UV-Vis Spectroscopy for Pharmaceutical Impurity Monitoring: A Modern Guide to Methods, Troubleshooting, and Validation

This article provides a comprehensive guide for researchers and drug development professionals on the application of Ultraviolet-Visible (UV-Vis) spectroscopy for monitoring impurities in pharmaceuticals.

UV-Vis Spectroscopy for Pharmaceutical Impurity Monitoring: A Modern Guide to Methods, Troubleshooting, and Validation

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on the application of Ultraviolet-Visible (UV-Vis) spectroscopy for monitoring impurities in pharmaceuticals. It covers the foundational principles of the technique, explores advanced methodological applications including spectralprint analysis supported by chemometrics, and offers practical troubleshooting strategies for common laboratory challenges. The content also details the rigorous validation requirements per ICH Q2(R1) guidelines and compares UV-Vis with orthogonal techniques like NMR and HPLC, providing a holistic framework for implementing robust, compliant, and effective impurity control strategies in quality assurance and quality control (QA/QC) workflows.

The Unbeatable Value of UV-Vis: Core Principles and Its Role in Modern Pharma Impurity Profiling

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a cornerstone analytical technique in pharmaceutical research, particularly for the identification and quantification of impurities in drug substances and products. This application note details the fundamental principles of electronic transitions and the Beer-Lambert Law, providing a structured framework for their application in impurity monitoring. The content is tailored for researchers, scientists, and drug development professionals who require robust and reliable methodologies to ensure product quality and safety. The ability to accurately detect and measure impurities, which often feature distinct chromophores, is critical for compliance with stringent regulatory standards. By leveraging the specific interactions between light and matter, UV-Vis spectroscopy offers a powerful, often non-destructive, means of analysis. This document synthesizes theoretical foundations with practical protocols and contemporary instrumentation trends to support effective method development within the pharmaceutical industry.

Theoretical Foundations

Electronic Transitions

The fundamental principle of UV-Vis spectroscopy involves the promotion of electrons from a ground state to an excited state through the absorption of light in the ultraviolet (190-400 nm) or visible (400-800 nm) range of the electromagnetic spectrum [1] [2] [3]. The energy of the absorbed photon must exactly match the energy difference between the two electronic states. Molecules that absorb this light are known as chromophores [1] [3].

The specific wavelength and intensity of absorption depend on the type of electronic transition involved, which is determined by the molecular structure of the chromophore. The following table summarizes the primary electronic transitions relevant to organic molecules and potential impurities.

Table 1: Characteristics of Key Electronic Transitions in UV-Vis Spectroscopy

| Transition Type | Energy Order | Typical Wavelength Range | Chromophore Example | Molar Absorptivity (ε) |

|---|---|---|---|---|

| σ → σ* | Highest | < 200 nm | Molecular Hydrogen (H₂) | Varies |

| Ï€ → Ï€* | High | 160-260 nm (isolated); longer with conjugation | Ethene (165 nm); 1,3-Butadiene (217 nm) | High (ε > 10,000 L·molâ»Â¹Â·cmâ»Â¹) |

| n → Ï€* | Lowest | 250-500 nm | Carbonyl group (e.g., in 4-methyl-3-penten-2-one, 314 nm) | Low (ε ~ 10-100 L·molâ»Â¹Â·cmâ»Â¹) |

For impurity monitoring in pharmaceuticals, π → π transitions in conjugated systems and n → π transitions in carbonyl groups are particularly significant. As conjugation increases, the energy required for a π → π* transition decreases, leading to absorption at longer wavelengths (a phenomenon known as a bathochromic shift) [1]. This allows for the selective detection of impurities with extended conjugated systems against the backdrop of the active pharmaceutical ingredient (API).

The Beer-Lambert Law

The Beer-Lambert Law establishes the quantitative relationship between the concentration of an absorbing species and the amount of light it absorbs, forming the basis for quantitative analysis in UV-Vis spectroscopy [1] [2].

The law is mathematically expressed as: A = ε · c · L Where:

- A is the Absorbance (a dimensionless quantity).

- ε is the Molar Absorptivity (or extinction coefficient) with units of L·molâ»Â¹Â·cmâ»Â¹.

- c is the Concentration of the analyte in mol·Lâ»Â¹.

- L is the Path Length of the sample cell (cuvette) in cm [1] [2].

The relationship shows that absorbance is directly proportional to both concentration and path length. The intensity of light before (Iâ‚€) and after (I) passing through the sample is related to absorbance and transmittance (T = I/Iâ‚€) by A = logâ‚â‚€(Iâ‚€/I) = -logâ‚â‚€(T) [2].

For accurate quantitation, especially in impurity profiling, absorbance readings should ideally be kept below 1.0 to remain within the instrument's linear dynamic range. Samples with high absorbance can be diluted or measured in a cuvette with a shorter path length to obtain reliable data [2].

Application in Pharmaceutical Impurity Monitoring

The principles of electronic transitions and the Beer-Lambert Law are directly applied to monitor impurities such as starting materials, intermediates, degradation products, and isomeric impurities. The workflow for method development and analysis is outlined below.

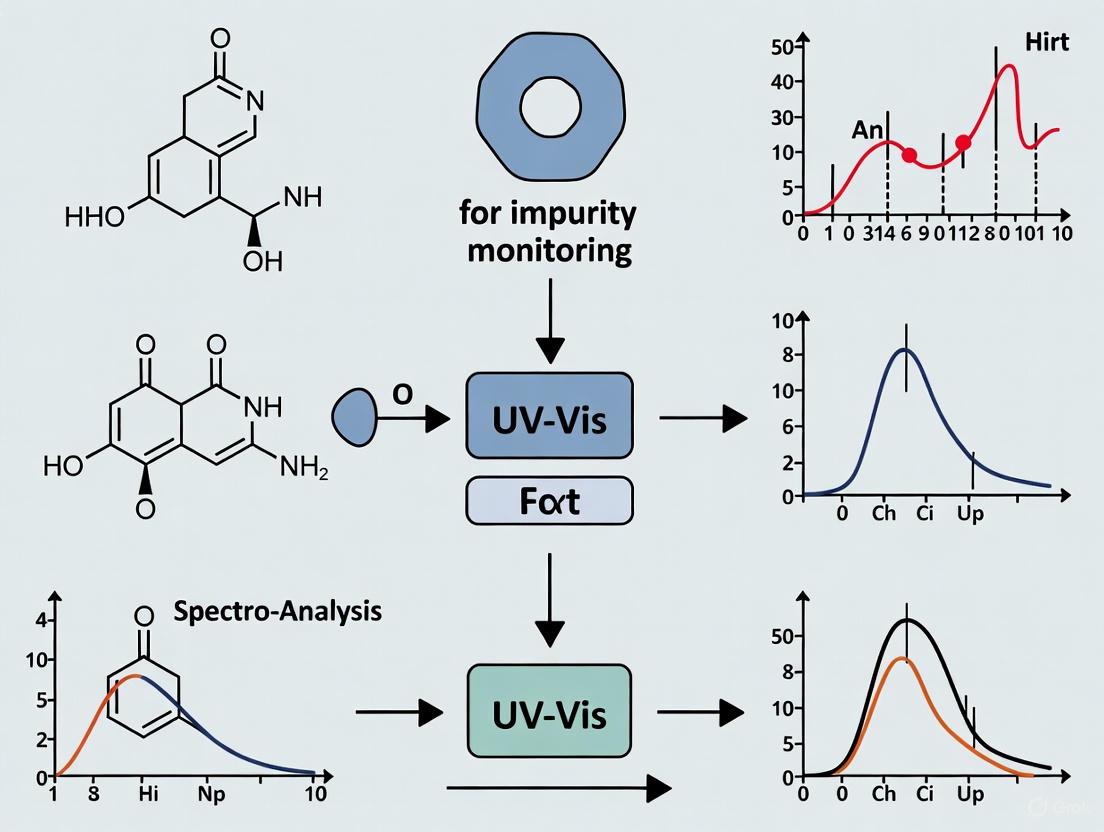

Diagram 1: UV-Vis Impurity Analysis Workflow

Key Considerations for Impurity Analysis

- Chromophore Identification: Impurities must contain a chromophore that absorbs UV or visible light. Understanding the types of electronic transitions allows scientists to predict and confirm the absorption characteristics of known impurities [1] [3].

- Selectivity: The impurity should ideally have a distinct absorption maximum (λmax) separate from the API to enable selective detection. If not, chromatographic separation may be required prior to spectroscopic analysis.

- Sensitivity: The molar absorptivity (ε) of the impurity at its λmax determines the sensitivity of the method. Impurities with high ε values can be detected at lower concentrations, which is critical for monitoring low-level impurities with toxicological concerns [1] [2].

- Validation: Methods must be validated per ICH guidelines to demonstrate specificity, accuracy, precision, linearity, range, and robustness for their intended use in quality control.

Experimental Protocol: Quantification of an Impurity

Scope

This protocol describes a general method for quantifying a known organic impurity in a drug substance using a double-beam UV-Vis spectrophotometer.

The Scientist's Toolkit: Essential Materials

Table 2: Key Research Reagent Solutions and Materials

| Item | Function/Description | Key Considerations |

|---|---|---|

| UV-Vis Spectrophotometer | Instrument to measure light absorption by the sample. | Use a double-beam instrument for stable baseline and high-precision quantification [2] [3]. |

| Quartz Cuvettes | Sample container/holder. | Quartz is transparent down to 190 nm; required for UV analysis. Path length is typically 1 cm [2]. |

| High-Purity Solvent | Dissolves the sample and reference (e.g., methanol, water, buffer). | Must be transparent in the spectral region of interest and not react with the analyte [2]. |

| Reference Standard | Highly purified and characterized impurity compound. | Used to establish the calibration curve and determine molar absorptivity (ε) [2]. |

| Volumetric Flasks & Pipettes | For accurate preparation of standard and sample solutions. | Required to ensure precise and accurate dilutions for reliable quantitative results. |

| 2'',4''-Di-O-(E-p-Coumaroyl)afzelin | 2'',4''-Di-O-(E-p-Coumaroyl)afzelin | |

| 3-O-(E)-Coumaroylbetulin | 3-O-(E)-Coumaroylbetulin, MF:C39H56O4, MW:588.9 g/mol | Chemical Reagent |

Step-by-Step Procedure

Diagram 2: Impurity Quantification Protocol

Step 1: Instrument Preparation

- Power on the UV-Vis spectrophotometer and the computer. Allow the instrument to initialize for the time recommended by the manufacturer (typically 15-30 minutes).

- Clean quartz cuvettes with the chosen solvent. Handle cuvettes by the frosted sides to avoid fingerprints on the optical surfaces.

Step 2: Preparation of Standard Solutions

- Accurately weigh an appropriate amount of the impurity reference standard.

- Dissolve and dilute in a suitable solvent to prepare a stock solution of known concentration (e.g., 100 µg/mL).

- Using serial dilution, prepare at least five standard solutions covering a concentration range that includes the expected impurity level (e.g., 1, 5, 10, 15, 20 µg/mL).

Step 3: Determination of Wavelength of Maximum Absorbance (λmax)

- Fill a cuvette with the solvent alone to serve as the blank. Place it in the reference beam (if using a double-beam instrument) or run a baseline correction.

- Fill another cuvette with an intermediate standard solution (e.g., 10 µg/mL).

- Perform a spectral scan over an appropriate wavelength range (e.g., 200-400 nm) to identify the λmax for the impurity.

Step 4: Measurement of Standard Absorbances

- Set the spectrophotometer to the fixed wavelength determined in Step 3 (λmax).

- Measure the absorbance of each standard solution and the blank. Perform measurements in triplicate.

Step 5: Construction of Calibration Curve

- Record the average absorbance for each standard concentration.

- Plot a graph of average absorbance (y-axis) versus concentration (x-axis). The data should conform to a straight line as per the Beer-Lambert Law.

- Using statistical software, perform a linear regression analysis to obtain the equation of the line (y = mx + b, where y is absorbance, m is the slope, and x is concentration) and the correlation coefficient (R²). The slope (m) is equivalent to ε·L.

Step 6: Sample Analysis

- Prepare a solution of the pharmaceutical sample (drug substance or product) at a specified concentration.

- Measure the absorbance of the sample solution at the same λmax.

Step 7: Quantification of Impurity

- Use the regression equation from the calibration curve to calculate the concentration of the impurity in the sample solution.

- Report the impurity level as a percentage relative to the concentration of the API.

Advanced Applications and Current Trends

The field of UV-Vis spectroscopy is evolving with advancements in instrumentation and data processing. Recent developments highlighted at the 2025 Pittcon conference & exposition include [4]:

- Portable and Handheld Devices: Enabling at-line and in-field quality control testing.

- Enhanced Integration: Systems like A-TEEM (Absorbance-Transmittance & Excitation-Emission Matrix) biopharma analyzers combine UV-Vis and fluorescence for advanced characterization of biologics like monoclonal antibodies and vaccines [4].

- Automation and Software: Improved software with guided workflows simplifies method development and data analysis, making the technique more accessible [4].

Furthermore, the integration of computational chemistry and text-mining is accelerating materials discovery. High-throughput calculations using density functional theory (DFT) can predict λmax and oscillation strengths, showing strong correlation with experimental data. This allows for in silico screening of compounds and their potential impurities, enriching materials databases and aiding in the identification of unknown chromatophores [5].

The fundamental principles of electronic transitions and the Beer-Lambert Law provide a robust scientific foundation for the application of UV-Vis spectroscopy in pharmaceutical impurity monitoring. By understanding the electronic structure of molecules and the quantitative relationship between absorption and concentration, scientists can develop reliable, validated methods to ensure drug safety and efficacy. The technique remains vital to quality control laboratories, and its continued evolution through portable instrumentation, advanced data analysis, and computational integration promises to further enhance its utility in pharmaceutical research and development.

In the highly regulated world of pharmaceutical quality control and assurance (QA/QC), the Ultraviolet-Visible (UV-Vis) spectrophotometer remains an indispensable analytical tool. Despite the emergence of more complex analytical techniques, UV-Vis spectroscopy maintains its critical role in impurity profiling and drug substance quantification due to its unparalleled simplicity, cost-effectiveness, and rapid analysis capabilities.

The global UV-Vis spectroscopy market, valued at $1.57 billion in 2024 and projected to reach $2.12 billion by 2029, underscores its sustained importance [6]. Its prominence in pharmaceutical applications is particularly notable, with the sector accounting for approximately 48% of the total market share [7]. This widespread adoption stems from the technique's fundamental strengths, which align perfectly with the demands of modern QA/QC workflows where reliability, speed, and regulatory compliance are paramount.

Core Strengths of UV-Vis in QA/QC

UV-Vis spectroscopy delivers specific, measurable advantages that secure its position as a QA/QC staple. The technique's value proposition is built on four foundational pillars:

Operational Simplicity and Ease of Use: Modern instruments feature intuitive interfaces, pre-programmed methods, and guided workflows that minimize training time and reduce operational errors [8]. This user-friendly design allows even non-expert personnel to produce reliable results, a significant advantage in multidisciplinary teams and high-turnover environments.

Rapid Analysis and High Throughput: UV-Vis instruments are engineered for speed, enabling quick, stable readings without compromising precision [8]. The technique's minimal sample preparation and fast scan speeds facilitate the processing of dozens to hundreds of samples daily, directly supporting lean manufacturing and just-in-time production schedules.

Significant Cost-Efficiency: Compared to other analytical techniques like HPLC or mass spectrometry, UV-Vis spectroscopy offers lower initial investment, reduced maintenance costs, and minimal consumable requirements [2] [7]. This cost profile makes sophisticated analytical capability accessible to laboratories of all sizes and budgets.

Non-Destructive Analysis: As a non-destructive technique, UV-Vis allows the same sample to be tested multiple times or used for subsequent analyses [9]. This preserves valuable materials, enables confirmatory testing, and supports investigative methodologies without sample depletion.

Table 1: Quantitative Advantages of UV-Vis Spectroscopy in Pharmaceutical QA/QC

| Strength Category | Performance Metric | Value in QA/QC Context |

|---|---|---|

| Market Adoption | Used in >70% of pharma QC labs [7] | Establishes regulatory acceptance and method validation pathways |

| Operational Efficiency | Rapid integration times (millisecond scale) [7] | Enables real-time process monitoring and rapid batch release |

| Economic Impact | Lower cost vs. HPLC/MS; minimal consumables [7] | Reduces cost-per-test while maintaining analytical rigor |

| Analytical Performance | Correlation coefficients (r²) of 0.999 achievable [10] | Provides required precision for impurity quantification and drug substance assay |

| Method Sensitivity | LOD values in μg/mL range achievable [10] | Suitable for detecting and quantifying potential impurities |

UV-Vis in Pharmaceutical Impurity Monitoring

The application of UV-Vis spectroscopy for impurity monitoring leverages its strengths in quantitative analysis and method validation. The technique is particularly valuable for detecting chromophoric impurities that absorb light in the UV or visible range.

In practice, impurity profiling often involves:

- Specified impurity quantification against known standards

- Unknown impurity detection through deviation from reference spectra

- Degradation product monitoring through accelerated stability studies

The regulatory framework for pharmaceutical analysis requires methods to be validated per ICH guidelines, which UV-Vis methods readily satisfy through demonstration of accuracy, precision, specificity, linearity, and range [10]. The technique's robustness makes it suitable for various sample types including active pharmaceutical ingredients (APIs), finished dosage forms, and in-process samples.

Table 2: Research Reagent Solutions for UV-Vis Pharmaceutical Analysis

| Reagent/Material | Function in Analysis | Application Example |

|---|---|---|

| High-Purity Reference Standards | Calibration and method validation | Quantification of API and known impurities [10] |

| Spectrophotometric Grade Solvents | Sample preparation and dilution | Minimize background absorbance and interference [2] |

| Quartz Cuvettes | Sample containment for UV analysis | Transparent to UV light; required for wavelengths <350 nm [2] |

| Buffer Systems | pH control and sample stability | Maintains analyte integrity during analysis [10] |

| Validation Materials | Accuracy, precision, and linearity assessment | System suitability verification per ICH guidelines [10] |

Experimental Protocol: Impurity Monitoring Method

The following protocol outlines the development and validation of a UV-Vis spectrophotometric method for impurity assessment, based on established methodologies [10] with applications for pharmaceutical QA/QC.

Equipment and Materials

- UV-Vis spectrophotometer with deuterium and tungsten/halogen lamps [2]

- 1 cm pathlength quartz cuvettes [2]

- Analytical balance (0.1 mg sensitivity)

- Volumetric flasks (10 mL, 100 mL)

- Micropipettes (0.5-3 mL range)

- Reference standard of analyte and potential impurities

- Spectrophotometric grade water or solvent

- Pharmaceutical formulation or API sample

Method Development Procedure

Standard Solution Preparation

- Accurately weigh 10 mg of reference standard into a 100 mL volumetric flask

- Dissolve in 20 mL of appropriate solvent (e.g., distilled water) with shaking

- Dilute to volume with solvent to obtain 100 μg/mL stock solution [10]

Wavelength Selection (λmax determination)

- Pipette 0.5 mL of stock solution into a 10 mL volumetric flask

- Dilute to volume with solvent to obtain 5 μg/mL working solution

- Scan against solvent blank from 200-400 nm [10]

- Identify wavelength of maximum absorbance (λmax) for the analyte

Calibration Curve Construction

- Prepare standard solutions across concentration range (e.g., 5-30 μg/mL)

- Transfer aliquots of stock solution (0.5, 1.0, 1.5, 2.0, 2.5, 3.0 mL) to series of 10 mL volumetric flasks

- Dilute each to volume with solvent [10]

- Measure absorbance at λmax against solvent blank

- Plot absorbance versus concentration and determine regression equation

UV-Vis Method Development Workflow

Method Validation Parameters

Linearity

- Prepare and analyze minimum of six concentration levels

- Calculate correlation coefficient (r²) - target ≥0.999 [10]

- Determine regression equation (y = mx + c)

Accuracy (Recovery Studies)

- Spike pre-analyzed samples at 80%, 100%, 120% of target concentration

- Analyze spiked samples using developed method

- Calculate percentage recovery (98-102% acceptable) [10]

Precision

- Intra-day precision: Analyze three concentrations in triplicate same day

- Inter-day precision: Analyze three concentrations over three days

- Calculate %RSD for each (<2% acceptable) [10]

Sensitivity (LOD and LOQ)

- Calculate using formulae: LOD = 3.3 × N/B and LOQ = 10 × N/B

- Where N = standard deviation of blank, B = slope of calibration curve [10]

Specificity

- Demonstrate ability to assess analyte unequivocally in presence of impurities

- Compare spectra of pure analyte versus spiked samples

Case Study: Terbinafine Hydrochloride Analysis

A practical application demonstrates the implementation of this protocol for antifungal drug analysis [10]:

- Analytical Target: Terbinafine hydrochloride in bulk and pharmaceutical formulations

- λmax Determination: 283 nm in aqueous solution

- Linear Range: 5-30 μg/mL with regression equation y = 0.0343x + 0.0294 (r² = 0.999)

- Accuracy Results: 98.54-99.98% recovery across 80-120% concentration range

- Precision Data: %RSD <2% for both intra-day and inter-day studies

- Application: Successfully applied to pharmaceutical formulation with 99.19% agreement with label claim

This case exemplifies how UV-Vis delivers regulatory-ready data with minimal resource investment, confirming its utility in routine pharmaceutical analysis.

Technological Advancements Enhancing UV-Vis Utility

Modern UV-Vis instruments incorporate technological improvements that further strengthen their QA/QC applications:

- Enhanced Optical Stability: Robust optical components with fewer moving parts reduce calibration frequency and improve measurement consistency [8]

- Digital Integration: Connectivity features including SD card slots and PC software interfaces facilitate data integrity and electronic record keeping [8]

- Compact Footprints: Space-efficient designs conserve valuable bench space without compromising performance [8]

- Automated Systems: Advanced instruments offer high-throughput screening and micro-volume sampling capabilities [7]

These innovations address historical limitations while preserving the technique's fundamental advantages, ensuring UV-Vis spectroscopy remains compatible with contemporary laboratory informatics and compliance requirements.

UV-Vis spectroscopy maintains its essential position in pharmaceutical QA/QC by delivering a powerful combination of analytical reliability, operational simplicity, and economic efficiency. Its proven performance in impurity monitoring, method validation readiness, and adaptability to modern laboratory requirements ensures this established technique will continue as a cornerstone of quality systems for the foreseeable future.

As the pharmaceutical industry evolves with increased emphasis on quality by design and process analytical technology, UV-Vis spectroscopy adapts through technological enhancements while retaining the fundamental characteristics that make it indispensable for routine and investigative analysis alike.

In the pharmaceutical industry, impurity profiling is a critical component of drug development and quality control, directly impacting product safety and efficacy. The International Council for Harmonisation (ICH) guidelines, such as ICH Q3D, have revolutionized this field by promoting a risk-based approach to elemental impurity analysis, moving beyond traditional non-specific methods to targeted, sensitive techniques that provide actionable data for human health risk assessment [11]. Within this regulatory framework, spectral interpretation serves as the foundational process for identifying and quantifying unknown impurities, degradation products, and metabolites in drug substances and products. This application note details the methodologies and protocols for implementing spectral interpretation within impurity control strategies, with particular focus on its application in UV-VIS spectrophotometry and related techniques for pharmaceutical analysis.

Regulatory Framework and Current Trends in Impurity Analysis

Modern pharmaceutical impurity control strategies are governed by a harmonized regulatory landscape requiring rigorous analytical validation and risk assessment. The implementation of ICH Q3D and United States Pharmacopeia (USP) chapters <232> and <233> has aligned compendial testing with practices long established in environmental and biological laboratories, enabling more detailed, sensitive, and accurate information to support human health risk assessment and decision-making [11]. These guidelines facilitate targeted monitoring of elements based on risk assessment, minimizing unnecessary testing while ensuring product safety.

Current trends in pharmaceutical analysis indicate sustained utilization of UV-VIS spectrophotometry alongside advanced chromatographic techniques. A comprehensive examination of literature from 2015-2023 reveals that 56% of UV-VIS spectrophotometric methods are applied to pharmaceutical dosage forms, with the majority of analyses conducted in the 200-300 nm range [12]. This demonstrates the continued relevance of UV-VIS for routine impurity monitoring, particularly when combined with robust spectral interpretation protocols.

Table 1: Distribution of UV-VIS Spectrophotometric Applications in Pharmaceutical Analysis (2015-2023)

| Sample Type | Percentage of Studies | Common Wavelength Ranges |

|---|---|---|

| Pharmaceutical Dosage Forms | 56% | 200-240 nm (28%), 240-300 nm (27%) |

| Bulk Substances | 27% | >300 nm (44%) |

| Pure Substances | 16% | Varies based on chromophores |

| Biological Materials | 2% | Varies with sample complexity |

| Herbal Materials | 0.4% | Broad spectrum analysis |

Experimental Design and Workflow for Impurity Profiling

A systematic approach to impurity profiling integrates sample preparation, analytical separation, spectral acquisition, and data interpretation. The following workflow diagram outlines the comprehensive process for impurity identification and quantification through spectral interpretation:

Diagram 1: Comprehensive Workflow for Impurity Identification and Quantification (Width: 760px)

Sample Preparation Protocols

Forced Degradation Studies: To determine method selectivity and identify potential degradation products, forced degradation studies should be conducted under various stress conditions [13] [14]:

- Acidic Degradation: Treat sample with 1N HCl at 80°C for 1 hour [13]

- Alkaline Degradation: Treat sample with 1N NaOH at 80°C for 1 hour [13]

- Oxidative Degradation: Expose sample to 3% Hâ‚‚Oâ‚‚ at room temperature for 3 hours [13]

- Thermal Degradation: Heat sample at 80°C for 6 hours [13]

- Photolytic Degradation: Expose sample to light at 5000 lx + 90 μW for 24 hours [13]

Solution Preparation: For HPLC analysis, accurately weigh reference standards and samples into volumetric flasks. Dissolve using appropriate solvent with sonication. Dilute to volume and filter through 0.45μm membrane filters before injection [13].

Chromatographic Separation Conditions

Effective spectral interpretation requires optimal separation of impurities from the active pharmaceutical ingredient (API). The following protocol, adapted from carvedilol analysis, demonstrates typical chromatographic conditions for impurity monitoring [13]:

Table 2: Optimized HPLC Conditions for Impurity Separation

| Parameter | Specification | Notes |

|---|---|---|

| Column | Inertsil ODS-3 V (4.6 mm × 250 mm, 5 μm) | C18 stationary phase |

| Mobile Phase A | 0.02 mol/L potassium dihydrogen phosphate (pH 2.0) | pH adjusted with phosphoric acid |

| Mobile Phase B | Acetonitrile (HPLC grade) | Organic modifier |

| Detection Wavelength | 240 nm | Optimal for carvedilol and impurities |

| Injection Volume | 10 μL | Consistent sample loading |

| Flow Rate | 1.0 mL/min | Optimal separation efficiency |

| Temperature Program | 20°C (0-20 min), 40°C (20-40 min), 20°C (40-60 min) | Enhanced separation of critical pairs |

Table 3: Gradient Elution Program for Impurity Separation

| Time (min) | Mobile Phase A (%) | Mobile Phase B (%) | Column Temperature (°C) |

|---|---|---|---|

| 0 | 75 | 25 | 20 |

| 10 | 75 | 25 | 20 |

| 38 | 35 | 65 | 40 |

| 50 | 35 | 65 | 40 |

| 50.1 | 75 | 25 | 20 |

| 60 | 75 | 25 | 20 |

Spectral Interpretation and Method Validation

UV-VIS Spectral Interpretation Fundamentals

Spectral interpretation for impurity monitoring requires understanding of chromophore behavior, absorption maxima, and spectral patterns. The following decision pathway guides analysts through systematic spectral interpretation:

Diagram 2: UV Spectral Interpretation Decision Pathway (Width: 760px)

Method Validation Parameters

For regulatory acceptance, analytical methods must demonstrate reliability through comprehensive validation. The following table summarizes validation parameters and acceptance criteria based on carvedilol impurity method validation [13]:

Table 4: Method Validation Parameters and Acceptance Criteria for Impurity Quantification

| Validation Parameter | Protocol | Acceptance Criteria |

|---|---|---|

| Linearity | Analyze 5 concentrations in triplicate | R² > 0.999 for all analytes |

| Precision | Six replicate injections of standard solution | RSD% < 2.0% |

| Accuracy | Spike recovery at 50%, 100%, 150% of target | Recovery rates 96.5-101% |

| Specificity | Forced degradation studies | Baseline separation of all impurities |

| Robustness | Deliberate variations in flow rate, temperature, pH | RSD% < 2.0% under all conditions |

| Stability | Analyze solutions over 24-48 hours | Variation in peak areas < 5% |

Case Study: Impurity Profiling of Baloxavir Marboxil

A comprehensive impurity profiling study of Baloxavir Marboxil (BXM) demonstrates the application of spectral interpretation in modern pharmaceutical analysis. The study identified five metabolites, twelve degradation products, fourteen chiral compounds, and forty process-related impurities through systematic spectral interpretation [14].

Advanced Analytical Techniques for Complex Impurity Profiling

For complex impurity profiles, hyphenated techniques provide the necessary specificity and sensitivity:

- Liquid Chromatography-Mass Spectrometry (LC-MS): Structural elucidation of unknown impurities

- Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS): Confirmation of impurity structures through fragmentation patterns

- Photodiode Array (PDA) Detection: Peak purity assessment and spectral comparison

These techniques enable identification and quantification of impurities at levels required by ICH guidelines, typically reporting thresholds of 0.05-0.1% for unknown impurities [14].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 5: Key Research Reagent Solutions for Pharmaceutical Impurity Analysis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| HPLC Grade Acetonitrile | Mobile phase component | Low UV cutoff, minimal interference |

| Potassium Dihydrogen Phosphate | Buffer preparation | For pH control in mobile phase |

| Phosphoric Acid (HPLC Grade) | Mobile phase pH adjustment | High purity, minimal UV absorption |

| Reference Standards | Method calibration and quantification | Certified purity >99.5% |

| Volumetric Flasks (Class A) | Solution preparation | Accurate volume measurement |

| Membrane Filters (0.45μm) | Sample filtration | Particulate removal, column protection |

| pH Meter | Mobile phase adjustment | Accurate pH measurement ±0.01 units |

| Forced Degradation Reagents | Stress testing studies | HCl, NaOH, Hâ‚‚Oâ‚‚ for degradation studies |

| 1,2,5,6-Tetrabromocyclooctane | 1,2,5,6-Tetrabromocyclooctane (TBCO) - CAS 3194-57-8 | High-purity 1,2,5,6-Tetrabromocyclooctane, a brominated flame retardant (BFR) for material science and toxicology research. For Research Use Only. Not for human or veterinary use. |

| (1R)-Chrysanthemolactone | Chrysanthellin B|Natural Saponin|For Research Use | Chrysanthellin B is a natural pentasaccharide saponin for research. This product is for Research Use Only (RUO) and not for human or veterinary use. |

Spectral interpretation forms the foundation of effective impurity monitoring in pharmaceutical products. Through systematic application of validated chromatographic methods, comprehensive forced degradation studies, and advanced spectral interpretation techniques, pharmaceutical scientists can ensure product quality and patient safety. The protocols detailed in this application note provide a framework for implementing robust impurity control strategies aligned with current regulatory expectations. As pharmaceutical compounds grow more complex, continued refinement of spectral interpretation methodologies will remain essential for comprehensive impurity profiling and control.

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a fundamental analytical technique within the pharmaceutical industry for the quantification of active pharmaceutical ingredients (APIs) and the monitoring of impurities. Its applicability is firmly supported by major regulatory frameworks including the International Council for Harmonisation (ICH), the United States Food and Drug Administration (FDA), and the United States Pharmacopeia (USP). These bodies provide structured guidelines that define the validation and application requirements for UV-Vis methods, ensuring that the generated data is reliable, accurate, and suitable for making critical decisions regarding drug quality and safety. In the context of impurity monitoring, UV-Vis spectroscopy offers a robust, cost-effective solution for quantifying known chromophoric impurities, especially when employed within a well-defined and validated analytical procedure. This article delineates the specific regulatory backing for UV-Vis methodologies and provides a detailed application note for its use in impurity profiling.

Regulatory Framework and Validation Requirements

Adherence to regulatory guidelines is paramount for the acceptance of any analytical method. The following table summarizes the core validation parameters as defined by ICH and USP, which are directly applicable to UV-Vis methods for impurity quantification.

Table 1: Key Validation Parameters for UV-Vis Methods as per ICH and USP

| Validation Parameter | Regulatory Reference | Definition & Purpose | Typical Acceptance Criteria for UV-Vis |

|---|---|---|---|

| Accuracy | ICH Q2(R2); USP <1225> [15] | Closeness of test results to the true value. Demonstrates method reliability. | Recovery of 98–102% for API; ±10% for impurities [16]. |

| Precision | ICH Q2(R2); USP <1225> [15] | Degree of agreement among individual test results. Includes repeatability and intermediate precision. | RSD < 2.0% for assay; RSD < 5-10% for impurities [17] [16]. |

| Specificity | ICH Q2(R2); USP <1225> [15] | Ability to assess the analyte unequivocally in the presence of other components. | No interference from blank, placebo, or known impurities at the λmax of the analyte [16]. |

| Linearity | ICH Q2(R2); USP <1225> [15] | Ability to obtain test results proportional to the analyte concentration. | Correlation coefficient (r) > 0.998 [17]. |

| Range | ICH Q2(R2); USP <1225> [15] | Interval between the upper and lower concentrations with acceptable accuracy, precision, and linearity. | From the reporting threshold to at least 120% of the specification limit for impurities [16]. |

| Detection Limit (LOD) | ICH Q2(R2); USP <1225> [15] | Lowest amount of analyte that can be detected, but not necessarily quantified. | Signal-to-Noise ratio ≥ 3:1. |

| Quantitation Limit (LOQ) | ICH Q2(R2); USP <1225> [15] | Lowest amount of analyte that can be quantified with acceptable accuracy and precision. | Signal-to-Noise ratio ≥ 10:1; Accuracy and Precision at LOQ level meet pre-defined criteria. |

The validation process must establish that the method is suitable for its intended purpose, a requirement stated in both ICH Q2(R1) and USP general chapter <1225> [15] [16]. For impurity methods, this is closely tied to the principles outlined in ICH Q3A(R2) on impurities in new drug substances, which mandates the reporting, identification, and qualification of impurities [18]. Furthermore, the FDA's emphasis on controlling specific impurities, such as nitrosamines, underscores the need for accurate and sensitive quantitative techniques, including UV-Vis, where applicable [19].

Application Note: UV-Vis Method for the Quantification of Dexibuprofen in Pharmaceutical Dosage Forms

The following section provides a detailed protocol, adapted from published research, for developing and validating a UV-Vis method for assay and impurity quantification [17].

Background and Principle

Dexibuprofen, the pharmacologically active enantiomer of ibuprofen, is a non-steroidal anti-inflammatory drug (NSAID). This method describes a simple, rapid, and sensitive UV-Vis spectrophotometric procedure for the determination of Dexibuprofen in tablet formulation at its λmax of 222.0 nm [17]. The method avoids complex sample preparation and is suitable for routine quality control.

Experimental Workflow

The diagram below illustrates the logical workflow for method development, validation, and application.

Materials and Reagents

Table 2: Research Reagent Solutions and Essential Materials

| Item | Specification / Source | Function in the Protocol |

|---|---|---|

| Dexibuprofen Reference Standard | Noven Life Sciences Pvt. Ltd. [17] | Provides a certified reference material for preparing calibration standards and determining method accuracy. |

| HPLC Grade Methanol | Qualigens Fine Chemicals [17] | Serves as a primary solvent for preparing standard and sample solutions, ensuring minimal UV background interference. |

| HPLC Grade Water | Milli-QRO Water Purification System [17] | Used as a diluent and solvent component to maintain consistent solution matrix. |

| UV-Vis Spectrophotometer | Shimadzu UV-160 [17] | Instrument for measuring light absorbance of analytical solutions at the specified wavelength. |

| Quartz Cuvette | 1.0 cm path length [17] | Holds the sample solution during analysis; quartz is required for UV range measurements. |

| Analytical Balance | Not specified in source, but essential | For accurate weighing of reference standard and sample powder. |

| Volumetric Flasks | Class A | For precise preparation and dilution of standard and sample solutions. |

Detailed Methodology

Preparation of Standard Solutions

- Primary Standard Stock Solution (1000 µg/mL): Accurately weigh and transfer 100.0 mg of Dexibuprofen reference standard into a 100 mL volumetric flask. Dissolve and make up to volume with a mixture of water and methanol (50:50, v/v).

- Calibration Curve Standards: From the primary stock solution, prepare a series of dilutions in the same solvent mixture to obtain concentrations of 2.0, 4.0, 6.0, 8.0, 10.0, and 12.0 µg/mL [17].

Preparation of Sample Solutions

- Weigh and finely powder twenty tablets.

- Accurately weigh a portion of the powder equivalent to about 10 mg of Dexibuprofen and transfer to a 100 mL volumetric flask.

- Add approximately 70 mL of the water-methanol (50:50) solvent, sonicate for 15-20 minutes to ensure complete dissolution of the API, and dilute to volume with the same solvent.

- Filter the solution, if necessary, and then further dilute a suitable aliquot to obtain a final concentration of ~4.0 µg/mL (within the linear range of the method) for analysis [17].

Instrumental Parameters and Analysis

- Instrument: UV-Vis Spectrophotometer.

- Mode: Absorbance.

- Wavelength (λ): 222.0 nm [17].

- Cuvette: 1.0 cm matched quartz cell.

- Blank: Water and methanol mixture (50:50, v/v).

- Procedure: Measure the absorbance of the blank, followed by the standard and sample solutions. Ensure the cuvette is properly rinsed with the subsequent solution between measurements.

Method Validation Protocol

The method was validated according to ICH guidelines [17]. The following table summarizes the key experimental procedures for validation.

Table 3: Summary of Method Validation Experiments and Results

| Validation Parameter | Experimental Procedure | Results & Acceptance |

|---|---|---|

| Linearity & Range | Analyzed standard solutions at 6 concentration levels (2–12 µg/mL) in triplicate [17]. | Correlation coefficient (r) = 0.9973 [17]. |

| Accuracy (Recovery) | Spiked placebo with known amounts of Dexibuprofen at multiple levels (e.g., 80%, 100%, 120%). | Mean recovery = 101.91% (at 6.0 µg/mL), meeting acceptable criteria [17]. |

| Precision (Repeatability) | Analyzed six independent sample preparations from a homogeneous powder blend [17]. | RSD < 5%, demonstrating high repeatability [17]. |

| Specificity | Analyzed tablet placebo and compared its spectrum/absorbance with that of the Dexibuprofen standard. | No interference from excipients was observed at the analytical wavelength [17]. |

Diagram: Relationship Between Regulatory Guidelines and Method Validation

The successful implementation of a UV-Vis method for regulatory purposes relies on the interrelationship between overarching guidelines and practical validation, as shown below.

UV-Vis spectroscopy remains a vitally important technique in the pharmaceutical analyst's toolkit for impurity monitoring and assay. Its use is firmly underpinned by the ICH, FDA, and USP regulatory frameworks, which provide clear directives on the required validation parameters to ensure method reliability and robustness. The detailed application note for Dexibuprofen demonstrates a practical implementation of these guidelines, showcasing a validated method that is fit-for-purpose in a quality control environment. By rigorously adhering to the outlined validation protocols and understanding the regulatory expectations, scientists and drug development professionals can confidently employ UV-Vis methods to ensure the safety, quality, and efficacy of pharmaceutical products.

Ultraviolet-Visible (UV-Vis) spectroscopy is a cornerstone technique in pharmaceutical quality assurance and quality control (QA/QC) due to its speed, simplicity, and cost-effectiveness for routine quantification [20]. It is extensively used to ensure consistent concentration of Active Pharmaceutical Ingredients (APIs), assess drug product uniformity, and monitor impurities [20]. However, the application of UV-Vis for impurity monitoring in complex pharmaceutical matrices is inherently challenged by issues of specificity and spectral overlap. These limitations are critical in the context of stringent regulatory requirements for impurity profiling, which is essential for ensuring drug safety, efficacy, and stability [21] [22]. This application note details these inherent limitations and provides validated protocols and strategic approaches to mitigate them, ensuring reliable data for pharmaceutical research and development.

The Core Challenge: Specificity and Spectral Overlap

The fundamental principle of UV-Vis spectroscopy involves measuring the absorbance of light as a compound undergoes electronic transitions [20]. The resulting spectrum is a plot of absorbance versus wavelength. The primary challenge in impurity analysis arises because:

- Lack of Specificity: UV-Vis spectra typically present broad absorption bands. In a mixture containing an API and its impurities, which often share similar chromophores, these bands can significantly overlap [20].

- Spectral Overlap: This overlap makes it difficult or impossible to distinguish the absorbance contribution of a trace impurity from the dominant API using a single wavelength. This compromises the accurate identification and quantification of the impurity, especially when it is present at low levels, as required by International Council for Harmonisation (ICH) guidelines [22].

The following workflow diagram illustrates this core problem and the decision-making process for method selection.

Advanced Strategies to Overcome Limitations

To address the challenges of specificity and spectral overlap, researchers must move beyond simple, single-wavelength measurements. The following strategies are employed to enhance the reliability of UV-Vis methods for impurity monitoring.

Signal Deconvolution and Derivative Spectroscopy

Derivative spectroscopy is a mathematical processing technique that can enhance the resolution of overlapping spectral bands. While the zero-order (standard) spectrum shows absorbance, the first derivative plots the rate of change of absorbance (dA/dλ) against wavelength, and the second derivative plots the rate of change of the first derivative (d²A/dλ²). This transformation can convert broad peaks into sharper, more defined features, allowing for the resolution of closely spaced absorption maxima that are indistinguishable in the original spectrum. This method is particularly useful for quantifying a specific impurity in the presence of a structurally similar API.

Hyphenated Techniques: LC-UV-Vis

The most robust solution to the problem of spectral overlap is the use of hyphenated techniques, primarily Liquid Chromatography coupled with UV-Vis detection (LC-UV-Vis) [21] [22]. This approach combines the high separation power of chromatography with the detection capability of spectroscopy.

- Workflow: The complex mixture is first separated by an HPLC column based on chemical properties. As individual components (API and individual impurities) elute from the column at different times, they pass through a UV-Vis flow cell.

- Advantage: This physical separation prior to analysis virtually eliminates spectral overlap, allowing for a clean, individual spectrum of each component to be obtained. This enables definitive identification and accurate quantification against certified reference standards. Hyphenated techniques like LC-MS are extensively exploited for impurity profiling of drugs [22].

The following diagram outlines the workflow of a hyphenated LC-UV-Vis system for impurity analysis.

Experimental Protocols

Protocol for Method Development and Validation using LC-UV-Vis

This protocol describes the steps for developing and validating a specific, robust LC-UV-Vis method for monitoring a known degradation impurity in a hypothetical API.

1. Aim: To develop and validate an LC-UV-Vis method for the quantification of Impurity A in API X at a level of 0.1% (w/w).

2. Experimental Conditions:

- Apparatus: HPLC system equipped with a multi-wavelength or diode-array UV-Vis detector.

- Column: C18, 150 mm x 4.6 mm, 5 µm.

- Mobile Phase: Gradient elution from 70% 25 mM Phosphate Buffer (pH 6.8) to 50% Acetonitrile over 15 minutes.

- Flow Rate: 1.0 mL/min.

- Detection: Diode-array detection from 200 nm to 400 nm. Quantification of Impurity A at 275 nm and API X at 255 nm.

- Injection Volume: 10 µL.

- Standard Solutions: Prepare separate stock solutions of API X and Impurity A reference standard. Dilute to appropriate concentrations for calibration curves (e.g., 0.05 - 2.0 µg/mL for Impurity A).

3. Procedure:

- Chromatographic Separation: Optimize the mobile phase composition and gradient program to achieve baseline separation between the API X peak and the Impurity A peak (Resolution, Rs > 2.0).

- Specificity: Inject blank (solvent), API X standard, Impurity A standard, and a spiked mixture. Use the diode-array detector to confirm peak purity and the absence of co-elution.

- Linearity: Inject a series of standard solutions in triplicate. Plot peak area versus concentration and determine the correlation coefficient (R²). A value of >0.999 is typically expected.

- Accuracy (Recovery): Spike a pre-analyzed sample of API X with known quantities of Impurity A at three levels (e.g., 0.1%, 0.5%, 1.0%). Calculate the percentage recovery of the added impurity.

- Precision: Assess repeatability by injecting six replicate preparations of the sample spiked at the 0.1% level. Calculate the %RSD of the impurity content.

- Limit of Quantification (LOQ): Determine the lowest concentration of Impurity A that can be quantified with acceptable accuracy and precision (typically %RSD < 5% and recovery 80-120%).

Protocol for Resolving Spectral Overlap using Derivative Spectroscopy

1. Aim: To resolve and quantify two compounds with overlapping UV spectra using second-derivative spectroscopy.

2. Experimental Conditions:

- Apparatus: UV-Vis spectrophotometer with derivative functionality.

- Software: Data analysis software capable of calculating derivative spectra.

3. Procedure:

- Standard Spectra: Record the zero-order UV spectra of individual, pure standard solutions of the API and the target impurity over the relevant wavelength range.

- Generate Derivatives: Apply the derivative function (typically first or second derivative) to the standard spectra. Optimize the derivative window (Δλ) to maximize signal-to-noise while maintaining spectral features.

- Identify Zero-Crossing Points: In the derivative spectrum of the API, identify a wavelength where its signal is zero (a "zero-crossing") but where the derivative spectrum of the impurity shows a significant positive or negative value. This wavelength can be used to quantify the impurity without interference from the API.

- Calibration: Prepare a calibration curve of the derivative amplitude (peak-to-trough) for the impurity standard at the selected zero-crossing wavelength.

- Sample Analysis: Record the zero-order spectrum of the sample mixture, convert it to the derivative spectrum, and measure the amplitude at the same wavelength to quantify the impurity.

Data Presentation and Analysis

Table 1: Comparison of Analytical Techniques for Impurity Profiling

| Technique | Principle | Key Strength | Key Limitation for Impurity Analysis | Applicability to Complex Matrices |

|---|---|---|---|---|

| UV-Vis Spectroscopy | Electronic transitions [20] | Fast, simple, inexpensive quantification [20] | Low specificity; spectral overlap [20] | Low (without prior separation) |

| HPLC-UV | Separation + UV detection [21] | High resolution with separation [21] | Limited structural information [21] | High |

| LC-Mass Spectrometry (LC-MS) | Separation + mass detection [21] [22] | High sensitivity and structural elucidation [21] [22] | High cost and operational complexity [21] | Very High |

| IR Spectroscopy | Vibrational transitions [20] | Excellent for functional group and identity testing [20] | Low sensitivity for trace analysis [20] | Medium |

| NMR Spectroscopy | Magnetic nuclear properties [20] | Definitive structural elucidation; quantitative [20] | Very low sensitivity; high cost [20] | Medium (requires pure compound) |

| Validation Parameter | Acceptance Criteria (Example for 0.1% Impurity) | Experimental Outcome (Hypothetical) |

|---|---|---|

| Specificity | No interference from API or other components | Resolution (Rs) > 2.0; Peak purity > 990 |

| Linearity | Correlation coefficient (R²) > 0.999 | R² = 0.9995 |

| Accuracy (% Recovery) | 90% - 110% | Mean Recovery = 98.5% |

| Precision (%RSD) | ≤ 5.0% for repeatability | %RSD = 2.1% (n=6) |

| Limit of Quantification (LOQ) | Signal-to-Noise ≥ 10 | 0.05% (of API concentration) |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for UV-Vis Based Impurity Profiling

| Item | Function | Key Considerations |

|---|---|---|

| High-Purity Solvents | Dissolving samples and as mobile phase components. | UV-grade Acetonitrile and Methanol for HPLC to avoid high background absorbance [20]. |

| Buffer Salts | Controlling mobile phase pH to ensure reproducible separation. | High-purity (e.g., HPLC grade) salts like Potassium Phosphate; volatile buffers (Ammonium Formate) for LC-MS [20]. |

| Certified Reference Standards | Calibration and positive identification of impurities. | Sourced from official suppliers (e.g., USP, EP); crucial for accurate quantification [22]. |

| HPLC Columns | Chromatographic separation of API from impurities. | C18 is most common; column chemistry (e.g., phenyl, cyano) may be selected based on analyte properties [21]. |

| Syringe Filters | Clarifying samples prior to injection into the HPLC system. | 0.45 µm or 0.22 µm pore size, compatible with solvent (e.g., Nylon, PTFE) [20]. |

| Hematoporphyrin dihydrochloride | Hematoporphyrin dihydrochloride, CAS:17696-69-4, MF:C34H40Cl2N4O6, MW:671.6 g/mol | Chemical Reagent |

| Normetanephrine hydrochloride | Normetanephrine hydrochloride, CAS:1011-74-1, MF:C9H14ClNO3, MW:219.66 g/mol | Chemical Reagent |

From Simple Quantification to Advanced Spectralprints: Method Development and Real-World Applications

Essential Steps for Robust Method Development

In the pharmaceutical industry, robust analytical methods are essential for ensuring drug safety, efficacy, and quality. Impurity profiling has become a critical component of pharmaceutical development and quality control, requiring systematic approaches to identify, characterize, and quantify impurities that may arise from synthesis processes, excipients, residual solvents, or degradation products [21]. These impurities, even in trace amounts, can significantly impact product safety and stability, making reliable monitoring techniques indispensable. Ultraviolet-Visible (UV-Vis) spectrophotometry serves as a valuable technique within this framework, offering simplicity, specificity, and cost-effectiveness for impurity estimation and quantification in pharmaceutical formulations [10]. This application note outlines essential steps for developing and validating robust UV-Vis methods specifically for impurity monitoring, providing researchers and drug development professionals with structured protocols aligned with regulatory standards.

Fundamentals of UV-Vis Spectroscopy in Pharmaceutical Analysis

UV-Vis spectroscopy measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample compared to a reference or blank sample [2]. This absorption property provides information about sample composition and concentration, making it particularly useful for quantifying active pharmaceutical ingredients (APIs) and detecting impurities.

The technique operates on the principle that electrons in different bonding environments require specific energy amounts to reach higher energy states, leading to absorption at characteristic wavelengths [2]. The fundamental relationship between absorbance and concentration is described by Beer-Lambert's law:

A = ε × L × C

Where:

- A = Absorbance (no units)

- ε = Molar absorptivity (L·molâ»Â¹Â·cmâ»Â¹)

- L = Path length (cm)

- C = Concentration (mol·Lâ»Â¹)

This relationship forms the basis for quantitative analysis in pharmaceutical applications, including impurity monitoring [2]. For impurity profiling, the high sensitivity of modern UV-Vis spectrophotometers enables detection of trace components that may indicate synthetic intermediates, degradation products, or process-related impurities [21].

Method Development Workflow

Robust method development requires a systematic approach with careful optimization at each stage. The following workflow provides a structured pathway from initial planning to final validation:

Define Method Objectives and Requirements

Clearly establish the method's purpose—whether for qualitative identification, quantitative determination, impurity profiling, or stability monitoring. Specific requirements should include target analytes, expected concentration ranges, required sensitivity (LOD and LOQ), and compatibility with sample matrices [10] [21]. For impurity monitoring, determine the specific impurities of interest and their chemical properties to guide subsequent development steps.

Select Analytical Wavelength (λmax)

Identify the maximum absorption wavelength (λmax) for the target analyte through spectral scanning. This process involves:

- Preparing standard solutions at appropriate concentrations

- Scanning across the UV-Vis range (typically 200-400 nm for UV, 400-780 nm for visible)

- Identifying wavelength with maximum absorbance for optimal sensitivity

For example, in terbinafine hydrochloride analysis, the λmax was determined to be 283 nm, while oxytetracycline exhibits maximum absorption at 268 nm [10] [23]. For impurity profiling, multiple wavelengths may be required to adequately detect different impurity species [21].

Optimize Sample Preparation and Solvent System

Select appropriate solvents that dissolve the analyte without interfering with absorbance measurements. Consider solvent transparency in the target wavelength region, chemical compatibility, and safety aspects. For chalcone analysis, specific solvent systems were developed to ensure complete extraction and dissolution [24], while oxytetracycline analysis used 0.01 N hydrochloric acid to maintain stability and solubility [23].

Establish Analytical Range and Linearity

Determine the concentration range over which the method will provide accurate and precise results. Prepare standard solutions at multiple concentration levels (typically 5-8 points) across the expected range. For terbinafine hydrochloride, excellent linearity was demonstrated in the range of 5-30 μg/mL with a correlation coefficient of 0.999 [10].

Develop Standard and Sample Preparation Protocols

Create detailed, reproducible procedures for standard and sample preparation. This includes:

- Preparation of stock solutions

- Dilution schemes

- Storage conditions and stability timelines

- Matrix-matching for complex samples

In oxytetracycline method development, independent stock solutions were prepared in the same matrix as the samples to account for potential matrix effects [23].

Method Validation Parameters

Once developed, analytical methods must be rigorously validated to ensure reliability, accuracy, and reproducibility. The International Council for Harmonisation (ICH) guidelines provide the framework for validation parameters, each with specific acceptance criteria [10] [21].

Table 1: Method Validation Parameters and Acceptance Criteria

| Validation Parameter | Description | Acceptance Criteria | Example from Literature |

|---|---|---|---|

| Linearity | Ability to obtain results proportional to analyte concentration | R² ≥ 0.998 | Terbinafine HCl: R² = 0.999 [10] |

| Accuracy | Closeness between measured and true values | Recovery: 98-102% | Terbinafine HCl: 98.54-99.98% recovery [10] |

| Precision | Degree of scatter in repeated measurements | %RSD < 2% | Intraday RSD < 2% [10] |

| Limit of Detection (LOD) | Lowest detectable concentration | Signal-to-noise ≥ 3:1 | Terbinafine HCl: 1.30 μg [10] |

| Limit of Quantification (LOQ) | Lowest quantifiable concentration | Signal-to-noise ≥ 10:1 | Terbinafine HCl: 0.42 μg [10] |

| Specificity | Ability to measure analyte accurately in presence of interferences | No interference from impurities | Identification via spectrum comparison [23] |

| Robustness | Capacity to remain unaffected by small parameter variations | %RSD < 2% | Ruggedness tested via multiple analysts [10] |

The relationship between these validation parameters can be visualized as an interconnected system where each element supports overall method reliability:

Experimental Protocols

Protocol 1: Wavelength Selection and Method Optimization

Objective: Determine optimal analytical wavelength and establish fundamental method parameters [10] [23].

Materials:

- Reference standard of target analyte

- Appropriate solvent system

- Volumetric flasks (10 mL, 50 mL, 100 mL, 200 mL)

- UV-Vis spectrophotometer with scanning capability

- Quartz cuvettes (1 cm path length)

Procedure:

- Prepare stock solution (e.g., 10 mg of analyte in 100 mL solvent = 100 μg/mL)

- Dilute appropriately to working concentration (e.g., 0.5 mL stock in 10 mL = 5 μg/mL)

- Scan solution from 200-400 nm using solvent blank as reference

- Identify wavelength of maximum absorption (λmax)

- Verify λmax consistency across multiple concentrations

- Optimize solvent system to ensure complete dissolution and stability

Acceptance Criteria: Clear λmax with sufficient absorbance (ideally 0.3-1.0 AU), minimal background interference, and reproducible spectra across preparations.

Protocol 2: Linearity and Range Determination

Objective: Establish analytical range and demonstrate linear concentration-response relationship [10].

Materials:

- Stock standard solution

- Series of volumetric flasks

- UV-Vis spectrophotometer

Procedure:

- Prepare stock solution at highest concentration (e.g., 100 μg/mL)

- Create dilution series (e.g., 5, 10, 15, 20, 25, 30 μg/mL)

- Measure absorbance at λmax for each concentration

- Plot absorbance versus concentration

- Calculate regression equation and correlation coefficient (R²)

- Verify linearity through three independent experiments

Acceptance Criteria: R² ≥ 0.998, residuals randomly distributed, minimal deviation from regression line.

Protocol 3: Accuracy Assessment via Recovery Studies

Objective: Determine method accuracy through standard addition recovery experiments [10].

Materials:

- Pre-analyzed sample solution

- Standard stock solution

- UV-Vis spectrophotometer

Procedure:

- Analyze sample solution to establish baseline concentration

- Add known amounts of standard at three levels (80%, 100%, 120% of target)

- Reanalyze spiked solutions by proposed method

- Calculate recovery percentage: (Found/Expected) × 100

- Perform in triplicate at each level

Acceptance Criteria: Mean recovery 98-102%, %RSD < 2% at each level.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful method development requires carefully selected reagents and materials. The following table outlines essential components for robust UV-Vis method development for impurity monitoring:

Table 2: Essential Research Reagents and Materials for UV-Vis Method Development

| Item | Function | Specification Considerations | Example Applications |

|---|---|---|---|

| Reference Standards | Quantitation and identification | High purity (>95%), well-characterized | Terbinafine HCl, oxytetracycline RS [10] [23] |

| Solvent Systems | Sample dissolution and dilution | UV-transparent, appropriate polarity | 0.01 N HCl for oxytetracycline [23] |

| Volumetric Glassware | Precise solution preparation | Class A, calibrated | 10, 50, 100, 200 mL flasks [10] |

| UV Cuvettes | Sample holder for measurement | Quartz for UV, matched path length | 1 cm path length quartz cells [2] [23] |

| pH Buffers | Control of ionization state | Appropriate pKa range, UV transparency | Phosphate buffer for hemoglobin [2] |

| Filter Materials | Sample clarification | Chemical compatibility, appropriate pore size | 0.22 μm filter for oxytetracycline [23] |

| Z-Lys-obzl benzenesulfonate | Z-Lys-obzl benzenesulfonate, CAS:68973-36-4, MF:C27H32N2O7S, MW:528.6 g/mol | Chemical Reagent | Bench Chemicals |

| DL-ornithine hydrochloride | DL-ornithine hydrochloride, CAS:16682-12-5, MF:C5H13ClN2O2, MW:168.62 g/mol | Chemical Reagent | Bench Chemicals |

Applications in Pharmaceutical Impurity Monitoring

UV-Vis spectrophotometry provides valuable capabilities for impurity monitoring in pharmaceutical development and quality control. For chalcone analysis, a specific method was developed for estimating total chalcone content, demonstrating the technique's application for natural product-derived compounds [24]. In the case of terbinafine hydrochloride, the method was successfully applied to both bulk drug substance and pharmaceutical formulations, with results showing 99.19% agreement with label claim, confirming its utility for quality control [10].

The technique is particularly valuable for stability-indicating methods where degradation products can be monitored through absorbance changes at specific wavelengths. For impurity profiling, even trace amounts of impurities can be significant, requiring the high sensitivity that modern UV-Vis spectrophotometers provide [21]. The oxytetracycline method development study demonstrated practical application to marketed products, with 28 of 47 samples complying with specifications while 19 failed, highlighting the importance of robust quality control methods in detecting substandard products [23].

Robust method development for UV-Vis spectrophotometry in pharmaceutical impurity monitoring requires systematic approaches encompassing careful wavelength selection, method optimization, and comprehensive validation. By following the structured workflow and experimental protocols outlined in this application note, researchers can develop reliable methods that meet regulatory requirements and ensure product quality. The essential steps detailed—from initial planning through validation—provide a framework for establishing methods that are accurate, precise, and fit-for-purpose in the critical task of impurity monitoring in pharmaceutical research and quality control.

Ultraviolet-visible (UV-Vis) spectroscopy is an indispensable analytical technique in pharmaceutical research used to obtain the absorbance spectra of compounds in solution or as a solid. The technique measures the amount of discrete wavelengths of UV or visible light that are absorbed by or transmitted through a sample in comparison to a reference or blank sample [2]. This property is influenced by the sample composition, providing critical information on what is in the sample and at what concentration [2]. In the context of impurity monitoring, UV-Vis spectroscopy offers the sensitivity and precision required to detect and quantify trace-level contaminants that may compromise drug safety or efficacy.

The fundamental principle underlying UV-Vis spectroscopy is the Beer-Lambert Law (Equation 1), which states that absorbance (A) is proportional to the concentration (c) of the absorbing species, the pathlength (b) of the sample holder, and the molar absorptivity (ε) of the compound [25]. This relationship forms the mathematical foundation for all quantitative impurity analysis, making proper sample preparation not merely a preliminary step but a critical determinant of analytical accuracy.

Equation 1: Beer-Lambert Law [ A\ =\ \varepsilon b c ]

Where:

- A = Absorbance (unitless)

- ε = Molar absorptivity (Mâ»Â¹cmâ»Â¹)

- b = Pathlength (cm)

- c = Concentration (M)

The pharmaceutical industry's escalating demand for high-purity solvents, projected to grow from $32.7 billion in 2025 to $45 billion by 2030 at a 6.6% compound annual growth rate (CAGR), underscores the critical importance of solvent selection in analytical methodologies [26]. This growth is driven by stringent purity standards in drug development, where exacting purity levels are non-negotiable for critical applications like impurity profiling [26].

Solvent Selection for UV-Vis Analysis

Fundamental Solvent Properties and Requirements

Solvent selection constitutes the primary foundation of reliable UV-Vis spectroscopy for impurity monitoring. The chosen solvent must not only dissolve the analyte and potential impurities but also exhibit suitable UV transparency in the spectral region of interest. Key considerations for solvent selection include:

UV Cutoff and Transparency: The solvent must have minimal absorbance in the spectral region where measurements are to be taken. Solvents have a characteristic "UV cutoff" wavelength below which they absorb too strongly for practical use. For impurity detection, which often requires broad spectral scanning, solvents with low UV cutoffs are essential to avoid masking the signals of trace components [2].

Purity Grades and Specifications: Pharmaceutical impurity analysis necessitates solvents of appropriate purity grades. Spectrophotometric grade solvents are specifically designed for UV-Vis applications, with stringent specifications for UV transparency and minimal fluorescent impurities [26]. HPLC-grade solvents may also be suitable, though their specifications are optimized for different separation mechanisms.

Solvent-Effect Spectral Shifts: The solvent environment can cause shifts in the absorption maxima (λmax) of both the active pharmaceutical ingredient (API) and impurities through solvatochromism. This phenomenon must be characterized during method development to ensure consistent identification and quantification [2].

High-Purity Solvent Grades for Pharmaceutical Applications

Table 1: High-Purity Solvent Grades for Pharmaceutical UV-Vis Analysis

| Solvent Grade | Key Characteristics | Primary Applications in Impurity Monitoring | Common Solvents Available |

|---|---|---|---|

| Spectrophotometric Grade | Specially purified for UV-Vis spectroscopy; low UV cutoff, high transmission | Scanning for unknown impurities; quantitative analysis at low wavelengths | Acetonitrile, methanol, water, hexanes |

| HPLC Grade | High purity with low UV absorbance; filtered to remove particulates | Impurity quantification when correlating with HPLC-UV methods | Acetonitrile, methanol, water, tetrahydrofuran |

| LC/MS Grade | Ultra-high purity with minimal additives; LC-MS compatibility | Impurity identification and structural characterization | Acetonitrile, methanol, water |

| ACS Reagent Grade | Meets American Chemical Society specifications; general chemical purity | Preparation of standard solutions; general laboratory use | Various polar and non-polar solvents |

The market for these specialized solvents continues to evolve, with spectrophotometric solvents representing a distinct category within the broader high-purity solvents market [26]. Leading manufacturers including Merck KGaA, Thermo Fisher Scientific Inc., and Avantor Inc. offer specialized solvent lines such as SpectroSolv, OmniSolv, and BioSolv tailored to specific analytical requirements [26].

Solvent Selection Protocol

Protocol 2.3: Solvent Suitability Assessment for Impurity Monitoring

Purpose: To systematically evaluate and qualify solvents for use in UV-Vis based impurity monitoring methods.

Materials and Equipment:

- Candidate solvent (appropriate purity grade)

- Reference solvent (identical lot for blank measurement)

- Quartz cuvettes (1 cm pathlength, matched pair)

- UV-Vis spectrophotometer with scanning capability

- Class A volumetric flasks

- Inert atmosphere glove box (for oxygen-sensitive solvents)

Procedure:

- Instrument Preparation: Power on the UV-Vis spectrophotometer and allow the lamps to stabilize for at least 30 minutes. Set the instrument parameters to the intended method conditions (bandwidth, data interval, scan speed).

Baseline Correction: Fill both sample and reference cuvettes with the candidate solvent. Perform a baseline correction across the entire spectral range of interest (typically 200-800 nm for full spectrum analysis).

Solvent Absorbance Scan:

- Place the solvent-filled sample cuvette in the sample compartment.

- Scan the solvent from 800 nm to 200 nm (or the instrument's lower limit).

- Record the absorbance values at the critical wavelengths for analysis.

Acceptance Criteria Evaluation:

- The solvent absorbance should not exceed 0.5 AU at the lowest wavelength used for quantification.

- No significant absorption bands should be present in regions where analyte or impurity detection will occur.

- The blank spectrum should be smooth without sharp peaks that might indicate contaminants.

Documentation: Record the UV cutoff (wavelength where absorbance = 1.0 AU) and the absorbance values at all analytical wavelengths in the method notebook.

Figure 1: Solvent Selection and Qualification Workflow

Sample Clarification Techniques

The Critical Role of Sample Clarification

Sample clarification is an essential step in UV-Vis sample preparation, particularly for pharmaceutical formulations that may contain particulate matter, undissolved components, or exhibit inherent turbidity. The presence of such light-scattering components represents a significant interference in UV-Vis spectroscopy, as scattering rather than true absorption can dominate the measured signal [25]. This is particularly problematic for impurity monitoring, where the target analytes are present at low concentrations and can be easily masked by scattering effects.

UV-Vis instruments generally analyze liquids and solutions most efficiently, while suspensions of solid particles in liquid will scatter the light more than absorb the light, resulting in skewed data [25]. The apparent absorbance from scattering follows different physical principles than electronic absorption, violating the assumptions underlying the Beer-Lambert Law and introducing significant quantitative errors.

Clarification Method Selection Guide

Table 2: Sample Clarification Methods for Pharmaceutical UV-Vis Analysis

| Clarification Method | Mechanism of Action | Application Scope | Limitations and Considerations |

|---|---|---|---|

| Membrane Filtration | Physical barrier with defined pore size (0.2-0.45 µm) | Aqueous and organic solutions; heat-labile compounds | Potential analyte adsorption to membrane; solvent compatibility |

| Centrifugation | Sedimentation by gravitational force (2000-15000 × g) | Suspensions, colloidal systems; large sample volumes | Incomplete clarification for sub-micrometer particles; equipment requirements |

| Solid-Phase Extraction (SPE) | Selective adsorption and elution | Complex matrices; simultaneous concentration and cleanup | Method development intensive; potential for incomplete recovery |

| Degassing | Removal of dissolved micro-bubbles by sonication or vacuum | Aqueous buffers and mobile phases | Addresses light scattering from bubbles, not particulates |

Advanced purification technologies including membrane filtration are experiencing increased adoption in high-purity solvent production and are equally applicable to sample preparation [26]. These technologies enable the effective removal of sub-micrometer particulates that contribute to light scattering without introducing significant contamination.

Sample Clarification Protocol

Protocol 3.3: Comprehensive Sample Clarification for Impurity Analysis

Purpose: To remove particulate matter and gas bubbles from samples to minimize light scattering interference in UV-Vis measurements.

Materials and Equipment:

- Syringe filters (0.2 µm or 0.45 µm pore size, appropriate membrane composition)

- Centrifuge and compatible tubes

- Ultrasonic bath

- Vacuum filtration apparatus

- In-line degasser (for continuous flow systems)

Procedure:

- Preliminary Assessment: Visually inspect the sample against strong light. Note any cloudiness, opalescence, or visible particles.

Filtration Method Selection:

- For aqueous samples: Use cellulose acetate or mixed cellulose ester membranes.

- For organic solvents: Use polytetrafluoroethylene (PTFE) or polyvinylidene fluoride (PVDF) membranes.

- For protein-containing solutions: Use low protein-binding polyethersulfone (PES) membranes.

Filtration Protocol:

- Pre-rinse the filter with an appropriate solvent (typically the same as the sample solvent).

- Discard the first 1-2 mL of filtrate to minimize adsorption effects.

- Collect the clarified filtrate in a clean, particulate-free container.

Alternative Centrifugation Protocol:

- Transfer the sample to a centrifuge tube compatible with the solvent.

- Centrifuge at 10,000 × g for 10 minutes at controlled temperature.

- Carefully pipette the supernatant without disturbing the pellet.

Degassing (if required):

- Place the clarified sample in an ultrasonic bath for 5-10 minutes.

- Alternatively, sparge with inert gas (helium) for 5 minutes.

Verification: Measure the absorbance of the clarified sample at a wavelength where the analyte does not absorb (e.g., 700 nm). The absorbance should be <0.01 AU, indicating minimal scattering.

Troubleshooting Notes:

- High background after filtration may indicate membrane contamination - pre-rinse more thoroughly.

- Low analyte recovery suggests adsorption to filter - change membrane material.

- Persistent turbidity after centrifugation may require smaller pore size filtration.

Pathlength Optimization Strategies

Fundamental Principles of Pathlength Optimization

Pathlength, traditionally defined as the distance light travels through the sample, represents a critical parameter in UV-Vis spectroscopy that directly influences measurement sensitivity and dynamic range [27]. According to the Beer-Lambert Law, absorbance is directly proportional to pathlength, providing a straightforward mechanism to enhance detection capability for low-concentration impurities [25]. The strategic selection of pathlength enables analysts to maintain absorbance values within the optimal range of the instrument's detector, typically between 0.5 and 1.5 absorbance units (AU) for the best signal-to-noise ratio [27].

The relationship between pathlength and concentration has practical implications for impurity monitoring. As the concentration of the analyte of interest increases, there are more molecules to absorb and scatter light, potentially driving absorbance beyond the linear range of the detector [27]. Conversely, for trace-level impurities, increasing the pathlength enhances the effective detection capability without the need for sample pre-concentration, which might introduce artifacts or losses.

Pathlength Selection Guide for Impurity Analysis