Achieving Regulatory Acceptance of UV-Vis Spectroscopy in Pharma GMP: A Guide to Compliance, Validation, and Modern Applications

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on securing regulatory acceptance of UV-Vis spectroscopy within pharmaceutical Good Manufacturing Practice (GMP) frameworks.

Achieving Regulatory Acceptance of UV-Vis Spectroscopy in Pharma GMP: A Guide to Compliance, Validation, and Modern Applications

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on securing regulatory acceptance of UV-Vis spectroscopy within pharmaceutical Good Manufacturing Practice (GMP) frameworks. It explores the foundational regulatory standards from USP, Ph. Eur., and JP, alongside FDA 21 CFR Part 11 compliance for data integrity. The scope covers methodological applications from raw material testing to real-time Process Analytical Technology (PAT), addresses common troubleshooting and optimization challenges, and details the analytical method validation process per ICH Q2(R1). The article synthesizes key takeaways to empower confident integration of UV-Vis in GMP environments, ensuring product quality and regulatory readiness.

The Regulatory Landscape: Foundations of UV-Vis Acceptance in GMP

In the tightly regulated world of pharmaceutical development and manufacturing, analytical instrument qualification is not merely a formality but a fundamental requirement for ensuring product safety, efficacy, and quality. Ultraviolet-Visible (UV-Vis) spectroscopy serves as a cornerstone technique for a multitude of analyses, from raw material identification and assay quantification to dissolution testing and impurity detection. The evidence of control demonstrated through rigorous instrument qualification forms the bedrock of data integrity within a Good Manufacturing Practice (GMP) environment [1]. Global pharmacopoeia standards, including the United States Pharmacopeia (USP) Chapter <857>, the European Pharmacopoeia (Eur. Ph.) Chapter 2.2.5, and the Japanese Pharmacopoeia (JP) Chapter <2.24>, provide the specific frameworks for this qualification. Recent revisions to these chapters have shifted the paradigm from a one-size-fits-all set of tests to a more nuanced, risk-based approach centered on demonstrating fitness for purpose [1] [2]. This guide provides a detailed comparison of these pivotal standards, offering scientists and compliance professionals a clear roadmap for navigating the converging and diverging requirements to ensure global regulatory acceptance.

Comparative Analysis of Global Pharmacopoeia Standards

While the core principles of UV-Vis instrument qualification are harmonized across major pharmacopoeias, significant differences exist in their scope, specific requirements, and acceptable tolerances. The following sections and tables provide a point-by-point comparison to elucidate these critical distinctions.

Scope and Overarching Principles

A fundamental divergence lies in the scope of the chapters. USP <857> and JP <2.24> are dedicated specifically to UV-Vis spectrophotometry used in analytical methods [1] [3]. In contrast, the Eur. Ph. 2.2.5 has been expanded to include other applications of the technology, such as high-performance liquid chromatography (HPLC) detectors and Process Analytical Technology (PAT) [2]. This broader scope means that a single qualification protocol for a stand-alone spectrophotometer may not suffice for a spectrometer used as an in-line PAT probe under the European standard.

Furthermore, all three pharmacopoeias now emphasize that qualification must be relevant to the instrument's intended use. This means that the operational qualification (OQ) must demonstrate that the instrument performs adequately across the specific wavelength, absorbance, and other parameter ranges required by the analytical methods (monographs) it will execute [1]. The concept of "bracketing" these analytical conditions with certified reference materials (CRMs) is a recommended best practice emerging from this principle [2].

Instrument Qualification Parameters and Tolerances

The essential parameters requiring control are consistent across the board: wavelength accuracy, absorbance accuracy, stray light, resolution (spectral bandwidth), and photometric linearity [1] [2]. However, the required tests and permitted tolerances can vary. The Eur. Ph., for instance, provides a detailed table linking the required tests to the purpose of the analysis (e.g., identification vs. quantification), a nuance not as explicitly detailed in the USP [2].

Table 1: Comparison of Key Qualification Parameters and Tolerances

| Qualification Parameter | USP <857> | European Pharmacopoeia 2.2.5 | Japanese Pharmacopoeia <2.24> |

|---|---|---|---|

| Wavelength Accuracy | ±1 nm (< 400 nm)±3 nm (≥ 400 nm) [2] | ±1 nm (< 400 nm)±3 nm (≥ 400 nm) [2] | Mandatory, specifics aligned with USP/EP [3] |

| Absorbance Accuracy | Defined using CRM uncertainty [1] | Defined using CRM uncertainty [2] | Mandatory, specifics aligned with USP/EP [3] |

| Stray Light | Required; Potassium Chloride (1% w/v) at 198-200 nm is common [1] | Required; Potassium Chloride solution specified [2] | Required [3] |

| Resolution (Spectral Bandwidth) | "If required in the monograph" [1] | "If required in the monograph" [2] | Mandatory for operational qualification [3] |

| Photometric Linearity | Required [1] | Required [2] | Required [3] |

Reference Material Requirements

A significant area of convergence in the updated standards is the strong preference for using Certified Reference Materials (CRMs) over laboratory-prepared solutions [1]. CRMs must be obtained from an accredited source and provide independently verified, traceable value assignments with a calculated uncertainty budget. When qualifying an instrument, the total allowed tolerance is the sum of the certificate's uncertainty and the instrument manufacturer's specified accuracy [1]. This ensures an unbroken chain of metrological traceability, which is crucial for regulatory audits.

Table 2: Common Pharmacopoeia-Recommended Reference Materials

| Material Type | Examples & Key Uses | Pharmacopoeia Citation |

|---|---|---|

| Liquid Filters/Solutions | Holmium Oxide (wavelength), Potassium Chloride/Dichromate (stray light/stray light & absorbance), Neutral Density Filters (photometric linearity) | [1] [2] |

| Solid Glass Filters | Didymium Glass, Holmium Glass (wavelength verification) | [2] |

| Atomic Emission Lamps | Deuterium, Mercury (built-in wavelength checks) | [2] |

Experimental Protocols for Instrument Qualification

The following workflow, based on the Analytical Instrument Qualification (AIQ) framework outlined in USP <1058>, details the standard process for ensuring an instrument is fit for its intended use in a GMP environment [1]. This four-stage process, known by the acronym DQ, IQ, OQ, PQ, is a consistent requirement across regulatory frameworks.

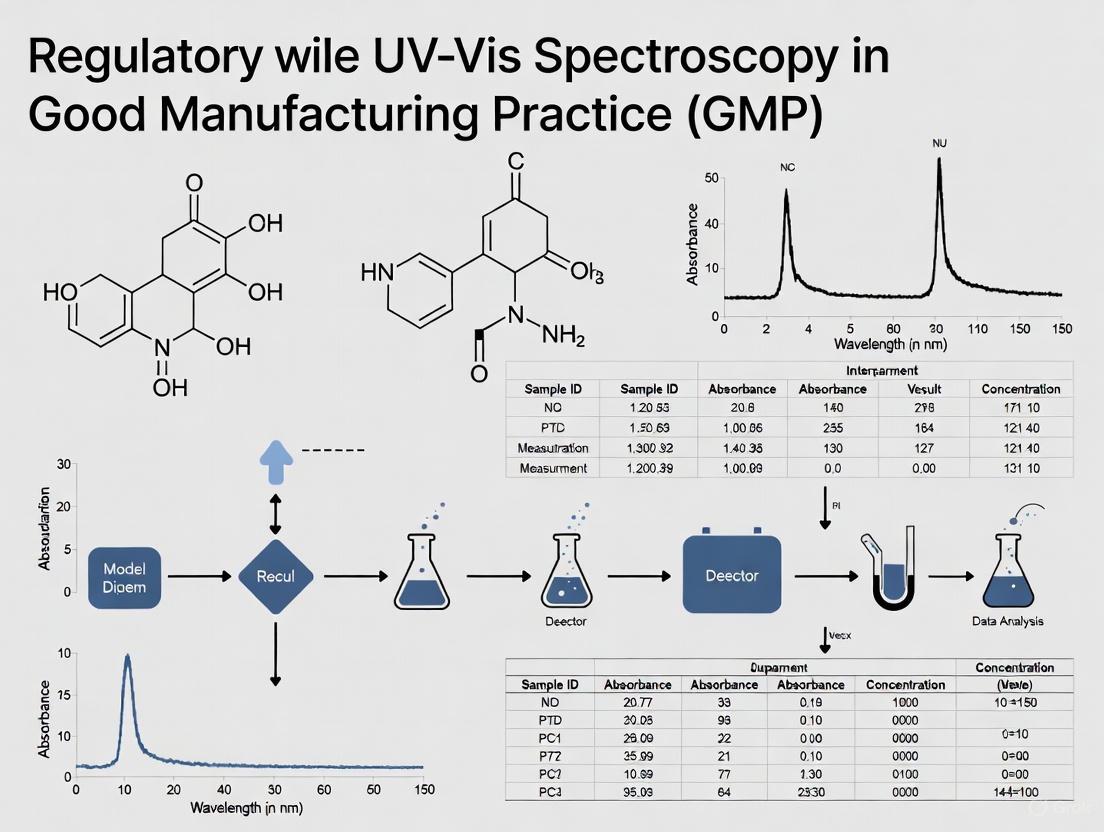

Diagram 1: UV-Vis Spectrophotometer Qualification Workflow. This AIQ process ensures ongoing instrument compliance.

Detailed Operational Qualification (OQ) Procedures

OQ is the critical phase where "fitness for purpose" is empirically demonstrated. The tests must be performed under conditions that bracket the instrument's intended analytical use [2].

Wavelength Accuracy Procedure:

- Select a CRM with peaks bracketing your analytical range (e.g., Holmium Oxide for UV-Vis, Cerium Oxide for Far-UV) [2].

- Scan the CRM according to the instrument and CRM manufacturer's instructions, using the spectral bandwidth specified in your analytical methods.

- Record the measured peak wavelengths. The difference between the measured values and the certified values must be within the pharmacopoeia tolerances (±1 nm below 400 nm, ±3 nm at or above 400 nm) [2].

Absorbance Accuracy Procedure:

- Select a suitable absorbance CRM, such as a traceable neutral density filter or potassium dichromate solution, with certified values at specific wavelengths.

- Measure the absorbance of the CRM at the certified wavelengths.

- The measured absorbance must agree with the certified value within the combined uncertainty (certificate uncertainty + instrument specification) [1].

Stray Light Procedure:

- Prepare a solution specified by the pharmacopoeia, such as a 1.2% w/v potassium chloride solution in a quartz cuvette [1] [2].

- Measure the transmittance or absorbance of this solution at a wavelength where it is opaque (e.g., 198-200 nm for KCl). The measured transmittance represents the instrument's level of stray light at that wavelength and must be below the limit set in the standard (typically < 0.1% T or > 3.0 A).

Photometric Linearity Procedure:

- Use a series of CRMs (e.g., a set of neutral density filters or a dilution series of a stable analyte) covering the absorbance range required by your methods (e.g., 0.1 A to 3.0 A).

- Measure the absorbance of each standard.

- Plot the measured values against the certified or expected values. The system is linear if the plot yields a straight line with a coefficient of determination (R²) exceeding the minimum required by the method or standard.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table details key materials required for the qualification experiments described above. The use of accredited CRMs is non-negotiable for providing the traceability and defensible data demanded in a pharmaceutical GMP setting.

Table 3: Essential Reagents and Materials for UV-Vis Pharmacopoeia Compliance

| Item | Function/Description | Critical Compliance Attribute |

|---|---|---|

| Holmium Oxide CRM | A solution or solid filter used for wavelength accuracy verification across the UV-Vis range (e.g., peaks at 241.1, 361.3, 536.6 nm) [2]. | Individually certified peak wavelengths with documented uncertainty, traceable to a national metrology institute (NMI). |

| Cerium Oxide CRM | A solution used for wavelength accuracy verification in the far-UV region, with certified peaks down to 201 nm [2]. | Certified for use at low UV wavelengths, essential for methods operating below 240 nm. |

| Potassium Chloride Solution | A 1.2% w/v aqueous solution used for stray light verification at the far-UV cutoff (~200 nm) [1]. | Must be prepared with high-purity water and KCl in a scrupulously clean quartz cuvette, or obtained as a sealed CRM. |

| Neutral Density Filter Set | A set of solid filters or liquid standards with certified absorbance values across a defined range (e.g., 0.5, 1.0, 2.0 A) [1]. | Used for absorbance accuracy and photometric linearity testing. Each filter must have a certified value and uncertainty at specified wavelengths. |

| Spectrophotometric Cuvettes | High-quality quartz (for UV) or glass (for Vis) cells for holding liquid samples and standards. | Must meet path length tolerance (e.g., ±0.5% for 10 mm) and matched absorbance characteristics (e.g., <0.093 A at 240 nm for quartz) to prevent introduction of error [2]. |

Navigating the updated global pharmacopoeia standards for UV-Vis spectrophotometry requires a meticulous and informed approach. The overarching trend is a move away from simplistic, pass/fail instrument checks toward a more holistic, science-based, and application-specific paradigm of continuous performance verification. While differences persist—most notably in the scope of Eur. Ph. 2.2.5—the core principles of wavelength, absorbance, stray light, and linearity control underpin all three major standards [1] [2]. Success in this environment is achieved by implementing a robust AIQ process, leveraging accredited CRMs to ensure metrological traceability, and thoroughly documenting all procedures to provide a defensible "evidence of control." For the modern pharmaceutical scientist, mastering these requirements is not just about regulatory compliance; it is about fostering a culture of quality that underpins every data point and ensures the safety and efficacy of the final drug product.

In the pharmaceutical industry, ultraviolet-visible (UV-Vis) spectroscopy serves as a cornerstone analytical technique for applications ranging from raw material identification and assay quantification to dissolution testing. Within current Good Manufacturing Practice (cGMP) environments, the integrity of the data generated by these instruments is paramount. The U.S. Food and Drug Administration's (FDA) 21 CFR Part 11 regulation sets forth the criteria under which electronic records and electronic signatures are considered trustworthy, reliable, and equivalent to paper records [4]. Enhanced Security (ES) software is the technological implementation designed specifically to ensure that UV-Vis systems comply with this rule. This guide provides a detailed, objective comparison of ES software capabilities, framed within the broader thesis that robust, software-driven data integrity controls are a prerequisite for regulatory acceptance of UV-Vis spectroscopy in pharmaceutical cGMP research and quality control.

Understanding the Regulatory Framework: 21 CFR Part 11 and Data Integrity

Core Principles of 21 CFR Part 11

Title 21 CFR Part 11 applies to electronic records created, modified, and maintained under any FDA record-keeping requirement [4]. Its primary goal is to ensure data authenticity, integrity, and confidentiality. For pharmaceutical manufacturers, compliance is not optional; failure can trigger regulatory actions, with data integrity violations cited in nearly half of all FDA warning letters [5]. The regulation mandates a series of controls for closed computer systems, which include most standalone analytical instruments [4].

The ALCOA+ Principle and Its Implementation

A fundamental concept underpinning 21 CFR Part 11 is ALCOA+, which stands for data that must be:

- Attributable: Who created or modified the record and when.

- Legible: Readable and accessible throughout the records retention period.

- Contemporaneous: Recorded at the time of the activity.

- Original: The first recording of the data.

- Accurate: Free from errors, with edits not obscuring the original record.

The "+" adds Complete, Consistent, Enduring, and Available. ES software is engineered to enforce these principles by design, moving beyond paper-based logbooks and manual checks to automated, unalterable system enforcement [5] [6].

Comparative Analysis of Enhanced Security (ES) Software Solutions

The following section provides an objective comparison of ES software features and performance across different vendor platforms, based on publicly available specifications and methodologies for instrument qualification.

Key Feature Comparison of Select ES Software Platforms

Table 1: Feature comparison of Enhanced Security (ES) software from different UV-Vis vendors.

| Feature / Control | Thermo Scientific Insight Pro | PerkinElmer Spectrum UV | Avantes Panorama Pro | Bellingham + Stanley Suite |

|---|---|---|---|---|

| Audit Trail | Comprehensive, time-stamped | Independent recording of entries and actions [3] | Comprehensive activity report [7] | Non-switchable, stores >10,000 entries [6] |

| User Access Control | Controlled user account access [8] | Authority checks for authorized individuals | Hierarchical permission levels [7] | Definable user roles with unique login [6] |

| Electronic Signatures | Supports digital signatures [8] | Legally binding electronic signatures | Not specified | Multi-verification (Submitter>Reviewer>Approver) [6] |

| Data Integrity & Export | Database storage for FDA submissions [8] | Ensures data integrity and streamlines management [3] | Not specified | Encrypted PDF/XML with MD5 checksum verification [6] |

| System Validation | Includes IQ/OQ verification methods [8] | Streamlines validation [3] | Not specified | Provides validation (IQ, OQ, PQ) and traceable calibration [6] |

Performance and Compliance Verification

Experimental Protocol for System Validation

A critical component of deploying any ES software is the instrument qualification process, which follows the Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) framework outlined in USP General Chapter <1058> [1]. The protocol below is a generalized method for OQ/PQ, which should be tailored to specific analytical methods.

- Objective: To verify that the UV-Vis system with ES software performs in accordance with predefined specifications and is fit for its intended analytical purpose.

- Reference Materials: Use Certified Reference Materials (CRMs) sourced from accredited producers, with traceable and documented measurement uncertainty (e.g., holmium oxide filters for wavelength accuracy, neutral density filters for photometric accuracy) [1].

- Procedure:

- Installation Qualification (IQ): Document that the correct hardware and software have been installed as specified.

- Operational Qualification (OQ): Using CRMs, perform and document the following tests with the ES software's validation methods:

- Wavelength Accuracy: Measure the absorbance peaks of a holmium oxide filter. The measured values must be within the instrument's specified tolerance of the certified values.

- Photometric Accuracy: Measure the absorbance of a neutral density filter at specified wavelengths. The measured values must be within the instrument's specified tolerance of the certified values.

- Stray Light: Measure the absorbance of a suitable liquid filter (e.g., potassium chloride) at a specified wavelength to ensure it meets the required limit.

- Performance Qualification (PQ): Regularly verify system performance under actual use conditions, for example, by measuring a system suitability standard relevant to the daily analytical methods.

Data Integrity Testing Protocol

- Objective: To verify that the ES software's data integrity controls function as intended.

- Procedure:

- Audit Trail Test: A user performs a series of actions (e.g., creating a method, running a sample, reprocessing data). A second user with administrator privileges exports and reviews the audit trail to confirm all actions are captured, time-stamped, and attributable.

- Data Alteration Test: Attempt to manually alter a stored result or method parameter. The system should prevent this or record the change in the audit trail without obscuring the original data.

- Electronic Signature Test: Execute a full electronic signature cycle (Submitter > Reviewer > Approver) on a set of results and verify that the signature manifestation (printed name, date, time, and meaning) is permanently linked to the electronic record [4] [6].

The workflow for this comprehensive qualification and testing process is outlined in the diagram below.

Diagram: Workflow for UV-Vis system validation and data integrity testing under 21 CFR Part 11.

The Scientist's Toolkit: Essential Research Reagent Solutions

A compliant analytical workflow relies on more than just software. The following tools and materials are essential for maintaining data integrity and ensuring accurate, reproducible results.

Table 2: Essential reagents and materials for compliant UV-Vis spectroscopy.

| Item | Function & Importance in a Regulated Lab |

|---|---|

| Certified Reference Materials (CRMs) | Holmium oxide, nickel sulfate, and neutral density filters for instrument qualification. Their use is emphasized in USP <857> to provide traceable, auditable proof of instrument performance [1]. |

| System Suitability Standards | Compound-specific standards (e.g., USP-grade reference standards) used during PQ to verify the entire analytical system's fitness for a specific method before sample analysis [1]. |

| Qualification Filter Kits | Vendor-provided kits containing multiple CRMs needed to execute standardized IQ/OQ/PQ protocols, ensuring all pharmacopeia performance characteristics are tested [8]. |

| Validation Documentation | Pre-packaged documentation (IQ/OQ/PQ protocols and reports) provided by the instrument vendor. This is critical for demonstrating compliance during regulatory inspections [6]. |

The transition from traditional UV-Vis systems to those governed by Enhanced Security software represents a fundamental shift in pharmaceutical quality control. ES software moves data integrity from a manual, procedural effort to an automated, system-enforced reality. As the comparative analysis shows, while vendors may implement features differently, the core controls—immutable audit trails, granular user access, and enforceable electronic signatures—are non-negotiable for 21 CFR Part 11 compliance. When integrated with a rigorous instrument qualification program using traceable CRMs, ES software provides the foundational assurance of data integrity. This enables pharmaceutical researchers and quality control professionals to generate trustworthy data that meets global regulatory standards, thereby accelerating drug development and ensuring patient safety.

Within the stringent framework of pharmaceutical Good Manufacturing Practice (GMP), Instrument Operational Qualification (OQ) is a critical documented process that verifies an instrument performs according to its specification and operates correctly in its selected environment [3]. For UV-Vis spectroscopy, a technique foundational to identity, purity, and potency testing, OQ provides the assurance that data generated is accurate, reliable, and defensible during regulatory audits [9]. Key regulatory guidelines, including the United States Pharmacopeia (USP) <857>, European Pharmacopoeia (Ph. Eur.) 2.2.5, and Japanese Pharmacopoeia (JP) <2.24>, mandate the verification of fundamental performance parameters, with wavelength accuracy, photometric accuracy, and stray light being paramount [3]. This guide details the experimental protocols for these verifications, providing a direct comparison of methods and standards to support robust OQ compliance in pharmaceutical research and development.

Core OQ Parameters and Verification Methodologies

The following parameters are essential for establishing the fitness of a UV-Vis spectrophotometer for use in a GMP-regulated environment.

Wavelength Accuracy

Objective: To verify that the wavelength scale of the spectrophotometer is correct and that the instrument detects absorbance maxima at the known wavelengths of a certified reference material.

Protocol 1: Holmium Oxide Filter Method

- Principle: Holmium oxide glass contains rare earth ions that produce sharp, characteristic absorption peaks at known wavelengths. This method involves measuring the transmission spectrum of a holmium oxide filter and comparing the recorded peak maxima to their certified values.

- Procedure:

- Ensure the instrument is warmed up and stable.

- Perform a baseline correction with an empty compartment or an air background.

- Place the certified holmium oxide filter in the light path.

- Scan the transmission spectrum over a specified range (e.g., 240-650 nm).

- Identify the observed wavelengths for key peaks (e.g., 241.0 nm, 279.3 nm, 287.5 nm, 360.8 nm, 418.5 nm, 453.0 nm, 536.0 nm).

- Calculate the deviation (observed wavelength - certified wavelength) for each peak.

- Acceptance Criteria: The maximum deviation should typically be within ±1 nm for a high-quality instrument, as per pharmacopoeial standards [3].

Protocol 2: Didymium Filter Method

- Principle: Similar to holmium oxide, a didymium filter (a mixture of praseodymium and neodymium) produces a series of characteristic absorption peaks. It is often used as a secondary or supplementary standard.

- Procedure: The workflow is identical to the holmium oxide method, but using a certified didymium filter and comparing its characteristic peaks (e.g., around 528 nm and 585 nm) to certified values.

- Acceptance Criteria: Typically within ±1 nm.

The experimental workflow for wavelength verification is consistent across different standard materials, as shown in the diagram below.

Photometric Accuracy

Objective: To confirm the accuracy of the absorbance or transmittance scale of the instrument. This ensures that concentration measurements derived from absorbance are correct.

Protocol 1: Neutral Density Glass Filters

- Principle: These filters are certified to have specific absorbance values at given wavelengths. They provide a stable, non-liquid standard for photometric verification.

- Procedure:

- After baseline correction, place a certified neutral density filter in the light path.

- Measure the absorbance at the specified wavelength(s) (e.g., 440 nm, 465 nm, 590 nm, 750 nm).

- Record the average absorbance from multiple measurements.

- Compare the measured absorbance to the certified value and its tolerance range.

- Acceptance Criteria: The deviation should typically be within ±0.5% T or ±0.01 A, or as specified by the filter certificate and pharmacopoeia.

Protocol 2: Potassium Dichromate Solutions

- Principle: A solution of potassium dichromate in perchloric acid is a well-characterized liquid standard with known absorbance values at specific wavelengths, traceable to national institutes (e.g., NIST) [10].

- Procedure:

- Prepare a fresh solution of potassium dichromate in 0.001 M perchloric acid as per a defined protocol (e.g., concentration of ~60 mg/L).

- Using a matched quartz cuvette, measure the absorbance against a blank of 0.001 M perchloric acid.

- Record absorbance at key wavelengths such as 235 nm, 257 nm, 313 nm, and 350 nm.

- Compare the measured values against the known certified absorbances.

- Acceptance Criteria: Deviations should generally be within ±1.0% A.

Stray Light

Objective: To detect the presence of any non-wavelength-selected light that reaches the detector, which can cause deviations from the Beer-Lambert law, particularly at high absorbances, and limit the instrument's usable dynamic range [11].

Protocol 1: High-Purity Solvent Cut-off Method

- Principle: A high-purity liquid that is transparent in the visible region but absorbs strongly in the UV is used. At a wavelength where the solvent is fully absorbing, any signal detected is defined as stray light.

- Procedure:

- Fill a cuvette with a high-purity solvent known for a sharp cut-off, such as potassium chloride (1.2% w/v KCl) for checking ~200 nm or sodium iodide (NaI) for ~220 nm.

- Measure the transmittance of the solvent against a water blank at the target wavelength (e.g., 200 nm for KCl).

- The recorded %Transmittance value is the instrument's stray light at that wavelength.

- Acceptance Criteria: For a quality instrument, stray light should be <0.1% T at 200 nm with KCl, and often much lower (e.g., <0.01% T) for high-performance systems [11].

Protocol 2: Liquid Stray Light Filters

- Principle: Similar to the solvent method, but uses certified, stable liquid filters sealed in cuvettes, specifically designed for stray light verification at multiple wavelengths (e.g., 220 nm, 340 nm, 370 nm) [10].

- Procedure:

- Insert the sealed stray light filter into the sample compartment.

- Measure the %Transmittance at the specified wavelength against an air or water background.

- The measured value is the stray light.

- Acceptance Criteria: Must be below the limit specified by the pharmacopoeia or the instrument manufacturer's specifications.

The logical process for evaluating stray light and its impact on data integrity is summarized below.

Comparative Analysis of OQ Verification Standards

The choice of standard can impact the convenience, traceability, and cost of OQ procedures. The table below provides a structured comparison of the common verification methodologies.

Table 1: Comparative Analysis of OQ Verification Standards and Methods

| OQ Parameter | Verification Standard/Method | Key Experimental Data & Typical Specification | Relative Cost | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Wavelength Accuracy | Holmium Oxide Filter | Deviation of ±1 nm or less at key peaks (e.g., 360.8 nm, 536.0 nm) [3] | Low | Stable, durable, easy to use, non-hazardous. | Peaks can be broad on low-resolution instruments. |

| Didymium Filter | Deviation of ±1 nm or less at key peaks (e.g., 528 nm, 585 nm) | Low | Good for visual range verification. | Less sharp peaks than holmium oxide in UV region. | |

| Photometric Accuracy | Neutral Density Glass Filters | Absorbance accuracy within ±0.01 A or ±0.5% T [10] | Medium | Highly stable, no preparation required, traceable. | Can be wavelength-specific; potential for scratches. |

| Potassium Dichromate Solutions | Absorbance accuracy within ±1.0% A at specific wavelengths (e.g., 235 nm, 350 nm) | Low | Aqueous solution, high traceability to NIST. | Requires preparation; light-sensitive; hazardous waste. | |

| Stray Light | Potassium Chloride Solution (1.2%) | Stray light < 0.1% T at 200 nm [11] [10] | Very Low | Inexpensive, well-documented in pharmacopoeias. | Requires solution preparation; can degrade. |

| Sealed Liquid Stray Light Filters | Stray light < 0.05% T at specified wavelengths (e.g., 220 nm, 340 nm) | Medium | Ready-to-use, stable, certified for multiple wavelengths. | Higher initial cost. |

The Scientist's Toolkit: Essential Reagents and Standards for OQ

A successful OQ program relies on the use of certified, traceable materials. The following table details the key reagent solutions and standards required.

Table 2: Essential Research Reagent Solutions for UV-Vis OQ

| Item Name | Function in OQ Protocol | Critical Specification/Handling |

|---|---|---|

| Holmium Oxide Filter | To verify wavelength accuracy by providing sharp, known absorption peaks. | Must be accompanied by a valid certificate stating peak wavelengths and tolerances. Handle with gloves to avoid fingerprints. |

| Certified Neutral Density Filter | To verify photometric accuracy of the absorbance/transmittance scale. | Certified for specific absorbance values at defined wavelengths. Store in a protective case to prevent scratches. |

| Potassium Dichromate (K₂Cr₂O₇) | A primary liquid standard for verifying photometric accuracy. | High-purity grade, traceable to a national metrology institute. Prepare fresh solutions as required; dispose of as hazardous waste. |

| Potassium Chloride (KCl) | Used to prepare a solution for stray light verification at 200 nm. | High-purity (e.g., Certipur) to ensure no contaminants affect the cut-off [10]. Use high-quality water as solvent. |

| Sealed Cuvette Stray Light Standards | A ready-to-use alternative to prepared solutions for stray light verification. | Sealed cuvettes containing stable, absorbing solutions for specific wavelengths (e.g., 220 nm) [10]. |

| Spectroquant PhotoCheck / AQA Kits | Integrated kits for simplified operational qualification, often pre-programed in instruments [10]. | Contains multiple sealed color standards for verifying both wavelength and photometric performance across a range. |

The rigorous execution of Operational Qualification protocols for wavelength accuracy, photometric accuracy, and stray light is non-negotiable for the regulatory acceptance of UV-Vis spectroscopy in pharmaceutical GMP research. The experimental data and comparative analysis provided herein demonstrate that while multiple paths to verification exist—from traditional solution-based methods to modern, integrated kits—the fundamental goal remains unchanged: to ensure data integrity and instrument reliability. By adhering to these detailed protocols and utilizing traceable standards, scientists and drug development professionals can confidently generate data that meets the stringent requirements of global regulatory bodies, thereby underpinning the safety, quality, and efficacy of pharmaceutical products.

The Role of FDA 483s and Warning Letters in Enforcing Spectroscopic Method Compliance

In the tightly regulated environment of pharmaceutical manufacturing, spectroscopic methods serve as critical tools for ensuring drug identity, strength, quality, and purity. The U.S. Food and Drug Administration (FDA) employs a graduated enforcement system to ensure compliance with Current Good Manufacturing Practices (CGMP), utilizing Form FDA 483 for initial observations and Warning Letters for more serious, unresolved violations. These regulatory actions directly impact how spectroscopic techniques—particularly UV-Vis and IR spectroscopy—are validated, implemented, and documented within quality control laboratories. Recent enforcement trends reveal an intensified focus on data integrity issues within spectroscopic systems, with numerous citations addressing inadequate audit trails, insufficient method validation, and poor control over electronic records [12]. This guide examines how these regulatory instruments shape spectroscopic practices and provides comparative analysis of compliance approaches for pharmaceutical professionals.

Understanding FDA's Enforcement Tools

The FDA's compliance enforcement operates through a structured escalation process, beginning with Form FDA 483 and potentially culminating in a Warning Letter:

Form FDA 483: Issued at the conclusion of an inspection when investigators observe conditions that may violate the Food, Drug, and Cosmetic Act. These observations are not final determinations of non-compliance but rather document potential deviations from CGMP requirements [13]. For spectroscopic methods, common 483 observations include uncontrolled data storage, inadequate instrument qualification, and absent audit trails [12].

Warning Letters: Represent formal FDA notification of significant regulatory violations that require immediate correction. These are publicly available and indicate that a company has failed to adequately address issues raised in a Form 483 or that serious CGMP deviations exist [13]. Warning Letters specific to spectroscopic compliance often cite fundamental design control failures, inadequate software validation, and systemic data integrity problems [14] [12].

The relationship between these regulatory tools and their impact on spectroscopic operations can be visualized through the following compliance pathway:

Analysis of Spectroscopic Compliance Violations

Recent FDA enforcement actions reveal persistent patterns of non-compliance affecting both UV-Vis and IR spectroscopic methods in pharmaceutical settings. The following table quantifies common violations documented in Form 483 observations and Warning Letters:

Table 1: Analysis of Spectroscopic Compliance Violations (2019-2025)

| Violation Category | Specific Technical Deficiencies | Frequency in Citations | Regulatory Reference |

|---|---|---|---|

| Data Integrity Controls | Absent or disabled audit trails; Ability to delete or manipulate spectral files; Inadequate user access controls | 37% of IR spectroscopy citations [12] | 21 CFR 211.68(b) [15] |

| Method Validation | Lack of demonstrated suitability for intended use; Failure to verify compendial methods; Inadequate system suitability testing | 46% of drug quality control citations [16] | 21 CFR 211.165(a) [17] |

| Instrument Qualification | No Performance Qualification (PQ) before use; Inadequate calibration; Missing user requirements specification | 6% of pre-operational citations [12] | USP <1058> [12] |

| Laboratory Controls | Failure to establish scientifically sound specifications; Inadequate stability-indicating methods; No DEG/EG testing for glycerin | Repeated in multiple Warning Letters [15] [17] [18] | 21 CFR 211.160(b) [15] |

| Supplier Qualification | No initial or periodic evaluation of suppliers; Over-reliance on Certificate of Analysis without verification | Documented in Spectra Therapy LLC [14] | 21 CFR 820.50(a)(1) [14] |

Data Integrity Failures in Spectroscopic Systems

A comprehensive analysis of 47 Form 483 observations and Warning Letters for infrared spectrometers revealed that 42% of citations occurred before instruments became operational, primarily due to inadequate software architecture and design [12]. Common deficiencies included:

Commercial software without deletion prevention: Multiple observations cited instruments equipped with software that "does not prevent accidental or intentional deletion of files containing data" [12].

Optional data saving features: Some systems provided QC operators with "the option of not saving the IR spectra," creating critical gaps in data completeness [12].

Standalone system limitations: Most IR software implementations utilized directory-based file storage in operating systems rather than secure database architectures, allowing users to delete spectral files without application-level tracking [12].

These findings highlight how instrument selection decisions directly impact regulatory compliance, with systems lacking inherent data integrity controls creating persistent compliance challenges.

Method Validation and Testing Deficiencies

Recent Warning Letters demonstrate consistent failures in spectroscopic method validation and implementation:

Inadequate identity testing: Multiple manufacturers failed to perform appropriate identity testing for components using spectroscopic methods, including failure to test for dangerous contaminants like diethylene glycol (DEG) and ethylene glycol (EG) in glycerin using USP methods [17] [18].

Unverified compendial methods: Firms frequently adopted pharmacopeial methods (e.g., Chinese Pharmacopeia) without establishing they were "scientifically sound and appropriate" or equivalent to USP methods [15].

Insufficient release testing: Companies released drug products without appropriate laboratory determination of "identity and strength of each active ingredient," using spectroscopic methods that had not been properly validated [15] [17].

Comparative Analysis: Compliant vs. Non-Compliant Spectroscopic Practices

The following table contrasts deficient practices observed in FDA enforcement actions with compliant approaches that meet regulatory expectations:

Table 2: Compliant vs. Non-Compliant Spectroscopic Practices in Pharma GMP Environments

| Practice Area | Non-Compliant Approach (Cited in Enforcement) | Compliant Alternative (Regulatory Expectation) |

|---|---|---|

| Data Management | Standalone systems with file-based storage; User-deletable data; Disabled audit trails | Networked systems with secure database storage; Automatic data saving; Enabled, immutable audit trails [12] |

| Instrument Qualification | Only installation and operational qualification performed; No performance qualification | Full lifecycle qualification per USP <1058>; Regular performance verification; Documented user requirements [12] |

| Method Validation | Adoption of compendial methods without verification; Non-validated changes to established methods | Full validation for intended use; Verification of compendial methods; Proper change control with revalidation [15] |

| System Security | Shared user accounts; No role-based access; Ability to alter system date/time | Unique user accounts; Role-based permissions; Controlled access to system settings [15] [12] |

| Raw Material Testing | Reliance on supplier Certificate of Analysis alone; No specific identity testing | Supplier qualification with COA verification; Specific identity tests including DEG/EG for high-risk materials [17] [18] |

Experimental Protocols for Spectroscopic Method Compliance

Protocol 1: UV-Vis Method Validation for Pharmaceutical Applications

Objective: Establish validated UV-Vis spectroscopic methods compliant with FDA expectations for drug substance quantification [15] [3].

Materials and Equipment:

- Dual-beam UV-Vis spectrophotometer with 21 CFR Part 11 compliant software (e.g., PerkinElmer LAMBDA 365+ with Spectrum UV) [3]

- Reference standards of drug substance with certified purity

- Appropriate solvents meeting spectroscopic grade requirements

- Matched quartz cuvettes with documented pathlength

Procedure:

- Specificity: Demonstrate absence of interference from excipients or degradation products using forced degradation samples

- Linearity: Prepare minimum of five concentrations across specified range (e.g., 50-150% of target concentration); correlation coefficient (R²) ≥0.998

- Accuracy: Spike placebo with known drug quantities; recovery should be 98-102%

- Precision: Perform six replicate measurements of target concentration; RSD ≤2%

- Robustness: Deliberately vary instrumental parameters (wavelength ±2nm, slit width) to establish system suitability criteria

Documentation Requirements: Complete validation report including all raw data, electronic records with audit trails, and evidence of QCU approval prior to implementation.

Protocol 2: Data Integrity Assessment for Spectroscopic Systems

Objective: Evaluate and remediate data integrity vulnerabilities in spectroscopic systems based on common FDA 483 observations [15] [12].

Materials and Equipment:

- Spectroscopic systems (UV-Vis, IR) with associated data systems

- User access management protocols

- Data backup and archival systems

Assessment Procedure:

- User Privilege Review: Document all user accounts and access privileges; verify role-based segregation (e.g., operators cannot delete or modify files)

- Audit Trail Verification: Confirm audit trails are enabled, comprehensive, and regularly reviewed

- Data Deletion Testing: Attempt to delete files through both application and operating system; document any vulnerabilities

- System Clock Validation: Verify users cannot alter system date/time settings

- Backup and Recovery Testing: Perform full data restoration from backup media

Acceptance Criteria: Zero ability to delete or alter data without audit trail capture; successful data recovery; documented evidence of regular audit trail reviews by quality unit.

Essential Research Reagent Solutions for Compliant Spectroscopy

Table 3: Essential Materials for Regulatory-Compliant Spectroscopic Analysis

| Material/Equipment | Function in Compliant Spectroscopy | Regulatory Consideration |

|---|---|---|

| GMP-Compliant UV-Vis Spectrophotometer (e.g., LAMBDA 365+) | Drug identity testing, assay, dissolution testing | 21 CFR Part 11 compliant software; automated verification modules; pharmacopeia compliance [3] [16] |

| Certified Reference Materials | System suitability testing; method validation | USP-traceable certifications; documented stability; proper storage conditions |

| Spectroscopic Grade Solvents | Sample preparation; mobile phase components | Supplier qualification; appropriate testing; expiration dating |

| Validation Kits (wavelength, photometric accuracy) | Instrument qualification per USP <857> | Documentation of traceability; inclusion in equipment logs |

| Data Integrity Software Packages | Audit trail management; electronic record retention | Configuration for automatic data saving; user access controls; backup functionality |

FDA 483s and Warning Letters serve as critical catalysts for improving spectroscopic method compliance in pharmaceutical manufacturing. Recent enforcement trends demonstrate that data integrity and method validation remain primary areas of regulatory scrutiny, with particular focus on adequate instrument qualification and proper implementation of electronic systems. The comparative analysis presented in this guide reveals that compliant spectroscopic practices require proactive quality systems rather than reactive corrections. Pharmaceutical manufacturers should implement robust lifecycle approaches to spectroscopic method validation, from initial instrument qualification through routine monitoring and data management. As the regulatory landscape evolves with emerging technologies and increasingly sophisticated analytical demands, maintaining compliance requires both technical excellence and rigorous quality systems that align with FDA expectations. Companies that treat regulatory observations as opportunities for systematic improvement rather than mere compliance obligations will achieve sustainable spectroscopic operations that withstand regulatory scrutiny.

From Lab to Line: Implementing UV-Vis Methods in Pharmaceutical Workflows

Ultraviolet-Visible (UV-Vis) spectroscopy is a cornerstone analytical technique in pharmaceutical quality assurance and quality control (QA/QC). Its widespread regulatory acceptance in Good Manufacturing Practice (GMP) research is anchored in its ability to provide fast, accurate, and non-destructive analysis of critical quality attributes. This guide compares the application of UV-Vis spectroscopy against other common spectroscopic techniques for three core QA/QC functions: raw material identification, Active Pharmaceutical Ingredient (API) potency determination, and content uniformity testing [9].

Technique Comparison: UV-Vis, IR, and NMR in Pharma QA/QC

The selection of a spectroscopic technique is driven by the specific analytical question. The table below provides a comparative overview of UV-Vis, Infrared (IR), and Nuclear Magnetic Resonance (NMR) spectroscopy.

Table 1: Comparative Overview of Spectroscopic Techniques in Pharmaceutical QA/QC

| Feature | UV-Vis Spectroscopy | IR Spectroscopy | NMR Spectroscopy |

|---|---|---|---|

| Primary Principle | Electronic energy level transitions [9] | Vibrational energy level transitions [9] | Magnetic properties of atomic nuclei [9] |

| Key Strength | Fast, simple, inexpensive, ideal for routine quantification [9] | Excellent for qualitative analysis and structural verification [9] | High specificity and detailed structural elucidation [9] |

| Core QA/QC Uses | API potency, content uniformity, dissolution testing [9] [19] | Raw material identification, polymorph screening [9] | Structural confirmation, impurity profiling [9] |

| Regulatory Status | Pharmacopeial methods defined (e.g., USP <857>) [3] [19] | Accepted for identity testing [9] | Recognized for structural confirmation and quantitative analysis (qNMR) [9] |

Experimental Protocols and Performance Data

The following sections detail the experimental methodologies for each core application and present experimental data demonstrating the performance of UV-Vis spectroscopy.

Raw Material Identification

While IR spectroscopy is often the primary technique for identity testing due to its detailed molecular fingerprinting capabilities [9], UV-Vis can serve as a rapid, complementary identity check based on a substance's characteristic absorption spectrum.

Experimental Protocol:

- Standard Preparation: Dissolve a reference standard of the API in a suitable solvent to create a stock solution. Further dilute to an absorbance within the linear range of the instrument (typically 0.1-1.0 AU) [19].

- Sample Preparation: Prepare the unknown raw material sample using the identical solvent and dilution factor.

- Instrumentation: Use a double-beam UV-Vis spectrophotometer for high stability and reproducibility [19]. Quartz cuvettes are required for UV light transmission [20].

- Data Acquisition: Scan the sample and standard solutions over a relevant wavelength range (e.g., 200-400 nm).

- Identification Criteria: Confirm identity by matching the λ_max (wavelength of maximum absorbance) and the overall shape of the absorption spectrum between the sample and the standard [19].

API Potency Determination

UV-Vis is a dominant technique for quantifying API concentration due to its simplicity and robust quantitative nature governed by the Beer-Lambert Law [9] [19].

Experimental Protocol:

- Calibration Curve: Prepare a series of standard solutions of known API concentration. Use a suitable solvent and ensure all absorbance readings fall within the linear range (0.1-1.0 AU) [19].

- Sample Preparation: Accurately weigh and dissolve the pharmaceutical dosage form (e.g., tablet or capsule contents) in the same solvent. Filter if necessary to obtain a clear solution [19].

- Absorbance Measurement: Measure the absorbance of the sample solution at the predetermined λ_max of the API [19].

- Concentration Calculation: Use the linear regression equation from the calibration curve to calculate the concentration of the API in the sample solution. The potency of the dosage form is then calculated based on the initial sample weight and dilution factors [9].

Table 2: Experimental Data for UV-Vis Potency Assay Reproducibility

| Sample ID | Theoretical Concentration (mg/mL) | Measured Absorbance (AU) | Calculated Concentration (mg/mL) | Accuracy (%) |

|---|---|---|---|---|

| Standard 1 | 0.05 | 0.255 | 0.0498 | 99.6 |

| Standard 2 | 0.10 | 0.505 | 0.1001 | 100.1 |

| Standard 3 | 0.15 | 0.752 | 0.1503 | 100.2 |

| Batch A (Sample) | Unknown | 0.411 | 0.0803 | - |

| Batch B (Sample) | Unknown | 0.398 | 0.0778 | - |

Content Uniformity Testing

Content uniformity testing requires high-precision analysis of individual dosage units, and UV-Vis is well-suited for this high-throughput application [9] [19].

Experimental Protocol:

- Sample Preparation: Individually weigh and dissolve not less than 10 dosage units in a defined volume of solvent [19].

- Analysis: Measure the absorbance of each individual solution at the API's λ_max.

- Calculation: Calculate the API content in each dosage unit using a previously established calibration curve or validated method.

- Acceptance Criteria: The batch meets pharmacopeial requirements if the amount of API in each unit is within a specified range (e.g., 85-115% of the label claim) with a defined low relative standard deviation (RSD) [19].

Performance data from a color analysis study using a JASCO V-700 spectrophotometer demonstrates the high reproducibility required for such tests. Ten repeated measurements of a blue pellet showed a maximum-minimum difference of 0.07 for L* (brightness) and 0.09 for b* (yellowness-blueness) in the Lab* color space, with a coefficient of variation (CV%) for brightness of just 0.4% [21]. This level of precision directly supports reliable content uniformity testing.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following materials and reagents are essential for executing the UV-Vis protocols described above.

Table 3: Essential Reagents and Materials for UV-Vis QA/QC Analysis

| Item | Function & Importance |

|---|---|

| High-Purity Solvents | To dissolve samples without introducing UV-absorbing impurities that interfere with analysis [9]. |

| Matched Quartz Cuvettes | To hold sample and reference solutions; quartz is transparent to UV light, unlike plastic or glass [20]. |

| Certified Reference Standards | To establish accurate calibration curves for potency determination, ensuring traceability and validity [9]. |

| UV-Vis Spectrophotometer | The core instrument, with a double-beam optical system recommended for high measurement stability and accuracy in QC environments [21] [19]. |

Analytical Workflow for UV-Vis in Pharmaceutical QA/QC

The following diagram illustrates the logical workflow for deploying UV-Vis spectroscopy in a GMP environment for the three core applications discussed.

UV-Vis spectroscopy maintains a critical position in the pharmaceutical analyst's toolkit. Its speed, cost-effectiveness, and robust quantitative performance make it the technique of choice for API potency and content uniformity testing, while also providing supportive data for raw material identification. As evidenced by its inclusion in global pharmacopeias and its ability to meet the stringent validation requirements of ICH Q2(R1) and 21 CFR Part 211, UV-Vis spectroscopy is a fundamentally accepted and reliable method for ensuring drug product quality, safety, and efficacy within a GMP framework [9] [3] [19].

Ultraviolet-Visible (UV-Vis) spectroscopy has emerged as a critical Process Analytical Technology (PAT) tool within modern pharmaceutical manufacturing, enabling real-time quality assurance and alignment with Good Manufacturing Practice (GMP) standards. As a well-established analytical technique, UV-Vis measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample, providing valuable information about sample composition and concentration [20]. The integration of UV-Vis into PAT frameworks represents a significant advancement over traditional off-line testing methods, allowing manufacturers to monitor Critical Quality Attributes (CQAs) and Critical Process Parameters (CPPs) in real-time during production [22].

The regulatory landscape for pharmaceutical manufacturing is increasingly emphasizing quality Risk Management and real-time release testing, with agencies like the FDA encouraging the adoption of PAT principles [22] [23]. UV-Vis spectroscopy serves as an ideal PAT tool due to its simplicity, speed, and high sensitivity compared to more complex spectroscopic techniques [22]. With the pharmaceutical industry moving toward continuous manufacturing and more sophisticated quality control systems, UV-Vis has found applications ranging from drug substance quantification to impurity detection and dissolution testing, providing a versatile solution for in-line and at-line monitoring needs [24] [22].

Technology Comparison: UV-Vis Versus Other PAT Spectroscopic Tools

Performance Characteristics and Selection Criteria

When selecting a PAT tool for pharmaceutical applications, researchers must evaluate several technical and operational factors. The table below provides a structured comparison of UV-Vis spectroscopy against other common spectroscopic techniques used in PAT applications:

Table: Comparison of UV-Vis Spectroscopy with Other PAT Tools

| Parameter | UV-Vis Spectroscopy | NIR Spectroscopy | Raman Spectroscopy |

|---|---|---|---|

| Spectral Information | Electronic transitions | Molecular vibrations (overtone, combination) | Molecular vibrations (scattering) |

| Sensitivity | High (ppm-ppb for chromophores) | Moderate to Low | Variable (fluorescence interference) |

| Measurement Speed | Very Fast (milliseconds) | Fast (seconds) | Moderate to Slow (seconds-minutes) |

| Setup Complexity | Simple | Complex | Complex |

| Interpretation Ease | Straightforward | Requires multivariate analysis | Requires multivariate analysis |

| Fiber Optic Compatibility | Limited for deep UV | Excellent | Good |

| Cost | Low to Moderate | High | High |

| Quantitative Performance | Excellent for chromophores | Good with calibration | Good with calibration |

| PAT Implementation | Well-established | Established | Growing |

| Water Interference | Minimal | Significant | Minimal |

UV-Vis spectroscopy offers distinct advantages in measurement speed and interpretation ease, making it particularly suitable for rapid process monitoring and control. As noted in research findings, "UV-Vis tends to be simple and fast both to set up and to interpret. The short integration time in the millisecond-range delivers rapid results with high sensitivity" [22]. This characteristic is especially valuable in continuous manufacturing environments where real-time decisions are necessary to maintain product quality.

However, the technique is primarily limited to analytes containing chromophores – functional groups that absorb UV or visible light. For compounds lacking these structural features, NIR or Raman spectroscopy may be more appropriate despite their higher complexity and cost [22]. NIR spectroscopy provides broader molecular information but typically requires sophisticated chemometric models for data interpretation, while Raman spectroscopy offers excellent specificity but can be affected by fluorescence in some pharmaceutical compounds [23].

Regulatory Acceptance and Compliance Considerations

All three spectroscopic techniques are accepted within regulatory frameworks when properly validated, but UV-Vis benefits from its long-established history in pharmacopeial methods [24] [25]. The technique is specifically referenced in various pharmacopeias for identity testing, assay, and impurity quantification, facilitating its adoption as a PAT tool in regulated environments [24].

Experimental Applications and Methodologies

In-Line Monitoring of Hot Melt Extrusion

Hot melt extrusion (HME) has gained significant attention as a continuous manufacturing process for producing amorphous solid dispersions to enhance the bioavailability of poorly water-soluble drugs [22]. The following case study demonstrates the implementation of in-line UV-Vis spectroscopy to monitor PRX (piroxicam) in Kollidon VA64, documenting both the experimental methodology and results.

Table: Key Reagents and Materials for HME Monitoring

| Material/Reagent | Specification | Function in Experiment |

|---|---|---|

| Piroxicam (PRX) | USP/EP Standards | Model API (BCS Class II) |

| Kollidon VA64 | Pharmaceutical Grade | Matrix Polymer |

| Methanol/Water | HPLC Grade | Solvent for reference analysis |

| Extrusion Equipment | Leistritz Nano16 | Continuous manufacturing platform |

| UV-Vis Spectrophotometer | In-line fiber optic | Real-time potency monitoring |

| HPLC System | Validated Method | Reference analysis for model validation |

Experimental Protocol:

- Formulation Preparation: PRX and Kollidon VA64 were blended in varying concentrations (10-30% w/w) using a tubular mixer for 10 minutes [22].

- Extrusion Parameters: The blended formulation was processed using a co-rotating twin-screw extruder with temperature zones set between 120-170°C, screw speeds of 100-300 rpm, and feed rates of 4-8 g/min [22].

- In-Line UV-Vis Monitoring: A fiber-optic UV-Vis probe was installed at the extruder die, collecting spectra from 230-700 nm with a resolution of 2 nm. Absorbance values at specific wavelengths and color lightness (L*) values were recorded every 5 seconds [22].

- Reference Analysis: Samples collected at various process conditions were analyzed off-line using HPLC for PRX content, DSC for solid-state characterization, and XRD for crystallinity assessment [22].

The experimental workflow below illustrates the complete HME monitoring process:

Figure 1: HME Experimental Workflow with UV-Vis PAT Integration

Results and Findings: The study demonstrated that UV-Vis spectroscopy could effectively identify the solubility threshold of PRX in the polymer matrix. PRX concentrations exceeding 20% w/w resulted in oversaturation, detectable through increased scattering in the visible region and baseline shifts [22]. The real-time data enabled immediate process adjustments, reducing the traditional development timeline from several weeks to approximately one week [22].

Statistical analysis of the data revealed interaction effects between API concentration and temperature on both absorbance and L* values, while screw speed showed minimal impact within the studied range [22]. The optimum HME process conditions were determined to be 20% w/w PRX, 140°C die temperature, 200 rpm screw speed, and 6 g/min feed rate, demonstrating how UV-Vis PAT facilitates Quality by Design (QbD) implementation [22].

PAT Model Lifecycle Management

The implementation of UV-Vis as a PAT tool requires careful management of the analytical models throughout their lifecycle. Based on the experience of major pharmaceutical companies, the PAT model lifecycle encompasses five critical phases [23]:

Figure 2: PAT Model Lifecycle Management Process

Vertex Pharmaceuticals' approach to PAT model lifecycle management offers valuable insights for UV-Vis implementation [23]. Their system involves:

- Data Collection: Implementing QbD principles with experiments designed to capture variability from APIs, excipients, multiple lots, and process variations [23].

- Calibration: Applying appropriate spectral preprocessing techniques (smoothing, standard normal variate, mean centering) and developing robust calibration models [23].

- Validation: Challenging models with official samples, wider variability sets, and historical production data (potentially tens of thousands of spectra) [23].

- Maintenance: Continuous monitoring during production with real-time diagnostics and annual parallel testing [23].

- Redevelopment: Updating models when performance trends indicate deterioration, typically requiring 4-5 weeks for complete redevelopment and validation [23].

This systematic approach ensures that UV-Vis PAT methods remain effective despite changes in raw materials, equipment aging, or process modifications, maintaining regulatory compliance throughout the method's lifespan [23].

Regulatory Framework and GMP Compliance

Current Regulatory Expectations

The regulatory acceptance of UV-Vis spectroscopy within pharmaceutical GMP environments is well-established, with specific recognition in major pharmacopeias including the United States Pharmacopeia (USP), European Pharmacopoeia (EP), and Japanese Pharmacopoeia (JP) [24]. These regulatory bodies define precise performance requirements for UV-Vis instrumentation and methodologies, particularly for pharmaceutical applications such as:

- Identity testing to confirm material authenticity [25]

- Assay and potency testing to quantify API concentration [24]

- Impurity quantification to detect and measure undesired components [24]

- Dissolution testing to evaluate drug release characteristics [24] [25]

Regulatory guidance emphasizes the importance of method validation and instrument qualification to ensure data integrity and result reliability. As stated in one source, "For UV-Visible spectrophotometers in regulated laboratories, performance verification at installation and at set intervals thereafter is needed. National pharmacopeias with international reach define specific performance levels for various criteria in the pharmaceutical industry" [24].

Emerging Trends in GMP Standards

As pharmaceutical manufacturing evolves, GMP standards are increasingly incorporating advanced technologies and data-driven approaches. Key trends impacting PAT implementation include:

- Data Integrity Emphasis: Stricter requirements for electronic record-keeping and data management, with guidelines covering system access, change control, and audit trails [26] [27].

- Risk-Based Approaches: Greater focus on proactive risk identification and mitigation throughout the product lifecycle [26] [27].

- Real-Time Release Testing: Movement toward continuous quality verification that reduces end-product testing [26] [23].

- Continuous Manufacturing: Regulatory acceptance of continuous processes that inherently depend on PAT tools like UV-Vis for quality control [22] [27].

The FDA's 2015 approval of Vertex's Orkambi and the 2016 approval for Janssen's continuous manufacturing of Prezista marked significant milestones in regulatory acceptance of PAT-intensive continuous manufacturing processes [22]. These precedents demonstrate that properly validated UV-Vis methods are fully acceptable within modern regulatory frameworks when supported by comprehensive data and appropriate lifecycle management [23].

UV-Vis spectroscopy represents a mature, robust, and regulatory-accepted PAT tool for advanced in-line and at-line monitoring in pharmaceutical development and manufacturing. Its strengths in measurement speed, ease of interpretation, and sensitivity make it particularly valuable for real-time process monitoring and control, especially when compared to more complex spectroscopic techniques.

The successful implementation of UV-Vis within PAT frameworks requires careful attention to model lifecycle management and regulatory compliance, but offers significant rewards through enhanced process understanding, reduced development timelines, and improved product quality. As pharmaceutical manufacturing continues evolving toward more integrated continuous processes, UV-Vis spectroscopy will undoubtedly maintain its position as a fundamental PAT tool for the industry's quality assurance arsenal.

In the highly regulated pharmaceutical industry, cleaning validation is a critical component of current Good Manufacturing Practices (cGMP) to prevent cross-contamination and ensure product safety. Traditional methods for monitoring residues, such as Total Organic Carbon (TOC) analysis and conductivity measurement, while useful, lack the specificity and real-time capabilities needed for modern Pharma 4.0 manufacturing facilities [28]. Ultraviolet-Visible (UV-Vis) spectroscopy has emerged as a powerful, semi-specific analytical technique that can provide continuous, in-line monitoring of cleaning processes, particularly at the 220 nm wavelength, which is sensitive to many residual cleaning agents and degraded product molecules [28]. This monitoring approach aligns with regulatory expectations for continuous process verification and supports initiatives in Quality by Design and Process Analytical Technology [28].

The regulatory framework for cleaning validation, as outlined in FDA guidance documents, requires that equipment be "visually clean" and that contaminant residues be reduced to "scientifically justified limits" [29]. While the FDA does not set specific acceptance specifications, it expects manufacturers to establish limits that are "logical, practical, achievable, and verifiable" [29]. UV-Vis spectroscopy at 220 nm provides a scientifically sound methodology for verifying these limits in real-time, offering significant advantages over traditional at-line or off-line testing methods that can lead to false positives and delayed equipment release [28].

Theoretical Foundation: UV-Vis Spectroscopy at 220 nm

Scientific Principle of Detection

UV-Vis spectroscopy operates on the fundamental principle of the Beer-Lambert Law, which states that the absorbance (A) of a solution is directly proportional to its concentration (c), the path length (l) of the light through the sample, and the extinction coefficient (ε) of the absorbing species: A = εlc [28]. This relationship provides the theoretical basis for quantitative analysis of residual contaminants in cleaning validation.

The selection of 220 nm as the monitoring wavelength is based on the absorption characteristics of formulated cleaning agents and degraded pharmaceutical products. Research has demonstrated that many alkaline and acidic cleaners, along with degraded biomolecules, exhibit a localized absorption maximum at this wavelength [28]. While these compounds may show higher absorbance at lower ranges (190-200 nm), the 220 nm wavelength provides greater specificity by reducing interference from other organic molecules that commonly absorb in the lower UV range [28].

Advantages of In-line UV Monitoring

- Real-time Data Acquisition: In-line UV spectroscopy enables continuous monitoring of the entire cleaning cycle, allowing for immediate detection of deviations and prompt corrective actions [28].

- Detection of Degraded Products: Unlike specific chromatographic methods that may not detect degraded forms, UV spectroscopy at 220 nm can identify both intact and degraded product residues, which is particularly important for biologics that denature under cleaning conditions [28].

- Sensitivity Adjustment Capability: The sensitivity of the method can be optimized by adjusting the sanitary flow path length, with increased pathlength (e.g., from 1 cm to 10 cm) significantly lowering the limits of detection and quantification [28].

Comparative Performance Analysis: UV-Vis vs. Alternative Techniques

Direct Methodology Comparison

Table 1: Performance comparison of major cleaning validation monitoring techniques

| Analytical Technique | Detection Principle | Specificity | Real-time Capability | LOD/LOQ Sensitivity | Suitable for Degraded Products |

|---|---|---|---|---|---|

| UV-Vis at 220 nm | Electronic transitions | Semi-specific | Yes, continuous in-line | Moderate to High (adjustable via pathlength) | Yes, detects degraded forms |

| Total Organic Carbon (TOC) | Carbon oxidation | Non-specific | Limited (at-line) | Moderate | Yes, but cannot differentiate forms |

| Conductivity | Ionic content measurement | Non-specific | Yes, in-line | High for ionic species | No, limited to ionic compounds |

| HPLC/UV | Separation + UV detection | Highly specific | No (off-line) | Very High | Limited to intact molecules |

| ATP Bioluminescence | Enzymatic reaction | Non-specific | No (point sampling) | Low to Moderate | No, affected by cleaning agents [30] |

Quantitative Performance Data

Table 2: Experimental performance data for UV-Vis monitoring of typical cleaning validation analytes

| Analyte | Optimal Wavelength | Linear Range | LOD | LOQ | Precision (RSD%) | Key Interferences |

|---|---|---|---|---|---|---|

| Formulated Alkaline Cleaner | 220 nm | 25-1000 ppm | 5 ppm | 25 ppm | <5% | Organic compounds at lower wavelengths |

| Formulated Acid Cleaner | 220 nm | 10-1000 ppm | 2 ppm | 10 ppm | <5% | Organic compounds at lower wavelengths |

| Monoclonal Antibody Residues | 220 nm | 10-500 ppm | 8 ppm | 25 ppm | <8% | High protein concentrations |

| Bovine Serum Albumin | 220 nm | 5-300 ppm | 3 ppm | 10 ppm | <6% | Other proteinaceous materials |

Experimental Protocols for Method Validation

Wavelength Selection and Method Optimization

Protocol Objective: To determine the optimal wavelength and validate the analytical method for monitoring residual cleaning agents and degraded products.

Materials and Equipment:

- UV-Vis spectrophotometer (e.g., ThermoScientific GENESYS 50 UV-Vis)

- 10 mm quartz cuvettes (e.g., Fisher Part #14-958-112) [28]

- Formulated cleaning agents (alkaline and acidic)

- Model process soils: Bovine Serum Albumin (BSA), monoclonal antibody drug substances, insulin drug product [28]

- Type 1 water for dilutions

Experimental Procedure:

- Prepare approximately 1000 ppm solutions of each cleaner diluted in type 1 water [28].

- Collect full spectra from 190–400 nm to identify characteristic absorption profiles [28].

- Determine the localized maximum absorbance at 220 nm for both cleaning agents and model process soils.

- Qualify the analytical range by characterizing linearity and precision across the concentration range of interest (e.g., 25-1000 ppm for alkaline cleaner, 10-1000 ppm for acidic cleaner) [28].

- Perform triplicate preparation and analysis of calibration curves to establish linearity, precision, and accuracy.

- Prepare separate sample preparations at concentrations within the linear range and quantitate using the established calibration curves to assess method accuracy.

Interference and Enhancement Testing

Protocol Objective: To evaluate potential interference or enhancement effects between cleaning agents and product residues.

Materials and Equipment:

- UV-Vis spectrophotometer with 10 mm quartz cuvettes

- Formulated alkaline and acid cleaners

- Model process soils: BSA, monoclonal antibody, insulin

- Type 1 water

Experimental Procedure:

- Dilute each model soil to concentrations across the analytical range established for the alkaline cleaner [28].

- Characterize the UV response for each solution individually, monitoring absorbance at 220 nm.

- Prepare 1:1 mixtures of the model soils and the alkaline cleaner.

- Collect spectra for each mixture solution and monitor absorbance at 220 nm.

- Compare the measured absorbance values of the mixtures with the expected additive values from individual components to identify any enhancement or depression effects.

- Document any cumulative effects similar to those observed in Total Organic Carbon analysis [28].

Degradation Studies for Biopharmaceutical Products

Protocol Objective: To verify that UV detection at 220 nm can detect both intact and degraded biopharmaceutical products.

Materials and Equipment:

- UV-Vis spectrophotometer with cuvettes

- Monoclonal antibody drug product

- Formulated alkaline cleaner (1% and 3% concentrations)

- Type 1 water

- Heating apparatus capable of maintaining 60°C

Experimental Procedure:

- Prepare and preheat stock solutions of alkaline cleaner to 60°C [28].

- Dilute the mAb drug product with the degradation solutions 1:10 and maintain temperature for five minutes [28].

- Quench the reaction by diluting the degradation solution to 100 mL with ambient temperature type 1 water [28].

- For UV analysis, dilute solutions to cleaning agent concentrations ranging from 5–1000 ppm [28].

- Perform measurements as described in the method development protocol.

- Compare the detection capability for degraded versus intact product molecules.

Implementation in Regulatory-Compliant Environments

Meeting Pharmacopoeia and Regulatory Standards

Modern UV-Vis systems designed for pharmaceutical applications must comply with global pharmacopoeia standards including USP <857>, Ph. Eur. 2.2.5, and JP <2.24> [3]. The LAMBDA 365+ UV/Vis spectrophotometer represents such a compliant system, incorporating enhanced security (ES) software with client-server architecture that ensures data integrity and supports 21 CFR Part 11 compliance [3]. These systems include automated instrument operational qualification protocols that streamline the validation process in regulated environments.

The FDA's perspective on cleaning validation emphasizes that "the test of any validation process is whether scientific data shows that the system consistently does as expected and produces a result that consistently meets predetermined specifications" [29]. UV-Vis spectroscopy at 220 nm provides this scientific basis through its foundation in the Beer-Lambert law and demonstrated performance in detecting residuals at pharmaceutically relevant levels.

Integration with Process Life-Cycle Approach

Implementation of UV-Vis monitoring should align with the process life-cycle model for cleaning validation, which includes design, qualification, and ongoing verification stages [31]. This approach requires:

- Robust Method Design: Establishing scientific justification for wavelength selection, sampling points, and acceptance criteria during initial method development.

- Performance Qualification: Verifying that the UV-Vis method consistently detects residues at or below the established limits during validation studies.

- Continued Process Verification: Implementing routine monitoring with trending and statistical process control, such as calculating process capability indices (Cpk) for cleaning process performance [31].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key research reagents and materials for UV-Vis cleaning validation studies

| Item | Specification/Example | Function in Experimental Protocol |

|---|---|---|

| UV-Vis Spectrophotometer | LAMBDA 365+ with Spectrum UV Software [3] | Primary analytical instrument for detection and quantification |

| Quartz Cuvettes | 10 mm pathlength (Fisher Part #14-958-112) [28] | Sample holder with UV-transparent properties |

| Formulated Cleaners | Alkaline and acidic compositions with chromophores [28] | Target analytes for method development |

| Model Process Soils | BSA, mAb drug substance, insulin drug product [28] | Representative challenging residues for testing |

| Type 1 Water | ASTM D1193-91 Standard | Diluent and blank reference material |

| Sanitary Flow Cell | Adjustable pathlength (1-10 cm) [28] | In-line monitoring interface for real-time analysis |

| Reference Standards | NIST-traceable polystyrene standard [32] | System qualification and performance verification |

UV-Vis spectroscopy at 220 nm provides a scientifically sound, regulatorily acceptable methodology for real-time cleaning validation in pharmaceutical manufacturing. The technique offers significant advantages over traditional non-specific methods through its semi-specific detection capability, sensitivity to degraded products, and compatibility with continuous monitoring approaches aligned with Pharma 4.0 initiatives. When implemented within a robust quality system that includes proper method validation, equipment qualification, and ongoing verification, this technique provides a reliable means to demonstrate equipment cleanliness and maintain compliance with global regulatory requirements. As the industry continues to embrace real-time monitoring and continuous process verification, UV-Vis spectroscopy at 220 nm is positioned to become an increasingly valuable tool in the cleaning validation arsenal.

The analysis of biologics and complex biomolecules, such as monoclonal antibodies (mAbs), therapeutic proteins, and vaccines, presents significant challenges that distinguish them from traditional small-molecule drugs. These macromolecular therapeutics exhibit inherent heterogeneity due to their complex structure and susceptibility to post-translational modifications, making comprehensive characterization essential for ensuring product safety, efficacy, and quality [33]. Biopharmaceutical manufacturers are required to demonstrate thorough characterization of structural, physiochemical, immunological, and biological properties according to regulatory guidelines from agencies including the FDA and European Medicines Agency (EMA) [33]. This article examines the role of UV-Vis spectroscopy within the analytical toolkit for biologics, comparing its performance against other techniques while considering the framework of regulatory acceptance in pharmaceutical Good Manufacturing Practice (GMP) research.

Critical Quality Attributes of Biologics