A Practical Guide to Cleaning and Maintaining Spectrometer Optical Windows for Reliable Pharmaceutical Analysis

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the critical practices of cleaning and maintaining spectrometer optical windows.

A Practical Guide to Cleaning and Maintaining Spectrometer Optical Windows for Reliable Pharmaceutical Analysis

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the critical practices of cleaning and maintaining spectrometer optical windows. It covers the foundational science behind contamination's impact on data integrity, step-by-step cleaning methodologies for various window types, advanced troubleshooting for common analytical issues like drift and inaccurate results, and validation strategies to ensure compliance with pharmaceutical regulations. By synthesizing current best practices and emerging trends, this guide aims to enhance the reliability, reproducibility, and longevity of spectroscopic data in biomedical research and quality control.

Understanding Spectrometer Optical Windows: Why Purity is Non-Negotiable in Pharma Analysis

The Role of Optical Windows in Spectrometer Performance and Data Fidelity

Technical Support Center

Optical windows are critical components in spectrometers, serving as the interface between the sample and the instrument's sensitive internal optics. Their cleanliness and structural integrity are paramount for ensuring data fidelity. Contamination or damage to these windows can lead to significant signal loss, increased noise, and inaccurate quantitative results. This technical support center provides researchers and scientists with practical guidelines for troubleshooting, maintaining, and cleaning spectrometer optical windows to uphold optimal instrument performance and data quality.

Troubleshooting Guide: Optical Window-Related Issues

Table 1: Common Symptoms and Solutions for Optical Window Problems

| Problem Symptom | Potential Cause | Recommended Solution | Preventive Measure |

|---|---|---|---|

| Drifting readings or need for frequent recalibration [1] | Dirty optical windows causing inconsistent light transmission. | Clean the windows located in front of the fiber optic and in the direct light pipe [1]. | Implement a regular schedule for inspecting and cleaning optical windows. |

| Low signal intensity or inaccurate analysis [1] | Lens or window misalignment, preventing optimal light collection. | Check and realign the lens or optical window to ensure it is correctly focused on the light source [1]. | Train operators on proper handling and alignment checks during routine maintenance. |

| Low readings for carbon, phosphorus, and sulfur [1] | Vacuum pump failure, introducing atmosphere into the optic chamber and blocking low-wavelength light. | Service or replace the vacuum pump. Monitor for pump issues like noise, heat, or oil leaks [1]. | Follow the manufacturer's recommended maintenance schedule for the vacuum pump. |

| Inconsistent results or poor analysis [2] | Contamination on the optical window from fingerprints, oil, or residues. | Clean the optical windows with appropriate solvents and lint-free cloths [2]. | Always handle optical components with gloves and use clean, filtered gases like argon where applicable. |

| Negative absorbance readings [2] | The blank measurement was performed with a dirtier or different optical surface than the sample. | Ensure the optical path, including windows, is identically clean for both blank and sample measurements [2]. | Use consistent procedures and clean the optical windows before a set of experiments. |

Experimental Protocol: Laser Cleaning of Optical Windows

The following detailed methodology is adapted from a published procedure for laser cleaning of contaminated optical windows on a rubidium vapor cell [3].

Objective

To remove an opaque layer of contamination from the inner surface of a quartz optical window to restore its transparency without damaging the substrate.

Materials and Equipment

- Contaminated optical cell: A worn Rubidium vapor cell with a quartz optical window showing black/grey discoloration [3].

- Laser system: Q-switched Nd:YAG laser (e.g., Quantel Brilliant) operating at 1064 nm wavelength with a pulse width of 3.2 ns [3].

- Focusing optics: A biconvex converging lens (focal length: 295 mm) [3].

- Safety equipment: Appropriate laser safety goggles and interlocks.

Procedure

- Contamination Analysis: Before cleaning, analyze the contaminant using a technique like Raman spectroscopy to understand its composition (e.g., found to be rubidium silicate in the cited study) [3].

- Laser Setup: Configure the laser for single-pulse operation to minimize heat stress on the glass [3].

- Beam Positioning: Direct the laser beam through the intact (clean) window of the cell [3].

- Focusing: Focus the beam using the converging lens to a point approximately 1 mm in front of the contaminated surface (i.e., inside the cell). This defocusing is critical to minimize heat stress on the glass and prevent the formation of micro-cracks [3].

- Energy Calibration: Start with low pulse energy (e.g., 50 mJ) and cautiously increase if necessary (up to 360 mJ in the cited study). The calculated fluence at 50 mJ with these parameters is approximately 400 J/cm² [3].

- Cleaning Execution: Fire a single laser pulse. A single pulse is often sufficient to clear the contamination at the focal spot and locally restore transparency [3].

- Inspection: Visually inspect the cleaned area. Further analysis via microscopy or spectroscopy can confirm the removal of contamination and the integrity of the substrate [3].

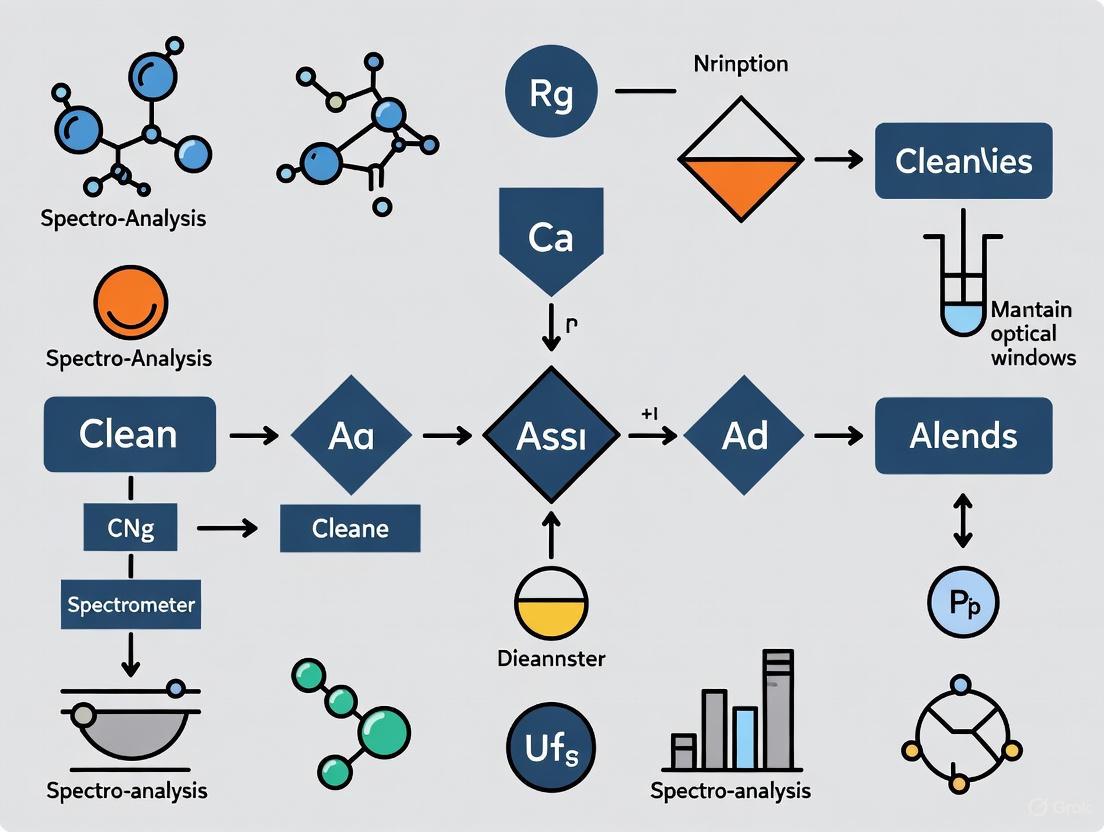

Visualization of Laser Cleaning Setup

The following diagram illustrates the experimental setup for the laser cleaning procedure.

Key Reagents and Materials

Table 2: Research Reagent Solutions for Optical Window Maintenance

| Item | Function | Application Note |

|---|---|---|

| Lint-free cloth | To wipe optical surfaces without leaving fibers or scratches [2]. | Use with appropriate solvents for cleaning. |

| Appropriate solvents | To dissolve and remove organic or inorganic contaminants from optical surfaces. | Select based on contamination type and window material compatibility. |

| Filtered, dry argon gas | To provide an inert atmosphere within the spectrometer optic chamber. | Prevents oxidation and contamination; ensure argon is not contaminated [1]. |

| Certified calibration standards | To verify spectrometer performance after maintenance or cleaning [4]. | Use NIST-traceable standards for accurate calibration. |

Frequently Asked Questions (FAQs)

Q1: How often should I clean the optical windows on my spectrometer? There is no fixed schedule, as it depends on the instrument's usage environment and the types of samples analyzed. It is good practice to inspect the windows visually as part of your regular preventive maintenance. Symptoms like drifting baselines or reduced signal intensity often indicate that cleaning is needed [1] [2].

Q2: What is the proper way to clean an optical window? Always handle optical windows with gloves to avoid transferring skin oils. Use a lint-free cloth and a suitable solvent (e.g., methanol, isopropanol). Gently wipe the surface, avoiding abrasive motions. For internal windows or complex contaminants, refer to the manufacturer's guidelines or established protocols like laser cleaning [3] [2].

Q3: Can a dirty optical window affect the detection of specific elements? Yes. Contamination can scatter or absorb light, but a more specific issue is a failing vacuum pump. If the pump fails, the atmosphere enters the optic chamber and absorbs low-wavelength light, leading to incorrect values for elements like Carbon, Phosphorus, and Sulfur. A dirty window can exacerbate general signal loss across wavelengths [1].

Q4: My spectrometer's readings are unstable. Could the optical window be the cause? Yes, a dirty window is a common cause of unstable or drifting readings. Other causes include air bubbles in the sample, an instrument that has not warmed up sufficiently, or environmental vibrations. Cleaning the optical windows is a primary troubleshooting step for this issue [1] [2].

Q5: Are there automated solutions for maintaining optical components in manufacturing? Yes, the field of optical fabrication is increasingly adopting automation. This includes robotic systems for handling and cleaning optics, as well as AI-driven models to predict and schedule maintenance, enhancing consistency and throughput in industrial settings [5].

In spectroscopic analysis, the optical window is a critical interface between your sample and the detection system. Even minor contamination on these windows—whether from routine sample analysis, environmental deposits, or improper handling—directly compromises data quality by reducing light throughput and introducing measurement artifacts. For researchers in drug development, where results dictate critical decisions, maintaining window clarity is not merely a maintenance task but a fundamental requirement for data integrity. This guide details how contamination skews results and provides proven methodologies for maintaining optical components.

Troubleshooting Guides

Common Symptoms of a Contaminated Optical Window

If your spectrometer exhibits any of the following signs, a contaminated optical window is likely the root cause.

| Symptom | Specific Manifestations in Data & Instrument Operation | Primary Elements Affected (for OES) |

|---|---|---|

| Analysis Drift | Frequent need for recalibration; results for the same sample change over time [1]. | - |

| Poor Precision | High variation between replicate measurements of the same sample [1]. | - |

| Reduced Sensitivity | Consistently low readings for elements, particularly in the low UV range [1] [6]. | Carbon (C), Phosphorus (P), Sulfur (S), Nitrogen (N) [1] |

| Calibration Failures | Wavelength calibration fails specifically for wavelengths less than 190 nm [6]. | - |

| Visual Inspection | Visible film, dust, or deposits on the window surface [6]. | - |

Diagnostic Flowchart: Is Your Optical Window Contaminated?

Follow this logical workflow to systematically diagnose if a contaminated optical window is the source of your analytical problems.

Frequently Asked Questions (FAQs)

Q1: How does a dirty optical window directly cause analytical drift and inaccurate results? A contaminated window acts as an unintended optical filter, absorbing and scattering light before it reaches the detector. This reduces the overall light intensity, leading to suppressed signals and low results [1]. The non-uniformity of the contamination causes subtle, unpredictable changes in this filtering effect, which manifests as analytical drift and poor precision, requiring more frequent recalibration [1].

Q2: Which optical components are most susceptible to contamination, and where are they located? In spectrometers, two primary windows are critical:

- The window in front of the fiber optic cable. [1]

- The window in the direct light pipe. [1] In ICP-OES systems, the axial and radial pre-optic windows are located directly opposite the plasma torch and are highly vulnerable to deposition of sample aerosols and particulates [6].

Q3: Why do contaminated windows disproportionately affect elements like Carbon, Phosphorus, and Sulfur? These crucial elements have their strongest spectral lines in the far ultraviolet (UV) region of the spectrum [1]. Low-wavelength UV light is more readily absorbed and scattered by thin films of organic or inorganic contaminants on a window compared to higher wavelength visible light. A malfunctioning vacuum pump, which allows atmosphere into the optic chamber, will also cause a loss of intensity for these same low-wavelength elements [1].

Q4: What is the recommended step-by-step procedure for cleaning an optical window? Follow this detailed protocol for safe and effective cleaning [6]:

- Power Down & Cool: Always turn off the instrument and allow the torch compartment (for ICP-OES) to cool completely to avoid burn risk and electrical hazard.

- Remove Window Assembly: Carefully remove the optical window assembly from its housing, handling it only by the edges to avoid transferring skin oils to the optical surface.

- Initial Detergent Clean: Soak the window in a dilute (5% v/v) laboratory detergent solution for 30 minutes.

- Rinse: Thoroughly rinse the window with de-ionized water to remove all detergent residue.

- Acid Wash (if needed): If contamination persists, soak the window in a dilute (5% v/v) nitric acid solution for 1 hour.

- Final Rinse: Rinse thoroughly with de-ionized water followed by a rinse with reagent-grade isopropyl alcohol to promote streaking-free drying.

- Dry: Air-dry at room temperature, use a low-temperature drying oven (40–80 °C), or use a stream of clean, filtered compressed gas (argon, nitrogen, or air).

- Reinstall & Stabilize: Reinstall the clean window assembly. For ICP-OES, excite several waste samples to allow the system to stabilize before performing standardization.

Warning: Always wear appropriate personal protective equipment (PPE) when handling acids. Never use hydrofluoric acid (HF) to clean quartz windows, as it will severely etch and damage them [6] [7].

The Scientist's Toolkit: Essential Materials for Maintenance

| Category | Item | Function & Application Notes |

|---|---|---|

| Cleaning Solvents | Dilute Laboratory Detergent (5% v/v) | Removes general organic and particulate contaminants through soaking [6]. |

| Dilute Nitric Acid (5% v/v) | Used for stubborn inorganic deposits; highly effective for ICP-related contamination [6]. | |

| Reagent-Grade Isopropyl Alcohol | Final rinse solvent for rapid, streak-free drying [6]. | |

| De-ionized Water | Primary rinse agent to remove all cleaning solvent residues [6]. | |

| Handling & Drying | Lint-Free Wipes / Cloths | For gentle handling and drying; prevents scratching and fiber residue [2]. |

| Filtered Compressed Gas (Argon, Nâ‚‚, Air) | For drying optical surfaces without physical contact, preventing streaks [6]. | |

| Heat-Resistant Gloves | Mandatory for handling components that may be hot, such as the ICP torch compartment [6]. | |

| Consumables | High-Purity Argon Gas (>99.999%) | Maintains an oxygen-free light path; low purity can mimic contamination effects [8]. |

| Nitrile or Powder-Free Gloves | Prevents contamination from skin oils during handling of windows and samples [1]. | |

| Einecs 302-056-4 | Einecs 302-056-4, CAS:94088-55-8, MF:C47H50N2O8, MW:770.9 g/mol | Chemical Reagent |

| cis-2-Tridecenal | cis-2-Tridecenal|High Purity|For Research Use Only | cis-2-Tridecenal for research. This high-purity aldehyde is for lab use. For Research Use Only (RUO). Not for human consumption. |

Advanced Maintenance and Best Practices

Proactive Maintenance Schedule

Adhering to a regular maintenance schedule prevents contamination from impacting your results.

| Maintenance Task | Recommended Frequency | Key Purpose |

|---|---|---|

| Visual Inspection of Windows [6] | Before each analytical sequence | Identify early signs of buildup. |

| Cleaning of Entrance Lenses/Windows [8] | Twice per week (for OES in high-use environments) | Maintain consistent light throughput. |

| Full Window Cleaning/Validation | Weekly or as diagnostic triggers indicate | Remove contaminants before they affect data. |

| Excitation Table/Spark Chamber Cleaning [8] | Every 100-200 excitations | Prevent cross-contamination and discharge issues. |

Environmental and Operational Controls

Contamination control extends beyond the window itself. Implement these practices to minimize the introduction of contaminants:

- Grinding Samples: Always use a new grinding pad for each sample to remove plating, carbonization, or coatings before analysis, and avoid quenching samples in water or oil [1].

- Handling: Never touch the analytical surface of a sample or a clean optical window with bare hands, as skin oils are a common source of contamination [1].

- Environmental Control: Maintain stable laboratory temperature and humidity, as fluctuations can cause spectral drift and affect the optical system [8].

- Argon Purity: Ensure a constant supply of high-purity argon (>99.999%) with appropriate pressure and flow rates, as contaminated argon is a common cause of poor excitation and unstable plasma [8].

FAQs: Optical Window Contamination

Q1: What are the most common contaminants that affect spectrometer optical windows? The most frequent contaminants are dust, fingerprints, and chemical residues. Dust particles scatter light, causing signal instability and elevated background noise. Fingerprints, which deposit oils and salts from the skin, can absorb light and leave permanent etchings on sensitive materials. Chemical residues, from solvents or sample carryover, can form films that absorb or scatter light, and may even chemically attack and permanently damage optical coatings or substrates [9] [10].

Q2: How does contamination physically degrade instrument performance? Contamination leads to measurable performance issues by interfering with light transmission. This manifests as:

- Reduced Optical Throughput: Surface deposits absorb light, diminishing signal strength [11].

- Increased Scatter: Dust and films scatter incident light, elevating background noise and reducing the signal-to-noise ratio [11] [10].

- Inaccurate Readings: These effects combine to cause drifting calibration, unstable readings, and negative absorbance values, as the instrument's baseline is compromised [2] [9] [1].

Q3: How often should optical windows be cleaned? Cleaning frequency depends entirely on the laboratory environment. A general recommendation for flame detectors, for instance, is to clean optical windows every 30 days as a minimum [12]. However, instruments in dirty or high-traffic areas may require more frequent cleaning. The best practice is to inspect windows regularly by holding them up to a bright light and looking for scattering from dust and stains [10]. A good rule is: if it's not dirty, don't clean it, as unnecessary handling risks damage [10].

Q4: Can the wrong cleaner damage my optical windows? Yes, using an incorrect cleaner is a primary cause of irreversible damage. For example:

- Sapphire windows must be cleaned with a specified, ammonia-based glass cleaner, as other commercial cleaners will cause damage [12].

- Coated optics can be dissolved by certain solvents; water should not be used on coatings above 1550 nm unless their water solubility is confirmed [13].

- Plastic optics or housings will be damaged by acetone [10]. Always consult the instrument manual or manufacturer's notes for approved cleaning procedures.

Q5: What is the universal first step in cleaning any optical window? Before wiping, always use a clean-air duster. Blowing off the surface with canned air, compressed air, or dry nitrogen removes abrasive grit and dust. Wiping a dusty optic is akin to cleaning it with sandpaper and will scratch the surface [10].

Troubleshooting Guides

Symptom: Unstable or Drifting Readings

If your spectrophotometer readings are unstable or drift over time, follow this diagnostic pathway to identify and resolve the issue.

Symptom: Instrument Fails to Zero or Blank

A failure to zero the instrument or set 100% transmittance often points to issues with the blank measurement, light source, or optical path blockage.

Possible Causes and Solutions:

| Problem | Possible Cause | Recommended Solution |

|---|---|---|

| Fails to Zero | Sample compartment lid open [2]. | Ensure the lid is fully closed to block external light. |

| High humidity affecting internal components [2]. | Allow instrument to acclimate; replace desiccant packs if present. | |

| Fails to Blank | Light source (lamp) is near end of life [2]. | Check lamp usage hours in software; replace if old. |

| Internal optics are dirty or misaligned [2]. | Instrument likely requires professional servicing. | |

| Optical window is heavily contaminated [1]. | Clean the optical window using the appropriate protocol. |

Experimental Protocols: Cleaning Methodologies

Standard Cleaning Protocol for Common Optical Windows

This protocol synthesizes best practices for cleaning materials like quartz, glass, and coated optics, excluding specialized materials like sapphire or CaFâ‚‚.

Research Reagent Solutions:

| Material/Item | Function | Key Consideration |

|---|---|---|

| Spectroscopy-Grade Solvents (Acetone, Methanol, Isopropanol) | Dissolve organic residues and oils without leaving streaks [10]. | A 60:40 acetone-methanol blend is often optimal; acetone alone dries too quickly [10]. |

| Lint-Free Wipes (Lens tissue, cotton swabs) | Provide an abrasive-free surface for physically removing contaminants with a solvent [10]. | Never use dry. Never re-use a wipe or swab on multiple areas [13] [10]. |

| Compressed Gas (Canned air, dry Nitrogen) | Removes loose particulate matter without physical contact [10]. | Always the first cleaning step. Ensure the can is upright to avoid spraying propellant [13]. |

| Powder-Free Gloves (Vinyl or Nitrile) | Prevents fingerprint oils and salts from being transferred to optical surfaces during handling [9] [10]. | Ensure they are acetone-impermeable if using that solvent [13]. |

Step-by-Step Workflow:

- Preparation: Work in a clean, low-dust environment. Gather all materials: solvents, lint-free wipes (e.g., lens tissue, clean-room swabs), and compressed air/gas. Wear powder-free gloves [10].

- Inspection & Dry Dusting: Hold the optical window under a bright light at an angle to visualize contaminants. Always start by blowing off the surface with clean, dry compressed air or nitrogen. This removes abrasive grit [10].

- Solvent Cleaning:

- Moisten a fresh lint-free wipe or swab with an appropriate solvent (e.g., spectroscopy-grade acetone or methanol). Do not soak it—fling off excess solvent to prevent chilling and condensation [13] [10].

- For unmounted optics: Use the "drop and drag" technique. Lay a piece of unfolded lens tissue over the optic, drop solvent onto it, and slowly drag the tissue across the optic's face [10].

- For mounted or small optics: Use the "brush" technique. Fold lens tissue into a brush, grip it with tweezers, wet it with solvent, and wipe slowly from one edge to the other in a single, straight motion [10].

- Final Drying: If necessary, use a clean, dry swab or a final swipe with a solvent-dampened swab to accelerate evaporation and prevent streaking. Allow the window to air-dry fully before use [12] [10].

- Re-inspection: Inspect the window again under bright light. If stains persist, the process may need to be repeated with a different solvent or method.

Specialized Cleaning Protocols

The standard protocol must be adapted for specific window materials, as incorrect cleaning can cause irreversible damage.

Summary of Material-Specific Protocols:

| Optical Window Material | Key Cleaning Consideration | Approved Solvents/Cleaners | Prohibited Actions |

|---|---|---|---|

| Sapphire (Coated) [12] [13] | Use only manufacturer-specified cleaners. | Industrial Strength Windex with Ammonia D or spectroscopy-grade acetone [12] [13]. | Using any other commercial glass cleaner. Using ultrasonic cleaning [13]. |

| Calcium Fluoride (CaFâ‚‚) [14] | Sensitive to shock and temperature; gentle handling is critical. | Acetone for initial cleaning, followed by deionized water for water-soluble residues [14]. | Applying excessive pressure during wiping. |

| General Coated Optics [13] | Confirm coating solubility before using water or alcohols. | Spectroscopy-grade acetone, methanol, propanol, hexane. De-ionized water only for coatings below 1550nm if not water-soluble [13]. | Using water on water-soluble coatings. |

Research-Grade Maintenance Workflow

Adhering to a systematic workflow for diagnosing and addressing contamination ensures data integrity and protects sensitive optical components.

Frequently Asked Questions

Q1: What are the key material properties to consider when selecting an optical window for a spectrometer? The selection of an optical window is critical and depends on several key material properties that must align with your experimental conditions [15] [16]. The most important considerations are:

- Transmission Range: The wavelengths of light the material must transmit efficiently [15] [16].

- Refractive Index: Determines how much light is reflected at each surface and how much the light path is bent [15] [16].

- Knoop Hardness: Indicates the material's resistance to scratches and abrasion, which is vital for durability and cleanability [15] [16].

- Chemical Resistance: The material's ability to withstand exposure to cleaning solvents and other chemicals [17].

- Coefficient of Thermal Expansion: Describes how the material's dimensions change with temperature, affecting stability in varying thermal environments [15] [16].

Q2: How does the Abbe number relate to the performance of an optical window? The Abbe number (νd) quantifies the dispersion of an optical material, which is the variation of its refractive index with wavelength [15] [16]. A low Abbe number indicates high dispersion, which can lead to chromatic aberrations (color fringing) in some optical systems. For optical windows, which typically introduce no optical power, dispersion is less critical than for lenses. However, for high-precision spectroscopic applications, selecting a material with an appropriate Abbe number helps minimize any potential broadening of spectral lines [15].

Q3: My ZnSe window appears cloudy after cleaning. What might have caused this? Cloudiness on a Zinc Selenide (ZnSe) window is often due to water condensation or improper cleaning technique [18]. ZnSe is a soft, fragile material that requires specific handling.

- Cause: Using an overly soaked swab can cause the window to chill rapidly due to solvent evaporation, drawing moisture from the air and leaving water spots or a cloudy film [18].

- Solution: Ensure cleaning swabs are damp but not dripping wet. When using solvents like acetone, "fling off excess solvent by a flip of the wrist" before contacting the optic [18]. If water marks persist, a subsequent cleaning with a sparing amount of de-ionized water followed immediately by an acetone-dampened swab can help remove them [18].

Q4: Can I use a standard glass cleaner on my sapphire optical window? No, you must not use standard glass cleaners on sapphire windows unless explicitly recommended by the manufacturer. For instance, one manufacturer of flame detectors with sapphire optics specifically mandates the use of Industrial Strength Windex with Ammonia D and warns that other commercial glass cleaners will cause permanent damage [12]. Always consult the manufacturer's guidelines, as the chemical resistance of coated and uncoated surfaces can vary significantly.

Q5: What does a "scratch-dig" specification of 60-40 mean? The scratch-dig specification is a U.S. standard (MIL-PRF-13830B) for evaluating surface imperfections [15] [16]. The first number (60) refers to the scratch designation, which is determined by comparing surface scratches to a set of standard scratches under controlled lighting. The second number (40) refers to the dig designation, which is the maximum allowable diameter of a dig (a small pit) in microns divided by 10. Therefore, a 60-40 specification is a commercial grade, suitable for many imaging systems and non-critical applications where some minor surface defects are acceptable [16].

Troubleshooting Guide

Problem: Poor Signal-to-Noise Ratio or Reduced Transmission

Potential Cause 1: Surface Contamination (Dust, Fingerprints, Residue) Contaminants on the window surface scatter and absorb light, reducing throughput and increasing noise.

Diagnosis:

- Perform a visual inspection of the window under bright, oblique lighting. Look for fingerprints, dust, stains, or film.

- Check if the signal loss is consistent across all wavelengths or if it has worsened over time.

Solution: Perform Appropriate Cleaning

- Initial Dust Removal: Always start by blowing off the window surface with clean, dry, compressed air or nitrogen to remove loose, abrasive particles [19] [18].

- Solvent Cleaning:

- Don clean, powder-free vinyl or latex gloves to prevent fingerprint oils from transferring to the optic [18] [17].

- Use a clean, lint-free swab or cloth (e.g., Easy-Laser Cleaning cloth, lens tissue) [19].

- Moisten the swab with a few drops of a high-purity solvent (e.g., spectroscopy grade acetone, methanol, or isopropyl alcohol). Do not soak the swab; it should be damp, not dripping [18].

- Wipe the surface gently using a circular motion, starting from the center and moving outwards to the edge. Rotate the swab continuously to present a clean surface [18] [20].

- Use a new swab for each cleaning pass. Never wipe a cleaned area with a used swab [18].

- Streak Removal: A final wipe with a swab dampened with high-purity alcohol can help eliminate streaks left by other solvents [20].

Prevention: Handle windows only by the edges while wearing gloves. Store optics in a clean, dry environment when not in use [17].

Potential Cause 2: Material Absorption or Incompatible Transmission Range The window material itself may be absorbing light in your required spectral range.

Diagnosis:

- Consult the transmission range chart for your window material. For example, Germanium (Ge) is opaque in the visible spectrum but transmits in the IR, while UV Fused Silica transmits well in the UV but not in the far-IR [16].

- Measure the transmission of your system with and without the window installed.

Solution:

- Select a window material with a transmission range that encompasses your experimental wavelengths. See Table 1 for a comparison.

Problem: Visible Scratches on the Window Surface

Potential Cause: Improper Cleaning or Handling Technique Scratches are often caused by wiping a dry surface or using a cloth/swab that has trapped abrasive dust particles [19] [18].

Diagnosis: Visual inspection under magnification will reveal linear surface defects.

Solution:

- For minor scratches, if they are outside the specified scratch-dig tolerance and not in a critical part of the beam path, they may be tolerable for some applications [16].

- For deep scratches that affect performance, the window may need to be repolished or replaced.

- For future cleaning, always use a solvent-dampened swab, never a dry one, and always blow off loose particles first [18].

Problem: Cracked or Shattered Window

Potential Cause: Thermal Shock Rapid temperature changes can cause catastrophic failure, especially in materials with a higher coefficient of thermal expansion, even those known for good thermal properties like fused quartz [17].

Diagnosis: Check the operating environment for rapid heating or cooling cycles.

Solution:

- Ensure gradual heating and cooling of the optical assembly. Avoid exposing the window to extreme temperature gradients.

- For high-power laser applications, ensure the window is specified to handle the associated thermal load.

Material Properties and Selection Data

Table 1: Optical and Mechanical Properties of Common Window Substrates

This table summarizes key properties to guide material selection. Data is compiled from industry standards [15] [16].

| Material | Refractive Index @ 587.6 nm (nd) | Transmission Range (µm) | Knoop Hardness (HK) | Density (g/cm³) | Coefficient of Thermal Expansion (×10â»â¶/°C) |

|---|---|---|---|---|---|

| UV Fused Silica | 1.458 | 0.18 - 2.1 | 500 | 2.20 | 0.55 |

| N-BK7 | 1.517 | 0.35 - 2.0 | 610 | 2.46 | 7.1 |

| Sapphire | 1.768 | 0.17 - 5.5 | 2200 | 3.97 | 5.3 |

| Calcium Fluoride (CaFâ‚‚) | 1.434 | 0.13 - 10 | 158 | 3.18 | 18.85 |

| Zinc Selenide (ZnSe) | 2.403 | 0.6 - 20 | 120 | 5.27 | 7.1 |

| Germanium (Ge) | 4.003 | 2.0 - 14 | 780 | 5.33 | 6.1 |

| Magnesium Fluoride (MgFâ‚‚) | 1.413 | 0.12 - 7.0 | 415 | 3.18 | 13.7 |

| Acrylic (PMMA) | 1.49 | 0.4 - 1.6 | 18 | 1.18 | 72 |

Table 2: Scratch-Dig Specifications and Common Applications

Surface quality is defined by the MIL-PRF-13830B standard [16].

| Scratch-Dig Specification | Description and Typical Applications |

|---|---|

| 80-50 | Commercial Grade. Common for non-critical imaging and light gathering where cost is a primary factor. |

| 60-40 | Standard Grade. The most common specification for commercial applications where surface quality is not critical. |

| 40-20 | Precision Grade. Used for low to medium-power laser systems and precision applications where surface quality is important. |

| 20-10 / 10-5 | High-Precision Grade. Required for high-power laser systems and very high-precision systems where surface quality is critical. |

Experimental Protocols

Detailed Methodology: Cleaning and Visual Inspection of Optical Windows

This protocol is adapted from standard procedures for handling precision optics, with specific considerations for fragile materials like ZnSe [18] [21].

1. Objective To effectively remove particulate and film-based contamination from optical window substrates without introducing scratches, streaks, or residue, thereby restoring optimal transmission and performance.

2. The Scientist's Toolkit: Research Reagent Solutions

| Item | Function and Specification |

|---|---|

| Compressed Duster / Dry Nitrogen Gas | To remove loose, abrasive particulate matter before any physical contact with the optic surface. A regulated supply of dry nitrogen is preferred [18]. |

| Lint-Free Swabs / Wipes | To apply solvents without introducing fibers or scratches. Examples: Easy-Laser Cleaning cloth, cotton swabs, or lint-free tissue [19] [18]. |

| High-Purity Solvents | To dissolve and remove organic residues and fingerprints. Must be spectroscopy grade to prevent streaking. Common solvents: Acetone, Methanol, Isopropyl Alcohol [18]. |

| Powder-Free Gloves | To prevent contamination from skin oils and salts. Clean room vinyl or latex gloves are recommended [18] [17]. |

| De-ionized Water | To dissolve and remove water-soluble residues. Used after initial solvent cleaning if water marks or stains persist [18]. |

| Inspection Light Source | A 40W incandescent lamp or high-intensity desk lamp in a darkened room to illuminate surface defects against a black background [18] [20]. |

3. Workflow The following diagram outlines the logical decision process for inspecting and cleaning an optical window.

4. Step-by-Step Procedure

- Preparation: Work in a clean, dust-free environment, preferably under a laminar flow hood. Clear the work surface and wear clean, powder-free gloves [18]. Set up a black background and illuminate the window with a bright light at an oblique angle for inspection [18] [20].

- Initial Dust Removal: Without touching the surface, blow off the window using a can of clean, dry air or regulated dry nitrogen gas. Hold the can upright to avoid spraying propellant onto the optic [18].

- Solvent Cleaning (for fingerprints/oils):

- Moisten a fresh, lint-free swab with a small amount of spectroscopy-grade solvent (e.g., acetone). Flung off excess solvent to prevent chilling and condensation [18].

- Gently wipe the optical surface using a circular motion, working from the center toward the edge. Rotate the swab as you proceed to ensure a clean surface is always in contact with the window [18] [20].

- Use a new swab for each pass. Do not re-use swabs or go back over a cleaned area with a dirty swab [18].

- Streak and Residue Removal: If streaks remain, repeat the process with a different high-purity solvent (e.g., follow acetone with isopropyl alcohol) [20]. For persistent water-soluble marks, a sparingly dampened swab with de-ionized water can be used, followed immediately by an acetone-dampened swab to dry the surface quickly [18].

- Final Inspection and Storage: Perform a final visual inspection under light. If the surface is not clean, repeat the process. Once clean, place the window in a protective container or a clean, dry storage cabinet to prevent recontamination [17].

5. Important Notes and Precautions

- ZnSe Warning: Zinc Selenide is a soft and fragile material. Avoid excessive pressure during cleaning. Do not use ultrasonic cleaning for ZnSe viewports, as it can cause damage [18].

- Coating Compatibility: Always verify that the cleaning solvents are compatible with any anti-reflection (AR) coatings on the window. When in doubt, consult the manufacturer.

- Quartz Glass: While highly chemical-resistant, fused quartz should be cleaned with mild detergents or solvents and rinsed with de-ionized water. Avoid abrasive cleaners [17].

In spectroscopic analysis, the clarity of optical windows is not merely a matter of data quality—it is the foundation of regulatory compliance and research integrity. Neglecting the maintenance of these critical components introduces unseen costs that extend far beyond the spectrometer itself. Contaminated windows scatter light, distort baselines, and introduce errors that can compromise drug purity assays, invalidate research findings, and lead to costly regulatory non-compliance. This technical support center provides actionable guidance to safeguard your data, ensure compliance, and protect your research investments.

Troubleshooting Guides: Identifying and Resolving Common Issues

Q1: Why are my absorbance readings unstable or drifting?

Possible Causes & Solutions:

- Insufficient Lamp Warm-up: The instrument's lamp requires 15-30 minutes to stabilize after being turned on. Solution: Allow the spectrophotometer to warm up for at least 15-30 minutes before taking measurements [2].

- Air Bubbles in Sample: Air bubbles in the cuvette can scatter the light beam. Solution: Remove the cuvette and gently tap it to dislodge bubbles. If bubbles persist, prepare a new sample [2].

- Environmental Factors: Vibrations or temperature fluctuations from drafts or equipment can affect stability. Solution: Ensure the spectrophotometer is on a stable, level bench away from sources of vibration [2].

Q2: Why does the instrument fail to blank or set to 100% transmittance?

Possible Causes & Solutions:

- Failing Light Source: The deuterium or tungsten lamp may be near the end of its life and have insufficient energy. Solution: Check the lamp's usage hours in the instrument’s software and replace the lamp if necessary [2].

- Dirty or Misaligned Optics: Contamination on internal optical components, including windows, can block or scatter light. Solution: Clean the accessible optical windows following proper procedures. If the problem persists, the instrument may require professional servicing for internal optical alignment [2].

Q3: Why am I getting negative absorbance readings?

Possible Causes & Solutions:

- Improper Blanking Technique: The blank solution may have been "dirtier" or contained in a dirtier cuvette than the sample. Solution: Always use the exact same cuvette for both blank and sample measurements. Ensure the cuvette is meticulously clean before blanking [2].

Experimental Protocols for Cleaning and Validation

Standard Operating Procedure: Cleaning Optical Windows

Objective: To safely remove contamination from spectrometer optical windows without damaging delicate surfaces.

Principle: Use a stepped approach, starting with the least invasive method to avoid scratching coatings or substrates [10] [22].

Workflow: Optical Window Cleaning & Inspection

Materials & Reagents:

- Powder-free, acetone-impenetrable gloves [10]

- Canned, compressed, or nitrogen air duster [10] [22]

- Low-lint lens tissue [10] [22]

- Reagent-grade solvents (e.g., isopropyl alcohol, or a 60/40 mix of acetone and methanol) [10] [22]

- Cotton-tipped swabs [22]

Methodology:

- Handling & Inspection: Always wear gloves and handle optics only by the edges [22]. Inspect the window by holding it under a bright light at different angles to reveal dust and stains through light scattering [10].

- Dry Air Cleaning: Always begin by blowing off dust with a clean air duster. "Wiping a dusty optic is like cleaning it with sandpaper" [10].

- Solvent Cleaning (Drop and Drag Method):

- Place the optic on a clean, lint-free wiper.

- Lay a piece of unfolded lens tissue over the optic.

- Drop a small amount of solvent onto the tissue to saturate it.

- Slowly drag the soaked tissue across the optic's face in a single, straight motion [10].

- Final Storage: Once clean, wrap the optic in clean lens tissue and store it in a dedicated container to prevent scratches and contamination [10] [22].

Safety Notes:

- NEVER touch or clean the internal mirrors or grating; this must be done by a trained service engineer [23].

- NEVER use acetone on plastic optics or housings, as it will cause damage [10] [22].

- Never reuse lens tissue [10].

Advanced Protocol: Laser Cleaning of Stubborn Contaminants

For specialized applications where chemical cleaning is ineffective, laser cleaning offers a non-contact, precise alternative. This method, demonstrated effectively on a contaminated rubidium vapor cell, uses a focused laser to ablate tenacious deposits without damaging the underlying quartz substrate [3].

Experimental Workflow:

- Sample Analysis: The opaque contaminant layer on the inner window of a vapor cell was first analyzed via Raman spectroscopy, identifying it as rubidium silicate [3].

- Laser Setup: A Q-switched Nd:YAG laser (1064 nm, 3.2 ns pulse width) was used. The beam was focused by a lens to a point 1 mm in front of the contaminated surface inside the cell [3].

- Cleaning Execution: A single laser pulse was directed through the intact front window. The defocused positioning on the inner surface minimized heat stress to the glass, preventing micro-cracks. A single pulse was sufficient to clear the black discoloration and restore transparency locally [3].

Key Parameter: The success of this method hinged on the significant difference in laser light absorption between the contaminant and the quartz window, allowing selective removal without substrate damage [3].

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function & Application | Key Considerations |

|---|---|---|

| Low-Lint Lens Tissue | Wiping optical surfaces in conjunction with solvents. | Never use dry, as it can scratch. Never reuse [10]. |

| Reagent-Grade Isopropyl Alcohol | Safe and effective general-purpose solvent for optics. | Evaporates slower than acetone; can leave drying marks [10] [22]. |

| Reagent-Grade Acetone | Powerful solvent for removing stubborn contaminants. | Dries very quickly. Not compatible with plastic optics [10] [22]. |

| Compressed Air / Nitrogen Duster | Removing loose particulate matter without contact. | Essential first step before any wiping [10]. |

| Powder-Free Gloves | Handling optics without transferring skin oils. | Human sweat is highly corrosive to optical coatings [10]. |

| Cotton-Tipped Swabs | Applying solvent to small or hard-to-reach areas. | Useful for mirrors and filters [22]. |

| 2-(Oxolan-3-ylmethoxy)oxane | 2-(Oxolan-3-ylmethoxy)oxane, CAS:76742-53-5, MF:C10H18O3, MW:186.25 g/mol | Chemical Reagent |

| Manganese neononanoate | Manganese neononanoate, CAS:93918-16-2, MF:C18H34MnO4, MW:369.4 g/mol | Chemical Reagent |

Cost of Neglect: Quantitative Impact Analysis

The financial and operational consequences of poor maintenance are quantifiable. The table below summarizes key data linking neglect to tangible outcomes.

Table: Quantitative Impact of Instrument Neglect & Maintenance

| Metric | Impact of Proper Maintenance | Impact of Neglect | Data Source |

|---|---|---|---|

| Instrument Readiness | Consistent performance after 15-30 min warm-up [2]. | Unstable, drifting readings; failed calibrations [2]. | Spectrophotometer Troubleshooting Guide [2] |

| Data Accuracy | Absorbance values in optimal 0.1-1.0 AU range [2]. | Negative absorbance; inconsistent replicates [2]. | Spectrophotometer Troubleshooting Guide [2] |

| Cuvette Lifespan | Quartz cuvettes can last for years with proper care [24]. | Scratches and chemical etching require frequent replacement. | Quartz Cuvette Guide [24] |

| OSA Market Demand | USD 264.5M by 2035, driven by need for precision [25]. | High cost of non-compliance and faulty data in telecom/R&D. | US Optical Spectrum Analyzer Market Report [25] |

| Laser Cleaning Efficacy | Contaminants removed with 400 J/cm² fluence, restoring function [3]. | Permanent damage to optics; requires costly component replacement. | Scientific Reports on Laser Cleaning [3] |

Frequently Asked Questions (FAQs)

Q1: How often should I clean the optical windows on my spectrometer?

A: Clean them "only when necessary" [10]. Perform regular visual inspections. If you notice increased noise, baseline drift, or failure to blank, inspect and clean the windows as needed. Unnecessary cleaning increases the risk of damaging the optical surfaces.

Q2: Can I use laboratory wipes or my lab coat to clean an optical window?

A: Absolutely not. Always use materials specified for optics, such as low-lint lens tissue [10]. Common wipes and clothing can contain abrasives that will permanently scratch delicate optical coatings.

Q3: What is the single most important practice for maintaining optical performance?

A: Consistent, careful technique is paramount [2]. This includes proper handling of cuvettes, using the correct cuvette type (e.g., quartz for UV work) [24], preparing a proper blank, and allowing the instrument adequate warm-up time [2].

Q4: Our lab works with hydrofluoric acid (HF). What special precautions are needed for our quartz windows?

A: Quartz is incompatible with HF, which will corrode and dissolve the silica material [24]. For applications involving HF, you must use cuvettes and optics made from alternative inert materials like PTFE (Teflon).

Q5: When should I seek professional service instead of cleaning myself?

A: Internal optics like mirrors, gratings, and beam splitters should only be cleaned by a trained service engineer [23]. If basic cleaning of accessible windows does not resolve performance issues, the problem may be internal misalignment or a failing component that requires professional attention [2].

Step-by-Step Cleaning Protocols: Best Practices for Pristine Optical Surfaces

Maintaining the optical windows of spectrometers and other sensitive laboratory instruments is a critical but often underestimated aspect of experimental research. Contamination on optical surfaces is a well-known problem that can negatively affect performance by decreasing transmitted light intensity, modifying laser wavefronts, and facilitating laser-induced damage [26]. For researchers in drug development and other fields requiring precise quantitative measurements, proper cleaning is not merely a matter of optics clarity but of data integrity. This guide details the essential supplies and methods for effective and safe cleaning.

Essential Cleaning Supplies: A Researcher's Toolkit

The following table categorizes the fundamental supplies needed for cleaning delicate optical surfaces, along with their specific functions.

| Supply Category | Example Products | Key Function & Characteristics |

|---|---|---|

| Cleaning Wipes | Absorbond Cleanroom Wipes [27], Premium Lens Tissues [28], High-Density Cleanroom Wipes [29], Microfiber Cloths [30] | Low-lint, soft, and non-abrasive materials for physically removing contamination without scratching surfaces or leaving fibers. |

| Solvents | Acetone [30], Lens-grade Isopropyl Alcohol (IPA) [29] | High-purity solvents used to dissolve and remove organic residues, oils, and other contaminants. Compatibility with wipes is crucial. |

| Dusters | Cans of Compressed Propellant [28] | Used for dry, non-contact removal of loose particulate matter before wiping. |

| Application Tools | Cotton-Tipped Applicators [28], Wash & Dropper Bottles [28] | Tools for precise application and control of solvents to optical surfaces, minimizing waste and spill risk. |

| Polymer Cleaners | Red First Contact Polymer [28] | A specialized polymer that is applied as a liquid and peeled away, lifting contaminants from the surface. |

| beta-D-Ribulofuranose | beta-D-Ribulofuranose|CAS 131064-70-5 | Research-grade beta-D-Ribulofuranose (CAS 131064-70-5). This biochemical monosaccharide is for Research Use Only. Not for human or veterinary diagnostic or therapeutic use. |

| 3-Hydroxybutyl dodecanoate | 3-Hydroxybutyl dodecanoate, CAS:89457-37-4, MF:C16H32O3, MW:272.42 g/mol | Chemical Reagent |

Frequently Asked Questions (FAQs)

Q1: What are the consequences of having dirty optical windows on a spectrometer? Dirty windows on a spectrometer can cause instrument analysis to drift more frequently, necessitating more frequent recalibration. Ultimately, this results in very poor analysis readings and inaccurate data [1].

Q2: How do I know if my spectrometer's issues are related to a dirty window versus another component? Monitor your results. If you observe a consistent drift in calibration or poor analysis readings, and other factors like argon purity and sample preparation are ruled out, the optical windows are a primary suspect. Regular maintenance scheduling can preempt this troubleshooting [1].

Q3: Can I use any wipe to clean an expensive optical component? No. Standard laboratory wipes or tissues can be too abrasive and may leave lint or fibers on the optical surface. It is essential to use wipes specifically designed for optics, which are soft, non-abrasive, and have low linting properties to prevent scratches and contamination [27] [28].

Q4: Is it safe to clean the faceplate of a CCD sensor? Yes, but it requires extreme care and the correct materials. The process involves using a solvent like acetone and a single, gentle wipe with a microfibre cloth in one direction to push dust off without scratching the surface. Note that this procedure voids many warranties and carries a risk of damage if not performed correctly [30].

Troubleshooting Common Optical Window Issues

Problem: Drifting Calibration or Poor Analysis Results

This is a classic symptom of contamination on the internal optical windows of a spectrometer [1].

- Possible Cause: Accumulation of residues on the windows located in front of the fiber optic and in the direct light pipe.

- Solution: The windows require cleaning. This is often part of scheduled professional maintenance. For end-users, if the instrument design allows access, use the cleaning protocol detailed below.

Problem: Visible Dust or Debris on External Optics

This is common on exposed lenses, windows, or camera sensors and creates artifacts like "dust donuts" in images [30].

- Possible Cause: Environmental dust settling on the optical surface.

- Solution:

- Dry Cleaning: Use a can of compressed air or a duster to blow off loose particles without making contact [28].

- Wet Cleaning: If debris remains, proceed with a solvent-based cleaning method using appropriate wipes, as described in the following protocol.

Experimental Cleaning Protocol for Optical Windows

The following workflow outlines a standardized, multi-step method for safely cleaning sensitive optical surfaces, from initial inspection to final verification.

Step-by-Step Methodology:

Initial Inspection: Before cleaning, examine the optical surface under a bright light using magnification (e.g., a powerful lens) [30]. This helps identify the type and extent of contamination (dust, oils, films).

Dry Dust Removal: Use a can of compressed air or a duster to remove any loose, dry particulate matter [28]. This initial non-contact step prevents grinding particles into the surface during wiping.

Solvent Application: Apply a few drops of a high-purity solvent (e.g., lens-grade isopropyl alcohol or acetone) onto a folded optical wipe or directly onto the surface [30]. Using dispenser bottles minimizes solvent evaporation and contamination [28].

- Note: Acetone is a stronger solvent but should be used with caution as it can damage some plastics or coatings. Always verify material compatibility.

Wiping the Surface: Gently wipe the optical surface using the saturated wipe. Employ a single, continuous stroke from one end to the other to push contaminants off the surface [30]. Avoid circular motions or sweeping back over the same area with the same part of the wipe.

Final Inspection and Re-Cleaning: Re-inspect the surface under bright light. If any contamination remains, repeat the solvent application and wiping process with a fresh wipe until the surface is clean.

Comparison of Optical Cleaning Wipe Specifications

Selecting the right wipe is critical. The table below compares key specifications from leading suppliers to inform procurement decisions.

| Product Name | Material / Type | Key Features | Dimensions | Quantity | Price |

|---|---|---|---|---|---|

| Absorbond Cleanroom Wipes [27] | Cleanroom Optic Wipe | Designed for cleanroom use; low solvent extractable levels; leaves minimal nonvolatile residue. | Not Explicitly Stated | 1200 | $126.66 |

| Lens Cleaning Tissues (MC-5) [28] | Premium Grade Sheets | Extremely soft; meets U.S. Government specification A-A-50177B; free from contaminants and adhesives. | 4.9" x 2.9" (124 x 73 mm) | 125 sheets (5 booklets of 25) | $12.48 |

| OPTO-WIPES [28] | Precision Lens Cleaning Wipes | Not Specified | 2" x 4" | Not Specified | Not Specified |

| Cloth Cleaning Wipes [31] | Advanced Microfiber | Reusable, smooth white cloths; highly absorbent for water, grease, and oil; low-lint and machine-washable. | 4" x 4" | Not Specified | Starting at $24.75 (qty 1-9) |

| High-Density Cleanroom Wipes [29] | High-Density Microfiber | Fast particle & residue removal; low linting; reusable for non-critical tasks; can be used with common optical cleaners. | Not Specified | Not Specified | Not Specified |

Keywords: optical cleaning, spectrometer maintenance, loose contaminants, blowing technique, optical windows

## Frequently Asked Questions

Why is blowing off loose contaminants always the recommended first cleaning step? This non-contact method removes abrasive particulates like dust safely. Skipping this step risks grinding these particles into the delicate optical surface during subsequent wiping, which can cause permanent scratches and scatter light [32].

Can I use the compressed air from my lab's standard air line? No. You must use a regulated supply of dry, clean, compressed nitrogen gas or a canister of inert dusting gas designed for optical use [33]. Standard compressed air lines often contain oil, moisture, and particulates that will contaminate the optic.

What is the safest technique for holding the gas nozzle? Hold the can or nozzle upright and roughly 6 inches (15 cm) from the optic [32]. Angle the nozzle at a shallow, grazing angle to the optical surface rather than directing it straight on [32].

## Troubleshooting Common Problems

| Problem | Likely Cause | Solution |

|---|---|---|

| Lint or fibers remain on surface | Blowing force was insufficient to dislodge clinging debris. | Use short, firm blasts of gas. For stubborn lint, consider re-blowin after lightly moistening a swab with solvent (proceed to wet cleaning if protocol allows) [33]. |

| Streaks or spots appear after blowing | Canned air was tipped, releasing propellant solvent onto the optic [33]. | Always keep canned air upright. Use dry compressed nitrogen for a cleaner alternative [33]. |

| Contaminants are not removed | The blowing technique did not cover the entire surface. | Systematically trace a figure-eight pattern over the entire optical surface to ensure full coverage [32]. |

## Experimental Protocol: Validating the Blowing-Off Technique

### 1. Objective

To establish and validate a standardized, non-destructive protocol for the removal of loose particulate contamination from spectrometer optical windows prior to any solvent-based cleaning.

### 2. Materials and Reagents

Table: Research Reagent Solutions for Blowing Protocol

| Item | Function & Specification | Rationale |

|---|---|---|

| Regulated Nitrogen Gas | Oil-free, dry, compressed nitrogen source with a pressure regulator. | Provides a clean, moisture-free gas stream without the risk of liquid propellant contamination associated with canned air [33]. |

| Canned Inert Dusting Gas | A canister of inert gas specifically designed for cleaning optics. | A convenient alternative to nitrogen. Precaution: Must be held upright during use to prevent propellant discharge [32]. |

| Blower Bulb | A manual rubber bulb. | A low-cost, solvent-free option that provides a gentle burst of air, though it may be less effective for strongly adhered particles [32]. |

| 40W Illumination Lamp | A lamp with a ground glass diffuser. | Provides bright, even lighting essential for visualizing contaminants and verifying cleaning efficacy against a black background [33]. |

| Black Background | A non-reflective black card or material. | Placed behind the optic during inspection, it dramatically improves contrast, making tiny particles and defects more visible [33]. |

### 3. Step-by-Step Methodology

- Preparation: Conduct all work in a clean, low-traffic environment, ideally under a HEPA-filtered laminar flow hood [33]. Gather materials and ensure the gas source is operational.

- Inspection: Place the black background approximately 18 inches behind the optic [33]. Illuminate the optical surface at a right angle to your line of sight [33]. Inspect the window, noting the type and distribution of contaminants.

- Gas Source Check: If using canned gas, start the flow with the nozzle pointed away from the optic to clear any initial irregularities [32].

- Application:

- Post-Cleaning Inspection: Re-inspect the optic under illumination against the black background. Compare the surface state to your initial notes. The process may be repeated if significant particulates remain.

### 4. Logical Workflow

The diagram below outlines the decision-making workflow for the blowing-off technique.

Critical Safety Notes

- Never use your mouth to blow on an optical surface, as saliva will contaminate it [32].

- Do not use standard, unregulated compressed air, which can contain oil and water vapor [33].

- Handle with care: Always wear powder-free cleanroom gloves or use optical tweezers to avoid transferring skin oils to the optic [32].

Within the broader research on maintaining spectrometer optical windows, the Drag Method stands out as a preferred technique for cleaning flat optical surfaces. This guide details the methodology, which involves gently dragging a solvent-dampened lens tissue across the optic to remove contaminants like oils and small adhered particles with minimal physical contact [32]. Proper execution is critical for preserving the performance and longevity of sensitive components, such as optical windows in spectrometers, where contamination can increase light scatter and create damaging hot spots [32] [10]. The following sections provide researchers and drug development professionals with a comprehensive, practical framework for implementing this technique.

Frequently Asked Questions (FAQs) and Troubleshooting

Q1: On which types of optical components is the Drag Method recommended? The Drag Method is specifically recommended for cleaning flat optical surfaces that are elevated above any surrounding surfaces [32]. It is highly effective for optics like mirrors and unmounted windows [10]. However, it should never be used on extremely delicate surfaces such as holographic gratings, ruled gratings, first surface unprotected metallic mirrors, and pellicle beamsplitters, for which only blowing with inert gas is approved [32] [34].

Q2: Why did my optic have streaks after using the Drag Method? Streaking is a common issue that can arise from several factors, primarily related to solvent volume and technique:

- Excess Solvent: Using too much solvent, which then pools and evaporates unevenly, is a leading cause of streaks [32] [10].

- Incorrect Drying: Dragging the tissue too quickly does not allow for uniform solvent evaporation [10].

- Edge Streaking: Streaks can form at the edge of the lens tissue if the wiping path is not continuous [32].

- Solution: Ensure the lens tissue is damp but not dripping. Use a slow, steady drag and a continuous path that eliminates wiped interfaces on the optical surface. A solvent blend like 60% acetone/40% methanol can reduce streaking by slowing evaporation time [10].

Q3: What should I do if blowing off the surface is not sufficient? If blowing off dust and loose particles does not fully clean the optic, the Drag Method is an appropriate next step for removing more tenacious contaminants like fingerprints and oils [32]. The key is to always blow off the surface first; wiping a dusty optic can grind particles into the surface, causing scratches [10].

Q4: The contaminant is still present after one pass. Should I repeat the process? Yes, you can repeat the process with a fresh sheet of lens tissue each time. Heavy concentrations of contaminants often require repeated treatments [32]. Always inspect the optic between cleaning attempts.

Q5: Can this method damage the anti-reflection coating on my spectrometer's optical window? If performed correctly with the recommended materials and minimal pressure, the risk is low. However, the method should be used with caution on soft or delicate coatings [10]. Always consult the optic manufacturer's guidelines if available [32].

Essential Materials and Reagents

The following table lists the key materials required for successfully executing the Drag Method.

Table 1: Research Reagent Solutions and Essential Materials for the Drag Method

| Item Name | Function/Description | Key Considerations |

|---|---|---|

| Powder-Free Gloves (Acetone-impenetrable) | Prevents skin oils and sweat, which are corrosive, from contaminating the optical surface [10]. | Nitrile or powder-free latex are suitable. Always wear them during handling and cleaning [34]. |

| Lens Tissue | A low-lint, soft paper that makes light contact with the optical surface to lift contaminants [32] [35]. | Must be used with solvent; never use dry. Use each sheet only once [10]. |

| Reagent-Grade Solvents (e.g., Acetone, Methanol, Isopropanol) | Dissolves organic contaminants like oils and fingerprints. A blend can optimize cleaning and drying [32] [10]. | Use spectrophotometric or reagent-grade purity. Most are poisonous and flammable [32]. A 60% acetone, 40% methanol blend is often effective [10]. |

| Inert Dusting Gas / Blower Bulb | Removes loose abrasive dust and particles before wiping. This is a critical first step to prevent scratches [32] [35]. | Do not use your mouth to blow, as saliva will contaminate the surface. Hold the can upright and use short blasts [32]. |

| Clean, Non-Abrasive Surface (e.g., Clean-room wiper) | Provides a stable, contaminant-free base for holding the optic during the cleaning procedure [10]. | Ensures the optic is not contaminated from the back or bottom during handling. |

Experimental Protocol: Executing the Drag Method

Step-by-Step Methodology

- Preparation and Inspection: Work in a clean, temperature-controlled, low-dust environment. Put on powder-free, acetone-impenetrable gloves [10]. Before cleaning, inspect the optic under a bright light to determine the type and location of contaminants. This allows you to plan your drag path to lift contaminants off the surface as quickly as possible [32].

- Blow Off Loose Contaminants: Using a canister of inert dusting gas or a blower bulb, remove all dust and loose particles from the optical surface. Hold the can about 6 inches (15 cm) away, use short blasts, and wave the nozzle at a grazing angle in a figure-eight pattern over the surface [32]. Never skip this step, as wiping a dusty optic is akin to cleaning with sandpaper [10].

- Position the Optic: Place or hold the optic on a clean, non-abrasive surface so that it will not move during the drag. The surface should be stable against a weak lateral force [32].

- Prepare the Lens Tissue: Take a fresh, clean sheet of lens tissue and hold it above (not in contact with) the optic [32].

- Apply Solvent: Place one or two drops of an approved quick-drying solvent (e.g., the acetone-methanol blend) onto the lens tissue held above the optic. The correct amount of solvent will keep the tissue damp for the entire drag but will not leave a visible trace of solvent on the optic afterward [32].

- Execute the Drag: The weight of the solvent will cause the lens tissue to contact the optical surface. Slowly but steadily drag the damp lens tissue across the optic, being careful not to lift the tissue off the surface. Continue dragging until the tissue is completely off the optical surface [32].

- Inspection and Repetition: Inspect the optic again. If contaminants remain, repeat the process with a new sheet of lens tissue. Use each sheet only once [32].

Workflow Diagram

The following diagram illustrates the logical workflow and decision points for the Drag Method cleaning procedure.

Diagram 1: Drag Method Cleaning Workflow

Quantitative Data and Comparisons

Table 2: Solvent Properties and Selection Guide

| Solvent | Evaporation Rate | Effectiveness | Risk of Streaking | Recommended Use |

|---|---|---|---|---|

| Acetone | Very Fast | High for most oils and organics [10] | High if used alone [10] | Not for plastics; use with impenetrable gloves [35] [10] |

| Methanol | Fast | Good; dissolves some debris acetone does not [10] | Medium | Often blended with acetone to slow evaporation and improve cleaning [10] |

| Isopropyl Alcohol (IPA) | Slow | Safe and effective, but less aggressive [10] | High (can leave drying marks) [10] | General-purpose cleaning where slower drying is acceptable [35] |

| 60% Acetone / 40% Methanol Blend | Moderate | High; combines strengths of both solvents [10] | Low | Recommended blend for effective cleaning with minimal streaking [10] |

| De-ionized Water with Mild Soap | Slow | Low for oils, safe for most materials [35] | Medium (can leave streaks) | Safest option for unknown coatings or plastic optics [35] |

This guide details the Lens Tissue and Swab Method for cleaning curved and mounted optical windows, a critical skill for maintaining data integrity in spectroscopic research. Proper technique minimizes surface damage and ensures measurement accuracy.

Key Cleaning Technique: Lens Tissue with Forceps or Applicator

The Lens Tissue with Forceps or Applicator Method is the recommended protocol for cleaning curved surfaces or mounted optics where standard "drag" methods are impractical [34] [32].

Experimental Protocol:

- Inspection: Before cleaning, inspect the optic to locate contaminants and plan a wiping path that avoids dragging particles across the optical surface [34] [32].

- Tissue Preparation: Fold a sheet of lens tissue so that the portion contacting the optic remains untouched. Secure the folded tissue with forceps [34] [32].

- Solvent Application: Apply a few drops of an optical-grade solvent (e.g., acetone, methanol, or isopropyl alcohol) to the tissue. The tissue should be damp, not dripping [34] [32].

- Wiping Motion: Wipe the optical surface in a single, smooth motion. Continuously and slowly rotate the forceps during the wipe to present a clean tissue area to the surface and lift contaminants away [34] [32].

- Post-Cleaning Inspection: Inspect for streaks or remaining contamination. Repeat the procedure with a fresh lens tissue if necessary. Streaks often indicate excess solvent or an incorrect wiping technique [34] [32].

Troubleshooting Common Cleaning Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Streaks on Surface | Too much solvent used; edge of lens tissue left a residue [34] [32]. | Use a drier tissue, apply less solvent, or use a larger applicator for a continuous wiping path [34] [32]. |

| Lint or Fibers Left Behind | Wipe edges were not folded; using non-recommended materials like facial tissue [34] [36]. | Always use a folded edge of a lens tissue or Webril wipes. Never use paper towels or standard lab wipes [34] [36]. |

| Contaminants Are Not Removed | Solvent is not appropriate for the contaminant (e.g., water for oil) [34] [36]. | Re-inspect contaminant. Use a mild distilled water/optical soap solution for water-soluble marks, or a quick-drying solvent like acetone for oils [34] [36]. |

| Scratches After Cleaning | Dust or hard particles were dragged across the surface during wiping [34]. | Always blow off loose dust with an air blower or inert gas before any physical wiping [34] [32]. |

Frequently Asked Questions (FAQs)

Q1: What is the safest first step before touching any optical window with a swab? A1: The safest and most critical first step is to use pressurized inert gas or an air blower to remove loose abrasive particles. This non-contact method prevents scratching during subsequent wiping [34] [32].

Q2: Can I use acetone or isopropyl alcohol on all optical windows? A2: No. While common, solvent compatibility must be verified. Always consult the window or instrument manufacturer's guidelines, as some coatings or materials can be damaged by certain solvents [32] [36].

Q3: Why is it important to rotate the swab during the wiping process? A3: Continuous rotation ensures that a clean portion of the swab is always in contact with the optical surface. This prevents re-depositing lifted contaminants and is key to effective cleaning [34] [32].

Q4: What is the consequence of using too much solvent? A4: Excess solvent can pool on the surface and seep into mounts or edges, potentially damaging adhesives. As it dries, it will almost certainly leave behind streaks and residue, compromising optical clarity [34] [32].

Workflow and Signaling

The following diagram illustrates the logical decision pathway for selecting and executing the correct cleaning method for curved and mounted windows.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details essential materials required for the lens tissue and swab cleaning method.

| Item | Function & Application Note |

|---|---|

| Lens Tissue | Soft, lint-free paper for handling and cleaning; provides a safe surface for optical contact. Must be folded to create a clean contact point [34] [32]. |

| Optical-Grade Solvents (Acetone, Methanol, Isopropanol) | High-purity solvents for dissolving contaminants like oils and fingerprints. Caution: Most are toxic and flammable; always check material compatibility [34] [32]. |

| Powder-Free Gloves (Latex or Cotton) | Worn during handling to prevent permanent transfer of skin oils to optical surfaces [34] [32]. |

| Forceps (Optical or Vacuum Tweezers) | For securely holding lens tissue or handling small mounted optics without touching optical surfaces [34]. |

| Air Blower (Bulb or Inert Gas) | For non-contact removal of loose dust and particles. Never use breath from your mouth, as saliva will contaminate the surface [34] [32] [36]. |

| Magnification Device | Used for pre- and post-cleaning inspection to identify small contaminants and surface defects not visible to the naked eye [34] [32]. |

| Einecs 262-488-3 | Einecs 262-488-3|C23H27FO7 |

| Einecs 299-159-9 | Einecs 299-159-9, CAS:93857-27-3, MF:C27H26N2O7, MW:490.5 g/mol |

FAQs: Handling and Maintaining Fragile Optical Substrates

What makes ZnSe a particularly fragile material?

Zinc Selenide (ZnSe) is considered very fragile due to its specific mechanical properties. It is a relatively soft material with a Knoop hardness of 120 (using a 500g indenter), which makes it highly susceptible to scratching and mechanical damage during handling [37]. Its physical characteristics necessitate extreme care during cleaning and installation to prevent compromising optical performance and surface integrity [18].

What is the most critical rule when cleaning ZnSe optics?

The most critical rule is: DO NOT USE ULTRASONIC CLEANING for Zinc Selenide components [18]. The aggressive physical vibrations generated by ultrasonic cleaners can easily damage the delicate substrate. Always use gentle, manual cleaning methods with appropriate solvents.

Can I use standard glass cleaning solvents on ZnSe windows?

No, you should avoid standard glass cleaning solvents. It is recommended to use spectroscopy-grade solvents such as acetone, alcohol, methanol, propanol, or hexane, which have low acidity [18]. General-purpose glass cleaners can cause streaks or potentially react with the material [19].

What are the temperature limitations for ZnSe optics?

ZnSe has significant thermal limitations. While it has a high melting point of 1525°C, it oxidizes significantly at 300°C and undergoes plastic deformation around 500°C. For practical purposes in normal atmosphere, it is generally recommended not to use ZnSe windows over 250°C [37].

How should I handle ZnSe optics to avoid damage?

Always handle ZnSe optics with powder-free vinyl gloves to prevent contamination from skin oils [18]. Hold the window carefully by the edges with your thumb and forefinger when placing it in a holder or fixture. Avoid any contact with hard or sharp objects that could scratch or chip the material.

Experimental Protocols: Cleaning ZnSe Optical Windows

Detailed Cleaning Methodology

This protocol is designed for cleaning uncoated Zinc Selenide viewports and windows before use in spectroscopic systems [18].

Materials and Supplies Needed

- Solvents: Spectroscopy grade Acetone, Alcohol, Methanol, Propanol, Hexane, Distilled Water (all with low acidity)

- Water: De-ionized, ultra-filtered, low particulate water

- Gloves: Clean room vinyl, powder-free gloves

- Cleaning Tools: Clean room, lint-free swabs; lint-free tissue

- Gas Duster: Regulated supply of commercial dry compressed nitrogen gas or dusters like Stoner Spray Anyway 360o GUST 360o Duster

- Environment: Laminar flow hood; darkened room with 40 Watt illumination and black background

Step-by-Step Procedure

Preparation: Collect supplies and work in a darkened room equipped with a laminar flow bench. Provide a blackened background approximately 18 inches behind and beneath the window to enhance visibility of contaminants [18].

Initial Dust Removal: Wearing powder-free gloves, hold the window with your thumb and forefinger in front of the light source. Blow off the window surface first with clean, dry nitrogen or compressed air to remove any gritty dust that could cause scratching during wiping [18].

Solvent Cleaning: Wet a clean, lint-free swab with spectroscopic grade acetone. Flung off excess solvent with a flip of the wrist to prevent dripping. Clean from the outer edge to the center using small circular motions, rotating the window to a new section frequently [18].

Swab Management: Never reuse swabs on cleaned areas. Use a new swab for each section and discard it after use. Use a damp, but not dripping, swab to prevent excessive solvent evaporation that causes window chilling and condensation [18].

Stubborn Contamination: If debris or water marks persist after acetone cleaning, repeat the same procedure using de-ionized water sparingly. Dry the area afterward with an acetone-dampened swab [18].

Final Inspection: Examine the window under illumination. Repeat cleaning steps until all visible contamination is removed, working slowly and systematically from cleaned to dirty areas [18].

Data Presentation: ZnSe Material Properties

Quantitative Properties of ZnSe for Optical Applications

Table 1: Key optical and thermal properties of ZnSe relevant to spectroscopic applications [37]

| Property | Value at 10.6 μm | Significance for Applications |

|---|---|---|

| Refractive Index (n) | 2.4028 | Determines lens focal length and reflection losses |

| Refractive Index Temp Coefficient (dn/dT) | +61 × 10â»â¶ /°C | Causes thermal lensing in high-power systems |

| Absorption Coefficient | 0.0005 cmâ»Â¹ | Critical for minimizing heat generation in laser systems |

| Transmission Range | 0.6 μm to 21 μm | Suitable for broad IR applications including FTIR spectroscopy |

| Thermal Conductivity | 18 W·mâ»Â¹Â·Kâ»Â¹ | Governs heat dissipation speed |

| Thermal Expansion | 7.57 × 10â»â¶ /°C | Contributes to focal shift under thermal load |

| Knoop Hardness | 120 (500g) | Indicates susceptibility to scratching during handling |

Table 2: Research Reagent Solutions for ZnSe Maintenance

| Item | Function | Specification Requirements |

|---|---|---|

| Acetone | Primary solvent for removing organic residues | Spectroscopy grade, low acidity |

| Compressed Nitrogen Gas | Initial dust removal and drying | Dry, oil-free, regulated supply |

| De-ionized Water | Secondary cleaning for stubborn deposits | Ultra-filtered, low particulate |