Optimizing Slit Width in Pharmaceutical UV-Vis Spectroscopy: A Guide to Enhanced Accuracy, Sensitivity, and Green Analysis

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on optimizing slit width in UV-Vis spectrophotometry for pharmaceutical analysis.

Optimizing Slit Width in Pharmaceutical UV-Vis Spectroscopy: A Guide to Enhanced Accuracy, Sensitivity, and Green Analysis

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on optimizing slit width in UV-Vis spectrophotometry for pharmaceutical analysis. It covers the fundamental principles of slit width and its impact on spectral data, explores methodological applications in modern chemometric assays, addresses common troubleshooting and optimization challenges, and validates performance through comparative green metrics. By integrating foundational knowledge with practical application, this resource aims to empower professionals to develop robust, sensitive, and environmentally sustainable analytical methods for quality control and drug development.

Slit Width Fundamentals: Mastering Resolution, Signal, and Noise in Pharmaceutical Assays

In UV-Vis spectroscopy for pharmaceutical research, spectral fidelity—the accuracy and truthfulness of a measured spectrum—is paramount. It is the foundation upon which reliable quantitative and qualitative analyses are built. Two instrumental parameters are the cornerstones of achieving this fidelity: slit width and spectral bandwidth.

Spectral bandwidth is formally defined as the full width at half the maximum intensity (FWHM) of the band of light exiting the monochromator [1] [2]. It represents the purity, or narrowness, of the wavelengths used to probe your sample. The slit width is the physical aperture that primarily controls this bandwidth in a monochromator-based system [1]. In essence, the slit width acts as a gatekeeper: a narrower slit permits a narrower range of wavelengths to pass, resulting in a smaller spectral bandwidth and higher resolution, albeit at the cost of light intensity and signal-to-noise ratio [1] [3].

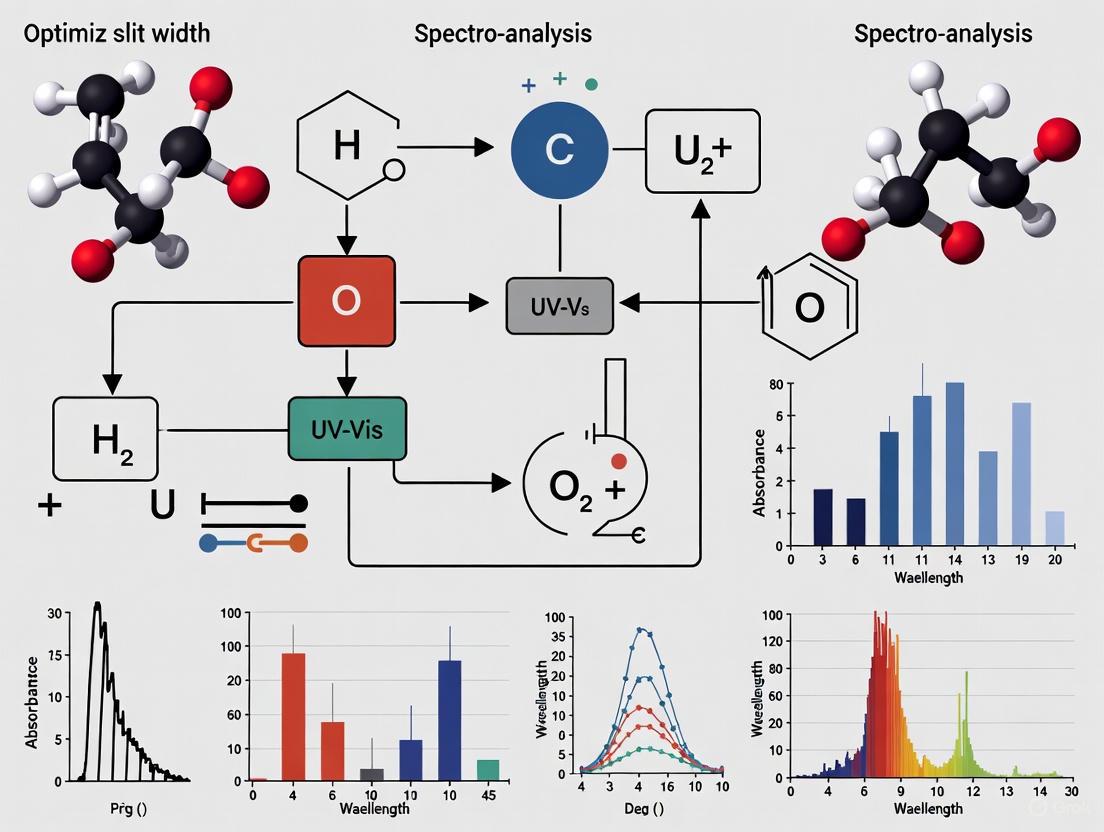

For pharmaceutical scientists, mastering these parameters is non-negotiable. The accuracy of absorbance measurements for drug compounds like sofosbuvir, simeprevir, and ledipasvir is critically dependent on the relationship between the instrument's spectral bandwidth and the sample's natural bandwidth—the inherent width of the sample's absorption band at half its maximum height [1] [4]. Optimal fidelity is achieved when the spectral bandwidth is 1/10 or less of the natural bandwidth, a condition that keeps measurement errors at or below 0.5% [2] [4]. The following diagram illustrates the core relationship between slit width, spectral bandwidth, and the resulting analytical performance, which forms the basis for the optimization strategies discussed in this guide.

Key Definitions and Instrumental Differences

Understanding the distinction between spectrometer types is crucial for correctly interpreting specifications and limitations.

Monochromator-Based Spectrophotometers

These instruments utilize a single detector and a monochromator containing an adjustable slit and a dispersive element (like a diffraction grating) to isolate individual wavelengths sequentially [1].

- Definition of Spectral Bandwidth: The width of the wavelength of light at half the maximum intensity of the light leaving the monochromator [1].

- Role of Slit Width: The slit width is the primary adjustable parameter determining the spectral bandwidth. It represents a critical trade-off: a narrower slit provides higher spectral resolution but reduces light throughput, potentially increasing noise and requiring longer measurement times [1] [3].

Diode-Array Spectrophotometers

These instruments use an array of detectors (diodes), each simultaneously responsible for detecting a specific, narrow wavelength range [1].

- Definition of Spectral Bandwidth: The wavelength range that each diode in the array can detect simultaneously [1].

- Role of Slit Width: While a slit is still present to control the amount of light entering the system, the spectral bandwidth is largely a fixed property determined by the physical design and spacing of the diode array itself [1]. This offers less user flexibility but enables extremely rapid data acquisition.

Table 1: Comparison of Spectrophotometer Types in Pharmaceutical Analysis

| Feature | Monochromator-Based | Diode-Array |

|---|---|---|

| Spectral Bandwidth | User-adjustable via slit width [1] | Fixed by diode array design [1] |

| Measurement Speed | Sequential wavelength measurement (slower) [1] | Simultaneous wavelength measurement (faster) [1] |

| Resolution Control | High degree of user control [1] | Limited user control [1] |

| Typical Pharmaceutical Use | High-resolution analysis for method development and validation | High-throughput analysis, reaction monitoring, and quality control |

The Scientist's Toolkit: Essential Materials for UV-Vis Analysis

Table 2: Key Research Reagent Solutions and Materials for Pharmaceutical UV-Vis

| Item | Function/Description | Example from Antiviral Drug Analysis [5] |

|---|---|---|

| Reference Standards | High-purity compounds used for calibration and method validation. | Sofosbuvir (99.25%), Simeprevir (98.96%), Ledipasvir (99.75%) from a regulatory authority. |

| HPLC-Grade Solvent | A high-purity solvent with minimal UV absorbance in the working range to prepare samples and blanks. | Ethanol (HPLC grade) used to dissolve drug standards and formulations. |

| Quartz Cuvettes | Cells that hold liquid samples. Quartz is essential for UV range measurements due to its high transmittance of UV light [6]. | 10 mm matched quartz cells for consistent path length. |

| Validated Software | Software for instrument control, data acquisition, and advanced chemometric analysis. | UV Probe software (v2.43) for acquisition; MATLAB for implementing CRACLS/SRACLS chemometric models [5]. |

| Vitexin2''-O-p-coumarate | Vitexin2''-O-p-coumarate, MF:C30H26O12, MW:578.5 g/mol | Chemical Reagent |

| 10α-Hydroxyepigambogic acid | 10α-Hydroxyepigambogic acid, CAS:887606-04-4, MF:C38H44O8, MW:628.7 g/mol | Chemical Reagent |

Optimizing Slit Width: A Practical Methodology

The following experimental protocol, inspired by a chemometric study on antiviral drugs, provides a framework for systematically optimizing slit width to achieve spectral fidelity [5].

1. Define Analytical Goal and Sample Characteristics:

- Identify the analytes (e.g., sofosbuvir, simeprevir, ledipasvir) and their expected concentration ranges [5].

- Acquire reference spectra for pure standards to estimate the natural bandwidth of the primary absorption peaks [1].

2. Establish the Initial Instrumental Setup:

- Use a double-beam UV-Vis spectrophotometer with an adjustable slit width [5].

- Employ a matched pair of quartz cuvettes with a 10 mm path length [5] [6].

- Prepare a stock solution of a target analyte in an appropriate solvent (e.g., 100 µg/mL in ethanol) [5].

- Set a sampling interval (data interval) that is equal to or slightly less than the spectral bandwidth you intend to test (e.g., for a 2 nm bandwidth, use a 1 or 2 nm interval) [1].

3. Execute the Slit Width Optimization Experiment:

- Prepare a series of dilutions from the stock solution to span the expected calibration range.

- Starting with the narrowest available slit width, record the absorbance spectrum of a mid-range concentration standard.

- Gradually increase the slit width in steps (e.g., 0.5 nm, 1 nm, 2 nm, 5 nm) and record the spectrum of the same standard each time.

- For each resulting spectrum, document the Signal-to-Noise Ratio (SNR) by measuring the peak height and the noise in a flat, non-absorbing region of the spectrum. Also, record the Absorbance Maxima and the Observed Peak Width at half the height (FWHM).

4. Analyze Data and Determine Optimal Slit Width:

- Plot SNR and Absorbance vs. Slit Width: This visualizes the trade-off. The optimal slit is often at the point where the SNR is high and absorbance begins to stabilize.

- Apply the 10% Rule: Calculate the ratio of the spectral bandwidth (dictated by the slit) to the natural bandwidth. The optimal setting should have a ratio of ≤ 0.1 for 99.5% accuracy [2] [4].

- Assess Resolution: If analyzing mixtures with close or overlapping peaks (like the antiviral drugs), ensure the chosen slit width allows for clear distinction between them.

Table 3: Quantitative Data from a Simulated Slit Width Optimization Experiment

| Slit Width (nm) | Spectral Bandwidth (nm) | *Measured Absorbance | Signal-to-Noise Ratio (SNR) | Observed Peak Width (FWHM, nm) |

|---|---|---|---|---|

| 0.5 | ~0.5 | 0.495 | 25:1 | 15.5 |

| 1.0 | ~1.0 | 0.499 | 100:1 | 15.8 |

| 2.0 | ~2.0 | 0.500 | 250:1 | 16.2 |

| 5.0 | ~5.0 | 0.485 | 500:1 | 18.5 |

Theoretical true absorbance is 0.500. A 5 nm slit causes a measurable decrease in peak height due to poor resolution [3].

The decision-making process for selecting the optimal slit width based on experimental goals is summarized in the workflow below.

Troubleshooting Guide and FAQs

This section addresses common issues related to slit width, bandwidth, and general instrument performance encountered in pharmaceutical research.

Frequently Asked Questions (FAQs)

Q1: How does slit width directly influence the shape and height of a spectral peak? A1: A wider slit width increases the spectral bandwidth, allowing a broader range of wavelengths to hit the detector simultaneously. This can cause absorption peaks to appear broader and their maximum height to be lower than the true value because the instrument is averaging the absorbance over a wider wavelength range [3]. This effect is critical when measuring substances with narrow natural bandwidths.

Q2: My spectrophotometer is giving inconsistent readings (drift). What should I check? A2:

- Light Source: An aging lamp (deuterium or tungsten) is a common cause. Replace the lamp if it is near or beyond its rated lifetime [7] [8].

- Warm-up Time: Ensure the instrument has stabilized for at least 20-30 minutes after powering on [7] [6].

- Calibration: Regularly perform a full baseline correction (with blank solvent) and recalibrate with certified reference standards [7] [9].

Q3: Why is my blank measurement failing, or why does the absorbance value keep fluctuating? A3:

- Cuvette Issues: Inspect the cuvette for scratches, residue, or fingerprints. Ensure it is correctly aligned in the holder and that you are using the correct type (e.g., quartz for UV) [7] [6] [8].

- Solvent Evaporation: If measuring over an extended period, solvent evaporation can change concentration and cause drift [6].

- Stray Light: Check for obstructions or debris in the light path [8].

Q4: When I try to set 0 Absorbance (100% Transmittance), the instrument displays an energy error (e.g., "L0" or "ENERGY ERROR"). What does this mean? A4: This indicates the detector is not receiving enough light. Likely causes include [8]:

- Failed Lamp: The lamp (especially the deuterium lamp for UV) may have reached the end of its life and needs replacement.

- Blocked Path: A cuvette with too high an absorbance or an object blocking the light path.

- Power Supply: In rare cases, a fault in the lamp's power supply or ignition circuit could be the cause.

Advanced Troubleshooting: Resolving Spectral Performance Issues

Table 4: Advanced Troubleshooting Guide for Spectral Fidelity

| Problem | Potential Causes | Diagnostic Steps | Solutions |

|---|---|---|---|

| Unexpected/High Noise | 1. Slit width too narrow [1].2. Lamp aging [7].3. Dirty optics or cuvette [7].4. Low source power (faulty power supply). | 1. Check noise level across a flat baseline region.2. Inspect lamp hours and energy output.3. Visually inspect and clean optics/cuvettes. | 1. Slightly increase slit width to improve SNR [1].2. Replace lamp [8].3. Clean components with recommended solvents.4. Contact technical service. |

| Poor Resolution (Cannot distinguish close peaks) | 1. Slit width too wide [1] [3].2. Incorrect sampling interval (larger than spectral bandwidth) [1].3. Instrument optical misalignment. | 1. Measure a standard with known fine structure (e.g., holmium oxide filter).2. Review and adjust data interval in method settings. | 1. Reduce slit width to the minimum practical for required SNR [1].2. Set sampling interval ≤ spectral bandwidth [1].3. Perform instrument qualification/service. |

| Photometric Inaccuracy (Absorbance too low) | 1. Spectral bandwidth too large relative to natural bandwidth (violates 10% rule) [1] [4].2. Stray light [3].3. Instrument requires calibration. | 1. Compare absorbance of a narrow-band standard at different slit widths.2. Perform a stray light test (e.g., with NiSO₄ or KCl solutions). | 1. Narrow the slit width to achieve a spectral bandwidth ≤ 10% of natural peak width [2] [4].2. Identify and eliminate source of stray light; service instrument.3. Perform full photometric accuracy calibration. |

Core Concepts: Slit Width and Its Impact on Spectrometer Performance

In a dispersive UV-Vis spectrophotometer, the slit is a critical adjustable aperture that controls the amount of light entering and exiting the monochromator. Its primary function is to govern both the spectral resolution and the intensity of light reaching the detector, creating a fundamental trade-off that researchers must manage [10] [11].

The width of the slit directly determines the spectral bandpass—the range of wavelengths that simultaneously pass through to the sample and detector. A narrower slit allows for a smaller bandpass, yielding higher spectral resolution and the ability to distinguish fine spectral details. Conversely, a wider slit increases the bandpass, which can obscure closely spaced peaks but allows significantly more light to pass through the system [10] [11].

The effect on light intensity is profound. As the slit width increases, two factors combine to boost the total light throughput:

- The total slit area increases, allowing a greater spatial fraction of the light source to enter.

- The spectral bandpass increases, allowing a broader range of wavelengths from the continuum source to pass through [10].

These factors cause the light level incident on the sample to increase with the square of the slit width. This heightened intensity directly improves the Signal-to-Noise Ratio (SNR), but the exact relationship depends on the dominant type of noise in the measurement system [10].

Table 1: How Slit Width Affects Key Spectrometer Performance Parameters

| Performance Parameter | Narrow Slit Width | Wide Slit Width |

|---|---|---|

| Spectral Resolution | Higher (Fine details are visible) | Lower (Peak broadening occurs) |

| Light Throughput | Lower | Higher (Increases with the square of the width) |

| Photon-Noise-Limited SNR | Lower | Higher (SNR ∠Slit Width) |

| Detector-Noise-Limited SNR | Lower | Higher (SNR ∠(Slit Width)²) |

| Deviation from Beer's Law | Lower (More linear calibration) | Higher (Increased non-linearity) |

Experimental Protocols for Slit Width Optimization

Protocol: Establishing the Optimal Slit Width for a Given Absorber

This methodology provides a systematic approach for determining the slit width that offers the best balance of signal quality and spectral fidelity for a specific analytical application, such as quantifying a pharmaceutical compound [10].

Key Reagent Solutions:

- Standard Solution: A pure sample of the analyte dissolved in an appropriate solvent.

- Blank Solution: The solvent used to dissolve the analyte.

- Certified Reference Materials: (e.g., Holmium Oxide filters) for wavelength calibration [12].

Procedure:

- System Preparation: Turn on the UV-Vis spectrophotometer and allow the light source (deuterium and/or tungsten lamp) to warm up for the recommended time, typically 20-30 minutes, to ensure stable output [6].

- Wavelength Calibration: Calibrate the wavelength accuracy of the instrument using a certified reference material like a Holmium Oxide filter [12].

- Initial Spectral Scan: Prepare a standard solution of the target analyte at a concentration expected in actual samples. Using a narrow slit width (e.g., 0.5 nm), record a high-resolution absorption spectrum of the standard to identify the wavelength of maximum absorption (λ_max) and observe the natural width of the absorption band [10].

- Slit Width Series: Set the instrument to the λ_max identified in the previous step. Measure the absorbance of the standard solution while systematically increasing the slit width. Record the absorbance value and any observable peak broadening at each setting.

- Signal-to-Noise Assessment: For each slit width setting, take multiple rapid readings of the blank solution at λ_max. Calculate the standard deviation of these readings, which represents the noise (N). The signal (S) is the average absorbance of the standard. Compute SNR as S/N [10].

- Data Analysis: Plot SNR versus slit width and absorbance versus slit width. The optimal slit width is typically the point just before the absorbance value begins to significantly decrease due to excessive bandpass, while the SNR has reached an acceptably high plateau [10].

Protocol: Verifying Analytical Curve Linearity at Different Slit Widths

This experiment assesses whether the chosen slit width is suitable for quantitative analysis by testing the linearity of the Beer-Lambert law calibration curve [10] [12].

Procedure:

- Standard Preparation: Prepare a series of standard solutions of the analyte across the desired concentration range.

- Measurement: Using the slit width selected from Protocol 2.1, measure the absorbance of each standard solution at λ_max.

- Calibration Curve: Plot absorbance versus concentration and perform a linear regression analysis.

- Linearity Evaluation: Examine the R² value and the residuals of the fit. A sufficiently wide slit may cause negative deviations from linearity, especially at higher absorbances, due to the polychromaticity effect [10]. If non-linearity is observed (e.g., R² < 0.999), consider using a narrower slit width and repeat the validation, accepting a potential reduction in SNR for improved quantitative accuracy.

Table 2: Troubleshooting Guide for Slit Width-Related Issues in Pharmaceutical Analysis

| Problem | Potential Cause | Solution |

|---|---|---|

| Low Signal or Noisy Baseline | Slit width is too narrow for the application, or detector noise is dominant. | Gradually increase the slit width until an acceptable SNR is achieved. Ensure the light source is warmed up [6] [8]. |

| Poor Resolution of Overlapping Peaks | Slit width is too wide, causing spectral bandpass to be larger than the separation between peaks. | Reduce the slit width to improve resolution, even if it results in a noisier signal that may require averaging multiple scans [11] [13]. |

| Deviation from Beer's Law (Non-linearity) | Excessive spectral bandpass from a wide slit introduces polychromatic light, violating a core assumption of the Beer-Lambert law [10]. | Narrow the slit width. Ensure the spectral bandpass is ≤ 1/10th the full width at half maximum (FWHM) of the absorption peak [10]. |

| Inaccurate Absorbance Readings | Stray light, which can be exacerbated by very wide slit settings, is reaching the detector [12]. | Clean the instrument's optics, use high-quality cuvettes, and avoid using slit widths that push the instrument beyond its design limits. Perform a stray light test [13]. |

FAQs on Slit Width Optimization

Q1: What is the single most important rule for choosing a slit width? There is no universal rule, as the optimal setting depends on your analytical goal. For recording an accurate absorption spectrum (e.g., for identity testing), prioritize resolution by using a narrow slit. For quantitative analysis where high SNR is critical for low-concentration detection, a wider slit is often preferable, provided it does not introduce significant non-linearity in the calibration curve [10].

Q2: How does the choice of slit width impact the analysis of pharmaceutical formulations? Excipients and degradation products in formulations can create complex, overlapping spectra. A narrow slit width is essential to resolve the analyte's peak from these interferences. Furthermore, for dissolution testing or assaying high-potency drugs where samples are highly diluted, a wider slit can enhance SNR and lower the limit of detection [10] [12].

Q3: My readings are noisy, but when I widen the slit, the absorbance of my standard changes. What should I do? A change in absorbance with slit width indicates your spectral bandpass is too wide relative to your analyte's absorption band, leading to a deviation from the Beer-Lambert law. You have reached a practical limit. Instead of widening the slit further, improve SNR by other means, such as increasing the source integration time, using a cuvette with a longer pathlength, or concentrating your sample [10] [12].

Q4: How often should I check or calibrate the slit width mechanism on my instrument? While the slit width setting itself doesn't typically require user calibration, the overall performance of the spectrophotometer should be verified regularly. Follow a quality control procedure that includes checks for wavelength accuracy, absorbance accuracy, and stray light using certified reference materials. Significant drifts in these parameters could indicate issues with the optical path, including the slits [12] [8].

Decision Pathways and Workflows

The following diagram illustrates the logical decision process for optimizing slit width based on analytical objectives:

The Scientist's Toolkit: Essential Materials for UV-Vis Spectroscopic Analysis

Table 3: Key Research Reagents and Materials for Pharmaceutical UV-Vis Analysis

| Item | Function / Explanation |

|---|---|

| Quartz Cuvettes | Provide high transmission of UV and visible light. Essential for accurate absorbance measurements below ~350 nm where plastic or glass absorbs strongly [6]. |

| Certified Reference Materials (CRMs) | Holmium Oxide solution or filters are used for wavelength calibration. Neutral density filters or potassium dichromate solutions can be used for absorbance accuracy verification [12]. |

| High-Purity Solvents | Spectroscopic-grade solvents (e.g., methanol, acetonitrile, water) with low UV absorbance are crucial to minimize background noise and avoid masking the analyte's signal [12] [13]. |

| Neutral Density Filters | Used to attenuate light source intensity without shifting its spectral composition. Helpful in diagnostics and for verifying detector linearity [14]. |

| Syringe Filters (0.45 µm or 0.2 µm) | Used to filter sample solutions immediately before analysis to remove particulates or micro-bubbles that cause light scattering, a common source of error and noise [12] [13]. |

| Antidepressant agent 1 | Antidepressant agent 1, MF:C16H19BrN2, MW:319.24 g/mol |

| Galanthamine hydrobromide | Galanthamine hydrobromide, CAS:69353-21-5, MF:C17H22BrNO3, MW:368.3 g/mol |

Theoretical Foundations: How Slit Width Influences Key Analytical Parameters

The Fundamental Relationship Between Slit Width and Spectrophotometer Performance

In UV-Vis spectrophotometry, the slit width is a crucial mechanical or software-controlled parameter that directly governs the bandwidth of light reaching the sample. This width represents a fundamental compromise in analytical performance, creating an inverse relationship between signal-to-noise ratio (sensitivity) and spectral resolution.

- Wider Slits allow more light to pass through the system, which increases the signal intensity at the detector and improves the signal-to-noise ratio. This enhancement typically leads to improved sensitivity and lower limits of detection (LOD). However, this comes at the cost of spectral resolution, as wider slits can cause adjacent spectral peaks to merge, potentially reducing the linear dynamic range at higher concentrations due to the Beer-Lambert law deviation [15].

- Narrower Slits provide higher spectral resolution by permitting a narrower band of wavelengths to interact with the sample. This is critical for distinguishing between analytes with close absorbance maxima or for obtaining fine spectral details for qualitative identification. The trade-off is reduced light throughput, which can increase baseline noise, potentially raising the LOD and limiting the lower end of quantification (LOQ) [15].

Table 1: Primary Effects of Slit Width Adjustment on Analytical Figures of Merit

| Analytical Figure of Merit | Effect of Wider Slit | Effect of Narrower Slit |

|---|---|---|

| Signal-to-Noise Ratio | Increases | Decreases |

| Spectral Resolution | Decreases | Increases |

| Limit of Detection (LOD) | Generally Lowers | May Increase |

| Limit of Quantification (LOQ) | Generally Lowers | May Increase |

| Linearity Range | May narrow at high concentrations | Can be preserved or improved |

Interaction with Data Sampling and Signal Processing

The effect of slit width is further modulated by instrument settings for data acquisition. A faster data sampling rate captures more data points across a chromatographic or spectral peak, improving its modeling and reproducibility. However, this can also capture more high-frequency noise. The time constant (or response time) acts as an electronic filter to smooth this noise. Finding the optimal balance is key; excessively fast sampling with inadequate filtering can degrade the signal-to-noise ratio, indirectly impacting the perceived LOD and LOQ [15].

Troubleshooting Guide: Slit Width Optimization FAQs

This section addresses common practical challenges faced by researchers when configuring slit width for pharmaceutical applications.

FAQ 1: How should I systematically adjust the slit width to lower the detection limit for a trace impurity?

Challenge: The current method lacks the sensitivity to detect and quantify a low-concentration degradation product.

Solution: Implement a systematic optimization protocol.

- Baseline Measurement: Begin with the current slit width setting and record the baseline noise over a region where no analyte elutes.

- Incremental Widening: Gradually increase the slit width in small steps. At each step, inject a standard at a concentration near the expected LOD.

- Signal-to-Noise Calculation: For each injection, calculate the signal-to-noise (S/N) ratio by dividing the analyte peak height by the amplitude of the baseline noise.

- Identify Optimum: The optimal slit width for the lowest LOD is the point at which the S/N ratio is maximized. Further widening may decrease resolution without meaningful S/N gain [15].

Precaution: Continuously monitor the resolution between the impurity peak and the main API peak. A wider slit might cause co-elution, leading to inaccurate quantification.

FAQ 2: Why did my calibration curve become non-linear after I changed the slit width to improve sensitivity?

Challenge: A wider slit setting, intended to improve LOD, has caused deviation from the Beer-Lambert law at higher concentrations.

Root Cause: Excessively wide slit widths can introduce stray light or cause a phenomenon known as "bandwidth error." If the slit's spectral bandwidth becomes a significant fraction of the natural width of the analyte's absorption band, the relationship between absorbance and concentration ceases to be linear, particularly at higher absorbances [16] [15].

Solution:

- Re-optimize: Slightly narrow the slit width until linearity is restored across your required concentration range. The ideal width provides sufficient sensitivity while maintaining a correlation coefficient (R²) of ≥ 0.999 for the calibration curve.

- Validate the Method: After selecting the new slit width, perform a full validation of the method's linearity, as per ICH guidelines, to ensure it meets the criteria for your intended application [17] [18].

FAQ 3: How do I balance slit width with data sampling rate to get the best peak shape and lowest LOQ in USP/UHPLC methods?

Challenge: Modern high-efficiency separations with UHPLC produce very narrow peaks, requiring careful instrument settings to prevent data loss and maintain low LOQs.

Solution: Integrate the optimization of slit width with data acquisition parameters.

- Set Sampling Rate First: Ensure your detector's data sampling rate is fast enough to capture at least 20-25 data points across the narrowest peak of interest. This is critical for accurate peak integration and quantification [15].

- Adjust Slit Width for Sensitivity: Widen the slit to improve S/N, as previously described.

- Apply Time Constant/Filtering: If a faster sampling rate introduces excessive high-frequency noise, use the instrument's time constant (or digital filtering) to smooth the baseline. The goal is to reduce noise without distorting the peak shape. A slightly wider slit can sometimes allow for the use of a lighter filter, preserving peak fidelity [15].

Table 2: Troubleshooting Guide for Common Slit Width-Related Issues

| Problem | Potential Root Cause | Corrective Action |

|---|---|---|

| High Baseline Noise | Slit width too narrow for the application. | Gradually increase slit width while monitoring the signal-to-noise ratio of a low-level standard. |

| Poor Resolution of Co-eluting Peaks | Slit width is too wide, reducing spectral resolution. | Narrow the slit width to improve peak separation; consider alternative wavelengths for greater specificity. |

| Loss of Linearity at High Concentrations | Bandwidth error or stray light from an excessively wide slit. | Slightly narrow the slit width and re-establish the calibration curve. |

| Poor Reproducibility of Integration | Inconsistent peak shape due to suboptimal slit width/data rate combination. | Optimize slit width for a stable baseline, then ensure a sufficiently high data sampling rate (>20 pts/peak). |

Experimental Protocols for Method Development and Validation

Protocol for Establishing the Linear Range and Determining LOD/LOQ

This protocol provides a step-by-step guide for validating the key figures of merit during method development, incorporating slit width as a critical variable.

Principle: A series of standard solutions are analyzed to construct a calibration curve. The linearity, sensitivity, and precision of the method are evaluated statistically. The standard deviation of the response and the slope of the calibration curve are used to determine LOD and LOQ [17] [19].

Materials & Reagents:

- API Reference Standard: Certified material of high and known purity.

- Appropriate Solvent: HPLC-grade or spectrophotometric-grade solvent that does not interfere with the analysis [16].

- Volumetric Flasks: Class A, for accurate preparation of standard solutions.

- UV-Vis Spectrophotometer or HPLC-UV System: Calibrated and with controllable slit width.

Procedure:

- Stock Solution Preparation: Accurately weigh and dissolve the API reference standard to prepare a stock solution of known concentration (e.g., 1000 μg/mL).

- Working Standard Dilutions: Dilute the stock solution serially to prepare at least 5-6 standard solutions covering the expected working range (e.g., from 50% to 150% of the target assay concentration).

- System Optimization: Set the initial slit width based on instrument recommendations or prior knowledge. Analyze the standards.

- Analysis: Measure the absorbance (or peak area) for each standard solution. Perform replicate measurements (n=3) to assess precision.

- Data Analysis:

- Linearity: Plot the mean response (y-axis) against concentration (x-axis). Calculate the regression equation (y = mx + c) and the correlation coefficient (R²). A value of ≥ 0.999 is typically expected for quantitative assays.

- LOD and LOQ Calculation: Calculate using the formulas based on the standard deviation of the response (σ) and the slope (S) of the calibration curve.

- Iterative Optimization: Repeat steps 3-5 with different slit widths to find the setting that provides the best combination of linearity (R²), low LOD/LOQ, and acceptable signal-to-noise.

Case Study: Simultaneous Determination of Atorvastatin and Aspirin

A published study on the development of a first-derivative synchronous fluorometric method for Atorvastatin (ATO) and Aspirin (ASP) exemplifies the rigorous validation of figures of merit, principles that are directly transferable to slit width optimization in UV-Vis.

Methodology:

- Technique: First-derivative synchronous fluorescence spectroscopy (FDSFS) was used to resolve the spectral overlap of the two drugs.

- Optimization: Parameters influencing fluorescence intensity, including spectral scanning speed and data interval (conceptually analogous to sampling rate in UV-Vis), were optimized for enhanced sensitivity and selectivity [17].

Validation Results:

- Linearity: Excellent linearity was demonstrated over defined ranges (0.4–6 μg/mL for ATO and 1–10 μg/mL for ASP) with high correlation coefficients.

- Sensitivity: The method achieved low LOD (0.03 μg/mL for ATO, 0.342 μg/mL for ASP) and LOQ (0.248 μg/mL for ATO, 0.714 μg/mL for ASP), confirming its suitability for trace analysis [17].

This case study underscores that systematic optimization of instrumental parameters is fundamental to achieving robust analytical figures of merit for pharmaceutical assays.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table lists key materials and reagents critical for successfully conducting experiments related to method development and validation as discussed in this guide.

Table 3: Key Research Reagent Solutions for Pharmaceutical UV-Vis Analysis

| Reagent/Material | Function/Application | Critical Quality Attributes |

|---|---|---|

| Certified Reference Standards | Used for accurate preparation of calibration standards to establish method linearity, LOD, and LOQ [17] [19]. | High purity (>98%), certified concentration, and stability. |

| HPLC-Grade Solvents | Used for dissolving samples and standards, and as mobile phase components. Minimizes background UV absorption and interference [16]. | Low UV cutoff, high purity, free of particulate matter. |

| Holmium Oxide Filter | A wavelength verification standard for calibrating the spectrophotometer, ensuring accuracy of the absorbance maxima used for quantification [16]. | NIST-traceable certification. |

| Quartz Cuvettes | Sample holders for UV-Vis measurement. Quartz is transparent across the UV and visible range. | Matched path length, clear optical surfaces without scratches. |

| Buffer Components | Used to prepare mobile phases or sample solutions at controlled pH, which can affect analyte stability and spectral properties [17]. | Analytical grade, low UV absorbance. |

| Monomethyl lithospermate | Monomethyl lithospermate, MF:C28H24O12, MW:552.5 g/mol | Chemical Reagent |

| Cyclopentolate Hydrochloride | Cyclopentolate Hydrochloride, CAS:60452-44-0, MF:C17H26ClNO3, MW:327.8 g/mol | Chemical Reagent |

Ultraviolet-Visible (UV-Vis) spectroscopy is an indispensable analytical technique in pharmaceutical research and drug development. This method measures how molecules absorb light across the ultraviolet and visible regions of the electromagnetic spectrum (typically 100-900 nm), providing critical insights into molecular structure, concentration, purity, and functional groups. The resulting spectrum reveals electronic transitions within a molecule, enabling researchers to identify compounds, quantify active pharmaceutical ingredients (APIs), and assess sample quality. Within this field, the choice of spectrophotometer configuration—single-beam, double-beam, or array detector system—profoundly impacts data quality, analytical throughput, and method robustness. Furthermore, instrumental parameters such as slit width require careful optimization to balance spectral resolution and signal-to-noise ratio, a consideration particularly crucial for regulatory-compliant pharmaceutical applications where data integrity is paramount.

Comparative Analysis of Spectrophotometer Configurations

The core configurations of UV-Vis spectrophotometers differ fundamentally in their optical designs, each presenting distinct advantages and limitations for pharmaceutical analysis.

Single-Beam Systems

Operating Principle: Single-beam instruments utilize a single light path that passes sequentially through the reference and sample. The instrument first measures the intensity of the incident light (Iâ‚€) with the reference blank in place, then replaces the blank with the sample to measure the transmitted light (I). Absorbance is calculated as A = log(Iâ‚€/I).

Characteristics and Pharmaceutical Applications:

- Advantages: Simpler optical design often translates to lower cost, higher light throughput, and potentially higher sensitivity due to fewer optical components. This can be beneficial for detecting low-concentration impurities.

- Limitations: Susceptible to source drift because any fluctuation in the lamp intensity between the Iâ‚€ and I measurements directly affects the calculated absorbance. This requires regular recalibration and stable power conditions.

- Typical Pharmaceutical Use: Best suited for quantitative single-wavelength assays (e.g., content uniformity testing, dissolution profiling at a fixed wavelength) where high throughput and cost-effectiveness are prioritized, and environmental conditions are well-controlled.

Double-Beam Systems

Operating Principle: Double-beam instruments employ a beam splitter or chopper to create two synchronous light paths: one through the sample and another through a reference blank. The detector measures both beams almost simultaneously, continuously rationing the intensities to calculate absorbance in real-time.

Characteristics and Pharmaceutical Applications:

- Advantages: Excellent stability and compensation for source drift, fluctuations in power supply, and electronic noise. This enhances long-term measurement reliability and is ideal for kinetic studies and spectral scanning.

- Limitations: More complex optics, typically higher cost, and reduced light throughput compared to single-beam systems due to the beam-splitting mechanism.

- Typical Pharmaceutical Use: Ideal for applications requiring high stability, such as full spectral scans for identity testing, kinetic reaction monitoring (e.g., enzyme activity assays), and any analysis where environmental fluctuations may be a concern.

Array Detector (Diode Array) Systems

Operating Principle: Instead of a monochromator before the sample, these systems use a polychromatic light source that passes through the sample first. The transmitted light is then dispersed onto a fixed array of hundreds of individual photodiodes, allowing for simultaneous detection of all wavelengths.

Characteristics and Pharmaceutical Applications:

- Advantages: Extremely fast acquisition (complete spectra in milliseconds), enabling real-time monitoring of fast reactions (e.g., stopped-flow kinetics) and HPLC detection. Offers high reproducibility as there are no moving mechanical parts in the monochromator.

- Limitations: Generally has lower resolution compared to high-quality scanning monochromators and a typically lower dynamic range. The light source's spectral output can also affect the signal-to-noise ratio across the wavelength range.

- Typical Pharmaceutical Use: Perfect for hyphenated techniques like HPLC-DAD (Diode Array Detection) for peak purity assessment, monitoring rapid reaction kinetics, and quality control environments requiring very high throughput.

Table 1: Quantitative Comparison of UV-Vis Spectrophotometer Systems

| Feature | Single-Beam | Double-Beam | Array Detector |

|---|---|---|---|

| Measurement Speed | Slow (sequential) | Moderate (rapid alternation) | Very Fast (simultaneous) |

| Stability / Drift Correction | Poor | Excellent | Good |

| Wavelength Selection | Sequential scanning | Sequential scanning | Simultaneous all wavelengths |

| Mechanical Complexity | Low | High | Moderate |

| Typical Cost | Low | High | Moderate to High |

| Best for Pharmaceutical Applications | Routine quantitative analysis at fixed wavelength | High-precision scanning, kinetics, R&D | HPLC detection, fast kinetics, process monitoring |

The Critical Role of Slit Width Optimization

The slit width is a crucial yet often overlooked parameter in UV-Vis spectroscopy. It controls the bandwidth of light that passes through the sample and enters the detector, directly influencing two key, competing spectral properties: resolution and signal-to-noise ratio.

How Slit Width Works: A narrower slit allows a smaller, more monochromatic band of light to pass, resulting in higher spectral resolution. This means you can distinguish between two closely spaced absorption peaks. Conversely, a wider slit permits a broader band of light to pass, which delivers more light energy to the detector, thereby increasing the signal-to-noise ratio and reducing spectral noise.

The Trade-Off: The relationship between slit width and data quality is a fundamental trade-off. Excessively narrow slits can lead to excessive noise, making it difficult to discern true absorption peaks. On the other hand, overly wide slits can cause a loss of spectral detail, including broader peaks and lower peak heights, as the instrument can no longer resolve fine spectral features. In extreme cases, a slit width equal to or larger than the natural width of an absorption band (Full Width at Half Maximum, or FWHM) will lead to inaccurate, lower absorbance measurements and poorly resolved bands [3].

Table 2: Effect of Slit Width on Spectral Data

| Slit Width Setting | Spectral Resolution | Signal-to-Noise Ratio | Peak Shape & Height | Ideal Application Context |

|---|---|---|---|---|

| Narrow (e.g., 1 nm) | High (sharp peaks) | Low (more noise) | Accurate height and fine structure preserved | Identifying sharp peaks, analyzing complex mixtures with overlapping bands |

| Wide (e.g., 5 nm) | Low (broad peaks) | High (less noise) | Peaks are broader and may have lower apparent height | Quantitative analysis of a single, well-resolved peak, analyzing low-absorbance samples |

Optimization for Pharmaceutical Applications: For most quantitative pharmaceutical analyses (e.g., API concentration determination via Beer-Lambert Law), a primary goal is a high signal-to-noise ratio. Therefore, the slit width should be opened as wide as possible without causing a significant loss in the definition of the absorbance peak being measured. A practical protocol is to perform a slit-width scan on a standard solution: start with a narrow slit and gradually increase the width while monitoring the peak shape and the baseline noise. Choose the widest slit width where the peak height and width remain constant, ensuring robust and reproducible quantitative results.

Troubleshooting Guide: FAQs on Instrument-Specific Issues

Q: My spectrophotometer is giving very noisy or unstable absorbance readings, particularly at higher absorbance values (above 1.0). What could be the cause?

A: Noisy data can stem from several instrument-specific and methodological factors.

- Instrument Check: For single-beam systems, ensure the lamp has warmed up sufficiently (typically 20-30 minutes for tungsten halogen or arc lamps) to stabilize [6]. Verify that the instrument is set to an appropriate integration time or scan speed; slowing down the measurement can improve the signal-to-noise ratio.

- Methodology Check: Adhere to the ideal absorbance range. Absorbance readings often become unstable and non-linear above 1.0 due to instrumental limitations like stray light [20] [21]. If your sample is too concentrated, dilute it to bring the absorbance at λmax between 0.1 and 1.0 for reliable quantitative analysis [21]. Ensure your cuvettes are clean and free of scratches, and that the sample is fully dissolved and free of particles that could scatter light.

Q: Why won't my spectrometer calibrate, or why does it show an error like 'Calibration Failed'?

A: Calibration failures are often related to fundamental setup issues.

- Procedure: Remember that you must calibrate the spectrometer (using an appropriate blank solvent) every time you use it in Absorbance or Transmittance mode [20].

- Blank Issues: Ensure the blank cuvette is perfectly clean and made of the correct material (e.g., quartz for UV work). The blank must be compatible with the solvent and not absorb in the wavelength range you are using. Confirm that the blank is properly positioned in the beam path.

- Instrument Health: A failing or cold light source can prevent successful calibration. Allow the lamp to warm up and listen for any unusual sounds. In severe cases, the lamp may need replacement.

Q: I am seeing unexpected peaks in my spectrum. How should I investigate this?

A: Unexpected peaks are most frequently related to sample or cuvette contamination.

- Contamination Investigation: Thoroughly clean your cuvettes using a recommended protocol. Handle cuvettes only with gloves to avoid fingerprint oils [6]. Check your solvents and reagents for purity, as contaminants or degraded solvents can introduce new chromophores.

- Solvent Interference: Verify that your solvent does not absorb significantly in the wavelength range you are scanning. For example, acetone absorbs strongly in the UV region and can obscure sample absorption below ~330 nm [21].

Q: What is the impact of resolution (slit width) on my spectral results for a pharmaceutical compound?

A: As detailed in Section 3, the slit width has a direct impact.

- Too Wide: A slit width set too large will broaden your absorption peaks and can decrease the measured peak height. This lack of resolution can hide the fine structure of a peak and make it impossible to distinguish between two closely eluting compounds in a mixture, which is critical for peak purity assessment [3].

- Too Narrow: A very narrow slit provides high resolution but reduces the light energy reaching the detector, resulting in a noisier spectrum that can mask low-intensity features.

- Action: Always justify and document the slit width used in your standard operating procedures (SOPs) for regulatory purposes.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Their Functions in Pharmaceutical UV-Vis Analysis

| Item | Function & Importance | Technical Notes |

|---|---|---|

| Quartz Cuvettes | Sample holder for liquid analysis. Quartz is essential for UV range measurements (below ~350 nm) as glass and plastic absorb UV light. | Reusable; handle with gloves; ensure pathlength (e.g., 1 cm) is appropriate for concentration [20] [6]. |

| Optically Matched Cuvettes | A matched pair for double-beam instruments. | Critical for accurate blank subtraction; eliminates errors from slight differences in cuvette transmission [21]. |

| High-Purity Solvents | To dissolve the analyte and serve as the blank matrix. | Must be "spectroscopic grade" to ensure low UV absorption and avoid introducing contaminant peaks [21]. |

| Standard Reference Materials | Certified reference materials of the target analyte. | Used for validation of the method, calibration curve creation, and verifying instrument performance [21]. |

| Cuvette Cleaning Kit | Solutions and tools for proper cuvette cleaning. | Prevents cross-contamination between samples; essential for data integrity. |

| Phorbol 12,13-Dibutyrate | Phorbol 12,13-Dibutyrate, CAS:61557-88-8, MF:C28H40O8, MW:504.6 g/mol | Chemical Reagent |

| 2-(Morpholin-4-yl)ethane-1-sulfonamide | 2-(Morpholin-4-yl)ethane-1-sulfonamide, MF:C6H14N2O3S, MW:194.25 g/mol | Chemical Reagent |

Experimental Workflow and Decision Logic

The following diagram illustrates the logical workflow for selecting and utilizing a UV-Vis system for pharmaceutical analysis, incorporating key considerations like slit width optimization and troubleshooting.

Diagram 1: UV-Vis Analysis Workflow

Strategic Slit Width Selection for Chemometric and Multicomponent Analysis

Technical FAQ: Resolving Spectral Overlap

Question: What are the primary spectrophotometric methods for resolving severely overlapping spectra of co-administered antiviral drugs like Remdesivir (RDV) and Moxifloxacin (MFX)?

Several sophisticated mathematical spectrophotometric techniques have been successfully developed and validated to resolve the significant spectral overlap between RDV and MFX without requiring preliminary separation. These methods enable accurate, simultaneous quantification in pharmaceutical dosage forms and spiked human plasma [22].

Key Methodologies and Their Parameters:

Table 1: Spectrophotometric Methods for Resolving RDV and MFX Spectral Overlap

| Method Name | Underlying Principle | Key Analytical Wavelengths | Measured Parameter |

|---|---|---|---|

| Ratio Derivative (1DD) [22] | Derivative of the ratio spectrum of the mixture using a standard divisor. | RDV: 250 nm, MFX: 290 nm | Amplitude of the first derivative of the ratio spectrum |

| Ratio Difference (RD) [22] | Difference in amplitudes at two carefully selected wavelengths in the ratio spectrum. | RDV: 247 nm & 262 nm, MFX: 299 nm & 313 nm | Difference in peak amplitudes (ΔP) |

| Mean Centering (MC) [22] | Mathematical transformation of the ratio spectrum to a mean-centered form. | RDV: 247 nm, MFX: 299 nm | Mean-centered value |

| Area Under the Curve (AUC) [22] | Calculation of the area under the zero-order spectrum for two selected wavelength ranges. | Ranges: 243–248 nm & 290–300 nm | Area under the curve (AUC) |

| Absorbance Subtraction (AS) [23] | Uses an absorbance factor and the isoabsorptive point to mathematically separate contributions. | 229 nm (λiso) & 360 nm | Absorbance at isoabsorptive point |

Question: How does spectral bandwidth (slit width) impact the accuracy of these multicomponent analyses?

The spectral bandwidth of a spectrophotometer, determined by its physical slit width, is a critical parameter that directly affects resolution and accuracy [24].

- Narrower Bandwidth (Smaller Slit Width): Provides higher spectral resolution, which is essential for accurately distinguishing between the closely overlapping peaks of drugs like RDV and MFX. This leads to more precise results when applying mathematical techniques like ratio derivative or ratio difference [24].

- Wider Bandwidth (Larger Slit Width): Allows more light to reach the detector, which can be beneficial for signal-to-noise ratio in some cases, but at a cost. It can lower resolution and accuracy, particularly for samples with sharp, overlapping absorption peaks, by effectively "averaging" the absorbance over a wider range of wavelengths [24].

For the quantitative determination of overlapping drugs, the instrument's spectral bandwidth should be optimized and kept below the width of the spectral peaks of the analytes to ensure accurate measurement of their true extinction coefficients [24].

Experimental Protocol: Implementing the Ratio Difference Method

This protocol provides a step-by-step guide for the simultaneous determination of Remdesivir (RDV) and Moxifloxacin (MFX) using the Ratio Difference method, as derived from the literature [22].

Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Item | Specification / Function |

|---|---|

| Remdesivir (RDV) & Moxifloxacin (MFX) Standards | High purity (e.g., 99.15% and 99.45% respectively) for calibration [22]. |

| Methanol | HPLC/spectroscopic grade, used as the solvent [22] [23]. |

| Volumetric Flasks | Class A, for precise preparation of standard and sample solutions. |

| UV-Vis Spectrophotometer | Equipped with 10 mm quartz cells and software for spectral manipulation (e.g., Shimadzu UV-1800) [22] [23]. |

| Ultrasonic Bath | To ensure complete dissolution of standards and samples. |

Step-by-Step Procedure:

Preparation of Standard Stock Solutions: Accurately weigh and dissolve 100 mg each of RDV and MFX pure powders separately in 70 mL methanol. Sonicate for 15 minutes and dilute to 100 mL with methanol to obtain 1000 µg/mL stock solutions. Further dilute these stocks with methanol to prepare 100 µg/mL working standard solutions [22].

Construction of Calibration Curves:

- Into a series of 10 mL volumetric flasks, transfer aliquots of RDV working standard solution to produce final concentrations of 1–15 µg/mL.

- Similarly, prepare a separate series for MFX with final concentrations of 1–10 µg/mL.

- Dilute all flasks to the mark with methanol.

- Record the zero-order absorption spectra (200–400 nm) of all solutions against a methanol blank [22].

Optimization of Divisor Concentration:

- To select the optimal concentration for the divisor spectrum, test different concentrations of one drug (e.g., 6 µg/mL MFX) by dividing the spectrum of the other drug (RDV) by them. The divisor that produces a clean ratio spectrum with minimal noise is selected [22].

Processing of Ratio Spectra and Data Analysis:

- Using the instrument software, divide the stored zero-order spectra of all RDV standard solutions by the spectrum of the optimized MFX divisor (e.g., 6 µg/mL). This generates the ratio spectra for RDV.

- Similarly, divide the spectra of all MFX standard solutions by the spectrum of the optimized RDV divisor (e.g., 8 µg/mL) [22].

- For RDV, measure the amplitudes of its ratio spectrum at 247 nm and 262 nm.

- For MFX, measure the amplitudes of its ratio spectrum at 299 nm and 313 nm.

- For each drug, plot the difference in amplitudes (ΔP) between the two selected wavelengths against its corresponding concentration to establish the calibration curve and regression equation [22].

Analysis of Laboratory-Prepared Mixtures or Samples:

- Prepare mixtures of RDV and MFX in known ratios in 10 mL volumetric flasks and dilute to volume with methanol.

- Record the zero-order spectrum of the mixture.

- Process the mixture spectrum using the exact same divisors and wavelengths established in the calibration steps.

- Use the regression equations to calculate the concentration of each drug in the mixture from the measured ΔP values [22].

The logical workflow for the entire experiment, from setup to analysis, is summarized below.

Troubleshooting Guide: Common Issues and Solutions

Problem: Poor reproducibility and high noise in ratio spectra.

- Potential Cause 1: Inconsistent or non-optimized divisor concentration.

- Potential Cause 2: Excessive spectral bandwidth (slit width) leading to poor resolution.

- Solution: Reduce the spectrophotometer's slit width to achieve a narrower spectral bandwidth. This improves the resolution of fine spectral features, which is critical for mathematical methods [24].

- Potential Cause 3: Stray light within the instrument, especially critical at high absorbance values.

- Solution: Ensure the instrument is well-maintained. Use appropriate pathlengths or dilute samples to keep absorbance readings within the validated linear range of the method and instrument [24].

Problem: Inaccurate quantification of one drug in the presence of the other.

- Potential Cause 1: Wavelength selection not optimal for the specific method.

- Solution: Re-investigate the ratio spectra to confirm the selected wavelength pairs (for Ratio Difference) or the single wavelength (for Mean Centering) show a linear and significant change with concentration while being insensitive to the other component [22].

- Potential Cause 2: Significant matrix interference from excipients or plasma components.

- Solution: The proposed methods have been applied to spiked human plasma. If interference is suspected, ensure the sample preparation procedure (e.g., protein precipitation, dilution) is followed precisely as validated. The use of multiple mathematical techniques (e.g., Ratio Difference and Mean Centering) can serve as a cross-check [22].

Why is slit width so critical in UV-Vis method development?

Slit width directly controls the bandwidth of light reaching your sample. This creates a fundamental trade-off: a narrower slit provides better spectral resolution, allowing you to distinguish between closely spaced absorbance peaks, while a wider slit increases light throughput, improving the signal-to-noise ratio and detector sensitivity for more reliable quantification of low-concentration analytes [16]. Optimizing this balance is essential for developing a robust analytical method, particularly for complex pharmaceutical mixtures.

Troubleshooting Guide: Slit Width and Experimental Design FAQs

Q1: How do I systematically determine the optimal slit width for a new method? A1: Follow this structured protocol:

- Initial Setup: Use a standard solution of your target analyte at a mid-range concentration. Set the spectrophotometer to its default or median slit width setting [16].

- Spectral Scan: Perform a full spectral scan (e.g., 200-400 nm) of the standard to identify its maximum absorbance wavelength (λmax) [16].

- Iterative Testing: At the identified λmax, sequentially measure the absorbance of the standard using a range of slit widths, from the narrowest to the widest available on your instrument.

- Data Analysis: Plot the recorded absorbance against the slit width.

- Optimization Rule: Select the widest slit width that does not result in a significant decrease in measured absorbance. This point ensures maximum signal intensity without sacrificing the spectral detail required for accurate quantification [16].

Q2: My peaks are broad and poorly resolved. Could slit width be the cause? A2: Yes, this is a classic symptom of an inappropriately wide slit width. An overly wide slit passes a broader range of wavelengths, which can cause adjacent peaks to merge and reduce your method's ability to distinguish individual components in a mixture [16].

- Solution: Progressively narrow the slit width and observe the effect on your chromatogram. You should see peaks become sharper and better separated. Be aware that an excessively narrow slit will lead to a noisier baseline; the goal is to find a width that provides the best compromise between resolution and signal stability [16].

Q3: How does slit width interact with other factors in an Experimental Design (DoE)? A3: In a DoE, slit width is a critical instrumental factor that can interact with chemical and sample preparation variables. A robust method requires testing slit width in combination with other parameters.

Table: Key Factor Interactions for DoE

| Factor | Interaction with Slit Width | DoE Consideration |

|---|---|---|

| Analyte Concentration | Low concentrations may require wider slits for a detectable signal. | Treat as a critical response variable to model. |

| Sample Purity/Spectral Overlap | Complex mixtures with overlapping peaks need narrower slits for resolution. | A key constraint that defines the required resolution goal. |

| Solvent Type | Can influence baseline noise and spectral profile. | Include as a categorical factor in the design. |

| pH / Mobile Phase | Can shift λmax, altering the optimal slit condition. | Test slit width at different pH/phase levels to find a robust setting [5]. |

Q4: I've optimized the slit width, but now my baseline is too noisy. What should I do? A4: This indicates the slit may be too narrow, severely limiting light energy to the detector [16].

- Primary Action: Slightly widen the slit width until the baseline stabilizes to an acceptable level, even if it involves a minor loss in resolution.

- Supplementary Strategy: If possible, increase the concentration of your sample or use a cuvette with a longer path length to enhance the signal without adjusting the slit.

Q5: How can I use a factorial design to model the effect of slit width? A5: A screening design, such as a Two-Level Full or Fractional Factorial, is highly effective.

- Define Factors and Ranges: Select slit width (e.g., 1 nm vs. 2 nm), analyte concentration, and pH as your key factors.

- Set Responses: Define your measurable outputs, such as peak absorbance, signal-to-noise ratio, and peak width at half height (a measure of resolution).

- Run Experiments: Execute the experimental runs prescribed by the design matrix.

- Statistical Analysis: Use the results to build a model that quantifies how slit width and other factors individually and interactively affect the responses. This model will pinpoint the optimal, robust settings for your method [5].

Experimental Protocol: A DoE-Based Approach for Slit Width Optimization

This protocol provides a step-by-step methodology for integrating slit width optimization into a systematic experimental design.

1. Goal Definition To determine the optimal instrument slit width and its interactions with sample concentration for the quantification of [Active Pharmaceutical Ingredient] in [Matrix, e.g., tablet formulation] using UV-Vis spectrophotometry, ensuring maximum signal-to-noise ratio and acceptable spectral resolution.

2. Materials and Equipment

- UV-Vis Spectrophotometer (e.g., Shimadzu UV-1800 or equivalent) with adjustable slit width [5].

- Matched quartz cuvettes (10 mm path length) [16].

- High-purity reference standard of the analyte.

- HPLC-grade or spectrophotometric-grade solvent (e.g., ethanol) [5].

- Volumetric flasks, pipettes, and analytical balance.

- Statistical software for DoE analysis (e.g., Design Expert, MATLAB) [5].

3. Experimental Workflow

4. Step-by-Step Procedure

Step 1: Define Factors and Ranges. Based on initial scouting runs, select the factors and their levels for the DoE. A typical two-factor design is shown below:

Table: Two-Factor Experimental Design for Slit Width Optimization

| Factor | Low Level (-1) | High Level (+1) |

|---|---|---|

| Slit Width | 1.0 nm | 2.0 nm |

| Analyte Concentration | 10 μg/mL | 30 μg/mL |

Step 2: Prepare Stock and Working Standards.

- Accurately weigh and dissolve the reference standard to prepare a primary stock solution (e.g., 100 μg/mL) in the selected solvent [5].

- Serially dilute the stock solution to prepare working standards covering the concentration range defined in your DoE.

Step 3: Execute the DoE Runs.

- Using the standard solutions and the instrument settings (slit width) specified in your DoE run table, measure the absorbance at the predetermined λmax.

- For each run, also record the baseline signal over a short period (e.g., 60 seconds) to calculate the signal-to-noise ratio.

- Randomize the run order to minimize the impact of systematic error.

Step 4: Data Analysis and Modeling.

- Input the responses (Absorbance, S/N Ratio) into your statistical software.

- Fit the data to a model (e.g., a linear or quadratic model) and analyze the Variance (ANOVA) to identify significant factors and interactions.

- Use the software's optimization function to find the parameter settings (slit width and concentration) that jointly maximize absorbance and S/N ratio.

Step 5: Validation.

- Confirm the model's predictive power by preparing a new validation standard at the predicted optimal conditions and measuring its absorbance and S/N. The results should agree closely with the model's prediction.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table: Key Materials for UV-Vis Method Development and Slit Width Optimization

| Item | Function / Purpose | Critical Notes |

|---|---|---|

| Quartz Cuvettes | Holds sample for light absorption measurement. | Required for UV range below ~300 nm; ensure cleanliness and matched path length (e.g., 10 mm) for accuracy [16]. |

| Spectrophotometric-Grade Solvent | Dissolves analyte and serves as blank/reference. | High purity is essential to minimize background absorbance from impurities [16]. |

| Certified Reference Material (CRM) | Provides a known standard for instrument verification and calibration. | Used to validate method accuracy by comparing measured vs. known absorbance values [16]. |

| Holmium Oxide Filter | Validates wavelength accuracy of the spectrophotometer. | A critical tool for periodic instrument performance qualification [16]. |

| Pennogenin 3-O-beta-chacotrioside | Pennogenin 3-O-beta-chacotrioside, CAS:65607-37-6, MF:C45H72O17, MW:885.0 g/mol | Chemical Reagent |

| Sofosbuvir impurity F | Sofosbuvir impurity F, MF:C34H45FN4O13P2, MW:798.7 g/mol | Chemical Reagent |

Enhancing Machine Learning and Chemometric Models through Controlled Spectral Data

Troubleshooting Guides

Guide 1: Resolving Poor Model Performance Due to Suboptimal Spectral Resolution

Problem: Your machine learning model (e.g., PCA, PLS, SVM) is performing poorly, showing low classification accuracy or poor quantification in pharmaceutical analysis. This often manifests as an inability to distinguish between similar compounds or inconsistent results across different instruments.

Root Cause: The spectral data used to train the model was likely acquired with a non-optimal slit width, leading to incorrect resolution of spectral features [3] [1]. A slit width that is too wide can decrease spectral resolution, causing peaks to broaden and appear less intense, which directly alters the quantitative data the model learns from [3].

Solution: Optimize the Slit Width

- Understand Your Instrument: First, determine if your spectrophotometer is monochromator-based (slit width is often adjustable) or a diode-array system (spectral bandwidth is typically fixed) [1]. This guide primarily applies to monochromator-based systems.

- Determine the Natural Bandwidth: Find the full width at half maximum (FWHM) of the sharpest absorption peak of your active pharmaceutical ingredient (API). The natural bandwidth is the width of this absorption band at half of its maximum intensity [1].

- Apply the 0.1 Rule: For highly accurate absorbance measurements (99.5% or better), set the spectral bandwidth (determined by the slit width) to be one-tenth or less of the natural bandwidth of your sample's absorption peak [1].

- Balance with Signal-to-Noise (SNR): A narrower slit provides higher resolution but reduces the amount of light reaching the detector, which can increase noise [3] [1]. A wider slit increases light throughput and SNR but at the cost of resolution. You must find a balance where resolution is sufficient without the SNR degrading model performance.

- Set Sampling Interval: For digital data analysis, set the sampling interval (the wavelength step between data points) to be approximately equal to or slightly less than the spectral bandwidth to ensure proper digital resolution [1].

Verification: After optimization, collect spectra of a standard with known sharp peaks. The measured peak shapes and intensities should be consistent and reproducible. Retrain your model with data collected using this optimized slit width.

Guide 2: Addressing Inconsistent Results Between Different Instruments

Problem: A chemometric model developed on one UV-Vis instrument fails to produce accurate results when used with data from another instrument, even for the same pharmaceutical sample.

Root Cause: A primary reason for this inconsistency is that the two instruments were using different slit widths or have different fixed spectral bandwidths, leading to variations in the generated spectral profiles [1].

Solution: Standardize the Spectral Bandwidth

- Audit Instrument Specifications: Create a table for all instruments involved in method development and deployment. Document the instrument type (monochromator or diode-array) and its spectral bandwidth specification or available slit width settings [1].

- Align Bandwidths: For monochromator-based systems, adjust the slit widths to match the spectral bandwidth as closely as possible. If one instrument has a fixed, wider bandwidth, you may need to accept a lower ultimate resolution or develop a separate model calibrated for that specific instrument's characteristics.

- Use Certified Reference Materials (CRMs): Validate and correct for instrument-related variances by regularly running CRMs with known absorbance values and characteristic peaks [16]. The model can be adjusted if a consistent deviation is observed.

The following workflow outlines the core process for optimizing slit width to ensure high-quality spectral data for machine learning models:

Guide 3: Managing High Noise Levels in Spectral Data for Sensitive Analysis

Problem: Spectral data is too noisy, obscuring weak absorption signals and reducing the predictive power of chemometric models, particularly for low-concentration analytes.

Root Cause: The slit width may be set too narrow, severely limiting the light energy reaching the detector and thus lowering the signal-to-noise ratio (SNR) [3].

Solution: Optimize for Signal-to-Noise Ratio

- Widen the Slit: Systematically increase the slit width. A larger slit width allows more light to pass, which increases the signal intensity and improves the SNR [3] [1].

- Assess the Trade-off: Monitor the effect on spectral resolution. Widen the slit only until the noise is reduced to an acceptable level without causing significant broadening of your API's critical absorption peaks [3].

- Alternative Noise Reduction: If widening the slit degrades resolution unacceptably, consider:

Frequently Asked Questions (FAQs)

Q1: What is the difference between spectral bandwidth and slit width? A: Slit width is the physical width of the entrance slit to the monochromator, which controls the physical size of the light beam. Spectral bandwidth (SBW), often determined by the slit width and optical dispersion, is the width of the wavelength of light at half its maximum intensity (FWHM) exiting the monochromator. It is a measure of the instrument's resolution at a given setting [1].

Q2: How does slit width directly influence my machine learning model's accuracy? A: The slit width controls the resolution and the signal-to-noise ratio of your spectral data [3]. ML models learn from features within this data. Incorrect slit settings can:

- Suppress Peak Intensity: An overly wide slit can cause peaks to appear shorter and broader than they truly are, providing incorrect quantitative information to the model [3].

- Reduce Feature Separation: Overlapping peaks from excipients and APIs may not be resolved, preventing the model from identifying unique spectral fingerprints [3].

- Introduce Noise: An overly narrow slit can increase noise, obscuring subtle spectral features critical for accurate prediction [3].

Q3: My instrument is a diode-array spectrophotometer. Can I adjust its slit width? A: Typically, no. In diode-array instruments, the spectral bandwidth is a fixed property determined by the physical design and spacing of the diodes in the detector array. Users have less flexibility to adjust the resolution compared to monochromator-based systems [1].

Q4: For a general method in pharmaceutical analysis, what is a good starting point for slit width? A: While the optimal setting depends on your specific API's natural bandwidth, a common and safe starting point for many small-molecule drugs is a spectral bandwidth of 1-2 nm. However, this must be rigorously optimized and validated for your specific application, following the principles of the 0.1 rule [1].

Key Experimental Parameters for Slit Width Optimization

The table below summarizes the effects of slit width adjustments and provides guidance for method development.

Table 1: Slit Width Optimization Guide for Pharmaceutical Applications

| Slit Width Setting | Spectral Bandwidth | Impact on Resolution | Impact on Signal-to-Noise | Recommended Use Case |

|---|---|---|---|---|

| Narrow | Small | High: Can distinguish closely spaced peaks. | Low: Reduced light leads to more noise. [3] | Analysis of APIs with very sharp, distinct absorption bands. |

| Wide | Large | Low: Peaks broaden and merge; apparent peak height decreases. [3] | High: More light leads to a stronger, cleaner signal. [3] | Measuring low-concentration analytes or when analyzing broad, featureless peaks. |

| Optimized | Matched to sample (per 0.1 rule) | Sufficient for accurate quantification. | Adequate for reliable detection. | General-purpose pharmaceutical analysis; ensures data integrity for chemometric models. [1] |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Spectral Method Development

| Item | Function in Experiment | Critical Consideration |

|---|---|---|

| Holmium Oxide Filter | Verifies wavelength accuracy during instrument calibration to ensure peaks appear at their true known positions. [16] | Use certified reference materials. Essential for method validation and transfer. |

| Potassium Chloride (KCl) Solution | Used for stray light calibration in the UV range, ensuring low stray light levels for accurate high-absorbance measurements. [16] | Use high-purity, spectrophotometric-grade chemicals. |

| Certified Reference Materials (CRMs) | Validates the accuracy of both the instrument and the analytical method. Serves as a ground truth for machine learning models. [16] | Must have traceable certificates and cover the absorbance range of interest. |

| Quartz Cuvettes (10 mm path length) | Holds liquid samples for analysis. | Must be pristine; scratches or residues scatter light. Use for UV range measurements. [16] |

| Methyl protogracillin | Methyl protogracillin, MF:C52H86O23, MW:1079.2 g/mol | Chemical Reagent |

| Gemcitabine-O-Si(di-iso)-O-Mc | Gemcitabine-O-Si(di-iso)-O-Mc, MF:C24H36F2N4O7Si, MW:558.6 g/mol | Chemical Reagent |

FAQs: Troubleshooting Green UV-Vis Methods

FAQ 1: How can I reduce the volume of solvent consumed in my UV-Vis sample preparation?

- A: Several strategies can significantly reduce solvent use:

- Micro-volume Cuvettes: Use cuvettes with a smaller path length (e.g., 1 mm instead of 10 mm). This allows for accurate measurement of highly concentrated samples with a much smaller sample volume [6].

- Optimize Sample Concentration: Avoid using overly concentrated samples that require excessive dilution. For very high concentrations, a smaller path length cuvette can be used instead of dilution to bring the absorbance into the ideal range [6].

- Scale-Down Methods: When developing new methods, consider if the analysis can be miniaturized using microplates or specialized micro-volume accessories that require only a few microliters of sample.

FAQ 2: My baseline is unstable during a gradient HPLC-UV run, leading to poor quantification. How can I stabilize it using green principles?

- A: Baseline drift during gradient elution is often due to changing mobile phase composition and its refractive index. You can stabilize it without using additional solvents by:

- Setting a Reference Wavelength: Utilize the reference wavelength function on your diode array detector. Set the reference wavelength to a point where your analytes do not absorb (ensure absorbance is negligible, e.g., <0.1 mAu) but close to your signal wavelength. This compensates for fluctuations in lamp intensity and mobile phase background absorbance [15].

- Optimize Slit Width: A wider slit width allows more light to reach the detector, improving signal-to-noise ratio and baseline stability. However, this slightly reduces spectral resolution. Find a balance that provides a stable baseline without compromising necessary spectral detail [15].

FAQ 3: I am getting unexpected peaks in my UV-Vis spectrum. What are the most common causes related to sample preparation?

- A: Unexpected peaks are frequently traced back to sample and container handling:

- Contaminated Cuvettes/Solvents: Ensure all cuvettes and glassware are meticulously clean. Residue from previous runs or impurities in solvents can introduce spurious signals. Always use high-purity solvents [6].

- Sample Contamination: The sample itself can become contaminated during preparation, for example, from dirty spatulas, impure solvents, or containers [6].

- Inappropriate Cuvette Material: Using plastic disposable cuvettes with incompatible organic solvents can dissolve the plastic, creating contaminants and unexpected peaks. For broadest compatibility, use quartz cuvettes [6].

FAQ 4: How can I make my analytical workflow more sustainable without compromising data quality?

- A: A powerful approach is to recycle the mobile phase and consolidate analyses.

- Multi-Analyte Methods: Develop a single HPLC-UV method that can analyze multiple active pharmaceutical ingredients (APIs) from different dosage forms produced by the same manufacturer. This dramatically reduces the time, cost, and solvent waste associated with running separate analyses for each product [25].

- Mobile Phase Recycling: In isocratic HPLC methods, the mobile phase can be collected and re-used for subsequent runs, leading to a drastic reduction in solvent consumption and waste generation [25].

Troubleshooting Guide: Common Issues and Green Solutions

The following table outlines specific problems, their potential causes, and corrective actions aligned with green chemistry principles.

| Problem | Potential Cause | Green Troubleshooting Action |

|---|---|---|