UV-Vis Spectroscopy for Syrup Concentration Verification: Method Development, Optimization, and Validation in Pharmaceutical Analysis

This article provides a comprehensive guide for researchers and drug development professionals on implementing Ultraviolet-Visible (UV-Vis) spectroscopy for accurate concentration verification in syrup formulations.

UV-Vis Spectroscopy for Syrup Concentration Verification: Method Development, Optimization, and Validation in Pharmaceutical Analysis

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on implementing Ultraviolet-Visible (UV-Vis) spectroscopy for accurate concentration verification in syrup formulations. It covers foundational principles of UV-Vis spectroscopy, detailed methodological development for multi-component analysis, advanced troubleshooting and optimization strategies, and rigorous validation protocols compared with chromatographic techniques. By integrating recent applications from cough syrups to adulteration detection and leveraging chemometric tools, this resource addresses the critical need for rapid, cost-effective, and reliable quality control methods in pharmaceutical manufacturing and research.

UV-Vis Spectroscopy Fundamentals: Principles and Applications in Syrup Analysis

Core Principles of UV-Vis Spectroscopy and Light-Matter Interactions

Ultraviolet-Visible (UV-Vis) spectroscopy is a foundational analytical technique in modern laboratories, enabling the identification and quantification of a vast range of analytes. The technique is revered for its simplicity, cost-effectiveness, and rapid analysis capabilities [1] [2]. This article details the core principles of UV-Vis spectroscopy, with a specific focus on its application for concentration verification in syrup-based matrices, a critical requirement in pharmaceutical and food industries to ensure product quality and authenticity [3] [4].

Core Principles and Theoretical Framework

The Basis of Light-Matter Interaction

At its core, UV-Vis spectroscopy involves the interaction of ultraviolet (190–400 nm) or visible (400–800 nm) light with matter [1] [2]. When light in these wavelengths strikes a molecule, electrons in the molecular orbitals can absorb specific amounts of energy, prompting their transition from a ground state to a higher-energy excited state [5]. The specific wavelength of light absorbed is characteristic of the molecular structure, as the energy difference between electronic states is unique for different chemical compounds [1]. This results in an absorption spectrum, a plot of absorbance versus wavelength, which serves as a fingerprint for the substance [1].

The Beer-Lambert Law

The quantitative power of UV-Vis spectroscopy is governed by the Beer-Lambert Law [1] [5] [6]. This law establishes a linear relationship between the absorbance (A) of a sample and the concentration (c) of the absorbing species in a solution, for a given path length (L).

The mathematical expression of the law is: A = εlc Where:

- A is the measured absorbance (unitless)

- ε is the molar absorptivity or extinction coefficient (L molâ»Â¹ cmâ»Â¹)

- l is the path length of the light through the sample (cm)

- c is the concentration of the absorbing analyte (mol Lâ»Â¹) [1] [5]

This principle is the cornerstone of concentration verification, allowing researchers to determine unknown concentrations by measuring absorbance and referencing a calibration curve constructed from standards of known concentration [1].

Conceptual Workflow

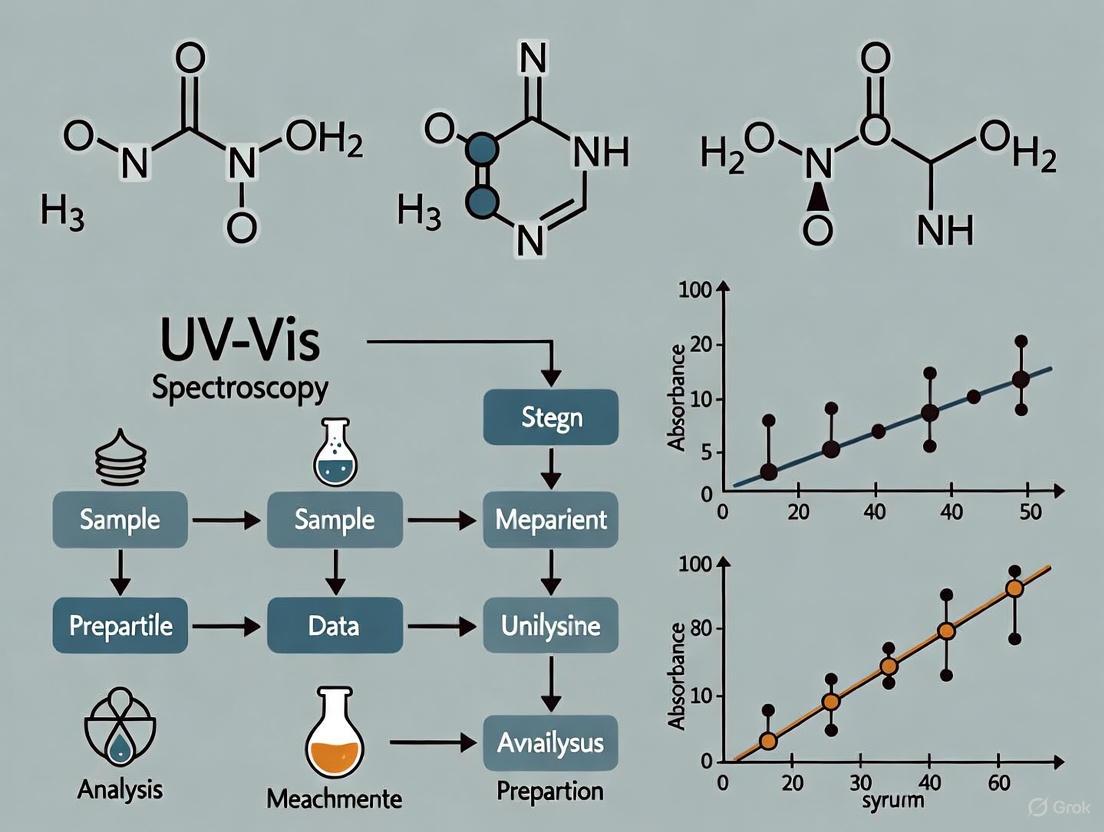

The following diagram illustrates the logical workflow from the initial light-matter interaction to the final quantitative analysis, grounded in the Beer-Lambert Law.

Instrumentation and Research Toolkit

A UV-Vis spectrophotometer is composed of several key components that work in concert to measure light absorption.

Instrument Components and Workflow

The sequential process within a spectrophotometer is visualized in the experimental workflow below.

Essential Research Reagents and Materials

Successful experimentation requires the use of specific materials. The following table details key reagents and their functions in the context of syrup analysis.

Table 1: Essential Research Reagent Solutions and Materials

| Item | Function & Importance in Syrup Analysis |

|---|---|

| Quartz Cuvettes | Holds the sample for analysis. Quartz is transparent to UV light, making it essential for work in the ultraviolet range (e.g., detecting compounds at 280 nm) [1] [5]. |

| High-Purity Solvents (e.g., Water, Ethanol) | Used to dissolve and dilute syrup samples. Must not absorb significantly in the spectral region of interest to avoid interference [7]. |

| Standard/Reference Compounds | High-purity analytes (e.g., sucrose, APIs) used to construct calibration curves based on the Beer-Lambert Law for accurate quantification [4]. |

| Buffering Agents | Maintain a constant pH, which can critical for stabilizing the analyte and ensuring consistent absorbance spectra, especially for pH-sensitive molecules [1]. |

| Syrup-Based Samples | The matrix of interest. Adulterants or active ingredients within the syrup are the target analytes for concentration verification [3] [8]. |

| AT-130 | AT-130, MF:C22H22BrN3O5, MW:488.3 g/mol |

| Halymecin A | Halymecin A, MF:C42H76O14, MW:805.0 g/mol |

Application Note: Verification of Syrup Composition

Background and Objective

Adulteration of natural syrups, such as honey, with inexpensive sugar syrups is a pervasive issue in the food industry [3] [8]. Similarly, verifying the concentration of active pharmaceutical ingredients (APIs) in medicinal syrups is crucial for drug safety and efficacy [7]. This protocol outlines a method to detect and quantify adulterants or APIs in syrup matrices using UV-Vis spectroscopy coupled with chemometric analysis.

Detailed Experimental Protocol

1. Sample and Standard Preparation:

- Authentic Syrup Samples: Obtain certified pure samples (e.g., authentic honey, pharmaceutical-grade syrup) to serve as the baseline [3] [8].

- Adulterant/API Standards: Prepare standard solutions of the target analyte (e.g., sucrose syrup, paracetamol, ibuprofen) [4] [7].

- Adulterated/Formulated Samples: Prepare calibration samples by mixing the authentic syrup with the adulterant/API at known concentrations (e.g., 5%, 10%, 20%, 30%, 40%, 50% w/w) [8]. Homogenize mixtures thoroughly using a magnetic stirrer [4].

- Sample Dilution: Dilute all samples in an appropriate solvent (e.g., water, ethanol-NaOH mixture) to ensure absorbance readings fall within the ideal range of 0.1–1.0 to comply with the dynamic range of the instrument and the Beer-Lambert Law [1] [7].

2. Instrumental Setup and Data Acquisition:

- Instrument: Use a double-beam UV-Vis spectrophotometer for enhanced stability by automatically comparing the sample to a blank reference [1] [2].

- Parameters: Set the wavelength range to 200–800 nm. Use a quartz cuvette with a 1 cm path length [4].

- Blank Measurement: Fill a cuvette with the pure solvent and use it to zero the instrument, establishing a baseline [1].

- Spectral Collection: Record the absorption spectrum for each standard and unknown sample. Each sample should be measured in replicate to ensure precision [3].

3. Data Processing and Model Development:

- Pre-processing: Apply spectral pre-processing techniques such as offset correction (OFF), linear baseline correction (LBC), or Savitzky–Golay derivative (SGD) to minimize scattering effects and enhance spectral features [3].

- Chemometric Analysis: For complex syrup matrices, employ machine learning models to handle overlapping spectral data.

- Use Partial Least Squares Regression (PLSR) or Support Vector Regression (SVR) to build a quantitative model that correlates spectral data with the concentration of the adulterant/API [4].

- Use Principal Component Analysis (PCA) for exploratory analysis to identify natural clustering between pure and adulterated samples [8].

4. Quantification and Validation:

- Input the absorption spectrum of the unknown sample into the calibrated PLSR or SVR model to predict the concentration of the target analyte [4].

- Validate the model's accuracy using internal cross-validation or an external validation set not used in model building [3].

Key Experimental Parameters and Figures of Merit

The table below summarizes quantitative data and performance metrics from relevant studies on syrup adulteration detection, providing a benchmark for expected outcomes.

Table 2: Performance Metrics in UV-Vis-Based Syrup Analysis

| Analyte / Matrix | Adulterant / API | Key Wavelengths (nm) | Chemometric Model | Performance (R² / Detection Limit) |

|---|---|---|---|---|

| Honey [4] | Sucrose Syrup | 216, 280, 316, 603 | Support Vector Regression (SVR) | R² = 0.98, RMSE = 0.97 |

| Honey [3] | Corn & Agave Syrups | N/S* | SPA-MLR & SPA-LDA | Successful discrimination & quantification |

| Romanian Honey [8] | Corn & Inverted Syrups | N/S* | Artificial Neural Network (ANN) | Detection level > 10% |

| Pharmaceutical Syrup [7] | Paracetamol | 243 | Beer-Lambert Linear Regression | Linear Calibration |

| Pharmaceutical Syrup [7] | Ibuprofen | 221 | Beer-Lambert Linear Regression | Linear Calibration |

*N/S: Not Specified in the source material.

UV-Vis spectroscopy remains an indispensable tool for concentration verification, offering a blend of simplicity, speed, and cost-effectiveness. Its fundamental principle, the Beer-Lambert Law, provides a direct path to quantification, while its coupling with advanced chemometric techniques like PLSR and machine learning empowers researchers to solve complex analytical challenges in intricate matrices such as syrups. The protocols outlined herein provide a reliable framework for ensuring the authenticity of food products and the quality of pharmaceutical formulations, underpinning both consumer safety and industrial standards.

Ultraviolet-Visible (UV-Vis) spectroscopy has emerged as a powerful analytical technique for the analysis of syrups across food and pharmaceutical industries. This application note details its specific advantages for the concentration verification of active ingredients and quality markers in syrup matrices. The technique's inherent cost-effectiveness, rapid analysis time, and operational accessibility make it particularly suitable for routine quality control (QC), authenticity testing, and process monitoring. By integrating modern instrumentation and advanced chemometric data analysis, UV-Vis spectroscopy provides a robust, non-destructive, and reagent-free analytical solution for researchers and drug development professionals [9]. This document, framed within a broader thesis on analytical method development, provides validated experimental protocols and data to support the adoption of this technique.

Key Advantages and Supporting Quantitative Data

The utility of UV-Vis spectroscopy for syrup analysis is demonstrated through its performance in diverse applications, from direct active pharmaceutical ingredient (API) quantification to the grading of food-grade syrups based on color standards.

Table 1: Quantitative Analysis of Syrup Components and Properties Using UV-Vis

| Analyte / Sample | Key Wavelength(s) | Analytical Output / Model Performance | Reference Application |

|---|---|---|---|

| Glucose (Aqueous Solutions) | 200-400 nm (UV Region) | Artificial Neural Network (ANN) achieved a correlation coefficient (R) > 0.98 for concentration prediction [10]. | Concentration verification of simple sugar solutions [10]. |

| Active Ingredients in Oral Liquid Syrups (e.g., Acetaminophen, Guaifenesin) | Full-spectrum with multivariate regression | Partial Least Squares (PLS) model with R² > 0.9784; detection limits as low as 0.02 mg/mL [11]. | Multicomponent quantification of APIs in over-the-counter medications without sample extraction [11]. |

| Maple Syrup (Color Grading) | 560 nm (% Transmittance) | % Transmittance directly correlates with official color grades (Golden, Amber, Dark) and CIE L*a*b* color scales [12]. | Quality assurance and product grading according to USDA standards [12]. |

| Sugar Syrup Adulteration in Honey | Full-spectrum fingerprint | Chemometric models (e.g., SPA-LDA/MLR) successfully discriminated and quantified adulterants like corn and agave syrup [3]. | Food authenticity and fraud detection for complex natural sweeteners [3]. |

Detailed Experimental Protocols

Protocol 1: Quantification of Active Ingredients in Medicinal Syrups

This protocol is adapted from research on the analysis of over-the-counter oral liquid syrups, demonstrating a direct method for quantifying multiple active ingredients without extensive sample preparation [11].

Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Syrup Analysis via UV-Vis

| Item | Function / Explanation |

|---|---|

| UV-Vis Spectrophotometer | Instrument with a photodiode array (PDA) detector is preferred for full-spectrum acquisition. Must have a validated photometric range (e.g., up to 5 Abs for concentrated syrups) [12]. |

| Quartz Cuvettes (10 mm pathlength) | For holding liquid samples. Quartz is essential for measurements in the UV range (<350 nm). |

| Micropipettes and Volumetric Flasks | For accurate and precise sample preparation and dilution. |

| Solvent (e.g., Water, Ethanol) | High-purity solvent for diluting syrup samples to within the instrument's linear dynamic range. |

| Standard Reference Materials | High-purity (>99%) compounds of the target analytes (e.g., D-glucose, acetaminophen) for calibration [10] [11]. |

Procedure

- Sample Preparation: For medicinal syrups, no extraction is needed. Gently homogenize the syrup product, then accurately weigh and dilute an aliquot with an appropriate solvent (e.g., deionized water) to a target concentration within the analytical range. For highly colored or concentrated syrups, serial dilutions may be necessary to bring the absorbance below 1.0 AU [11].

- Instrument Setup and Calibration: Power on the UV-Vis spectrophotometer and allow the lamp to warm up as per manufacturer's instructions. Set the scanning parameters to a range of 200-800 nm. Perform a baseline correction (blank) using the solvent used for dilution in a matched quartz cuvette.

- Standard Curve Acquisition: Prepare a series of standard solutions of the target active ingredient(s) across a concentration range encompassing the expected sample concentration. Record the full absorbance spectrum for each standard.

- Sample Measurement: Place the diluted sample solution into a clean quartz cuvette and acquire its full UV-Vis spectrum under the same conditions as the standards.

- Data Analysis and Chemometric Modeling: For single-component analysis, plot absorbance at the λmax of the target analyte against concentration to create a univariate calibration curve. For multi-component analysis, export the full spectral data and build a multivariate calibration model (e.g., Partial Least Squares - PLS) using chemometric software to quantify each component simultaneously [11].

The workflow for this quantitative analysis is summarized below.

Protocol 2: Authenticity and Color Analysis of Food Syrups

This protocol outlines a fingerprinting approach for detecting adulteration and a colorimetric method for objective color grading, as applied to honey and maple syrup [12] [3].

Procedure

- Sample Preparation (for authenticity): For liquid syrups like honey, a simple dissolution in warm water (e.g., 0.5 g/mL) is sufficient to create a homogeneous solution for analysis. Ensure all samples and potential adulterant reference materials are prepared identically [3].

- Spectral Acquisition: Using a UV-Vis spectrophotometer, collect the full UV-Vis absorbance spectrum (e.g., 200-800 nm) of each prepared sample. For color analysis specifically, the % Transmittance mode is used, with key data recorded at 560 nm for maple syrup [12].

- Data Preprocessing: Apply preprocessing techniques to the raw spectral data to minimize irrelevant noise and enhance features. Common methods include Savitzky-Golay smoothing (e.g., window size=7, polynomial order=2) and baseline correction [10].

- Chemometric Analysis for Discrimination: For authenticity testing, employ pattern recognition techniques. The Successive Projections Algorithm (SPA) can be used for variable selection to identify the most informative wavelengths, which are then used in Linear Discriminant Analysis (SPA-LDA) to build a classification model that discriminates between pure and adulterated samples [3].

- Color Scale Interpretation: For color grading, use integrated color analysis software to convert the transmittance spectrum into CIE L*a*b* color values. Compare the L* (lightness), a* (red/green), and b* (yellow/blue) values against established grading standards or internal specifications [12].

The logical flow for the authenticity screening and color grading is depicted in the following diagram.

Discussion

The data and protocols presented confirm the central thesis that UV-Vis spectroscopy is a highly advantageous technique for syrup analysis. Its cost-effectiveness is rooted in the relatively low initial investment and minimal ongoing operational costs compared to techniques like HPLC, NMR, or LC-HRMS [13] [3]. Furthermore, the technique is rapid, providing results in minutes, and requires minimal sample preparation, avoiding complex derivatization or extraction steps [10] [11].

The integration of chemometrics has been a transformative development, allowing researchers to extract meaningful information from the broad, overlapping spectral bands typical of complex syrup matrices [9]. Techniques like PLS regression and machine learning models such as Artificial Neural Networks (ANNs) enable accurate multicomponent quantification and sophisticated pattern recognition for authenticity screening, overcoming the traditional limitations of UV-Vis spectroscopy [10] [3] [11]. This synergy of an accessible physical technique with powerful data analysis software makes modern UV-Vis spectroscopy an indispensable sensor for quality control and research in syrup-based product development.

Ultraviolet-Visible (UV-Vis) spectrophotometry serves as a cornerstone analytical technique within pharmaceutical laboratories for the quantitative analysis of active pharmaceutical ingredients (APIs) and excipients. Its principles, rooted in the Beer-Lambert Law, provide a robust foundation for ensuring product quality, stability, and efficacy. This article details specific application protocols for analyzing common syrup formulations, contextualized within a broader research thesis on UV-Vis method development for concentration verification. The methodologies outlined below are designed for researchers and drug development professionals, emphasizing practical, reproducible protocols that leverage both conventional and advanced chemometric approaches to overcome common analytical challenges such as spectral overlapping and matrix effects from complex formulations [14].

Theoretical Foundations and Key Principles

The quantitative application of UV-Vis spectroscopy in pharmaceutical analysis is predominantly governed by the Beer-Lambert Law. This law states that the absorbance (A) of a light beam by a solution is directly proportional to the concentration (c) of the absorbing species and the pathlength (l) of the light through the solution, expressed as A = εlc, where ε is the molar absorptivity coefficient [15]. This relationship forms the basis for concentration determination.

For complex mixtures where APIs exhibit significant spectral overlap, conventional single-wavelength analysis becomes insufficient. Multivariate calibration techniques offer a powerful solution. Methods such as Partial Least Squares (PLS-1), Principal Component Regression (PCR), and Hybrid Linear Analysis (HLA) utilize full-spectrum data to mathematically resolve the contribution of individual analytes without the need for physical separation [14]. Furthermore, three-way analysis methods like Parallel Factor Analysis (PARAFAC) can be applied to more complex datasets, such as those generated from pH-absorbance measurements, enabling simultaneous quantification and the determination of physicochemical properties like pKa values [16].

Application Notes & Experimental Protocols

Protocol 1: Simultaneous Determination of Asthma Drugs in Syrup Using Multivariate Calibration

This protocol describes the simultaneous quantification of Theophylline (THEO), Montelukast (MKST), and Loratadine (LORA) in a synthetic syrup matrix, resolving their significantly overlapping UV spectra through chemometric modeling [14].

- 1. Objective: To determine the concentration of THEO, MKST, and LORA in a syrup formulation using UV-Vis spectroscopy coupled with PLS-1, PCR, or HLA multivariate calibration models.

- 2. Principle: Multivariate calibration models correlate the spectral data of calibration mixtures with known concentrations to predict the concentration of unknown samples, effectively handling spectral interference [14].

- 3. Experimental Workflow:

- 4. Materials & Reagents:

- Theophylline, Montelukast, Loratadine (Reference Standards): High-purity APIs for preparing stock solutions [14].

- Methanol (HPLC Grade): Solvent for dissolving APIs and preparing all standard solutions [14].

- Simulated Syrup Base: A solution containing sucrose, preservatives, and flavorants to mimic the final product matrix.

- Human Plasma: For method validation in biological matrices [14].

5. Procedure:

- Stock Solution Preparation: Accurately weigh and dissolve 20 mg of each API in 10 mL methanol to obtain stock solutions [14].

- Calibration Set Design: Prepare a series of 15 standard mixtures according to a Central Composite Design (CCD). The concentration range for each drug should be 2.0–14.0 mg Lâ»Â¹ [14].

- Sample Preparation (Simulated Syrup): Dilute a weighed amount of the syrup sample with methanol. Centrifuge if necessary to remove insoluble excipients and use the supernatant for analysis.

- Spectra Acquisition: Using a UV-Vis spectrophotometer, record the absorption spectrum of each calibration standard and the prepared sample from 190 nm to 400 nm against a methanol blank [14].

- Model Development & Prediction: Import the spectral data and known concentrations of the calibration set into chemometric software (e.g., MATLAB). Develop PLS-1, PCR, or HLA models. Validate the model using cross-validation. Finally, apply the validated model to the spectrum of the unknown syrup sample to predict the concentrations of THEO, MKST, and LORA [14].

6. Results & Data Analysis:

- Table 1: Figures of Merit for Multivariate Calibration Models [14]

| Analyte | Best-Fit Model | RMSEP (mg Lâ»Â¹) | LOD (mg Lâ»Â¹) | Linear Range (mg Lâ»Â¹) |

|---|---|---|---|---|

| Theophylline (THEO) | PCR | 0.173 | 0.03 | 1.0 – 25.0 |

| Montelukast (MKST) | PLS-1 | 0.187 | 0.05 | 1.0 – 25.0 |

| Loratadine (LORA) | HLA | 0.251 | 0.05 | 1.0 – 25.0 |

Protocol 2: Determination of Synthetic Colorants in Vitamin Syrups using pH-Dependent Three-Way Analysis

This protocol utilizes a pH-UV-Vis strategy with PARAFAC modeling to quantify Allura Red (E129) in the presence of complex syrup matrix interferents, simultaneously estimating the colorant's pKa [16].

- 1. Objective: To quantify Allura Red in a commercial vitamin syrup and determine its acid dissociation constant (pKa) using three-way analysis of pH-UV-Vis data.

- 2. Principle: Recording UV-Vis spectra of the sample at multiple pH levels creates a three-way data array (wavelength × sample × pH). PARAFAC decomposes this array, uniquely identifying the spectral, concentration, and pH profiles of the colorant [16].

- 3. Experimental Workflow:

- 4. Materials & Reagents:

- Allura Red AC (E129) Standard: For preparing calibration solutions [16].

- Britton-Robinson (BR) Buffer Solutions: Prepare at five different pH levels (e.g., 8, 9, 10, 11, 12) to induce spectral changes in the colorant [16].

- Vitamin Syrup Sample: Commercial product containing the colorant.

- Sodium Hydroxide (0.1 M): For pH adjustment [16].

- 5. Procedure:

- Buffer and Stock Preparation: Prepare BR buffer solutions and adjust their pH accurately. Prepare a stock solution of Allura Red (e.g., 100 µg/mL) in each buffer [16].

- Calibration and Sample Preparation: Prepare calibration standards (e.g., 0.8–19.2 µg/mL) in all five buffers. For the syrup sample, dilute an aliquot in each of the five buffer solutions [16].

- Three-Way Data Acquisition: Record the full UV-Vis spectrum of every calibration standard and the prepared sample solutions at all five pH levels.

- PARAFAC Modeling: Arrange the spectral data into a three-way array and process it using the PARAFAC algorithm in a platform like MATLAB. The model will output the estimated spectral profile of the colorant, its relative concentration in the sample, and the pH profile from which the pKa can be derived (as the inflection point) [16].

- 6. Results & Data Analysis:

- Table 2: Validation Parameters for Allura Red Determination by PARAFAC [16]

| Parameter | Value / Result |

|---|---|

| Working Range | 0.8 – 19.2 µg/mL |

| Estimated pKa | 11.28 |

| Recovery in Spiked Samples | 101.5% – 103.5% |

| Comparison with UPLC | No significant difference |

Protocol 3: Direct Concentration Assay of Protein-Based Nutraceuticals using Variable Pathlength Technology

This protocol employs variable pathlength slope spectroscopy to accurately determine the concentration of protein analytes (e.g., in protein supplements or antibody-based nutraceuticals) without the need for dilutions, minimizing analytical error [15].

- 1. Objective: To directly determine the concentration of a protein in a viscous nutraceutical syrup using a UV-Vis spectrometer equipped with variable pathlength technology.

- 2. Principle: The Slope Spectroscopy equation (c = m / ε) is derived from the Beer-Lambert law. The system automatically measures absorbance at multiple pathlengths, plots a regression line (A vs. l), and uses the slope (m) with the known extinction coefficient (ε) to calculate concentration [15].

- 3. Experimental Workflow:

- 4. Materials & Reagents:

- Protein Standard: Pure protein for establishing or verifying the molar absorption coefficient (ε).

- Appropriate Dilution Buffer: A buffer compatible with the protein and formulation (e.g., phosphate buffer saline).

- Viscous Syrup Sample: The protein-based nutraceutical product.

- 5. Procedure:

- Sample Preparation: For highly viscous syrups, a minimal dilution with an appropriate buffer may be required to facilitate pipetting. For many samples, analysis can be performed "neat" [15].

- Instrumental Analysis: Load the sample into the Solo VPE system or a similar variable pathlength spectrophotometer. The instrument's software will automatically determine the optimal pathlength range, take 5-10 absorbance measurements at different pathlengths, and plot the linear regression [15].

- Concentration Calculation: The software calculates the slope (m) of the regression line. Using the predefined extinction coefficient (ε) for the protein at 280 nm (A280), the concentration is automatically computed using the equation c = m / ε [15].

- 6. Results & Data Analysis:

- Table 3: Advantages of Variable Pathlength Technology vs. Traditional A280 [15]

| Parameter | Traditional Fixed Pathlength | Variable Pathlength (Slope Spectroscopy) |

|---|---|---|

| Typical Turnaround Time | Hours (due to dilutions) | Minutes (neat analysis) |

| Primary Source of Error | Sample dilution & handling | Instrument precision (~2%) |

| Sample Volume | Microliters to milliliters | 10 – 300 µL |

| Hands-on Time | High (technique sensitive) | Low (minimal manipulation) |

The Scientist's Toolkit: Essential Research Reagents & Materials

- Table 4: Key Reagents and Materials for UV-Vis Pharmaceutical Analysis

| Item | Function / Application | Example in Protocol |

|---|---|---|

| API Reference Standards | High-purity compounds for preparing calibration curves and method validation. | Theophylline, Montelukast, Allura Red standard [14] [16]. |

| HPLC Grade Solvents | High-purity solvents for preparing stock and standard solutions to minimize UV-absorbing impurities. | Methanol [14]. |

| Buffer Salts & Components | To maintain constant pH during analysis, which is critical for analyte stability and spectral shape. | Britton-Robinson buffer components [16]. |

| Chemometric Software | Platform for developing, validating, and applying multivariate calibration models. | MATLAB with N-Way Toolbox [14] [16]. |

| Variable Pathlength System | Enables direct analysis of concentrated samples without dilution, reducing error. | Solo VPE system [15]. |

| Penicillin V | Penicillin V, CAS:132-98-9; 87-08-1, MF:C16H18N2O5S, MW:350.4 g/mol | Chemical Reagent |

| Pyralomicin 2c | Pyralomicin 2c, MF:C18H17Cl2NO8, MW:446.2 g/mol | Chemical Reagent |

Ultraviolet-Visible (UV-Vis) spectrophotometry is a foundational analytical technique in research and industrial laboratories. For applications requiring high precision in concentration verification, such as in syrup-based pharmaceuticals or food adulteration studies, the choice between single and dual beam instrumentation is critical. This document outlines the core principles, instrumental designs, and practical protocols for employing UV-Vis spectroscopy in the concentration verification of syrups, providing a structured guide for researchers and drug development professionals.

Core Instrumentation: Single Beam vs. Double Beam Designs

The fundamental operational difference between single and double beam spectrophotometers lies in their optical layout and how they correct for instrumental noise, directly impacting measurement stability and accuracy [17].

Single Beam Spectrophotometer

Principle of Operation: A single beam instrument utilizes a single light path that passes sequentially through a monochromator, the sample, and then to the detector [17] [18].

- Workflow: The instrument is first "blanked" with a reference solvent to measure the initial light intensity (Iâ‚€). The sample is then inserted, and the transmitted light intensity (I) is measured [19] [20]. Absorbance is calculated as A = logâ‚â‚€(Iâ‚€/I) [17].

- Key Characteristics: This design is simpler, resulting in a lower initial cost and high energy throughput due to the non-split beam, which can enhance sensitivity [17] [19] [20].

Double Beam Spectrophotometer

Principle of Operation: A double beam instrument splits the source light into two parallel paths: a sample beam and a reference beam [17] [20].

- Workflow: The beams pass through the sample and a reference blank, respectively. A beamsplitter, often a rotating chopper, alternates the light between the two paths, and a detector measures the intensities of both beams simultaneously or in rapid succession [17] [20]. Absorbance is calculated based on the ratio of the two beams (A = logâ‚â‚€(Iáµ£/Iâ‚›)) [17].

- Key Characteristics: This design is self-compensating, as any fluctuation in the lamp intensity or electronic noise affects both beams equally, thereby canceling out the drift and ensuring superior stability and precision [17] [20].

The following diagram illustrates the logical decision-making process for selecting the appropriate instrument type based on analytical needs and constraints.

Performance Comparison

The choice of instrument design directly translates to differences in key performance metrics, as summarized in the table below.

Table 1: Performance comparison of single beam and double beam UV-Vis spectrophotometers

| Feature | Single Beam | Double Beam |

|---|---|---|

| Optical Path | Single light path through monochromator, sample, and detector [17]. | Single beam is split into reference and sample beams; recombined before detector [17]. |

| Accuracy | Limited due to direct impact of source fluctuations and baseline drift [17]. | Superior, self-compensating for source fluctuations; improved baseline stability [17]. |

| Precision | Lower due to baseline drift and noise from source fluctuations [17]. | Significantly higher due to reduced drift and self-compensating design [17]. |

| Dynamic Range | Limited, particularly at high/low absorbance values [17]. | Wider, allowing accurate analysis of samples with very high or low absorbance [17]. |

| Cost | Lower initial purchase price [17] [20]. | More expensive and complex design [17] [20]. |

| Typical Applications | Routine analyses, teaching laboratories, cost-sensitive settings [17]. | Research, quality control, high-throughput analysis, demanding applications [17]. |

Principles of Wavelength Selection

The interaction of light with matter in UV-Vis spectroscopy involves the promotion of electrons to higher energy states, and the specific wavelengths absorbed are characteristic of the molecular structure [18] [1].

Beer-Lambert Law

The fundamental principle for quantitative analysis is the Beer-Lambert Law, which states a linear relationship between absorbance (A), concentration (c) of the absorbing species, and the path length (l) of the sample [18] [1]: A = εcl where ε is the molar absorptivity (a compound-specific constant at a given wavelength) [18]. This law forms the basis for all concentration verification protocols.

Chromophores and Solvent Effects

- Chromophores: Functional groups responsible for UV-Vis absorption (e.g., -C=O, -N=N-, -C=C-) due to n→π* and π→π* electronic transitions [18].

- Auxochrome: Functional groups that, when attached to a chromophore, alter the wavelength and/or intensity of absorption (e.g., -OH, -NHâ‚‚) [18].

- Solvent and pH Effects: The solvent and pH of the solution can cause shifts in the absorption maximum (λmax). A bathochromic (red) shift is a shift to a longer wavelength, while a hypsochromic (blue) shift is a shift to a shorter wavelength [18].

Application in Syrup Concentration Verification

UV-Vis spectroscopy, combined with chemometrics, has proven highly effective for quantifying analytes in complex syrup matrices, from active pharmaceutical ingredients (APIs) to adulterants in honey.

Experimental Protocol: Quantification of Active Ingredients in Oral Syrups

This protocol is adapted from research demonstrating the quantification of acetaminophen, guaifenesin, dextromethorphan HBr, and phenylephrine HCl in flavored syrups using Raman and UV-Vis spectroscopy with PLS regression [21].

1. Instrument and Materials Setup

- Spectrophotometer: Double-beam UV-Vis spectrophotometer is recommended for stability during analysis.

- Chemometrics Software: Software capable of Partial Least Squares (PLS) regression.

- Cuvettes: Quartz cuvettes (1 cm path length) [18] [1].

- Syrup Base Matrix: Use a placebo syrup base identical to the commercial product, including flavors, binders, dyes, and preservatives, to match the real-world sample matrix [21].

- Standard Solutions: Prepare standard stock solutions of each pure API. Spike the placebo syrup base with known concentrations of APIs to create the calibration set.

2. Sample Preparation

- No extraction or drying is required [21]. The syrup OTCMs can be analyzed directly after appropriate dilution if the absorbance falls outside the instrument's ideal dynamic range (typically above 1 AU) [1].

- Ensure homogeneity by gently mixing the sample before analysis.

3. Spectral Acquisition

- Wavelength Range: Acquire full spectra from 200 nm to 800 nm [4].

- Blank: Use the placebo syrup base (without APIs) as the blank to zero the instrument [1].

- Replication: Measure each sample in triplicate or quadruplicate to ensure reproducibility [4] [10].

4. Chemometric Modeling and Quantification

- Data Pre-processing: Apply pre-processing techniques to the raw spectral data (200-800 nm) such as smoothing (e.g., Savitzky-Golay) or baseline correction to reduce noise and enhance signals [4] [10].

- Model Development: Build a PLS regression model using the pre-processed spectra of the calibration set and their known API concentrations.

- Model Validation: Validate the model's predictive performance using an independent set of validation samples. The published method achieved R² values >0.978 and accuracies of 88-94% for simultaneous multi-component quantification [21].

Experimental Protocol: Detection of Sucrose Syrup Adulteration in Honey

This protocol is based on multiple studies using UV-Vis spectroscopy and machine learning for rapid honey adulteration screening [3] [4] [8].

1. Instrument and Materials Setup

- Spectrophotometer: A standard UV-Vis spectrophotometer (single or double beam).

- Software: Software for machine learning algorithms (e.g., Support Vector Regression (SVR), Partial Least Squares Regression (PLSR), Artificial Neural Networks (ANN)).

- Cuvettes: Quartz cuvettes (1 cm path length).

- Samples: Authentic, pure honey samples and suspected adulterated or commercial honey samples.

2. Sample Preparation

- Direct Analysis: For a fingerprinting approach, honey samples can be measured directly or with minimal dilution [3] [8].

- Homogeneity: Ensure samples are well-mixed and fully liquefied if crystallized.

3. Spectral Acquisition and Analysis

- Spectral Range: Record absorbance spectra from 200 nm to 800 nm [4].

- Blank: Use distilled water as a reference blank.

- Diagnostic Wavelengths: Studies have identified key wavelengths for sucrose detection, including 216 nm, 280 nm, 316 nm, and 603 nm [4]. While the visible region around 603 nm can be used, the most pronounced concentration-dependent changes are often observed in the UV region below 400 nm [4] [10].

- Modeling: Use chemometric tools (e.g., SVR, PLSR) to correlate spectral features with adulteration levels. SVR has been shown to perform better than PLSR in some honey adulteration studies, with an R² of 0.98 and RMSE of 0.97 [4]. Neural network models can detect adulteration levels higher than 10% [8].

The following workflow diagram summarizes the key steps involved in a syrup concentration verification assay.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key materials and reagents for UV-Vis analysis of syrups

| Item | Function & Rationale |

|---|---|

| Quartz Cuvettes | Sample holders transparent to UV and visible light (190 nm - 2500 nm), essential for measurements in the UV range where glass and plastic absorb strongly [18] [1]. |

| Placebo Syrup Base | A matrix containing all formulation components (flavors, preservatives, dyes) except the analyte(s) of interest. Serves as the ideal blank to compensate for matrix absorbance and is crucial for building accurate calibration models in complex formulations [21]. |

| High-Purity Solvents | Solvents (e.g., water, ethanol, buffers) used for dilution or as a sample medium must be spectrophotometric grade to ensure they do not contain UV-absorbing impurities that interfere with the analysis [1]. |

| Standard Reference Materials | High-purity certified reference materials of the target analyte (e.g., API, sucrose) for preparing accurate calibration standards, which is the foundation of reliable quantitative analysis [21] [4]. |

| Chemometrics Software | Software packages capable of multivariate calibration methods (e.g., PLS, SVR, ANN) are essential for deconvoluting the broad, overlapping spectral features often encountered in complex syrup matrices [3] [21] [4]. |

| Griseusin B | Griseusin B, MF:C22H22O10, MW:446.4 g/mol |

| JPD447 | JPD447, MF:C20H23FN4, MW:338.4 g/mol |

Understanding Spectral Characteristics of Common Syrup Active Ingredients

Ultraviolet-Visible (UV-Vis) spectroscopy has emerged as a powerful, cost-effective analytical technique for the quantitative analysis of active pharmaceutical ingredients (APIs) in syrup formulations. This method operates on the fundamental principle of the Beer-Lambert Law (A = εbc), which establishes a linear relationship between the absorbance of light (A) by a solution and the concentration (c) of the absorbing species [22]. The technique measures the excitation of electrons from the ground state to the first singlet excited state when molecules absorb light in the UV-Vis region (200-800 nm), providing both qualitative and quantitative information about the sample [22].

In pharmaceutical quality control, UV-Vis spectroscopy offers significant advantages for syrup analysis, including minimal sample preparation, rapid analysis times, and the ability to perform non-destructive testing [23]. Unlike more complex chromatographic methods that often require extensive sample extraction and sophisticated instrumentation, UV-Vis spectroscopy provides a simpler alternative that is particularly valuable for routine quality assurance and screening purposes [11] [24]. The combination of UV-Vis spectroscopy with multivariate regression analysis has further enhanced its capability for accurate multicomponent quantification of active ingredients in complex syrup matrices [24].

Spectral Characteristics of Common Syrup Active Ingredients

Fundamental Spectral Properties

The analysis of active ingredients in syrups via UV-Vis spectroscopy relies on the distinctive spectral fingerprints of each compound. These fingerprints are characterized by specific absorption maxima (λ_max) and molar absorptivity coefficients (ε), which are intrinsic molecular properties dependent on the chemical structure and chromophores present in each molecule.

Table 1: Spectral Characteristics of Common Syrup Active Ingredients

| Active Ingredient | Absorption Maxima (λ_max, nm) | Molar Absorptivity (ε) | Linear Range (mg/mL) | Detection Limit (mg/mL) |

|---|---|---|---|---|

| Acetaminophen | 248-255 | High | 0.02-20.0 | 0.02 |

| Guaifenesin | 224-228, 274-278 | Moderate | 0.02-20.0 | 0.02 |

| Dextromethorphan HBr | 220-224, 278-282 | Moderate | 0.05-20.0 | 0.05 |

| Phenylephrine HCl | 216-220, 268-272 | Moderate | 0.05-20.0 | 0.05 |

The spectral data reveals that each active ingredient exhibits unique absorption patterns, with acetaminophen demonstrating the highest sensitivity (lowest detection limit) among the commonly analyzed compounds [24]. These characteristic absorption profiles enable both identification and quantification when coupled with appropriate chemometric tools.

Quantitative Performance Metrics

The analytical performance of UV-Vis spectroscopy for syrup analysis has been rigorously validated through various studies. When combined with Partial Least Squares (PLS) regression, the method demonstrates excellent linearity with R² values exceeding 0.9784 for multiple active ingredients [24]. The accuracy of multicomponent quantification ranges from 88% to 94%, which is sufficient for quality control screening purposes [24]. This level of performance is achieved without the need for complex sample extraction procedures, significantly streamlining the analytical workflow compared to traditional chromatographic methods [11].

Experimental Protocols

Sample Preparation and Instrumentation

Materials and Reagents:

- Pharmaceutical-grade active ingredients (acetaminophen, guaifenesin, dextromethorphan HBr, phenylephrine HCl)

- Appropriate solvent system (based on solubility characteristics)

- Reference standards for calibration

- Syrup base matrix (sugar-based or sugar-free) for method validation

Sample Preparation Protocol:

- Standard Solution Preparation: Accurately weigh reference standards of each active ingredient and dissolve in appropriate solvent to create stock solutions of known concentration (typically 1 mg/mL).

- Calibration Series: Prepare a series of standard solutions spanning the expected concentration range (e.g., 0.02-20.0 mg/mL) by serial dilution of stock solutions.

- Sample Preparation: For syrup formulations, dilute an appropriate aliquot with solvent to bring the concentration within the linear range of the method. Typical dilution factors range from 1:10 to 1:100, depending on the expected API concentration.

- Blank Preparation: Prepare a blank solution consisting of the syrup base matrix without active ingredients to account for any matrix interference.

Instrumental Parameters:

- Wavelength Range: 200-400 nm for full spectral acquisition

- Scan Speed: Medium (approximately 240 nm/min)

- Slit Width: 1-2 nm for optimal resolution

- Data Interval: 1 nm for sufficient data points

- Cell Path Length: 1 cm standard quartz cuvettes

Chemometric Method Development

The successful application of UV-Vis spectroscopy to syrup analysis requires the implementation of chemometric methods to handle spectral overlapping and matrix effects.

Principal Component Analysis (PCA) Protocol:

- Acquire full UV-Vis spectra for all calibration standards and samples.

- Pre-process spectral data using standard normal variate (SNV) or first-derivative transformation to minimize scattering effects.

- Perform PCA on the pre-processed spectral data matrix to identify inherent patterns and outliers.

- Visualize sample clustering in the principal component space to identify natural groupings and potential anomalies.

Partial Least Squares (PLS) Regression Protocol:

- Construct a calibration set with known concentrations of all active ingredients of interest.

- Acquire UV-Vis spectra for all calibration samples under identical conditions.

- Pre-process spectra using appropriate methods (mean-centering, standard normal variate, or derivative transformations).

- Develop PLS regression models using leave-one-out cross-validation to determine the optimal number of latent variables.

- Validate the model using an independent set of validation samples not included in the model development.

- Apply the validated model to predict unknown sample concentrations.

Method Validation Parameters

To ensure analytical reliability, the following validation parameters should be assessed:

- Linearity: Evaluate over the specified concentration range with R² > 0.99

- Precision: Determine repeatability (intra-day) and intermediate precision (inter-day) with RSD < 2%

- Accuracy: Assess through recovery studies (85-115%)

- Specificity: Verify ability to quantify analytes in the presence of matrix components

- Detection and Quantitation Limits: Establish based on signal-to-noise ratio of 3:1 and 10:1, respectively

Experimental Workflow and Chemometric Relationships

UV-Vis Analysis Workflow

Chemometric Modeling Relationships

Essential Research Reagents and Materials

Table 2: Essential Research Reagent Solutions for UV-Vis Analysis of Syrups

| Reagent/Material | Specification | Function in Analysis | Application Notes |

|---|---|---|---|

| Pharmaceutical Reference Standards | USP/EP grade, ≥98% purity | Primary calibration standards | Essential for method development and validation |

| HPLC-grade Water | Resistivity ≥18 MΩ·cm | Solvent for aqueous preparations | Minimizes UV-absorbing impurities |

| Methanol/Acetonitrile | HPLC grade, UV cutoff <210 nm | Organic solvent for less polar compounds | Suitable for compound extraction |

| Buffer Salts | Analytical grade (e.g., phosphate, acetate) | pH control for ionization stability | Critical for pH-dependent chromophores |

| Quartz Cuvettes | 1 cm pathlength, spectral range 200-2500 nm | Sample containment for spectral measurement | Must be matched for quantitative work |

| Syrup Base Matrix | Sugar-based and sugar-free formulations | Method development and validation | Accounts for matrix effects in real samples |

Advanced Applications and Methodologies

Three-Way Analysis for Complex Matrices

For particularly challenging analytical scenarios involving complex syrup matrices, three-way analysis methods such as Parallel Factor Analysis (PARAFAC) can be employed. This advanced approach involves arranging UV-Vis spectroscopic data matrices as a three-way array (wavelength × sample × pH) and decomposing them into sets of trilinear components [16]. Each set of three components relates to spectral, pH, and relative concentration profiles of the active ingredients and sample matrix, enabling mathematical resolution of analyte signals even in the presence of significant interference [16].

This methodology has been successfully demonstrated for simultaneous quantification and pKa determination of colorants in energy drink formulations, suggesting potential applications in pharmaceutical syrup analysis where multiple active ingredients with acid-base characteristics are present [16]. The approach provides a powerful alternative to chromatographic methods while maintaining the cost and simplicity advantages of spectroscopic techniques.

Method Comparison and Selection Criteria

Table 3: Comparison of Analytical Techniques for Syrup Analysis

| Analytical Technique | Detection Capability | Analysis Time | Cost Considerations | Skill Requirements |

|---|---|---|---|---|

| UV-Vis Spectroscopy | 0.02-0.05 mg/mL | 5-10 minutes | Low instrument and operational costs | Moderate |

| HPLC with UV Detection | 0.01-0.05 mg/mL | 15-30 minutes | High instrument and consumable costs | High |

| Raman Spectroscopy | 0.05-0.1 mg/mL | 5-10 minutes | Moderate to high instrument costs | Moderate to High |

| LC-MS/MS | 0.001-0.01 mg/mL | 20-40 minutes | Very high instrument and operational costs | Very High |

The selection of an appropriate analytical method depends on the specific requirements of the analysis, including the required sensitivity, precision, available resources, and sample throughput needs. UV-Vis spectroscopy with chemometric analysis represents an optimal balance between performance characteristics and practical considerations for routine quality control applications in pharmaceutical syrup analysis [23] [24].

Developing Robust UV-Vis Methods for Multi-Component Syrup Analysis

Systematic Sample Preparation Protocols for Syrup Matrices

Sample preparation is a critical preliminary step in the analytical process, ensuring that raw syrup samples are converted into a state suitable for accurate and reliable analysis [25]. For syrup matrices—complex, viscous, and sugar-rich substances—systematic preparation is paramount to overcome challenges such as high sugar content, potential interferents, and variable viscosity, which can significantly impact the results of downstream analytical techniques like UV-Vis spectroscopy [3] [26]. This document outlines standardized protocols for the preparation of syrup matrices, specifically tailored for concentration verification using UV-Vis methods within pharmaceutical and food research contexts. The primary goal is to enable researchers to achieve high accuracy, reproducibility, and sensitivity in their analyses by controlling for matrix effects and isolating target analytes effectively [27] [25].

Fundamental Challenges in Syrup Matrix Preparation

Syrup matrices present unique challenges that necessitate specialized preparation protocols. Their high sugar content, often around 70% (w/w) of monosaccharides like glucose and fructose, can interfere with analysis by increasing viscosity and contributing to matrix effects during ionization in mass spectrometry or by causing spectral interferences in UV-Vis spectroscopy [3] [26]. The inherent viscosity of syrups complicates sample handling, pipetting, and homogenization, potentially leading to inaccuracies in aliquot measurements [25]. Furthermore, syrups often contain a complex mixture of organic acids, enzymes, polyphenols, and other solid particles that may co-extract with the target analytes, necessitating efficient clean-up steps to avoid inaccurate quantification [3] [28]. Addressing these challenges requires a methodical approach to sample preparation to ensure that the analyte of interest is effectively isolated and concentrated while interfering components are removed.

Sample Preparation Techniques for Syrup Matrices

Matrix-Induced Sugaring-Out Centrifugation

Principle: This technique exploits the high natural sugar content of the syrup itself to induce phase separation when mixed with an acetonitrile (ACN)-water mixture [26]. The sugars "force out" the ACN from the aqueous solution, forming a two-phase system. Target analytes partition into the upper ACN-rich phase, while sugars and other highly polar matrix components remain in the lower aqueous phase [26].

Optimized Protocol:

- Weighing: Accurately weigh 2 g of homogenized syrup sample into a suitable centrifuge tube.

- Solvent Addition: Add 4 mL of an ACN-water mixture (60:40, v/v) to the tube.

- Vortexing: Vigorously vortex the mixture for 1-2 minutes to ensure complete homogenization and interaction between the syrup and solvent.

- Centrifugation: Centrifuge the mixture at 4000-5000 rpm for 5-10 minutes to facilitate clear phase separation.

- Collection: Carefully collect the upper ACN-rich layer using a micropipette, avoiding disturbance of the lower aqueous phase or any interphase precipitate.

- Analysis: The collected extract can be directly injected into an HPLC system or diluted as needed for UV-Vis analysis [26].

Critical Parameters: The ACN-to-water ratio and the sample-to-solvent ratio are crucial for optimal recovery. A 60:40 (v/v) ACN-water ratio with a 1:2 (w/v) sample-to-solvent ratio has been demonstrated to provide high recovery (over 91%) for various analytes, including neonicotinoid pesticides [26].

Solvent Extraction with Ultrasonication

Principle: This method uses solvent polarity and ultrasonic energy to enhance the extraction efficiency of target compounds from the viscous syrup matrix. Ultrasonication creates cavitation bubbles that disrupt the matrix, improving analyte transfer into the solvent [28].

Optimized Protocol:

- Weighing: Accurately weigh a representative sample of syrup (e.g., 1-2 g) into a volumetric flask or centrifuge tube.

- Solvent Addition: Add an appropriate extraction solvent. Common choices include:

- Sonication: Sonicate the mixture in an ultrasonic water bath for 15-20 minutes at ambient temperature.

- Centrifugation: Centrifuge the sonicated mixture to pellet any insoluble debris.

- Collection & Dilution: Collect the supernatant and perform necessary dilutions with the same solvent to bring the analyte concentration within the linear range of the UV-Vis spectrophotometer [28] [30].

Critical Parameters: The choice of solvent, sample-to-solvent ratio (e.g., 1:2 w/v is often effective), and sonication time are key factors that require optimization based on the analyte's polarity and the specific syrup matrix [28].

Dilution and Filtration (Dilute-and-Shoot)

Principle: This is the simplest preparation technique, involving the dilution of the syrup in a compatible solvent to reduce matrix viscosity and concentration, followed by filtration to remove particulate matter [27] [25]. It is most suitable for high-concentration analytes or when matrix effects are minimal.

Optimized Protocol:

- Dilution: Dilute the syrup sample directly with a solvent such as 0.1 N HCl, purified water, or the HPLC mobile phase [27] [30]. The dilution factor must be optimized to fall within the instrument's calibration range while minimizing matrix interference.

- Vortexing: Mix thoroughly to ensure homogeneity.

- Filtration: Pass the diluted solution through a 0.45 μm (or 0.22 μm) membrane syringe filter to remove any particulates that could clog instrumentation or cause light scattering in UV-Vis analysis [25].

- Analysis: The filtrate is directly analyzed.

Critical Parameters: This method offers minimal matrix removal. Its success is highly dependent on the dilution factor and the complexity of the syrup. It is best applied to relatively simple syrup matrices or for quick, routine analyses where high sensitivity is not required [27].

Table 1: Comparison of Sample Preparation Techniques for Syrup Matrices

| Technique | Principle | Best For | Advantages | Limitations |

|---|---|---|---|---|

| Matrix-Induced Sugaring-Out [26] | Phase separation driven by high sugar content | HPLC/LC-MS analysis of pesticides, phenolic compounds | Simple, rapid, no added salts required, utilizes inherent matrix property | Limited to ACN-based extractions, may not suit all analytes |

| Solvent Extraction with Ultrasonication [28] | Solvent partitioning enhanced by ultrasonic energy | Metabolomics, extraction of polyphenols, broad-range profiling | Good for a wide range of polar metabolites, improves extraction yield | Requires optimization of solvent and time |

| Dilution and Filtration [27] [30] | Reduction of viscosity and concentration via dilution | Quick quality control, high-potency APIs, simple matrices | Very fast, simple, low cost, minimal equipment | Minimal clean-up, high matrix effects possible, lower sensitivity |

Analytical Workflow for UV-Vis Concentration Verification

The following workflow integrates the sample preparation techniques described above with UV-Vis analysis, providing a logical pathway from sample receipt to data interpretation. This is particularly useful for verifying the concentration of an active pharmaceutical ingredient (API) in a syrup formulation.

Diagram 1: UV-Vis concentration verification workflow for syrup matrices.

The Scientist's Toolkit: Essential Reagents and Materials

Successful sample preparation requires high-quality materials and reagents. The following table details essential items for the protocols described in this document.

Table 2: Key Research Reagent Solutions and Essential Materials

| Item | Function/Application | Specification/Notes |

|---|---|---|

| Acetonitrile (ACN) | Primary extraction solvent for sugaring-out and ultrasonication; HPLC mobile phase component [29] [26]. | HPLC/LC-MS grade; ensures low UV background and minimal interference. |

| High-Purity Water | Diluent and solvent component; critical for mobile phase preparation and sample dilution [31] [30]. | Type I (18.2 MΩ·cm) from a Milli-Q or equivalent purification system. |

| Acid Additives (TFA, H₃PO₄) | Mobile phase modifiers to improve chromatographic peak shape and separation [29] [31]. | Use at low concentrations (e.g., 0.1%); pH adjustment can enhance stability and recovery [28]. |

| Syringe Filters | Removal of particulate matter from diluted or extracted samples prior to HPLC or UV-Vis injection [25]. | 0.45 μm or 0.22 μm pore size; nylon or PTFE membrane, compatible with organic solvents. |

| Internal Standard (IS) | Corrects for analyte loss during preparation and instrument variability; crucial for robust quantification [31] [27]. | Stable isotope-labeled (SIL-IS) is ideal; should be added at the beginning of sample prep [27]. |

| MK-8527 | MK-8527, MF:C13H13ClN4O3, MW:308.72 g/mol | Chemical Reagent |

| BRD1401 | BRD1401, MF:C17H17N5O3, MW:339.3 g/mol | Chemical Reagent |

Advanced Spectrophotometric Resolution Techniques

For syrup formulations containing multiple active ingredients with overlapping UV spectra, advanced mathematical techniques can resolve the individual components without physical separation.

Independent Concentration Extraction (ICE)

Principle: ICE is a novel spectrophotometric method that extracts the concentration of two analytes (e.g., M and N) with severely overlapped spectra directly from their binary mixture using a series of mathematical operations on the ratio spectra [32].

Protocol Workflow:

- Record Spectra: Obtain the zero-order UV spectra of the binary mixture (M+N) and the normalized spectrum of one of the pure components (e.g., N).

- Divide: Divide the mixture spectrum by the normalized spectrum of N. This creates a ratio spectrum.

- Calculate Difference and Sum: In the ratio spectrum, measure the amplitudes (P) at two carefully selected wavelengths (λ1 and λ2). Calculate both the difference (ΔP) and the sum (∑P) of these amplitudes.

- Construct Calibration: Using pure M standards, divided by the normalized spectrum of N, establish a regression equation that correlates ΔP to the summed amplitude for M.

- Extract Concentration: For the unknown mixture, use the measured ΔP and ∑P values in the regression equation to first find the concentration of M. The concentration of N can then be found by back-calculation [32].

Diagram 2: ICE methodology for resolving overlapped UV spectra.

Method Validation and Quality Control

Ensuring the reliability of the analytical method is as important as the preparation itself. Key validation parameters for UV-Vis methods include [31] [30]:

- Linearity: The calibration curve should demonstrate a direct proportional relationship between absorbance and concentration. A correlation coefficient (R²) of ≥0.999 is typically expected [30].

- Precision: Expressed as %RSD, both repeatability (intra-day) and intermediate precision (inter-day, different analysts) should be less than 2% [30].

- Accuracy: Determined by recovery studies, where a known amount of standard is added to the sample. Recoveries should be within 98-102% [31] [30].

- LOD and LOQ: The Limit of Detection and Limit of Quantification define the sensitivity of the method. For example, in a validated method for caffeine, LOD and LOQ were found to be 0.55 μg/mL and 1.66 μg/mL, respectively [30].

Routine quality control should include the analysis of blanks, calibration standards, and quality control samples at low, medium, and high concentrations with each batch to monitor performance [27].

In the context of developing a robust UV-Vis method for concentration verification in syrups, the optimization of the mobile phase is a critical step. This process ensures sufficient selectivity and resolution for accurate quantification of active pharmaceutical ingredients (APIs) and the detection of potential adulterants [3]. The mobile phase's composition, pH, and flow rate directly influence the separation efficiency, peak shape, and analysis time in reversed-phase high-performance liquid chromatography (RP-HPLC), which is often coupled with UV-Vis detection for method verification [33] [31].

For the analysis of syrups, which are complex matrices often containing sugars, preservatives, and active compounds, a meticulously optimized method is paramount to overcome challenges related to co-elution and interference. This application note provides detailed protocols and data for developing and validating such methods, framed within a broader research thesis on UV-Vis concentration verification.

The Influence of Mobile Phase pH

The pH of the mobile phase is a paramount parameter in RP-HPLC, as it can profoundly affect the ionization state of analytes, thereby influencing their retention and the overall selectivity of the separation.

Mechanism of pH Impact

For ionizable compounds, a pH value near the analyte's pKa can lead to peak tailing and inconsistent retention. Controlling the pH using buffers ensures that the analytes are in a single, predictable state (either ionized or non-ionized), leading to symmetrical peaks and reproducible retention times [33] [31]. The pH also affects the residual silanols on the stationary phase surface, which can cause secondary interactions with basic analytes if not properly controlled [34].

Quantitative Data on pH Optimization

Table 1: Effect of Mobile Phase pH on Resolution Factor (Râ‚›) and Analysis Time [33]

| Acetic Acid (%) | pH Value | Resolution Factor (Râ‚›) | Total Elution Time (min) |

|---|---|---|---|

| 0.0 | 7.0 | 0.79 | 8.5 |

| 0.5 | 4.0 | 1.92 | 6.0 |

| 1.0 | 3.5 | 1.98 | 5.5 |

| 1.5 | 3.2 | 1.99 | 5.3 |

| 2.0 | 3.0 | 2.00 | 5.3 |

Data from a study optimizing the separation of phenolic compounds (BHA, BHT, and OMC) demonstrates that decreasing the pH from 7.0 to 3.5 significantly improved the resolution factor between critical pairs (e.g., BHT and OMC) while simultaneously reducing the total analysis time [33]. A pH of 3.5 provided an optimal compromise, achieving excellent resolution (Râ‚› > 1.5) with a short run time.

Optimization of Mobile Phase Composition

Solvent Selectivity

The choice of organic modifier is crucial for adjusting selectivity. Solvents can be categorized into selectivity groups based on their properties (e.g., proton-acceptor, proton-donor, dipole-interaction). If a solvent from one group does not provide sufficient selectivity, choosing a solvent from a distant group on the selectivity triangle is more likely to succeed than choosing one from the same group [34].

Isocratic vs. Gradient Elution

- Isocratic Elution: Uses a constant mobile phase composition throughout the run. It is simpler but may be inadequate for complex mixtures with a wide range of analyte polarities [34].

- Gradient Elution: Systematically increases the percentage of the strong solvent (e.g., acetonitrile or methanol) over time. This is essential for mixtures containing many components with varying polarities, as it improves peak shape for later-eluting compounds, enhances overall resolution, and reduces run time [34].

Experimental Protocols

Protocol 1: Systematic pH Scouting

This protocol is designed to empirically determine the optimal pH for separation.

- Objective: To evaluate the impact of pH on resolution and retention time for target analytes in a syrup matrix.

- Materials:

- HPLC system with UV-Vis detector

- C18 column (e.g., 250 mm x 4.6 mm, 5 µm)

- Stock solutions of target analytes and internal standard

- Acids/Buffers: Orthophosphoric acid, acetic acid, ammonium formate/acetate

- Organic solvent: HPLC-grade acetonitrile

- Syrup sample, blank placebo formulation

- Procedure:

- Prepare a mobile phase with a fixed organic-to-aqueous ratio (e.g., 60:40 Acetonitrile:Buffer) [31].

- Prepare a series of aqueous buffer phases at different pH levels (e.g., 3.0, 3.5, 4.0, 4.5, 7.0). Adjust pH using acids like orthophosphoric acid [31] or acetic acid [33].

- Filter and degas all mobile phases.

- Inject the standard mixture and sample at each pH condition.

- Measure critical parameters: resolution between the closest-eluting peaks, retention factor (k) of the first and last peaks, tailing factor, and analysis time.

- Data Analysis: Plot resolution and analysis time against pH. Select the pH that provides a resolution >1.5 for all critical pairs with the shortest possible analysis time [33].

Protocol 2: Optimization of Mobile Phase Ratio and Flow Rate

- Objective: To fine-tune the organic modifier percentage and flow rate for optimal efficiency.

- Materials: As in Protocol 1.

- Procedure:

- At the optimal pH determined in Protocol 1, prepare mobile phases with the organic solvent concentration varying in 5% increments (e.g., 50%, 55%, 60%).

- Analyze the standard mixture at each composition.

- For the optimal composition, further optimize the flow rate, testing values around 0.8 mL/min to 1.2 mL/min [33] [31].

- Data Analysis: The goal is to achieve all retention factors (k) between 2 and 10. The final flow rate should provide good efficiency without generating excessive backpressure.

The following workflow summarizes the strategic approach to mobile phase and pH optimization:

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagent Solutions for Mobile Phase and Sample Preparation

| Item | Function / Role in Method Development |

|---|---|

| Orthophosphoric Acid / Acetic Acid | Used to adjust the pH of the aqueous mobile phase to suppress analyte ionization and improve peak shape [33] [31]. |

| Ammonium Acetate / Formate Buffers | Provides buffering capacity at specific pH ranges (e.g., 3.5-5.5) for highly reproducible separations, especially in LC-MS. |

| HPLC-Grade Acetonitrile & Methanol | Common organic modifiers for reversed-phase chromatography; choice affects selectivity, viscosity, and UV cutoff [33] [31]. |

| Internal Standard (e.g., Dexibuprofen) | A compound added in a constant amount to samples and standards to correct for variability in injection volume and sample processing [31]. |

| n-Hexane | Used in sample preparation for the removal of non-polar interferents (e.g., lipids, oils) from complex matrices like syrups or creams [33]. |

| Propeptin | Propeptin, MF:C113H142N26O27, MW:2296.5 g/mol |

| Ferrocin A | Ferrocin A, MF:C51H84FeN13O18, MW:1223.1 g/mol |

Method Validation and Application in Syrup Analysis

Once the mobile phase and pH are optimized, the method must be validated. Key parameters include:

- Linearity: A coefficient of determination (r²) > 0.99 is typically required over the intended concentration range [31].

- Precision: Both repeatability (intra-day) and intermediate precision (inter-day) should demonstrate a relative standard deviation (RSD) of less than 2% [31].

- Accuracy: Recovery studies should yield results between 98% and 102% for the target concentration [31].

- Specificity: The method must be able to distinguish the analyte from placebo components and known degradation products, a critical aspect for syrup analysis where excipients can interfere [3] [31].

In the context of syrup analysis, this optimized and validated HPLC-UV method can be applied not only for the quantification of APIs like Ambroxol hydrochloride [31] but also for authenticity testing. For instance, UV-Vis spectral fingerprints combined with chemometric tools can detect and quantify adulteration of honey with sugar syrups [3].

The verification of active ingredient concentrations in syrup formulations is a critical quality control step in the pharmaceutical industry, as well as a common challenge in food authenticity research. Traditional methods, such as high-performance liquid chromatography (HPLC), though highly accurate, are often time-consuming, require extensive sample preparation, and involve costly instrumentation and specialized personnel [11] [35]. Within this context, Ultraviolet-Visible (UV-Vis) spectroscopy emerges as a powerful, cost-effective, and rapid alternative. However, the analysis of syrups—complex mixtures containing active components, flavors, dyes, and preservatives—presents a challenge due to significant spectral overlapping of the individual constituents [35].

To overcome this limitation, the implementation of chemometric tools is essential. Principal Component Analysis (PCA) and Partial Least Squares (PLS) Regression are multivariate statistical methods that unlock the quantitative potential of UV-Vis spectroscopy for complex mixtures. PCA simplifies complex spectral data sets by identifying patterns and reducing the number of variables while preserving critical information, allowing for the visual grouping of samples based on their composition [11] [35]. Subsequently, PLS regression establishes a mathematical model between the spectral data (X-variables) and the concentration of the analytes (Y-variables), enabling the precise simultaneous quantification of multiple components despite the absence of well-resolved peaks [11] [14].

This protocol details the application of PCA and PLS regression to UV-Vis spectral data for the multicomponent analysis of syrups, providing a robust framework for concentration verification in pharmaceutical and food research.

Theoretical Foundation

Principal Component Analysis (PCA)

PCA is a dimensionality-reduction technique used to extract the most critical information from a complex, multidimensional dataset. In spectroscopic analysis, it transforms the original, often collinear, absorbance variables into a new set of orthogonal variables called Principal Components (PCs). The first PC captures the greatest possible variance in the data, with each succeeding component capturing the next highest variance. This process allows researchers to visualize dominant patterns, identify natural sample groupings (clusters), and detect outliers in a reduced dimensional space, often using 2D or 3D scores plots [11].

Partial Least Squares (PLS) Regression

PLS regression is a supervised chemometric technique that relates the variations in a spectral matrix (X) to the variations in a concentration matrix (Y). Unlike PCA, which only considers the X-data, PLS explicitly models the relationship between X and Y. It finds latent variables in X that are most predictive of Y, maximizing the covariance between the two matrices. The resulting calibration model can then be used to predict the concentration of active ingredients in unknown samples based on their UV-Vis spectra [11] [14]. The model's performance is typically evaluated using the coefficient of determination (R²) and the Root Mean Square Error of Prediction (RMSEP), which indicate its predictive accuracy and precision [14].

Experimental Protocols

Sample Preparation Protocol

Pharmaceutical Syrup Active Components

- Stock Solution Preparation: Accurately weigh reference standards of the target active ingredients (e.g., acetaminophen, guaifenesin, dextromethorphan HBr). Dissolve each in an appropriate solvent, typically the same flavored oral syrup vehicle used in the commercial drug product, to create concentrated stock solutions [35].

- Calibration Set: Prepare a series of standard mixtures according to an experimental design (e.g., Central Composite Design). This ensures that the concentration ranges of all components are varied systematically to build a robust model. The design should cover the expected concentration range of each analyte and include a suitable number of samples (e.g., 15 mixtures for three components) [14].

- Validation Set: Prepare an independent set of standard mixtures with known concentrations that are not used in the model calibration. This set is used to validate the predictive ability of the final PLS model [14].

Food Syrup Adulteration Analysis

Instrumentation and Spectral Acquisition

- Equipment: Standard UV-Vis spectrophotometer equipped with 1 cm quartz cuvettes [10] [14].

- Parameters:

- Wavelength Range: 200 - 400 nm (can be extended into the visible region if colored compounds are present) [10] [14].

- Spectral Resolution: 1 nm [10].

- Blank/Baseline: Use the appropriate solvent or unadulterated base syrup matrix for baseline correction [10].

- Replication: Record spectra in triplicate for each sample to ensure reproducibility [10].

Data Preprocessing and Chemometric Analysis

- Data Preprocessing: Export the absorbance data for all samples and wavelengths. Common preprocessing steps include:

- Averaging of replicate spectra.

- Baseline Correction to remove instrumental offsets.

- Smoothing (e.g., Savitzky-Golay) to reduce high-frequency noise [10].

- Chemometric Modeling:

- Exploratory Analysis with PCA: Input the preprocessed spectral matrix (samples × wavelengths) into a PCA algorithm. Examine the scores plot to identify trends, clusters, or outliers related to concentration or adulteration levels [11] [36].

- Quantitative Model with PLS:

- Split the data into calibration and validation sets.

- Construct a PLS regression model using the calibration set's spectra and known concentrations.

- Use cross-validation (e.g., leave-one-out) to determine the optimal number of latent variables to prevent overfitting.

- Validate the model by predicting the concentrations in the independent validation set and calculating performance metrics (R², RMSEP) [11] [14].

The following workflow summarizes the key steps from sample preparation to final quantification:

Application Data & Performance

The following tables summarize exemplary quantitative data from published studies utilizing UV-Vis spectroscopy coupled with PLS regression for multicomponent analysis.

Table 1: Performance of UV-Vis/PLS in Pharmaceutical Syrup Analysis [35]

| Active Pharmaceutical Ingredient | Accuracy (%) | Linearity (R²) | Detection Limit (mg/mL) |

|---|---|---|---|

| Acetaminophen | 88 - 94 | > 0.9784 | 0.02 |

| Guaifenesin | 88 - 94 | > 0.9784 | 0.02 |

| Dextromethorphan HBr | 88 - 94 | > 0.9784 | Not Specified |

| Phenylephrine HCl | 88 - 94 | > 0.9784 | Not Specified |

Table 2: Analysis of Drug Mixtures using Multivariate Calibration [14]

| Drug | Optimal Model | RMSEP (mg/L) | LOD (mg/L) |

|---|---|---|---|

| Theophylline | PCR | 0.173 | 0.03 |

| Montelukast | PLS1 | 0.187 | 0.05 |

| Loratadine | HLA | 0.251 | 0.05 |

Table 3: Honey Adulteration Detection with UV-Vis and Machine Learning [36]

| Adulterant Syrup | Detection Level | Analytical Technique | Key Metric |

|---|---|---|---|

| Corn Syrup | > 10% | UV-Vis & ANN | Successful Identification |

| Inverted Syrup | > 10% | UV-Vis & ANN | Successful Identification |

| Fruit Syrup | > 10% | UV-Vis & ANN | Successful Identification |

The Scientist's Toolkit

Table 4: Essential Research Reagents and Materials

| Item | Function / Specification |

|---|---|

| Analytical Reference Standards | High-purity active ingredients (e.g., acetaminophen ≥99%) for preparing accurate calibration curves [10] [35]. |

| Flavored Syrup Vehicle | A placebo matrix identical to the commercial product's base, ensuring realistic analysis conditions [35]. |