NIR Spectroscopy for Food Authentication: Field Applications, Challenges, and Future Directions

This article provides a comprehensive overview of the field application of Near-Infrared (NIR) spectroscopy for food authentication, tailored for researchers and industry professionals.

NIR Spectroscopy for Food Authentication: Field Applications, Challenges, and Future Directions

Abstract

This article provides a comprehensive overview of the field application of Near-Infrared (NIR) spectroscopy for food authentication, tailored for researchers and industry professionals. It explores the foundational principles of NIR technology and its advantages for non-destructive, rapid analysis. The scope extends to methodological applications across key food sectors—including nuts, spices, and powdered foods—detailing the integration of chemometrics and portable devices. The content also addresses critical troubleshooting aspects, such as mitigating moisture interference and spectral complexity, and offers a comparative validation against traditional techniques. By synthesizing current advancements and persistent challenges, this review outlines a path forward for integrating NIR spectroscopy into robust food quality control and safety systems.

The Principles and Promise of NIR Spectroscopy in Food Analysis

Near-Infrared (NIR) spectroscopy has emerged as a cornerstone analytical technique for non-destructive food authentication, capable of verifying geographical origin, production methods, and detecting economic adulteration. Its operational principle rests on probing the fundamental molecular vibrations of chemical bonds within a food matrix when irradiated with NIR light. The resulting complex, information-rich absorption pattern constitutes a spectral fingerprint that is unique to the sample's chemical composition. This application note details the core principles linking molecular vibrations to spectral fingerprints and provides standardized protocols for researchers deploying NIR spectroscopy in field-based food authentication research. The integration of robust chemometrics is emphasized as essential for deconvoluting the subtle spectral patterns that authenticate food products and safeguard against fraud.

Core Principles: From Molecular Vibrations to Spectral Fingerprints

The Physical Basis of NIR Spectroscopy

NIR spectroscopy operates within the electromagnetic spectrum range of 780–2500 nm (wavenumbers 12,500–3800 cmâ»Â¹). This region is characterized by the absorption of light energy causing molecular bonds to vibrate through overtone and combination bands of fundamental mid-infrared vibrations [1] [2].

When a molecule is exposed to NIR radiation, it absorbs energy at specific wavelengths corresponding to the natural vibrational frequency of its chemical bonds. The energy absorbed is a function of the bond's mass and strength, following Hooke's law for a simple harmonic oscillator. The technique is particularly sensitive to bonds involving hydrogen, such as C-H, O-H, and N-H groups, which are abundant in major food constituents like water, fats, proteins, and carbohydrates [1] [3]. The broad, overlapping absorption bands resulting from these vibrations form a unique spectral signature for any given biological material.

The Concept of Spectral Fingerprints

A spectral fingerprint is a distinctive, multi-variable pattern of absorbance values across the NIR range that collectively characterizes the unique physicochemical profile of a food sample [3]. Unlike targeted analytical methods that seek a single marker compound, the fingerprinting approach uses the entire spectrum, or informative regions thereof, for authentication.

The position and intensity of absorption bands in the fingerprint are directly determined by the sample's chemical composition:

- Bands around 1450 and 1940 nm are predominantly associated with O-H stretching and bending vibrations from water [4].

- The region from 1700–1800 nm features C-H stretching vibrations first overtones, prominent from oils and fats [1].

- Bands near 1980, 2060, and 2180 nm are combination bands associated with C-H and C-O bonds in carbohydrates [4].

- The 1500–1800 nm and 2000–2500 nm regions contain N-H combination bands and C-H stretching second overtones related to protein content [1].

Variations in a food's origin, processing, or adulteration alter its molecular composition, thereby producing detectable changes in its NIR spectral fingerprint, even in the absence of a single, identifiable "marker" [5] [6].

Experimental Protocols for Food Authentication

Protocol 1: Sample Preparation and Spectral Acquisition

This protocol is designed for the authentication of powdered or homogenized food samples (e.g., flour, powdered milk, ground nuts) using a portable NIR spectrometer with a diffuse reflectance probe.

- Objective: To acquire high-quality, reproducible NIR spectra that accurately reflect the sample's chemical composition for subsequent model development.

- Materials: Portable NIR spectrometer with diffuse reflectance probe, sample cups, analytical balance, temperature-controlled environment (±2 °C).

- Procedure:

- Sample Homogenization: Grind solid samples to a consistent particle size (e.g., < 500 µm). For liquids, ensure homogeneity. Inhomogeneity and air bubbles are major sources of spectral variance and must be minimized [4] [2].

- Temperature Equilibration: Allow samples to equilibrate to a constant temperature (e.g., 25 °C) for at least 30 minutes prior to analysis, as NIR spectra are temperature-sensitive [4].

- Instrument Warm-up and Calibration: Power on the spectrometer and allow it to stabilize for the manufacturer-recommended time. Perform a background calibration (using a Spectralon or ceramic standard) and a dark current correction.

- Spectral Acquisition: Fill a clean sample cup consistently, avoiding density gradients. Acquire spectra in reflectance mode. A minimum of 32 scans per spectrum is recommended to improve the signal-to-noise ratio [1]. Record triplicate spectra from different sub-sampling points for representative data.

- Data Logging: Label spectra clearly with a unique sample ID and link to all relevant metadata (e.g., origin, date, reference chemistry values).

Protocol 2: Data Preprocessing and Chemometric Modeling

This protocol outlines the standard workflow for transforming raw spectral data into a validated classification or regression model for authentication.

- Objective: To preprocess spectral data to remove non-chemical artifacts and develop a robust chemometric model for predicting food authenticity.

- Software Requirements: Chemometric software package (e.g., PLS_Toolbox, The Unscrambler, or open-source alternatives in R/Python).

- Procedure:

- Data Preprocessing: Load the raw absorbance spectra and apply preprocessing techniques to enhance chemical signals.

- Scatter Correction: Apply Standard Normal Variate (SNV) or Multiplicative Scatter Correction (MSC) to correct for light scattering effects due to particle size differences [4] [2].

- Smoothing and Derivatives: Apply a Savitzky-Golay filter (e.g., 2nd order polynomial, 11-15 point window) to calculate first or second derivatives. This corrects baseline offsets and resolves overlapping peaks [2].

- Exploratory Analysis: Perform Principal Component Analysis (PCA) on the preprocessed data to visualize natural sample clustering, identify outliers, and understand the major sources of spectral variance [4] [5].

- Model Development:

- For Classification (e.g., origin, organic/conventional): Use Partial Least Squares-Discriminant Analysis (PLS-DA) or Soft Independent Modelling of Class Analogy (SIMCA). Split data into training (e.g., 70%) and test sets (e.g., 30%) [5].

- For Quantification (e.g., adulterant level): Use Partial Least Squares Regression (PLSR) to correlate spectral data with reference method values (e.g., HPLC) [4].

- Model Validation: Validate models using an external test set or cross-validation (e.g., Venetian blinds, 10-fold). Report key performance metrics: for classification, sensitivity, specificity, and accuracy; for regression, coefficient of determination (R²), Root Mean Square Error of Prediction (RMSEP), and Residual Predictive Deviation (RPD) [2].

- Data Preprocessing: Load the raw absorbance spectra and apply preprocessing techniques to enhance chemical signals.

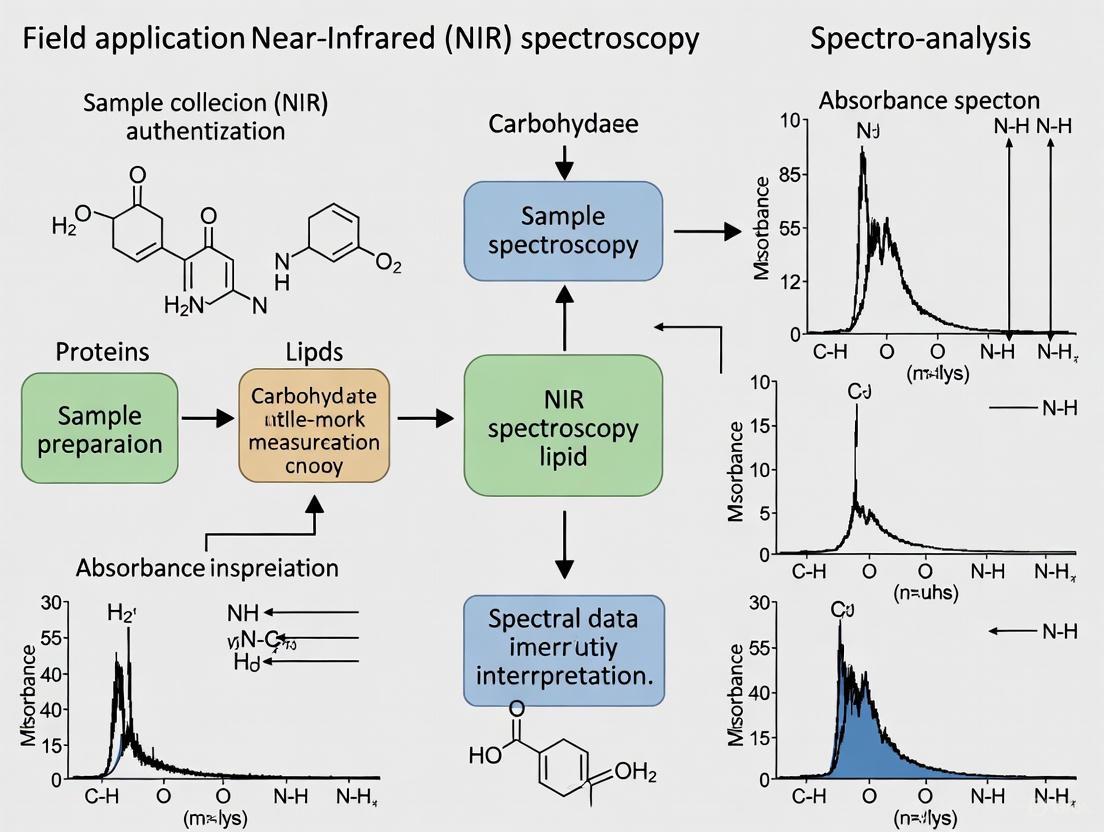

The following workflow diagram illustrates the complete experimental pathway from sample to validated result.

Application Data in Food Authentication

NIR spectroscopy, combined with chemometrics, has been successfully applied to authenticate a wide range of food products. The table below summarizes key findings from recent research, demonstrating the technique's versatility.

Table 1: Summary of NIR Spectroscopy Applications in Food Authentication

| Food Matrix | Authentication Target | Chemometric Method(s) | Performance Summary | Reference |

|---|---|---|---|---|

| Salted Anchovies | Geographical Origin (Morocco, Spain, Tunisia, Croatia) | OPLS-DA | High sensitivity, specificity, and accuracy in discriminating origin based on lipid/protein patterns. | [5] |

| Honey | Adulteration with Syrups & Botanical Origin | PLSR, PCA, LDA | Detection of adulteration at 5-10% levels; >90% classification accuracy for botanical origin. | [4] |

| Almonds | Adulteration with Bitter Almonds | Classification Models | Excellent capability for discrimination between commercial sweet and bitter almond kernels. | [7] |

| Pork | Lipid Oxidation Monitoring | CNN with HSI | Successful evaluation of oxidative spoilage, demonstrating synergy of AI with NIR. | [1] |

| Poultry Meat | Added Water and Retaining Agents | PCA | Clear separation in PCA scores plot between authentic and adulterated samples. | [6] |

The Scientist's Toolkit: Essential Reagents and Materials

Successful implementation of NIR-based authentication requires specific materials and computational tools. The following table details essential components of the research toolkit.

Table 2: Essential Research Reagent Solutions and Materials for NIR Authentication

| Item Name | Function / Application | Technical Notes |

|---|---|---|

| Portable NIR Spectrometer | Core device for spectral acquisition in the field or at-line. | Prefer models with InGaAs detectors for range 1100-2500 nm. Key for real-time monitoring [8]. |

| Spectralon Reference Standard | Provides a background/reference spectrum with ~99% diffuse reflectance for instrument calibration. | Critical for ensuring consistent and accurate absorbance measurements across sessions. |

| Chemometrics Software | For spectral preprocessing, exploratory analysis, and model development (PLS, PCA, SVM, etc.). | Essential for interpreting complex spectral data; platforms include commercial (e.g., The Unscrambler) and open-source (e.g., R, Python with scikit-learn) options [2]. |

| Reference Data | Results from primary analytical methods (e.g., HPLC, GC-MS) used for chemometric model calibration. | The accuracy of the NIR model is directly dependent on the quality of the reference data [4] [2]. |

| Temperature Control Chamber | Maintains consistent sample temperature during analysis. | Mitigates spectral variance induced by temperature fluctuations, improving model robustness [4]. |

| GS-443902 trisodium | GS-443902 trisodium, MF:C12H13N5Na3O13P3, MW:597.15 g/mol | Chemical Reagent |

| EZM0414 TFA | SETD2-IN-1 TFA|Potent SETD2 Inhibitor|For Research Use | SETD2-IN-1 TFA is a potent, selective, orally bioactive SETD2 inhibitor for cancer research. This product is for research use only, not for human use. |

The fundamental relationships between molecular bonds, their vibrations, and their resulting positions in the NIR spectrum are visualized below.

Rapid, Non-Destructive, and High-Throughput Analysis

Near-Infrared (NIR) spectroscopy has emerged as a cornerstone analytical technique for modern food authentication research, particularly in field applications where traditional laboratory methods are impractical. Operating in the 780–2500 nm wavelength range of the electromagnetic spectrum, NIR spectroscopy measures molecular overtone and combination vibrations primarily from C-H, O-H, and N-H bonds present in organic compounds [2] [9]. This technology provides researchers with a powerful tool for rapid, non-destructive, and high-throughput analysis of food composition, authenticity, and quality parameters without requiring extensive sample preparation or chemical reagents [4] [9]. The integration of NIR spectroscopy with advanced chemometrics and machine learning algorithms has significantly enhanced its capability to handle complex food matrices, making it indispensable for addressing growing concerns about food fraud, adulteration, and mislabeling in global supply chains [10] [11].

For field applications in food authentication research, NIR spectroscopy offers distinct advantages over traditional destructive methods such as HPLC and GC-MS, which are time-consuming, require skilled operation, and destroy samples in the process [2] [4]. The non-destructive nature of NIR analysis preserves sample integrity, allowing for longitudinal studies and further analysis using complementary techniques. Furthermore, the development of portable and handheld NIR devices has revolutionized field applications, enabling real-time authentication at various points along the food supply chain—from production and processing to retail and regulatory inspection [12] [1]. This technical note outlines detailed protocols and applications that demonstrate how NIR spectroscopy delivers rapid, non-destructive, and high-throughput analysis specifically tailored for food authentication research in field settings.

Key Advantages and Quantitative Performance

The fundamental advantages of NIR spectroscopy align perfectly with the requirements of field-based food authentication research. These benefits are not merely theoretical but demonstrate quantifiable performance across diverse food matrices, as established by recent research and practical applications.

Table 1: Core Advantages of NIR Spectroscopy for Field-Based Food Authentication

| Advantage | Technical Basis | Research Impact |

|---|---|---|

| Rapid Analysis | Real-time measurements (seconds); Minimal sample preparation [2] [9] | High-frequency sampling; Immediate decision-making in the field |

| Non-Destructive | Photon interaction with sample (absorption, reflection, transmission); No chemical alteration [10] [13] | Sample preservation; Longitudinal studies; Further analysis with other techniques |

| High-Throughput | Automated sampling; Integration with conveyor systems; Rapid spectral acquisition [10] [12] | Large-scale screening; Comprehensive supply chain monitoring |

| Green Technology | No chemical reagents; Minimal waste generation; Low energy consumption [10] [2] | Environmentally sustainable research practices; Safe field deployment |

| Versatile Deployment | Portable, handheld, and benchtop configurations; Online, inline, at-line, and offline operation [12] [1] | Adaptability to diverse field conditions and research objectives |

The non-destructive nature of NIR spectroscopy stems from its physical principle of measuring how near-infrared light interacts with a sample through reflectance or transmission without altering its chemical composition [10] [9]. This photon-matter interaction, primarily with hydrogen-containing functional groups, generates a unique spectral fingerprint for each sample while preserving sample integrity. This is particularly valuable for authentication studies involving high-value food products or when sample preservation is necessary for regulatory or further analytical purposes.

High-throughput capability is achieved through rapid spectral acquisition (typically seconds per sample) and the potential for automation, allowing researchers to analyze hundreds of samples per day with minimal manual intervention [12]. This efficiency is further enhanced by the minimal sample preparation requirements, eliminating time-consuming steps such as extraction, derivatization, or purification that are common in conventional analytical techniques.

Table 2: Quantitative Performance of NIR Spectroscopy in Food Authentication Applications

| Food Matrix | Authentication Parameter | Performance Metrics | Reference |

|---|---|---|---|

| Honey | Adulteration with sugar syrups | >90% classification accuracy; Detection at 5-10% adulteration levels [4] | |

| Milk | Geographical origin traceability | 97.33% classification accuracy using FDLDA-KNN classifier [11] | |

| Sorghum Grain | Protein content prediction | R² = 0.87 using handheld MicroNIR [12] | |

| Flaxseeds | Germinability prediction | R² = 0.78-0.82 using Vis-NIR HSI [12] | |

| Plums | Maturity classification | 100% accuracy using FT-NIR with discriminant analysis [12] | |

| Mackerel | Freshness (TVB-N prediction) | 91% accuracy using SWIR HSI [12] | |

| Peanut Oil | Adulteration quantification | R² > 0.9311; RMSECV < 4.43 [11] | |

| Fava Bean Bread | Protein content classification | >99% accuracy using HSI [12] |

The quantitative performance data in Table 2 demonstrates that NIR spectroscopy achieves sufficiently high accuracy for most field authentication applications. The technique consistently delivers classification accuracies exceeding 90% for various authentication parameters across diverse food matrices, with particularly strong performance in detecting adulteration, verifying geographical origin, and classifying quality parameters [12] [4] [11]. While NIR is considered a secondary analytical technique that relies on reference methods for calibration, the prediction models for key compositional parameters typically achieve R² values above 0.85, even with portable instruments, making them highly reliable for field-based screening applications [2] [12].

Experimental Protocols for Food Authentication

Protocol 1: Authentication of Honey and Detection of Adulteration

Purpose: To rapidly authenticate honey botanical origin and detect adulteration with sugar syrups using portable NIR spectroscopy.

Background: Honey is susceptible to economically motivated adulteration through the addition of inexpensive sugar syrups, compromising its quality and authenticity. Traditional methods like stable isotope analysis are destructive and laboratory-bound. This protocol utilizes NIR spectroscopy for non-destructive, rapid screening in field settings [4].

Materials and Reagents:

- Pure honey samples of declared botanical origins (e.g., acacia, clover, manuka)

- Suspected adulterated honey samples

- Portable NIR spectrometer with reflectance probe (e.g., Viavi MicroNIR OnSite-W)

- Quartz cuvettes or transflectance cells with path length of 1-2 mm

- Temperature control bath (25°C)

- Magnetic stirrer for sample homogenization

- Reference standards for validation (if available)

Procedure:

- Sample Preparation:

- Pre-condition all honey samples to 25°C in a temperature-controlled bath to minimize spectral variance due to temperature differences.

- If crystallized, gently warm the honey containers in a water bath at ≤40°C until crystals dissolve, then cool to 25°C.

- Mix samples thoroughly using a magnetic stirrer to ensure homogeneity and eliminate air bubbles.

Spectral Acquisition:

- Initialize the portable NIR spectrometer according to manufacturer specifications.

- Configure spectral acquisition parameters: 1000-2500 nm range, 8 cmâ»Â¹ resolution, 32 scans per spectrum.

- For each sample, fill a transflectance cell and acquire spectra in triplicate.

- Include background scans every 30 minutes during analysis sessions.

Data Preprocessing:

- Apply Standard Normal Variate (SNV) transformation to remove scattering effects.

- Process spectra using Savitzky-Golay first derivative (2nd polynomial, 15-point window) to enhance spectral features.

- Employ Multiplicative Scatter Correction (MSC) if necessary for path length variations.

Chemometric Analysis:

- For botanical origin authentication:

- Utilize Principal Component Analysis (PCA) for exploratory data analysis and outlier detection.

- Develop a classification model using Linear Discriminant Analysis (LDA) with cross-validation.

- For adulteration detection:

- Construct a Partial Least Squares Regression (PLSR) model correlating spectral data with reference adulteration percentages.

- Validate models using leave-one-out cross-validation or an independent test set.

- For botanical origin authentication:

Interpretation:

- Botanical origin is confirmed when samples cluster with reference groups in PCA/LDA space.

- Adulteration is detected when predicted values exceed established thresholds (typically 5-10% for sugar syrups).

Troubleshooting Tips:

- If classification accuracy is low, ensure sample temperature is consistent throughout analysis.

- High spectral noise may indicate insufficient mixing or air bubbles in samples.

- Model transfer between instruments may require standardization techniques such as Piecewise Direct Standardization (PDS).

Protocol 2: Geographical Origin Verification of Liquid Foods

Purpose: To verify the geographical origin of liquid foods (milk, oils) using handheld NIR spectrometers combined with machine learning algorithms.

Background: Geographical origin is a key authentication parameter that influences the economic value of many food products. This protocol outlines a procedure for rapid, non-destructive verification of geographical origin in field settings, applicable to various liquid food matrices [11] [1].

Materials and Reagents:

- Liquid food samples (milk, edible oils) with verified geographical origins

- Handheld NIR spectrometer (e.g., with InGaAs detector)

- Transmission flow cells or disposable cuvettes

- Temperature recording device

- GPS device for recording sampling locations

- Reference databases for geographical authentication

Procedure:

- Sample Collection and Logging:

- Collect samples directly from production sites where possible.

- Record precise geographical coordinates using GPS.

- Document sampling date, time, and temperature conditions.

Spectral Collection:

- Calibrate the handheld NIR spectrometer using manufacturer-provided standards.

- Use transmission mode with appropriate path length (0.5-2 mm for liquids).

- Acquire triplicate spectra for each sample across 800-2500 nm range.

- Randomize sample analysis order to minimize systematic bias.

Data Preprocessing:

- Apply Savitzky-Golay smoothing (2nd polynomial, 11-point window).

- Use SNV normalization to correct for path length differences.

- Employ Sequential Preprocessing through Orthogonalization (SPORT) if dealing with multiple instruments.

Feature Selection and Modeling:

- Implement Competitive Adaptive Reweighted Sampling (CARS) to identify informative wavelengths.

- Apply Successive Projections Algorithm (SPA) for variable selection.

- Develop classification models using:

- Fuzzy Direct Linear Discriminant Analysis (FDLDA)

- Support Vector Machine (SVM)

- Convolutional Neural Networks (CNN) for complex pattern recognition

Validation:

- Validate models using external validation sets from different harvest periods.

- Calculate classification accuracy, sensitivity, and specificity.

- Establish confidence thresholds for origin verification.

Field Application Notes:

- For consistent results, maintain stable ambient temperature during analysis.

- Establish a reference spectral library specific to geographical origins of interest.

- Regular instrument validation with control samples is critical for reliable field measurements.

Research Reagent Solutions and Essential Materials

Table 3: Essential Research Reagents and Materials for NIR-Based Food Authentication

| Item | Specification | Application/Function |

|---|---|---|

| Portable NIR Spectrometer | Wavelength range: 800-2500 nm; Detector: InGaAs; Resolution: <10 nm | Field-deployable spectral acquisition for on-site authentication [12] [1] |

| Reference Standards | Certified composition/authenticity; Traceable to national standards | Calibration validation and method verification [4] |

| Chemometrics Software | PCA, PLS-R, LDA, SVM algorithms; Cross-validation capabilities | Spectral data processing, model development, and classification [2] [11] |

| Temperature Control Unit | ±0.5°C accuracy; Portable design | Sample temperature stabilization for spectral reproducibility [4] |

| Sample Presentation Accessories | Quartz cuvettes (1-10 mm path length); Fiber optic reflection probes | Standardized light interaction with diverse sample types [2] [9] |

| Spectral Validation Sets | Geographically diverse samples; Documented provenance | Model testing and transferability assessment [14] [11] |

Workflow Visualization

NIR Food Authentication Workflow

Technical Considerations and Implementation Challenges

While NIR spectroscopy offers significant advantages for field applications in food authentication, researchers must address several technical considerations to ensure reliable results. Model transferability remains a challenge, as calibration models developed on one instrument may not perform optimally on another due to variations in spectral resolution, detector sensitivity, or environmental conditions [14]. This issue can be mitigated through standardization techniques such as Piecewise Direct Standardization (PDS) and by developing models using instruments from the same manufacturer with consistent specifications [4].

The development of robust chemometric models requires large and diverse sample sets that adequately represent natural variability in authentic and adulterated products. For geographical authentication, this means collecting representative samples across multiple harvest seasons and production regions to build models resilient to seasonal and environmental variations [11]. Researchers should prioritize establishing comprehensive spectral libraries specific to their authentication questions, as model performance directly correlates with the quality and representativeness of the calibration dataset [14] [11].

Environmental factors such as temperature fluctuations, humidity, and ambient light can significantly impact spectral measurements in field settings. Temperature control during analysis is particularly critical, as temperature variations can cause peak shifts and intensity changes in NIR spectra [4]. Portable temperature control units and consistent sample preconditioning protocols help minimize these effects. Additionally, researchers should document environmental conditions during spectral acquisition to identify potential confounding factors during data analysis.

Despite these challenges, the integration of artificial intelligence and machine learning approaches continues to enhance the capabilities of NIR spectroscopy for food authentication. Deep learning algorithms such as Convolutional Neural Networks (CNNs) can automatically extract relevant features from complex spectral data, potentially reducing the need for manual preprocessing and wavelength selection [11] [1]. As these technologies mature and portable instruments become more sophisticated, NIR spectroscopy is poised to become an even more powerful tool for rapid, non-destructive, and high-throughput food authentication in field research applications.

Near-infrared (NIR) spectroscopy (780–2500 nm) has emerged as a cornerstone technique for food authentication, enabling rapid, non-destructive analysis of compositional traits and fraud detection. By measuring overtone and combination vibrations of C–H, O–H, and N–H bonds, NIR captures molecular-level data that form unique "fingerprints" for food products [4] [3]. Its integration with chemometrics—multivariate statistical tools like PCA (principal component analysis) and PLSR (partial least squares regression)—transforms spectral data into actionable insights for quality control, regulatory compliance, and supply chain transparency [4] [15]. This application note details experimental protocols, data interpretation frameworks, and technical specifications for implementing NIR in food authentication research.

Key Application Fields and Quantitative Capabilities

NIR spectroscopy addresses diverse authentication challenges, from quantifying core components to detecting adulterants. The following table summarizes its performance across major food categories:

Table 1: Quantitative and Qualitative Applications of NIR in Food Authentication

| Application Field | Analyte/Parameter | Performance Metrics | References |

|---|---|---|---|

| Honey Authentication | Sugar content (glucose, fructose) | R² > 0.95 via PLSR | [4] |

| Adulteration (corn syrup) | Detection at 5–10% levels; >90% classification accuracy with PCA-LDA | [4] | |

| Botanical origin | Distinct clustering via PCA/SIMCA | [4] | |

| Animal Products | Species fraud (meat) | Spectral differentiation of horse, cattle, pork | [15] [16] |

| Fat/protein/moisture in cheese | Compliance with standards (e.g., mozzarella: ≤52% moisture) | [16] | |

| Grains and Cereals | Protein in wheat | Accurate prediction in whole/ground grains | [17] |

| Mycotoxins (e.g., DON in wheat) | Non-destructive identification | [18] | |

| Oils and Beverages | Olive oil adulteration | Detection via phenolic compound analysis | [16] |

| Wine grading | Alcohol, pH, and phenol quantification | [16] |

Experimental Protocols for Food Authentication

Protocol 1: Honey Adulteration Detection

Objective: Identify syrup adulteration and verify botanical origin. Materials:

- Benchtop/portable NIR spectrometer (e.g., with InGaAs detector for 1100–2500 nm)

- Temperature-controlled sample cell (~25°C)

- Reference honey samples (authentic and adulterated)

Procedure:

- Sample Preparation:

- Heat honey to 40°C to dissolve crystals, then cool to 25°C.

- Ensure homogeneity (no bubbles) for transmission/transflectance measurements.

Spectral Acquisition:

- Wavelength range: 1000–2500 nm; resolution: 4–16 cmâ»Â¹.

- Collect triplicate spectra per sample.

Data Preprocessing:

- Apply Standard Normal Variate (SNV) or Savitzky–Golay derivatives to reduce scattering.

- Use multiplicative scatter correction (MSC) for baseline alignment.

Model Development:

- Quantification (PLSR): Correlate spectral data with reference lab values (e.g., sugar content via HPLC).

- Classification (PCA-LDA): Build models to distinguish pure vs. adulterated samples.

Validation:

- Use cross-validation; report RMSEP (root mean square error of prediction) and R².

- For adulteration, validate with external sample sets containing 5–20% syrups.

Pitfalls: Overfitting—limit PLSR latent variables; control temperature to avoid spectral drift [4].

Protocol 2: Meat Species Identification

Objective: Discriminate species in fresh, frozen, or processed meat. Materials:

- Portable NIR device (e.g., Felix Instruments F-750)

- Grinding apparatus (for homogenized samples)

- Reference meat samples (e.g., beef, horse, pork)

Procedure:

- Sample Preparation:

- Homogenize cuts to ensure consistent fat-protein distribution.

- For processed products (e.g., sausages), grind to uniform particle size.

Spectral Collection:

- Use reflectance mode; scan 10–15 positions per sample.

- Wavelength range: 780–2500 nm.

Data Analysis:

- Preprocess with SNV and first derivatives.

- Apply SIMCA or PCA to cluster spectra by species.

- Use PLSR to quantify adulterant percentages (e.g., soya in beef).

Validation:

Notes: Spectral libraries must account for processing-induced variations (e.g., freezing alters water-band features) [16].

Diagram 1: NIR Food Authentication Workflow

The Scientist's Toolkit: Essential Research Reagents and Equipment

Table 2: Key Materials and Instruments for NIR Authentication

| Item | Function | Examples/Specifications |

|---|---|---|

| NIR Spectrometer | Spectral acquisition | Portable (e.g., Felix F-750) for field use; Benchtop (e.g., with InGaAs detector) for lab analysis |

| Reference Databases | Model calibration | Food fingerprint libraries (e.g., botanical origins, species spectra) |

| Chemometric Software | Data processing | PCA, PLSR, LDA algorithms (e.g., in MATLAB, R, or proprietary suites) |

| Sample Handling Tools | Preparation consistency | Temperature-controlled cells, grinding mills, reflectance probes |

| Validation Kits | Model verification | Certified reference materials (e.g., predefined adulterant mixtures) |

| AST5902 trimesylate | AST5902 trimesylate, MF:C30H41F3N8O11S3, MW:842.9 g/mol | Chemical Reagent |

| AS1810722 | AS1810722, MF:C25H25F2N7O, MW:477.5 g/mol | Chemical Reagent |

Advanced Approaches and Data Integration

- Data Fusion: Combine NIR with complementary techniques (e.g., Raman or MIR) to overcome inherent limitations. For instance, NIR's broad water absorption bands can be supplemented with Raman's sensitivity to non-polar bonds (C=C, C≡C) [19] [3].

- Portable Systems: Handheld NIR devices enable in-field screening, though they require calibration transfer protocols (e.g., piecewise direct standardization) to align with lab-grade instruments [4] [16].

- AI Enhancements: Machine learning (e.g., CNN-LSTM models) automates feature extraction from complex spectra, improving prediction robustness for heterogeneous samples [3] [18].

Diagram 2: Data Analysis and Integration Pathway

NIR spectroscopy, supported by rigorous protocols and chemometrics, provides a versatile platform for food authentication. From quantifying key components in honey and meat to detecting sophisticated fraud, its non-destructive nature and adaptability to portable formats make it indispensable for modern food labs. Future advancements will focus on AI-driven spectral interpretation, standardized validation frameworks, and miniaturized devices for real-time supply chain monitoring [3] [18]. By adhering to the methodologies outlined herein, researchers can ensure accuracy, reproducibility, and compliance in food authentication workflows.

Food fraud represents a significant and persistent challenge to the global food industry, encompassing deliberate actions such as adulteration, dilution, and mislabeling for economic gain. The economic impact is staggering, with estimated annual losses of approximately $40 billion worldwide, affecting about 16,000 tons of food and beverages [20]. Beyond financial consequences, food fraud poses substantial public health risks, ranging from immediate allergic reactions to chronic health issues like neurotoxicity from adulterated spices [20]. Historical incidents, such as the 2008 melamine-contaminated powdered milk scandal that affected 300,000 infants, underscore the catastrophic potential of these practices [20]. This application note examines the current food fraud landscape, emphasizing the economic and safety drivers that necessitate robust authentication technologies, with a specific focus on the field application of Near-Infrared (NIR) spectroscopy.

The Food Fraud Landscape: Key Drivers

Economic Drivers

Food fraud is primarily economically motivated, with fraudulent practices cutting across numerous product categories. High-value products are particularly vulnerable; olive oil, fish, organic foods, milk, grains, honey, maple syrup, coffee, tea, spices, and wine represent the most at-risk categories [21]. The incentives for fraud are multifaceted, including the potential for substantial illicit profits through practices such as substituting premium ingredients with inferior or counterfeit alternatives. For instance, extra virgin olive oil is frequently targeted, often being blended with cheaper vegetable oils like sunflower, corn, palm, and rapeseed oils yet sold as pure olive oil [21]. These activities not only result in direct financial losses for industry and consumers but also erode brand integrity and consumer trust, the restoration of which requires significant investment.

Safety and Public Health Drivers

The safety implications of food fraud are profound and directly impact public health. Adulterants can introduce unintended and hazardous substances into the food supply. Risks include:

- Allergenic Hazards: The presence of undeclared allergens, such as peanut or walnut shells in adulterated cinnamon, can trigger severe allergic reactions [20].

- Toxicological Hazards: Adulteration with non-food substances like melamine or heavy metals can lead to chronic toxicity, organ damage, and, in severe cases, death [20].

- Nutritional Deficiencies: Fraudulent products often fail to deliver the expected nutritional value, potentially leading to public health issues related to malnutrition or deficiency [21].

Regulatory and Social Drivers

The regulatory landscape is evolving to combat food fraud. In the United States, the Food and Drug Administration (FDA) has implemented the Food Defense program and the Mitigation Strategies to Protect Food Against Intentional Adulteration rule [21]. Similarly, in the European Union, the establishment of the EU Food Fraud Network in 2013 has led to more structured cooperation, with honey being a recent focus for enhanced regulatory controls [22]. Beyond regulations, there is growing emphasis on addressing social vulnerability within food supply chains. This involves considering how power imbalances and inequitable risk distribution can make certain actors, such as small-scale beekeepers, more susceptible to the impacts of fraud [22]. Consequently, authentication technologies are not merely analytical tools but are integral to promoting supply chain transparency, fair trade, and social equity.

NIR Spectroscopy as an Authentication Tool

Fundamental Principles

Near-Infrared (NIR) spectroscopy is an analytical technique that measures the interaction of matter with electromagnetic radiation in the 780–2500 nm wavelength range [11]. This region captures overtone and combination vibrations of fundamental molecular bonds, primarily C-H, O-H, and N-H, which are characteristic of organic compounds [20]. The resulting spectra provide a unique "fingerprint" of the sample's chemical composition, enabling both qualitative identification and quantitative analysis [3]. The technique is non-destructive, requires minimal sample preparation, and is capable of rapid analysis, making it ideally suited for in-line, at-line, and field-based authentication [11] [4].

Advantages Over Traditional Methods

Traditional methods for food authentication, such as High-Performance Liquid Chromatography (HPLC), Gas Chromatography-Mass Spectrometry (GC-MS), and DNA-based techniques, are highly accurate but possess significant limitations for routine screening. These include being time-consuming, destructive, requiring specialized laboratories and personnel, and incurring high operational costs [4] [20]. In contrast, NIR spectroscopy offers a rapid, non-destructive, and often portable alternative that can be deployed directly in the field or at various points in the supply chain, providing real-time or near-real-time results for decision-making [3].

Table 1: Comparison of Food Authentication Methods

| Method | Analysis Speed | Sample Preparation | Destructive | Cost | Portability |

|---|---|---|---|---|---|

| NIR Spectroscopy | Very Fast (seconds) | Minimal | No | Low (after initial investment) | High (portable devices available) |

| HPLC/GC-MS | Slow (hours) | Extensive | Yes | High | Low |

| DNA Analysis | Slow (hours-days) | Moderate | Yes | High | Low |

| Classical Wet Chemistry | Slow (hours) | Extensive | Yes | Moderate | Low |

Experimental Protocols for NIR-Based Authentication

The following protocols detail the application of NIR spectroscopy for food authentication, adaptable for both benchtop and portable instruments.

Protocol 1: General Workflow for Food Powder Authentication

This protocol is designed for detecting adulteration in powdered foods (e.g., spices, milk powder, flour).

1. Sample Preparation:

- Homogenization: Ensure the powder is thoroughly mixed to a consistent particle size. For some applications, grinding and sieving to a specific particle size range (e.g., < 250 µm) is recommended to reduce spectral scatter [20].

- Conditioning: Allow samples to equilibrate to a consistent ambient temperature (e.g., 20–25 °C) and humidity to minimize spectral variance [20].

2. Spectral Acquisition:

- Instrument Setup: Use a benchtop or portable NIR spectrometer. For powdered samples, Diffuse Reflectance is the standard acquisition mode [20].

- Calibration: Perform instrument calibration using a certified white reference (e.g., Spectralon) and a dark current measurement prior to sample analysis [23].

- Measurement Parameters: Collect spectra in the range of 780–2500 nm. A resolution of 4–16 cmâ»Â¹ is typical. Average 32–64 scans per spectrum to improve the signal-to-noise ratio [23].

- Replication: Acquire a minimum of three replicate spectra from different sub-samples of the same homogeneous batch to assess reproducibility [23].

3. Data Preprocessing: Apply mathematical treatments to raw spectra to remove physical artifacts and enhance chemical information. Common techniques, often used in combination, include:

- Savitzky-Golay (SG) Smoothing: Reduces high-frequency noise [20].

- Standard Normal Variate (SNV): Corrects for scattering effects due to particle size differences [4] [20].

- Detrending (DET): Removes baseline curvature [20].

- First or Second Derivative (Savitzky-Golay): Enhances resolution of overlapping peaks and removes baseline offsets [4].

4. Chemometric Modeling and Analysis:

- Qualitative Analysis (Authentication/Classification):

- Use Principal Component Analysis (PCA) for exploratory data analysis to identify natural clusters and outliers [4].

- Employ classification models like Linear Discriminant Analysis (LDA), Support Vector Machine (SVM), or Soft Independent Modeling of Class Analogy (SIMCA) to differentiate authentic from adulterated samples or to classify by botanical/geographical origin [11] [4].

- Quantitative Analysis (Level of Adulteration):

5. Model Validation:

- Validate models using cross-validation (e.g., leave-one-out or k-fold) and an external validation set not used in model development.

- Evaluate performance using Root Mean Square Error of Calibration (RMSEC), Root Mean Square Error of Prediction (RMSEP), and the coefficient of determination (R²) [4] [23].

The following workflow diagram illustrates the key steps in this protocol:

Protocol 2: Authentication of Liquid Foods (Honey)

This protocol is specific to liquid matrices like honey, which are susceptible to adulteration with sugar syrups.

1. Sample Preparation:

- Liquefaction: If crystallized, gently warm the honey in a water bath at 40°C until crystals dissolve, then mix thoroughly. Avoid overheating to prevent the formation of 5-Hydroxymethylfurfural (5-HMF) [4].

- Degassing: Allow the honey to stand or gently stir to remove air bubbles introduced during mixing, as bubbles can cause light scattering [4].

- Temperature Equilibration: Bring all samples to a consistent temperature (e.g., 25°C) before measurement [4].

2. Spectral Acquisition:

- Instrument Setup: Utilize a transmission or transflectance cell with a fixed pathlength (e.g., 1 mm). Alternatively, a fiber optic probe can be used for direct measurement [4].

- Measurement: Acquire spectra in the 1000–2500 nm range. The number of scans and resolution can be aligned with Protocol 1.

3. Data Preprocessing & Modeling:

- Follow the preprocessing steps outlined in Protocol 1. SNV is particularly useful for correcting path length variations in liquid samples.

- For quantitative prediction of adulterants (e.g., corn syrup) or quality parameters (e.g., moisture, 5-HMF, sugar profiles), use PLSR calibrated against reference laboratory data (e.g., from HPLC or refractometry) [4].

Table 2: Key Honey Quality Parameters Measurable by NIR [4]

| Parameter | Significance for Authentication | Common NIR Prediction Accuracy (R²) |

|---|---|---|

| Sugar Content (Glucose/Fructose) | Detects dilution with sugar syrups | > 0.95 |

| Moisture Content | Indicator of quality and fermentation risk | > 0.90 |

| 5-HMF | Marker for overheating or aging | Varies with model |

| Proline | Amino acid linked to natural origin | Varies with model |

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for NIR-Based Authentication

| Item | Function/Application | Technical Specifications |

|---|---|---|

| Certified White Reference (e.g., Spectralon) | Calibrates the spectrometer's reflectance baseline before measurement. | >99% Reflectance across NIR range [23]. |

| Chemometrics Software | Used for spectral preprocessing, model development (PCA, PLSR, etc.), and validation. | Includes algorithms like SNV, Savitzky-Golay, PLS, SVM [11] [20]. |

| Reference Materials | Authentic, well-characterized samples for building and validating calibration models. | Certified for specific parameters (e.g., protein, fat, geographic origin) [24]. |

| Quartz Cuvettes / Transflectance Cells | Holds liquid samples (honey, oil, milk) for transmission/transflectance measurements. | Pathlength: 0.5 - 5 mm; Quartz for optimal NIR transmission [4]. |

| Portable NIR Spectrometer | Enables on-site, in-field screening at various points in the supply chain. | Wavelength range: 900-1700 nm or wider; InGaAs detector [4] [20]. |

| (R)-M8891 | (R)-M8891, MF:C20H17F2N3O3, MW:385.4 g/mol | Chemical Reagent |

| (3S,4S)-A2-32-01 | (3S,4S)-A2-32-01, MF:C19H27NO2, MW:301.4 g/mol | Chemical Reagent |

The economic and public health imperatives driven by food fraud create an urgent need for effective, rapid, and deployable authentication technologies. NIR spectroscopy, particularly when enhanced with chemometrics, meets this need by providing a powerful tool for verifying food authenticity directly in the field. Its non-destructive nature, speed, and growing portability make it an indispensable asset for researchers and industry professionals dedicated to ensuring food safety, protecting brand integrity, and promoting transparency throughout the global food supply chain.

Implementing NIR for Food Authentication: From Benchtop to Field

Food fraud, particularly concerning high-value agricultural products like nuts, represents a significant global challenge, resulting in an estimated $40 billion in annual economic losses and posing substantial risks to public health and consumer trust [20]. Nut fraud typically manifests in two forms: economic adulteration, where nuts are adulterated with lower-cost substances such as other nuts, shells, or starches, and misrepresentation of geographical origin, where the premium value associated with a specific growing region is fraudulently claimed for lower-quality products. Near-infrared (NIR) spectroscopy has emerged as a powerful, rapid, and non-destructive analytical technique ideally suited for field-based food authentication research. This Application Note provides detailed protocols for using NIR spectroscopy, coupled with advanced chemometrics, to detect adulterants and verify the geographical origin of nuts, supporting the broader thesis of deploying robust, on-site authentication systems.

Technical Principles: NIR Spectroscopy for Nut Authentication

NIR spectroscopy operates on the principle of measuring the absorption of light in the 780–2500 nm wavelength range due to molecular vibrations, primarily from bonds in C–H, O–H, and N–H functional groups [20] [11]. These vibrations create a unique "fingerprint" that reflects the chemical composition of a sample. For nut matrices, which are rich in fats (C-H), proteins (N-H), and water (O-H), NIR spectra contain a wealth of compositional information.

The technique offers key advantages for field application:

- Non-Destructive: Analysis preserves the sample integrity.

- Rapid: Results can be obtained in seconds to minutes.

- Minimal Sample Preparation: Often requires only grinding into a coarse or fine powder to ensure consistent particle size and packing density, which minimizes light scattering effects [20].

- Portability: Modern portable NIR spectrometers (e.g., 900–1700 nm range) enable on-site analysis at farms, processing facilities, or border checkpoints [20] [25].

A primary limitation is its indirect nature; NIR requires robust chemometric models—the application of mathematical and statistical methods to chemical data—to correlate spectral data with the property of interest (e.g., adulterant concentration or origin) [11]. The general workflow, from sample preparation to result interpretation, is outlined below.

Application Note 1: Detecting Adulteration in Nut Flours and Powders

Experimental Objective

To rapidly and non-destructively identify and quantify common adulterants (e.g., almond shell in almond flour, peanut in walnut powder, or starches in protein powders) in nut-based powders using a portable NIR spectrometer combined with chemometric models.

Detailed Protocol

Step 1: Sample Preparation and Spectral Acquisition

- Grinding: Homogenize nut samples and potential adulterants using a laboratory-grade mill. Standardize the particle size (e.g., pass through a 500 μm sieve) to reduce spectral variability [20].

- Sample Set Creation: Create calibration samples by mixing pure nut powder with known concentrations of the adulterant (e.g., 0-40% w/w in 5% increments). Ensure a representative number of replicates (e.g., n=5 per concentration level).

- Environmental Control: Perform NIR measurements in a stable environment (approx. 25 °C) to minimize instrumental drift [25].

- Data Collection: Using a portable NIR spectrometer (e.g., 900-1700 nm), collect spectral data from each sample. For each sample, take multiple readings (e.g., 3-5 scans) and average them to improve the signal-to-noise ratio. Ensure the probe is in consistent contact with the sample surface [25].

Step 2: Spectral Preprocessing

Raw NIR spectra are affected by physical light scattering and noise. Preprocessing is critical to enhance chemical information [20].

- Savitzky-Golay (SG) Smoothing: Apply with a window size of 11 points and a 2nd or 3rd-order polynomial to reduce high-frequency noise [25].

- Standard Normal Variate (SNV) or Multiplicative Scatter Correction (MSC): Use to correct for baseline shifts and scattering effects caused by particle size differences [20] [26].

- Derivatives (1st or 2nd): Apply Savitzky-Golay 1st or 2nd derivatives to resolve overlapping peaks and remove baseline variations [20] [26].

Step 3: Model Development and Validation

Two primary modeling approaches are used:

- For Quantification (PLS-R): Use Partial Least Squares Regression (PLS-R) to build a model that predicts the concentration of the adulterant. The model correlates the preprocessed spectral data (X-matrix) with the known adulterant concentrations (Y-matrix) [27].

- For Classification (PLS-DA or SVM): Use Partial Least Squares Discriminant Analysis (PLS-DA) or Support Vector Machine (SVM) to classify samples as "pure" or "adulterated" [27] [26].

Validation: Always validate models using an independent set of samples not used in model calibration. Employ k-fold cross-validation (e.g., 5-fold) during model development to avoid overfitting and to robustly assess performance [25].

Performance Data and Expected Outcomes

Table 1: Exemplary performance metrics for NIR-based detection of food adulteration, as reported in recent literature. These demonstrate the potential of the technique when applied to nut matrices.

| Food Matrix | Adulterant | Chemometric Model | Performance Metrics | Source |

|---|---|---|---|---|

| Honey | Six sugar syrups | PLS-DA & PLS-R | Classification: 100% accuracy; Quantification: R² > 0.98 | [27] |

| Powdered Foods | Various | Spectroscopy & Chemometrics | Detection accuracy > 90% for many powdered dairy, spices, and cereals | [20] |

| Tartary Buckwheat | Common Buckwheat | SVR (Support Vector Regression) | Flavonoid prediction: R²p = 0.98; Protein prediction: R²p = 0.92 | [28] |

Application Note 2: Verifying the Geographical Origin of Nuts

Experimental Objective

To distinguish the geographical origin of nut samples (e.g., pistachios from Iran vs. the USA, or almonds from California vs. Spain) based on subtle differences in their chemical profiles revealed by NIR spectroscopy.

Detailed Protocol

Step 1: Sample Sourcing and Spectral Library

- Sample Collection: Obtain authentic nut samples (e.g., 80-100 per region) from well-documented growing regions. The number of samples is critical for model robustness [25].

- Spectral Acquisition: Follow the same rigorous spectral acquisition protocol as described in Application Note 1, Section 3.2, ensuring consistency across all samples.

Step 2: Feature Extraction and Dimensionality Reduction

NIR data is high-dimensional. Feature extraction is essential to highlight spectral features most relevant to geographical discrimination.

- Principal Component Analysis (PCA): An unsupervised method used for initial exploration to identify natural clustering of samples by origin and to detect outliers [26].

- Uncorrelated Discriminant Transform (UDT): A powerful supervised feature extraction method that projects data into a new space where classes (origins) are well-separated while ensuring the features are uncorrelated. It has been shown to outperform methods like DPCA and FST in some studies [25].

Step 3: Classification Modeling

Apply advanced classifiers to the extracted features:

- k-Nearest Neighbors (KNN): A simple, effective classifier that can achieve high accuracy, as demonstrated in kimchi origin authentication [26].

- XGBoost (eXtreme Gradient Boosting): A powerful ensemble method that builds multiple decision trees sequentially, correcting the errors of previous ones. It is highly effective for complex, non-linear data and has achieved 100% classification accuracy for black bean origin when combined with UDT [25].

- Support Vector Machine (SVM): Effective for finding the optimal boundary (hyperplane) to separate classes in high-dimensional space [25] [26].

The logical sequence for building a robust origin verification model is depicted below.

Performance Data and Expected Outcomes

Table 2: Exemplary performance of NIR spectroscopy coupled with machine learning for determining the geographical origin of various foodstuffs.

| Food Matrix | Geographical Origins | Feature Extraction / Classifier | Performance Metrics | Source |

|---|---|---|---|---|

| Black Beans | 5 regions in China | UDT + XGBoost | 100% Classification Accuracy | [25] |

| Black Beans | 5 regions in China | UDT + KNN/SVM | 96.25% Classification Accuracy | [25] |

| Kimchi | Domestic vs. Imported | FT-NIR + KNN | Accurate classification, superior performance | [26] |

| Milk | Various | FDLDA-KNN | 97.33% Classification Accuracy | [11] |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential materials, reagents, and software for implementing NIR-based authentication protocols.

| Item Category | Specific Examples / Functions | Key Application in Protocol |

|---|---|---|

| Portable NIR Spectrometer | NIR-M-F1-C (900-1700 nm); Must have a high signal-to-noise ratio (e.g., >6000:1) and wavelength accuracy (±1 nm). | Primary instrument for non-destructive spectral acquisition in the field and lab. [25] |

| Sample Preparation Equipment | Laboratory mill, sieves (e.g., 500 μm), moisture analyzer. | Homogenization and particle size standardization to minimize spectral scatter. [20] |

| Chemometric Software | Python (scikit-learn, XGBoost libraries), MATLAB, R, PLS_Toolbox. | Platform for spectral preprocessing, feature extraction, and model development/validation. [25] |

| Spectral Preprocessing Algorithms | Savitzky-Golay (SG), Standard Normal Variate (SNV), Derivatives. | Correct for physical effects (scatter, baseline) and enhance chemical signal in raw spectra. [20] [26] |

| Feature Extraction Methods | Uncorrelated Discriminant Transform (UDT), Principal Component Analysis (PCA). | Reduce data dimensionality and highlight features most relevant for discrimination. [25] |

| Classification & Regression Models | XGBoost, k-NN, SVM, PLS-DA, PLS-R. | Perform the final task of classifying origin or quantifying adulterant concentration. [25] [28] [26] |

| dCBP-1 | dCBP-1, MF:C51H63F2N11O10, MW:1028.1 g/mol | Chemical Reagent |

| limertinib | limertinib, MF:C29H32ClN7O2, MW:546.1 g/mol | Chemical Reagent |

The integration of portable NIR spectroscopy with advanced chemometric models presents a formidable solution for combating nut fraud. The protocols outlined herein for detecting adulteration and verifying geographical origin are robust, rapid, and suitable for deployment in field settings. This approach empowers researchers, regulatory bodies, and industry stakeholders to safeguard the integrity of the global nut supply chain, protect consumer health, and ensure economic fairness. Future research directions will focus on the development of self-adaptive models, larger shared spectral libraries, and the deeper integration of these systems into digital traceability platforms for real-time, on-site authentication [20] [3].

The global spice trade, a multi-billion dollar industry, faces significant challenges related to authenticity and geographic origin fraud. Economically motivated adulteration and mislabeling not only undermine consumer trust but also pose potential health risks and economic losses. Traditional analytical methods, while accurate, are often destructive, time-consuming, and require laboratory settings, making them unsuitable for rapid screening throughout the supply chain. Near-Infrared (NIR) spectroscopy has emerged as a powerful, non-destructive analytical technique capable of addressing these challenges through rapid, on-site authentication. This application note details protocols and methodologies for implementing NIR spectroscopy in spice authentication, framed within broader research on field applications of NIR for food authentication.

Theoretical Foundations of NIR Spectroscopy

Near-Infrared spectroscopy operates in the electromagnetic radiation range of 780–2500 nm (800–2500 nm, or 12,500–3800 cmâ»Â¹), measuring molecular overtone and combination vibrations primarily associated with C-H, O-H, and N-H bonds [2] [16] [4]. These chemical bonds are abundant in organic compounds, making NIR spectroscopy particularly suitable for analyzing complex biological matrices like spices. When NIR radiation interacts with a sample, the resulting absorption, reflection, and transmission patterns create a unique spectral fingerprint that reflects its chemical composition [16]. This fingerprint enables both qualitative discrimination between samples and quantitative prediction of chemical constituents.

The NIR spectrum consists of broad, overlapping peaks, necessitating advanced chemometric techniques for interpretation [2] [4]. Spectra acquisition can occur via different methods: diffuse reflection is typically used for solid samples (e.g., powdered spices), where photons penetrate a few millimeters into the sample, while transmission and transflectance techniques are applied to liquids or colloidal samples [2]. For solid spices, the diffuse reflection method is most applicable, though particle size and homogeneity must be carefully controlled to minimize detrimental scattering phenomena [2].

Experimental Design and Protocols

Sample Preparation Techniques

Proper sample preparation is critical for obtaining reproducible NIR spectra. Based on comparative studies of nuts and similar matrices, the following techniques are recommended for spice authentication:

Table 1: Comparison of Sample Preparation Methods for Spice Authentication

| Preparation Method | Processing Time | Sample Amount | Reproducibility | Classification Accuracy | Best Use Cases |

|---|---|---|---|---|---|

| Whole Spices | Minimal (minutes) | Entire spice pod/seed | Lower | Moderate | Initial screening, quality control |

| Bisected Spices | Low (<30 min) | Half seeds | Moderate | Good | Internal composition analysis |

| Ground Spices | High (30-60 min) | 5-10g homogenized powder | High | Very Good | Standard authentication protocols |

| Freeze-Dried & Ground | Highest (24-72 hours) | 5-10g dried powder | Highest | Excellent | Research studies, reference methods |

Based on systematic comparisons for geographical origin determination of almonds, freeze-drying combined with grinding emerged as the most reliable preparation technique despite higher time investment, as it removes interfering water bands and improves spectral reproducibility [29]. For routine analysis, finely ground homogeneous powder provides an optimal balance between preparation effort and analytical performance.

Spectral Acquisition Parameters

The following protocol outlines standardized parameters for spice analysis using Fourier Transform Near-Infrared (FT-NIR) spectroscopy:

Instrument Calibration:

- Perform daily calibration using certified white reference standards and dark current measurements [23]

- Validate calibration using control samples with known spectral properties

Spectral Acquisition:

- Spectral Range: 780–2500 nm (12,500–4,000 cmâ»Â¹) for comprehensive molecular information [2] [23]

- Resolution: 4–16 cmâ»Â¹; higher resolution for complex spice mixtures [4]

- Scan Number: 32–64 scans per spectrum to improve signal-to-noise ratio [23]

- Measurement Mode: Diffuse reflectance for powdered spices; interactance for whole spices

- Replication: Minimum three replicate spectra per sample from different sub-samples [23]

Environmental Controls:

- Maintain consistent temperature (20–25°C) and humidity (30–60%) during analysis [23]

- Allow samples to equilibrate to room temperature before measurement

Chemometric Analysis and Model Development

NIR spectral data requires multivariate analysis for meaningful interpretation. The following workflow outlines the standard approach:

Data Preprocessing: Apply mathematical treatments to reduce scattering effects and enhance spectral features:

- Multiplicative Scatter Correction (MSC) or Standard Normal Variate (SNV) to correct for light scattering effects [2] [4]

- Savitzky-Golay derivatives (first or second derivative) to resolve overlapping peaks and remove baseline offsets [2]

- Detrending to eliminate non-linear baseline drift

Exploratory Analysis:

- Principal Component Analysis (PCA) for unsupervised pattern recognition and outlier detection [2] [4]

- Cluster Analysis (CA) to identify natural groupings in the data

Model Development:

- Classification Models: Use Support Vector Machines (SVM), Linear Discriminant Analysis (LDA), or Soft Independent Modeling of Class Analogy (SIMCA) for geographical origin discrimination [4] [29]

- Regression Models: Apply Partial Least Squares Regression (PLSR) or Principal Component Regression (PCR) for quantitative analysis of adulterants [2] [4]

Model Validation:

- Employ cross-validation (e.g., leave-one-out or k-fold) to assess model robustness [4]

- Use external validation sets not included in model calibration

- Evaluate using metrics including sensitivity, specificity, precision, and accuracy [2]

Performance Metrics and Validation

Quantitative Assessment of NIR Performance

Table 2: Performance Metrics for NIR Authentication of Various Food Matrices

| Food Matrix | Authentication Target | Chemometric Method | Accuracy/R² | LOD/LOQ | Reference |

|---|---|---|---|---|---|

| Protein Powders | Melamine adulteration | PLSR | R²P = 0.96 | LOD ≈ 0.1% | [30] |

| Honey | Adulterant detection | PLS-DA | 100% classification | N/A | [27] |

| Honey | Sugar quantification | PLSR | R² > 0.95 | N/A | [4] |

| Almonds | Geographical origin | SVM | High classification | N/A | [29] |

| Fast Food | Protein content | PLSR | No significant difference from reference | N/A | [23] |

For spice authentication, expected performance metrics should meet or exceed these benchmarks, with classification accuracy >90% for geographical origin discrimination and R² > 0.90 for quantification of major adulterants.

Validation Against Reference Methods

NIR spectroscopy serves as a secondary analytical technique whose accuracy depends on reference methods [2]. Validation should include:

- Comparison with standard methods (e.g., HPLC for chemical markers, DNA analysis for botanical identification)

- Statistical tests (e.g., paired t-tests, ANOVA) to evaluate differences between NIR predictions and reference values [23]

- Assessment of repeatability and reproducibility through replicate analyses

Studies have demonstrated excellent agreement between NIR and classical methods for major components including protein, fat, and carbohydrates, though components like sugars and dietary fiber may show systematic deviations [23].

Implementation Considerations

The Researcher's Toolkit: Essential Materials and Reagents

Table 3: Essential Research Reagent Solutions for Spice Authentication

| Item | Specifications | Function | Application Notes |

|---|---|---|---|

| FT-NIR Spectrometer | Spectral range: 780-2500 nm, Resolution: 4-16 cmâ»Â¹ | Spectral acquisition | Benchtop for lab, portable for field use |

| Reference Standards | Certified white reference (e.g., Spectralon) | Instrument calibration | Essential for measurement reproducibility |

| Grinding Apparatus | Analytical mill with temperature control | Sample homogenization | Controlled particle size (≤250 μm) |

| Sieving Equipment | Standardized sieve series (e.g., 60-80 mesh) | Particle size control | Improves spectral reproducibility |

| Freeze-Dryer | Temperature: -50°C, Pressure: <0.1 mbar | Water removal | Eliminates water interference in spectra |

| Chemometric Software | PCA, PLSR, SVM capabilities | Data analysis | MATLAB, R, Python, or commercial packages |

| Sample Cells | Quartz cuvettes, reflective plates | Sample presentation | Pathlength optimization for spice matrices |

| PF-05381941 | PF-05381941, MF:C27H26N6O2, MW:466.5 g/mol | Chemical Reagent | Bench Chemicals |

| LY3509754 | LY3509754, MF:C24H27F5N8O4, MW:586.5 g/mol | Chemical Reagent | Bench Chemicals |

Practical Challenges and Mitigation Strategies

- Sample Heterogeneity: Implement rigorous grinding and mixing protocols; increase replicate measurements

- Moisture Interference: Control storage conditions or implement freeze-drying for sensitive applications [29]

- Model Transferability: Use calibration transfer techniques (e.g., Piecewise Direct Standardization) when applying models across different instruments [4]

- Environmental Effects: Standardize temperature during analysis or incorporate temperature correction algorithms

NIR spectroscopy, coupled with appropriate chemometric tools, offers a powerful, non-destructive approach for authenticating spices and verifying their geographic origin. The protocols outlined in this application note provide researchers with a standardized framework for implementing this technology in both laboratory and field settings. As the spice trade continues to globalize, such rapid authentication methods will become increasingly vital for protecting consumers, ensuring fair trade practices, and maintaining the integrity of this valuable agricultural sector. Future developments in portable NIR devices, advanced machine learning algorithms, and data fusion techniques will further enhance the capabilities of this technology for spice authentication.

The authentication of powdered foods is a critical challenge within the global food supply chain. High-value powdered products, including dairy, cereals, and dietary supplements, are particularly vulnerable to economically motivated adulteration due to their high commercial value and physical form, which facilitates fraudulent practices [20]. Such adulteration poses significant economic and public health risks, including allergic reactions, chronic toxicity, and in historical cases like the 2008 melamine scandal, catastrophic health outcomes [20]. Traditional analytical methods, such as high-performance liquid chromatography (HPLC) or polymerase chain reaction (PCR), while accurate, are destructive, time-consuming, and require specialized laboratory settings and personnel [20] [31].

Near-infrared (NIR) spectroscopy has emerged as a rapid, non-destructive, and cost-effective alternative for the detection of adulterants in powdered foods. This technique, which operates on the principle of molecular overtone and combination vibrations of C–H, O–H, and N–H bonds, is highly suitable for industrial quality control and on-site screening [20] [11] [3]. When combined with chemometrics—the application of mathematical and statistical methods to chemical data—NIR spectroscopy enables robust qualitative and quantitative analysis of food authenticity [20] [11]. This document provides detailed application notes and experimental protocols for researchers and scientists on the application of NIR spectroscopy for authenticating powdered dairy, cereals, and dietary supplements, framed within a thesis on the field application of NIR for food authentication research.

Technical Principles and Instrumentation

Fundamentals of NIR Spectroscopy

NIR spectroscopy operates in the electromagnetic spectrum region of 780–2500 nm (wavenumber range of approximately 12,820 cmâ»Â¹ to 4000 cmâ»Â¹) [11] [4]. It measures the absorption of radiation resulting from the overtone and combination vibrations of hydrogen-containing functional groups, primarily C–H, O–H, and N–H bonds, which are fundamental constituents of organic molecules [20] [11] [3]. The absorption of light at specific wavelengths follows the Beer-Lambert law, where absorbance is proportional to the concentration of the absorbing species and the path length [20] [30]. These absorption patterns create a unique "fingerprint" for a material, allowing for the identification and quantification of its chemical composition [11] [3].

For powdered foods, the diffuse reflectance mode is most commonly employed. In this mode, light penetrates the powder particles, and the reflected (scattered) light is collected and measured. The resulting spectrum contains complex information about the molecular composition of the sample, which can be used to identify deviations caused by adulterants [20].

Instrumentation Types: Benchtop vs. Portable/Hyphenated Systems

A significant advancement in NIR technology is the development of portable and handheld devices, enabling real-time, on-site analysis at various points in the food supply chain [20] [31].

| Feature | Benchtop Spectrometers | Portable/Handheld Spectrometers |

|---|---|---|

| Primary Use | Laboratory-based, high-precision analysis | On-site, rapid screening in the field/facility |

| Technology Examples | Fourier Transform (FT-NIR), Grating-based [30] | MEMS (Micro-Electro-Mechanical System) [30] [31], DLP-based [32] |

| Typical Performance | Higher signal-to-noise ratio, broader spectral range, superior for quantifying low-concentration adulterants [30] | Slightly lower predictive accuracy but highly effective for classification and screening [30] [31] |

| Advantages | High accuracy and reproducibility; suitable for building robust calibration models [20] | Portability, cost-effectiveness, enables decentralized testing and real-time decision-making [20] [31] |

| Limitations | High cost, not portable, requires sample presentation to the lab | Slightly lower sensitivity; spectra can be affected by environmental factors and operator handling [30] |

Core Experimental Protocols

This section outlines a standardized workflow for developing a NIR-based method to detect and quantify adulterants in powdered foods.

Sample Preparation and Spectral Acquisition

Objective: To ensure spectral data is reproducible and representative of the sample's chemical composition.

Materials:

- Pure, authentic powdered food matrix (e.g., pure whey protein, grape seed extract, coriander powder).

- Known adulterants (e.g., melamine, urea, pea protein, pine bark extract, sawdust) [30] [32] [33].

- Laboratory balance, mortar and pestle or mill, and sample cells (e.g., glass vials, Petri dishes, or cups with a quartz window).

- NIR spectrometer (benchtop or portable).

Protocol:

- Sample Preparation: For consistency, standardize the particle size of all samples (pure and adulterated) by milling or grinding and sieving to a uniform particle size (e.g., < 250 µm) [20]. This minimizes light scattering effects caused by particle size variability.

- Adulterated Sample Creation: Create a calibration set by accurately mixing the pure matrix with one or more adulterants at multiple concentration levels. For example, adulterate whey protein with melamine at 0.1% to 10% (w/w) or grape seed extract with pine bark extract from 0.5% to 13% [30] [32]. Ensure homogeneous mixing.

- Spectral Acquisition:

- Allow the instrument to warm up for the recommended time (e.g., 10 minutes) [31].

- Collect a background reference spectrum (e.g., using a Spectralon standard with 99% reflectance) [31].

- Fill the sample cell uniformly with the powder, ensuring a consistent and reproducible packing density for each measurement.

- Acquire spectra in diffuse reflectance mode. For each sample, collect multiple spectra (e.g., 3–5) from different spots or by rotating the sample cup, and average them to improve the signal-to-noise ratio [31].

- Record spectra over the full operational range of the instrument (e.g., 1000–2500 nm) [4].

Spectral Data Preprocessing

Objective: To remove non-chemical, physical sources of spectral variation (e.g., light scattering, baseline offset, noise) to enhance the chemical information.

Protocol:

- Smoothing: Apply the Savitzky-Golay (SG) filter to reduce high-frequency noise without significantly distorting the signal [20] [33].

- Scatter Correction: Use Standard Normal Variate (SNV) or Multiplicative Scatter Correction (MSC) to correct for additive and multiplicative scattering effects caused by particle size and packing differences [20] [4].

- Derivative Processing: Calculate the first (FD) or second derivative (SD) of the spectra using the Savitzky-Golay algorithm. This helps to remove baseline offsets, resolve overlapping peaks, and enhance small spectral features [20] [4].

Table 2: Common Spectral Preprocessing Techniques and Their Purposes [20] [4].

| Technique | Main Purpose | Effect on Spectrum |

|---|---|---|

| Savitzky-Golay (SG) | Smoothing | Reduces high-frequency noise |

| Standard Normal Variate (SNV) | Scatter correction | Corrects for multiplicative and additive scattering effects |

| Multiplicative Scatter Correction (MSC) | Scatter correction | Corrects for multiplicative and additive scattering effects |

| First Derivative (FD) | Baseline removal & feature enhancement | Removes constant baseline offset; highlights slopes |

| Second Derivative (SD) | Baseline removal & peak resolution | Removes constant and linear baseline offsets; resolves overlapping peaks |

The following diagram illustrates the complete workflow from sample preparation to model evaluation.

Chemometric Modeling and Validation

Objective: To develop mathematical models that correlate spectral data with the identity or concentration of adulterants.

Protocol:

- Data Splitting: Split the preprocessed spectral data and reference values into a calibration/training set (e.g., 70-80% of samples) and an independent validation/test set (e.g., 20-30%). The test set must not be used in model building.

- Quantitative Model (for predicting concentration):

- Use Partial Least Squares Regression (PLSR). PLSR is the most common method for quantifying adulterant levels [30] [32] [4].

- The model correlates the spectral matrix (X) with the concentration of the adulterant (Y).

- Determine the optimal number of latent variables (LVs) to avoid overfitting, typically using cross-validation on the calibration set.

- Qualitative Model (for classification):

- Use Principal Component Analysis (PCA) for exploratory data analysis to identify natural clustering of samples (e.g., pure vs. adulterated) [4] [3].

- Follow with a classification algorithm like Linear Discriminant Analysis (LDA) or Support Vector Machine (SVM) to build a predictive classification model based on the principal components (PCs) or spectral features [11] [4].

- Model Validation:

- Internal Validation: Use cross-validation (e.g., leave-one-out or k-fold) on the calibration set to optimize model parameters and prevent overfitting.

- External Validation: Apply the final model to the independent test set to evaluate its real-world performance.

- Performance Metrics: