if the ratio is ≥ 1.5 [36] [37].

Key Considerations for Pharmaceutical Labs

- Regulatory Compliance: This test is a requirement for instrument qualification under pharmacopeial standards like USP <857> and Ph. Eur. 2.2.25 [36] [37]. Ensure your Standard Operating Procedure (SOP) references the current version of these chapters.

- Proactive Lamp Management: Maintain a log of lamp usage hours and replace lamps proactively based on manufacturer specifications to prevent unexpected failures and data integrity issues [19].

- Data Integrity: All calibration activities, including the resolution test, must be fully documented. Records should include instrument ID, date, standard used, observed values, acceptance criteria, and analyst signature to ensure GMP/GLP compliance and provide a complete audit trail [36] [38].

Sample Preparation Best Practices for Accurate Pharmaceutical Analysis

This technical support center provides targeted troubleshooting guides and FAQs to help researchers and scientists overcome common challenges in pharmaceutical analysis, with a specific focus on issues affecting UV-Vis calibration and results.

Troubleshooting Guides

Fluctuating or Inconsistent Absorbance Readings

| Potential Cause | Symptoms | Diagnostic Steps | Corrective Actions |

|---|---|---|---|

| Instrument Lamp Degradation [19] | Baseline drift, noise across wavelengths, unstable readings | Check lamp usage hours (Xenon: ~500h; Deuterium: 1,000–3,000h) [19] | Replace lamp approaching end-of-life; allow 30-minute warm-up [19] [39] |

| Sample Preparation Errors [1] | Air bubbles, particulate matter in solution, scratched cuvettes | Visually inspect sample for cloudiness or bubbles; check cuvette integrity [1] | Filter sample (0.45µm); degas solvents; use high-quality quartz cuvettes [40] [1] |

| Improper Sample Concentration [33] | Absorbance readings >1.2 AU (Beer-Lambert law deviation) [33] | Review sample dilution factor and absorbance values | Dilute sample to ideal range (0.2–1.0 AU) [1] [33] |

| Environmental Factors [1] | Drift in controlled or variable environments | Monitor lab temperature and humidity fluctuations | Stabilize room temperature; use instrument covers; control drafts [1] |

Incomplete Drug Extraction from Solid Dosage Forms

| Potential Cause | Symptoms | Diagnostic Steps | Corrective Actions |

|---|---|---|---|

| Insufficient Particle Size Reduction [40] | Low and variable potency recovery, high RSD | Observe particle size after grinding; check method for size specification | Grind tablets to fine powder using mortar/pestle or mill; use freezer mill for hard tablets [40] |

| Non-Optimized Extraction Technique [40] | Low recovery even after extended preparation time | Vary sonication/shaking time during investigation; check for undissolved particles | Optimize sonication time/shaking speed; use heated shaking for low-solubility APIs [40] |

| Incorrect Diluent Selection [40] | API precipitation, cloudy solution | Check diluent pH and solvent strength against API properties | Use organic solvent (ACN, MeOH) for initial solubilization; ensure diluent compatibility with mobile phase [40] |

Frequently Asked Questions (FAQs)

Sample Preparation

Q1: What are the critical weighing considerations for drug substance analysis? Accurately weighing 25-50 mg of a drug substance is an error-limiting step. Use a five-place analytical balance (±0.1 mg) with a folded weighing paper or boat to facilitate transfer [40]. For hygroscopic or refrigerated APIs, allow the sample to reach room temperature before opening to prevent moisture condensation, and handle speedily [40].

Q2: When should I filter a sample, and what type of filter should I use? For drug products (tablets, capsules), filtration is a standard step to remove insoluble excipients. Filter the extract through a 0.45 µm nylon or PTFE syringe filter, discarding the first 0.5 mL of the filtrate [40]. For cloudy solutions, use a 0.2 µm filter or centrifugation. Filtration is generally discouraged for drug substance (API) solutions as they should not contain particulates [40].

Q3: How can I ensure complete dissolution of my API? The optimal dissolution method (sonication, vortex mixing, or shaking) and time should be determined during method development and strictly followed [40]. Scrutinize the final solution to ensure no particles remain. For APIs with low aqueous solubility, a mixed-solvent approach (e.g., initial solubilization in an organic solvent) may be necessary [40].

Instrumental and Analytical Performance

Q4: My calibration curve is non-linear. What should I do? Non-linearity, especially at high concentrations (>1.2 AU), often indicates a deviation from the Beer-Lambert law [1] [33]. Dilute your samples to ensure absorbance readings fall within the ideal linear range of 0.2–1.0 AU [1]. Also, verify the spectrophotometer's photometric linearity using certified standards like potassium dichromate [39].

Q5: How often should I calibrate my UV-Vis spectrophotometer? Perform a full wavelength and photometric accuracy calibration regularly—typically before a critical set of measurements or weekly, depending on use and operational procedures [1]. This follows standards like USP 857 or Ph.Eur. Use certified reference materials (e.g., holmium oxide for wavelength, potassium dichromate for absorbance) for calibration [1] [39].

Q6: What causes a noisy or drifting baseline, and how can I fix it? A fluctuating baseline can be caused by an aging lamp, temperature instability, or stray light [19] [1]. First, check the lamp usage hours and replace it if necessary [19]. Ensure the instrument has warmed up for at least 30 minutes and is located in a stable temperature environment. Using a double-beam instrument can also compensate for these fluctuations [1].

Experimental Workflow for Robust Sample Preparation

The following workflow outlines a general procedure for preparing solid oral dosage forms, incorporating key precautions to ensure accuracy.

Key Reagents and Materials for Pharmaceutical Sample Prep

| Item | Function & Description | Key Considerations |

|---|---|---|