UV-Vis Spectroscopy in QC Labs: From Fundamentals to Advanced Applications in Pharmaceutical Analysis

This article explores the critical role of UV-Vis spectroscopy as a robust, versatile, and cost-effective analytical tool in quality control laboratories, with a specific focus on pharmaceutical development.

UV-Vis Spectroscopy in QC Labs: From Fundamentals to Advanced Applications in Pharmaceutical Analysis

Abstract

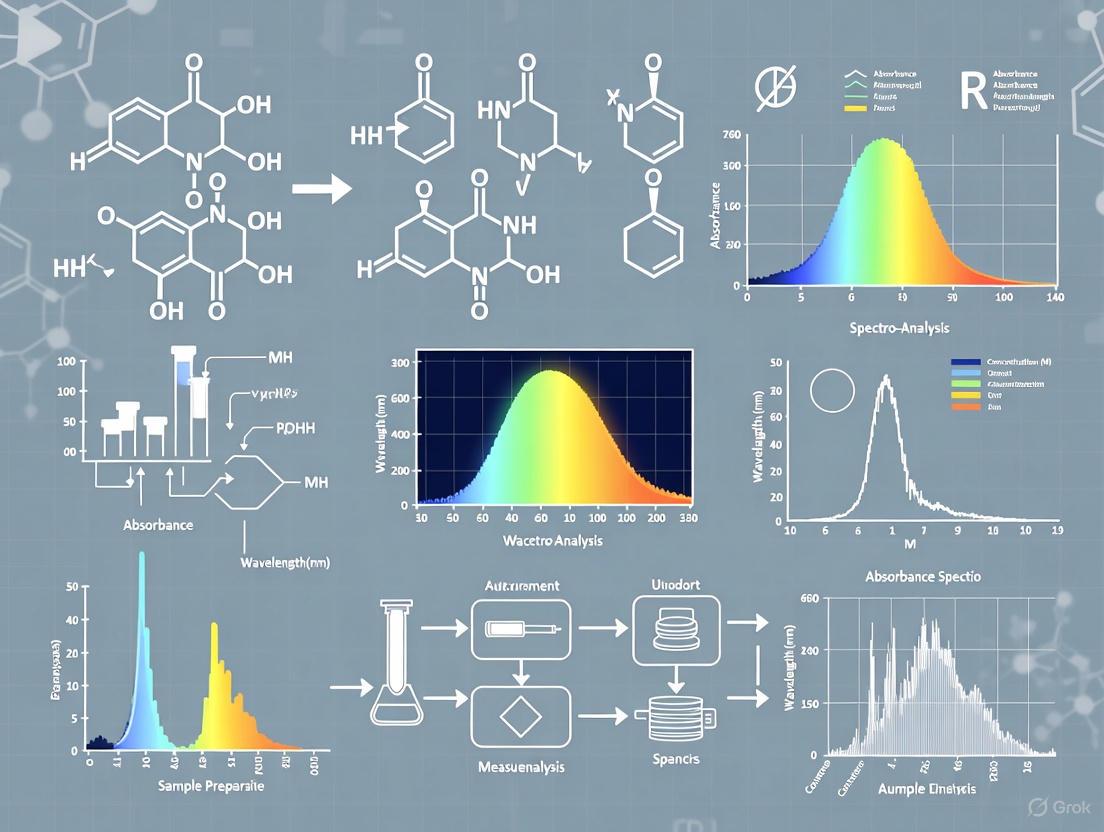

This article explores the critical role of UV-Vis spectroscopy as a robust, versatile, and cost-effective analytical tool in quality control laboratories, with a specific focus on pharmaceutical development. It covers foundational principles and the evolving capabilities of modern UV-Vis systems, including their integration with chemometrics for spectralprint analysis. The scope extends to detailed methodological applications for drug stability testing, content uniformity, and in-line process monitoring. Practical guidance is provided for troubleshooting common instrumental and sample-related issues, alongside a rigorous framework for method validation and comparative analysis with techniques like HPLC, ensuring compliance with ICH guidelines and alignment with Analytical Quality by Design (AQbD) principles for real-time release testing.

UV-Vis Fundamentals: Core Principles and the Modern Spectralprint Revolution

In the landscape of analytical chemistry, few principles are as fundamentally indispensable to quality control and research laboratories as the Beer-Lambert Law. This law establishes the foundational relationship between the absorption of light and the properties of the material through which the light is traveling, thereby enabling precise quantitative analysis of solutions [1] [2]. Within pharmaceutical drug development, environmental monitoring, and food and beverage quality control, this principle underpins the critical spectroscopic methods used to ensure product safety, efficacy, and compliance [3] [4].

The core utility of the Beer-Lambert Law lies in its ability to determine the concentration of an analyte in a solution by measuring its absorbance at a specific wavelength [1]. This guide will revisit the law's principles, detail experimental protocols for its application, explore modern instrumentation, and discuss its vital role and limitations within the context of a modern quality control laboratory.

Theoretical Foundations of the Beer-Lambert Law

Core Principles and Mathematical Formulation

The Beer-Lambert Law (also known as Beer's Law) describes a linear relationship between the absorbance of light by a substance and its concentration. The modern formulation of the law is expressed as:

A = εcl

Where:

- A is the Absorbance (a dimensionless quantity) [2] [3].

- ε is the Molar Absorptivity (or molar extinction coefficient), with units typically of L·molâ»Â¹Â·cmâ»Â¹ [3]. This is a substance-specific constant that measures how strongly a chemical species absorbs light at a given wavelength [1].

- c is the Concentration of the absorbing species in the solution, expressed in mol·Lâ»Â¹ (M) [1] [3].

- l is the Path Length, which is the distance the light travels through the solution, typically measured in centimeters (cm) [3].

Absorbance itself is defined through the incident and transmitted light intensities [2]:

A = logâ‚â‚€(Iâ‚€/I)

Where:

- Iâ‚€ is the intensity of the incident light [1] [2].

- I is the intensity of the transmitted light after it has passed through the sample [1] [2].

This logarithmic relationship means that absorbance increases as transmittance decreases. Table 1 illustrates this inverse relationship and demonstrates how absorbance serves as a sensitive measure of light attenuation.

Table 1: Relationship Between Absorbance and Transmittance

| Absorbance (A) | Transmittance (T) | % Transmittance (%T) |

|---|---|---|

| 0 | 1 | 100% |

| 0.3 | 0.5 | 50% |

| 1 | 0.1 | 10% |

| 2 | 0.01 | 1% |

| 3 | 0.001 | 0.1% |

The Logical Workflow of Quantitative Analysis

The following diagram outlines the logical process of using the Beer-Lambert Law for quantitative analysis, from measurement to concentration determination.

Experimental Protocol: Establishing a Calibration Curve

The primary application of the Beer-Lambert Law in quality control is the creation of a calibration curve to determine the concentration of an unknown sample. The following protocol uses a standard solution, such as Rhodamine B or potassium permanganate, to demonstrate the process [1] [5].

Detailed Methodology

Preparation of Standard Solutions:

- Prepare a stock solution of the analyte with a accurately known concentration (e.g., 2 M) [5].

- Perform a serial dilution to create a series of standard solutions covering a range of concentrations from low to high (e.g., from 0.0001 M to 0.5 M). Ensure all dilutions are performed with volumetric glassware for accuracy [5].

Spectrophotometer Setup and Measurement:

- Turn on the UV-Vis spectrophotometer and allow the lamp to warm up for the time specified by the manufacturer (typically 15-30 minutes).

- Select the appropriate wavelength

λ_maxfor the analyte. This is the wavelength of maximum absorption, which can be determined from a preliminary full-wavelength scan [1]. - Using a cuvette with a known path length (typically 1 cm), fill it with the pure solvent (the "blank") and measure its absorbance to zero the instrument.

- Rinse the cuvette with a small portion of the first standard solution. Then, fill the cuvette with the solution, ensure the clear optical faces are free of smudges or bubbles, and place it in the sample compartment.

- Record the absorbance value at

λ_max. Repeat this measurement for each standard solution in the series [1] [5].

Calibration Curve Generation and Analysis:

- Plot the recorded absorbance values (y-axis) against the corresponding known concentrations (x-axis) for all standard solutions.

- Perform a linear regression analysis on the data points to obtain the equation of the best-fit line, which typically takes the form y = mx + b, where

mis the slope andbis the y-intercept. In an ideal system, the slope is equal toεland the intercept is zero [1]. - Finally, measure the absorbance of the unknown sample under the same instrumental conditions. Use the calibration curve equation to calculate its concentration by substituting the measured absorbance for

yand solving forx(concentration).

The Scientist's Toolkit: Essential Materials and Reagents

Table 2: Key Research Reagent Solutions and Essential Materials

| Item Name | Function / Explanation |

|---|---|

| UV-Vis Spectrophotometer | Instrument used to measure the absorption of light by the sample. Modern versions offer touchscreen interfaces and pre-programmed methods for ease of use [6]. |

| Cuvette | The sample container, typically with a 1 cm path length, that holds the solution during analysis. It must be transparent to the wavelengths of light being used [1]. |

| Analytical Grade Solvent (e.g., Water) | A high-purity solvent to dissolve the analyte without introducing interfering absorbances in the UV-Vis range [5]. |

| Primary Standard (Analyte) | A high-purity reference material of the analyte (e.g., potassium permanganate, Rhodamine B) used to prepare the stock solution of known, accurate concentration [1] [5]. |

| Volumetric Flasks and Pipettes | Precision glassware required for accurately preparing standard solutions via serial dilution to ensure the integrity of the calibration curve [5]. |

| Holmium Glass Filter | A reference material used for wavelength accuracy verification of the spectrophotometer, ensuring the instrument is free from instrumental errors before analysis begins [5]. |

| ML364 | ML364, MF:C24H18F3N3O3S2, MW:517.5 g/mol |

| Thioacetamide | Thioacetamide, CAS:65680-21-9, MF:C2H5NS, MW:75.14 g/mol |

The experimental workflow for this protocol is systematic and can be visualized as follows:

The Beer-Lambert Law in Modern Quality Control Laboratories

Applications in Pharmaceutical and Industrial Settings

The Beer-Lambert Law is the workhorse for quantitative analysis in regulated environments.

- Pharmaceutical Analysis: It is critical for drug discovery, development, and quality control (QC). Applications include raw material identification, dissolution testing, impurity quantification, and verifying the concentration of active pharmaceutical ingredients (APIs) to ensure they meet stringent global pharmacopoeia standards (USP, Eur. Ph., JP) [7] [4]. Modern systems are designed for full compliance with electronic record-keeping regulations like 21 CFR Part 11 [7].

- Food and Beverage QC: Used to measure the concentration of specific ingredients, such as caffeine, and to ensure that additives like food dyes are within safe legal limits, complying with labeling acts [3] [4].

- Environmental Monitoring: Enables the detection and quantification of pollutants in water and air, such as heavy metals and organic compounds, supporting public health safety and sustainability goals [8] [3] [4].

- Biomolecule Analysis: A standard method for quickly verifying the purity and concentration of DNA and RNA samples, which is a crucial step in genetic research and sequencing preparation [4].

Evolution of UV-Vis Instrumentation

The principles of the Beer-Lambert Law remain constant, but the instrumentation for measuring absorbance has evolved significantly to better serve the needs of modern labs.

- Enhanced Usability: Modern instruments feature intuitive touchscreen interfaces, guided workflows, and pre-programmed methods. This reduces training time and minimizes user error, making them accessible to multidisciplinary teams in fast-paced environments [6].

- Improved Efficiency and Footprint: To maximize valuable bench space, newer spectrophotometers are designed with a smaller footprint without compromising performance. They also feature faster scan speeds and higher throughput to meet the demands of labs processing dozens or hundreds of samples daily [6].

- Connectivity and Compliance: Integration with digital lab ecosystems is now a priority. Features like SD card slots, PC software connectivity, and client-server architectures streamline data management, ensure traceability, and support compliance with electronic record-keeping requirements in regulated industries [6] [7].

Limitations and Advanced Considerations

Despite its widespread utility, the Beer-Lambert Law is an idealization, and users must be aware of its limitations to avoid inaccurate results.

Known Deviations and Pitfalls

Deviations from the expected linear relationship between absorbance and concentration can arise from several factors:

- Fundamental (Real) Deviations: At high concentrations (>0.01 M), the average distance between absorbing molecules decreases, leading to electrostatic interactions (e.g., dimerization) that can alter the molar absorptivity

ε. Furthermore, the refractive index of the solution changes with concentration, which can cause a non-linear dependence of absorbance on concentration [9] [5]. - Chemical Deviations: Changes in the chemical environment of the analyte, such as variations in pH, temperature, or solvent composition, can shift the chemical equilibrium. This may result in the formation of species with different absorption spectra, leading to apparent deviations from Beer's Law [5] [3].

- Instrumental Deviations: The use of polychromatic light (as opposed to truly monochromatic light), stray light within the spectrometer, or misalignment of the sample cell can all cause measurable deviations from the ideal linear relationship [9] [5].

Beyond the Classical Law: An Electromagnetic Framework

The classical Beer-Lambert Law does not fully account for the wave nature of light and its interaction with matter as described by electromagnetic theory. Recent research has developed a unified electromagnetic framework that extends the law, particularly to address fundamental deviations at high concentrations [9] [5].

This advanced model incorporates the complex refractive index, where the imaginary component k is related to absorption. It accounts for the fact that the refractive index n itself has a concentration dependence. The model expands this dependence into a polynomial:

k ≈ βc + γc² + δc³

Substituting this into the derivation of the absorption law leads to a modified expression for absorbance [5]:

A = [4πν / ln10] (βc + γc² + δc³) l

Where β, γ, and δ are refractive index coefficients. This model has demonstrated superior performance with a lower root mean square error (RMSE) for various solutions at high concentrations compared to the classical law, offering a path toward more accurate quantitative measurements in complex systems [5].

The Beer-Lambert Law remains an indispensable pillar of quantitative analysis in UV-Vis spectroscopy. Its elegant simplicity provides a direct and powerful means to determine analyte concentrations, forming the bedrock of protocols in pharmaceutical development, quality control, and environmental monitoring. While users must be mindful of its limitations and the conditions that can lead to deviations, the law's core principle is as relevant as ever. Ongoing research into its electromagnetic foundations and the continuous evolution of instrumentation towards greater efficiency, connectivity, and usability ensure that the Beer-Lambert Law will continue to be a vital tool for scientists and researchers, enabling precise and reliable measurements that drive innovation and ensure quality in the modern laboratory.

Ultraviolet-Visible (UV-Vis) spectroscopy has undergone a profound transformation, evolving from bulky, slow laboratory instruments to sophisticated systems that offer unprecedented speed, portability, and integration. In quality control (QC) laboratories, particularly within the demanding pharmaceutical and biotechnology sectors, this evolution is not merely a matter of convenience but a critical enhancement of capability. The shift from traditional scanning monochromators to photodiode array (PDA) detectors and the emerging frontier of portable sensors represent pivotal advances. These technologies are redefining the roles of researchers and scientists, enabling faster release times, more robust data integrity, and novel analytical approaches in drug development. This guide examines the technical principles of these modern instruments, their practical applications in regulated environments, and the future trajectory of spectroscopic analysis.

The Technological Shift: From Scanning to Simultaneous Detection

The fundamental difference between traditional and modern UV-Vis instrumentation lies in the mechanism of wavelength selection and detection.

Traditional Scanning Monochromators

Traditional instruments utilize a scanning monochromator, a device that employs a diffraction grating to isolate a single, narrow wavelength of light from a broad-spectrum source [10]. This single wavelength is passed through the sample, and the transmitted light intensity is measured by a detector, such as a photomultiplier tube (PMT). The monochromator then mechanically rotates the grating to step through the entire spectral range, building the spectrum one wavelength at a time [10]. While this method can produce high-resolution data, its primary limitation is speed, as the sequential nature of the measurement is inherently slow.

The Photodiode Array (PDA) Revolution

Photodiode Array (PDA) instruments, also known as diode array detectors, fundamentally reversed this process. Instead of using a monochromator before the sample, a PDA instrument passes polychromatic light (containing all wavelengths) through the sample simultaneously [11] [12]. The transmitted light is then dispersed onto a solid-state array containing hundreds of individual photodiode detectors. Each photodiode measures the intensity of a specific wavelength, capturing the entire UV-Vis spectrum (190-1100 nm) in under one second [11]. This simultaneous detection eliminates moving parts, enhancing mechanical robustness and reliability. A key application leveraging this speed is dissolution testing, where a single PDA instrument can analyze samples from multiple dissolution systems in a high-volume pharmaceutical QC lab [11].

Table 1: Comparison of UV-Vis Spectrophotometer Technologies

| Feature | Scanning Monochromator | Photodiode Array (PDA) | Modern Hybrid/Portable Systems |

|---|---|---|---|

| Detection Principle | Sequential wavelength measurement | Simultaneous full-spectrum acquisition | Varies (PDA or miniaturized components) |

| Speed | Slower, sequential scanning | Very fast (<1 sec per spectrum) [11] | Fast, designed for rapid analysis |

| Optical Path | Single or double beam [12] | Single beam, polychromatic light | Typically single beam |

| Mechanical Parts | Moving grating | Few to no moving parts [11] | Minimal moving parts |

| Primary Advantages | High wavelength accuracy, traditional robustness | Speed, stability, ruggedness [11] | Portability, connectivity, ease of use [13] |

| Typical QC Applications | Reference methods, high-precision quantitation | High-throughput dissolution, multi-component analysis [11] | Field-based QC, raw material verification, point-of-need testing |

Implementation in the Quality Control Laboratory

The adoption of modern UV-Vis instrumentation is driven by its ability to address specific, critical needs within the pharmaceutical quality control workflow.

Key Applications and Experimental Protocols

1. Drug Dissolution Testing Dissolution testing is a critical quality control procedure for solid oral dosage forms (e.g., tablets). PDA-based UV-Vis systems are ideally suited for this application due to their high speed and ability to perform multi-component analysis [11].

- Objective: To monitor the rate and extent of drug release from a dosage form in a dissolution medium over time.

- Materials & Reagents: Dissolution apparatus (paddles or baskets), dissolution medium (e.g., buffer at pH 1.2, 4.5, or 6.8), temperature-controlled UV-Vis spectrophotometer (e.g., PDA type), standard solutions of the Active Pharmaceutical Ingredient (API).

- Methodology:

- Dosage forms are placed in vessels containing a specified volume of dissolution medium, maintained at 37°±0.5 °C.

- At predetermined time intervals (e.g., 10, 20, 30, 45 minutes), aliquots are automatically withdrawn from the vessels.

- The aliquots are passed through a flow cell in the PDA spectrophotometer, which instantly captures the full spectrum.

- The concentration of the dissolved API is determined against a calibrated standard, often using multi-wavelength analysis to compensate for potential excipient or degradation product interference [11] [14].

- Data Analysis: The cumulative percentage of drug released is plotted versus time to generate a dissolution profile, which is compared to pharmacopeial standards (USP, EP, JP) for batch release.

2. Chemical Identification and Purity Assessment UV-Vis spectroscopy is a primary test for confirming the identity and purity of drug substances and products, as mandated by pharmacopeias like the United States Pharmacopeia (USP) [14].

- Objective: To verify the identity of an incoming raw material or finished product and assess its purity against a known standard.

- Materials & Reagents: UV-Vis spectrophotometer (validated for use in a GxP environment), high-quality quartz cuvettes, appropriate solvent (e.g., methanol, water), reference standard of the analyte.

- Methodology:

- A solution of the test sample is prepared at a specified concentration.

- The absorbance spectrum from 200 nm to 400 nm (or wider as required) is recorded.

- The sample spectrum is compared to a spectrum from a reference standard recorded under identical conditions.

- Data Analysis: Identification is confirmed if the sample's spectrum exhibits absorption maxima (λmax) and minima at the same wavelengths as the reference standard. Purity can be assessed by comparing the ratios of absorbances at different wavelengths or by applying spectral overlay software to check for anomalies [14].

3. Quantification of Impurities Many pharmaceutical monographs specify limits for related compounds or impurities that can be quantified using UV-Vis [14].

- Objective: To determine the concentration of a specific impurity in a drug substance.

- Materials & Reagents: Validated UV-Vis spectrophotometer, volumetric glassware, solvents, primary reference standard of the impurity.

- Methodology:

- A calibration curve is constructed using a series of standard solutions of the impurity at known concentrations.

- The absorbance of the test sample solution is measured at the wavelength of maximum absorbance (λmax) for the impurity.

- The concentration in the test sample is interpolated from the calibration curve.

- Data Analysis: The calculated concentration is compared to the established acceptance criterion. Software in modern instruments, such as Thermo Scientific Insight Pro, can automate this process and ensure data integrity and compliance with 21 CFR Part 11 regulations [14].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for UV-Vis Analysis in QC

| Item | Function & Importance |

|---|---|

| Pharmacopeial Reference Standards | Certified materials with known purity; essential for instrument qualification, method validation, and definitive identification/quantitation as per USP/EP/JP [14]. |

| High-Purity Solvents (HPLC Grade) | To prepare sample and standard solutions; minimizes UV-absorbing impurities that cause high background noise and inaccurate baseline. |

| Quartz Cuvettes | Sample holders that are transparent across the UV and visible range; required for accurate UV analysis below ~350 nm, where glass and plastic absorb light [10]. |

| Buffer Salts | For preparing dissolution media and mobile phases that mimic physiological conditions, ensuring consistent pH and ionic strength for robust analysis. |

| System Suitability Test Kits | Pre-made kits containing certified materials to verify critical instrument performance parameters (e.g., wavelength accuracy, photometric accuracy, stray light) before analytical runs [14]. |

| NVS-PAK1-C | NVS-PAK1-C, MF:C22H23ClF3N5O, MW:465.9 g/mol |

| Bivalirudin TFA | Bivalirudin TFA, MF:C100H139F3N24O35, MW:2294.3 g/mol |

The Future: Integration, Miniaturization, and Portable Sensors

The evolution of UV-Vis instrumentation continues to accelerate, focusing on connectivity and accessibility.

Integration with Digital Lab Ecosystems: Modern instruments are no longer standalone devices. They feature integrated data storage (e.g., SD cards) and connectivity options (USB, Ethernet) that allow for secure data handling, automatic backing up of results, and direct transfer to Laboratory Information Management Systems (LIMS) [13]. This connectivity is vital for maintaining data integrity and electronic records in compliance with regulatory standards.

The Rise of Portable and Handheld Spectrometers: A significant market trend is the miniaturization of spectroscopic equipment. The portable spectrometer market is projected to grow from $1.68 billion in 2020 to $4.07 billion by 2030, reflecting a compound annual growth rate of 9.1% [15]. These portable devices enable the laboratory to be brought to the sample, facilitating on-site raw material identification, in-process checks in manufacturing, and forensic analysis at the point of need [15]. This trend is supported by advances in solid-state light sources, miniature detectors, and battery technology.

The following workflow diagram illustrates the integrated and evolving role of modern UV-Vis spectroscopy in the quality control laboratory, from sample to decision-making.

The journey from photodiode arrays to portable sensors marks a significant leap forward for UV-Vis spectroscopy in quality control. PDA technology addressed the critical need for speed and stability in high-throughput environments like dissolution testing, while the ongoing shift toward miniaturization and connectivity is making analytical power more accessible and integrated than ever before. For researchers and drug development professionals, these advancements translate directly into enhanced efficiency, robust compliance, and more confident decision-making. As instrumentation continues to evolve, becoming faster, smaller, and more intelligent, its role as an indispensable pillar of the quality control laboratory is firmly secured.

In the landscape of quality control laboratories, particularly within pharmaceutical and biotechnology sectors, Ultraviolet-Visible (UV-Vis) spectroscopy has long been a fundamental tool for targeted quantitative analysis. Traditionally applied to determine the concentration of specific, known analytes via the Beer-Lambert law, this technique is undergoing a revolutionary transformation. The emergence of spectralprint analysis—a nontargeted approach that utilizes the entire UV-Vis spectrum as a unique fingerprint—represents a significant paradigm shift from single-analyte quantification to comprehensive sample characterization [16]. This evolution from a simple data provider to an advanced analytical sensor has been made possible through the essential support of chemometrics, which enables the extraction of meaningful chemical information from complex, overlapping spectral data [16] [17].

The driving force behind this transformation is multifaceted. Modern UV-Vis instrumentation, equipped with photodiode array detectors, can now generate complete spectra almost instantaneously, producing rich datasets that extend beyond a few discrete wavelengths [16]. Concurrently, increasing regulatory emphasis on comprehensive quality assessment, especially for complex formulations and biologics, demands techniques that can detect unexpected variations and impurities [18]. Within this context, spectralprint analysis fulfills a critical need by providing a holistic view of sample composition, enabling quality control researchers to identify subtle batch-to-batch differences, verify authenticity, and detect adulteration without prior knowledge of specific contaminants [16].

Theoretical Foundations: From Targeted to Nontargeted Analysis

Defining the Spectralprint Concept

A spectralprint is defined as the complete absorbance profile of a sample across the ultraviolet and visible wavelength range (typically 200–700 nm) [16]. Unlike traditional analysis that focuses on absorbance at specific wavelengths corresponding to target compounds, the spectralprint approach treats the entire spectrum as a unique pattern or fingerprint that characterizes the overall chemical composition of the sample [16] [17]. This comprehensive profile contains information about all chromophores present in the sample, including their identities, concentrations, and potential interactions, thereby encoding the complete light-absorbing signature of the material [16].

The theoretical basis for spectralprint analysis rests on several key principles. Each chemical compound with chromophoric groups exhibits a characteristic absorption pattern defined by band positions, intensities, and shapes [16]. In complex mixtures, these individual patterns overlap to form a composite spectrum that is unique to that specific combination of constituents [16]. While this overlapping traditionally presented challenges for quantification, chemometric tools now enable deconvolution and interpretation of these complex signals, transforming what was once considered interference into valuable multivariate information [16].

Comparative Framework: Targeted vs. Nontargeted Analysis

The transition from targeted to nontargeted analysis represents a fundamental shift in analytical philosophy and practice. The table below summarizes the key distinctions between these approaches in the context of UV-Vis spectroscopy.

Table 1: Comparison between Targeted and Nontargeted Analysis Approaches Using UV-Vis Spectroscopy

| Feature | Targeted Analysis | Nontargeted (Spectralprint) Analysis |

|---|---|---|

| Analytical Focus | Quantification of specific, known analytes | Comprehensive profiling of all chromophoric components |

| Data Utilization | Discrete wavelengths corresponding to target compounds | Entire spectral range (200-700 nm) |

| Information Output | Concentration of predefined compounds | Pattern recognition, classification, and multivariate calibration |

| Primary Applications | Content uniformity, assay, potency testing | Authenticity verification, batch consistency, adulteration detection |

| Chemometric Requirements | Minimal (often none) | Essential (multivariate calibration, pattern recognition) |

| Handling of Unknowns | Limited to no capability | Designed specifically for detecting unexpected variations |

| Regulatory Framework | Well-established | Emerging guidelines and validation approaches |

The Critical Role of Chemometrics

Chemometrics provides the mathematical foundation that enables the extraction of meaningful information from complex spectralprint data [16]. Without these multivariate tools, UV-Vis spectra of complex mixtures often present broad, overlapping bands that are difficult to associate with individual chromophores [16]. Key chemometric techniques employed in spectralprint analysis include:

- Spectral Preprocessing: Methods such as smoothing, normalization, and derivative spectroscopy that enhance spectral features and reduce irrelevant variation [16].

- Multivariate Calibration: Techniques including Principal Component Regression (PCR) and Partial Least Squares (PLS) that correlate spectral data with sample properties [16].

- Pattern Recognition: Both supervised (e.g., PLS-DA, SIMCA) and unsupervised (e.g., PCA, HCA) methods for sample classification and discrimination [16].

- Variable Selection: Algorithms that identify the most informative wavelengths to improve model robustness and interpretability [16].

The integration of these chemometric techniques with modern UV-Vis instrumentation has revitalized the application of this classic analytical tool, endowing it with "new vitality as an analytical sensor" capable of addressing increasingly complex analytical challenges in quality control [16].

Technical Workflow for Spectralprint Analysis

Instrumentation and Sample Presentation

Modern UV-Vis spectrometers designed for spectralprint analysis typically feature photodiode array or charge-coupled device (CCD) detectors that enable rapid acquisition of full spectra [16]. These instruments offer significant advantages for nontargeted analysis, including minimal scanning time, high sensitivity, and excellent wavelength reproducibility [16]. For quality control applications, the selection of appropriate sampling accessories is crucial and depends on sample characteristics:

- Liquid Samples: Standard cuvettes with pathlengths from 0.01 mm to 100 mm, selected based on absorbance characteristics and concentration [16]. Microvolume systems requiring only 2 μL samples are particularly valuable for precious pharmaceutical compounds [19].

- Flow Cells: Enable automated analysis and integration with process analytical technology (PAT) applications for real-time monitoring [16].

- Diffuse Reflection Accessories: Facilitate analysis of solid samples such as tablets or powders without requiring dissolution [16].

The critical instrumentation consideration for spectralprint analysis is measurement reproducibility, as subtle variations can significantly impact multivariate models. Modern systems with fixed pathlength microcuvettes demonstrate exceptional precision, with accuracy within 2% and precision within 1%, making them suitable for rigorous quality control applications [19].

Comprehensive Workflow Diagram

The following diagram illustrates the integrated workflow for spectralprint-based nontargeted analysis in quality control settings:

Data Processing and Model Building

The data processing pipeline transforms raw spectral data into actionable information:

Spectral Preprocessing: Raw spectra are subjected to preprocessing to remove physical artifacts and enhance chemical information. Common techniques include:

- Standard Normal Variate (SNV): Corrects for light scattering effects

- Savitzky-Golay Smoothing: Reduces high-frequency noise while preserving spectral features

- Derivative Spectroscopy: Enhances resolution of overlapping bands and eliminates baseline offset

Exploratory Analysis: Unsupervised pattern recognition techniques, particularly Principal Component Analysis (PCA), are employed to visualize natural clustering within the data and identify potential outliers [16]. This step provides initial insights into batch-to-batch variability and sample classification without prior assumptions.

Multivariate Model Development: Depending on the analytical objective, different modeling approaches are implemented:

- Classification Models (PLS-DA, SIMCA): For authentication and quality grading applications

- Quantitative Models (PLS, PCR): For prediction of multiple quality parameters simultaneously

- Cluster Analysis (HCA): For visualization of sample relationships

Model Validation: Rigorous validation is essential for implementation in regulated environments. This includes internal cross-validation to assess predictive ability and external validation with independent sample sets to evaluate model robustness [16]. For quality control applications, establishing statistically based confidence limits for classification and quantification is critical.

Case Study: Pharmaceutical Formulation Analysis

Experimental Protocol: Parent Spectrum Extraction Method

A recent innovative approach called Parent Spectrum Extraction (PSE) demonstrates the practical application of spectralprint analysis for quality control of complex pharmaceutical formulations [20]. This methodology was developed for the simultaneous analysis of a triple antihypertensive combination—valsartan (VAL), amlodipine besylate (AML), and hydrochlorothiazide (HCT)—in challenging ratio formulations (32.0:1.0:2.5 and 16.0:1.0:2.5) [20].

Table 2: Key Reagent Solutions for Spectralprint Analysis of Pharmaceutical Formulations

| Reagent/Material | Specification | Function in Analysis |

|---|---|---|

| Reference Standards | USP-grade VAL, AML, HCT | Method development and calibration |

| Solvent System | Methanol or specified dissolution medium | Sample dissolution and spectral measurement |

| Synthetic Mixtures | Prepared with exact known ratios of APIs | Model training and validation |

| Commercial Tablet Formulation | Exforge HCT tablets | Real-world method application |

| Buffer Solutions | pH-controlled as required | Maintaining consistent ionization states |

The PSE method comprises two complementary resolution steps:

Auxiliary Resolution: AML is resolved from the ternary mixture through constant multiplication (CM) followed by spectrum subtraction (SS), resulting in a resolved binary mixture of VAL and HCT [20].

Data Analysis Resolution (DAR): The binary mixture is analyzed through one of three novel approaches:

- Absorbance Extraction (AE): Utilizes analyzed absorbance values

- Peak-Amplitude Extraction (PE): Employs analyzed peak-amplitude data

- Ratio Extraction (RE): Uses amplitude difference calculations [20]

The following diagram illustrates the stepwise PSE methodology for resolving the three-component mixture:

Analytical Performance and Validation

The developed PSE methodology demonstrated excellent analytical performance validated according to ICH guidelines:

Table 3: Validation Parameters for the PSE Spectralprint Method

| Validation Parameter | Valsartan (VAL) | Amlodipine (AML) | Hydrochlorothiazide (HCT) |

|---|---|---|---|

| Linear Range (μg/mL) | 4.0–44.0 | 4.0–40.0 | 2.0–24.0 |

| Correlation Coefficient (r) | ≥0.9999 | ≥0.9999 | ≥0.9999 |

| Accuracy (% Recovery) | Within acceptable limits | Within acceptable limits | Within acceptable limits |

| Precision (% RSD) | Within acceptable limits | Within acceptable limits | Within acceptable limits |

The greenness of the proposed spectrophotometric methods was evaluated using multiple assessment tools (NEMI, Analytical Eco-Scale, GAPI, and AGREE), all of which confirmed the eco-friendly nature of the approach [20]. This aligns with modern pharmaceutical industry initiatives toward sustainable analytical chemistry.

Implementation in Quality Control Laboratories

Strategic Integration Pathways

Implementing spectralprint analysis in quality control laboratories requires thoughtful consideration of both technical and operational factors:

Method Selection Criteria: The choice between traditional targeted analysis and spectralprint approaches should be based on specific analytical needs:

- Targeted Methods: Appropriate for routine quantification of specific analytes in well-characterized formulations

- Spectralprint Methods: Ideal for complex formulations, authenticity verification, stability profiling, and detecting unexpected variations

Instrumentation Requirements: While modern array detectors are ideal for spectralprint analysis, conventional scanning spectrophotometers can also be employed with appropriate protocol adjustments. Key considerations include wavelength accuracy (<0.5 nm), photometric linearity, and reproducibility [16].

Data Management Infrastructure: Spectralprint analysis generates substantial datasets requiring appropriate storage, processing, and backup solutions. Integration with Laboratory Information Management Systems (LIMS) facilitates data traceability and audit trails for regulated environments.

Regulatory Considerations and Validation

For implementation in pharmaceutical quality control, spectralprint methods must demonstrate compliance with regulatory requirements:

Method Validation: While traditional validation parameters (accuracy, precision, specificity, linearity, range) remain relevant, additional validation elements are required for multivariate methods, including:

- Model Robustness: Evaluation of performance under slight variations in instrumental parameters

- Transferability: Assessment of model performance across multiple instruments

- Lifecycle Management: Established procedures for model maintenance and updating

Data Integrity: Compliance with ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate) is essential, particularly for electronic spectral data and multivariate models [18].

Documentation: Comprehensive documentation should include model development procedures, validation protocols, and ongoing monitoring plans to ensure continued model performance.

Future Perspectives and Emerging Trends

The evolution of spectralprint analysis in UV-Vis spectroscopy continues to advance through several emerging trends:

Multi-Spectral Data Fusion: Combining UV-Vis spectral data with information from other analytical techniques (e.g., NIR, Raman) provides a more comprehensive chemical profile and enhanced predictive capability [16].

Real-Time Process Monitoring: The integration of fiberoptic probes and flow cells enables real-time monitoring of manufacturing processes, supporting Quality by Design (QbD) and Process Analytical Technology (PAT) initiatives [16].

Miniaturized and Portable Systems: Advancements in miniaturized UV-Vis spectrometric systems facilitate at-line and field-based quality assessment, expanding applications to point-of-care testing and supply chain verification [16].

Artificial Intelligence Integration: Machine learning and deep learning algorithms are being increasingly applied to spectralprint analysis, enabling more sophisticated pattern recognition and predictive modeling without extensive preprocessing [16].

Standardization Initiatives: Community-wide efforts, such as the Benchmarking and Publications for Non-Targeted Analysis (BP4NTA) working group, are addressing challenges associated with terminology, reporting practices, and performance assessment in nontargeted analysis [21].

These developments position spectralprint analysis as an increasingly vital tool for modern quality control laboratories, offering comprehensive chemical characterization that aligns with the evolving regulatory landscape and the increasing complexity of pharmaceutical formulations and biotherapeutics.

Spectralprint analysis represents a significant advancement in the application of UV-Vis spectroscopy for quality control, transforming it from a technique for single-analyte quantification to a comprehensive tool for holistic sample characterization. By leveraging the entire spectral profile combined with chemometric analysis, this approach enables detection of subtle variations, authentication of complex formulations, and identification of unexpected components that would remain undetected using traditional targeted methods.

The implementation of spectralprint methodologies aligns with pharmaceutical quality initiatives that emphasize comprehensive product understanding and control strategy. As instrumentation continues to advance and data analysis tools become more sophisticated, the role of UV-Vis spectroscopy in quality control is poised to expand further, solidifying its position as a versatile, information-rich analytical sensor capable of addressing the complex challenges of modern drug development and manufacturing.

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a cornerstone analytical technique in quality control laboratories worldwide, providing a unique combination of rapid analysis, cost-effectiveness, and operational simplicity. This technical guide examines the core principles governing the practical working range of UV-Vis spectroscopy, addressing both its strengths and limitations within pharmaceutical, biotechnology, and research environments. By exploring the fundamental boundaries of spectral range, concentration detection, and quantitative accuracy, this review equips scientists with the knowledge to optimize experimental protocols, mitigate analytical pitfalls, and leverage UV-Vis spectroscopy as a robust tool in quality assurance and research applications. Particular emphasis is placed on the practical implementation of the Beer-Lambert law, instrumental parameters affecting performance, and strategic methodologies to extend the usable working range for diverse sample types.

Ultraviolet-visible (UV-Vis) spectroscopy is an analytical technique that measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample in comparison to a reference or blank sample [10]. This property is influenced by the sample composition, providing critical information about sample identity and concentration. In quality control laboratories, particularly within pharmaceutical and biotechnology sectors, UV-Vis spectroscopy provides an indispensable tool for nucleic acid and protein quantification, purity assessment, and reaction monitoring [22] [19].

The practical working range of any analytical technique defines its boundaries of reliable operation, and understanding these boundaries is fundamental to generating accurate, reproducible data. For UV-Vis spectroscopy, this encompasses the spectral range (wavelengths of light that can be effectively used), the concentration range (the minimum and maximum analyte concentrations that can be accurately quantified), and the linear dynamic range where the Beer-Lambert law reliably holds [10] [23]. This guide systematically addresses these parameters, providing researchers with a comprehensive framework for maximizing the utility of UV-Vis spectroscopy in quality-driven environments.

Fundamental Principles and Instrumentation

Core Principles of Light Absorption

The fundamental principle of UV-Vis spectroscopy revolves around the absorption of electromagnetic radiation in the ultraviolet (typically 190-400 nm) and visible (400-800 nm) regions by molecules in solution [10] [4]. When incident light at a specific energy interacts with a molecule, electrons may be promoted from a ground state to an excited state. This phenomenon, known as an electronic transition, results in the characteristic absorption of energy at wavelengths dependent on the molecular structure of the chromophore (the light-absorbing moiety) [4].

The energy required for these transitions corresponds to specific wavelengths of light, following the relationship (E = hc/\lambda), where (E) is energy, (h) is Planck's constant, (c) is the speed of light, and (\lambda) is the wavelength. Different functional groups and conjugated systems within molecules give rise to distinct absorption patterns, creating spectral fingerprints that can be used for both identification and quantification [23]. Key electronic transitions include ( \pi \rightarrow \pi^* ) (common in conjugated systems and aromatic compounds) and ( n \rightarrow \pi^* ) (found in carbonyl compounds), each occurring at characteristic wavelength ranges [23].

Essential Instrumentation Components

A UV-Vis spectrophotometer's ability to accurately measure light absorption depends on several key components, each contributing to the practical working range of the instrument [10]:

- Light Sources: Instruments typically employ multiple lamps to cover the full UV-Vis range. A deuterium lamp provides high-intensity UV light (190-400 nm), while a tungsten or halogen lamp covers the visible range (350-800 nm). The switch between sources typically occurs around 300-350 nm to ensure seamless spectral acquisition [10].

- Wavelength Selector (Monochromator): This component isolates specific wavelengths from the broad spectrum emitted by the source. Most modern systems use diffraction gratings, with groove densities (e.g., 1200 grooves per mm) determining the optical resolution. Higher groove frequency provides better resolution but a narrower usable wavelength range [10].

- Sample Holder: Cuvettes, typically with a standard path length of 1 cm, hold the liquid sample. Material selection is critical: quartz is required for UV range analysis (<300 nm) as glass and most plastics absorb strongly in this region, while glass or plastic may suffice for visible light measurements only [10].

- Detector: The detector converts transmitted light intensity into an electrical signal. Photomultiplier tubes (PMTs) offer high sensitivity for low-light applications, while photodiodes and charge-coupled devices (CCDs) provide robust detection for standard measurements [10].

Strengths of UV-Vis Spectroscopy

Operational Advantages in Quality Control

UV-Vis spectroscopy offers numerous practical strengths that cement its position in quality control laboratories:

- Rapid Analysis and High Throughput: Measurements are typically completed within seconds to minutes, enabling rapid quality assessment. Modern systems like the Unchained Labs Lunatic can measure 96 samples in approximately 10 minutes, significantly accelerating workflows in nucleic acid and protein quantification [19].

- Minimal Sample Consumption: Advanced microcuvette systems require only 2 μL of sample volume, a critical advantage when working with precious or limited-quantity biological samples [19].

- Non-Destructive Nature: Samples typically remain unaltered after analysis and can be recovered for subsequent testing or processing, which is particularly valuable in quality control workflows where sample preservation is essential [4].

- Quantitative Precision: When operated within optimal parameters, UV-Vis spectroscopy delivers exceptional quantitative accuracy. Instruments can achieve measurement accuracy within 2% of certified reference materials and precision within 1%, complying with stringent USP and Ph. Eur. guidelines for pharmaceutical analysis [19].

- Simplicity and Ease of Use: The technique requires minimal specialized training compared to more complex analytical methods like HPLC or mass spectrometry, making it accessible to a broad range of laboratory personnel [23].

- Wide Dynamic Range: Technological advancements have extended the measurable absorbance range. For instance, systems employing multiple pathlength microcuvettes (0.1 mm and 0.7 mm) can quantify IgG concentrations from 0.02 to 200 mg/mL and nucleic acids from 1.5 to 13,750 ng/μL without dilution [19].

Application Versatility

The strength of UV-Vis spectroscopy extends beyond its operational advantages to its remarkable application versatility across multiple domains of quality control and research:

Table 1: Applications of UV-Vis Spectroscopy in Quality Control and Research

| Application Domain | Specific Use Cases | Key Analytical Parameters |

|---|---|---|

| Nucleic Acid Analysis | DNA/RNA quantification, purity assessment (A260/A280 ratio) [19] | λmax = 260 nm, A260/A280 ≈ 1.8-2.0 [22] |

| Protein Analysis | Protein quantification, antibody concentration [19] | λmax = 280 nm (tryptophan/tyrosine) [19] |

| Pharmaceutical QC | Drug identity verification, impurity quantification, dissolution testing [4] | Specific λmax for API, degradation monitoring |

| Food & Beverage | Caffeine quantification, additive verification, authenticity testing [24] [4] | Compound-specific λmax with chemometric analysis [24] |

| Environmental Monitoring | Water quality assessment, contaminant detection [4] | Absorption signatures of pollutants |

| Nanoparticle Characterization | Synthesis monitoring, size determination [25] [26] | Surface Plasmon Resonance (SPR) peak position and shift [25] |

Limitations and Practical Working Range Constraints

Spectral Limitations

Despite its widespread utility, UV-Vis spectroscopy encounters several fundamental limitations that define its practical working range:

- Spectral Range Boundaries: Conventional UV-Vis spectrophotometers typically operate effectively within the 190-900 nm range [23]. Measurements below 190 nm require specialized instrumentation with argon or nitrogen-purged optical systems to eliminate absorption by molecular oxygen in air, making routine analysis in this vacuum UV region impractical for most laboratories [10].

- Solvent Cutoff Effects: Solvents used for sample preparation exhibit their own absorption characteristics, which can limit the usable spectral range. For example, water absorbs strongly below ~190 nm, ethanol below ~210 nm, and chloroform below ~245 nm. These solvent cutoff wavelengths establish the practical lower limit for measurement in solution [10] [23].

- Spectral Overlap: Complex samples containing multiple chromophores often exhibit broad, overlapping absorption bands, complicating the identification and quantification of individual components without prior separation or advanced chemometric analysis [24].

Concentration and Pathlength Constraints

The quantitative application of UV-Vis spectroscopy is governed by the Beer-Lambert law, which establishes the relationship between absorbance and concentration:

[A = \varepsilon \cdot c \cdot l]

Where (A) is absorbance, (\varepsilon) is the molar absorptivity (L·molâ»Â¹Â·cmâ»Â¹), (c) is concentration (mol·Lâ»Â¹), and (l) is pathlength (cm). This relationship defines critical constraints for quantitative analysis:

- Optimal Absorbance Range: For reliable quantification, absorbance values should ideally fall between 0.1 and 1.0 Absorbance Units (AU) [10] [23]. Below 0.1 AU, the signal-to-noise ratio decreases, compromising measurement precision. Above 1.0 AU, the amount of light reaching the detector becomes insufficient for accurate measurement, and deviations from the Beer-Lambert law often occur [10].

- Detector Saturation: At high absorbance values (typically >2 AU), the intensity of transmitted light becomes extremely low, potentially approaching the detector's noise floor and resulting in non-linear response and unreliable data [10] [23].

- Pathlength Considerations: While standard cuvettes have a 1 cm pathlength, the availability of different pathlengths (from 1 mm to 10 cm) provides a practical means to adjust the effective concentration range. Shorter pathlengths are employed for highly concentrated samples, while longer pathlengths enhance sensitivity for dilute analytes [10].

Table 2: Practical Working Range Constraints and Solutions

| Constraint | Typical Limit | Impact on Analysis | Practical Solutions |

|---|---|---|---|

| Lower Wavelength | ~190 nm (standard) | Cannot detect chromophores absorbing at lower wavelengths | Use specialized purged instruments for far-UV |

| Upper Wavelength | ~900 nm (standard) | Limited application for NIR-absorbing species | Employ NIR spectrophotometers |

| Lower Concentration | A < 0.1 AU | Poor signal-to-noise ratio | Use longer pathlength cuvettes; concentrate sample |

| Upper Concentration | A > 1.0-2.0 AU | Beer-Lambert law deviations; detector saturation | Dilute sample; use shorter pathlength cuvettes |

| Solvent Interference | Varies by solvent | Obscures sample absorption | Choose transparent solvents; use solvent blanks |

Experimental Protocols for Optimal Performance

Standard Quantitative Analysis of Proteins and Nucleic Acids

Principle: This protocol utilizes the characteristic absorption of proteins at 280 nm (due to tryptophan and tyrosine residues) and nucleic acids at 260 nm (due to purine and pyrimidine bases) for quantification [19].

Materials:

- UV-Vis spectrophotometer with deuterium lamp

- Quartz cuvettes (1 cm pathlength)

- Appropriate buffer for blank and sample dilution

- Protein or nucleic acid samples

Procedure:

- Power on the spectrophotometer and allow the lamp to warm up for at least 15 minutes.

- Set the instrument to concentration mode and select the appropriate analyte (protein or DNA/RNA).

- Prepare a blank solution containing only the buffer used for sample preparation.

- Pipette the blank solution into a quartz cuvette, place it in the sample holder, and initiate the blank measurement.

- For protein quantification, dilute the unknown sample in the same buffer to achieve a predicted absorbance between 0.1 and 1.0 AU at 280 nm.

- For nucleic acid quantification, use a similar dilution scheme targeting A260 between 0.1 and 1.0 AU.

- Replace the blank with the diluted sample and measure the absorbance.

- Record the concentration value calculated by the instrument using the predefined extinction coefficients, or calculate manually using the Beer-Lambert law.

Calculations: For double-stranded DNA: Concentration (ng/μL) = A260 × 50 × Dilution Factor For proteins using A280: Concentration (mg/mL) = A280 / ε × Pathlength (cm) × Dilution Factor (where ε is the extinction coefficient for the specific protein)

Purity Assessment of Nucleic Acids Using Spectral Ratios

Principle: This method assesses nucleic acid purity by evaluating the ratio of absorbances at specific wavelengths, detecting potential contaminants such as proteins or residual solvents [22].

Materials:

- UV-Vis spectrophotometer capable of scanning 220-320 nm

- High-quality quartz cuvettes

- Nuclease-free water or TE buffer

- Purified nucleic acid sample

Procedure:

- Initialize the spectrophotometer and perform instrument calibration according to manufacturer specifications.

- Set up a full spectrum scan from 220 nm to 320 nm.

- Prepare the blank using the same solution as the sample diluent (nuclease-free water or TE buffer).

- Dilute the nucleic acid sample to achieve an A260 of approximately 0.2-0.8 AU.

- Measure the blank and then the sample, recording the full spectrum.

- Identify the peak absorbance at ~260 nm and record values at 260 nm, 280 nm, and 230 nm.

- Calculate the following ratios:

- A260/A280: Indicator of protein contamination (pure DNA ~1.8, pure RNA ~2.0)

- A260/A230: Indicator of salt or organic solvent contamination (should be >2.0)

Interpretation: Significant deviations from expected ratios indicate potential contamination requiring further purification before proceeding with downstream applications such as sequencing or PCR [22].

Sample Preparation Guidelines for Reliable Results

Proper sample preparation is critical for obtaining accurate UV-Vis spectroscopy results:

- Clarity Requirements: Ensure samples are free of particulates or turbidity that can cause light scattering, particularly problematic at shorter wavelengths. Centrifuge or filter samples if necessary [23].

- Solvent Compatibility: Select solvents that do not absorb significantly at the wavelengths of interest. Use high-purity solvents and match the solvent between sample and blank precisely [23].

- Concentration Optimization: Perform preliminary dilutions to target the optimal absorbance range of 0.1-1.0 AU. For unknown samples, try a 1:10 or 1:100 dilution initially and adjust accordingly [10].

- Cuvette Handling: Use optically matched cuvettes for sample and reference measurements. Avoid touching the optical surfaces, and clean cuvettes thoroughly between measurements with an appropriate solvent [23].

Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for UV-Vis Spectroscopy in Quality Control

| Reagent/Material | Specification Requirements | Function in Analysis |

|---|---|---|

| Quartz Cuvettes | High UV transparency (190-900 nm), standard 1 cm pathlength | Sample containment with minimal light absorption |

| Buffer Solutions | UV-transparent, appropriate ionic strength and pH | Sample dilution and blank preparation |

| Nuclease-free Water | Absorbance A260 < 0.05 (1 cm pathlength) | Solvent for nucleic acid samples |

| Protein Standards | Certified concentration, high purity (BSA, IgG) | Calibration curve generation |

| DNA/RNA Standards | Certified concentration and purity | Nucleic acid quantification reference |

| Certified Reference Materials | NIST-traceable (e.g., NISTmAb) [19] | Instrument qualification and validation |

UV-Vis spectroscopy remains an indispensable analytical tool in quality control laboratories, offering an optimal balance of analytical performance, operational efficiency, and practical implementation. Its strengths of rapid analysis, minimal sample consumption, and quantitative precision are balanced against limitations in spectral range, concentration constraints, and potential interference issues. By thoroughly understanding the practical working range of this technique—including spectral boundaries, optimal absorbance ranges, and Beer-Lambert law limitations—researchers and quality control professionals can implement appropriate methodological adjustments to ensure data reliability. Strategic application of pathlength modifications, sample dilution/concentration techniques, and proper solvent selection enables scientists to extend the effective working range of UV-Vis spectroscopy, thereby maximizing its utility in pharmaceutical analysis, biotechnology applications, and research environments demanding rigorous quality assessment.

Practical Applications: From Drug Stability to In-Line Process Control

Drug Stability and Shelf-Life Determination Under Stress Conditions

Stability testing is a critical component of pharmaceutical development, ensuring that drugs maintain their identity, strength, quality, and purity throughout their shelf life. These studies determine how the quality of a drug substance or product varies with time under the influence of environmental factors such as temperature, humidity, and light. For pharmaceutical companies, stability testing provides essential data for establishing appropriate shelf life, storage conditions, and usage instructions, while also helping predict which drugs will be commercially viable early in the development process [27]. The International Council for Harmonisation (ICH) guidelines provide standardized frameworks for stability testing, including real-time, accelerated, and forced degradation studies [28] [29].

Within this landscape, UV-Visible (UV-Vis) spectroscopy has emerged as a versatile, efficient, and increasingly sophisticated analytical technique that supports stability assessment across multiple stages of drug development. This technical guide explores the integral role of UV-Vis spectroscopy in modern stability testing protocols, detailing instrumentation advances, methodological frameworks, and innovative approaches that enhance efficiency while maintaining rigorous quality standards expected in pharmaceutical quality control laboratories.

UV-Vis Spectroscopy: Principles and Instrumentation Advances

Fundamental Principles in Stability Assessment

UV-Vis spectroscopy quantifies the absorption of ultraviolet or visible light by chemical compounds, providing information about electronic transitions and molecular structure. In stability testing, this technique leverages the Beer-Lambert law to correlate absorbance with concentration, enabling researchers to monitor changes in active pharmaceutical ingredients (APIs) and detect degradation products formed under stress conditions [27] [30]. The technique is particularly valuable for tracking API degradation, quantifying oxidation-sensitive compounds, and conducting kinetic studies of degradation reactions through shifts in UV absorbance profiles [30].

Modern Instrumentation and Efficiency Gains

The UV-Vis instrumentation landscape has evolved significantly, with 2025 market analyses projecting growth to $27.62 billion by 2030, driven by pharmaceutical sector adoption [31]. Modern systems emphasize improved efficiency, miniaturization, and connectivity:

- User Interface Innovations: Contemporary instruments feature touchscreen interfaces with guided workflows and real-time visual feedback, reducing training time and minimizing user error even for non-specialists [32].

- Performance Enhancements: The Techcomp UV2500 exemplifies modern high-speed systems engineered for rapid, stable readings without compromising precision, essential for labs processing high sample volumes [32].

- Footprint Reduction: Compact benchtop designs now deliver full-spectrum performance with minimal space requirements, ideal for shared and mobile laboratories [32].

- Optical Stability: Robust optical components with fewer moving parts, thermal regulation, enhanced detectors, and solid-state light sources improve measurement stability, reduce drift, and extend instrument lifespan [32].

Technological differentiation continues across optical designs, with diode-array configurations achieving a 7.76% compound annual growth rate (CAGR) due to their ability to capture entire spectra in milliseconds—particularly valuable for peak-purity checks and forced-degradation profiling aligned with ICH Q1 guidelines [31].

Research Reagent Solutions

Table 1: Essential Materials for UV-Vis-Based Stability Testing

| Item | Function | Application Examples |

|---|---|---|

| Quartz Cuvettes | Sample holder with UV transparency | Spectral measurements across 200-400 nm range [33] |

| Certified Reference Materials | Wavelength and photometric accuracy verification | Automated validation modules (e.g., Mettler-Toledo's CertiRef) [31] |

| Hydrochloric Acid (HCl) | Acid-catalyzed hydrolysis stressor | Forced degradation studies (typically 0.1-1 mol/L) [29] |

| Sodium Hydroxide (NaOH) | Base-catalyzed hydrolysis stressor | Alkaline degradation testing (typically 0.1-1 mol/L) [29] |

| Hydrogen Peroxide | Oxidative stress agent | Oxidation stability assessment [29] |

| Neutralization Agents | Arrest degradation post-stressing | Acid/base neutralization prior to analysis [29] |

Stability Testing Frameworks and Methodologies

Regulatory Framework and Study Designs

Stability testing follows standardized regulatory frameworks, primarily ICH guidelines, which define specific storage conditions and testing intervals:

- Long-term studies: 25°C ± 2°C/60% RH ± 5% RH for 24 months with testing at 0, 3, 6, 9, 12, 18, and 24 months [28]

- Accelerated studies: 40°C ± 2°C/75% RH ± 5% RH for 6 months with testing at 0, 3, and 6 months [28]

- Forced degradation: Intentional exposure to extreme conditions (acid, base, oxidation, heat, light) to identify potential degradation pathways [29]

Traditional reduction approaches include bracketing (testing only extreme strengths) and matrixing (testing a subset of samples at each time point) as outlined in ICH Q1D [28]. These methods remain relevant in the 2025 regulatory landscape, with the recent draft revision of ICH Q1 guideline reaffirming their applicability under defined conditions [28].

Advanced Statistical Approaches

A 2025 study published in Pharmaceutics explores factorial analysis as an innovative statistical approach to optimize stability study designs beyond conventional bracketing and matrixing [28]. This method systematically evaluates multiple factors (e.g., batch, orientation, filling volume, API supplier) and their interactions to identify worst-case scenarios and critical stability-influencing factors.

The methodology involves:

- Applying factorial analysis to accelerated stability data to determine critical factors

- Identifying worst-case scenarios based on factor significance

- Strategically reducing long-term testing while maintaining reliability

- Validating reductions through regression analysis of long-term data [28]

Research on three parenteral products demonstrated that this approach could reduce long-term stability testing by at least 50% while maintaining reliable stability assessment, offering significant resource savings without compromising quality [28].

Standard Experimental Protocols for UV-Vis Stability Assessment

Table 2: UV-Vis Experimental Protocols for Drug Stability Testing

| Stress Condition | Standard Protocol | UV-Vis Monitoring Parameters | Acceptable Degradation Range |

|---|---|---|---|

| Acid Hydrolysis | 0.1-1 M HCl, room temperature to reflux, 24h [29] | Spectral shifts & new absorbance peaks, concentration decrease of API | 5-20% degradation [29] |

| Base Hydrolysis | 0.1-1 M NaOH, room temperature to reflux, 24h [29] | Spectral shifts & new absorbance peaks, concentration decrease of API | 5-20% degradation [29] |

| Oxidative Stress | 0.3-3% Hâ‚‚Oâ‚‚, room temperature, 24h [29] | Increased absorbance indicative of oxidation products | 5-20% degradation [29] |

| Thermal Stress | 40-80°C, dry & humid conditions, 1-3 months [29] | Changes in spectral profile over time | 5-20% degradation [29] |

| Photostability | Exposure to UV & visible light per ICH Q1B [29] | Appearance of new chromophores | 5-20% degradation [29] |

Advanced Applications and Data Analysis Techniques

Chemometrics and Machine Learning Integration

The integration of artificial intelligence with UV-Vis spectroscopy represents a significant advancement in stability testing methodologies. A 2025 study demonstrated the successful application of artificial neural networks (ANN) coupled with firefly algorithm (FA) optimization for simultaneous determination of multiple cardiovascular drugs in ternary mixtures [33].

The experimental approach included:

- Recording UV absorption spectra of calibration and validation sample sets

- Employing backpropagation algorithm to train ANN models using UV fingerprints as inputs and drug concentrations as outputs

- Implementing firefly algorithm as a variable selection tool to identify optimal wavelengths

- Validating models using relative root mean square error of prediction (RRMSEP) and coefficient of determination [33]

This FA-ANN approach demonstrated excellent accuracy, precision, and selectivity per ICH guidelines while offering environmental benefits through reduced solvent consumption compared to traditional HPLC methods [33].

Stability Testing Workflow

The following diagram illustrates the integrated stability testing workflow incorporating UV-Vis spectroscopy and advanced data analysis:

Novel Assessment Tools: The STABLE Framework

The Stability Toolkit for the Appraisal of Bio/Pharmaceuticals' Level of Endurance (STABLE) has emerged as a comprehensive software tool for standardized stability assessment [29]. This open-source platform evaluates API stability across five stress conditions: oxidative, thermal, acid-catalyzed hydrolysis, base-catalyzed hydrolysis, and photostability.

STABLE employs a color-coded scoring system:

- Colorful sections: Indicate sufficient stability under that condition

- Gray sections: Represent moderate stability

- Black sections: Signify instability [29]

This toolkit provides a standardized approach to stability assessment, addressing inconsistencies in interpretation and implementation across different regions and organizations [29]. The system assumes linear degradation kinetics for practical comparative assessment, prioritizing ease of use and consistent stability scores across multiple stress conditions.

Implementation in Quality Control Laboratories

Integration with Regulatory Compliance

Modern UV-Vis systems increasingly incorporate features that address regulatory requirements, particularly FDA data integrity rules issued in 2024 [31]. Automated verification modules perform wavelength, photometric, and stray-light checks using certified reference materials, enabling comprehensive audit trails essential for compliance [31]. This functionality is particularly valuable for pharmaceutical quality control laboratories operating under GMP constraints, where documentation rigor is paramount.

Green Analytical Chemistry Considerations

The environmental impact of analytical techniques has gained significant attention, with UV-Vis spectroscopy positioned favorably compared to traditional chromatographic methods. The technique's minimal solvent requirements and lower energy consumption contribute to its green credentials [33]. Assessment tools such as Analytical Greenness (AGREE), Blue Applicability Grade Index (BAGI), and Red-Green-Blue (RGB) models have confirmed the environmental benefits of UV-Vis-based approaches, particularly when enhanced with machine learning algorithms [33].

UV-Vis spectroscopy continues to evolve as an indispensable tool for drug stability and shelf-life determination, integrating advanced optical technologies, sophisticated data analysis algorithms, and user-friendly platforms. The technique's adaptability across multiple stages of pharmaceutical development—from early formulation screening to commercial batch quality control—ensures its enduring relevance in quality control laboratories. As regulatory frameworks advance and sustainability considerations intensify, UV-Vis spectroscopy coupled with innovative computational approaches offers an effective strategy for comprehensive stability assessment while addressing efficiency, compliance, and environmental impact requirements. The ongoing development of standardized assessment tools and methodological refinements promises to further enhance the role of UV-Vis spectroscopy in ensuring drug safety and efficacy throughout product lifecycles.

Quantification of Active Pharmaceutical Ingredients (APIs) and Impurities

Ultraviolet-Visible (UV-Vis) spectroscopy has established itself as a cornerstone analytical technique in pharmaceutical quality control laboratories. This method measures the absorption of ultraviolet or visible light by a compound as it transitions between electronic energy levels, providing valuable data on chemical composition, concentration, and purity. The technique operates within the 190–800 nm wavelength range, making it particularly suitable for analyzing aromatic compounds and those with multiple conjugated double bonds commonly found in active pharmaceutical ingredients (APIs) [34]. In the context of modern pharmaceutical manufacturing, UV-Vis spectroscopy serves as a rapid, cost-effective, and non-destructive tool for ensuring drug identity, potency, and purity throughout development and production cycles [35].

The application of UV-Vis spectroscopy extends across multiple facets of pharmaceutical analysis, from raw material testing to final product release. Its fundamental principle relies on the Beer-Lambert law, which states that the absorbance of a solution is directly proportional to the concentration of the absorbing species and the path length of the light through the solution. This relationship provides the theoretical foundation for quantitative analysis of APIs and detection of impurities [36]. Furthermore, the technique aligns well with Process Analytical Technology (PAT) initiatives, enabling real-time monitoring of critical quality attributes during manufacturing through in-line and at-line applications [37] [34]. As regulatory bodies continue to emphasize quality by design principles, UV-Vis spectroscopy has evolved to incorporate analytical quality by design (AQbD) methodologies, enhancing method robustness and facilitating continuous improvement in analytical procedures [37].

Theoretical Foundations of UV-Vis Analysis

The quantitative application of UV-Vis spectroscopy for API and impurity analysis rests on well-established physicochemical principles that govern the interaction between light and matter. Understanding these theoretical foundations is essential for developing robust analytical methods that meet regulatory requirements and ensure patient safety.

The Beer-Lambert Law and Quantitative Analysis

The Beer-Lambert law forms the mathematical basis for quantitative UV-Vis spectroscopy, establishing the relationship between the concentration of an analyte in solution and its absorbance of monochromatic light. The law is expressed as A = εlc, where A represents the measured absorbance, ε is the molar absorptivity coefficient (L·molâ»Â¹Â·cmâ»Â¹), l is the path length of the light through the solution (cm), and c is the concentration of the analyte (mol·Lâ»Â¹) [36]. This linear relationship holds true across specific concentration ranges, typically yielding optimal results between 0.1–1.0 absorbance units (AU) [34]. Deviations from linearity can occur at higher concentrations due to molecular interactions or instrumentation limitations, necessitating appropriate sample preparation through dilution to maintain accuracy [34].

The molar absorptivity coefficient (ε) is a fundamental molecular property that indicates how strongly a chemical species absorbs light at a specific wavelength. Pharmaceuticals containing chromophores—functional groups that absorb UV-Vis radiation—exhibit characteristic ε values that facilitate their identification and quantification. For impurity analysis, the relative difference in ε values between the API and potential impurities enables detection and quantification of even trace components within complex mixtures [38]. Modern UV-Vis instruments equipped with diode array detectors can rapidly scan multiple wavelengths, generating complete absorption spectra that provide molecular fingerprints for both identification and quantification purposes [35].

Spectral Interpretation for API and Impurity Analysis

UV-Vis spectra provide rich information beyond simple concentration measurements. The position and shape of absorption bands indicate electronic transitions within molecules, while spectral shifts can reveal structural changes or molecular interactions. For API quantification, analysts typically select the wavelength of maximum absorption (λmax) to maximize sensitivity and minimize potential interference from other components [34]. Impurity detection often relies on identifying unexpected absorption peaks or shoulders in the spectrum that deviate from the API reference standard, indicating the presence of contaminating species [22].

Advanced spectral analysis techniques include derivative spectroscopy, which enhances resolution of overlapping bands, and multiwavelength analysis, which improves accuracy in complex mixtures. For impurity profiling, the United States Pharmacopeia (USP) recommends establishing the ratio of absorbances at different wavelengths to detect spectral anomalies indicative of impurities [36]. The presence of unexpected absorbance peaks at characteristic wavelengths (e.g., 216, 280, 316, and 603 nm for sucrose adulteration in honey analysis) can signal specific contaminants, demonstrating the technique's versatility across different sample types [39]. These spectral interpretation skills are essential for pharmaceutical analysts tasked with ensuring product quality and compliance with regulatory standards.

Regulatory Framework and Compliance

Pharmaceutical applications of UV-Vis spectroscopy must adhere to stringent regulatory requirements established by global health authorities. Compliance with these standards ensures that analytical data supports claims regarding drug identity, strength, quality, and purity, ultimately safeguarding patient health.

International Regulatory Guidelines

The International Council for Harmonisation (ICH) provides globally recognized guidelines for analytical method validation, with ICH Q2(R1) defining key validation parameters including accuracy, precision, specificity, detection limit, quantitation limit, linearity, range, and robustness [34]. These criteria must be thoroughly demonstrated for UV-Vis methods used in regulatory submissions or quality control testing. The United States Pharmacopeia (USP) dedicates specific chapters to UV-Vis spectroscopy, with USP <857> addressing instrument qualification, wavelength accuracy, photometric accuracy, stray light, and resolution verification [36] [7]. Similar requirements exist in the European Pharmacopoeia (Ph. Eur. 2.2.5) and Japanese Pharmacopoeia (JP <2.24>), creating a harmonized global framework for spectroscopic method validation [7].