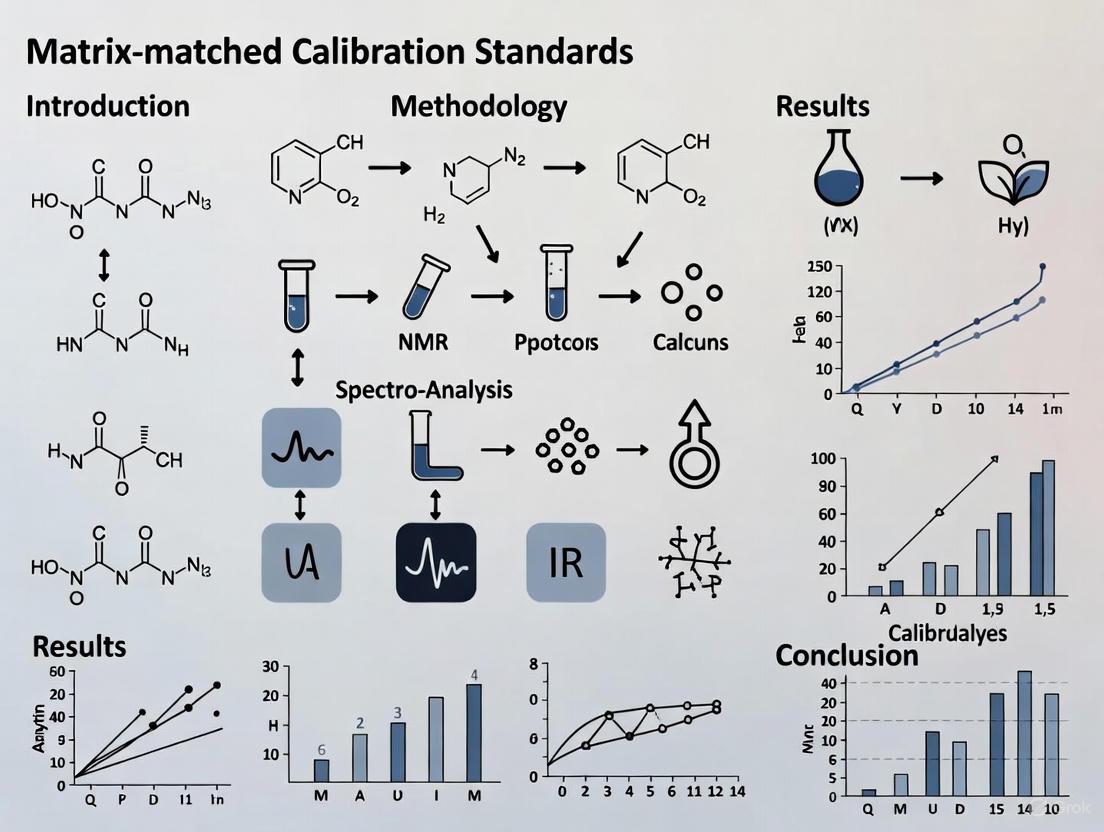

Matrix-Matched Calibration Standards: A Comprehensive Protocol for Accurate Bioanalytical Quantitation

This article provides a comprehensive protocol for developing and implementing matrix-matched calibration standards, specifically tailored for researchers and drug development professionals.

Matrix-Matched Calibration Standards: A Comprehensive Protocol for Accurate Bioanalytical Quantitation

Abstract

This article provides a comprehensive protocol for developing and implementing matrix-matched calibration standards, specifically tailored for researchers and drug development professionals. It covers the fundamental theory of matrix effects across analytical techniques including LC-MS, GC-MS, and ICP-based methods, detailed methodologies for standard preparation using blank matrices and analyte protectants, advanced troubleshooting for common challenges, and rigorous validation approaches comparing matrix-matching to standard addition and internal standard methods. The content synthesizes current research to deliver practical strategies for achieving accurate quantitation in complex biological matrices, ultimately supporting robust analytical method development in pharmaceutical and clinical research.

Understanding Matrix Effects: The Scientific Foundation for Calibration Matching

Matrix effects represent a significant challenge in analytical chemistry, particularly in quantitative analysis using techniques such as liquid chromatography-mass spectrometry (LC-MS) or gas chromatography-mass spectrometry (GC-MS). These effects occur when components within a sample matrix interfere with the ionization process of the target analyte, leading to either suppression or enhancement of the analytical signal [1]. This phenomenon was first documented in the early 1990s and has gained increasing attention as analytical methods have become more sensitive and applied to increasingly complex matrices [1].

The evolution of matrix effect understanding has progressed from initial observations of unexplained variability in results to sophisticated strategies for their characterization and mitigation. The primary objective of analyzing matrix effects is to ensure accurate quantitation across diverse sample types by developing robust analytical methods that either eliminate these effects or compensate for them through appropriate calibration strategies. This is particularly critical in regulated environments such as pharmaceutical analysis, clinical diagnostics, food safety testing, and environmental monitoring, where analytical accuracy directly impacts decision-making processes [1].

Mechanisms of Signal Suppression and Enhancement

Fundamental Mechanisms

Matrix effects stem from competitive interactions within the analytical system, primarily during the ionization process. The core mechanism involves co-eluting matrix components competing with the target analyte for available charge or space during ionization, thereby altering the efficiency of analyte ionization [1] [2].

In electrospray ionization (ESI), matrix effects typically manifest as signal suppression due to factors such as:

- Competition for charge in the droplet surface layer

- Altered droplet formation and evaporation dynamics

- Increased solution viscosity affecting spray stability

In atmospheric pressure chemical ionization (APCI), matrix effects are generally less pronounced but can still occur through gas-phase reactions that compete for available charge [1].

In GC systems, matrix effects are typically attributed to the presence of active sites, such as metal ions or silanols, in the GC inlet or column. These active sites can promote the adsorption and/or degradation of analytes containing heteroatoms such as nitrogen, oxygen, sulfur, or phosphorus in their structures [2].

Matrix-Induced Enhancement

Matrix-induced enhancement effects occur when matrix components interact with the analytical system to improve analyte response. In GC-MS applications, this enhancement arises when matrix components mask active sites in the GC system, making fewer sites available for analyte interaction. This results in reduced analyte losses and improved peak shapes [2]. This phenomenon is particularly observed when analyzing susceptible compounds in the presence of a complex matrix that contains components capable of passivating these active sites more effectively than the analytes themselves.

Negative Matrix Effects

Conversely, the gradual accumulation of nonvolatile matrix components in the GC system can result in the formation of new active sites and cause negative drift in analyte responses. This drift negatively affects the ruggedness of the system—the long-term repeatability of analyte peak intensities, shapes, and retention times—which is critically important in routine GC analysis [2].

Table 1: Mechanisms and Manifestations of Matrix Effects

| Mechanism | Primary Analytical Technique | Effect on Signal | Root Cause |

|---|---|---|---|

| Ion Competition | LC-ESI-MS | Suppression | Matrix components compete with analyte for charge during ionization |

| Active Site Interaction | GC-MS | Enhancement/Suppression | Matrix components mask or create active sites in GC system |

| Solution Property Alteration | LC-ESI-MS | Suppression | Matrix components change droplet formation/evaporation dynamics |

| Chromatographic Interference | LC-MS/GC-MS | Both | Co-eluting compounds affect separation or detection |

Experimental Protocols for Investigating Matrix Effects

Post-column Infusion Methodology

The post-column infusion experiment is a powerful qualitative technique for visualizing matrix effects throughout the chromatographic run.

Materials and Reagents:

- Analytical standard of target compound(s)

- Blank matrix extract

- Mobile phase solvents (HPLC grade)

- Syringe pump for continuous infusion

- LC-MS/MS or GC-MS/MS system

Procedure:

- Prepare a solution of the analyte at appropriate concentration in mobile phase.

- Connect the syringe pump to the post-column inlet of the LC system or appropriate inlet for GC system.

- Infuse the analyte solution at a constant rate while blank matrix extract is injected into the chromatographic system.

- Monitor the signal response of the analyte throughout the chromatographic run.

- Compare the signal baseline across the chromatogram, noting regions of suppression or enhancement.

Interpretation: Stable baseline indicates no matrix effects. Signal depression indicates regions of matrix-induced suppression, while signal elevation indicates enhancement.

Quantitative Matrix Effect Assessment

This protocol provides a standardized approach to quantify the extent of matrix effects.

Materials and Reagents:

- Analytical standards

- Blank matrix (free of target analytes)

- Pure solvent for comparison (typically acetonitrile/water or methanol/water mixtures)

- Appropriate solvents for standard preparation

Procedure:

- Prepare two sets of calibration standards at identical concentrations:

- Set A: Standards prepared in pure solvent

- Set B: Standards prepared in blank matrix extract

- Analyze both sets using the same instrumental conditions.

- Plot peak areas (or heights) against concentration for both sets.

- Calculate the slope of each calibration curve.

Calculation: Matrix Effect (ME%) = [(Slope of matrix-matched standards / Slope of solvent standards) - 1] × 100

Interpretation:

- ME% = 0: No matrix effect

- ME% > 0: Signal enhancement

- ME% < 0: Signal suppression

The SANTE 11312/2021 guideline recommends that matrix effects within ±20% are generally acceptable, while effects beyond this range require compensation strategies [3].

Matrix-Matched Calibration: A Primary Compensation Strategy

Theoretical Basis

Matrix-matched calibration (MMC) involves preparing calibration standards in a blank matrix similar to the samples being analyzed. This approach ensures that analytes in both calibration standards and samples experience the same matrix effects, leading to more accurate quantitation. The fundamental principle is that by subjecting both standards and samples to similar matrix interferences, the calibration curve accurately reflects the relationship between concentration and instrument response in the presence of the matrix [1] [4].

MMC is widely described for calibration purposes and is used in various fields of instrumental analysis, particularly in mass spectrometry. It is utilized to account for the effects on the ionization efficiency of the compounds being studied, which may be influenced by the co-presence of different organic compounds alongside the analytes [3].

Protocol for Matrix-Matched Standard Preparation

This protocol provides a detailed methodology for preparing matrix-matched standards for pesticide analysis in food matrices, adaptable to other analytical applications.

Research Reagent Solutions and Materials:

Table 2: Essential Research Reagents and Materials

| Item | Function/Application |

|---|---|

| Blank Matrix | Matrix free of target analytes, provides same background as samples |

| Standard Stock Solutions | Primary source of analytes for calibration |

| Acetonitrile | Extraction solvent and standard diluent |

| Water (HPLC grade) | Diluent for adjusting solvent strength |

| QuEChERS Extraction Kits | Sample preparation for complex matrices |

| Internal Standards | Correction for procedural variations |

Experimental Workflow:

Detailed Procedure:

Blank Matrix Preparation:

- Obtain matrix material free of target analytes

- For food matrices, homogenize thoroughly

- Store at appropriate conditions to prevent degradation

Matrix Extract Preparation:

- Weigh 2±0.1 g of homogenized blank matrix into a 50-mL centrifuge tube

- Add 10 mL of acetonitrile (containing 1% acetic acid if needed)

- Shake vigorously for 1 minute

- Add QuEChERS salt mixture (4 g MgSO₄, 1 g NaCl, 1 g Na₃Citrate, 0.5 g Na₂HCitrate)

- Shake immediately and vigorously for 1 minute

- Centrifuge at ≥3000 rpm for 5 minutes

- Transfer supernatant to a d-SPE tube (150 mg MgSOâ‚„, 25 mg PSA, 25 mg C18)

- Shake for 30 seconds and centrifuge at ≥3000 rpm for 5 minutes

- Collect the final extract for standard preparation [4] [3]

Standard Preparation:

- Prepare standard stock solutions in acetonitrile at 10 times the highest calibration concentration

- Create seven calibration levels plus a blank

- For matrix-matched standards: Add 10 μL standard + 10 μL matrix extract + 80 μL water

- For solvent standards (comparison): Add 10 μL standard + 10 μL acetonitrile + 80 μL water [4]

Critical Notes:

- Proper dilution after QuEChERS extraction is essential to ensure successful and reproducible LC-MS/MS analysis

- Pre-wet tips when handling volatile solvents like acetonitrile to reduce dripping

- Prepare matrix-matched standards fresh for each analysis as storage is often not feasible for long periods [4] [2]

Advanced Compensation Approaches

Internal Standard Calibration

Internal standard calibration uses compounds with similar chemical properties to the analytes but distinguishable during analysis. These standards are added to both samples and calibration standards at known concentrations to normalize instrument response and compensate for matrix effects. By comparing the response ratio of analyte to internal standard, quantitation becomes more reliable even in the presence of matrix interferences [1].

Selection Criteria for Internal Standards:

- Similar physicochemical properties to analytes

- Similar retention time to compensate for region-specific matrix effects

- Not present in original samples

- Stable isotopically labeled compounds are ideal

Analyte Protectants for GC-MS Analysis

Analyte protectants (APs) are compounds that can interact strongly with the active sites in a GC system, effectively inhibiting the degradation, adsorption, or co-injection of analytes. The introduction of suitable APs to sample extracts and matrix-free standards induces even response enhancements, resulting in effective equalization of the matrix-induced response enhancement effect [2].

Table 3: Common Analyte Protectants and Their Applications

| Analyte Protectant | Effective For | Concentration | Solvent Compatibility |

|---|---|---|---|

| Ethyl Glycerol | Early-eluting compounds | 10 mg/mL | Polar solvents |

| Gulonolactone | Middle-eluting compounds | 1 mg/mL | Polar solvents |

| Sorbitol | Late-eluting compounds | 1 mg/mL | Polar solvents |

| Shikimic Acid | Various compound classes | Varies | May require polar solvents |

The use of APs has led to significant progress in compensating for matrix effects during the quantification of pesticides in various food matrices. For flavor components, which differ from pesticides in having lower molecular weights and being commonly extracted using weakly or moderately polar solvents, specific AP combinations must be identified that account for these differences [2].

Analytical Considerations and Method Validation

Selection of Calibration Model

The selection of an appropriate calibration model is crucial for accurate quantification. For pesticide analysis, the calibration model must enable the most accurate quantification of concentrations near the lowest calibration point for compounds with very low maximum residue limits, while also being able to quantify other compounds with much higher limits at the upper end of the calibration range [3].

The simplest acceptable calibration models include:

- Linear model: y = a + bx

- Weighted linear model: y = a + bx with weights (typically 1/x)

- Second-order model: y = a + bx + cx²

An automated package (ChemACal) has been developed to calculate the best calibration model for matrix-matched calibration in food pesticide analysis. The algorithm development is based on three requirements for routine analysis: good working range fitness, detection capability for analysis with MRLs close to the limit of quantitation, and a simple working range problem detection model [3].

Method Validation Parameters

When implementing matrix-matched calibration, several validation parameters should be assessed:

- Linearity: Evaluated through residual plots, statistical tests (ANOVA, ANOVA-LOF, Mandel), or numerical parameters (R², quality coefficient)

- Precision and Recovery: Should meet established guidelines (e.g., 70-120% recovery with RSD ≤20%)

- Limit of Quantification (LOQ): Sufficiently low to detect analytes at required concentrations

- Uncertainty: Overall method uncertainty should be estimated and found acceptable for the intended purpose

The SANTE 11312/2021 guideline provides specific requirements for method validation in pesticide residue analysis, which can be adapted for other analytical fields [3].

Matrix effects, manifested as signal suppression or enhancement, present significant challenges in modern analytical chemistry. Understanding the mechanisms behind these effects—including competition for charge during ionization in LC-MS and interaction with active sites in GC systems—is fundamental to developing effective compensation strategies. Matrix-matched calibration represents a robust approach to mitigating these effects by ensuring that calibration standards and samples experience identical matrix interferences. When properly implemented with appropriate calibration model selection and method validation protocols, matrix-matched calibration enables accurate and reliable quantitation even in complex matrices, meeting the rigorous demands of pharmaceutical, environmental, and food safety analysis.

Matrix interference presents a significant challenge in quantitative analytical chemistry, particularly in techniques such as liquid chromatography-mass spectrometry (LC-MS), gas chromatography-mass spectrometry (GC-MS), and atomic absorption spectroscopy (AAS). The sample matrix is defined as "the combined effect of all components of the sample other than the analyte on the measurement of the quantity" [5]. When a specific component is identified as causing an effect, it is termed an interference [5]. These effects can lead to inaccurate quantification, affecting the reliability, accuracy, and precision of analytical results [6] [7]. This document outlines the primary sources of matrix interference and provides detailed protocols for their identification and mitigation within the framework of developing matrix-matched calibration standards.

Matrix interferences are broadly categorized into chemical, physical, and instrumental types. The table below summarizes the key characteristics and examples of each.

Table 1: Classification of Matrix Interferences

| Interference Type | Underlying Cause | Impact on Analysis | Common Examples |

|---|---|---|---|

| Chemical [8] | Formation of stable compounds or alteration of ionization efficiency. | Reduces atom population or changes analyte signal. | Formation of refractory oxides in AAS; ion suppression/enhancement in LC-MS [9] [10]. |

| Physical [8] | Differences in physical properties between sample and standard solutions. | Alters sample introduction efficiency, affecting analyte signal. | Variations in viscosity, surface tension, or dissolved solid content [8]. |

| Spectral [9] [8] | Absorption or emission of radiation by interferents at or near the analyte wavelength. | Causes falsely elevated or suppressed absorbance readings. | Overlapping atomic absorption lines; molecular absorption bands; light scattering by particulates [9] [8]. |

| Ionization [8] | Loss of atoms to the ionic state in high-temperature atomizers. | Depletes ground state atoms, reducing absorption signal. | Prevalent for Group I and II elements (e.g., Na, K, Ca) in hot flames [8]. |

Chemical Interferences

Chemical interferences occur when the analyte interacts with other matrix components to form stable compounds or experiences altered ionization efficiency.

- In Atomic Spectroscopy: A common issue is the formation of thermally stable compounds that do not dissociate in the atomizer. For example, the presence of phosphate or sulfate can suppress the calcium signal by forming stable calcium phosphates or sulfates [8]. Similarly, aluminum can form a heat-stable compound with magnesium, depressing its signal [8].

- In Mass Spectrometry: The matrix effect most frequently manifests as ion suppression or enhancement, particularly in LC-MS with electrospray ionization (ESI) [10] [7]. Co-eluting matrix components compete with the analyte for charge or disrupt the droplet formation and desolvation process, leading to a change in the analyte signal despite an unchanged concentration [10] [7]. This is a significant challenge in the analysis of complex samples like biological fluids, food, and environmental materials [11] [12].

Physical Interferences

Physical interferences are related to the physicochemical properties of the sample solution that differ from those of the calibration standards. These differences can affect the sample transport efficiency to the atomizer (in AAS) or the ionization process (in MS) [8]. Key factors include:

- Viscosity and surface tension: Impact nebulization efficiency in flame AAS and LC-MS sample introduction systems [8].

- High concentrations of dissolved salts or acids: Can clog nebulizers or chromatographic systems and contribute to non-specific absorption [8].

- Presence of organic solvents: Alters the chromatographic elution strength and the ionization process in the MS source [10].

Instrumental and Spectral Interferences

These interferences are directly related to the instrumental measurement process.

In Atomic Absorption Spectroscopy:

- Spectral Overlap: While rare due to narrow absorption lines, it can occur, such as with the vanadium line overlapping with an aluminum line [8].

- Background Absorption: A significant issue caused by the broad-band absorption of light by unvaporized solvent droplets, salt particles, or molecular species (e.g., oxide and hydroxide radicals) in the atomizer [9] [8]. This is especially problematic at wavelengths below 350 nm [9].

- Light Scattering: Caused by particulate matter from the matrix deflecting the source light, leading to falsely high absorbance measurements [9] [8].

In Chromatography-Mass Spectrometry:

Experimental Protocols for Assessing Matrix Effects

Accurate quantification requires a thorough assessment of matrix effects during method development and validation. The following protocols are standard in the field.

Protocol for Post-Column Infusion (Qualitative Assessment)

This method provides a visual map of regions in the chromatogram susceptible to ion suppression or enhancement [7].

- Principle: A constant infusion of the analyte is introduced post-column while a blank matrix extract is injected into the LC system. Signal disturbances indicate matrix effects [7].

- Procedure:

- Setup: Connect a syringe pump containing a solution of the target analyte(s) to a T-piece between the HPLC column outlet and the MS inlet.

- Infusion: Start the syringe pump to provide a constant flow of the analyte, establishing a stable baseline signal.

- Injection: Inject a processed blank sample extract (a sample containing the matrix but not the analyte) onto the LC column.

- Data Analysis: Monitor the analyte signal. A dip in the signal indicates ion suppression at that retention time, while a peak indicates ion enhancement [7].

- Applications: Ideal for early method development to identify problematic retention time windows and assess the effectiveness of sample clean-up procedures [7].

Protocol for Post-Extraction Spike Method (Quantitative Assessment)

This method provides a quantitative measure of the matrix effect for a given analyte and matrix [7] [12].

- Principle: The signal of the analyte in a pure solvent is compared to the signal of the analyte spiked into a blank matrix extract at the same concentration [7].

- Procedure:

- Prepare Solutions:

- Solution A (Neat Standard): Prepare the analyte at a known concentration in a pure, volatile solvent.

- Solution B (Spiked Matrix Extract): Take a blank matrix extract (the supernatant after sample preparation of a blank matrix) and spike it with the same concentration of analyte.

- Analysis: Analyze both solutions using the developed LC-MS/MS or GC-MS/MS method.

- Calculation: Calculate the Matrix Effect (ME) using the formula: ( ME (\%) = \left( \frac{\text{Peak Area of Solution B}}{\text{Peak Area of Solution A}} - 1 \right) \times 100 \% )

- ( \lvert ME \rvert \leq 20\% ): Negligible matrix effect.

- ( 20\% < \lvert ME \rvert \leq 50\% ): Medium matrix effect.

- ( \lvert ME \rvert > 50\% ): Strong matrix effect [12].

- Prepare Solutions:

- Applications: Used during method validation to quantify the extent of matrix effects for each analyte and to verify the effectiveness of mitigation strategies [7].

The Scientist's Toolkit: Key Reagents and Materials

The following table lists essential reagents and materials used to combat matrix interference in analytical methods.

Table 2: Key Research Reagent Solutions for Mitigating Matrix Effects

| Reagent/Material | Function & Rationale | Typical Application |

|---|---|---|

| Stable Isotope-Labeled Internal Standard (SIL-IS) [6] [7] | Co-elutes with the analyte, mimicking its chemical behavior during extraction and ionization, thereby correcting for signal fluctuations due to matrix effects. | Gold standard for quantitation in LC-MS/MS and GC-MS/MS, especially for endogenous compounds [13] [6]. |

| Matrix-Matched Calibrators [6] [3] | Calibration standards prepared in a processed blank matrix that is representative of the sample, ensuring that matrix influences affect samples and standards equally. | Widely used in pesticide residue analysis in food [11] [3] and bioanalysis when a suitable SIL-IS is unavailable [6]. |

| Releasing Agents (e.g., Lanthanum (La), Strontium (Sr) salts) [8] | A cation that preferentially reacts with the interfering anion, preventing it from forming stable compounds with the analyte. | Used in AAS to prevent phosphate interference in calcium determination [8]. |

| Ionization Suppressants (e.g., KCl, CsCl) [8] | An easily ionized element (e.g., K) that provides a high concentration of electrons in the flame, suppressing the ionization of the analyte by shifting the equilibrium back to the neutral atomic state. | Used in flame AAS for the determination of easily ionized elements like Ba and Ca [8]. |

| QuEChERS Kits [3] | A standardized sample preparation method (Quick, Easy, Cheap, Effective, Rugged, and Safe) that includes a dispersive solid-phase extraction (d-SPE) clean-up step to remove matrix components like organic acids, pigments, and sugars. | Routine analysis of pesticide residues in complex food matrices [11] [3]. |

| Analyte Protectants [11] | Compounds (e.g., gulonolactone) added to both standards and samples to mask active sites in the chromatographic system, reducing analyte degradation and adsorption, which can be mistaken for or exacerbate matrix effects. | Used in GC analysis of pesticides to improve peak shape and quantitation [11]. |

| Orchinol | Orchinol|Natural Phytoalexin|For Research Use | Orchinol is a natural phenanthrenoid with phytoalexin and antifungal activity, isolated from orchids. For Research Use Only. Not for human or veterinary use. |

| MPT0B002 | MPT0B002, CAS:946077-08-3, MF:C19H19NO4, MW:325.4 g/mol | Chemical Reagent |

Strategic Workflow for Managing Matrix Interference

The following diagram outlines a logical decision-making workflow for selecting the appropriate strategy to manage matrix effects based on the nature of the analysis and available resources.

Figure 1: Strategy selection workflow for managing matrix interference in analytical methods.

Matrix interference, stemming from chemical, physical, and instrumental factors, is an inherent challenge in the analysis of complex samples. A systematic approach involving initial assessment (e.g., post-column infusion and post-extraction spike methods) followed by the implementation of robust mitigation strategies is crucial. The use of stable isotope-labeled internal standards represents the most effective approach, while matrix-matched calibration serves as a widely applicable and practical alternative. The strategic workflow provided offers a logical path for researchers to develop reliable, accurate, and precise quantitative methods, ensuring data integrity in pharmaceutical development, food safety, and environmental monitoring.

Matrix-matched calibration (MMC) is a cornerstone technique in modern analytical chemistry, essential for achieving accurate quantitative results when analyzing complex samples. The fundamental principle underpinning MMC is the compensation for matrix effects, a phenomenon where components of the sample matrix, other than the analyte, alter the instrumental detection signal. This effect is particularly pronounced in techniques like liquid chromatography-mass spectrometry (LC-MS) and gas chromatography-mass spectrometry (GC-MS), where co-eluting matrix compounds can suppress or enhance the ionization of the target analyte, leading to inaccurate quantification [10] [14].

The necessity for MMC arises from a critical assumption in all quantitative analyses: that the calibration curve accurately represents the relationship between the instrumental response and the analyte concentration in the sample. When the matrix of the calibration standard differs significantly from that of the sample, this relationship is disrupted. Matrix-matched calibration corrects this by preparing calibration standards in a matrix that is identical or highly similar to the sample matrix, thereby ensuring that the analyte in both the standard and the sample experiences the same matrix-induced effects during analysis [3] [6]. This application note delineates the theoretical foundations of MMC and provides detailed protocols for its implementation in research and development.

Theoretical Foundations of Matrix Effects

The Fundamental Problem

The "matrix," defined as all components of a sample except the analyte, can profoundly influence the detection signal. In an ideal system, the matrix would have no effect on the detector's response to the analyte. However, in practice, several phenomena can lead to signal suppression or enhancement [10]:

- Ionization Suppression/Enhancement (MS Detection): In electrospray ionization, analytes compete with matrix components for available charge during desolvation. The presence of co-eluting compounds can reduce (suppress) or increase (enhance) the ionization efficiency of the analyte [10] [6].

- Solvatochromism (UV/Vis Absorbance Detection): The absorptivity of analytes can be affected by the solvent properties of the mobile phase, which may be altered by matrix components, leading to changes in UV/Vis light absorption [10].

- Fluorescence Quenching (Fluorescence Detection): Matrix components can affect the quantum yield of the fluorescence process, suppressing the observed signal [10].

- Effects on Aerosol Formation (ELSD/CAD Detection): Mobile phase additives from the matrix can influence aerosol formation processes, resulting in signal variability [10].

These effects cause a discrepancy between the measured concentration and the true concentration, compromising data integrity.

The Solution: Matrix-Matched Calibration

Matrix-matched calibration mitigates these issues by incorporating the matrix effect directly into the calibration curve. The core principle is that if the calibration standards and unknown samples experience identical matrix-induced perturbations, the calculated relationship between signal and concentration will remain accurate [3]. The calibration curve is constructed using standards prepared in a blank matrix, which is a sample material devoid of the analyte but retaining all other matrix components. This ensures that any signal suppression, enhancement, or other matrix-related interferences affect the calibrators and samples equally, allowing for correct interpolation of sample concentrations [6].

Table 1: Quantified Matrix Effects in Various Studies

| Analyte | Matrix | Observed Matrix Effect | Impact on Quantitation | Citation |

|---|---|---|---|---|

| Cocaine | Surface Water | -54.24% (Suppression) | Underestimation of concentration without MMC | [15] |

| Pesticides | Pepper, Wheat Flour | Signal suppression/enhancement | Affected recovery and accuracy; mitigated by MMC | [3] |

| Mycotoxins | Corn, Peanut Butter | Signal suppression | Required stable isotope dilution or MMC for accurate quantitation | [14] |

| Proteins/Peptides | Cerebrospinal Fluid (CSF) | Ion suppression | Necessitated MMC for quantitative proteomics | [13] |

Experimental Protocols

Protocol 1: General Workflow for Matrix-Matched Calibration

This protocol outlines the generic steps for developing and applying a matrix-matched calibration method.

3.1.1 Materials and Reagents

- Blank Matrix: A representative sample material confirmed to be free of the target analyte(s). For endogenous analytes, this may require stripping (e.g., with charcoal), dialysis, or synthesis of an artificial matrix [6].

- Analyte Standards: High-purity reference materials of the target analyte(s).

- Internal Standards (Recommended): Stable isotope-labeled (SIL) analogs of the analytes are ideal [6] [14].

- Solvents and Reagents: High-purity solvents and reagents for sample preparation and dilution.

3.1.2 Procedure

- Blank Matrix Preparation: Obtain and verify a blank matrix. For complex solid samples (e.g., food, tissue), this typically involves homogenization and extraction to create a matrix-based solution [3] [15].

- Calibration Standard Preparation: Prepare a series of calibration standards by spiking known concentrations of the analyte(s) into the blank matrix. The calibration levels should span the entire expected concentration range in samples [6].

- Sample Preparation: Process unknown samples using the same procedure as the blank matrix to maintain consistency.

- Instrumental Analysis: Analyze the calibration standards and samples using the chosen analytical platform (e.g., LC-MS, GC-MS).

- Calibration Curve Construction: Plot the instrumental response (e.g., peak area, or peak area ratio to internal standard) against the nominal concentration of the calibration standards. Apply appropriate regression models (linear, weighted linear, quadratic) based on data characteristics [3] [6].

- Quantification: Interpolate the concentrations of unknown samples from the constructed calibration curve.

Figure 1: General workflow for implementing matrix-matched calibration.

Protocol 2: Detailed Example - MMC for Pesticide Analysis in Food Matrices

This protocol, adapted from research on pesticide analysis in pepper and wheat flour, provides a specific application [3].

3.2.1 Research Reagent Solutions

Table 2: Essential Materials for Pesticide Analysis via MMC

| Item | Function | Example |

|---|---|---|

| Blank Matrix | Provides the sample background for calibration standards, matching the chemical environment of real samples. | Homogenized pepper or wheat flour verified to be pesticide-free. |

| QuEChERS Kits | Quick, Easy, Cheap, Effective, Rugged, and Safe method for extracting pesticides and cleaning up sample extracts. | Extraction salts (MgSOâ‚„, NaCl) and d-SPE sorbents for cleanup. |

| Stable Isotope-Labeled Internal Standards | Corrects for analyte loss during sample preparation and variability in ionization efficiency; the gold standard for compensation. | ¹³C- or ¹âµN-labeled versions of target pesticides. |

| Chromatography Solvents | High-purity mobile phases and solvents are critical for maintaining instrument performance and detection sensitivity. | LC-MS grade acetonitrile, methanol, and water. |

| Analytical Column | Separates target pesticides from each other and from matrix interferences to reduce ionization suppression. | Reversed-phase C18 column for LC-MS/MS. |

3.2.2 Procedure

- Sample Homogenization: Finely grind and homogenize the blank pepper or wheat flour matrix.

- Extraction: Use a validated QuEChERS method. Weigh 10 g of homogenized sample into a 50 mL tube. Add 10 mL acetonitrile and shake vigorously. Then add salt mixtures (e.g., 4 g MgSOâ‚„, 1 g NaCl) for liquid-liquid partitioning, vortex, and centrifuge [3] [14].

- Clean-up: Transfer an aliquot of the supernatant to a d-SPE tube containing sorbents (e.g., PSA, C18, MgSOâ‚„) for further cleanup, vortex, and centrifuge.

- Calibrator Preparation: Spike the blank matrix extract with pesticide standards at a minimum of six concentration levels to create the matrix-matched calibration curve [3] [6]. A fractional dilution series is recommended to prevent the propagation of pipetting errors [13].

- Data Acquisition and Analysis: Analyze the calibrators using LC-MS/MS or GC-MS/MS. Use an algorithm or statistical package to select the best calibration model (linear, weighted linear, or quadratic) based on the fitness-of-purpose and compliance with validation guidelines [3].

Figure 2: Workflow for MMC in pesticide analysis of food.

Data Analysis and Validation

Assessing Matrix Effect and Selecting Calibration Model

The magnitude of the matrix effect (ME) can be quantified using the following formula, which compares the slope of the matrix-matched calibration curve to that of the solvent-based curve [15]:

ME/% = [(Slope_matrix - Slope_solvent) / Slope_solvent] × 100

A result near zero indicates no significant matrix effect. A negative value indicates signal suppression, while a positive value indicates enhancement [15].

For the calibration model, simplicity and accuracy should guide selection. The model—whether linear, weighted linear (e.g., 1/x to address heteroscedasticity), or second-order—must provide accurate quantification across the entire range, particularly at concentrations near the limit of quantitation for analytes with low maximum residue limits (MRLs) [3] [6]. Automated scoring systems, like the one implemented in the R package ChemACal, can evaluate models based on goodness-of-fit (GOF) and capability of detection (COD) to objectively select the best-performing model [3].

Best Practices and Regulatory Considerations

- Internal Standardization: The use of a stable isotope-labeled internal standard (SIL-IS) is considered the most effective way to compensate for matrix effects, as it mimics the analyte throughout sample preparation and ionization [6] [14].

- Calibrator Commutability: The matrix used for calibration must be representative of the patient or sample matrix to avoid bias. The commutability of the calibrator matrix should be verified during method development [6].

- Quality Control: The inclusion of quality control samples at low, medium, and high concentrations in each analytical batch is essential to confirm ongoing assay performance and calibration validity [6] [16].

Matrix-matched calibration is a critical analytical strategy for ensuring data accuracy when matrix effects are present. Its theoretical foundation is built on equalizing the analytical environment between calibration standards and unknown samples, thereby canceling out matrix-induced biases. The detailed protocols for pesticide analysis in food matrices provide a template that can be adapted to various fields, including environmental monitoring, clinical chemistry, and pharmaceutical analysis. By rigorously applying MMC principles and leveraging internal standardization, researchers can generate reliable, quantitative data that meets the stringent demands of modern scientific research and regulatory standards.

Matrix-matched calibration is a fundamental analytical technique used to ensure accurate quantitation when analyzing target compounds in complex sample matrices. This method involves preparing calibration standards in a matrix that is free of the target analytes but otherwise closely mimics the chemical composition of the actual samples. The primary objective is to compensate for matrix effects, a phenomenon where components within the sample interfere with the detection or signal response of the target analyte, leading to either signal suppression or enhancement [1]. These effects represent one of the most significant challenges in analytical chemistry, particularly in quantitative analysis using techniques such as liquid chromatography (LC) or gas chromatography (GC) coupled with mass spectrometry (MS) [1].

The evolution of matrix effect understanding has progressed from initial observations of unexplained variability in results to sophisticated strategies for their characterization and mitigation. Matrix effects continue to present challenges across various fields including pharmaceutical analysis, environmental monitoring, food safety testing, and clinical diagnostics due to their unpredictable nature and potential impact on quantitative results [1]. The global analytical instrumentation market addressing these challenges is substantial, with the bioanalytical testing segment alone growing at approximately 12.8% annually, highlighting the increasing demand for reliable quantitation methods [1].

Key Principles and Definitions

Matrix Effects and Their Impact

Matrix effects occur when components within a sample matrix interfere with the ionization process or detection of analytes, leading to either enhancement or suppression of analytical signals [1]. In mass spectrometry, these effects particularly impact ionization efficiency, potentially causing erroneous quantitative results. The same analyte can demonstrate different responses in different matrices, and the same matrix can affect various analytes differently [6]. The extent of matrix effect interference can be variable and unpredictable, depending on interactions between the target and co-eluting molecules [6].

Comparison of Calibration Approaches

Several calibration strategies exist to address matrix effects, each with distinct advantages and limitations:

- Matrix-Matched Calibration (MMC): Standards are prepared in a blank matrix similar to the sample, subjecting both standards and samples to similar matrix effects [1].

- Standard Addition: Known amounts of analyte are added directly to the sample, creating an internal calibration curve specific to each sample's unique matrix [1].

- External Calibration: Standards are prepared in simple solvents without matrix components, which can lead inaccuracies when significant matrix effects exist.

- Internal Standard Calibration: Uses compounds with similar chemical properties to the analytes, often stable isotope-labeled versions, to normalize instrument response and compensate for matrix effects [1].

Table 1: Comparison of Calibration Approaches for Mitigating Matrix Effects

| Calibration Method | Principles | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Matrix-Matched Calibration | Calibration standards prepared in blank matrix similar to sample | Accounts for matrix effects; suitable for batch analysis; relatively simple implementation | Requires analyte-free matrix; may not capture all matrix variability | Routine analysis of similar sample types; regulatory testing |

| Standard Addition | Known analyte amounts added directly to sample aliquots | Accounts for unique matrix of each sample; highly accurate for specific samples | Time-consuming; requires more sample; not efficient for large batches | Unique or variable matrices; when blank matrix is unavailable |

| Internal Standard (IS) | IS added to both samples and standards to normalize response | Compensates for matrix effects and sample preparation losses; improves precision | Requires structurally similar IS; costly for stable isotope-labeled IS | Complex matrices; high-precision quantitation |

| External Calibration | Standards prepared in pure solvent without matrix | Simple and fast; minimal sample preparation | Does not account for matrix effects; prone to inaccuracies | Simple matrices with minimal interference |

Pharmaceutical Industry Applications

Drug Development and Quality Control

In pharmaceutical analysis, matrix-matched calibration ensures accurate quantification of active pharmaceutical ingredients (APIs), impurities, and metabolites during drug development and quality control processes. The stringent regulatory requirements from agencies like the FDA and EMA necessitate highly accurate analytical methods to ensure drug safety and efficacy [1]. Matrix-matched calibrators are particularly important when analyzing biological samples during pharmacokinetic studies, where complex matrices like blood, plasma, or urine can significantly suppress or enhance analyte signals [6].

The use of stable isotope-labeled internal standards (SIL-IS) represents a powerful approach in pharmaceutical analysis. An SIL-IS must behave identically to the target analyte in both sample extraction and ionization processes to effectively correct for matrix effects [6]. For this compensation to be effective, the internal standard must closely resemble the analyte in terms of physical and chemical properties, with structural similarity being more critical than coincidental retention time alignment [6].

Protocol: Matrix-Matched Calibration for Drug Quantification in Plasma

Materials and Reagents:

- Blank plasma matrix (commercially sourced or charcoal-stripped)

- Certified reference standards of target drug compounds

- Stable isotope-labeled internal standards (when available)

- Appropriate solvents (methanol, acetonitrile, water)

- Protein precipitation reagents (e.g., acetonitrile with formic acid)

- Solid-phase extraction (SPE) materials if required

Instrumentation:

- Liquid chromatography system coupled to tandem mass spectrometry (LC-MS/MS)

- Analytical column suitable for the target compounds

- Sample preparation equipment (centrifuge, evaporator, etc.)

Procedure:

- Blank Matrix Preparation: Source or prepare blank plasma through charcoal stripping or other methods to remove endogenous compounds that may interfere with analysis.

- Calibrator Preparation: Prepare a minimum of six non-zero calibration standards by spiking blank plasma with known concentrations of drug standards, covering the expected concentration range in samples [6].

- Quality Control (QC) Samples: Prepare QC samples at low, medium, and high concentrations within the calibration range to monitor assay performance.

- Sample Preparation: Add appropriate internal standard to all samples, calibrators, and QCs. Precipitate proteins using organic solvents (e.g., acetonitrile) and centrifuge to remove precipitates.

- Extraction and Cleanup: Transfer supernatants for analysis or perform additional cleanup using SPE if necessary to reduce matrix effects.

- Chromatographic Separation: Inject samples using LC conditions optimized to separate analytes from matrix components, particularly those causing ion suppression in the ionization source.

- MS Analysis and Quantification: Acquire data using MRM transitions for target compounds and internal standards. Construct calibration curves by plotting peak area ratios (analyte/IS) against concentration.

Validation Parameters:

- Assess linearity across the calibration range using appropriate statistical methods

- Determine accuracy and precision using QC samples

- Evaluate matrix effects by comparing spiked sample responses to pure standards

- Establish lower limit of quantification (LLOQ) based on signal-to-noise criteria

Clinical Analysis Applications

Clinical Mass Spectrometry and Diagnostic Testing

Clinical mass spectrometry laboratories rely heavily on matrix-matched calibration for accurate quantification of biomarkers, hormones, metabolites, and therapeutic drugs in patient samples. The complexity of biological matrices such as serum, plasma, urine, and cerebrospinal fluid presents significant challenges for accurate quantitation [6]. A key assumption in the calibration process is that the signal-to-concentration relationship is fully conserved between the calibration material matrix and the clinical sample matrix [6].

For endogenous analytes, obtaining a appropriate blank matrix presents particular challenges. These matrices are often generated through removal of analytes by dialysis, stripping with activated charcoal, or using synthetic matrix materials [6]. However, these processes may cause the blank matrix to deviate from the native human matrix, potentially making it less representative of clinical patient samples. It is desirable to verify the commutability of the calibrator matrix during method development, which can be performed following CLSI EP07 guidelines [6].

Protocol: Endogenous Biomarker Quantification in Serum

Materials and Reagents:

- Stripped human serum (charcoal-treated or synthetic)

- Certified reference standards of target biomarkers

- Stable isotope-labeled internal standards for each analyte

- Sample preparation reagents (buffers, organic solvents)

- Solid-phase extraction cartridges if needed

Instrumentation:

- High-performance liquid chromatography system

- Tandem mass spectrometer

- Sample preparation equipment

Procedure:

- Matrix Evaluation: Verify commutability of stripped serum matrix compared to native patient samples using spike-and-recovery experiments [6].

- Calibration Standards: Prepare at least six calibration standards in stripped serum matrix, covering the clinically relevant concentration range.

- Internal Standard Addition: Add stable isotope-labeled internal standards to all samples, calibrators, and quality controls at a fixed concentration.

- Sample Preparation: Perform protein precipitation, liquid-liquid extraction, or solid-phase extraction to clean up samples and reduce matrix components.

- Chromatographic Optimization: Optimize LC conditions to achieve separation of analytes from regions of ion suppression/enhancement in the matrix [6].

- MS Analysis: Acquire data using specific MRM transitions for each analyte and corresponding internal standard.

- Quantification: Generate calibration curves using linear or weighted regression based on peak area ratios (analyte/IS) versus concentration.

Method Validation:

- Conduct linearity studies with a minimum of six concentration levels

- Evaluate precision and accuracy across the measurement range

- Assess matrix effects using post-column infusion or post-extraction spiking

- Determine lower limit of quantification with acceptable precision (CV <20%)

Table 2: Clinical Analytics Suitable for Matrix-Matched Calibration

| Analyte Class | Specific Examples | Biological Matrix | Key Considerations |

|---|---|---|---|

| Therapeutic Drugs | Antiepileptics, antidepressants, immunosuppressants | Serum, plasma | Wide therapeutic ranges; requires precise quantification |

| Hormones | Cortisol, testosterone, vitamin D metabolites | Serum, plasma | Often low concentrations; significant matrix effects |

| Metabolites | Amino acids, organic acids, acylcarnitines | Plasma, urine | Complex metabolic pathways; multiple structurally similar compounds |

| Proteins/Peptides | Insulin, C-peptide, amyloid peptides | Serum, plasma, CSF | Proteolytic degradation; non-specific binding |

| Toxicology | Drugs of abuse, environmental toxins | Urine, blood, tissue | Variable matrices; unknown interferences |

Food Safety Analysis Applications

Pesticide Residue Analysis and Contaminant Monitoring

Food safety testing represents a rapidly growing segment with particular matrix effect challenges due to the extreme complexity of food samples [1]. Matrix-matched calibration has become a fundamental approach for quantifying pesticide residues, mycotoxins, veterinary drug residues, and other contaminants in diverse food matrices [17] [3]. The global food testing market is expected to reach $29.2 billion by 2026, highlighting the importance of accurate analytical methods [1].

Different food matrices present unique challenges for analysis. For instance, studies have shown that high water content samples (apples and grapes) often demonstrate strong signal enhancement for the majority of pesticides, while high starch and/or protein content samples with high oil and low water content (spelt kernels and sunflower seeds) typically exhibit signal suppression [17]. This variability necessitates careful selection and validation of matrix-matched calibration approaches for different food types.

Protocol: Multi-Residue Pesticide Analysis in Complex Food Matrices

Materials and Reagents:

- Blank food matrix (identical to samples but free of target pesticides)

- Certified pesticide reference standards

- Internal standards (if used)

- QuEChERS extraction kits or components

- Solvents (acetonitrile, methanol, water)

- Dispersive SPE cleanup sorbents

Instrumentation:

- Gas or liquid chromatography system coupled to mass spectrometry

- Sample preparation equipment (centrifuge, mixer, evaporator)

Procedure:

- Blank Matrix Preparation: Source or confirm analyte-free matrix representative of samples being analyzed.

- Calibration Standards: Prepare a minimum of five calibration levels in blank matrix, covering the concentration range from below MRL to above expected sample concentrations [3].

- Sample Extraction: Weigh representative sample portion and extract using QuEChERS or other validated methods. The QuEChERS method involves initial extraction with salts to separate organic solvent and water phases [3].

- Sample Cleanup: Transfer aliquot of organic phase to dispersive SPE tube containing different sorbents to remove matrix components [3].

- Calibration Curve Optimization: Evaluate different regression models (linear, weighted linear, quadratic) and select based on statistical criteria and compliance with regulatory requirements [3].

- Instrumental Analysis: Inject cleaned extracts into GC-MS or LC-MS/MS system using optimized chromatographic conditions.

- Quantification: Use matrix-matched calibration curves to quantify pesticide residues in samples, applying the selected regression model.

Validation Parameters:

- Validate using SANTE/11312/2021 guidelines for pesticide analysis [3]

- Ensure precision and recovery meet requirements (typically 70-120% recovery)

- Evaluate calibration model using statistical parameters and capability of detection

- Assess matrix effects by comparing solvent standards to matrix-matched standards

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents for Matrix-Matched Calibration

| Reagent/Material | Function/Purpose | Application Notes | Quality Requirements |

|---|---|---|---|

| Blank Matrix | Provides matrix-matched background for calibration standards | Should be identical or highly similar to sample matrix; may require stripping or synthesis | Commutable with native samples; verified analyte-free |

| Certified Reference Standards | Primary material for calibration curve construction | Purity and concentration well-characterized; stable under storage conditions | Traceable certification; appropriate purity for application |

| Stable Isotope-Labeled Internal Standards | Normalizes for matrix effects and preparation losses | Should closely mimic target analyte behavior; added at consistent concentration | High isotopic purity; chemical stability; minimal cross-talk |

| Sample Extraction Materials | Isolate analytes from matrix components | QuEChERS, SPE, liquid-liquid extraction; selected based on analyte properties | Low background interference; consistent performance |

| Chromatographic Supplies | Separate analytes from matrix interferences | Columns, solvents, mobile phase additives; optimized for specific separations | HPLC/MS grade; low background contamination |

| Quality Control Materials | Monitor assay performance over time | Prepared at low, medium, high concentrations; analyzed with each batch | Well-characterized; stable; cover measurement range |

| MT-7 | MT-7, CAS:946507-08-0, MF:C22H17N3O2, MW:355.4 g/mol | Chemical Reagent | Bench Chemicals |

| NE 10790 | NE 10790, CAS:152831-36-2, MF:C8H10NO6P, MW:247.14 g/mol | Chemical Reagent | Bench Chemicals |

Advanced Applications and Case Studies

Comparative Performance Across Industries

Recent studies have demonstrated the effectiveness of matrix-matched calibration across various applications. In food analysis, a 2024 study on pesticide quantification in pepper and wheat flour developed an automated package for calculating the best calibration model for matrix-matched calibration, finding that weighted linear calibration generally provided the best performance over simple linear or second-order calibration [3]. The algorithm focused on evaluating goodness-of-fit across the calibration range and the capability of detection for each calibration model.

In clinical proteomics, matrix-matched calibration curves have been used to discriminate between peptides that are merely detectable versus those that are truly quantitative in mass spectrometry experiments [13]. This approach enables assessment of whether a change in measured signal accurately reflects a change in peptide abundance, which is particularly important for biomarker verification studies.

Emerging Trends and Innovations

The field of matrix-matched calibration continues to evolve with several emerging trends:

- Automated Calibration Selection: Development of algorithms and software packages that automatically evaluate and select optimal calibration models based on statistical criteria and regulatory requirements [3].

- Alternative Matrix Approaches: When a true blank matrix is unavailable, methods such as standard addition with matrix-matched materials or surrogate matrices are being refined [18].

- Cross-Industry Harmonization: Efforts to standardize calibration approaches across pharmaceutical, clinical, and food safety applications to improve data comparability.

- Advanced Materials: Development of novel reference materials and custom matrices that more accurately mimic complex sample compositions [19].

Matrix-matched calibration represents a critical analytical approach for ensuring accurate quantification in complex matrices across pharmaceutical, clinical, and food safety applications. By compensating for matrix effects that can significantly impact analytical results, this approach supports data quality and regulatory compliance in these highly regulated fields. The continued development of optimized calibration strategies, standardized protocols, and advanced materials will further enhance the reliability of analytical measurements in these vital industries.

As analytical challenges evolve with increasing demands for sensitivity, specificity, and throughput, matrix-matched calibration remains a fundamental tool in the analytical scientist's toolkit. Proper implementation and validation of these approaches, tailored to specific application requirements, provides the foundation for generating reliable data that supports drug development, clinical diagnostics, and food safety monitoring.

Regulatory Considerations for Matrix-Matched Methods in Validated Analyses

Matrix effects, defined as the combined effect of all components of a sample other than the analyte on its measurement, present a significant challenge in quantitative analysis, particularly in complex matrices such as biological, pharmaceutical, food, and environmental samples [20]. These effects can cause ion suppression or enhancement in mass spectrometry, alter chromatographic behavior, and ultimately compromise the accuracy, precision, and reliability of analytical results [14] [6]. For regulated industries, including pharmaceuticals, effectively controlling for matrix effects is not merely a scientific best practice but a regulatory imperative to ensure the quality, safety, and efficacy of products.

Matrix-matched calibration has emerged as a fundamental strategy to mitigate these effects. This technique involves preparing calibration standards in a matrix that is as similar as possible to that of the unknown samples, thereby ensuring that the analyte experiences a comparable chemical environment during analysis [20] [6]. This application note delineates the critical regulatory considerations, detailed protocols, and essential documentation required for the successful development, validation, and implementation of matrix-matched methods in a regulated analytical setting, providing a framework for generating defensible data that meets global regulatory standards.

Regulatory Framework and Key Considerations

Adherence to regulatory guidelines is paramount when employing matrix-matched methods. The following table summarizes the primary regulatory bodies and their relevant guidance documents pertaining to method validation and calibration practices.

Table 1: Key Regulatory Bodies and Guidance for Matrix-Matched Methods

| Regulatory Body | Relevant Guidance/Documents | Key Considerations for Matrix-Matching |

|---|---|---|

| U.S. Food and Drug Administration (FDA) | Guidance for Industry: Bioanalytical Method Validation; ICH Q2(R2) | Emphasis on demonstrating selectivity and specificity in the presence of matrix components; requires a minimum of six non-zero calibrators [6]. |

| European Medicines Agency (EMA) | Guideline on Bioanalytical Method Validation | Recommends investigation of matrix effects; use of matrix-matched calibration standards is a recognized approach to compensate for matrix effects [6]. |

| International Council for Harmonisation (ICH) | ICH Q2(R2) - Validation of Analytical Procedures | Requires validation of the analytical procedure's specificity, demonstrating that the method is unaffected by the presence of interfering components [21]. |

| United States Pharmacopeia (USP) | USP General Chapters; Public Standards | USP standards play a critical role in ensuring product quality and regulatory predictability; compliance is expected for drug substances and products [22]. |

Critical Regulatory Aspects for Method Validation

When validating a matrix-matched method, several key aspects require thorough assessment and documentation to satisfy regulatory scrutiny:

- Commutability of the Calibration Matrix: A core assumption of matrix-matching is that the calibrator matrix behaves identically to the study sample matrix. The calibrator matrix must be representative of the native human matrix for which the measurements are intended [6]. The use of a non-commutable matrix (e.g., overly processed or synthetic) can introduce significant bias. It is recommended to verify commutability during method development, for instance, by performing spike-and-recovery experiments as outlined in CLSI EP07 guideline [6].

- Demonstration of Specificity and Selectivity: The method must demonstrate its ability to measure the analyte unequivocally in the presence of matrix components that may be present. This involves analyzing blank matrix samples from multiple sources to confirm the absence of interfering signals at the retention time of the analyte and internal standard [6].

- Accuracy and Precision: Validation must demonstrate that the method provides accurate (results close to the true value) and precise (repeatable and reproducible) results across the calibration range. This is typically assessed using quality control (QC) samples prepared in the same matrix as the calibrators [6].

- Comprehensive Documentation and Data Integrity: As per Good Manufacturing Practice (GMP) requirements, every step of the analytical procedure—from sample preparation and method validation to instrument calibration and final reporting—must be recorded accurately, contemporaneously, and completely [21]. These records form the basis for data integrity, ensuring that scientific work is reproducible, verifiable, and transparent for regulatory inspections and third-party audits. A robust audit trail that allows for complete reconstruction of the analytical process is non-negotiable [21].

Experimental Protocol: Preparation of a Matrix-Matched Calibration Curve

This protocol provides a detailed procedure for the preparation of a matrix-matched calibration curve for the quantification of pesticide residues in an apple matrix using LC-MS/MS, adaptable for other analytes and matrices [4].

Research Reagent Solutions and Essential Materials

Table 2: Essential Materials and Reagents for Matrix-Matched Calibration

| Item | Function/Description |

|---|---|

| Blank Matrix | A sample of the material under analysis (e.g., apple, plasma, urine) that is verified to be free of the target analytes. Serves as the foundation for preparing calibration standards. |

| Analyte Stock Solutions | Certified reference standard solutions of the target analytes (e.g., pesticide mix standard) at known concentrations [4]. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | For each target analyte, an isotopically labeled version that co-elutes with the analyte and corrects for matrix effects and losses during sample preparation [14] [6]. |

| Extraction Solvent (e.g., Acetonitrile) | Used to extract analytes from the sample matrix, as in QuEChERS methods [4]. |

| Diluent (e.g., Water, Mobile Phase) | Used to achieve the final dilution of the extract to ensure compatibility with the LC-MS/MS initial mobile phase conditions and prevent peak distortion [4]. |

| Solid-Phase Extraction (SPE) Cartridges | Used for sample cleanup to remove interfering matrix components, if necessary (e.g., mixed-mode cation-exchange for melamine) [14]. |

Detailed Step-by-Step Workflow

The following diagram illustrates the overall workflow for developing and validating a matrix-matched method, from sample preparation to regulatory submission.

Protocol: Automated Preparation of Matrix-Matched Calibration Standards

This protocol is designed for an automated pipetting system but can be performed manually with careful technique [4].

1. Preparation of Standard Stock Solutions (Column 1):

- Prepare a series of standard stock solutions in a solvent (e.g., acetonitrile) to yield concentrations that are 10 times the desired final concentration in the calibration curve. A typical series might include 7 non-zero levels (e.g., 10, 50, 100, 250, 500, 750, 1000 ppb) and a blank (solvent only) [4].

- Regulatory Note: The USFDA requires a minimum of six non-zero calibrators. The concentration levels should be spaced appropriately, sometimes logarithmically, to adequately map the detector response [6].

2. Preparation of Matrix-Matched Calibration Standards (Columns 2 & 3, in duplicate):

- For each calibration level, pipette 10 µL of the corresponding standard stock solution into a clean vial or well.

- Add 10 µL of the blank (analyte-free) apple matrix extract.

- Add 80 µL of water (or a compatible diluent) to bring the total volume to 100 µL. This dilution is critical to match the elution strength of the sample solvent to the initial mobile phase conditions of the LC-MS/MS method, preventing peak distortion and broadening [4].

- Mix the solution thoroughly. The final concentration of each analyte is now 1x (e.g., the 1000 ppb stock yields a 100 ppb final standard).

3. (Optional) Preparation of Solvent-Only Calibration Standards (Columns 4 & 5):

- To quantitatively assess the matrix effect, prepare a parallel set of calibration standards in solvent. Follow the same procedure as above, but replace the 10 µL of blank matrix with 10 µL of acetonitrile [4].

- Comparing the slopes of the matrix-matched and solvent-only calibration curves provides a direct measure of signal suppression or enhancement.

4. Addition of Internal Standard:

- A stable isotope-labeled internal standard (SIL-IS) should be added to all calibration standards, quality controls, and unknown samples at a fixed concentration. This can be added during the sample preparation step prior to extraction or to the final extract [14] [6]. The SIL-IS corrects for variability in sample processing, injection, and ionization efficiency.

Analysis and Calibration

- Analyze the calibration standards using the validated LC-MS/MS method.

- Construct the calibration curve by plotting the peak area ratio (analyte / internal standard) against the nominal concentration of the calibration standards.

- Use appropriate regression modeling (e.g., linear or quadratic with weighting, such as 1/x or 1/x²) to account for heteroscedasticity (non-constant variance across the concentration range) [6]. The model with the best fit and most accurate back-calculated concentrations should be selected.

Data Interpretation and Regulatory Submission

Assessing the Matrix Effect

The matrix effect (ME) can be quantitatively assessed using the following formula by comparing the solvent-only and matrix-matched calibration curves: ME (%) = (Slope of matrix-matched curve / Slope of solvent-only curve) × 100 A value of 100% indicates no matrix effect. Values <100% indicate signal suppression, and values >100% indicate signal enhancement [4]. A significant matrix effect (e.g., >±15-20%) typically necessitates the use of matrix-matched calibration or the standard addition method for accurate quantification.

Advanced Chemometric Approaches

For complex data analysis, advanced chemometric techniques like Multivariate Curve Resolution-Alternating Least Squares (MCR-ALS) can be employed to assess the matching between an unknown sample and a batch of calibration sets. This method evaluates both spectral and concentration profile interactions to identify the most appropriate matrix-matched calibration set, thereby improving prediction accuracy and robustness against unexpected matrix variations [20].

Documentation for Regulatory Compliance

Comprehensive documentation is the backbone of any validated method. The following diagram outlines the logical relationships and workflow for key documentation practices in a regulated laboratory.

The method validation report and analytical records must include, at a minimum:

- Method Validation Report: Demonstrating specificity, linearity, accuracy, precision, and robustness of the matrix-matched method [21] [6].

- Source and Characterization of Blank Matrix: Documentation proving the blank matrix is free of analyte and is commutable with the study samples.

- Complete Calibration Data: Including the regression model, weighting factor, and back-calculated concentrations of the calibrators with their acceptance criteria.

- Quality Control (QC) Sample Data: Proof that the method maintains accuracy and precision during the analysis of unknown samples.

- Audit Trail: A secure, time-stamped record of all instrumental data and processing steps, compliant with regulations like 21 CFR Part 11 for electronic records [21].

The implementation of matrix-matched calibration methods is a critical and defensible strategy for achieving accurate and reliable quantitative analysis in the presence of complex sample matrices. By adhering to the detailed protocols, rigorously validating the method against regulatory standards, and maintaining impeccable documentation, researchers and drug development professionals can ensure the generation of high-quality, submission-ready data. A thorough understanding and application of these principles not only facilitate regulatory compliance but also strengthen the scientific foundation of analytical results, ultimately supporting the development of safe and effective products.

Developing Robust Matrix-Matched Calibration Protocols: Step-by-Step Implementation

Blank Matrix Sourcing and Preparation Strategies for Biological Samples

Matrix effects represent a significant challenge in the bioanalysis of biological samples, potentially compromising the detection and quantification quality of assays [4]. Matrix-matched calibration is a critical strategy to compensate for these effects, where standards are prepared in a blank matrix that mirrors the composition of the study samples. The preparation of appropriate blank biological matrices ensures the accuracy and reliability of data supporting pharmacokinetic, toxicology, and biomarker studies [23] [13]. Recent supply chain challenges, exacerbated by the COVID-19 pandemic, have transformed previously common biological matrices into rare commodities, necessitating innovative sourcing and preparation strategies [23] [24]. This application note details contemporary approaches for sourcing blank matrices and provides standardized protocols for preparing matrix-matched calibration standards, framed within the broader context of method development for regulatory-compliant bioanalysis.

Current Challenges in Biological Matrix Supply

The biological matrix supply chain has experienced significant strain, leading to extended lead times and increased costs. Non-human primate (NHP) matrices, once routinely available, now face lead times of 3-6 months for serum and plasma, and 1-3 years for cerebral spinal fluid (CSF) [23] [24]. Simultaneously, costs for some NHP matrices have increased up to tenfold within a single year [23] [24]. These shortages potentially delay drug development programs and compromise data quality when substitute matrices of uncertain quality are employed [23] [24].

Table 1: Biological Matrix Supply Challenges and Mitigation Strategies

| Challenge | Impact on Bioanalysis | Mitigation Strategy |

|---|---|---|

| Supply Chain Shortages | Extended lead times (e.g., NHP matrices: 3-6 months) [23] | Project matrix needs ≥6 months in advance [23] |

| Increased Cost | 10-100% cost increase for various matrices [23] | Implement "empty biobank" model to reduce storage costs [25] |

| Quality Variability | Selectivity failure in ligand binding assays; recovery outside 80-120% range [24] | Enhance QC at collection; repurpose unused samples [25] |

| Ethical Sourcing Limitations | Limited availability of certain human and animal matrices [23] | Use surrogate matrices where scientifically justified [23] |

Sourcing Strategies for Blank Matrices

Intentional Procurement and Ethical Sourcing

The traditional model of biobanking, which emphasizes volume and long-term storage, is increasingly being replaced by the "empty biobank" approach [25]. This strategy focuses on intentional procurement, where collection is tightly regulated based on current research demands rather than speculative stockpiling [25]. This practice reduces financial burdens associated with storage and maintenance while ensuring matrices remain relevant to contemporary research needs. Furthermore, this approach honors the ethical responsibility to patient donors by ensuring their specimens are used purposefully to advance science rather than remaining in storage indefinitely [25].

Utilizing Surrogate Matrices

When obtaining authentic blank matrix is difficult or impossible, surrogate matrices provide a scientifically valid alternative for preparing calibration standards [23] [24]. Regulatory authorities permit surrogate matrix use provided the selection is scientifically justified [23]. The validation approach typically involves a full validation in the surrogate matrix with a partial validation in the primary matrix to demonstrate equivalence [23] [24].

Table 2: Surrogate Matrix Applications in Bioanalysis

| Primary Matrix | Potential Surrogate Matrix | Key Validation Considerations |

|---|---|---|

| Cynomolgus monkey CSF | Human CSF [24] | Parallelism evaluation; selectivity in primary matrix [23] |

| Cynomolgus monkey serum/plasma | Human serum/plasma or Rhesus monkey [24] | Impact on immunoassay specificity; conservation of primary matrix for QCs [23] |

| Transgenic mouse serum/plasma | CD-1 mouse serum/plasma [24] | Genetic differences affecting matrix composition [23] |

| Sprague Dawley rat serum/plasma | Wistar or Lewis rat serum/plasma [24] | Selectivity testing across multiple lots [23] |

Preparation of Matrix-Matched Calibration Standards

Protocol for Automated Preparation of Matrix-Matched Pesticide Standards

This protocol, adapted from Waters Corporation's automated approach, demonstrates high-throughput preparation of matrix-matched standards for LC-MS/MS analysis [4].

4.1.1 Experimental Workflow

4.1.2 Research Reagent Solutions

Table 3: Essential Materials for Matrix-Matched Standard Preparation

| Item | Function | Example/Specification |

|---|---|---|

| Andrew+ Pipetting Robot | Automated liquid handling for reproducibility | Andrew Alliance Bluetooth Electronic Pipette [4] |

| Blank Biological Matrix | Provides sample-matched background | Apple matrix extract, human plasma, NHP serum [4] |

| Standard Stock Solutions | Source of analytes for calibration | Waters 20 Pesticide Mix Standard [4] |

| Solvent Systems | Extraction and dilution | Acetonitrile, water with 0.1% formic acid [4] [13] |

| OneLab Software | Protocol design and execution | Browser-based interface for workflow automation [4] |

4.1.3 Step-by-Step Procedure

Standard Stock Solution Preparation: Prepare serial dilutions of standard solutions in Column 1 of a deepwell microplate to yield concentrations of 10, 50, 100, 250, 500, 750, and 1000 ppb [4].

Matrix Working Solution Preparation: For matrix-matched standards, prepare a blank matrix solution (e.g., apple matrix extract after QuEChERS preparation) at appropriate concentration. For solvent standards, replace matrix with acetonitrile [4].

Standard Addition: Transfer 10 µL of each standard stock solution to designated wells in Columns 2 and 3 (for matrix-matched standards) or Columns 4 and 5 (for solvent standards) [4].

Matrix/Solvent Addition: Add 10 µL of blank matrix solution to Columns 2 and 3, or 10 µL acetonitrile to Columns 4 and 5 [4].

Dilution: Add 80 µL water to all wells (standards and blank) to yield a final volume of 100 µL, creating a 10-fold dilution factor that ensures the sample solvent strength is compatible with initial LC mobile phase conditions [4].

Quality Control: Verify pipetting accuracy and mixing. For automated systems, implement tip pre-wetting steps when handling volatile solvents to reduce dripping [4].

4.1.4 Protocol Specifications

- Estimated Time: 17-19 minutes for full calibration curve preparation

- Tip Consumption: 41-66 tips (10-300 µL) depending on protocol

- Throughput: Capable of preparing seven calibration levels plus blank in duplicate [4]

Addressing Ion Suppression in Biological Sample Analysis

Ion suppression caused by matrix components represents a significant challenge in LC-MS/MS bioanalysis [26]. Phospholipids, in particular, cause significant ion suppression in the 7-8 minute region of chromatographic runs [26].

4.2.1 Workflow for Ion Suppression Assessment

4.2.2 Post-Column Infusion Experiment for Ion Suppression Evaluation

Setup: Configure LC-MS/MS system with a tee-fitting between column outlet and MS source. Connect a syringe pump containing a solution of the analyte of interest [26].

Infusion: Begin mobile phase flow and start syringe pump to deliver a constant stream of analyte into the MS source [26].

Injection: Inject a blank matrix sample prepared using the intended sample preparation method [26].