UV-Vis Spectrophotometry for Drug Potency Analysis: A Comprehensive Guide for Pharmaceutical Scientists

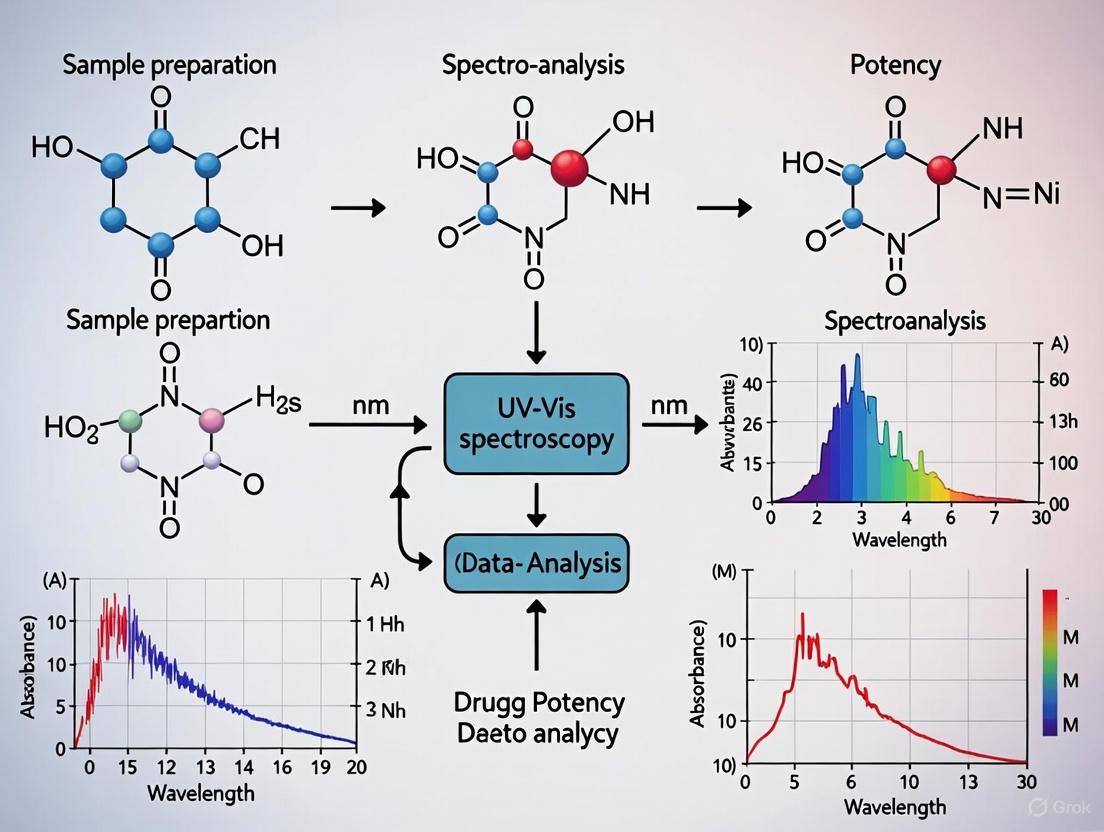

This article provides pharmaceutical researchers and drug development professionals with a current and comprehensive examination of UV-Vis spectrophotometry for determining drug potency.

UV-Vis Spectrophotometry for Drug Potency Analysis: A Comprehensive Guide for Pharmaceutical Scientists

Abstract

This article provides pharmaceutical researchers and drug development professionals with a current and comprehensive examination of UV-Vis spectrophotometry for determining drug potency. It covers foundational principles, advanced methodological applications including chemometric models for complex formulations, essential troubleshooting and optimization techniques to ensure data integrity, and rigorous validation protocols with comparisons to other analytical techniques. Aligned with green chemistry principles and regulatory guidelines, this resource supports robust, sustainable, and efficient potency analysis in quality control and research settings.

Understanding the Core Principles of UV-Vis Spectrophotometry in Pharmaceutical Analysis

The Beer-Lambert Law (also referred to as Beer's Law) represents a fundamental principle in optical spectroscopy that describes the relationship between the attenuation of light passing through a substance and the properties of that substance [1]. This law forms the theoretical foundation for quantitative analysis across numerous scientific disciplines, including pharmaceutical research, where it enables the precise determination of analyte concentrations in solutions [2]. In the specific context of drug potency analysis using UV-Vis spectrophotometry, this law provides the mathematical basis for correlating measured absorbance values with the concentration of active pharmaceutical ingredients (APIs) in solution.

The law establishes that the absorbance of light by a solution is directly proportional to the concentration of the absorbing species and the path length of light through the solution [3] [4]. This linear relationship enables researchers to construct calibration curves from standards of known concentration, which can then be used to determine unknown concentrations in test samples through absorbance measurements [1] [2]. For drug development professionals, this principle is indispensable for quantifying potency, assessing purity, and ensuring product consistency throughout the development and manufacturing processes.

Theoretical Foundation

Fundamental Concepts: Transmittance and Absorbance

When monochromatic light passes through a solution, its intensity decreases due to interactions with the molecules present. This attenuation is quantified through two interrelated concepts:

Transmittance (T) is defined as the ratio of the transmitted light intensity (I) to the incident light intensity (Iâ‚€) [1] [3]:

- ( T = \frac{I}{I_0} )

- Transmittance is commonly expressed as a percentage: ( \%T = \frac{I}{I_0} \times 100\% )

Absorbance (A) is defined as the negative logarithm of transmittance [1] [3] [4]:

- ( A = -\log{10}(T) = \log{10} \left( \frac{I_0}{I} \right) )

- Absorbance is a dimensionless quantity with an inverse logarithmic relationship to transmittance

Table 1: Relationship Between Absorbance and Transmittance

| Absorbance (A) | Transmittance (%T) |

|---|---|

| 0 | 100% |

| 0.3 | 50% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

| 4 | 0.01% |

Mathematical Formulation

The Beer-Lambert Law is mathematically expressed as:

A = εlc

Where:

- A = Absorbance (unitless)

- ε = Molar absorptivity (L·molâ»Â¹Â·cmâ»Â¹) or extinction coefficient

- l = Path length (cm) - typically the width of the cuvette

- c = Concentration of the absorbing species (mol/L or M) [1] [3] [4]

The molar absorptivity (ε) is a substance-specific constant that represents how strongly a chemical species absorbs light at a particular wavelength [4]. This value is both wavelength-dependent and compound-specific, making it a fundamental molecular property that determines the sensitivity of spectroscopic measurements.

Historical Context and Development

The principles underlying the Beer-Lambert Law were developed through contributions from multiple scientists over nearly two centuries:

- Pierre Bouguer (1729): First documented the exponential attenuation of light through the atmosphere [5]

- Johann Heinrich Lambert (1760): Formalized the mathematical relationship between absorbance and path length [5]

- August Beer (1852): Established the relationship between absorbance and concentration of solutions [5]

- Modern formulation: Robert Luther and Andreas Nikolopulos provided the contemporary mathematical form in 1913 [5]

The law is sometimes referred to as the Beer-Bouguer-Lambert Law to acknowledge all three principal contributors, though it is most commonly known as the Beer-Lambert Law in modern scientific literature [6] [5].

Practical Applications in Drug Potency Analysis

Quantitative Analysis of Cannabinoids and Pharmaceuticals

The Beer-Lambert Law serves as the fundamental principle for quantifying active pharmaceutical ingredients (APIs) in various analytical techniques:

- UV-Vis Spectroscopy for Potency Determination: Direct quantification of APIs in solution through absorbance measurements at specific wavelengths [2]

- HPLC with UV-Vis Detection: Measurement of analyte concentration as compounds elute from the chromatography column [2]

- Infrared Spectroscopy for Potency Analysis: Quantitative analysis of cannabis biomass, extracts, and finished products [2]

For cannabis potency analysis specifically, Beer's Law enables the quantification of major cannabinoids including THC, CBD, and their acidic precursors through both chromatographic and spectroscopic methods [2]. The law applies regardless of the wavelength region used, making it equally valid for UV, visible, and infrared spectroscopic techniques.

Contamination Detection in Biopharmaceutical Production

UV-Vis spectroscopy combined with machine learning algorithms has emerged as a powerful approach for detecting biological contamination in microalgae cultures used for pharmaceutical production [7]. This method leverages:

- Natural pigment chemistry of microorganisms that produce distinct spectral fingerprints

- Multivariate analysis techniques like Principal Component Analysis (PCA) to classify spectral differences

- Real-time monitoring capabilities for maintaining culture integrity in biopharmaceutical manufacturing

This application demonstrates how the fundamental principles of the Beer-Lambert Law can be enhanced with computational approaches to solve complex analytical challenges in pharmaceutical development.

Physiological Monitoring and Medical Diagnostics

Beyond traditional potency testing, modified versions of the Beer-Lambert Law find applications in medical diagnostics and physiological monitoring:

- Diffuse Correlation Spectroscopy (DCS): Modified Beer-Lambert algorithms enable non-invasive measurement of pulsatile cerebral blood flow and intracranial pressure [8]

- Lactate Monitoring: Near-infrared (NIR) spectroscopy applications for measuring lactate concentration in blood, serum, and phosphate buffer solutions [9]

- Critical Closing Pressure (CrCP) Determination: Frequency-domain modified Beer-Lambert methods help predict intracranial pressure elevations in clinical settings [8]

These advanced applications demonstrate how the core principles of light absorption and attenuation continue to evolve and find new implementations in biomedical research and clinical practice.

Experimental Protocols and Methodologies

Standard Calibration Protocol for Drug Potency Analysis

Table 2: Research Reagent Solutions for Spectroscopic Potency Analysis

| Reagent/Material | Specifications | Function in Experiment |

|---|---|---|

| Certified Reference Standards | ≥99% purity, known concentration of API | Primary standard for calibration curve generation |

| HPLC-grade Solvent | UV-cutoff below measurement wavelength, low impurity | Dissolution medium for standards and samples |

| Volumetric Flasks | Class A, various sizes (10mL, 25mL, 50mL, 100mL) | Precise preparation of standard solutions |

| Cuvettes | Optical grade, path length matched (typically 1cm) | Sample container for spectroscopic measurement |

| Buffer Salts | Analytical grade, appropriate for target analyte | pH control and matrix matching |

| Mobile Phase Components | HPLC-grade solvents and modifiers | Chromatographic separation (for HPLC-UV methods) |

Protocol: Development of Beer's Law Calibration Curve

Standard Solution Preparation

- Prepare a stock solution of certified reference standard at known concentration (e.g., 1 mg/mL)

- Create serial dilutions to generate at least 5 standard solutions covering the expected concentration range of samples

- Ensure all solutions use the same solvent matrix and are prepared in identical volumetric glassware

Spectrophotometer Setup and Blank Measurement

- Turn on UV-Vis spectrophotometer and allow adequate warm-up time (typically 30 minutes)

- Select the optimal analytical wavelength (λmax) for the target compound

- Place solvent blank in cuvette and record baseline measurement

- Zero the instrument using the blank to correct for solvent absorption

Absorbance Measurement of Standards

- Rinse cuvette with a small portion of the first standard solution

- Fill cuvette with standard solution, ensuring no air bubbles are present

- Measure and record absorbance at λmax

- Repeat for all standard solutions, measuring in triplicate for statistical reliability

Calibration Curve Generation

- Plot average absorbance values (y-axis) versus concentration (x-axis)

- Perform linear regression to obtain the equation: A = εlC + b

- Verify linearity (R² > 0.995) and assess y-intercept (should approach zero)

Direct Spectroscopic Potency Analysis of Solid Dosage Forms

For non-extractive analysis of solid pharmaceutical formulations:

Sample Preparation

- Grind representative sample to homogeneous powder using a mortar and pestle

- For infrared methods, mix powder with infrared-transparent matrix (e.g., KBr) for pellet preparation

- For reflectance UV-Vis methods, ensure uniform surface presentation

Reference Material Analysis

- Analyze matrix-matched reference materials with known analyte concentrations

- Collect spectra using appropriate sampling interface (ATR, diffuse reflectance, transmission)

- Establish multivariate calibration models using partial least squares (PLS) regression

Unknown Sample Measurement

- Prepare unknown samples identically to calibration standards

- Collect spectral data and apply pre-processing (normalization, derivative treatments)

- Predict concentration using established calibration model

Method Validation

- Assess accuracy through spike recovery experiments

- Determine precision via replicate measurements

- Establish detection and quantification limits

- Verify method robustness through inter-day and inter-operator testing

HPLC-UV Method for Cannabinoid Profiling

Protocol: Chromatographic Separation with Spectroscopic Detection

Mobile Phase Preparation

- Prepare aqueous phase: 0.1% formic acid in water

- Prepare organic phase: 0.1% formic acid in acetonitrile

- Filter both phases through 0.2μm membrane and degas

Standard and Sample Preparation

- Prepare calibration standards in concentration range of 0.1-100 μg/mL

- Extract sample material with appropriate solvent (typically methanol or acetonitrile)

- Filter extract through 0.2μm syringe filter before injection

Chromatographic Conditions

- Column: C18 reverse phase (150 × 4.6 mm, 2.6μm)

- Flow rate: 1.0 mL/min

- Injection volume: 10μL

- Column temperature: 40°C

- Gradient program: 5-95% organic phase over 15 minutes

Detection and Quantification

- UV detection at 228nm for cannabinoids

- Record peak areas for each calibration standard

- Construct calibration curve for each target compound

- Calculate sample concentrations using linear regression parameters

Data Analysis and Interpretation

Calibration Curve Statistics and Validation

A high-quality Beer's Law calibration should demonstrate:

- Linearity: R² value > 0.995 for the concentration range of interest

- Precision: Relative standard deviation (RSD) of replicate measurements < 2%

- Accuracy: Method recovery of 95-105% for quality control samples

- Sensitivity: Molar absorptivity (ε) sufficient for target detection limits

Table 3: Troubleshooting Common Beer's Law Deviations

| Observation | Potential Causes | Corrective Actions |

|---|---|---|

| Non-linear calibration at high concentrations | Molecular interactions, aggregation, instrument stray light | Dilute samples, use shorter path length, verify monochromaticity |

| Curvature at all concentrations | Polychromatic light source, chemical equilibrium shifts | Use narrower bandwidth, verify source wavelength accuracy |

| Y-intercept significantly non-zero | Blank contamination, cuvette mismatch, light scattering | Re-prepare blank, match cuvettes, filter particulate matter |

| Poor reproducibility | Inconsistent pipetting, evaporation, air bubbles | Improve technique, use sealed containers, degas solutions |

| Absorption band shifts | Solvent effects, pH variations, molecular complexation | Control solvent composition, buffer pH, verify chemical stability |

Advanced Modeling for Complex Matrices

In scattering media or complex biological matrices, traditional Beer's Law applications may require modifications:

- Multi-component Analysis: For mixtures of absorbing species, the total absorbance represents the sum of individual contributions [5]:

- ( A{total} = l\sum{i} \varepsiloni ci )

- Scattering Media Corrections: In highly scattering matrices like whole blood, modified algorithms such as frequency-domain analysis improve accuracy [9] [8]

- Multivariate Calibration: Partial least squares (PLS) and principal component regression (PCR) models handle overlapping spectral features and background interference [9]

Recent empirical investigations suggest that while nonlinearities due to high concentrations may be minimal, scattering matrices can introduce significant deviations that justify more complex, nonlinear modeling approaches [9].

Limitations and Practical Considerations

Fundamental Limitations of the Beer-Lambert Law

The Beer-Lambert Law operates under specific assumptions that, when violated, can lead to significant deviations:

- Chemical Deviations: Occur when concentration-dependent chemical equilibria (e.g., association, dissociation, polymerization) alter absorptivity [10] [6]

- Instrumental Deviations: Result from the use of polychromatic radiation, excessive spectral bandwidth, or stray light [9] [6]

- Matrix Effects: Scattering phenomena in heterogeneous samples cause non-absorption attenuation [9] [6]

Recent research indicates that deviations from electromagnetic theory become significant at high absorption levels, where the Beer-Lambert Law provides only an approximation of the true attenuation behavior [6].

Concentration Limitations

The linear relationship between absorbance and concentration typically holds within specific concentration ranges:

- Upper Limit: Deviations often occur above absorbance values of 1-2 (depending on instrument and sample characteristics) [10] [6]

- Lower Limit: Detection is constrained by signal-to-noise ratio of the instrument

- Dynamic Range: Typically 2-3 orders of magnitude for well-designed methods

Empirical studies with lactate solutions demonstrate that nonlinearities due to high concentrations alone may be minimal, with linear models performing well even at concentrations up to 600 mmol/L in clear solutions [9].

Electromagnetic Theory Considerations

Modern interpretations recognize that the Beer-Lambert Law represents an approximation that neglects certain electromagnetic phenomena:

- The law does not fully account for the wave nature of light and associated effects [6]

- Reflection losses at interfaces are typically neglected in standard formulations [6]

- Optical effects such as band shifts and intensity changes based on substrate interactions are not captured [6]

For precise quantitative work, especially in scattering media or at high concentrations, more comprehensive models based on electromagnetic theory may be necessary to account for these limitations [9] [6].

Future Perspectives and Advanced Applications

Integration with Machine Learning and Multivariate Analysis

The combination of Beer-Lambert principles with advanced computational methods represents the future of spectroscopic analysis:

- Machine Learning Enhancement: Algorithms like artificial neural networks (ANNs) and support vector regression (SVR) can model complex, non-linear relationships in scattering media [9]

- Real-time Contamination Monitoring: UV-Vis spectroscopy with machine learning enables automated detection of biological contaminants in pharmaceutical production systems [7]

- Multivariate Calibration: Methods like principal component regression (PCR) and partial least squares (PLS) handle overlapping spectral features in complex mixtures [9]

Modified Algorithms for Biomedical Applications

Advanced modifications of the Beer-Lambert Law continue to enable new biomedical applications:

- Frequency-Domain Modified Beer-Lambert Method: Improves filtering of extra-cerebral tissue contamination in diffuse correlation spectroscopy for non-invasive intracranial pressure monitoring [8]

- Pulsatile Flow Measurements: Enables determination of critical closing pressure (CrCP) as a proxy for intracranial hypertension [8]

- Non-invasive Metabolic Monitoring: Continuous measurement of biomarkers like lactate through scattering tissues using modified algorithms [9]

These advanced applications demonstrate how the fundamental principles of light absorption continue to evolve and find new implementations in pharmaceutical research and clinical diagnostics, ensuring the continued relevance of the Beer-Lambert Law in modern analytical science.

In the field of pharmaceutical research and drug development, the accurate determination of drug potency is a critical requirement. UV-Vis spectrophotometry stands as a cornerstone analytical technique for this purpose, enabling researchers to quantify analyte concentration based on the fundamental principles of light absorption. The choice between single-beam and dual-beam spectrophotometer configurations represents a significant decision point that directly impacts analytical precision, workflow efficiency, and data reliability. This application note provides a detailed technical comparison of these instrumental approaches within the specific context of pharmaceutical analysis, supported by structured protocols for determining drug potency.

Fundamental Operational Principles

Single-Beam Spectrophotometry

A single-beam spectrophotometer employs a straightforward optical path where all light from the source passes through the sample as a single beam [11] [12]. This design requires sequential measurement: first, a reference (blank) solution is measured to establish baseline intensity, then the sample is measured after manually replacing the reference [13] [14]. The absorbance is calculated by comparing these two sequential measurements. This simpler optical design results in lower initial cost, higher light throughput potentially increasing sensitivity, and a more compact instrument footprint [12] [13]. However, this configuration is more susceptible to measurement drift over time due to its inability to continuously correct for fluctuations in light source intensity or detector response [11] [14].

Dual-Beam Spectrophotometry

A dual-beam spectrophotometer incorporates an optical system that splits the source light into two separate paths immediately after the monochromator [11] [15]. One beam passes through the sample while the other simultaneously passes through a reference cell containing blank solvent [12] [14]. This simultaneous measurement enables real-time correction for instrumental fluctuations, including lamp intensity variations, detector sensitivity drift, and electronic noise [15] [13]. While this design comes at a higher cost and with greater mechanical complexity, it provides significantly enhanced measurement stability, accuracy for prolonged analyses, and automated operation that reduces manual intervention [11] [13].

Table 1: Comparative Analysis of Single-Beam vs. Dual-Beam Spectrophotometers

| Feature | Single-Beam Spectrophotometer | Dual-Beam Spectrophotometer |

|---|---|---|

| Optical Design | Single light path [11] | Two split light paths [11] |

| Measurement Mode | Sequential (blank then sample) [11] | Simultaneous sample and reference [11] |

| Stability & Drift Compensation | Lower stability; no real-time compensation [11] [13] | High stability; automatic compensation for source/detector fluctuations [11] [13] |

| Analytical Precision | Moderate, suitable for routine analysis [14] | High, essential for demanding applications [14] |

| Cost & Maintenance | Lower initial cost; simpler maintenance [11] [14] | Higher initial cost; more complex maintenance [11] [14] |

| Typical Wavelength Range | 190–750 nm (some to 1100 nm) [12] | Typically 190–1100 nm [12] [13] |

| Ideal Application Context | Educational labs, basic QC, field analysis [11] [13] | Research, pharmaceutical QA/QC, kinetic studies [11] [16] |

Application in Drug Potency Determination

Quantitative Analysis of Active Pharmaceutical Ingredients (APIs)

UV-Vis spectrophotometry is extensively employed for quantifying Active Pharmaceutical Ingredients (APIs) in drug formulations to ensure compliance with pharmacopeial standards [16]. The determination relies on the Beer-Lambert law, which establishes a linear relationship between absorbance and analyte concentration [16] [17]. Dual-beam instruments are particularly advantageous for this application due to their inherent stability, which is crucial for generating reproducible results in regulated environments [11] [16]. Furthermore, their continuous reference measurement capability makes them ideal for dissolution testing, where the concentration of a drug released from its dosage form is monitored over time, requiring compensation for both instrument drift and medium absorbance [16].

Analysis of Complex Formulations

Pharmaceutical analysis frequently involves resolving overlapping spectral signals from multiple active compounds or excipients. Advanced chemometric methods applied to spectrophotometric data enable the simultaneous determination of drugs with spectral overlaps [18] [19]. For instance, a dual-beam UV-Vis spectrophotometer was successfully used with dual-wavelength and derivative ratio methodologies to simultaneously determine ketorolac tromethamine and olopatadine hydrochloride in a challenging 4:1 ratio ophthalmic formulation, overcoming the obstacle presented by benzalkonium chloride as a UV-absorbing inactive ingredient [18].

Solubility Enhancement for Poorly Soluble Drugs

Many modern APIs exhibit poor aqueous solubility, presenting a significant challenge for spectrophotometric analysis. Hydrotropic solubilization offers an eco-friendly and effective solution. Research demonstrates that concentrated aqueous solutions of hydrotropic agents like urea can enhance drug solubility by more than 14-fold, enabling direct spectrophotometric analysis of compounds like rosiglitazone maleate without toxic organic solvents [17]. This application typically employs a double-beam spectrophotometer for its superior ability to provide accurate and stable measurements across a wide concentration range [17].

Experimental Protocols

Protocol 1: Simultaneous Assay of Two-Component Formulation

This protocol details the simultaneous quantification of Ketorolac Tromethamine (KET) and Olopatadine HCl (OLO) in a lab-prepared ophthalmic solution using a double-beam UV-Vis spectrophotometer [18].

Table 2: Research Reagent Solutions for Two-Component Assay

| Reagent/Material | Specification | Function in Protocol |

|---|---|---|

| Double-Beam UV-Vis Spectrophotometer | Shimadzu 1800 or equivalent [18] | Primary analytical instrument for absorbance measurement |

| Quartz Cuvettes | 1 cm path length, matched pair [18] | Sample and reference containment for UV range |

| Ketorolac Tromethamine (KET) | Reference Standard (98.81% purity) [18] | Active Pharmaceutical Ingredient (API) for analysis |

| Olopatadine HCl (OLO) | Reference Standard (99.20% purity) [18] | Active Pharmaceutical Ingredient (API) for analysis |

| Benzalkonium Chloride | 50% w/w solution [18] | Preservative (inactive ingredient) in simulated formulation |

| Distilled Water | Analytical Grade | Solvent for all aqueous solutions |

Procedure:

Preparation of Standard Solutions:

- Prepare separate stock solutions of KET and OLO in distilled water at a concentration of 1 mg/mL.

- Prepare working standard solutions: 20.0 µg/mL KET and 50.0 µg/mL OLO by appropriate dilution of stock solutions with distilled water.

Construction of Calibration Curves:

- For KET: Prepare calibration standards (3.0–12.0 µg/mL) from the KET working solution. Record the UV spectra (200–400 nm) using the double-beam instrument. Measure absorbance directly from the zero-order spectra at λmax 323 nm. Plot absorbance versus concentration to generate the calibration curve [18].

- For OLO (Dual Wavelength Method): Prepare calibration standards (4.0–40.0 µg/mL) from the OLO working solution. Record the UV spectra. Calculate the absorbance difference (ΔA) between 243 nm and 291 nm. Plot ΔA against concentration to generate the calibration curve [18].

- For OLO (Ratio Derivative Method): Using the same OLO standards, divide their stored spectra by the zero-order spectrum of 3.0 µg/mL KET (the divisor). Generate the first derivative (Δλ = 1 nm) of these ratio spectra. Measure the amplitude at the minima (234 nm) and plot against concentration [18].

Sample Preparation (Lab-Prepared Eye Drops):

- Prepare a mixture simulating the dosage form (40 mg KET, 10 mg OLO, 1 mg benzalkonium chloride) in 10 mL distilled water (stock test solution).

- Dilute 2.0 mL of this stock to 100 mL with distilled water to obtain the working assay solution.

Analysis:

- KET Determination: Dilute 1.0 mL of the working assay solution to 10 mL with distilled water (n=3). Measure the absorbance at 323 nm and determine the concentration using the KET regression equation.

- OLO Determination (Standard Addition): To a series of 10-mL volumetric flasks, each containing 1.0 mL of the working assay solution, add different volumes of OLO working standard solution (2, 3, 4, 5, 6, and 7 mL). Dilute to volume with distilled water. Apply the chosen method (DWM or 1DR) to these solutions. Plot the measured response versus the concentration of OLO standard added. The absolute value of the x-intercept gives the concentration of OLO in the sample [18].

Protocol 2: Analysis of a Poorly Water-Soluble Drug

This protocol utilizes hydrotropic solubilization for the analysis of Rosiglitazone Maleate (RZM) using a double-beam UV-Vis spectrophotometer, eliminating the need for organic solvents [17].

Table 3: Research Reagent Solutions for Poorly Soluble Drug Assay

| Reagent/Material | Specification | Function in Protocol |

|---|---|---|

| Double-Beam UV-Vis Spectrophotometer | Perkin Elmer Lambda 25 or equivalent [17] | Primary analytical instrument |

| Quartz Cuvettes | 1 cm path length, matched pair [17] | Sample and reference containment |

| Rosiglitazone Maleate (RZM) | Reference Standard [17] | Poorly water-soluble model drug |

| Urea | Analytical Grade [17] | Hydrotropic solubilizing agent (6M solution) |

| Whatman Filter Paper | No. 41 [17] | Filtration of solubilized sample |

| Distilled Water | Analytical Grade | Solvent for hydrotropic solution |

Procedure:

Preparation of Hydrotropic Solvent:

- Prepare a 6 M aqueous solution of urea in distilled water.

Solubility Enhancement and Sample Preparation:

- For Bulk Drug: Transfer powder equivalent to 100 mg of RZM into a 250 mL volumetric flask. Add approximately 150 mL of 6M urea solution, sonicate for 4 hours to dissolve, and make up to volume with the urea solution.

- For Tablet Formulation: Accurately weigh powder equivalent to 100 mg of RZM from twenty finely powdered tablets. Transfer to a 250 mL volumetric flask and proceed as for the bulk drug.

- Filter the resulting solution using Whatman filter paper No. 41.

Spectrophotometric Analysis:

- Dilute the filtrate appropriately with distilled water to obtain a concentration within the Beer-Lambert's law range (typically 5–300 µg/mL for RZM).

- Scan the diluted solution from 200–400 nm against a blank of 6M urea solution using the double-beam spectrophotometer. Identify the λmax (approximately 251 nm).

- Prepare standard solutions of RZM in the 6M urea system (5–50 µg/mL). Measure the absorbance at λmax.

- Construct a calibration curve by plotting absorbance versus concentration.

- Determine the concentration of RZM in the unknown sample solutions using the regression equation derived from the calibration curve.

Validation:

- Assess the method's accuracy through recovery studies by spiking a pre-analyzed sample with a known amount of standard drug.

- Evaluate precision via intra-day and inter-day replicate analyses (n=5).

The selection between single-beam and dual-beam spectrophotometers for drug potency determination is a strategic decision guided by analytical requirements, regulatory constraints, and operational considerations. Single-beam instruments offer a cost-effective solution for routine, high-throughput analyses where ultimate precision is not critical. In contrast, dual-beam spectrophotometers provide the superior stability, automatic compensation, and high reproducibility essential for research and development, rigorous quality control, dissolution testing, and the analysis of complex or challenging samples. The provided protocols demonstrate that, especially when coupled with advanced sample preparation and chemometric techniques, UV-Vis spectrophotometry remains a powerful, versatile, and indispensable technique in the modern pharmaceutical scientist's toolkit.

Ultraviolet-visible (UV-Vis) spectrophotometry is a fundamental analytical technique in pharmaceutical research and quality control, providing a rapid, cost-effective means for determining drug potency. The technique measures the amount of discrete wavelengths of UV or visible light absorbed by a sample, providing critical information about the identity, purity, and concentration of active pharmaceutical ingredients (APIs) [20] [21]. For drug potency studies, which form a core component of this thesis research, the accurate quantification of API concentration is paramount for ensuring therapeutic efficacy and patient safety. The reliability of these determinations hinges on the meticulous optimization of three key parameters: wavelength selection, absorbance range, and spectral interpretation. When properly controlled, UV-Vis spectroscopy serves as a robust tool for content uniformity testing, dissolution profile monitoring, and stability assessment in pharmaceutical development and manufacturing [21].

Core Principles and Instrumentation

Theoretical Foundation

UV-Vis spectroscopy operates on the principle that molecules absorb light in the ultraviolet (typically 100-400 nm) and visible (400-800 nm) regions of the electromagnetic spectrum, causing electronic transitions between molecular orbitals [20] [22]. The energy carried by a photon of light is inversely proportional to its wavelength; shorter wavelengths carry more energy and are capable of promoting electrons to higher energy states [20]. The primary molecular moieties that absorb light in this region are chromophores, which contain pi-electron systems and heteroatoms with non-bonding valence-shell electron pairs [22]. The fundamental relationship governing quantitative analysis is the Beer-Lambert Law, which states that absorbance (A) is directly proportional to the concentration (c) of the absorbing species, the path length (L) of the sample container, and the molar absorptivity (ε) of the compound [20].

A UV-Vis spectrophotometer consists of several key components: a light source, a wavelength selector, a sample holder, and a detector [20]. Most instruments utilize two lamps—a deuterium lamp for UV light and a tungsten or halogen lamp for visible light—with an automatic switchover occurring between 300 and 350 nm where light emission is similar from both sources [20]. Monochromators, typically based on diffraction gratings with a groove frequency of at least 1200 grooves per mm, are the most common wavelength selection method, providing a narrow band of wavelengths for sample examination [20]. Following interaction with the sample, the transmitted light is captured by a detector, such as a photomultiplier tube or a photodiode, which converts the light intensity into an electronic signal for data processing [20].

Table 1: Key Components of a UV-Vis Spectrophotometer

| Component | Description | Common Types |

|---|---|---|

| Light Source | Provides broad-spectrum UV and/or visible light | Deuterium lamp (UV), Tungsten/Halogen lamp (Visible), Xenon lamp |

| Wavelength Selector | Isolates specific wavelengths from the source | Monochromator (diffraction grating), Absorption filters, Interference filters |

| Sample Holder | Container for the sample solution | Cuvette (quartz for UV, glass/plastic for visible) |

| Detector | Measures the intensity of light after it passes through the sample | Photomultiplier Tube (PMT), Photodiode, Charge-Coupled Device (CCD) |

Key Parameter 1: Wavelength Selection

Principles of Wavelength Selection

Wavelength selection is the cornerstone of method development in UV-Vis spectrophotometry for drug analysis. The primary goal is to identify the wavelength of maximum absorbance (λmax) for the target analyte, which provides the highest sensitivity and minimizes the impact of minor instrumental fluctuations [23]. This parameter is influenced by the electronic structure of the molecule, particularly the presence of chromophores and the degree of conjugation [22]. Identifying λmax begins with a full spectral scan from 200 nm to 800 nm (or a relevant subset) of a standard solution of the pure API [24] [23]. The resulting spectrum reveals the characteristic electronic transitions, with the peak representing the most probable transition offering the optimal wavelength for quantitative work.

Advanced Selection Techniques

Beyond zero-order spectroscopy (direct absorbance measurement), advanced techniques can enhance method specificity, particularly for complex matrices. First-order derivative spectroscopy uses the first derivative of the absorption spectrum (dA/dλ) to resolve overlapping peaks from excipients or degradation products, transforming shoulder peaks into distinct zero-crossing points for more accurate quantification [24]. The Area Under the Curve (AUC) method offers another robust alternative by integrating the absorbance across a defined wavelength range rather than relying on a single wavelength [24]. This approach improves analytical sensitivity and can provide more reliable measurements when the baseline is unstable or when the analyte lacks a sharp, distinct peak.

Application Example: Tafamidis Meglumine Analysis

In a recent study to determine tafamidis meglumine, a spectral scan of the drug in methanol revealed a distinct absorption peak at 309 nm, which was established as the λmax for zero-order spectrophotometric analysis [24]. For the AUC approach, the wavelength range of 305-313 nm was selected as the optimal integration interval [24]. This multi-method approach to wavelength selection ensured both the sensitivity and the robustness of the potency determination across different pharmaceutical formulations.

Key Parameter 2: Absorbance Range

Optimal Absorbance Range and the Beer-Lambert Law

The relationship between absorbance and concentration is linear only within a specific range, making adherence to the optimal absorbance range critical for accurate potency calculations. The widely accepted optimal range for quantitative analysis is between 0.1 and 1.0 Absorbance Units (AU) [23]. Within this range, the Beer-Lambert Law maintains linearity, and the instrument demonstrates the highest sensitivity and accuracy. An absorbance of 1.0 corresponds to 10% transmittance (90% of the incoming light is absorbed), and beyond this point, the signal-to-noise ratio deteriorates as insufficient light reaches the detector for reliable measurement [20].

Managing Absorbance Outside Optimal Range

Samples with absorbance values outside the optimal range require corrective action. For excessively concentrated samples (A > 1.0), the recommended approaches are:

- Dilution: The sample is diluted with an appropriate solvent to bring its absorbance within the linear range [20] [21].

- Path Length Reduction: Using a cuvette with a shorter path length (e.g., 1 mm instead of the standard 10 mm) decreases the effective absorbance [20]. For samples with absorbance that is too low (A < 0.1), sensitivity can be increased by concentrating the sample or using a cuvette with a longer path length.

Table 2: Troubleshooting Absorbance Range Issues

| Problem | Cause | Solution |

|---|---|---|

| Absorbance Too High (>1.0 AU) | Sample concentration too high | Dilute sample with same solvent |

| Use a cuvette with a shorter path length | ||

| Absorbance Too Low (<0.1 AU) | Sample concentration too low | Concentrate the sample |

| Use a cuvette with a longer path length | ||

| Non-Linear Calibration Curve | Absorbance outside linear range | Ensure standards are within 0.1-1.0 AU |

| Stray light or instrumental limitations | Re-dilute samples and re-measure |

Key Parameter 3: Spectral Interpretation

Fundamentals of Spectrum Analysis

Interpreting a UV-Vis spectrum involves analyzing key features to extract meaningful chemical information about the sample. The spectrum is a plot of absorbance (y-axis) versus wavelength (x-axis), with peaks corresponding to specific electronic transitions within the molecule [23]. The two most critical parameters for interpretation are:

- Lambda Max (λmax): The wavelength at which a compound exhibits its highest absorbance, reflecting the energy required for a specific electronic transition. This value is characteristic of particular chromophores and functional groups [23].

- Peak Intensity: The height of the absorption peak, quantified by the molar absorptivity (ε). Intensity reflects the probability of the electronic transition and is directly used for concentration calculation via the Beer-Lambert Law [22].

Identifying Functional Groups and Impurities

Different functional groups and chromophores absorb at characteristic wavelengths, allowing for preliminary structural identification. For instance, aromatic compounds typically show π→π* transitions around 250-280 nm, while carbonyl compounds exhibit n→π* transitions around 270-300 nm [23]. The presence of unexpected absorbance peaks or shoulders can indicate impurities or degradation products [21]. A pure pharmaceutical compound should yield a consistent and reproducible spectrum; any deviation from the reference standard spectrum may suggest contamination, decomposition, or the presence of excipients interfering with the analysis [23] [21].

Analyzing Spectral Shifts

Spectral shifts provide valuable insights into molecular environment and interactions. A bathochromic shift (red shift) to longer wavelengths often results from increased conjugation, solvent effects, or the presence of auxochromes [23]. Conversely, a hypsochromic shift (blue shift) to shorter wavelengths may indicate reduced conjugation or conformational changes [23]. Changes in intensity are described as hyperchromic effects (increased absorption) or hypochromic effects (decreased absorption), which can result from changes in transition probability or molecular aggregation [23].

Experimental Protocol: Drug Potency Determination

Materials and Reagents

The following research reagent solutions and materials are essential for the experiment:

Table 3: Essential Research Reagent Solutions and Materials

| Item | Function/Application |

|---|---|

| High-Purity Reference Standard | Serves as the benchmark for identity and quantification of the API. |

| UV-Grade Solvent (e.g., Methanol) | Dissolves the analyte without introducing interfering absorbance. |

| Matched Quartz Cuvettes | Hold the sample and reference solutions; quartz is transparent to UV light. |

| Volumetric Flasks and Pipettes | Ensure accurate preparation and dilution of standard and sample solutions. |

| UV-Vis Spectrophotometer | Instrument for measuring light absorption across specified wavelengths. |

Step-by-Step Workflow for Potency Assay

The following workflow outlines the key steps for determining drug potency using UV-Vis spectrophotometry:

Wavelength Selection and Method Setup

- Prepare a standard solution of the reference API at an approximate concentration of 10 μg/mL in a suitable solvent (e.g., methanol, buffer) [24].

- Fill a quartz cuvette with the solvent alone to serve as the blank.

- Perform a spectral scan from 400 nm to 200 nm. Identify the wavelength of maximum absorbance (λmax) from the resulting spectrum [24] [23].

Preparation of Standard Solutions

- Prepare a stock solution of the reference standard with accurately known concentration.

- Serially dilute the stock solution to create at least five standard solutions covering a concentration range that will yield absorbances between 0.1 and 1.0 AU at the determined λmax [24].

Construction of Calibration Curve

- Measure the absorbance of each standard solution at the λmax against the solvent blank.

- Plot absorbance (y-axis) versus concentration (x-axis). The plot should yield a straight line. Perform linear regression to obtain the equation (y = mx + c) and the correlation coefficient (R²) [23].

Sample Preparation and Analysis

- Extract the API from the pharmaceutical formulation (e.g., capsule powder, tablet) using the same solvent.

- Dilute the sample extract appropriately to fall within the linear range of the calibration curve.

- Measure the absorbance of the diluted sample solution at the λmax.

Potency Calculation

- Use the equation from the calibration curve to calculate the concentration of the API in the sample solution.

- Account for all dilution factors to determine the absolute amount of API in the original formulation and calculate the potency as a percentage of the labeled claim.

Data Analysis and Regulatory Considerations

Validation Parameters for Potency Methods

For regulatory acceptance in pharmaceutical quality control, UV-Vis methods for potency determination must be validated according to international guidelines such as ICH Q2(R1) [24] [21]. Key validation parameters include:

Table 4: Key Method Validation Parameters as per ICH Q2(R1)

| Parameter | Description | Acceptance Criteria (Example) |

|---|---|---|

| Linearity | Ability to obtain results directly proportional to analyte concentration. | Correlation coefficient (R²) > 0.995 |

| Range | Interval between upper and lower concentration levels over which linearity is demonstrated. | Must encompass the test concentrations (e.g., 50-150% of target). |

| Accuracy | Closeness between the measured value and the true value. | Recovery of 98-102% |

| Precision | Closeness of agreement between a series of measurements. | Relative Standard Deviation (RSD) < 2.0% |

| Specificity | Ability to assess the analyte unequivocally in the presence of excipients. | No interference from placebo at λmax. |

Case Study: Application to Tafamidis Meglumine

The application of these principles is exemplified in a recent study developing UV spectrophotometric methods for tafamidis meglumine [24]. The researchers established a linear relationship between concentration and absorbance (Method A) in the range of 2-12 μg/mL at λmax 309 nm, with a correlation coefficient of 0.9996, demonstrating excellent linearity [24]. The method also showed high precision, with intra-day and inter-day relative standard deviations of less than 1.5%, and accuracy confirmed by recovery studies ranging from 99.2% to 100.4% [24]. This validates the method as reliable for the quantification of tafamidis meglumine in pharmaceutical dosage forms, underscoring the practical application of the discussed parameters in a real-world research scenario.

The Critical Role of UV-Vis in Pharmaceutical QA/QC for Identity, Purity, and Potency

Ultraviolet-Visible (UV-Vis) spectroscopy is a fundamental analytical technique in pharmaceutical quality assurance and quality control (QA/QC). It measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample compared to a reference or blank sample [20]. This property is influenced by the sample composition, providing critical information about what is in the sample and at what concentration [20]. The technique operates on the principle that electrons in different bonding environments require specific energy amounts to reach higher energy states, leading to absorption at characteristic wavelengths [20]. In pharmaceutical applications, UV-Vis spectroscopy offers a rapid, reliable, and non-destructive means to characterize drug substances and products, ensuring their identity, purity, and potency throughout development and manufacturing [21].

The widespread adoption of UV-Vis spectroscopy in pharmaceutical QA/QC stems from its numerous advantages. The technique is valued for being fast, simple, inexpensive, and suitable for routine quantification with high throughput [21]. Its compliance with regulatory standards from bodies like the FDA and EMA further solidifies its position as an indispensable tool for pharmaceutical analysis [21] [25]. This application note explores the specific implementations of UV-Vis spectroscopy for identity verification, purity assessment, and potency determination within the framework of drug potency research, providing detailed protocols and analytical frameworks for scientists and drug development professionals.

Determining Drug Identity with UV-Vis Spectroscopy

Principles of Identity Confirmation

Identity testing confirms that a material is correctly labeled and matches the intended drug substance. UV-Vis spectroscopy facilitates identity confirmation through the characterization of unique spectral fingerprints. Each pharmaceutical compound possesses a distinct absorption spectrum based on its molecular structure and chromophores [20]. The technique is particularly advantageous for detecting and quantifying compounds that absorb in the 190–800 nm range, making it suitable for a wide array of active pharmaceutical ingredients (APIs) and excipients [21].

The fundamental principle relies on the Beer-Lambert Law, which states that the absorbance (A) of a solution is directly proportional to the concentration (c) of the absorbing species and the path length (l) of the sample: A = ε × c × l, where ε is the molar absorptivity [26] [20]. This relationship allows scientists to not only identify substances based on their spectral characteristics but also quantify them accurately. For identity testing, the absorption spectrum of a test sample is compared against a reference standard of the known API, with matching peak positions (λmax) and spectral contours confirming identity [21] [25].

Advanced Identity Testing Protocol: Baseline Manipulation for Multicomponent Formulations

For complex formulations containing multiple active ingredients, advanced techniques like baseline manipulation spectroscopy provide robust identity and quantification solutions without requiring separation. The following protocol, adapted from research on drotaverine and etoricoxib combinations, demonstrates this application [26].

Protocol: Singular Baseline Manipulation Spectroscopy for Binary Mixtures

- Objective: Simultaneous identification and quantification of two drugs in a combined tablet dosage form.

- Principle: Using a solution of one analyte as the blank to isolate the spectral profile of the second analyte, creating independent wavelength regions for each component [26].

- Materials and Reagents:

- UV-Vis double beam spectrophotometer with matched quartz cells

- Analytical balance

- Methanol (spectroscopic grade)

- Double distilled water

- Standard drugs: Component A and Component B

- Combined tablet formulation

- Procedure:

- Standard Stock Solutions: Prepare separate stock solutions of Component A (100 μg/mL) and Component B (90 μg/mL) in methanol.

- Working Standard Solution: Prepare a working standard of Component A (20 μg/mL) in distilled water. This will serve as the blank for analysis.

- Mixed Standard Solutions: Prepare serial dilutions containing both Component A (4–20 μg/mL) and Component B (4.5–22.5 μg/mL) in distilled water.

- Spectral Acquisition:

- Scan the mixed standard solutions from 200–400 nm using the Component A working standard (20 μg/mL) as the blank.

- Identify the wavelength where Component A shows zero absorbance and Component B shows significant absorbance (e.g., 274 nm for quantification of Component B).

- Similarly, identify the wavelength where Component B shows zero absorbance and Component A shows significant absorbance (e.g., 351 nm for quantification of Component A).

- Calibration Curve: Measure instrument response at the selected wavelengths for the serial dilutions and prepare calibration curves for both components.

- Sample Analysis: Process tablet formulations similarly, using the same blank, and calculate component concentrations from the calibration curves [26].

Table 1: Validation Parameters for a Representative Baseline Manipulation Method (for Drotaverine and Etoricoxib)

| Validation Parameter | Drotaverine (DRT) | Etoricoxib (ETR) |

|---|---|---|

| Linear Range | 4–20 μg/mL | 4.5–22.5 μg/mL |

| Wavelength (λmax) | 351 nm | 274 nm |

| Correlation Coefficient | >0.999 | >0.999 |

| Precision (% RSD) | <2% | <2% |

| Accuracy (% Recovery) | 98–102% | 98–102% |

Assessing Pharmaceutical Purity with UV-Vis

Impurity and Degradation Product Monitoring

Purity assessment is critical for ensuring drug safety, and UV-Vis spectroscopy plays a crucial role in detecting potential contaminants or degradation products. The presence of impurities often manifests as unexpected absorbance peaks or shifts in the characteristic spectrum of the API [21]. The technique is particularly sensitive to chromophoric impurities, making it valuable for routine screening during stability testing and raw material qualification [21] [25].

A significant application in modern biopharmaceutical manufacturing is in-line UV spectrometry for cleaning validation. This ensures equipment cleanliness by detecting residual cleaning agents or product residues, including degraded forms that may lack biological activity but must still be removed [27]. Studies have demonstrated the effectiveness of UV spectroscopy at 220 nm for continuous, in-line monitoring of cleaning processes, with sensitivity adjustable by modifying the sanitary flow path length [27].

Advanced Purity Assessment Protocol: In-line Cleaning Validation

Protocol: In-line UV Monitoring for Cleaning Process Validation

- Objective: Real-time, continuous monitoring of residual cleaning agents and biopharmaceutical products during equipment cleaning cycles.

- Principle: UV absorbance at 220 nm provides a semi-specific method for detecting residual chromophores in cleaning agents and proteinaceous residues, enabling quality-by-design and Process Analytical Technology (PAT) initiatives [27].

- Materials and Reagents:

- In-line UV spectrometer with flow-through cell (e.g., pathlength adjustable from 1-10 cm)

- Formulated alkaline and acid cleaners

- Type 1 water

- Model process soils (e.g., Bovine Serum Albumin, monoclonal antibody drug substance, insulin)

- Procedure:

- Method Development:

- Collect spectra from 190–400 nm for ~1000 ppm solutions of each cleaner and model soil diluted in Type 1 water.

- Determine the optimal wavelength (e.g., 220 nm) based on absorbance and minimal interference.

- Linearity and Range Qualification:

- Qualify the method range (e.g., 10-1000 ppm for acidic cleaner, 25-1000 ppm for alkaline cleaner) by characterizing linearity and precision.

- Prepare and analyze calibration curves in triplicate across the concentration range.

- Accuracy and Precision:

- Prepare separate sample preparations at concentrations within the linear range.

- Quantitate using the established calibration curves to assess method accuracy.

- Determine precision via repeatability studies.

- Interference Testing:

- Prepare 1:1 mixtures of model soils and the alkaline cleaner.

- Collect spectra and monitor absorbance at the analytical wavelength to check for signal enhancement or depression.

- In-line Implementation:

- Install the UV probe in the flow path of the cleaning system's fluid stream.

- Monitor absorbance in real-time throughout the cleaning cycle.

- Establish a baseline and set action limits for acceptable cleanliness based on validation data [27].

- Method Development:

Table 2: Key Research Reagent Solutions for Purity Assessment

| Reagent/Material | Function/Explanation |

|---|---|

| Formulated Alkaline Cleaner | A multi-component cleaning agent used in biopharma; its removal must be validated. UV detection is often based on a proprietary chromophore [27]. |

| Formulated Acidic Cleaner | Used for removing scale and other deposits; its composition supports UV-based monitoring for residue clearance [27]. |

| Bovine Serum Albumin (BSA) | A standard model protein used in analytical method development to represent proteinaceous process soils [27]. |

| Type 1 Water | The high-purity solvent used for preparing standards, samples, and as the rinse fluid, ensuring no UV-absorbing contaminants interfere [27]. |

| Monoclonal Antibody (mAb) Drug Substance | A representative, complex biopharmaceutical product used to test the method's ability to detect intact and degraded product residues [27]. |

Quantifying Drug Potency using UV-Vis

Potency and Content Uniformity Testing

Potency determination, which verifies the quantity of the active pharmaceutical ingredient (API), is one of the most widespread applications of UV-Vis spectroscopy in pharmaceutical QC. The technique is a validated, reliable method for quantifying drugs in tablets, capsules, and liquid formulations, making it essential for content uniformity testing and batch release [21]. UV-Vis is commonly used to ensure consistent concentration of APIs and to assess drug product uniformity, directly impacting the therapeutic efficacy of the final product [21].

The quantification process relies heavily on the Beer-Lambert law. A calibration curve is constructed by measuring the absorbance of standard solutions of known concentration. The absorbance of the sample solution is then measured, and its concentration is determined from the calibration curve [20]. For results to be reliable, absorbance values should ideally be kept below 1 to remain within the instrument's dynamic range, achievable by sample dilution or decreased path length [20].

Advanced Potency Protocol: Chemometric Analysis of Multicomponent Formulations

For fixed-dose combination drugs where spectral overlap is significant, univariate analysis fails. Chemometric models coupled with UV-Vis provide a powerful solution, as demonstrated in the analysis of leprosy multidrug therapy (rifampicin, dapsone, and clofazimine) [28].

Protocol: Simultaneous Quantification Using PLS and MCR-ALS

- Objective: To quantify the content of multiple antibiotics (e.g., Clofazimine-CLZ and Dapsone-DAP) in a combined fixed-dose solid formulation despite significant spectral overlap.

- Principle: Multivariate calibration models like Partial Least Squares (PLS) and Multivariate Curve Resolution with Alternating Least Squares (MCR-ALS) correlate spectral information to concentration, overcoming the limitation of low analytical selectivity in complex mixtures [28].

- Materials and Reagents:

- UV-Vis spectrometer

- Pure standards of CLZ and DAP

- Excipients (β-cyclodextrin, Microcrystalline cellulose, etc.)

- Hydrochloric acid solution (for pH adjustment to 1.2)

- Procedure:

- Experimental Design:

- Use a 5² factorial design to construct a set of synthetic mixtures of CLZ and DAP covering the expected concentration ranges.

- Sample Preparation:

- Dissolve samples in HCl solution at pH 1.2 to ensure consistent solubility and ionization state.

- CLZ exhibits peaks at 286 nm and 495 nm, while DAP shows a peak at 235 nm with a low-intensity band between 250-280 nm [28].

- Spectral Acquisition:

- Collect full UV-Vis spectra of all calibration mixtures and the unknown tablet formulation solutions.

- Data Set Splitting:

- Divide the data into a calibration set (for model building) and a test set (for model validation).

- Model Development (PLS):

- The PLS regression algorithm correlates the spectral data (X-matrix) with the known concentrations (Y-matrix) to build a predictive model.

- Model Development (MCR-ALS):

- The MCR-ALS model decomposes the spectral data matrix to resolve the pure spectra and concentration profiles of CLZ and DAP iteratively.

- Apply constraints like non-negativity (concentrations and spectra cannot be negative) to obtain physically meaningful solutions [28].

- Content Determination:

- Use the developed and validated PLS and MCR-ALS models to predict the concentrations of CLZ and DAP in the unknown tablet solution spectra.

- Experimental Design:

The following workflow diagram illustrates the critical decision path for selecting the appropriate UV-Vis analytical method based on the complexity of the drug formulation.

UV-Vis Potency Analysis Workflow

Regulatory and Method Validation Considerations

Regulatory bodies globally recognize UV-Vis spectroscopy as a validated analytical tool when properly developed, validated, and documented. Compliance with guidelines is mandatory for QA/QC laboratories. The ICH Q2(R1) guideline defines the validation parameters required for analytical procedures, including accuracy, precision, specificity, detection limit, quantitation limit, linearity, range, and robustness [21]. Furthermore, 21 CFR Part 211 emphasizes strict controls over laboratory practices, requiring regular instrument calibration, qualification (IQ/OQ/PQ), and proper documentation adhering to ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, and Accurate) [21].

Method validation is not a one-time exercise. Methods must be revalidated after any significant changes in composition, equipment, or location. For methods used across multiple facilities, robust method transfer protocols are essential to ensure consistent performance [21]. The following table summarizes key validation parameters and their typical acceptance criteria for a UV-Vis potency method.

Table 3: UV-Vis Method Validation Parameters for Potency Assays

| Validation Parameter | Description | Typical Acceptance Criteria |

|---|---|---|

| Accuracy | Closeness between the conventional true value and the value found. | Recovery: 98–102% [26] |

| Precision | Degree of agreement among individual test results. | % RSD ≤ 2.0% [26] |

| Specificity | Ability to assess the analyte unequivocally in the presence of components. | No interference from excipients/impurities [21] |

| Linearity | Ability to obtain results proportional to analyte concentration. | Correlation coefficient (r) > 0.999 [26] |

| Range | Interval between the upper and lower concentration levels. | Established with acceptable accuracy, precision, and linearity [21] |

| LOD/LOQ | Detection Limit/Quantitation Limit. | LOD = (3.3 × σ)/b, LOQ = (10 × σ)/b [26] |

| Robustness | Capacity to remain unaffected by small, deliberate variations in method parameters. | Method withstands variations in e.g., wavelength (±2 nm), extraction time [26] |

UV-Vis spectroscopy remains a cornerstone of pharmaceutical QA/QC, providing critical data for identity, purity, and potency determinations that directly impact patient safety and drug efficacy. Its simplicity, speed, and cost-effectiveness make it ideal for routine analysis, while its adaptability to advanced techniques like baseline manipulation and chemometric modeling ensures its relevance for complex modern formulations. As the industry advances toward Pharma 4.0, the integration of UV-Vis with Process Analytical Technology (PAT) frameworks for real-time monitoring and real-time release testing will further enhance manufacturing efficiency and product quality. By adhering to rigorous method validation and regulatory guidelines, scientists can leverage this powerful technique with confidence throughout the drug development and commercialization lifecycle.

Potency assays are fundamental to the quality control of biological products, confirming a product's specific ability or capacity to effect a given result. This application note details how UV-Vis spectrophotometry fulfills the critical requirements for potency testing by offering significant advantages in speed, cost-effectiveness, and suitability for routine use. We demonstrate its application through a validated experimental protocol for quantifying levofloxacin, showcasing exemplary analytical performance with a correlation coefficient (R²) > 0.999 and recovery rates of 99.00–100.07%. The method's alignment with green chemistry principles further underscores its value in modern, sustainable pharmaceutical analysis.

In the development and quality control (QC) of pharmaceuticals, potency assays are critical quality tests that measure the biological activity of a product and ensure it elicits the intended therapeutic effect [29] [30]. For biological products, including cell therapies and traditional pharmaceuticals, regulators require a quantitative potency assay that is relevant to the product's mechanism of action (MoA) to guarantee consistent efficacy [30] [31].

While some potency assays are complex cell-based tests, UV-Vis spectrophotometry presents a robust analytical technique for potency determination that is particularly advantageous when the active ingredient's concentration correlates directly with its therapeutic activity. This technique measures the amount of discrete wavelengths of UV or visible light absorbed by a sample, providing a rapid and economic means of quantification [20] [32]. This application note delineates the core advantages of UV-Vis spectrophotometry for potency testing and provides a detailed protocol for its implementation.

Advantages of UV-Vis Spectrophotometry in Potency Testing

The integration of UV-Vis spectrophotometry into potency testing protocols offers compelling benefits for drug development pipelines and quality control laboratories.

Speed and High-Throughput Capability

The technique is renowned for its rapid analysis times, yielding results in a matter of seconds [33]. This speed is crucial in stability testing, which helps predict the commercial viability of drug candidates early in the development process [34]. The straightforward workflow minimizes manual steps and, when combined with microplate readers, can facilitate the high-throughput analysis necessary for screening numerous samples during formulation development and QC lot release.

Cost-Effectiveness

UV-Vis spectrophotometry represents a financially prudent choice for laboratories. The initial instrument investment and ongoing operational expenses are relatively low compared to more complex techniques like HPLC or mass spectrometry [33]. The hardware is characterized by its durability and low maintenance requirements, contributing to a favorable long-term cost-of-ownership profile. Furthermore, the consumption of solvents and samples is minimal, reducing both material costs and waste disposal overheads [32].

Superior Suitability for Routine Use

Perhaps its most significant advantage in a QC environment is its ease of use. The instruments feature intuitive interfaces that streamline operation, from sample preparation to data analysis, reducing training costs and ensuring quick adoption by laboratory personnel [33]. This user-friendliness, combined with the technique's renowned reliability and ability to deliver consistent, reproducible results, makes it an ideal mainstay for daily routine analyses [33].

High Accuracy and Quantitative Precision

UV-Vis spectrophotometers provide highly precise and accurate measurements, which is paramount for quantifying analytes across various concentrations. The technique's foundation, the Beer-Lambert Law, establishes a linear relationship between absorbance and concentration, enabling reliable quantitation of active pharmaceutical ingredients (APIs) with high sensitivity [20] [32].

Experimental Protocol: Potency Assay for Levofloxacin by UV-Vis Spectrophotometry

The following section provides a detailed methodology for determining the potency of the antibacterial drug levofloxacin in bulk and pharmaceutical dosage forms, adapted from a published study [35].

Principle

The method quantifies levofloxacin based on its inherent absorption of ultraviolet light at a wavelength of maximum absorption (λmax) of 292 nm. The concentration of the analyte in an unknown sample is determined by comparing its absorbance to a calibration curve constructed from reference standards.

Materials and Reagents

- Reference Standard: Levofloxacin hemihydrate powder.

- Solvents: Deionized water, methanol (HPLC grade), acetonitrile (HPLC grade).

- Diluent: Water:Methanol:Acetonitrile in a 9:0.5:0.5 ratio.

- Apparatus: UV-Vis spectrophotometer with matched quartz cells.

Procedure

Standard Solution Preparation

- Weigh accurately about 20 mg of levofloxacin reference standard.

- Transfer to a 100 mL volumetric flask, dissolve, and make up to volume with the diluent to obtain a primary stock solution of 200 µg/mL.

- Pipette 3 mL of this stock solution into a 10 mL volumetric flask and dilute to volume with the diluent to obtain a working standard solution of 6 µg/mL.

Sample Solution Preparation

- For tablet analysis, accurately weigh and finely powder not less than 20 tablets.

- Transfer a portion of the powder equivalent to about 20 mg of levofloxacin to a 100 mL volumetric flask.

- Add about 70 mL of diluent, sonicate for 15 minutes with intermittent shaking, and dilute to volume.

- Filter the solution, discard the first few mL of filtrate.

- Pipette 3 mL of the subsequent filtrate into a 10 mL volumetric flask and dilute to volume with the diluent.

Spectroscopic Analysis

- Fill a quartz cuvette with the diluent and use it as a blank to zero the spectrophotometer.

- Scan the working standard solution (6 µg/mL) from 190 nm to 400 nm to confirm the λmax at approximately 292 nm.

- Measure the absorbance of the standard and sample solutions at the predetermined λmax of 292 nm against the blank.

Data Analysis and Calculations

Construction of Calibration Curve

Prepare a series of standard solutions at concentrations of 1, 2, 4, 6, 8, 10, and 12 µg/mL from the primary stock solution by appropriate dilution. Measure their absorbances at 292 nm and plot absorbance versus concentration. The curve should demonstrate excellent linearity (R² > 0.999).

Calculation of Potency

The content of levofloxacin in a tablet (% of label claim) can be calculated using the formula:

Content (%) = (As / Ast) × (Wst / Ws) × (W / P) × CF × 100%

Where:

As= Absorbance of the sample solutionAst= Absorbance of the standard solutionWst= Weight of the levofloxacin reference standard (mg)Ws= Weight of the sample powder (mg)W= Average weight of one tablet (mg)P= Potency of the levofloxacin standard on an as-is basis (%)CF= Conversion factor for levofloxacin hemihydrate to levofloxacin (0.976)

Method Validation Results

The developed method was validated per ICH guidelines, yielding the following results [35]:

Table 1: Method Validation Parameters for the UV-Vis Determination of Levofloxacin

| Validation Parameter | Result | Acceptance Criteria |

|---|---|---|

| Linearity (Range: 1-12 µg/mL) | R² = 0.9998 | R² > 0.999 |

| Precision (RSD, n=3) | ||

| Â Â Intra-day (Repeatability) | 0.070 - 0.140% | RSD < 2% |

| Â Â Inter-day (Intermediate Precision) | 0.094 - 0.240% | RSD < 2% |

| Accuracy (% Recovery) | 99.00 - 100.07% | 98 - 102% |

| Specificity | No interference from excipients or degradation products | Verified |

Table 2: Assay Results for Marketed Levofloxacin Tablet Formulations

| Brand | Label Claim (mg) | Amount Found (mg) | Potency (%) |

|---|---|---|---|

| Brand 1 | 500 | 494.23 ± 0.33 | 98.85 |

| Brand 2 | 500 | 490.25 ± 0.66 | 98.05 |

| Brand 3 | 500 | 497.33 ± 0.33 | 99.47 |

| Brand 4 | 500 | 495.90 ± 0.46 | 99.18 |

| Brand 5 | 500 | 494.97 ± 0.46 | 98.99 |

Workflow and Logical Pathway

The following diagram illustrates the logical workflow for developing and implementing a UV-Vis spectrophotometric potency assay, from method setup through to sample analysis and data reporting.

Research Reagent Solutions

The successful execution of this potency assay relies on several key reagents and materials. The following table details these essential components and their functions.

Table 3: Key Research Reagents and Materials for UV-Vis Potency Assay

| Item | Function / Role in the Assay |

|---|---|

| Levofloxacin Hemihydrate Reference Standard | Serves as the primary standard for calibration, ensuring accurate and traceable quantification of the API. |

| Methanol & Acetonitrile (HPLC Grade) | High-purity organic solvents used in the diluent to ensure complete dissolution of the analyte and prevent interference. |

| Quartz Cuvettes | Required for UV range measurements, as they are transparent to the majority of UV light, unlike plastic or glass. |

| UV-Vis Spectrophotometer | The core instrument that generates the light source, selects specific wavelengths, and detects the absorbance of the sample. |

| Cryopreserved Cell Banks (for cell-based bioassays) | Provide a consistent, ready-to-use biological reagent that reduces inter-run variability in more complex functional potency tests [36]. |

This application note establishes that UV-Vis spectrophotometry is a powerful technique for potency assays, combining speed, cost-effectiveness, and exceptional suitability for routine quality control. The detailed protocol for levofloxacin quantification, validated for linearity, precision, accuracy, and specificity, serves as a robust template that can be adapted for other small molecule pharmaceuticals where the API concentration is a direct indicator of potency. By employing this technique, researchers and QC professionals can ensure the consistent efficacy and safety of drug products in an efficient and economically sustainable manner.

Advanced Method Development and Practical Applications for Drug Potency

In the determination of drug potency using UV-Vis spectrophotometry, the integrity of the analytical result is fundamentally dependent on the sample preparation process. Proper preparation is critical for obtaining accurate, reproducible absorbance measurements that reliably reflect the concentration of the active pharmaceutical ingredient (API). Inadequate sample preparation can introduce significant errors, compromising data used for critical decisions in drug development and quality control [37] [38]. This protocol details best practices for sample preparation, focusing on the tripartite foundation of proper solvent selection, effective homogenization, and strategic avoidance of interferences to ensure the validity of drug potency determinations.

Core Principles of Sample Preparation

The Role of Sample Preparation in Drug Potency Analysis

UV-Vis spectroscopy quantifies the absorption of ultraviolet or visible light by a sample, allowing for the determination of analyte concentration via the Beer-Lambert law [20]. For this relationship to hold true, the sample must be presented to the instrument in a state that ensures the measured absorbance is solely attributable to the target analyte(s) and is free from artifacts caused by light scattering, unintended absorption, or chemical interference. In pharmaceutical analysis, this translates to preparing a solution where the API is completely dissolved, molecularly dispersed, and free from contaminants in a solvent that does not itself interfere within the analytical wavelength range [37] [34].

Impact of Preparation Errors on Spectroscopic Results

Several common preparation pitfalls can lead to erroneous potency calculations:

- Incomplete Dissolution: Undissolved API particles scatter light, leading to falsely elevated absorbance readings [37].

- Solvent Absorption: Using a solvent with high absorbance at the analytical wavelength reduces the light throughput, degrading the signal-to-noise ratio and potentially obscuring the analyte peak [38].

- Sample Contamination: Contaminants from improperly cleaned cuvettes or impure solvents can introduce unexpected chromophores, leading to inaccurate absorbance measurements [38].

- Inappropriate Concentration: An overly concentrated sample will absorb all incident light, violating the conditions of the Beer-Lambert law, while a overly dilute sample will provide a signal too weak for reliable quantification [20].

Solvent Selection Strategy

The choice of solvent is a cornerstone of robust UV-Vis method development, directly impacting solubility, spectral characteristics, and environmental footprint.

Solvent Selection Criteria

Table 1: Key Criteria for UV-Vis Spectroscopic Solvent Selection

| Criterion | Description | Impact on Analysis |

|---|---|---|

| UV Cutoff | Wavelength below which the solvent absorbs most light (>1 AU) [38]. | Determines the usable low-wavelength range; must be below the analyte's absorption maximum. |

| Solvating Power | Ability to dissolve the analyte completely to form a stable solution [37]. | Prevents light scattering from particulates and ensures a homogeneous sample. |

| Purity Grade | Level of chemical impurities; "Spectroscopic" or "HPLC" grade is typically required [38]. | Minimizes background absorption from contaminants. |

| Chemical Inertness | Lack of reactivity with the analyte or cuvette material [37]. | Prevents degradation of the API and ensures solution stability during measurement. |

| Environmental & Safety | Toxicity, waste generation, and disposal considerations [19]. | Aligns with Green Analytical Chemistry (GAC) principles for sustainable lab practices. |

Recommended Solvents and Green Alternatives

Common high-purity solvents for UV-Vis include water (cutoff ~190 nm), methanol (~205 nm), acetonitrile (~190 nm), and hexane (~195 nm) [38]. The polarity of the solvent should match the analyte to ensure complete dissolution. A emerging and strongly encouraged trend is the adoption of green solvent systems. For instance, a binary mixture of water and ethanol (1:1, v/v) has been successfully demonstrated as a sustainable and effective solvent for the analysis of pharmaceuticals like meloxicam and rizatriptan, eliminating the need for more hazardous organic reagents without compromising analytical performance [19].

Homogenization and Sample Presentation

Achieving a perfectly homogeneous sample is essential for obtaining a representative and reproducible absorbance measurement.

Homogenization of Liquid Samples

For solution-based measurements, homogenization entails creating a uniform molecular dispersion of the API.

- Complete Dissolution: Ensure the drug substance is fully dissolved. Gentle heating or sonication can be used to facilitate dissolution, provided the API is thermally stable [37].

- Filtration: After dissolution, filter the solution using a syringe filter (e.g., 0.45 μm or 0.2 μm pore size) to remove any undissolved particles or contaminants that could cause light scattering [37] [38]. For sensitive techniques like ICP-MS, filtration is mandatory, and the filter material (e.g., PTFE) must be selected to avoid analyte adsorption [38].

- Mixing: Ensure the solution is thoroughly mixed before pipetting into the cuvette to avoid concentration gradients.

Preparation of Solid Dosage Forms

For tablet or powder analysis, additional steps are required to bring the API into solution.