Solid Phase Extraction for LC-MS Sample Preparation: A Complete Guide to Fundamentals, Methods, and Troubleshooting

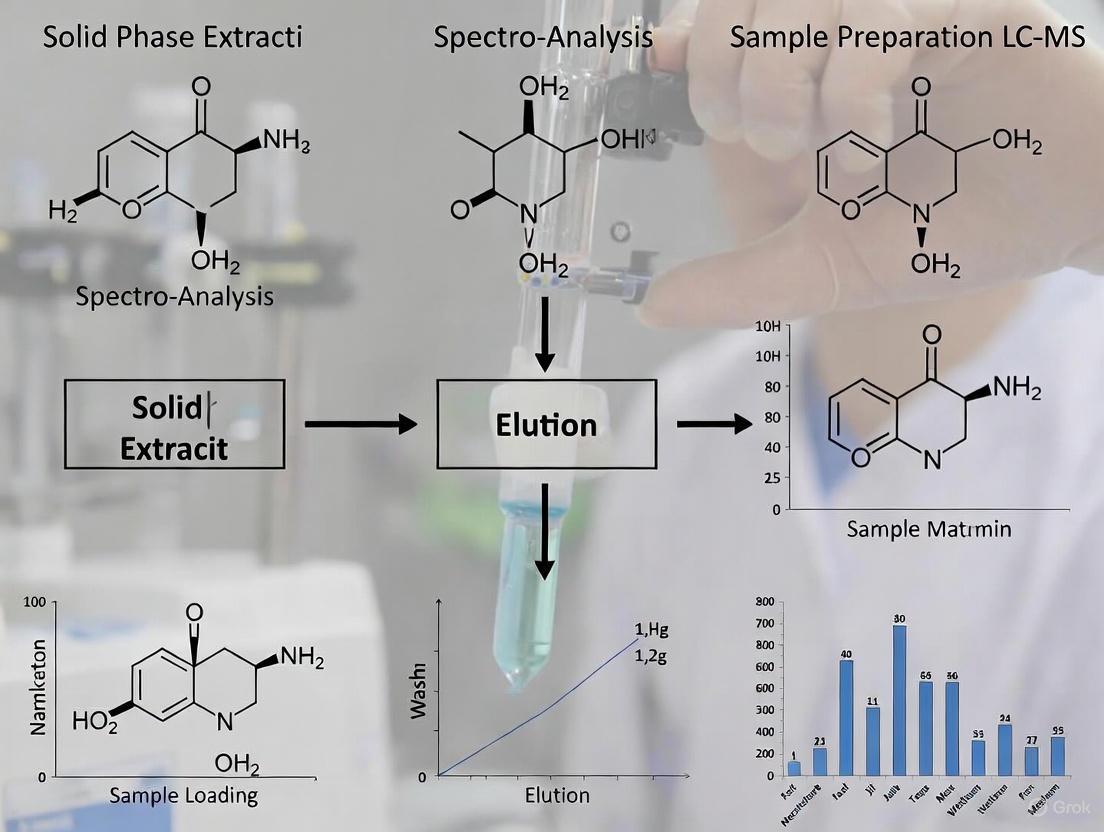

This comprehensive guide explores the critical role of solid-phase extraction (SPE) in preparing complex samples for liquid chromatography-mass spectrometry (LC-MS) analysis.

Solid Phase Extraction for LC-MS Sample Preparation: A Complete Guide to Fundamentals, Methods, and Troubleshooting

Abstract

This comprehensive guide explores the critical role of solid-phase extraction (SPE) in preparing complex samples for liquid chromatography-mass spectrometry (LC-MS) analysis. Tailored for researchers and drug development professionals, it covers foundational SPE principles and sorbent selection, details advanced methodological applications from environmental PFAS to pharmaceutical bioanalysis, provides practical troubleshooting for common issues like low recovery, and outlines rigorous validation protocols. By synthesizing the latest 2025 research and product developments, this article serves as an essential resource for developing robust, sensitive, and reliable SPE methods that ensure accurate LC-MS quantification by effectively removing matrix interferences and concentrating target analytes.

SPE Fundamentals: Principles, Sorbents, and Why It's Essential for LC-MS Success

Liquid chromatography-mass spectrometry (LC-MS) and tandem mass spectrometry (LC-MS/MS) have become the reference techniques for quantifying small molecules in complex matrices such as biological, environmental, and pharmaceutical samples due to their high sensitivity and selectivity [1] [2] [3]. However, the accuracy and reliability of these analyses are profoundly influenced by the sample preparation steps that precede instrumental analysis. Effective sample preparation is critical for isolating target analytes from interfering matrix components, thereby mitigating matrix effects and enhancing overall method sensitivity and robustness [2] [3]. Within this domain, Solid Phase Extraction (SPE) has emerged as a powerful and versatile sample preparation technique, capable of delivering cleaner extracts, concentrating analytes, and significantly improving data quality [4]. These application notes detail the fundamental challenges of LC-MS analysis, provide a comparative evaluation of sample preparation techniques, and offer optimized SPE protocols designed to support researchers and drug development professionals in achieving superior analytical outcomes.

The Problem: Matrix Effects and Their Impact on LC-MS Analysis

Matrix effects represent a major challenge in LC-MS/MS bioanalysis, defined as the alteration of ionization efficiency for a target analyte due to the co-elution of exogenous or endogenous compounds from the sample matrix [2]. In biological matrices, phospholipids are a primary cause of ion suppression, particularly when using electrospray ionization (ESI), which is highly susceptible to such interference [2] [3]. These effects can lead to inaccurate quantification, reduced method sensitivity, and poor reproducibility.

Beyond compromising data accuracy, matrix components can precipitate within the LC system, clogging the chromatography column and increasing system pressure [3]. Furthermore, each injection of a poorly prepared sample deposits residual matrix material on the mass spectrometer hardware. Over time, these deposits degrade ion handling, leading to a gradual loss of sensitivity and necessitating unscheduled instrument downtime for cleaning and maintenance, which can take up to 24 hours [3]. Consequently, investing in robust sample preparation is essential not only for data quality but also for ensuring operational robustness and maximizing instrument uptime.

Several sample preparation techniques are available, each offering different balances of simplicity, cost, and effectiveness in matrix depletion and analyte concentration. The table below summarizes the key characteristics of these common methods.

Table 1: Comparison of Common LC-MS Sample Preparation Techniques

| Technique | Analyte Concentration? | Relative Cost | Relative Complexity | Matrix Depletion |

|---|---|---|---|---|

| Dilution | No | Low | Simple | Less [3] |

| Protein Precipitation (PPT) | No | Low | Simple | Least [3] |

| Phospholipid Removal (PLR) | No | High | Relatively Simple | More (specific to phospholipids) [3] |

| Liquid-Liquid Extraction (LLE) | Yes | Low | Complex | More [3] |

| Supported Liquid Extraction (SLE) | Yes | High | Moderately Complex | More [3] |

| Solid Phase Extraction (SPE) | Yes | High | Complex | Most [4] |

Technique Selection Guide

The workflow for selecting an appropriate sample preparation method based on analytical requirements and sample matrix can be summarized as follows:

Solid Phase Extraction (SPE): Principles and Sorbent Selection

SPE works by passing a liquid sample through a solid sorbent material that retains the analytes of interest. After retained interferences are washed away, the analytes are eluted with a stronger solvent [4]. This process can follow a load-wash-elute sequence for retaining target analytes or a pass-through approach where interferences are captured and the analytes pass through [4].

The selectivity of SPE is largely determined by the sorbent chemistry. The choice of sorbent depends on the physicochemical properties of the analyte and the sample matrix.

Table 2: Guide to Common SPE Sorbent Chemistries

| Sorbent Type | Mechanism | Typical Applications |

|---|---|---|

| Oasis HLB | Hydrophilic-Lipophilic Balanced; retains a wide range of acids, bases, and neutrals without pH adjustment [4]. | Broad-spectrum drug extraction, multi-analyte methods. |

| C18 (Reversed-Phase) | Hydrophobic interactions; retains non-polar to moderately polar compounds. | Pesticides, pharmaceuticals, environmental contaminants [1] [4]. |

| Mixed-Mode Cation Exchange (MCX) | Combines reversed-phase and strong cation exchange for selective retention of basic compounds. | Basic drugs, tryptic peptides [2] [4]. |

| Mixed-Mode Anion Exchange (MAX) | Combines reversed-phase and strong anion exchange for selective retention of acidic compounds. | PFAS, acidic drugs, nucleic acids [4]. |

| Porous Graphite Carbon | Flat sheets of carbon atoms; no silanol groups; useful at extreme pH. | Reversed-phase and HILIC applications for polar compounds [1]. |

Comparative Performance Data

The selection of an appropriate sample preparation method has a measurable impact on key performance metrics. The following table summarizes quantitative data from comparative studies, highlighting the effectiveness of different protocols.

Table 3: Quantitative Comparison of Sample Preparation Method Performance

| Application Context | Method Compared | Key Performance Metric | Result | Citation |

|---|---|---|---|---|

| Oxylipins in Plasma | LLE (Ethyl Acetate) | Overall Sufficiency | Insufficient performance [5] | |

| SPE (Oasis/StrataX) | Matrix Removal | Insufficient removal of interfering matrix [5] | ||

| SPE (BondElut Anion) | Analyte Extraction Efficacy | Low [5] | ||

| SPE (C18 with water/n-hexane wash) | Overall Performance | Best for broad-spectrum analysis [5] | ||

| Pharmaceuticals, Pesticides, UV Filters in Water | SPE (C18) | General Applicability | Optimized via Response Surface Methodology [6] | |

| Benzodiazepines/Opioids in Urine | SPE (ExtraBond SCX) | Analyte Recovery Range | 9% to 107% [7] | |

| DLLME | Analyte Recovery Range | 14% to 86% [7] | ||

| DLLME vs SPE | Green Analytical Chemistry | DLLME required lower solvent volumes, less time, and less energy [7] |

Detailed SPE Protocols

Generic Protocol for SPE Using a Load-Wash-Elute Sequence

This protocol is adaptable for a wide range of analytes using sorbents like Oasis HLB or C18 [4] [8].

- Conditioning: Pass 1-2 column volumes of an organic solvent like methanol or acetonitrile through the sorbent bed, followed by 1-2 column volumes of water or a buffer compatible with your sample. Do not allow the sorbent to dry out.

- Loading: Apply the prepared sample to the cartridge at a controlled, slow flow rate (e.g., 1-2 mL/min) to ensure optimal analyte retention.

- Washing: Pass 1-2 column volumes of a wash solution through the cartridge to remove weakly retained interferences. A common wash is 5-95% organic solvent in water or a mild buffer. For enhanced cleanliness, a wash with n-hexane can be incorporated to remove lipophilic matrix [5].

- Elution: Elute the retained analytes with 1-2 column volumes of a strong organic solvent (e.g., 100% methanol, acetonitrile, or methyl formate [5]). Collect the eluate in a clean tube.

- Reconstitution: If necessary, evaporate the eluate to dryness under a gentle stream of nitrogen or in a vacuum concentrator. Reconstitute the dry residue in an initial LC mobile phase compatible solvent (e.g., 50:50 methanol:water) [1] [3], vortex, and inject into the LC-MS/MS system.

Specialized Protocol for Basic Analytes Using Mixed-Mode Cation Exchange (MCX)

This protocol is ideal for selective extraction of basic drugs and peptides [4].

- Conditioning: Condition the MCX cartridge with methanol followed by water or a low-ionic-strength acidified buffer (e.g., 0.1% formic acid).

- Loading: Load the sample, which should be acidified (pH ~2-3 below the analyte pKa) to ensure the basic analytes are positively charged.

- Washing: Perform two wash steps:

- Wash 1: Use water or a mild acid solution to remove neutral and acidic interferences.

- Wash 2: Use methanol or an organic solvent to remove uncharged, lipophilic interferences.

- Elution: Elute the basic analytes using an organic solvent (e.g., methanol) basified with 2-5% ammonium hydroxide. This neutralizes the analyte's charge, breaking the ionic interaction with the sorbent.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: Key Materials and Reagents for SPE-based LC-MS Sample Preparation

| Item | Function | Example Applications |

|---|---|---|

| Oasis HLB Sorbent | A hydrophilic-lipophilic balanced polymer sorbent for broad-spectrum retention of acidic, basic, and neutral compounds [4]. | Multi-analyte screening in biofluids, environmental water analysis. |

| Mixed-Mode Ion Exchange Sorbents (e.g., MCX, MAX) | Provide orthogonal selectivity by combining reversed-phase and ion-exchange mechanisms for specific analyte classes [2] [4]. | Selective extraction of basic (MCX) or acidic (MAX) drugs and metabolites. |

| Phospholipid Removal Plates | Plates packed with zirconia-coated silica that specifically capture and remove phospholipids from PPT supernatants [2] [3]. | Reducing matrix effects in plasma and serum analysis post-protein precipitation. |

| µElution Plates | SPE plates designed for low-volume elution, minimizing analyte loss from non-specific binding and enabling high sample concentration [4]. | Peptide analysis, sensitive bioanalysis where sample volume is limited. |

| High Purity Solvents and Buffers | Essential for mobile phase preparation and sample reconstitution to minimize background noise and contamination [1]. | All LC-MS applications. |

| 2-Bicyclo[2.1.1]hexanylmethanamine | 2-Bicyclo[2.1.1]hexanylmethanamine HCl | 2-Bicyclo[2.1.1]hexanylmethanamine hydrochloride is a rigid bicyclic amine building block for medicinal chemistry and drug discovery research. For Research Use Only. Not for human or veterinary use. |

| 2-Methyl-5-(quinoxalin-2-yl)aniline | 2-Methyl-5-(quinoxalin-2-yl)aniline, CAS:433318-46-8, MF:C15H13N3, MW:235.29 | Chemical Reagent |

Sample preparation is a critical determinant of success in LC-MS analysis. While simpler techniques like dilution and protein precipitation have their place, Solid Phase Extraction offers a superior balance of analyte concentration and matrix depletion, directly addressing the pervasive challenges of matrix effects and insufficient sensitivity. By understanding the principles outlined in these application notes—from sorbent selection to protocol optimization—researchers can develop robust, reproducible, and sensitive LC-MS methods. The continued evolution of sorbent chemistries and a strategic approach to SPE method development ensure that this technique will remain a cornerstone of reliable bioanalysis in pharmaceutical research and beyond.

Solid-phase extraction (SPE) serves as a critical sample preparation step in LC-MS workflows, designed to purify, concentrate, and isolate analytes from complex matrices. The selection of an appropriate SPE device format is paramount for achieving optimal recovery, sensitivity, and throughput. This application note provides a detailed comparison of three prevalent SPE formats—cartridges, 96-well plates, and µElution plates—contextualized within modern bioanalytical frameworks. We summarize key performance characteristics in structured tables, present validated experimental protocols for direct implementation, and offer a strategic guide for format selection to support researchers and drug development professionals in enhancing their LC-MS analyses.

Solid-phase extraction (SPE) is a sample preparation technique that leverages a solid stationary phase and a liquid mobile phase to isolate analytes of interest from a sample matrix. The fundamental principles of SPE mirror those of liquid chromatography, involving processes of retention, washing, and elution to achieve purification and concentration [9]. The choice of SPE device format directly influences critical parameters such as analysis time, solvent consumption, potential for automation, and suitability for specific sample volumes.

While traditional SPE cartridges have been the workhorse format for decades, the drive for higher throughput and efficiency in laboratories has led to the development of multi-well formats, notably the 96-well SPE plate. More recently, µElution plates have emerged as a specialized format designed to address the need for high sensitivity with minimal elution volumes, thereby eliminating the time-consuming evaporation and reconstitution steps [10] [11]. The following sections delineate the characteristics, applications, and protocols for these three primary formats.

Comparative Analysis of SPE Formats

The table below provides a quantitative and qualitative comparison of the three SPE formats, synthesizing data from recent scientific literature to guide the selection process.

Table 1: Comprehensive Comparison of SPE Device Formats

| Parameter | SPE Cartridges | 96-Well Plates | µElution Plates |

|---|---|---|---|

| Typical Sorbent Mass | 100 mg to 500 mg [12] | 3 mg to 200 mg [12] | ~2 mg [10] [11] |

| Sample Volume Range | 500 µL to 50 mL [12] | ~650 µL to 2 mL [12] | 10 µL to 375 µL [10] |

| Typical Elution Volume | 1-5 mL | 50-200 µL | 25-50 µL [10] [11] |

| Concentration Factor | Low to Moderate | Moderate | High (up to 15X) [10] |

| Throughput & Automation | Manual or semi-automated; lower throughput | High-throughput; amenable to full automation [13] [12] | High-throughput; amenable to full automation |

| Best-Suited Applications | Method development; small batch processing; large sample volumes | High-throughput bioanalysis; pharmacokinetic studies [11] | High-sensitivity assays; small sample volumes (e.g., micro-sampling) [10] |

| Key Advantages | • Flexibility in sorbent mass• Low cost per unit• Wide variety of available chemistries | • Processes 96 samples in parallel• Reduced solvent consumption vs. cartridges• Easily integrated with automated liquid handlers [13] | • No evaporation/reconstitution needed [11]• Maximizes sensitivity• Excellent recovery for diverse analytes [10] |

| Key Limitations | • Labor-intensive• Prone to channeling [12]• Lower reproducibility | • Higher initial cost for plates and compatible equipment• Potential for "edge effects" [14] | • Limited sample loading capacity• Not suitable for large volume samples |

A pivotal consideration for 96-well plate formats is the "edge effect," a phenomenon where wells on the perimeter of the plate exhibit higher evaporation rates, leading to inconsistent results. One study demonstrated that cells in the outer wells of certain 96-well plates showed a 16-35% reduction in metabolic activity compared to central wells [14]. This effect is brand-dependent and can be mitigated by using plates designed for homogeneity, resealing plates during incubation, or adding buffer solution between the wells [14].

Experimental Protocols

Protocol 1: µElution SPE for LC-MS/MS Determination of Drugs in Plasma

This protocol, adapted from a study on the analysis of simvastatin and simvastatin acid, leverages the µElution format to achieve high sensitivity with a streamlined workflow [11].

Research Reagent Solutions:

- Sorbent: Oasis HLB µElution Plate (2 mg sorbent per well) [11]

- Internal Standards: Stable isotope-labeled analogs of the target analytes.

- Buffers and Solvents: 2% methylamine in water, 10 mM ammonium acetate (pH ~4), methanol, and water.

Procedure:

- Conditioning: Load each well of the µElution plate with 200 µL of methanol.

- Equilibration: Load each well with 200 µL of water. Do not allow the sorbent to dry.

- Sample Loading: Acidify 300 µL of plasma sample with 300 µL of 2% methylamine solution. Load the entire sample mixture onto the conditioned sorbent.

- Washing: Wash the sorbent with 200 µL of 10 mM ammonium acetate (pH ~4), followed by 200 µL of a methanol/water (5:95, v/v) mixture.

- Elution: Completely elute the analytes into a clean collection plate using 2 x 50 µL of methanol. The low elution volume produces a ready-to-inject concentrate, eliminating the need for evaporation and reconstitution [11].

Key Outcome: The method achieved an extraction efficiency of 66% for simvastatin acid and 88% for simvastatin, with a lower limit of quantification (LLOQ) of 0.05 ng/mL using 0.3 mL of plasma, underscoring the format's suitability for high-sensitivity assays [11].

Protocol 2: Comparative Performance of 96-Well Plates vs. Pipette Tips for Proteomics

This protocol outlines a comparative study of two SPE formats (96-well plates vs. pipette tips) for peptide purification in a proteomic workflow, providing a template for evaluating format performance in specific applications [15].

Research Reagent Solutions:

- SPE Formats: SOLAµ HRP SPE 96-well spin plates (Thermo Fisher Scientific) and ZIPTIP C18 pipette tips (Merck Millipore).

- Biological Material: Porcine retinal tissue protein fractions extracted with 0.1% DDM or 1% TFA.

- Enzyme: Trypsin for in-gel digestion.

Procedure:

- Sample Preparation: Subject six technical replicates of each protein fraction to in-gel trypsin digestion.

- SPE Purification: Purify the resulting peptides using the two SPE workflows (N=3 per format per fraction).

- LC-MS Analysis: Analyze the purified peptides by LC-MS.

- Data Analysis: Compare the number of proteins and peptides identified, protein ion scores, and the quantitative recovery of 25 specific protein markers.

Key Outcome: The study found no significant difference in the number of identified proteins or peptides between the two formats. The 96-well plate format, however, offered superior analysis speed and was more convenient for semi-automation, making it preferable for high-throughput proteomic settings [15].

Format Selection Workflow

The following decision pathway provides a logical framework for selecting the most appropriate SPE device format based on project requirements.

The Scientist's Toolkit: Essential Research Reagents and Materials

The table below catalogs key materials and reagents essential for implementing the SPE protocols described in this note.

Table 2: Key Research Reagent Solutions for SPE Protocols

| Item Name | Function / Application | Specific Example(s) |

|---|---|---|

| µElution SPE Plate | Specialized 96-well plate for ultra-low elution volumes; eliminates evaporation/reconstitution. | Oasis µElution Plate [10] [11] |

| High-Capacity 96-Well SPE Plate | Standard 96-well format for high-throughput sample preparation with larger sample volumes. | SOLAµ HRP SPE Spin Plates [15] |

| Pipette-Tip SPE | Miniaturized SPE format for low-volume, manual or semi-automated sample clean-up. | ZIPTIP C18 Pipette Tips [15] |

| Mixed-Mode Sorbent | Sorbent providing both reversed-phase and ion-exchange mechanisms for superior clean-up. | Oasis MCX (Mixed-Mode Cation Exchange) [10] |

| Phospholipid Removal (PLR) Plate | Specialized plate that actively captures phospholipids to reduce matrix effects in LC-MS. | Microlute PLR Plate [16] |

| Stable Isotope-Labeled Internal Standards | For quantitative LC-MS/MS; corrects for matrix effects and variability in sample preparation. | 13CD3-Simvastatin and 13CD3-Simvastatin Acid [11] |

| 2-(2-Aminoethyl)isoindolin-1-one | 2-(2-Aminoethyl)isoindolin-1-one, CAS:350046-24-1, MF:C10H13BrN2O, MW:257.131 | Chemical Reagent |

| 2-(4-Ethylphenoxy)acetohydrazide | 2-(4-Ethylphenoxy)acetohydrazide, CAS:300821-52-7, MF:C10H14N2O2, MW:194.234 | Chemical Reagent |

The choice between SPE cartridges, 96-well plates, and µElution plates is a strategic decision that directly impacts the efficiency, sensitivity, and robustness of an LC-MS assay. SPE cartridges remain a versatile tool for method development and processing variable sample sizes. 96-well plates are the undisputed format for high-throughput bioanalysis, though vigilance regarding edge effects is advised. µElution plates represent a significant advancement for high-sensitivity applications where maximizing analyte concentration and minimizing workflow steps are critical. By aligning project requirements—sample volume, throughput, and sensitivity needs—with the inherent strengths of each format, scientists can optimize their SPE workflows to meet the demanding challenges of modern drug development and biomedical research.

Sorbent capacity is a fundamental parameter in solid-phase extraction (SPE) method development, directly determining how much sample can be processed effectively while maintaining high analyte recovery. It refers to the maximum amount of analyte and interfering matrix components that a sorbent can retain without breakthrough occurring. Understanding capacity is crucial for designing robust, reproducible SPE methods, particularly in LC-MS sample preparation where matrix effects can significantly impact analytical results. The capacity of an SPE sorbent is influenced by multiple factors, including the specific surface area, the nature of the functional groups, ligand density, and the physicochemical properties of both the analyte and the sample matrix [17] [18].

For researchers in drug development, properly matching sorbent capacity to sample load is essential for achieving reliable quantitation, maintaining instrument performance, and ensuring the longevity of chromatographic systems. Insufficient sorbent capacity leads to analyte breakthrough during sample loading, resulting in lower recoveries and poor consistency between samples [18]. This application note provides comprehensive, practical guidelines for determining and optimizing sorbent capacity across the three primary classes of SPE materials: silica-based, polymeric, and ion-exchange sorbents, with a specific focus on LC-MS applications in pharmaceutical analysis.

Fundamental Principles of Sorbent Capacity

Defining Sorbent Capacity and Key Influencing Factors

Sorbent capacity in SPE is governed by both the total surface area available for interactions and the specific chemistry of those interactions. Polymeric sorbents typically exhibit higher capacity than their silica-based counterparts for several reasons: they possess higher specific surface areas (e.g., 1200 m²/g for materials like LiChrolut EN), lack a non-interacting solid support core, and the entire polymer structure can participate in the retention mechanism. In contrast, silica-based sorbents have capacity limited to the bonded phase attached to the silica surface, which does not constitute the entire mass of the particle [17] [18].

The operational capacity is not an absolute value but is relative to the sample matrix. A single sorbent can have different effective capacities depending on whether it is processing plasma, urine, water, or tissue homogenates. This is because endogenous materials in the sample (e.g., proteins, lipids, salts) will compete with the target analytes for binding sites on the sorbent. As a general rule, polymeric sorbents can typically retain an amount of material equivalent to 10-15% of their total bed mass, while silica-based sorbents have a lower generic loading capacity of approximately 5% of total bed mass [18].

Mechanisms of Analyte Retention

The primary retention mechanisms in SPE include reversed-phase (hydrophobic interactions), ion-exchange (ionic interactions), and mixed-mode (a combination of both). The capacity for each mechanism differs significantly:

- Reversed-phase mechanisms depend on hydrophobic interactions between the analyte and the non-polar functional groups on the sorbent (e.g., C18, polystyrene-divinylbenzene). Capacity increases with analyte hydrophobicity and sorbent surface area [17].

- Ion-exchange mechanisms utilize ionic interactions between charged functional groups on the sorbent and ionized groups on the analyte. These interactions are typically stronger than hydrophobic interactions and can provide very high selectivity and capacity for ionizable compounds when operated at the appropriate pH [17] [19].

- Mixed-mode sorbents incorporate both reversed-phase and ion-exchange functionalities, allowing for orthogonal retention mechanisms. This is particularly valuable for purifying basic or acidic pharmaceuticals from complex biological matrices, as the sorbent can retain analytes based on both hydrophobicity and ionic interactions, often resulting in cleaner extracts [19].

Capacity Guidelines by Sorbent Chemistry

Silica-Based Sorbents

Silica-based sorbents, including those bonded with C18, C8, NH2, and other functional groups, are mechanically stable and resistant to organic solvents but have a limited pH stability range (typically pH 2-9). A significant consideration with silica-based materials is the presence of residual silanol groups, which can lead to secondary interactions (especially with basic compounds), potentially affecting both recovery and apparent capacity. These ionized silanols can create strong electrostatic interactions with protonated amines that are difficult to overcome during elution [17].

Table 1: Recommended Sample Loading Volumes for Silica-Based Sorbents [18]

| Sorbent Mass | Plasma/Serum | Urine | Particulate-Free Water | Food/Plant Material |

|---|---|---|---|---|

| 25 mg | 100 µL | 250 µL | 25 mL | 125 mg |

| 50 mg | 250 µL | 500 µL | 50 mL | 250 mg |

| 100 mg | 500 µL | 2 mL | 100 mL | 500 mg |

| 200 mg | 1 mL | 4 mL | 200 mL | 1 g |

| 500 mg | 2 mL | 8 mL | 500 mL | 2.5 g |

| 1 g | 5 mL | 20 mL | 1 L | 5 g |

Polymeric Sorbents

Polymeric sorbents, such as those based on polystyrene-divinylbenzene (PS-DVB) copolymers, offer distinct advantages including a wider pH tolerance (pH 0-14), no residual silanols, and higher surface areas leading to greater capacity. An important practical advantage is that polymeric phases can dry out during the SPE procedure without adversely affecting analyte recovery or reproducibility, unlike silica-based phases which can "dewet" and become deactivated [17].

Table 2: Recommended Sample Loading Volumes for Polymeric Sorbents [18]

| Sorbent Mass | Plasma/Serum | Urine | Particulate-Free Water | Food/Plant Material |

|---|---|---|---|---|

| 10 mg | 100 µL | 250 µL | 20 mL | 100 mg |

| 30 mg | 250 µL | 1 mL | 60 mL | 300 mg |

| 60 mg | 500 µL | 2 mL | 120 mL | 600 mg |

| 100 mg | 1 mL | 4 mL | 200 mL | 1 g |

| 200 mg | 2 mL | 8 mL | 400 mL | 2 g |

| 500 mg | 5 mL | 20 mL | 1 L | 5 g |

Comparative studies demonstrate the capacity advantage of polymeric sorbents. For instance, LiChrolut EN, an ethylvinylbenzene-DVB copolymer with a surface area of 1200 m²/g, showed an order of magnitude increase in capacity for polar compounds like caffeine compared to conventional C18 silica sorbents [17].

Ion-Exchange and Mixed-Mode Sorbents

Ion-exchange capacity depends on the number and type of ionic functional groups. Strong cation-exchange (SCX) sorbents contain sulfonic acid groups, weak cation-exchange (WCX) have carboxylic acids, strong anion-exchange (SAX) have quaternary amines, and weak anion-exchange (WAX) have primary or secondary amines. Mixed-mode sorbents combine ion-exchange with reversed-phase interactions, which is particularly useful for extracting ionizable pharmaceuticals from biological matrices [17] [19].

The capacity of ion-exchange sorbents is maximized when the analyte and sorbent functional groups are fully ionized and oppositely charged. This requires careful pH control during the sample loading step. For mixed-mode sorbents, the total capacity reflects both the ionic and hydrophobic retention sites. Recent advances include the development of zwitterionic mixed-mode sorbents functionalized with both strong cation- and strong anion-exchange moieties simultaneously, allowing for the extraction of both acidic and basic compounds in a single step [19].

Experimental Protocols for Capacity Determination

Protocol 1: Breakthrough Capacity Testing

Purpose: To determine the maximum sample loading capacity for a specific analyte-sorbent combination.

Materials:

- SPE manifolds and vacuum source

- SPE cartridges packed with test sorbent

- Standard solution of target analyte in appropriate solvent

- HPLC or LC-MS system for analysis

Procedure:

- Condition the SPE cartridge according to manufacturer recommendations (typically with methanol followed by water or buffer).

- Prepare a series of standard solutions with known concentrations of the target analyte.

- Load increasing volumes of the standard solution onto separate SPE cartridges.

- Collect the effluent (the liquid that passes through during sample loading).

- Wash the cartridge with an appropriate solvent (typically water or a weak buffer) and collect the wash fraction.

- Elute the retained analytes with a strong elution solvent and collect the eluate.

- Analyze all fractions (effluent, wash, and eluate) by LC-MS to quantify the analyte in each.

- Plot the recovery (%) against the absolute amount of analyte loaded (µg).

- The breakthrough capacity is defined as the amount loaded where recovery drops below 90-95%.

Calculation: Breakthrough Capacity = (Vbreakthrough × Canalyte) / msorbent Where Vbreakthrough is the volume at which breakthrough occurs, Canalyte is the analyte concentration, and msorbent is the mass of sorbent.

Protocol 2: Competitive Binding in Complex Matrices

Purpose: To evaluate effective capacity in the presence of matrix components that compete for binding sites.

Materials:

- Biological matrix (plasma, urine, tissue homogenate)

- Isotopically labeled internal standards

- Mixed-mode or selective sorbents

Procedure:

- Spike the biological matrix with a constant amount of internal standard and increasing concentrations of the target analyte.

- Process each sample through the SPE procedure using fixed sorbent mass.

- Analyze eluates by LC-MS/MS.

- Plot the measured analyte concentration against the spiked concentration.

- Note the point where the measured concentration deviates from linearity, indicating saturation of binding sites.

- Compare results across different sorbent masses (e.g., 30 mg vs. 60 mg) to determine optimal sorbent mass for the application.

This protocol is particularly important for methods intended for bioanalysis, as the presence of phospholipids, proteins, and other endogenous compounds can significantly reduce the available capacity for target analytes.

Advanced Sorbent Technologies and Applications

Monolithic vs. Particle-Based SPE

Monolithic SPE (m-SPE) utilizes a single, porous polymer structure rather than individual packed particles. Recent comparative studies between monolithic and particle-packed SPE (p-SPE) for selective separation applications have demonstrated that m-SPE columns offer enhanced performance due to their "high permeability, low backpressure, and robust porosity," which collectively result in "enhanced selectivity, reproducibility, and overall efficiency" [20]. These characteristics are particularly beneficial for processing large volume samples or samples with particulate matter that might clog traditional particle-based SPE columns.

Zwitterionic Mixed-Mode Sorbents

Recent innovations in sorbent technology include the development of zwitterionic mixed-mode sorbents that incorporate both cation- and anion-exchange functionalities in a single material. These sorbents are particularly valuable for screening methods that target both acidic and basic pharmaceuticals. In one application, researchers developed a sol-gel derived silica sorbent functionalized with 2-(methacryloxy)-ethyldimethyl-3-(sulfopropyl)ammonium hydroxide, which contains both sulfonic acid groups (strong cation-exchanger) and quaternary amines (strong anion-exchanger) [19]. This material demonstrated effective extraction of a panel of five acidic and five basic pharmaceuticals from environmental water samples, with apparent recoveries higher than 30% for most compounds and method detection limits at the low ng/L level.

High-Throughput SPE in Exposomics

The move toward high-throughput analysis in fields like exposomics has driven the adaptation of SPE to 96-well plate formats. A recent study developed a robust and scalable SPE protocol for human urine and plasma optimized for 94 diverse environmental contaminants [21]. The method achieved acceptable extraction recoveries (60-140%) for >70% of analytes and improved throughput approximately 10× compared to routine metabolomics-based protein precipitation approaches when processing 1000 samples. This demonstrates how proper sorbent capacity optimization can translate to significant efficiency gains in large-scale studies.

Table 3: Research Reagent Solutions for Sorbent Capacity Evaluation

| Reagent/Sorbent Type | Function & Application | Key Characteristics |

|---|---|---|

| LiChrolut EN (PS-DVB) | High-capacity polymeric sorbent for polar compounds | 1200 m²/g surface area, balanced hydrophobicity/hydrophilicity |

| Zwitterionic Mixed-Mode Sorbents | Simultaneous extraction of acidic and basic analytes | Contains both SCX and SAX moieties, wide pH stability |

| AnaLig Pb-02 | Selective for lead separation in environmental samples | Crown ether functionalized for molecular recognition |

| SampliQ OPT Polymer | Pharmaceutical extraction with drying tolerance | Polyamide-DVB character, unaffected by drying between steps |

| Monolithic SPE Columns | High-flow applications with low backpressure | Continuous porous polymer structure, high permeability |

| Strata-X Series | Versatile polymeric sorbents for various matrices | Multiple chemistries (reversed-phase, ion-exchange, mixed-mode) |

Sorbent capacity is a critical parameter that must be carefully considered during SPE method development for LC-MS sample preparation. The following best practices are recommended:

- Always conduct preliminary breakthrough experiments when developing methods for new analytes or matrices, as theoretical capacity may not reflect performance in complex samples.

- Select sorbent chemistry based on analyte properties - use reversed-phase for hydrophobic compounds, ion-exchange for ionizable compounds, and mixed-mode for complex matrices.

- Leverage the higher capacity of polymeric sorbents (10-15% of bed mass) when processing samples with high endogenous interferent levels or when analyzing multiple compound classes.

- Consider the sample matrix carefully when determining sorbent mass, as capacity guidelines differ significantly between plasma, urine, water, and other matrices.

- Utilize mixed-mode and zwitterionic sorbents for applications requiring simultaneous extraction of acidic and basic compounds, as they provide orthogonal retention mechanisms and often cleaner extracts.

By applying these guidelines and protocols, researchers in drug development can optimize SPE methods that deliver consistent, high-quality results in their LC-MS analyses, ultimately supporting more reliable pharmacokinetic, metabolomic, and bioanalytical studies.

Advanced SPE Method Development: Protocols for Diverse Applications and Matrices

Per- and polyfluoroalkyl substances (PFAS) represent a large class of over 4,700 synthetic fluorinated aliphatic compounds characterized by their environmental persistence and potential health impacts [22]. The analysis of these "forever chemicals" in environmental samples demands highly selective and robust analytical methods. The United States Environmental Protection Agency (EPA) Method 1633 has emerged as a comprehensive, multi-laboratory validated approach for measuring 40 target PFAS compounds across diverse matrices including aqueous, solid, biosolid, and tissue samples [23] [22].

This application note details the implementation of EPA Method 1633 using weak anion exchange (WAX) solid-phase extraction (SPE) cartridges for the selective isolation and concentration of PFAS from water matrices. The WAX sorbent provides specific retention mechanisms for anionic PFAS compounds, while the method's performance-based characteristics allow for adjustments to optimize recovery and sensitivity [22]. The workflow encompasses sample preparation, SPE using WAX cartridges, clean-up steps, and final analysis by liquid chromatography-tandem mass spectrometry (LC-MS/MS), achieving the rigorous sensitivity and precision required for environmental monitoring and regulatory compliance.

Experimental Protocols

Solutions and Standards Preparation

Native PFAS standards (40 compounds) and isotopically labeled standards (31 compounds) are prepared as methanolic stock solutions (50 µg/mL) [22]. The labeled compounds serve as either extracted internal standards (EIS, 24 compounds) added before extraction or non-extracted internal standards (NIS, 7 compounds) added post-cleanup for recovery determination [22]. A series of seven calibration solutions (CS1-CS7) is prepared with native PFAS concentrations ranging from 0.2-5 ng/mL (CS1) to 62.5-1560 ng/mL (CS7) to establish the instrument calibration curve [22].

Sample Preparation and Solid-Phase Extraction

The following protocol is optimized for 500 mL aqueous samples [22]:

- Sample Preservation: Collect water samples in high-density polyethylene (HDPE) bottles with liner-less polypropylene caps. Spike with 24 EIS standards immediately upon collection [22].

- SPE Cartridge Conditioning: Condition the Supelclean ENVI-WAX SPE tubes (500 mg/6 mL) with 15 mL of 1.0% NHâ‚„OH in methanol, then equilibrate with 5 mL of aqueous 0.3 M formic acid [22].

- Sample Loading: Load the 500 mL sample through the cartridge using a PTFE-free vacuum manifold [22].

- Washing: Rinse with 2 × 5 mL of reagent water followed by 5 mL of 0.1 M formic acid/methanol (1:1 v/v) [22].

- Elution: Elute analytes with 5 mL of 1.0% NHâ‚„OH in methanol [22].

- Clean-up: Add 25 µL concentrated acetic acid and approximately 10 mg Supelclean ENVI-Carb to the eluate. Vortex for <5 minutes, then centrifuge at 4000 × g for 10 minutes [22].

- Final Preparation: Filter supernatant through 0.2 µm nylon syringe filters into collection tubes containing NIS standards, achieving a 100:1 concentration factor [22].

Instrumental Analysis

LC-MS/MS analysis is performed using an Agilent 1290 Infinity II LC system coupled to an Agilent 6495C triple quadrupole mass spectrometer [22]. Key parameters include:

- Chromatography: Ascentis Express PFAS analytical column (5 cm × 2.1 mm, 2.7 µm) with a matching PFAS delay column to offset potential background contamination [22].

- Mobile Phase: Gradient elution with methanol/water containing ammonium acetate or formate [24].

- Mass Spectrometry: Negative electrospray ionization with multiple reaction monitoring (MRM) mode [22].

- Injection Volume: 1-5 µL using polypropylene snap-cap vials to prevent PFAS adsorption [22].

PFAS Analysis Workflow Using WAX SPE and EPA 1633 - This diagram illustrates the comprehensive sample preparation and analysis process for targeted PFAS analysis, from sample collection through final quantification.

Results and Discussion

Method Performance Characteristics

The WAX-based SPE method demonstrated robust performance across all 40 target PFAS compounds, with recoveries and precision meeting EPA Method 1633 acceptance criteria for aqueous matrices [22].

Table 1: PFAS Recovery Data from Spiked Water Samples Using WAX SPE Cartridges

| Fortification Level | Number of Compounds | Average Recovery Range (%) | RSD Range (%) |

|---|---|---|---|

| Low (2×CS1) | 40 PFAS + 24 EIS | 84.0 - 110.7 | 0.2 - 18.1 |

| Medium (12.5×CS1) | 40 PFAS + 24 EIS | 85.3 - 112.2 | 0.5 - 15.8 |

| High (40×CS1) | 40 PFAS + 24 EIS | 82.7 - 108.9 | 0.7 - 16.3 |

All recovery values fell within the EPA acceptable range of 70-130% with relative standard deviations (RSDs) below 20%, confirming the method's excellent precision and accuracy [22]. The WAX sorbent's selective retention mechanism for anionic PFAS compounds contributed to this consistent performance across diverse PFAS classes, including perfluoroalkyl carboxylic acids (PFCAs), perfluoroalkyl sulfonic acids (PFSAs), and emerging PFAS categories [22].

Sensitivity and Linear Range

The method achieved impressive sensitivity with method detection limits (MDLs) below 0.02 µg/g dry weight for most compounds in solid matrices [24]. For aqueous samples, reporting limits typically ranged from 1-100 ng/L, demonstrating the method's capability to detect PFAS at the low parts-per-trillion levels required for environmental monitoring [23]. Linear calibration curves exhibited determination coefficients (R²) ≥ 0.99 across the analytical range, enabling reliable quantification from minimal concentrations to over 1500 ng/mL [22].

Table 2: Key Method Performance Characteristics for Targeted PFAS Analysis

| Parameter | Performance Characteristics | Methodology |

|---|---|---|

| Target Analytes | 40 PFAS compounds across 9 classes | EPA Method 1633 [22] |

| Extraction Efficiency | 70-130% recovery for all compounds | Isotope dilution quantification [22] |

| Precision | RSD < 15% for most compounds | Triple quadrupole LC-MS/MS [24] [22] |

| Sensitivity | MDL < 0.02 µg/g for most compounds; Aqueous reporting limits: 1-100 ng/L | Optimized MRM transitions [23] [24] |

| Linearity | R² ≥ 0.99 across calibration range | 7-point calibration [22] |

Comparison with Other Methodologies

While EPA Methods 533 and 537.1 are validated for drinking water analysis, EPA Method 1633 provides broader applicability across multiple matrices including wastewater, surface water, groundwater, soil, sediment, biosolids, and fish tissue [25] [23]. The method's "performance-based" designation allows laboratories to modify specific parameters while demonstrating equivalent performance, facilitating method optimization for challenging matrices [22]. This flexibility is particularly valuable for addressing matrix effects in complex environmental samples like landfill leachate and wastewater, where co-extracted interferents can compromise analytical accuracy [23].

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of EPA Method 1633 requires careful selection of reagents and materials to minimize background contamination and ensure analytical integrity.

Table 3: Essential Research Reagent Solutions for PFAS Analysis Using WAX SPE

| Item | Function | Specification | Critical Notes |

|---|---|---|---|

| WAX SPE Cartridges | Selective retention of anionic PFAS | Supelclean ENVI-WAX (500 mg/6 mL) [22] | Dual-bed WAX/GCB cartridges available for enhanced cleanup [26] |

| Isotopically Labeled Standards | Quantification and recovery correction | 31 compounds (13C or D labeled) [22] | Essential for isotope dilution mass spectrometry |

| LC-MS/MS Solvents | Mobile phase preparation | PFAS-free LC-MS grade methanol, water [24] | Must be certified PFAS-free to prevent background contamination |

| Carbon Cleanup Sorbent | Removal of matrix interferents | Supelclean ENVI-Carb [22] | Added post-elution for dispersive SPE cleanup |

| Chromatography Columns | PFAS separation and delay | Ascentis Express PFAS analytical and delay columns [22] | Delay column traps system-derived PFAS contamination |

| Sample Containers | Sample collection and storage | HDPE bottles with polypropylene caps [22] | Liner-less caps prevent PFAS introduction |

| Filtration Materials | Post-cleanup filtration | 0.2 µm nylon syringe filters [22] | Avoid PTFE filters to prevent contamination [24] |

| 5-Bromo-3-fluoroisatoic anhydride | 5-Bromo-3-fluoroisatoic Anhydride| | 5-Bromo-3-fluoroisatoic Anhydride is a chemical synthesis building block For Research Use Only. Not for human or veterinary use. | Bench Chemicals |

| Methyl 2-cyclopropyl-2-oxoacetate | Methyl 2-cyclopropyl-2-oxoacetate, CAS:6395-79-5, MF:C6H8O3, MW:128.127 | Chemical Reagent | Bench Chemicals |

Technical Considerations and Optimization Strategies

Contamination Control

PFAS contamination presents a significant analytical challenge due to the ubiquitous presence of these compounds in laboratory environments and materials [27]. Critical control measures include:

- Using PTFE-free instrumentation and consumables throughout the analytical process [22]

- Implementing delay columns in the LC system to capture background PFAS [22]

- Employing PFAS-free water and solvents, verified through rigorous blank testing [28]

- Establishing dedicated laboratory areas for low-level PFAS analysis [27]

- Using polypropylene vials instead of glass to prevent PFAS adsorption [22]

Matrix-Specific Modifications

While this protocol focuses on aqueous matrices, EPA Method 1633 applies to diverse sample types. Solid matrices (soils, sediments, biosolids) typically require accelerated solvent extraction or ultrasound-assisted extraction prior to WAX SPE cleanup [24]. Tissue samples necessitate additional purification steps to remove co-extracted lipids and proteins that may interfere with analysis [26]. The method's performance-based nature allows for such modifications provided that all quality control criteria are met [22].

Analytical Scope and Limitations

Although EPA Method 1633 targets 40 PFAS compounds, this represents only a fraction of the thousands of PFAS in commercial use [23]. For comprehensive contamination assessment, analysts may complement targeted methods with approaches like the Total Oxidizable Precursor (TOP) assay or Adsorbable Organic Fluorine (AOF) analysis to capture non-target PFAS [23]. Method 1633 effectively captures legacy PFAS (PFOA, PFOS) and many emerging alternatives, though ultra-short-chain compounds (C2-C3) may require specialized approaches due to their high polarity and poor retention on WAX sorbents [29].

The application of WAX solid-phase extraction cartridges in conjunction with EPA Method 1633 provides a robust, sensitive, and reliable framework for targeted PFAS analysis in water matrices. The method demonstrates exceptional performance with recoveries of 84.0-110.7% for all 40 target PFAS compounds and corresponding RSDs below 20%, well within EPA acceptance criteria [22]. The selective retention properties of WAX sorbents for anionic PFAS, combined with effective clean-up using graphitized carbon black, enable precise quantification at environmentally relevant concentrations.

This comprehensive protocol offers environmental researchers and analytical laboratories a standardized approach for PFAS monitoring that supports regulatory compliance and environmental risk assessment. The performance-based nature of EPA Method 1633 allows for necessary adaptations to address specific project requirements and matrix challenges while maintaining data quality and defensibility [22]. As PFAS regulations continue to evolve globally, this methodology provides a foundation for consistent, accurate, and reproducible PFAS analysis across diverse environmental monitoring applications.

The analysis of pharmaceutical contaminants in wastewater is critical for environmental monitoring and public health protection. Solid-phase extraction (SPE) using Hydrophilic-Lipophilic Balanced (HLB) cartridges has emerged as a preferred sample preparation technique for isolating diverse pharmaceutical compounds from complex aqueous matrices prior to liquid chromatography-mass spectrometry (LC-MS) analysis. HLB sorbents provide simultaneous extraction of acidic, basic, and neutral compounds without pH adjustment, offering significant advantages over traditional sorbents [30]. This application note details optimized protocols and critical parameters for maximizing recovery efficiency of pharmaceutical contaminants using HLB cartridge technology, providing researchers with validated methods for reliable analyte extraction.

Theoretical Background

HLB Sorbent Chemistry and Mechanism

The Oasis HLB sorbent is a macroporous copolymer of divinylbenzene and N-vinylpyrrolidone designed with balanced hydrophilic and lipophilic properties. This unique chemistry enables effective retention of a wide spectrum of pharmaceuticals with varying polarities and physicochemical properties [30]. The lipophilic divinylbenzene components provide reversed-phase retention mechanisms for non-polar compounds, while the hydrophilic N-vinylpyrrolidone moieties retain polar compounds through hydrogen bonding and polar interactions. This dual functionality makes HLB particularly suitable for wastewater applications where pharmaceuticals with diverse chemical structures coexist.

Advantages for Pharmaceutical Extraction in Wastewater

HLB cartridges demonstrate superior performance for pharmaceutical extraction from wastewater matrices due to several key characteristics: high capacity (typically 10-30 mg/mL), excellent wettability allowing consistent flow even under dry conditions, and stability across the entire pH range (pH 1-14) [30]. The sorbent maintains performance with complex environmental samples containing humic acids, particulate matter, and other interfering substances commonly found in wastewater. Batch equilibrium studies have demonstrated partition ratios (K~D~) for organic pollutants on HLB sorbents ranging from 1.16 × 10³ L/kg to 1.07 × 10ⶠL/kg, confirming strong affinity for diverse contaminants [31].

Experimental Protocols

Sample Collection and Preservation

Proper sample handling is crucial for maintaining analyte integrity. Collect wastewater samples in clean, high-density polyethylene (HDPE) containers due to their chemical resistance and minimal analyte adsorption [32]. Immediately after collection, acidify samples to pH 2-3 using high-purity hydrochloric acid or formic acid to preserve analyte stability [33]. Store samples at 4°C and process within 24-48 hours of collection. For longer storage, maintain samples at -20°C. Filter samples through 0.45-μm glass fiber filters prior to SPE to remove suspended particulates that could clog extraction cartridges.

HLB Cartridge Conditioning and Loading

The conditioning sequence is critical for activating the sorbent and ensuring reproducible retention:

Conditioning: Sequentially pass 3-5 mL of methanol (or acetonitrile) and 3-5 mL of reagent-grade water through the HLB cartridge (60 mg, 3 cc) at a flow rate of approximately 1-2 mL/min [33]. Do not allow the sorbent to dry completely before sample loading.

Sample Loading: Pass the filtered wastewater sample (typically 100-500 mL depending on analyte concentration) through the conditioned HLB cartridge at a controlled flow rate of 5-10 mL/min using a vacuum manifold system [33]. Maintaining consistent flow is essential for optimal analyte retention.

Rinsing: After sample loading, wash the cartridge with 3-5 mL of reagent water containing 5% methanol to remove weakly retained interferents [30].

Analyte Elution and Concentration

Select appropriate elution solvents based on the physicochemical properties of target pharmaceuticals:

Elution: Pass 4-6 mL of organic solvent through the cartridge to desorb retained analytes. Common elution schemes include:

Concentration: Gently evaporate the eluate to dryness under a stream of nitrogen at 30-40°C. Reconstitute the residue in 100-500 μL of initial mobile phase composition (typically 50:50 methanol:water or acetonitrile:water) compatible with subsequent LC-MS analysis [33].

Quality Assurance Measures

Implement comprehensive quality controls for reliable data:

- Procedural Blanks: Analyze reagent water samples processed identically to wastewater samples to monitor contamination.

- Matrix Spikes: Fortify wastewater samples with target analytes before extraction to determine method recovery.

- Internal Standards: Use isotopically labeled analog internal standards (when available) to correct for procedural losses and matrix effects [33].

- Recovery Assessment: Calculate percentage recovery using the formula:

%recovery = (spiked sample concentration - unspiked sample concentration) / concentration used to spike × 100[33]. Acceptable recoveries typically range from 70-120% for most pharmaceuticals.

Critical Optimization Parameters

Flow Rate Control

Maintaining optimal flow rates during sample loading significantly impacts extraction efficiency. Excessive flow rates (>10 mL/min) can compromise analyte retention, particularly for more polar compounds. For 60 mg HLB cartridges, flow rates of 5-10 mL/min provide the best balance between processing time and extraction efficiency [33]. Using vacuum manifolds with adjustable pressure controls enables reproducible flow rate management across multiple samples.

Sample pH Adjustment

pH manipulation represents a powerful optimization strategy, particularly for ionizable pharmaceuticals:

- Acidic compounds (e.g., ibuprofen, diclofenac): Acidify samples to pH 2-3 to suppress ionization and enhance reversed-phase retention on HLB sorbent [33].

- Basic compounds (e.g., tramadol): For improved retention, adjust to alkaline conditions (pH 9-10) to maintain neutral form.

- Broad-spectrum analysis: For simultaneous extraction of multiple drug classes without pH adjustment, HLB sorbents still provide adequate retention for most compounds due to their balanced chemistry [30].

Elution Solvent Optimization

Elution efficiency varies significantly with solvent composition:

- Methanol: Effective for a wide range of moderate to high polarity pharmaceuticals.

- Acetonitrile: Superior for non-polar compounds and provides cleaner extracts with less co-elution of matrix interferents.

- Modified solvents: Addition of 2-5% ammonium hydroxide or formic acid can improve elution efficiency for strongly basic or acidic compounds, respectively [30].

Table 1: Pharmaceutical Contaminants in Wastewater and HLB Extraction Performance

| Pharmaceutical | Influent Concentration (μg/L) | HLB Extraction Recovery (%) | Optimal Sample pH | Preferred Elution Solvent |

|---|---|---|---|---|

| Ibuprofen | 28.00 [32] | 83-95 [30] | 2-3 | Methanol |

| Diclofenac | 27.20 [32] | 85-98 [30] | 2-3 | Methanol with 2% formic acid |

| Paracetamol | 22.03 [32] | 80-92 [30] | Unadjusted | Acetonitrile |

| Tramadol | <0.01 [32] | 88-102 [30] | 9-10 | Methanol with 2% NHâ‚„OH |

| Metformin | 1243 [33] | 83.17 [33] | Unadjusted | Methanol |

| Caffeine | NA | 86.42 [33] | Unadjusted | Acetonitrile:methanol (50:50) |

| Sulfamethoxazole | NA | 73.53 [33] | 6-7 | Acetonitrile |

Cartridge Capacity Considerations

The 60 mg HLB cartridge format typically accommodates 100-500 mL wastewater samples, but required sorbent mass depends on sample volume and contaminant loading. For highly contaminated wastewater, decrease sample volume or increase sorbent mass (e.g., 200 mg cartridges) to prevent breakthrough. Performance validation should demonstrate >85% recovery for target analytes at selected loading conditions [30].

Analytical Instrumentation and Method Parameters

LC-MS/MS Analysis Conditions

After HLB extraction, analyze pharmaceutical contaminants using optimized LC-MS/MS parameters:

- Chromatographic Column: C18 column (50-150 mm × 2.1 mm, 1.7-5 μm) [34]

- Mobile Phase: (A) 0.1% formic acid in water; (B) 0.1% formic acid in acetonitrile or methanol [34]

- Gradient Program: 5-95% B over 10-20 minutes, depending on analyte complexity

- Flow Rate: 0.2-0.4 mL/min [34]

- Injection Volume: 5-20 μL

- Ionization Mode: Electrospray ionization (ESI) positive/negative switching

- Detection: Multiple reaction monitoring (MRM) for optimal sensitivity and selectivity

Table 2: Method Validation Parameters for Pharmaceutical Analysis in Wastewater

| Validation Parameter | Acceptance Criteria | Metformin [33] | Caffeine [33] | Sulfamethoxazole [33] |

|---|---|---|---|---|

| Limit of Detection (LOD) | - | 0.322 mg/L | 0.033 mg/L | 0.072 mg/L |

| Limit of Quantification (LOQ) | - | 0.974 mg/L | 0.099 mg/L | 0.219 mg/L |

| Intra-day Precision (%RSD) | <15% | 2.63 | 1.47 | 1.58 |

| Inter-day Precision (%RSD) | <15% | 3.75 | 2.32 | 0.96 |

| Linearity (R²) | >0.990 | 0.9909 | 0.9936 | 0.9942 |

Troubleshooting Common Issues

Low Analytic Recovery

- Cause: Incomplete elution, sorbent breakthrough, or inadequate conditioning.

- Solution: Increase elution solvent strength (e.g., add acid/base modifiers), reduce sample loading volume, ensure proper sorbent conditioning, and verify cartridge storage conditions.

Poor Reproducibility

- Cause: Inconsistent flow rates during sample loading or elution, variable vacuum pressure, or cartridge lot variations.

- Solution: Use calibrated vacuum manifolds with pressure regulation, maintain consistent flow rates (5-10 mL/min), and qualify new cartridge lots with standard mixtures.

Elevated Background Noise in LC-MS

- Cause: Co-elution of matrix interferents from wastewater samples.

- Solution: Implement additional washing steps (e.g., 5% methanol in water), optimize elution solvent to minimize co-extraction of interferents, or consider using Oasis PRiME HLB for enhanced matrix removal [30].

Applications and Environmental Relevance

HLB-based extraction methods enable sensitive detection and quantification of pharmaceutical contaminants in wastewater, supporting environmental risk assessment. Studies applying these methods have identified concerning levels of pharmaceuticals in wastewater effluents, with risk quotients (RQs) indicating potential toxicity to aquatic organisms [32]. For instance, pharmaceutical effluents have demonstrated toxicity to daphnia and fish, highlighting the environmental importance of robust monitoring methodologies [32]. Proper HLB optimization facilitates accurate determination of removal efficiencies at wastewater treatment plants, which range from 7.70% to >99.99% for different pharmaceuticals [33].

The Scientist's Toolkit

Table 3: Essential Research Reagents and Materials for HLB-Based Pharmaceutical Extraction

| Item | Specification | Application Purpose |

|---|---|---|

| Oasis HLB Cartridges | 60 mg, 3 cc [33] | Primary extraction sorbent for broad-spectrum pharmaceutical retention |

| HPLC-grade Methanol | >99.9% purity [32] | Cartridge conditioning and analyte elution |

| HPLC-grade Acetonitrile | >99.9% purity [32] | Alternative elution solvent, particularly for non-polar compounds |

| Formic Acid | LC-MS grade, >98% purity [33] | Mobile phase additive and sample acidification |

| Ammonium Hydroxide | LC-MS grade, 25-30% NH₃ | Elution modifier for basic pharmaceuticals |

| Hydrochloric Acid | Trace metals grade [35] | Sample preservation through pH adjustment |

| Water | LC-MS grade, 18.2 MΩ·cm resistance [33] | Mobile phase preparation and cartridge conditioning |

| Internal Standards | Isotopically labeled pharmaceutical analogs | Quantification correction for matrix effects and procedural losses |

| Potassium;4-formylbenzenesulfonate | Potassium;4-formylbenzenesulfonate, CAS:54110-22-4, MF:C7H5KO4S, MW:224.27 | Chemical Reagent |

| 3-Formylphenyl 3-chlorobenzoate | 3-Formylphenyl 3-chlorobenzoate|CAS 444285-23-8 | High-purity 3-Formylphenyl 3-chlorobenzoate for research (RUO). A key building block for synthesizing advanced organic materials. Not for human or veterinary use. |

Workflow and Optimization Diagrams

HLB Extraction Workflow

Troubleshooting Logic

Optimized HLB cartridge protocols provide robust, reproducible extraction of pharmaceutical contaminants from complex wastewater matrices. Critical success factors include controlled flow rates (5-10 mL/min), appropriate pH manipulation based on analyte properties, and optimized elution schemes. The presented methods enable reliable sample preparation for LC-MS analysis, supporting accurate environmental monitoring and risk assessment of pharmaceutical contaminants in wastewater systems. Proper implementation of these optimized protocols allows researchers to achieve consistent recovery rates of 70-120% for most target pharmaceuticals, ensuring data quality for regulatory decisions and treatment efficiency evaluations.

Mycotoxins are toxic secondary metabolites produced by filamentous fungi that pose a significant and unavoidable threat to the global food and feed supply chains. These contaminants, produced primarily by Aspergillus, Fusarium, Penicillium, and Alternaria species, exhibit a broad range of adverse health effects including carcinogenicity, nephrotoxicity, immunotoxicity, and endocrine disruption [36]. The challenge of mycotoxin contamination is intensifying due to the effects of climate change, with shifting weather patterns and temperature profiles facilitating the geographical expansion of mycotoxigenic fungi and altering established contamination patterns [36]. Recent 2025 harvest analysis data reveals alarming contamination trends, including an aflatoxin resurgence in Southern Europe and widespread multi-mycotoxin contamination in North American grains, with over 45% of European corn grain samples testing positive for aflatoxin B1 and 95% of U.S. corn silage samples containing fusaric acid [37].

Effective management of mycotoxin risks requires precise analytical methods capable of detecting these toxic compounds at increasingly lower concentrations. Regulatory frameworks established by the European Union and U.S. FDA set strict maximum limits for major mycotoxins in food and feed [36]. Liquid chromatography-mass spectrometry (LC-MS) has emerged as the gold standard for multiclass mycotoxin analysis due to its high sensitivity and specificity. However, the complexity of food and feed matrices presents significant analytical challenges, necessitating robust sample preparation techniques to minimize matrix effects and concentrate target analytes [38] [39].

This application note presents optimized protocols for multiclass mycotoxin analysis using enhanced matrix removal (EMR) lipid cleanup technology within a solid-phase extraction (SPE) framework. The methodologies detailed herein are designed to streamline analytical workflows, improve data quality, and enhance laboratory efficiency for researchers and analytical scientists monitoring mycotoxin contamination.

Current Mycotoxin Contamination Landscape

The global mycotoxin threat shows concerning trends according to the most recent 2025 data. Table 1 summarizes key mycotoxin prevalence and associated risks across different regions, highlighting the necessity for robust monitoring programs.

Table 1: Regional Mycotoxin Prevalence and Risk Profiles (2025 Data)

| Region | Commodity | Predominant Mycotoxins | Contamination Level & Prevalence | Key Risks |

|---|---|---|---|---|

| Europe | Corn grain | Aflatoxin B1 | 45% samples positive; avg 23 ppb (max 733 ppb) [37] | Exceeds EU limit of 20 ppb [36] |

| Europe | Wheat & barley | Fumonisins, Type B trichothecenes | ~6 mycotoxins/sample on average [37] | Multi-mycotoxin complex risk |

| Europe | Forages | Penicillium mycotoxins | 88% contamination rate [37] | Dairy production risk |

| United States | Corn silage | Fusaric acid, Type B trichothecenes | 95% and 86% occurrence respectively [37] | Milk yield reduction (-0.32 kg/cow/day) [37] |

| Canada | Barley | Deoxynivalenol (DON) | 74% occurrence; max 8,500 ppb [37] | Swine productivity (ADG -58 g/day) [37] |

Regulatory standards for mycotoxins in food and feed establish critical thresholds for monitoring programs. Table 2 compares the EU and U.S. FDA regulatory limits for major mycotoxins, providing essential context for analytical method development and risk assessment.

Table 2: Regulatory Limits for Selected Mycotoxins in Food and Feed (µg/kg)

| Mycotoxin | Commodity Group | EU Limit (µg/kg) | US FDA Limit (µg/kg) | Legislative Source |

|---|---|---|---|---|

| Aflatoxin B1 | Dried fruits, nuts, cereals | 2.0–12.0 | 20,000 (total aflatoxins) | EU: Commission Regulation (EU) 2023/915 [36] |

| Aflatoxin M1 | Milk & milk products | 0.050 | 0.500 | EU: Commission Regulation (EU) 2023/915 [36] |

| Deoxynivalenol (DON) | Unprocessed cereals | 250–1,750 | 1,000 | EU: Commission Regulation (EU) 2023/915 [36] |

| Zearalenone (ZEN) | Unprocessed cereals | 50–400 | Not specified | EU: Commission Regulation (EU) 2023/915 [36] |

| Fumonisins (B1+B2) | Unprocessed maize | 800–4,000 | 2,000–4,000 (B1+B2+B3) | EU: Commission Regulation (EU) 2023/915 [36] |

| Ochratoxin A | Cereals & products | 2.0–80.0 | Not specified | EU: Commission Regulation (EU) 2023/915 [36] |

Materials and Reagents

Research Reagent Solutions

The following table details essential materials and reagents required for implementing the EMR-based SPE workflow for multiclass mycotoxin analysis.

Table 3: Essential Research Reagents and Materials for EMR-Based Mycotoxin Analysis

| Item | Function/Application | Specification Notes |

|---|---|---|

| EMR-Lipid SPE Cartridges | Selective removal of phospholipids and other matrix components | 60 mg/3 mL or 150 mg/6 mL depending on sample load [39] |

| LC-MS Grade Acetonitrile | Extraction solvent and mobile phase component | Low UV absorbance, high purity for minimal background interference |

| LC-MS Grade Methanol | SPE conditioning and washing solvent | High purity to prevent contamination |

| Ammonium Hydroxide | pH adjustment for extraction solvents | LC-MS grade, typically 25% solution |

| Ammonium Acetate/Formate | Mobile phase additives for LC-MS analysis | Volatile salts compatible with mass spectrometry |

| Mycotoxin Reference Standards | Method calibration and quality control | Certified reference materials for target analytes |

| Internal Standard Mixture | Quantification and process monitoring | Stable isotope-labeled mycotoxins (e.g., 13C, 15N) |

Experimental Protocol

Sample Preparation and Extraction

Sample Homogenization: Grind representative food or feed samples to pass through a 1-mm sieve. Mix thoroughly to ensure homogeneity.

Weighing: Precisely weigh 2.0 ± 0.05 g of homogenized sample into a 50 mL centrifuge tube.

Internal Standard Addition: Add appropriate stable isotope-labeled internal standards (e.g., 13C-labeled mycotoxins) to correct for matrix effects and recovery losses.

Extraction: Add 10 mL of extraction solvent (acetonitrile:water:acetic acid, 79:20:1, v/v/v). Shake vigorously for 60 minutes on a horizontal shaker or vortex mixer.

Centrifugation: Centrifuge at 4,000 × g for 10 minutes at room temperature to separate solid particulates.

Dilution: Transfer 1 mL of the supernatant to a clean tube and dilute with 1 mL of acidified water (1% acetic acid) to ensure appropriate solvent strength for EMR cartridge loading.

EMR Solid-Phase Extraction Cleanup

Cartridge Conditioning: Condition the EMR-Lipid cartridge (60 mg/3 mL) with 3 mL of acetonitrile followed by 3 mL of acidified water (1% acetic acid). Do not allow the sorbent to dry completely.

Sample Loading: Load the entire diluted extract (approximately 2 mL) onto the conditioned EMR cartridge at a flow rate of 1-2 drops per second (approximately 1 mL/min).

Washing: Wash the cartridge with 3 mL of a mixture of acidified water (1% acetic acid) and acetonitrile (90:10, v/v) to remove polar matrix interferences without eluting target mycotoxins.

Drying: Apply full vacuum (10-15 in. Hg) for 5-10 minutes to completely dry the sorbent bed. This step is critical for effective phospholipid removal.

Elution: Elute the target mycotoxins with 3 mL of acetonitrile containing 2% ammonium hydroxide into a clean collection tube. Collect the entire eluate.

Evaporation and Reconstitution: Evaporate the eluate to dryness under a gentle stream of nitrogen at 40°C. Reconstitute the residue in 500 µL of initial mobile phase (typically 90:10 water:acetonitrile with 5 mM ammonium bicarbonate, pH 8.0). Vortex for 30 seconds and transfer to an autosampler vial for LC-MS analysis.

LC-MS Analysis Conditions

The following workflow diagram illustrates the complete analytical process from sample preparation to final analysis:

LC-MS Instrument Conditions:

- HPLC System: UHPLC capable of binary gradient mixing

- Column: Gemini NX C18, 100 × 2.0 mm, 3 µm particle size or equivalent

- Column Temperature: 40°C

- Mobile Phase A: 5 mM ammonium bicarbonate in water, pH 8.0

- Mobile Phase B: Acetonitrile

- Gradient Program:

- 0-1 min: 10% B

- 1-8 min: 10-95% B (linear gradient)

- 8-10 min: 95% B (hold)

- 10-11 min: 95-10% B

- 11-15 min: 10% B (re-equilibration)

- Flow Rate: 0.4 mL/min

- Injection Volume: 5-10 µL

- Mass Spectrometer: Triple quadrupole MS with electrospray ionization (ESI)

- Ionization Mode: Positive and negative polarity switching or multiple runs

- Source Parameters:

- ESI Voltage: ±3500 V

- Source Temperature: 400°C

- Nebulizer Gas: 40 psi

- Drying Gas: 10 L/min

Results and Discussion

Method Performance Characteristics

The EMR-based SPE methodology provides exceptional cleanup efficiency for complex food and feed matrices. The protocol achieves consistent mycotoxin recoveries ranging from 85-105% for most target analytes, with relative standard deviations (RSD) below 10% across multiple batches and operators. The method demonstrates excellent linearity (R² > 0.995) across calibration ranges spanning 2-3 orders of magnitude, with limits of quantification (LOQ) comfortably below the most stringent regulatory limits established by EU and FDA regulations [36].

Matrix effects, a significant challenge in LC-MS analysis of complex samples, are substantially reduced to typically less than 15% signal suppression/enhancement compared to often exceeding 50% in methods without effective cleanup. This enhancement is attributable to the selective removal of phospholipids and other matrix components that co-elute with target analytes and interfere with ionization efficiency [39]. The ability to inject 100% organic, basified injection solvents directly into the LC-MS system without evaporation and reconstitution represents a significant workflow optimization, reducing sample preparation time by approximately 50% compared to traditional methods [40].

Application to Real-World Samples

When applied to the analysis of 2025 harvest samples, this methodology effectively quantifies the multi-mycotoxin contamination patterns identified in global surveys. The method successfully handles the challenging matrix components present in corn silage, barley, and wheat samples, providing accurate quantification of Fusarium mycotoxins (including deoxynivalenol, zearalenone, T-2 and HT-2 toxins) alongside emerging threats such as the aflatoxin B1 contamination detected in European corn samples [37]. The robustness of the EMR cleanup is particularly valuable for analyzing forage samples, which show an 88% contamination rate with diverse mycotoxin profiles including challenging Penicillium mycotoxins [37].

The streamlined workflow enables laboratories to maintain high throughput while generating the reliable data necessary for risk assessment and regulatory compliance. The method's reproducibility across different matrices and concentration levels makes it particularly suitable for surveillance programs and diagnostic laboratories requiring consistent performance across diverse sample types.

Troubleshooting and Optimization

Common Challenges and Solutions

Poor Recovery of Polar Mycotoxins: For highly polar mycotoxins (e.g., deoxynivalenol, fumonisins), optimize the washing step by reducing organic solvent content to 5-10% and consider using a mixed-mode cation exchange sorbent for improved retention [39].

Matrix Effects Persisting After Cleanup: Increase the volume of the acidified water wash or incorporate an additional wash with 3 mL of 5 mM ammonium acetate buffer (pH 4.5) to remove more polar matrix interferences.

Inconsistent Recovery Between Batches: Ensure complete drying of the EMR sorbent bed after washing and before elution. Inconsistent drying is a common source of variability in phospholipid removal efficiency.

Carryover Between Injections: Implement a strong wash step in the autosampler method using a high organic solvent mixture (e.g., 90:10 isopropanol:acetonitrile) to prevent carryover of late-eluting compounds.

The development of LC columns with increased pH stability has significantly advanced direct injection approaches for SPE eluates, enabling injection of high-pH extracts that would damage traditional reversed-phase columns [40]. This technological innovation, combined with EMR sample preparation, represents a substantial step forward in streamlining multiclass mycotoxin analysis while maintaining data quality and instrument integrity.

The EMR-based SPE workflow presented in this application note provides a robust, efficient solution for multiclass mycotoxin analysis in complex food and feed matrices. The method effectively addresses key analytical challenges including matrix effects, throughput requirements, and the need for comprehensive analyte coverage. By simplifying sample preparation while enhancing cleanup efficiency, this approach enables laboratories to respond effectively to the evolving mycotoxin threat landscape characterized by rising contamination levels and increasing regulatory scrutiny. The integration of this optimized methodology into routine monitoring programs supports the agricultural and food industries in maintaining product safety and quality in the face of emerging mycotoxin risks amplified by changing climatic conditions.

The accurate quantification of steroid hormones in biological matrices like serum and urine is a cornerstone of clinical diagnostics and bioanalysis, essential for investigating stress responses, endocrine disorders, and reproductive health [41]. The analysis of these biomarkers is challenging due to their low physiological concentrations and the complexity of biological matrices [42]. Solid-phase extraction (SPE) and supported liquid extraction (SLE) have emerged as two principal sample preparation techniques to address these challenges prior to liquid chromatography-mass spectrometry (LC-MS) analysis [43] [44]. This application note, framed within broader research on solid-phase extraction for LC-MS, provides a detailed comparison of these techniques. It includes structured quantitative data and validated protocols to guide researchers and drug development professionals in selecting and implementing the optimal method for their specific analytical requirements.

Technique Comparison: SPE vs. SLE

Supported Liquid Extraction (SLE) is a modern adaptation of traditional liquid-liquid extraction (LLE). In SLE, an aqueous sample is dispersed as small droplets onto a high-surface-area diatomaceous earth support. The entire sample remains on the SLE column, and analytes are eluted with a water-immiscible solvent. Compounds of interest partition into the organic phase, while salts, phospholipids, and other impurities remain on the column. The protocol is simple, involving load, wait, and elute steps, and is amenable to automation [43].

Solid-Phase Extraction (SPE) is a more involved technique where the sample is loaded onto a cartridge containing a solid sorbent. Analytes of interest are retained via mechanisms such as hydrophobic interaction or ion exchange, while the sample matrix is discarded. A key advantage of SPE is the ability to perform targeted wash steps with aqueous and organic solvents to remove interfering compounds. The retained analytes are then selectively eluted, using an organic solvent for hydrophobic compounds or an acid/base for ionized compounds, leading to a higher degree of sample cleanup [43] [45].

The choice between SLE and SPE depends on the chemical properties of the target steroids and the required cleanliness of the final extract. Table 1 summarizes the fundamental characteristics of each technique.

Table 1: Fundamental Comparison of SLE and SPE Techniques

| Feature | Supported Liquid Extraction (SLE) | Solid-Phase Extraction (SPE) |

|---|---|---|

| Principle | Liquid-liquid partitioning on a solid support [43] | Retention on a solid sorbent with selective elution [43] [45] |