UV-Vis Spectrophotometry in Pharma: A Complete Guide to Instrumentation, Applications, and Compliance

This comprehensive guide explores the essential role of UV-Vis spectrophotometry in the pharmaceutical industry, tailored for researchers, scientists, and drug development professionals.

UV-Vis Spectrophotometry in Pharma: A Complete Guide to Instrumentation, Applications, and Compliance

Abstract

This comprehensive guide explores the essential role of UV-Vis spectrophotometry in the pharmaceutical industry, tailored for researchers, scientists, and drug development professionals. It covers foundational instrument principles and components, details methodological applications from drug discovery to quality control, provides practical troubleshooting and optimization strategies for regulated environments, and examines method validation and comparative analysis with techniques like HPLC. The content aligns with current industry practices and regulatory standards, including USP, EP, and ICH guidelines, to ensure data integrity and compliance in pharmaceutical analysis.

UV-Vis Spectrophotometer Fundamentals: Core Components and Operating Principles for Pharma Analysis

This technical guide explores the fundamental principles and applications of Ultraviolet-Visible (UV-Vis) spectrophotometry within pharmaceutical research and development. Focusing on the core Beer-Lambert Law, this whitepaper details the instrumentation, operational mechanisms, and practical methodologies for quantitative analysis. It further examines the critical role of UV-Vis spectroscopy in ensuring drug quality, safety, and efficacy through applications in identity testing, assay, impurity profiling, and dissolution testing, providing drug development professionals with a foundational understanding of this essential analytical technique.

Ultraviolet-visible (UV-Vis) spectrophotometry is an analytical technique that measures the amount of discrete wavelengths of ultraviolet (UV) or visible (Vis) light absorbed by a substance in solution [1]. The technique operates within the wavelength range of approximately 100-400 nm (ultraviolet) and 400-800 nm (visible) of the electromagnetic spectrum [2]. In the pharmaceutical industry, UV-Vis spectroscopy is a well-established, indispensable tool for the qualitative and quantitative analysis of Active Pharmaceutical Ingredients (APIs), excipients, and finished drug products [3] [4]. Its widespread adoption is driven by its simplicity, reliability, cost-effectiveness, and ability to provide highly accurate measurements for regulatory compliance with pharmacopeial standards such as the United States Pharmacopeia (USP), European Pharmacopoeia (EP), and Japanese Pharmacopoeia (JP) [4].

The fundamental process involves promoting electrons in a molecule from a ground state to a higher energy excited state [2]. For organic molecules, this typically involves transitions of π, n, or σ electrons to π* or σ* anti-bonding orbitals [5]. The specific energy (wavelength) at which a compound absorbs light is characteristic of its molecular structure, particularly the presence of chromophores—functional groups capable of absorbing UV or visible radiation [2]. Conjugated systems, which are common in many drug molecules, often produce strong, characteristic absorption spectra [5].

Fundamental Principles: The Beer-Lambert Law

The quantitative foundation of UV-Vis spectroscopy is the Beer-Lambert Law (also known as Beer's Law). This law establishes a linear relationship between the absorbance of light by a solution and the concentration of the absorbing species within it [6] [7] [8]. It combines the work of Johann Heinrich Lambert, who stated that absorbance is proportional to the path length of light through the medium, and August Beer, who stated that absorbance is proportional to the concentration of the solution [6].

Mathematical Formulation

The Beer-Lambert Law is expressed by the equation: A = εcl Where:

- A is the Absorbance (a dimensionless quantity) [7] [8].

- ε is the Molar Absorptivity (or molar extinction coefficient), with units of Mâ»Â¹cmâ»Â¹ [6] [8].

- c is the Molar Concentration of the absorbing species, with units of M (mol/L) [6] [8].

- l is the Path Length, which is the distance the light travels through the solution, typically measured in cm (standard cuvettes use 1 cm) [6] [8].

Absorbance is defined mathematically as the negative logarithm of Transmittance (T): A = -logâ‚â‚€(T) = logâ‚â‚€(Iâ‚€/I) Where:

- T is the Transmittance (I/Iâ‚€), often expressed as a percentage (%T) [7].

- Iâ‚€ is the Intensity of the incident light [6] [7].

- I is the Intensity of the transmitted light after passing through the sample [6] [7].

The following table illustrates the inverse logarithmic relationship between absorbance and transmittance:

Table 1: Relationship Between Absorbance and Transmittance

| Absorbance (A) | Transmittance (%T) |

|---|---|

| 0 | 100% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

| 4 | 0.01% |

| 5 | 0.001% |

Molar Absorptivity and its Significance

The molar absorptivity (ε) is a crucial parameter in the Beer-Lambert Law. It is defined as the absorbance of a 1 Molar solution measured in a cuvette with a 1 cm path length [6]. This value is a physical constant for a given substance at a specific wavelength and under specific conditions of solvent and temperature [6]. It is a measure of how strongly a chemical species absorbs light at a particular wavelength. Absorption bands with ε values above 10â´ Mâ»Â¹cmâ»Â¹ are considered high-intensity, while those below 10³ Mâ»Â¹cmâ»Â¹ are classified as low-intensity [6].

Instrumentation of a UV-Vis Spectrophotometer

A UV-Vis spectrophotometer is designed to measure the absorption of light by a sample across a range of wavelengths. While designs vary (e.g., single-beam, double-beam, array-based), they share several core components that work in sequence.

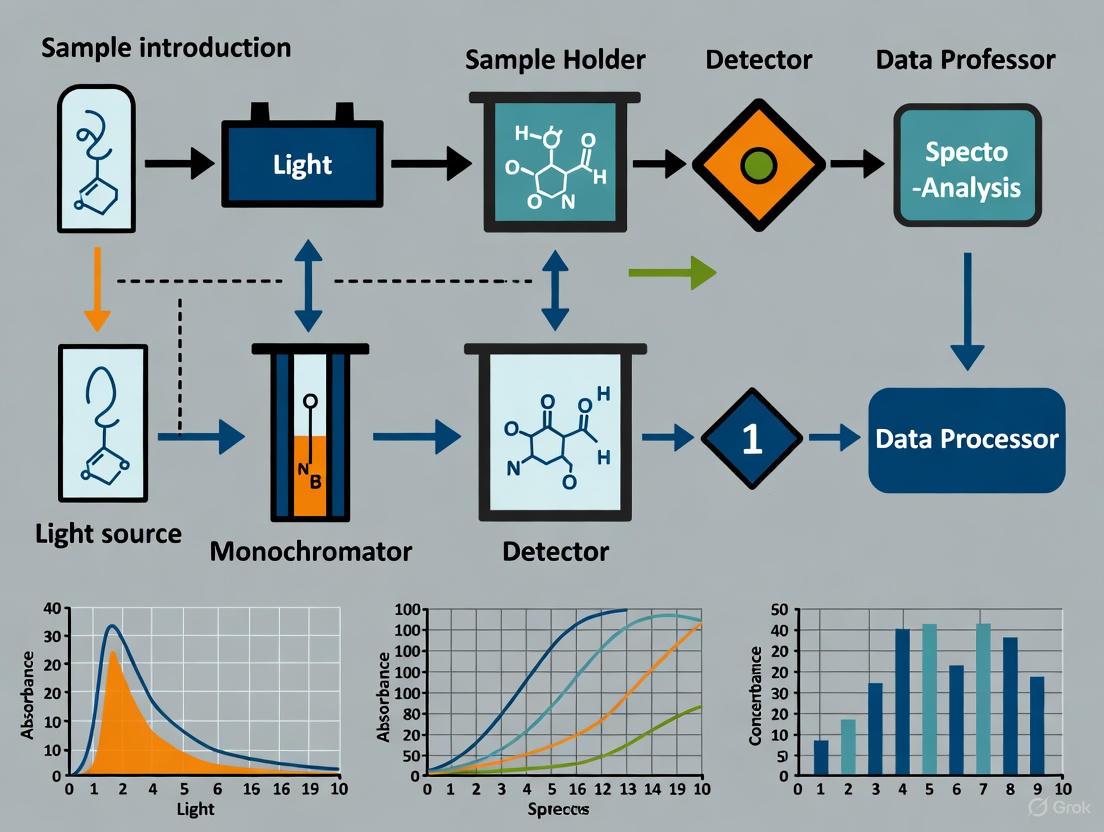

Diagram 1: Core Components and Workflow of a UV-Vis Spectrophotometer [1]

Core Components and Their Function

Table 2: Key Components of a UV-Vis Spectrophotometer

| Component | Function | Common Types & Notes |

|---|---|---|

| Light Source | Provides broad-spectrum UV and visible light. | Tungsten/Halogen lamp (visible), Deuterium lamp (UV), Xenon lamp (both). The instrument switches between lamps around 300-350 nm [1]. |

| Wavelength Selector (Monochromator) | Isolates a narrow band of wavelengths from the broadband source. | Typically a diffraction grating with 1200+ grooves/mm. Filters may be used for further refinement [1]. |

| Sample Holder | Holds the sample solution for analysis. | Cuvettes (typically with 1 cm path length). For UV light, quartz is essential; glass or plastic can be used for visible range only [1] [2]. |

| Detector | Measures the intensity of the transmitted light. | Photomultiplier Tube (PMT), photodiodes, or Charge-Coupled Devices (CCDs). Converts light intensity into an electrical signal [1]. |

| Computer/Readout | Processes the signal from the detector and displays the results. | Outputs an absorbance spectrum (Absorbance vs. Wavelength) or a single absorbance value [1]. |

The Measurement Process and Blank Correction

The measurement process involves a critical step of blank correction. The instrument first measures the intensity of light passing through a reference or blank cuvette containing only the solvent used to prepare the sample [1] [9]. This intensity is registered as Iâ‚€. The sample cuvette, containing the analyte dissolved in the same solvent, is then measured, giving I. The instrument's software then automatically calculates the absorbance using A = logâ‚â‚€(Iâ‚€/I). This process corrects for any absorption or reflection caused by the solvent and the cuvette itself, ensuring that the reported absorbance is due solely to the analyte of interest [1].

Quantitative Analysis and Experimental Protocols

The primary utility of the Beer-Lambert Law in pharmaceutical research is the quantitative determination of analyte concentration. This is typically achieved via the method of calibration curves.

Determining Unknown Concentration

If the molar absorptivity (ε) of a compound is known, its concentration can be directly determined by measuring its absorbance and applying the Beer-Lambert Law rearranged to: c = A / (εl) [9] However, the more common and reliable method, especially for ensuring accuracy under specific experimental conditions, is to use a calibration curve [7].

Experimental Protocol: Creating a Calibration Curve

This protocol outlines the standard method for determining the concentration of an unknown pharmaceutical sample, such as an API.

- Preparation of Standard Solutions: Prepare a series of standard solutions with known, increasing concentrations of the analyte. These should cover a range that includes the expected concentration of the unknown sample [7].

- Selection of Analytical Wavelength: Identify the wavelength of maximum absorption (λ_max) for the analyte, typically by obtaining a full absorption spectrum of one of the standard solutions.

- Measurement of Absorbance: Using the spectrophotometer, measure the absorbance of each standard solution at the λ_max. The blank solution (solvent without analyte) should be measured first to zero the instrument.

- Plotting the Calibration Curve: Plot the measured absorbance (y-axis) against the known concentration (x-axis) for each standard solution. The Beer-Lambert Law predicts a linear relationship, and the data points should be fitted with a straight line (y = mx + b, where m = εl) [7].

- Analysis of the Unknown: Measure the absorbance of the unknown sample at the same λ_max and under the same instrumental conditions. Locate this absorbance value on the y-axis of the calibration curve, trace horizontally to the best-fit line, and then vertically down to the x-axis to determine the corresponding concentration.

Table 3: Example Data for a Rhodamine B Calibration Curve

| Solution | Concentration (M) | Absorbance at λ_max |

|---|---|---|

| Standard 1 | 1.0 x 10â»â¶ | 0.15 |

| Standard 2 | 2.5 x 10â»â¶ | 0.38 |

| Standard 3 | 5.0 x 10â»â¶ | 0.72 |

| Standard 4 | 7.5 x 10â»â¶ | 1.05 |

| Standard 5 | 1.0 x 10â»âµ | 1.45 |

| Unknown Sample | To be determined | 0.89 |

Data adapted from an example in the search results [7].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Materials and Reagents for UV-Vis Analysis in Pharma

| Item | Function / Rationale |

|---|---|

| High-Purity Solvents (e.g., Water, Ethanol, Buffers) | To dissolve the analyte without introducing interfering absorbances. The solvent must be transparent in the spectral region of interest [5]. |

| Quartz Cuvettes (1 cm path length) | Standard sample holders for UV-Vis measurements. Quartz is transparent throughout the UV and visible range, unlike glass or plastic [1]. |

| Volumetric Flasks and Pipettes | For accurate preparation and dilution of standard and sample solutions. High accuracy is critical for reliable calibration curves. |

| Standard Reference Material (API) | A high-purity sample of the analyte of known concentration to prepare accurate standard solutions for calibration. |

| Buffer Solutions | To maintain a constant pH, which can critically affect the absorption spectrum of many pharmaceutical compounds (e.g., tyrosine) [5]. |

| Guvacoline Hydrobromide | Guvacoline Hydrobromide | Acetylcholine Analogue |

| 3-Fluoro-4-Iodopyridine | 3-Fluoro-4-Iodopyridine, CAS:22282-75-3, MF:C5H3FIN, MW:222.99 g/mol |

Applications in Pharmaceutical Research and Development

UV-Vis spectroscopy is deeply embedded in the drug development lifecycle, from initial discovery to final quality control (QC). Its applications directly support regulatory requirements for drug approval [3] [4].

Diagram 2: Key Pharmaceutical Applications of UV-Vis Spectroscopy in the Drug Development Workflow [3] [4]

- Identity Testing: UV-Vis spectroscopy can confirm the identity of a drug substance by verifying that its absorption spectrum (particularly λ_max) matches that of a reference standard, as required by pharmacopeias [3] [4]. For example, the USP and EP include UV-Vis identification tests for drugs like Ibuprofen [4].

- Assay and Potency Testing: This is a direct application of the Beer-Lambert Law to quantify the concentration of the API in a drug substance or finished product, ensuring it matches the labeled amount [3].

- Dissolution Testing: For solid oral dosage forms like tablets, UV-Vis spectrophotometers are routinely used to analyze dissolution testing results, monitoring the rate and extent to which the API dissolves from the dosage form into the dissolution medium [3] [4].

- Impurity and Purity Assessment: The technique can detect and quantify impurities in drug ingredients, especially if the impurities have different absorption characteristics than the API. It is also used to check the purity of biological samples like nucleic acids (DNA/RNA) and proteins [3] [4].

Practical Considerations and Limitations

While robust, the Beer-Lambert Law and UV-Vis spectroscopy have inherent limitations that scientists must recognize to ensure data accuracy.

Deviations from the Beer-Lambert Law

Deviations from linearity between absorbance and concentration can occur due to:

- High Concentration: At high concentrations (>0.01 M), electrostatic interactions between molecules can alter the absorptivity of the analyte [8] [10]. Furthermore, at very high absorbances, the instrument may struggle to detect the small amount of transmitted light.

- Chemical Associations: Equilibrium processes such as dimerization or polymerization can change the nature of the absorbing species [8].

- Instrumental Factors: Stray light (light reaching the detector at wavelengths outside the selected band) is a major cause of negative deviation at high absorbances [5]. A narrow spectral bandwidth is required for monochromatic light and linearity [5].

- Light Scattering: Samples that are turbid or contain particulate matter scatter light, leading to falsely high absorbance readings [2].

Best Practices for Accurate Measurements

- Concentration Range: Analyze samples within the absorbance range where the instrument provides a linear response, typically between 0.1 and 1.0 Absorbance Units (AU). Samples with A > 1 should be diluted [1].

- Wavelength Selection: Perform quantitative measurements at an absorption peak (λ_max) where the rate of change of absorbance with wavelength is lowest, minimizing errors from small inaccuracies in wavelength calibration [5].

- Sample Preparation: Ensure samples are homogeneous and free of bubbles or undissolved solids that could scatter light [2].

UV-Vis spectrophotometry, grounded in the fundamental Beer-Lambert Law, remains a cornerstone analytical technique in pharmaceutical research and quality control. Its ability to provide rapid, accurate, and quantitative data on drug identity, strength, purity, and performance is critical for ensuring the safety and efficacy of pharmaceutical products. A thorough understanding of its principles, instrumentation, applications, and limitations empowers scientists and drug development professionals to effectively leverage this versatile tool in meeting the rigorous demands of the industry and global regulatory standards.

Ultraviolet-Visible (UV-Vis) spectrophotometry serves as an indispensable analytical technique in pharmaceutical research and quality control. This instrumental method provides the foundation for ensuring drug identity, purity, and efficacy from early development through final product release. The reliability of UV-Vis spectroscopy hinges on the integrated performance of its core components, each playing a critical role in generating accurate, reproducible data that complies with stringent regulatory standards. For pharmaceutical scientists, understanding the instrument's inner workings is not merely academic—it is essential for method development, troubleshooting, and validating analytical procedures that satisfy pharmacopeial requirements from the United States Pharmacopeia (USP), European Pharmacopoeia (EP), and Japanese Pharmacopoeia (JP) [4]. This guide deconstructs the UV-Vis spectrophotometer into its fundamental components, examining the principle and operation of each from the light source to the detector.

The Operating Principle: Beer-Lambert Law

The fundamental principle underlying UV-Vis spectroscopy is the Beer-Lambert Law, which states that the absorbance of light by a solution is directly proportional to the concentration of the absorbing species and the path length of the light through the solution [11] [1].

The law is mathematically expressed as: A = εcl Where:

- A is Absorbance (unitless)

- ε is the molar absorptivity (L·molâ»Â¹Â·cmâ»Â¹)

- c is the concentration of the analyte (mol·Lâ»Â¹)

- l is the optical path length of the cell (cm) [11]

This linear relationship is the basis for quantitative analysis, allowing researchers to determine the concentration of an active pharmaceutical ingredient (API) or identify impurities by measuring absorbance at specific wavelengths [3].

Core Components of a UV-Vis Spectrophotometer

A UV-Vis spectrophotometer is an integrated system of optical, mechanical, and electronic modules. The sequential workflow between these components ensures precise measurement of a sample's interaction with light.

Light Source

The light source must provide stable, intense radiation across the entire UV-Vis range (typically 190–800 nm) [11]. No single lamp covers this entire range optimally, so instruments often use multiple sources.

Table 1: Common Light Sources in UV-Vis Spectrophotometry

| Source Type | Spectral Range | Key Characteristics | Pharmaceutical Application Context |

|---|---|---|---|

| Deuterium Lamp | 190–400 nm (UV) [11] [12] | Intense, continuous UV spectrum; often paired with a halogen lamp [11] [1]. | Essential for API quantification and impurity profiling at low UV wavelengths, as required by ICH guidelines [13]. |

| Tungsten-Halogen Lamp | 350–800 nm (Visible) [11] | Stable, smooth output in visible and NIR regions; long-lasting [12]. | Used for dissolution testing of colored tablets and visual purity assessment [3] [4]. |

| Xenon Lamp | 200–1000 nm (UV-Vis) [14] [12] | High-intensity, continuous broad spectrum; more expensive and less stable than dual-lamp systems [11] [1]. | Often found in research-grade instruments for rapid scanning and kinetic studies of drug reactions [4]. |

In instruments with two lamps, an automated switchover occurs between 300 and 350 nm, where the light output from both sources is comparable, ensuring a smooth transition [11] [1].

Wavelength Selector (Monochromator)

The monochromator isolates a narrow band of wavelengths from the broad spectrum emitted by the light source. Its key components include an entrance slit, a diffraction grating, and an exit slit [11] [1]. The grating, which can be rotated, disperses the light, allowing only a specific wavelength to pass through the exit slit and reach the sample. The quality of the monochromator is often defined by its groove frequency (typically 1200 grooves/mm or higher) and its optical resolution, which directly impacts the ability to resolve fine spectral details—a critical factor in identifying and quantifying complex pharmaceutical compounds [1].

Sample Container (Cuvette)

The sample holder is a critical yet sometimes overlooked component. The sample, typically in solution, is held in a transparent container called a cuvette.

Table 2: Common Cuvette Types and Properties

| Cuvette Material | Wavelength Range | Key Characteristics | Suitability for Pharma Analysis |

|---|---|---|---|

| Quartz | 190–2500 nm [12] | Transparent across UV and Vis ranges; chemically inert. | Essential for UV analysis below 350 nm, e.g., for nucleic acid purity checks or protein analysis [1]. |

| Glass | 350–2000 nm | Absorbs UV light below ~350 nm; economical. | Suitable for visible-range analyses only, such as colorimetric assays in dissolution testing [1]. |

| Plastic | ~400–800 nm | Disposable, low-cost; absorbs most UV light. | Limited to educational or specific visible-light QC checks; not suitable for regulated pharmaceutical QC [1]. |

Standard path lengths are 1 cm, but varying this length is a primary method for keeping absorbance within the ideal quantitative range (0.1–1.0 AU) for highly concentrated or absorbing samples [1].

Detector

The detector converts the transmitted light intensity into an electrical signal proportional to the light's intensity. The choice of detector significantly impacts the instrument's sensitivity and signal-to-noise ratio [15] [1].

Table 3: Detector Technologies in UV-Vis Spectrophotometry

| Detector Type | Principle of Operation | Sensitivity & Speed | Use Case in Pharmaceutical Analysis |

|---|---|---|---|

| Photomultiplier Tube (PMT) | Photoelectric effect; ejected electrons are amplified through a series of dynodes [15] [1]. | Very high sensitivity; fast response time [15] [1]. | The workhorse for high-precision QC assays requiring low detection limits, such as quantifying low-level impurities per ICH Q3A [13] [1]. |

| Photodiode Array (PDA) | An array of silicon photodiodes on a chip; measures all wavelengths simultaneously [13] [15]. | Less sensitive than PMT but offers instantaneous spectrum capture [15]. | Ideal for peak purity assessment in HPLC (DAD), method development, and rapid scanning without wavelength lag [13]. |

| Charge-Coupled Device (CCD) | Similar to PDA but uses an array of photo-capacitors (pixels) [15]. | High sensitivity for low-intensity light; low noise [15]. | Used in specialized applications requiring high sensitivity across a wide spectral range, such as advanced research instrumentation [15]. |

Essential Protocols for Pharmaceutical Analysis

The following standard operating procedures (SOPs) are foundational in pharmaceutical analysis and leverage the components described above.

Protocol 1: Verification of Identity and Purity via Absorption Scan

This protocol is used to confirm the identity of a drug substance and check for impurities by comparing its absorption spectrum to a reference standard [3] [4].

- Instrument Calibration: Perform a baseline correction (blanking) using the pure solvent in a matched quartz cuvette.

- Sample Preparation: Dissolve the drug substance to an appropriate concentration in a suitable solvent. A target absorbance below 1.0 AU is ideal for quantitative work [1].

- Data Acquisition: Place the sample in the spectrophotometer. Using a PMT or PDA detector, acquire a full absorption spectrum across a relevant range (e.g., 200–350 nm for many APIs).

- Analysis: Identify the wavelength of maximum absorption (λmax). Compare the sample's λmax and overall spectral shape to a reference standard. The presence of unexpected peaks or shoulder broadening can indicate impurities [3] [11].

Protocol 2: Quantification of an Active Pharmaceutical Ingredient (API)

This method uses the Beer-Lambert law to determine the concentration of an API in a solution, critical for assay and potency tests [3] [4].

- Standard Curve Generation: Prepare a series of standard solutions of the API reference material at known concentrations.

- Absorbance Measurement: Measure the absorbance of each standard at the predetermined λmax using a stable deuterium or tungsten-halogen light source.

- Calibration Plot: Construct a plot of absorbance versus concentration. The plot should be linear, and the slope is equivalent to εl [11].

- Sample Measurement: Measure the absorbance of the unknown sample under identical conditions and use the calibration plot to determine its concentration.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for UV-Vis Analysis in Pharma Research

| Item | Function & Importance |

|---|---|

| High-Purity Quartz Cuvettes (1 cm path length) | The standard container for liquid samples. Quartz is mandatory for UV analysis to ensure transparency at low wavelengths [1]. |

| Reference Standard Material | A highly characterized, pure sample of the analyte used to calibrate the instrument and create the standard curve for quantitative analysis [4]. |

| HPLC-Grade Solvents | High-purity solvents (e.g., water, methanol) minimize background absorbance (especially in the UV range), which can interfere with accurate sample measurement [1]. |

| Neutral Density Filters | Used for performance verification and qualification of the spectrophotometer to ensure adherence to USP/EP/JP requirements for photometric accuracy [4]. |

| Holmium Oxide Filter | A wavelength standard used for verifying the accuracy of the spectrophotometer's wavelength scale, a critical part of instrument qualification in a GLP/GMP environment [4]. |

| Win 45164 | Win 45164, MF:C26H27FN2O2, MW:418.5 g/mol |

| Mct-IN-1 | Mct-IN-1, MF:C19H26N2O3, MW:330.4 g/mol |

The UV-Vis spectrophotometer is a masterpiece of analytical engineering whose whole is greater than the sum of its parts. From the stable emission of the light source and the precise selection of wavelengths by the monochromator to the sensitive conversion of light by the detector, each component must perform optimally to generate reliable data. For professionals in drug development, this deep technical understanding is not optional—it is a prerequisite for developing robust analytical methods, troubleshooting instrumentation, and ultimately generating the high-quality data that underpins regulatory submissions and ensures that every drug product is safe, effective, and of the highest quality.

Within pharmaceutical research, the choice between single-beam and double-beam UV-Visible spectrophotometer configuration is a critical decision that directly impacts data integrity, regulatory compliance, and analytical efficiency. This technical guide provides drug development professionals with a comprehensive comparison of these core instruments, detailing their operational principles, performance characteristics in pharmacopeia-compliant workflows, and selection criteria tailored to modern laboratory environments. By synthesizing current instrumentation standards with practical application scenarios, this document serves as an authoritative resource for optimizing spectrophotometer configuration to support robust analytical methods from drug discovery through quality control.

Ultraviolet-Visible (UV-Vis) spectrophotometry stands as a cornerstone analytical technique in pharmaceutical laboratories, providing indispensable support for quantitative analysis, quality control, and regulatory compliance. This technique operates on the fundamental principle of measuring the absorption of light by molecules in solution, following the Beer-Lambert law which relates absorbance to concentration, path length, and a compound-specific molar absorptivity coefficient [16] [17]. In the highly regulated pharmaceutical environment, the choice of spectrophotometer configuration—single-beam or double-beam—extends beyond mere technical preference to become a strategic decision affecting analytical reliability, method validation, and operational efficiency. The instrument's role spans multiple critical applications including drug substance quantification, dissolution testing, impurity profiling, and verification of compendial methods, each demanding specific performance characteristics that align with either single-beam or double-beam architectures [18].

Core Principles and Instrument Design

Single-Beam Spectrophotometer Architecture

The single-beam spectrophotometer employs a straightforward optical path where light from the source (typically a deuterium lamp for UV and tungsten lamp for visible regions) passes sequentially through a monochromator for wavelength selection, through the sample cuvette, and finally to a single detector [16] [19]. This linear design necessitates a manual measurement sequence: the instrument first measures the intensity of incident light (Iâ‚€) with a blank reference solution, after which the operator replaces the blank with the sample cuvette to measure transmitted light intensity (I) [17] [20]. The absorbance is then calculated as A = logâ‚â‚€(Iâ‚€/I) [16]. This simplified optical pathway offers the advantage of high energy throughput since the light is not divided, potentially increasing sensitivity for specific applications [21].

Double-Beam Spectrophotometer Architecture

In contrast, double-beam instruments incorporate a beamsplitter (typically a rotating mirror or semitransparent optical component) that divides the original light beam into two separate paths after wavelength selection [16] [22]. One beam traverses through the sample cuvette while the other simultaneously passes through a reference cuvette containing the blank solvent [19] [20]. A single detector then alternately measures the intensity of both beams (through rapid switching) or, in some configurations, dual detectors measure each beam simultaneously [16] [22]. The instrument electronics calculate the absorbance based on the ratio of the two beam intensities (A = logâ‚â‚€(Iáµ£/Iâ‚›)), providing continuous real-time comparison between sample and reference [16]. This simultaneous measurement architecture forms the foundation for the enhanced stability and accuracy characteristics of double-beam systems.

Visualization of Optical Pathways

The fundamental difference between these configurations lies in their optical layouts, as illustrated below:

Performance Comparison and Technical Specifications

The architectural differences between single-beam and double-beam instruments translate directly to distinct performance characteristics that determine their suitability for specific pharmaceutical applications. The following comprehensive comparison details how each configuration performs across critical parameters that impact analytical methods and regulatory compliance.

Table 1: Comprehensive Performance Comparison of Single-Beam vs. Double-Beam Spectrophotometers

| Performance Characteristic | Single-Beam Spectrophotometer | Double-Beam Spectrophotometer |

|---|---|---|

| Accuracy | Limited accuracy due to direct impact of source fluctuations and baseline drift; errors increase at absorbance extremes [16] | Superior accuracy through real-time compensation for source intensity changes; consistent across wider absorbance range [16] [20] |

| Precision | Lower precision due to uncorrected baseline drift and noise; precision degrades over time as drift accumulates [16] | Significantly higher precision with reduced baseline drift; excellent reproducibility for repeated measurements [16] [19] |

| Dynamic Range | Limited dynamic range, particularly at high/low absorbance due to potential saturation or detector limitations [16] | Wider dynamic range with accurate measurement of samples with very high or low absorbance [16] |

| Measurement Speed | Faster individual measurements but slower overall process due to manual blank/sample switching [17] | Faster analysis throughput with simultaneous reference and sample measurement; minimal operator intervention [17] [20] |

| Stability | Susceptible to drift from voltage fluctuations, temperature changes, and source aging [21] [19] | High stability with automatic compensation for instrumental and environmental fluctuations [19] [20] |

| Sensitivity | Potentially higher energy throughput as light is not split [21] | Slightly reduced energy due to beam splitting, but advanced detectors mitigate this effect [16] |

| Spectral Acquisition | Suitable for fixed-wavelength quantitative analysis [16] | Ideal for full spectral scanning with stable baseline [16] |

Impact on Pharmaceutical Applications

In regulated pharmaceutical environments, the performance advantages of double-beam systems become particularly valuable for method development and validation activities. The inherent stability and real-time reference correction enable more reliable quantification of active pharmaceutical ingredients (APIs), especially at low concentrations, and more accurate assessment of impurities that may appear as minor spectral features [18]. Single-beam instruments, while capable for specific fixed-wavelength applications, require more frequent calibration and verification to maintain data integrity within acceptable regulatory standards [20].

Selection Guide for Pharmaceutical Applications

Decision Framework

Choosing between single-beam and double-beam configurations requires systematic evaluation of analytical requirements against technical capabilities. The following decision framework provides a structured approach to this selection process:

Application-Specific Recommendations

Table 2: Spectrophotometer Selection Guide for Pharmaceutical Applications

| Application Scenario | Recommended Configuration | Rationale |

|---|---|---|

| Quality Control Labs (Compendial testing, raw material verification) | Double-Beam | Superior accuracy and stability meet regulatory requirements; reduced calibration frequency improves efficiency in high-throughput environments [18] [20] |

| Research & Method Development (API quantification, impurity profiling) | Double-Beam | Excellent precision across spectral range supports method validation; scanning capability enables spectral characterization [16] [20] |

| Teaching/Academic Labs (Training, basic principles) | Single-Beam | Cost-effective for educational budgets; simpler operation reinforces fundamental concepts [16] [17] |

| Stability Studies (Long-term testing, accelerated degradation) | Double-Beam | Superior drift resistance essential for extended measurements; compensates for instrumental variations over time [19] [20] |

| Fixed-Wavelength Analysis (Routine quantification at single wavelength) | Single-Beam | Adequate performance for specific applications where cost and simplicity are prioritized [16] [20] |

| Field Testing (Environmental monitoring, manufacturing floor) | Single-Beam | Compact, portable design; lower sensitivity to rough handling [20] |

Economic Considerations

Beyond technical specifications, the total cost of ownership represents a critical factor in instrument selection. Single-beam systems offer significantly lower initial investment (approximately 30-50% less than comparable double-beam instruments) and generally lower maintenance costs due to simpler optical design [17] [19]. However, double-beam configurations may provide better long-term value in regulated environments through reduced recalibration requirements, lower operator intervention, and minimized repeat analyses due to superior data quality [16] [20]. Pharmaceutical facilities should conduct a comprehensive cost-benefit analysis that considers both capital expenditure and operational efficiency over the instrument's expected lifespan.

Pharmaceutical Standards and Validation Protocols

Regulatory Compliance Framework

In pharmaceutical applications, UV-Vis spectrophotometers must comply with pharmacopeia standards including the United States Pharmacopeia (USP) and European Pharmacopoeia (EP) [18]. These regulatory bodies mandate specific performance verification (PV) tests to ensure instrument suitability for intended analytical methods. The core validation parameters include wavelength accuracy, photometric (absorbance) accuracy, spectral resolution, and stray light characterization [18]. Regular verification against these parameters forms an essential component of quality assurance in drug development and manufacturing.

Essential Validation Reagents and Materials

Table 3: Essential Research Reagent Solutions for Spectrophotometer Validation

| Reagent/Standard | Composition/Type | Function in Validation | Pharmacopeia Reference |

|---|---|---|---|

| Holmium Oxide Filter/Solution | Holmium oxide in perchloric acid solution or glass filter | Wavelength accuracy verification across UV-Vis range (241-641 nm) [18] | USP <857>, EP 2.2.25 |

| Potassium Dichromate Solutions | 60-140 mg/L solutions in sulfuric acid | Photometric accuracy verification in UV region (specifically at 235, 257, 313, 350 nm) [18] | USP <857>, EP 2.2.25 |

| Neutral Density Glass Filters | Certified glass filters with calibrated absorbance values | Photometric accuracy verification in visible region (440, 465, 546.1, 590, 635 nm) [18] | USP <857>, EP 2.2.25 |

| Stray Light Standards | Potassium chloride (KCl), sodium iodide (NaI), sodium nitrite (NaNOâ‚‚) | Stray light verification at specific wavelengths (198, 220, 340 nm) [18] | USP <857>, EP 2.2.25 |

| Resolution Standard | Toluene in hexane (0.02% v/v) | Spectral bandwidth/resolution verification (fine structure evaluation) [18] | USP <857>, EP 2.2.25 |

| Mercury Vapor Lamp | Low-pressure mercury lamp with emission lines | Primary wavelength standard with absolute reference lines [18] | USP <857> |

Performance Verification Protocol

A comprehensive performance verification protocol should be established following a systematic workflow:

For double-beam instruments, this verification protocol typically demonstrates superior performance across all parameters, particularly in photometric accuracy and stray light rejection, directly supporting their application in regulated pharmaceutical environments [18]. Single-beam instruments require more frequent verification to ensure maintained performance, particularly when used in environments with temperature fluctuations or variable power supply conditions.

The selection between single-beam and double-beam spectrophotometer configurations represents a significant decision with far-reaching implications for pharmaceutical research and quality control. Single-beam instruments offer compelling advantages in terms of initial cost, simplicity, and specific sensitivity applications, making them suitable for educational settings, specific quantitative methods, and environments with budget constraints [16] [20]. However, double-beam spectrophotometers provide unequivocal benefits in accuracy, stability, and operational efficiency that align with the rigorous demands of pharmaceutical applications [16] [18].

For drug development professionals operating in regulated environments, the double-beam configuration generally represents the preferred choice due to its inherent compensation for instrumental variations, reduced requirement for frequent recalibration, and robust performance across the diverse analytical methods encountered in modern pharmaceutical laboratories. The investment in double-beam technology returns value through reliable data integrity, reduced method variability, and compliance with pharmacopeia standards that govern drug approval and manufacturing. As spectroscopic technology continues to evolve, both configurations will maintain relevance in the analytical landscape, with selection ultimately determined by aligning technical capabilities with specific application requirements within the framework of quality by design principles.

Ultraviolet-Visible (UV-Vis) spectrophotometry serves as a cornerstone analytical technique in pharmaceutical research, development, and quality control (QC). This technique measures the absorption of light in the ultraviolet (190–400 nm) and visible (400–800 nm) regions of the electromagnetic spectrum, providing critical data for the identification, quantification, and purity assessment of pharmaceutical compounds [4] [23]. The fundamental principle relies on the Beer-Lambert Law, which states that the amount of light absorbed by a sample is directly proportional to the concentration of the absorbing species and the path length of the light through the sample [14]. In the highly regulated pharmaceutical industry, the reliability of analytical data is paramount. Therefore, understanding and specifying the core technical parameters of a UV-Vis spectrophotometer—wavelength range, resolution, and accuracy—is essential for ensuring that the instrument is fit for its intended use and compliant with global pharmacopeial standards [4] [24].

This guide provides an in-depth examination of these technical specifications within the context of pharmaceutical applications. It is designed to assist researchers, scientists, and drug development professionals in selecting, qualifying, and operating UV-Vis instrumentation to generate accurate, precise, and regulatory-compliant data throughout the drug lifecycle, from initial research to final product release.

Core Technical Specifications and Pharmacopeial Standards

The performance of a UV-Vis spectrophotometer is defined by several key technical parameters. These specifications directly impact the instrument's ability to correctly identify and accurately quantify analytes, which is critical for activities like Active Pharmaceutical Ingredient (API) quantification, impurity profiling, and dissolution testing [4] [23]. Regulatory bodies and pharmacopeias, including the United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.), define specific performance criteria that instruments must meet for use in regulated laboratories [4] [25].

The following table synthesizes the key specifications of common UV-Vis spectrophotometer models used in pharmaceutical analysis, highlighting the variation in performance capabilities across different price and application segments [26].

Table 1: Comparison of UV-Vis Spectrophotometer Models for Pharmaceutical Applications

| Model | Wavelength Range | Resolution | Wavelength Accuracy | Best Use Case in Pharma |

|---|---|---|---|---|

| Jasco V-770 | 175–1100 nm | 0.01 nm | Not specified | Advanced research requiring sub-nanometer precision |

| Thermo Fisher Evolution 300 | 190–1100 nm | 0.1 nm | Not specified | High-precision pharmaceutical and chemical analysis |

| Agilent 8453 | 190–1100 nm | 0.5 nm | Not specified | Versatile routine and research applications |

| PerkinElmer Lambda 35 | 190–1100 nm | 0.5 nm | Not specified | Budget-conscious academic and industrial labs |

| Shimadzu UV-1800 | 190–1100 nm | 1 nm | Not specified | Basic spectroscopy and compact setups |

| PerkinElmer LAMBDA 1050+ | 175–3300 nm | <0.05 nm (UV-Vis) | Better than ±0.08 nm (UV-Vis) | Product quality control across multiple industries |

Detailed Specification Analysis

Wavelength Range: The span of wavelengths over which the instrument can operate is crucial. A standard range of 190–1100 nm covers most pharmaceutical applications, including the analysis of organic compounds and APIs that absorb in the UV region [26] [4]. An extended range down to 175 nm, as seen in the Jasco V-770, can be beneficial for specialized research involving specific functional groups, while extension into the Near-Infrared (NIR) region, as with the PerkinElmer LAMBDA 1050+, expands the utility for material characterization [26] [27].

Spectral Resolution and Bandpass: Resolution defines the instrument's ability to distinguish between two closely spaced absorption peaks. This is critical for identifying compounds with fine spectral features or for analyzing complex mixtures. High-resolution systems (<0.1 nm) are essential for research and method development, whereas a resolution of 1 nm may be sufficient for routine quantitative assays specified in monographs [26]. The monochromator, which separates light into individual wavelengths, is a key determinant of resolution [14].

Wavelength Accuracy: This parameter indicates how close the instrument's displayed wavelength is to the true wavelength. Pharmacopeias like the USP stipulate that deviation should be within ±1 nm for critical analyses [25]. High-performance instruments offer accuracies of ±0.3 nm or better, which is essential for reliable method transfer and regulatory compliance, particularly when comparing spectra against reference libraries [4] [28].

Regulatory Framework and Instrument Qualification

In pharmaceutical laboratories, UV-Vis spectrophotometers are subject to rigorous qualification and validation requirements to ensure data integrity and regulatory compliance. The updated USP general chapter <1058> on "Analytical Instrument and System Qualification" (AISQ) provides a lifecycle framework for establishing and maintaining instrument fitness for intended use [24].

The Integrated Lifecycle Approach

The modern approach to instrument qualification, as outlined in the draft update to USP <1058>, is an integrated, three-phase lifecycle model [24]:

- Specification and Selection: This initial phase involves defining the intended use of the instrument in a User Requirements Specification (URS). The URS must incorporate the operational parameters and acceptance criteria from mandatory pharmacopeial chapters (e.g., USP <857>) to ensure metrological capability and traceability to national or international standards [24].

- Installation, Qualification, and Validation: This phase involves installing the instrument and performing Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). For UV-Vis systems, this includes testing critical parameters like wavelength accuracy, photometric accuracy, and stray light against defined acceptance criteria [24].

- Ongoing Performance Verification (OPV): This continuous phase ensures the instrument remains in a state of control and within established acceptance limits throughout its operational life. It includes activities like regular calibration, preventive maintenance, and change control [24].

Key Regulatory Guidelines

- USP <857> and Ph. Eur. 2.2.25: These are the mandatory general chapters that define the performance tests and acceptance criteria for UV-Vis spectrophotometers [25] [24].

- ICH Q2(R1): Provides guidance on the validation of analytical procedures, which inherently relies on a properly qualified instrument [23].

- 21 CFR Part 11/211: FDA regulations that enforce strict controls over electronic records and laboratory practices, requiring instrument calibration, proper documentation, and personnel training [23].

Calibration and Performance Verification Protocols

Regular calibration and performance verification are critical components of the Ongoing Performance Verification (OPV) phase. The following protocols, derived from pharmacopeial methods, ensure the instrument continues to perform within specified limits [25].

Table 2: Standard Calibration Protocols for UV-Vis Spectrophotometers

| Parameter | Standard/Reagent Used | Experimental Protocol | Acceptance Criteria |

|---|---|---|---|

| Wavelength Accuracy | Holmium Oxide Filter | Scan the filter and record the characteristic peak wavelengths (e.g., 279.4, 287.5, 333.7, 360.9, 536.2 nm). | Deviation of observed peaks ≤ ±1 nm from certified values [25]. |

| Photometric Accuracy | Potassium Dichromate Solution (in 0.005 M H₂SO₄) | Measure the absorbance of the solution at specific wavelengths (235, 257, 313, 350 nm). | Absorbance deviation ≤ ±0.010 A from reference values [25]. |

| Stray Light | 1.2% w/v Potassium Chloride (KCl) Solution | Measure the absorbance of KCl in a 1 cm pathlength cell at 200 nm. | Absorbance ≥ 2.0 A [25]. |

| Resolution Power | Toluene in Hexane (0.02% v/v) | Scan the solution and identify the peak at 269 nm and the minimum at ~266 nm. Calculate the ratio of Abs269/Abs266. | Ratio ≥ 1.5 [25]. |

| Photometric Linearity | A series of progressively diluted potassium dichromate solutions. | Measure the absorbance of each standard and plot absorbance vs. concentration. | Correlation coefficient (R²) ≥ 0.999 [25]. |

Calibration Frequency

Calibration should be performed [25]:

- Upon initial installation of the instrument.

- After major maintenance, repairs, or lamp replacement.

- At regular periodic intervals, typically every 6 or 12 months, as defined by the laboratory's Standard Operating Procedure (SOP).

- As required by regulatory and data integrity principles.

Pharmaceutical Applications and Workflows

UV-Vis spectroscopy is deeply integrated into various pharmaceutical workflows. Its non-destructive nature, speed, and ease of use make it ideal for both research and high-throughput QC environments [4] [23] [14].

Table 3: Key Pharmaceutical Applications of UV-Vis Spectrophotometry

| Application | Typical Wavelength(s) | Protocol Summary | Relevant Specifications |

|---|---|---|---|

| API Quantification & Content Uniformity | λ_max of the API | A standard curve is constructed using known concentrations of the API. Tablets are dissolved and diluted, and their absorbance is measured to determine concentration [4] [23]. | Wavelength accuracy is critical for correct identification of λ_max. Photometric accuracy and linearity ensure precise and accurate concentration results. |

| Dissolution Testing | Varies by API | Samples are withdrawn from dissolution vessels at set time points, and the absorbance is measured to calculate the percentage of drug released [4]. | High photometric accuracy and low stray light are essential for reliable results across different time points and concentrations. |

| Impurity and Purity Assessment | Multiple wavelengths | The sample spectrum is scanned and compared to a reference standard. The presence of unexpected peaks or shifts can indicate impurities or degradation products [4] [23]. | High resolution is needed to distinguish between closely spaced peaks. A broad wavelength range allows for detection of various impurities. |

| Nucleic Acid & Protein Analysis (Biologics) | 260 nm (DNA/RNA), 280 nm (Protein) | Samples are pipetted directly, and pre-programmed methods calculate concentration and purity ratios (e.g., A260/A280) [4] [14]. | Microvolume capability and software integration are key for efficiency and sample conservation. |

The following diagram illustrates a generalized workflow for quantitative analysis in pharmaceutical QC, highlighting the role of instrument qualification and calibration.

Diagram 1: UV-Vis Instrument Qualification and Use Workflow. OPV = Ongoing Performance Verification.

The Scientist's Toolkit: Essential Reagents and Materials

The following table lists key reagents and materials required for the operation, calibration, and application of UV-Vis spectrophotometers in a pharmaceutical setting [25].

Table 4: Essential Research Reagent Solutions for UV-Vis Spectrophotometry

| Item | Function | Application Example |

|---|---|---|

| Holmium Oxide Filter | Certified wavelength reference standard. | Verification of wavelength accuracy during instrument calibration [25]. |

| Potassium Dichromate | Certified photometric reference standard. | Verification of photometric accuracy and establishment of photometric linearity [25]. |

| Potassium Chloride (KCl) | Stray light verification standard. | Checking for stray light at the lower end of the UV range (200 nm) [25]. |

| High-Purity Solvents (e.g., HPLC-grade water, acids) | Dissolution and dilution medium. | Preparation of sample and standard solutions to avoid interfering absorbances [23]. |

| Matched Quartz Cuvettes | Sample holder for liquid analysis. | Ensuring pathlength accuracy and transparency in the UV range; critical for quantitative accuracy [23]. |

| Neutral Density Filters | Alternative photometric standards. | Used for verifying photometric accuracy at various absorbance levels [25]. |

| Bimax2 | Bimax2, MF:C146H254N64O41, MW:3562.0 g/mol | Chemical Reagent |

| CC15009 | CC15009, MF:C20H21Cl2N5O2, MW:434.3 g/mol | Chemical Reagent |

In the pharmaceutical laboratory, the UV-Vis spectrophotometer stands as a cornerstone instrument for drug development and quality control, enabling critical analyses from identity confirmation to dissolution testing [4] [3]. While often overlooked, the sample holder—the interface between the instrument and the substance being analyzed—is a critical component whose selection directly impacts data integrity. The sample holder and its enclosed cuvette are not merely containers; they define the precise pathlength through which light travels, a fundamental variable in the Beer-Lambert Law (A = εbc), which dictates that absorbance (A) is directly proportional to the concentration (c) and the pathlength (b) [29]. An inappropriate choice can introduce errors in concentration calculations, degrade spectral quality, and ultimately compromise compliance with stringent pharmacopeial standards [4] [3].

This guide details the selection of appropriate sample holders and cuvettes, framing this choice within the broader context of ensuring accurate, reliable, and regulatory-compliant outcomes in pharmaceutical research.

Fundamental Principles of UV-Vis Spectroscopy and the Sample Holder's Role

The Beer-Lambert Law and Pathlength

The foundational principle of quantitative UV-Vis analysis is the Beer-Lambert Law: ( A = \varepsilon b c ) [29]. Here, A is the measured absorbance, ε is the molar absorptivity, b is the pathlength, and c is the concentration. The pathlength (b) is the distance light travels through the sample, a parameter almost exclusively defined by the cuvette itself. Any deviation from the assumed or calibrated pathlength due to cuvette manufacturing tolerances or improper seating in the holder introduces a direct systematic error into the concentration calculation.

Instrument Configuration and Sample Presentation

A UV-Vis spectrophotometer comprises a light source, a monochromator to select wavelengths, a sample holder, and a detector [29] [14]. The sample holder's function is to position the sample reproducibly within the light path. In a single beam instrument, the sample must be placed and removed for referencing, whereas in a double beam system, the beam is split to pass through both the sample and a reference cell simultaneously [29]. The holder ensures that every measurement is taken at the same precise position and pathlength, which is vital for method reproducibility and transferability between labs. Furthermore, holders often include a cover to prevent ambient light from entering, which could scatter into the detector and cause inaccurate absorbance readings [30].

Types of Cuvette Sample Holders

Sample holders are engineered for specific measurement types and sample volumes. Selecting the correct type is the first step in designing a robust analytical method.

Standard Absorption Holders

The most common holder in pharmaceutical analysis is the standard absorption holder, designed for a single light path transmitting directly through the sample. These are used with standard cuvettes, most often with a 10 mm pathlength [30]. To ensure precision, many modern holders feature adjustable ball-detents that accommodate minor variations in cuvette size and ensure repeatable placement for measurement consistency [30]. These holders form the workhorse of routine quality control tests, such as assay and identity verification [3].

Specialized Holder Configurations

For advanced applications, specialized holders are required:

- Fluorescence Holders: Used for quantification of impurities or specific assays, these holders position the detector at a 90-degree angle to the excitation light path. This geometry isolates the emitted light from the excitation beam, enhancing signal-to-noise ratio. Some models include SiO2-coated aluminum mirrors to further enhance the excitation and fluorescence signals [30].

- Temperature-Controlled Holders: Many chemical and physicochemical properties of pharmaceuticals, such as dissolution rate and stability, are temperature-dependent. Water-thermostatted and Peltier cell holders make accurate temperature-controlled measurements possible, which is critical for method robustness and predicting shelf-life [31].

- Microvolume Holders: A key advancement for analyzing precious samples, these holders enable measurements of sample volumes down to 4 μL (on the Cary 60) or even 0.5 μL with specialized pedestal designs [31] [14]. This eliminates the need for diluting concentrated nucleic acid or protein samples, saving time and conserving valuable material.

Table 1: Types of Cuvette Sample Holders and Their Pharmaceutical Applications

| Holder Type | Key Features | Primary Pharmaceutical Applications |

|---|---|---|

| Standard Absorption | Holds standard cuvettes (e.g., 10 mm path); often includes a filter slot and cover [30]. | Routine quantification of APIs, identity testing, purity assessment [4] [3]. |

| Fluorescence | Optical components arranged at a 90° angle; may include signal-enhancing mirrors [30]. | High-sensitivity impurity detection, specific enzymatic assays [30]. |

| Temperature-Controlled | Peltier or water-jacketed for precise temperature regulation [31]. | Dissolution testing, stability studies, reaction kinetics [31] [4]. |

| Microvolume | Requires minimal sample (e.g., 0.5-4 μL); no cuvette needed for some systems [31] [14]. | Analysis of concentrated DNA/RNA samples, proteins in early R&D [14]. |

| Long Pathlength | Accommodates pathlengths up to 10 cm for enhanced sensitivity [31]. | Measuring very dilute samples or weak absorbers. |

Cuvette Selection Based on Material and Design

The cuvette itself is as critical as the holder. Its material dictates the range of wavelengths that can be probed, and its design defines its suitability for different sample types.

Cuvette Material and Optical Properties

The choice of material is governed by the spectral region of interest.

- Glass and Optical Glass: Suitable for the visible light range (approximately 320 - 2500 nm). They are cost-effective for colorimetric assays, such as those used in beverage analysis or some dissolution endpoint tests [4]. However, they are not suitable for UV-range measurements.

- Quartz (Fused Silica): The material of choice for rigorous pharmaceutical analysis. Quartz cuvettes are transparent across both the UV and visible regions (below 200 - 2500 nm), making them essential for full-spectrum analysis as required by many pharmacopeial monographs [30]. They are chemically inert and can withstand high temperatures, which is valuable for cleaning or temperature studies.

- Plastic (PS, PMMA, ABS): Disposable plastic cuvettes are inexpensive and useful for avoiding cross-contamination, particularly in bioassays or when working with sticky samples. However, their optical clarity is inferior, they can be scratched easily, and many types are not transparent in the UV range. Their use is generally limited to educational settings or non-regulated Vis-range applications.

Cuvette Design and Pathlength

Cuvettes are available with different numbers of optical windows and various pathlengths.

- Standard (2-window): Used for routine absorption measurements, where light passes through two opposing windows [30].

- Four-window (Fluorescence): Featuring two additional polished windows, these cuvettes are ideal for fluorescence measurements. They allow excitation light to enter and emitted light to be detected at 90 degrees without sacrificing signal quality. They can also be used for dual-path absorption measurements with specialized holders [30].

- Pathlength Variants: While 10 mm is standard, shorter pathlengths (e.g., 2 mm, 5 mm) are available for measuring highly concentrated samples without the need for excessive dilution, thereby avoiding dilution error. Conversely, longer pathlengths (e.g., 5 cm, 10 cm) are used to enhance sensitivity for very dilute analytes [31].

Table 2: Cuvette Material and Design Selection Guide

| Cuvette Type | Wavelength Range | Pros | Cons | Ideal for Pharma Applications |

|---|---|---|---|---|

| Optical Glass | ~320 - 2500 nm | Low cost, durable. | Opaque in UV range. | Visible range colorimetry (e.g., beverage QC) [4]. |

| Quartz (Fused Silica) | ~180 - 2500 nm | Full UV-Vis transparency, chemically resistant, durable. | Higher cost. | USP/EP/JP monograph methods, API identity/assay, R&D [4] [30]. |

| Polystyrene (PS) | Vis to NIR | Disposable, low cost, good for avoiding cross-contamination. | Easily scratched, can leach organics, often opaque in UV. | Educational labs, non-regulated visible light assays. |

| Four-Window Quartz | ~180 - 2500 nm | Enables high-sensitivity fluorescence and dual-path measurements. | Higher cost than 2-window quartz. | Fluorescence-based impurity testing, high-sensitivity assays [30]. |

A Practical Guide for Pharmaceutical Scientists

Selection Workflow and Application Mapping

Selecting the correct sample holder and cuvette is a systematic process driven by the analytical goal, sample properties, and regulatory context. The following decision pathway provides a structured approach for scientists.

Compliance with Pharmacopeial Standards

Regulatory compliance is non-negotiable in pharmaceutical quality control. Instruments and methods must be performance-verified according to standards in the United States Pharmacopeia (USP), European Pharmacopoeia (EP), and Japanese Pharmacopoeia (JP) [4]. The use of high-quality quartz cuvettes and calibrated holders is implicit in meeting the stringent requirements for tests such as:

- Identity Testing: Confirming the drug substance is as labeled, often by comparing its absorbance spectrum against a standard [3].

- Assay: Precisely quantifying the amount of the Active Pharmaceutical Ingredient (API) [3].

- Impurity and Dissolution Testing: Detecting minor impurities and ensuring the drug product releases the API appropriately [4] [3].

Adherence to 21 CFR Part 11 is also critical for electronic data integrity, which extends to the metadata associated with the analysis, including instrument and accessory configuration [4].

Essential Research Reagent Solutions

The following table catalogues the core materials and tools required for effective sample handling and analysis in a pharmaceutical UV-Vis laboratory.

Table 3: The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function/Description | Application in Pharma Analysis |

|---|---|---|

| Quartz Cuvettes (10 mm, 2-window) | Provides high transparency across UV-Vis range; inert. | The default choice for most quantitative analyses (assay, identity) of APIs [30]. |

| Quartz Cuvettes (4-window) | Enables fluorescence detection with minimal signal loss. | High-sensitivity detection of low-level impurities or for specific fluorometric assays [30]. |

| Certified Reference Materials | High-purity analytes with certified concentrations and properties. | Essential for calibrating the spectrophotometer and creating validation-standard calibration curves [29]. |

| High-Purity Solvents | Spectrophotometric grade solvents with low UV absorbance. | Used to prepare sample and standard solutions, minimizing background interference (blank absorbance). |

| Cuvette Cleaning Kit | Brushes, solvents, and mild detergents for proper cuvette cleaning. | Prevents cross-contamination between samples, which is critical for data accuracy and integrity. |

Detailed Experimental Protocol: API Identity Confirmation by UV Spectra

This protocol outlines a standard procedure for confirming the identity of an Active Pharmaceutical Ingredient (API), such as Ibuprofen, according to pharmacopeial guidelines [4].

1. Objective: To confirm the identity of an unknown API sample by comparing its UV absorbance spectrum against a known standard, as per USP/EP monographs.

2. Materials and Reagents: - API Certified Reference Standard - Unknown API test sample - Spectrophotometric grade solvent (as specified in monograph, e.g., methanol) - Two matched quartz cuvettes (10 mm pathlength) - Volumetric flasks, pipettes

3. Instrument and Holder Setup: - Turn on the UV-Vis spectrophotometer and allow the lamp to warm up for the recommended time. - Install the standard absorption cell holder in the instrument compartment. - Select the spectrum mode in the instrument software. Set the wavelength range as specified (e.g., 200-300 nm). - Fill a quartz cuvette with the pure solvent, place it in the holder, and close the cover. Perform a blank correction to zero the instrument.

4. Sample Preparation: - Accurately weigh the reference standard and the test sample to prepare solutions at the concentration specified in the monograph. - Dissolve both in the specified solvent using volumetric flasks to ensure precise concentration.

5. Experimental Procedure: - Empty and rinse the blank cuvette with a small amount of the standard solution. - Fill the cuvette with the standard solution, place it in the holder, and run the spectral scan. Save the spectrum. - Repeat the rinsing process with the unknown test sample solution. - Fill the cuvette with the test sample solution, place it in the holder, and run the spectral scan. Save the spectrum.

6. Data Analysis and Acceptance Criteria: - Overlay the spectrum of the test sample with that of the reference standard. - The test sample is considered to meet the identity requirement if the wavelength of maximum absorbance (λmax) for both spectra correspond within the specified tolerance (e.g., ±2 nm as per pharmacopeia). - The shape of the absorption spectra should be visually identical.

In the highly regulated and precise world of pharmaceutical development, no component of an analytical system can be taken for granted. The sample holder and cuvette are fundamental in transforming a theoretical measurement into a reliable, actionable result. From ensuring the accurate application of the Beer-Lambert Law to enabling compliance with global pharmacopeias, the critical role of these components cannot be overstated. A deliberate, informed selection process—considering the analytical technique, sample properties, and regulatory requirements—is a hallmark of rigorous and successful pharmaceutical science. By treating the interface between the instrument and the sample with the same importance as the instrument itself, scientists safeguard the quality, safety, and efficacy of the medications that reach patients.

Pharmaceutical Applications in Action: From Drug Development to QA/QC Testing

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a fundamental analytical technique in pharmaceutical research and development, providing critical insights into the identity, purity, and concentration of Active Pharmaceutical Ingredients (APIs). This absorption spectroscopy method quantifies the amount of ultraviolet or visible light absorbed by a compound in solution or as a solid, exciting electrons from the ground state to the first singlet excited state [29]. The operational principle relies on the Beer-Lambert Law (A = εbc), where absorbance (A) is proportional to the molar absorptivity (ε), path length (b), and concentration (c) of the analyte [29]. For drug development professionals, UV-Vis spectroscopy offers a rapid, economical, and accurate method for assessing key quality parameters during both development and manufacturing stages, playing a crucial role in stability testing, quality control, and formulation development [32].

Fundamental Principles and Instrumentation

Theoretical Foundations

UV-Vis spectroscopy operates within the electromagnetic spectrum range of 200-800 nm, encompassing both ultraviolet (200-400 nm) and visible (400-800 nm) regions [33]. When sample molecules encounter light energy matching possible electronic transitions, electrons are promoted to higher energy orbitals, resulting in characteristic absorption patterns [33]. The resulting spectrum presents as a graph of absorbance versus wavelength, providing both qualitative and quantitative information about the compound of interest [33] [29]. The molar absorptivity (ε) reflects both chromophore size and the probability that light of a given wavelength will be absorbed, with strongly absorbing chromophores exhibiting values >10,000 [33].

Instrumentation Configuration

UV-Vis spectrophotometers comprise three essential components: a light source (typically deuterium or tungsten lamp), a sample holder, and a detector [29]. Instrument configurations vary based on application requirements:

- Single Beam Instruments: Feature a filter or monochromator between the source and sample to analyze one wavelength at a time [29].

- Double Beam Instruments: Incorporate a beam splitter and mirror system to direct light to both reference and sample simultaneously, allowing for more accurate readings [29].

- Simultaneous Instruments: Utilize a diode array detector to simultaneously detect absorbance at all wavelengths, providing significantly faster analysis [29].

Modern pharmaceutical applications increasingly employ in-line UV-Vis systems integrated directly into manufacturing processes, such as hot melt extrusion, enabling real-time monitoring of critical quality attributes [34].

Experimental Methodologies for API Analysis

Sample Preparation Protocols

Proper sample preparation is critical for obtaining accurate and reproducible UV-Vis results. The following protocols ensure data reliability:

- Solvent Selection: Use high-purity solvents that do not absorb significantly in the spectral region of interest. Common pharmaceutical solvents include water, buffers, methanol, hexanes, and acetonitrile [33] [29].

- Solution Preparation: Prepare solutions using digital pipettes and volumetric flasks rather than graduated cylinders for improved accuracy [29].

- Concentration Optimization: Adjust sample concentration to ensure absorbance values fall within the ideal range of 0.2-1.0 AU, minimizing measurement errors associated with very low or high absorbance [33].

- Blank Measurement: Always run a blank containing pure solvent to zero the instrument before sample analysis [29].

For solid formulations or suspensions, special considerations apply, as suspended particles can scatter light more than absorb it, potentially skewing data [29].

Qualitative Identification of APIs

UV-Vis spectroscopy facilitates API identification through characteristic absorption patterns:

- Spectral Scanning: Collect full spectrum data from 200-800 nm to identify wavelength of maximum absorption (λmax), which serves as a characteristic fingerprint for specific chromophores [33] [29].

- Chromophore Mapping: Identify specific functional groups based on known chromophore absorption characteristics (e.g., carbonyl groups, conjugated systems) [33].

- Excipient Interference Assessment: Compare spectra of pure API versus formulated product to identify potential excipient interactions [34].

The presence of conjugation generally moves absorption maxima to longer wavelengths (bathochromic shift), making conjugation a major structural feature identifiable by this technique [33].

Quantitative Determination of API Concentration

Accurate quantification of API concentration follows a systematic approach:

- Method Development: Select appropriate wavelength (typically λmax) and verify linearity range [29].

- Calibration Curve Construction: Prepare at least five standard solutions spanning the expected concentration range, spaced relatively equally [29].

- Sample Analysis: Measure absorbance of unknown samples under identical conditions [29].

- Concentration Calculation: Determine sample concentration using the linear regression equation from the calibration curve [29].

Table 1: Key Validation Parameters for UV-Vis Quantitative Methods

| Parameter | Target Specification | Experimental Approach |

|---|---|---|

| Linearity | Correlation coefficient ≥0.99 | Analyze minimum of 5 concentrations across specified range |

| Accuracy | Recovery 98-102% | Spike and recovery studies at multiple concentration levels |

| Precision | RSD ≤2% | Repeat analysis of homogeneous samples (n=6) |

| Range | Concentrations yielding absorbance 0.2-1.0 AU | Verify linear response across intended working range |

| Specificity | No interference from excipients | Compare API, placebo, and formulation spectra |

For advanced applications, the Analytical Quality by Design (AQbD) approach establishes an Analytical Target Profile (ATP) prior to method development, defining predefined method performance requirements [34].

Advanced Application: In-line UV-Vis for Process Monitoring

Real-time API Quantification in Hot Melt Extrusion

Recent advancements have demonstrated successful implementation of in-line UV-Vis spectroscopy for real-time API quantification during hot melt extrusion (HME) processes [34]. A validated method for piroxicam content determination in Kollidon VA64 achieved 95% β-expectation tolerance limits within ±5% acceptance limits, demonstrating robustness across screw speed (150-250 rpm) and feed rate (5-9 g/min) variations [34].

The experimental workflow for this application involves:

CIELAB Color Space Analysis

In-line UV-Vis systems can calculate CIELAB color space parameters from transmittance spectra (380-780 nm), providing additional quality attributes [34]:

- Lightness (L*): Indicates potential degradation or color changes

- Green-Red axis (a*): Monitors color shifts toward red or green

- Blue-Yellow axis (b*): Detects yellowing, potentially indicating thermal degradation [34]

These color parameters serve as in-process critical quality attributes linked to the ability to accurately measure API content [34].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Essential Materials for UV-Vis API Analysis

| Material/Reagent | Function/Application | Technical Specifications |

|---|---|---|

| High-Purity Solvents (HPLC grade) | Sample dissolution and reference measurements | Low UV absorbance; appropriate for API solubility |

| Volumetric Flasks | Precise solution preparation | Class A; appropriate volume for working concentration |

| UV-Compatible Cuvettes | Sample containment during analysis | Quartz for UV range; path length 1 cm standard |

| API Reference Standards | Method development and validation | Certified purity; structural confirmation |

| Placebo Formulation | Specificity assessment | Contains all excipients except API |

| Buffer Salts | pH control for ionizable APIs | High purity; minimal UV absorbance |

| Tak-632 | Tak-632, MF:C27H18F4N4O3S, MW:554.5 g/mol | Chemical Reagent |

| Propyl Gallate | Propyl Gallate, CAS:121-79-9; 56274-95-4, MF:C10H12O5, MW:212.20 g/mol | Chemical Reagent |

Method Validation and Regulatory Considerations

Validation Protocols

Comprehensive validation of UV-Vis methods for pharmaceutical analysis should address these critical parameters, particularly when employed as Process Analytical Technology (PAT) [34]:

- Accuracy Profile Strategy: Based on total error concept (trueness + precision) with β-expectation tolerance limits (e.g., ±5%) [34].

- Robustness Testing: Evaluate effects of minor method parameter variations (e.g., slit width, wavelength variation ±1 nm) [34].

- Forced Degradation Studies: Subject API to stress conditions (light, heat, pH, oxidation) to demonstrate method stability-indicating capability [32].

Pharmaceutical Quality Assessment Applications

UV-Vis spectroscopy supports multiple critical assessments in drug development:

- Stability Testing: Monitor API degradation under forced, accelerated, and real-time aging conditions to establish shelf-life [32].

- Dissolution Testing: Quantify API release from solid dosage forms using continuous flow systems.

- Content Uniformity: Verify consistent API distribution throughout manufactured batches.

- Impurity Profiling: Detect and quantify known impurities based on characteristic absorption.

The technique's sensitivity, simplicity, and rapid analysis time make it invaluable throughout the drug development lifecycle, from early-stage formulation screening to commercial quality control [32] [34].

Ultraviolet-Visible (UV-Vis) spectrophotometry stands as a cornerstone analytical technique in pharmaceutical research and quality control for ensuring product purity. This method measures the absorption of ultraviolet or visible light by chemical substances, providing valuable information about the concentration and characteristics of active pharmaceutical ingredients (APIs) and their impurities [3] [23]. The fundamental principle relies on the Beer-Lambert Law, which states that absorbance is directly proportional to the concentration of the absorbing species and the path length of the sample [35]. In the context of purity analysis, UV-Vis spectroscopy offers distinct advantages including non-destructive analysis, rapid results, cost-effectiveness, and high sensitivity for detecting even trace levels of impurities [35].

Pharmaceutical impurities and degradation products represent critical quality attributes that must be rigorously controlled throughout a drug's lifecycle. These unwanted chemical species can originate from various sources including starting materials, by-products of synthesis, degradation during storage, or interactions with excipients [36]. Regulatory bodies such as the FDA and EMA mandate strict controls over impurity profiles, requiring pharmaceutical manufacturers to identify, quantify, and control impurities to ensure product safety and efficacy [3] [23]. The FDA's Center for Drug Evaluation and Research (CDER) specifically addresses standards for identity, assay, impurities, and dissolution, highlighting the comprehensive approach required for pharmaceutical quality assurance [3].

Fundamental Principles of Impurity Quantification

Spectrophotometric Foundations