Green Spectroscopic Analysis of APIs: Sustainable Methodologies for Modern Pharmaceutical Development

This article provides a comprehensive overview of green spectroscopic methodologies for the analysis of Active Pharmaceutical Ingredients (APIs), addressing the pharmaceutical industry's need for sustainable, efficient, and compliant analytical techniques.

Green Spectroscopic Analysis of APIs: Sustainable Methodologies for Modern Pharmaceutical Development

Abstract

This article provides a comprehensive overview of green spectroscopic methodologies for the analysis of Active Pharmaceutical Ingredients (APIs), addressing the pharmaceutical industry's need for sustainable, efficient, and compliant analytical techniques. It explores the foundational principles of Green Analytical Chemistry (GAC) and their application across UV-Vis, NIR, MIR, and FT-IR spectroscopy. The content details practical method development, including chemometric modeling with PLS and advanced algorithms, in-line Process Analytical Technology (PAT) applications for real-time monitoring, and strategies for troubleshooting common spectral issues. A significant focus is placed on validation according to ICH guidelines and a comparative analysis of greenness using modern metric tools like AGREE, AES, and RGB models. Designed for researchers, scientists, and drug development professionals, this guide bridges the gap between analytical performance, regulatory requirements, and environmental responsibility.

Principles and Core Concepts of Green Spectroscopy in Pharma

Green Spectrometry represents a fundamental shift in analytical science, applying spectroscopic techniques with a pronounced emphasis on environmental responsibility and sustainability [1]. It is an environmentally conscious methodology within analytical chemistry that aims to mitigate the detrimental effects of analytical techniques on the natural environment and human health [2]. This approach emerges from the broader framework of Green Analytical Chemistry (GAC), which seeks to minimize the environmental footprint of analytical methods by reducing or eliminating dangerous solvents, reagents, and other materials while maintaining rigorous analytical performance [3] [4].

The driving force behind Green Spectrometry is a recognition that traditional analytical methods, while powerful, often involve significant consumption of chemicals, energy, and generate substantial waste [1]. In pharmaceutical analysis, where analytical procedures are employed at multiple stages from quality assurance of starting materials to finished product testing and stability studies, the cumulative environmental impact can be substantial [5]. Green Spectrometry addresses these concerns through a systematic application of green chemistry principles, focusing on miniaturization, reduced resource consumption, and inherently safer methodologies that maintain analytical precision and accuracy while dramatically lowering ecological impact [1] [4].

Core Principles of Green Spectrometry

The practice of Green Spectrometry is guided by several foundational principles derived from green chemistry but specifically adapted to spectroscopic analysis of active pharmaceutical ingredients (APIs).

Reduced Sample and Reagent Consumption

A fundamental principle involves minimizing the quantities of samples and chemical reagents required for analysis [1]. This approach directly translates to reduced waste generation and lower analytical costs. Techniques that enable this principle include micro-spectrometry and microvolume approaches that require only microliters of sample instead of milliliters traditionally used [1]. In practice, this manifests through miniaturized equipment, solvent-free methods, and direct analysis techniques that eliminate or drastically reduce sample preparation steps. For instance, the pressed pellet technique in FT-IR spectroscopy allows sample analysis without toxic solvents, significantly reducing chemical consumption compared to liquid chromatography methods [4].

Energy Efficiency Optimization

Spectroscopic instruments can consume considerable power, making energy optimization a crucial consideration [1]. Green Spectrometry encourages the use of energy-efficient instruments, optimization of measurement parameters to reduce analysis time, and adoption of techniques that inherently require less energy [1]. This principle extends to considering the total energy footprint of analytical procedures, including ancillary equipment such as ovens, chillers, and data processing systems. The development of portable spectrometers that typically have lower power requirements than their benchtop counterparts represents one advancement in this area [1].

Waste Minimization and Prevention

Rather than focusing solely on proper waste disposal, Green Spectrometry emphasizes waste prevention at the source [1]. This proactive approach involves developing methods that generate minimal waste through direct analysis techniques, reusable materials, and recovery systems for solvents and reagents [1]. The principle also encourages the design of methods that allow for sample reuse or that generate waste streams that are more easily treated or recycled. In pharmaceutical analysis, this might involve methods that eliminate derivatization steps or that use minimal quantities of green solvents [5].

Safer Solvents and Auxiliaries

Many conventional spectroscopic methods rely on hazardous solvents, creating potential risks for laboratory personnel and environmental burdens upon disposal [1]. Green Spectrometry promotes the substitution of hazardous solvents with less toxic or bio-based alternatives [1]. Preferred solvents include water, ethanol, acetone, and supercritical carbon dioxide, which offer reduced toxicity and environmental persistence compared to traditional organic solvents [1] [5]. The principle extends beyond solvents to include all auxiliary substances used in spectroscopic analysis, including calibration standards, matrix modifiers, and separation media.

Inherently Safer Analysis

Overall, Green Spectrometry strives for inherently safer analytical chemistry by choosing methods that reduce potential for accidents, exposure to hazardous substances, and generation of dangerous waste streams [1]. This includes selecting spectroscopic techniques that require minimal sample manipulation, avoid high temperatures or pressures where possible, and utilize reagents with favorable safety profiles. FT-IR spectroscopy exemplifies this principle through its non-destructive nature and minimal sample preparation requirements [4].

Table 1: Core Principles of Green Spectrometry and Their Implementation

| Principle | Key Objectives | Implementation Examples |

|---|---|---|

| Reduced Consumption | Minimize sample and reagent volumes; Reduce waste generation | Micro-spectrometry; Solvent-free extraction; Direct analysis |

| Energy Efficiency | Lower power consumption; Optimize analysis time | Portable instruments; Method parameter optimization; Energy-efficient hardware |

| Waste Prevention | Eliminate waste at source; Enable recycling | Direct analysis; Reusable materials; Solvent recovery systems |

| Safer Solvents | Replace hazardous chemicals; Use renewable resources | Water/ethanol-based systems; Bio-based solvents; Supercritical CO₂ |

| Inherently Safer Analysis | Reduce hazards; Minimize exposure risks | Non-destructive methods; Minimal sample preparation; Benign reagents |

Quantitative Greenness Assessment Metrics

The evaluation of method greenness has evolved from qualitative assessments to sophisticated quantitative metrics that provide comprehensive environmental profiling of analytical procedures [3].

Established Greenness Assessment Tools

Multiple metric systems have been developed to evaluate the environmental performance of analytical methods, each with specific strengths and applications in spectroscopic method assessment.

NEMI (National Environmental Methods Index) was one of the first green assessment tools, using a simple pictogram with four criteria: whether reagents are persistent, toxic, corrosive, or whether waste generation exceeds 50g per sample [3]. While user-friendly, its binary pass/fail approach and limited scope restricted its utility for comprehensive method evaluation [3].

GAPI (Green Analytical Procedure Index) provides a more comprehensive visual assessment using a five-part color-coded pictogram that evaluates the entire analytical process from sample collection to final detection [3]. This tool allows visual identification of high-impact stages within a method, though it lacks an overall numerical score and can involve subjective color assignments [3].

AGREE (Analytical Greenness Metric) represents a significant advancement by providing both a unified circular pictogram and a numerical score between 0 and 1, based on the 12 principles of GAC [3]. This tool enhances interpretability and facilitates direct method comparisons, though it may not fully account for pre-analytical processes [3].

AES (Analytical Eco-Scale) applies penalty points to non-green attributes which are subtracted from a base score of 100 [3]. The resulting score enables direct comparison between methods but relies on expert judgment in assigning penalties and lacks a visual component [3].

Recent Advances in Greenness Metrics

The field continues to evolve with new metrics addressing specific limitations of earlier tools:

AGREEprep focuses specifically on evaluating the environmental impact of sample preparation, often the most resource-intensive step in analytical workflows [3]. It provides both visual and quantitative outputs but must be used alongside broader tools for complete method evaluation [3].

MoGAPI (Modified GAPI) retains the pictographic approach of GAPI while introducing cumulative scoring systems to improve comparability and clarity [4]. Recent applications in pharmaceutical analysis have demonstrated its utility for evaluating FT-IR methods [4].

AGSA (Analytical Green Star Analysis) uses a star-shaped diagram to represent performance across multiple green criteria including reagent toxicity, waste generation, energy use, and solvent consumption [3]. The total area of the star offers direct visual comparison between methods [3].

CaFRI (Carbon Footprint Reduction Index) addresses growing climate concerns by estimating and encouraging reduction of carbon emissions associated with analytical procedures [3]. This tool aligns analytical chemistry with broader environmental targets by considering the carbon footprint of different methodological stages [3].

Table 2: Greenness Assessment Metrics for Spectroscopic Methods

| Metric | Scoring System | Key Advantages | Limitations |

|---|---|---|---|

| NEMI | Binary pictogram (pass/fail) | Simple; User-friendly | Limited scope; No gradation of greenness |

| AES | Penalty points from 100 | Quantitative score; Method comparison | Subjective penalties; No visualization |

| GAPI | Color-coded pictogram | Visualizes entire process; Comprehensive | No overall score; Some subjectivity |

| AGREE | 0-1 score + circular pictogram | Comprehensive; User-friendly; Quantitative | Limited pre-analytical assessment |

| AGREEprep | 0-1 score + pictogram | Sample preparation focus; Quantitative | Narrow scope (preparation only) |

| MoGAPI | Numerical score + pictogram | Combines GAPI visuals with scoring | Emerging method; Limited adoption |

| AGSA | Star area + numerical score | Multi-criteria; Visual comparison | Complex calculation |

| CaFRI | Carbon reduction score | Climate impact focus; Lifecycle perspective | New method; Limited validation |

Experimental Protocol: Green FT-IR Spectroscopic Quantification of APIs

The following detailed protocol demonstrates the application of Green Spectrometry principles to the simultaneous quantification of amlodipine besylate (AML) and telmisartan (TEL) in pharmaceutical formulations using FT-IR spectroscopy [4].

Principle

This method utilizes Fourier Transform Infrared (FT-IR) spectroscopy for the simultaneous quantification of two antihypertensive drugs in combined dosage forms without using organic solvents. The method is based on measuring the area under the curve (AUC) of specific absorption peaks for each drug after conversion of transmittance spectra to absorbance spectra [4].

Experimental Workflow

Materials and Reagents

Table 3: Research Reagent Solutions and Essential Materials

| Item | Specification | Function | Green Characteristics |

|---|---|---|---|

| Potassium Bromide (KBr) | FT-IR grade, 99.9% purity | Matrix for pellet preparation; Non-absorbing in mid-IR | Low toxicity; Reusable; Minimal environmental impact |

| Standard AML | Pharmaceutical secondary standard | Calibration reference | Precise quantification enables minimal material usage |

| Standard TEL | Pharmaceutical secondary standard | Calibration reference | Enables trace analysis reducing overall chemical consumption |

| FT-IR Spectrometer | With DTGS detector | Spectral acquisition | Energy-efficient modern instrumentation |

| Hydraulic Press | 10-15 ton capacity | Pellet preparation | Reusable equipment; Minimal energy requirements |

| Mortar and Pestle | Agate material | Sample homogenization | Reusable; No disposable consumables |

Step-by-Step Procedure

Standard Preparation

- Primary Standard Solutions: Accurately weigh 10 mg each of AML and TEL reference standards using an analytical balance.

- KBr Mixture: Combine 1 mg of each drug standard with 100 mg of dry KBr powder in an agate mortar.

- Homogenization: Grind the mixture thoroughly for 5 minutes to ensure uniform distribution and particle size reduction (<5 µm).

- Pellet Formation: Transfer approximately 50 mg of the homogenized mixture to a 7mm die set and compress under 10-ton pressure for 2 minutes under vacuum to form a transparent pellet.

Sample Preparation

- Tablet Powder Preparation: Weigh and finely powder not less than 20 tablets using a mortar and pestle.

- Sample Extraction: Accurately weigh powder equivalent to 10 mg of combined APIs and mix with 100 mg KBr.

- Homogenization: Follow the same grinding procedure as for standards (Section 4.4.1, Step 3).

- Pellet Formation: Prepare pellets as described in Section 4.4.1, Step 4.

Instrumental Analysis

- Instrument Calibration: Background spectrum collection using pure KBr pellet.

- Spectral Acquisition:

- Scan range: 4000-400 cm⁻¹

- Resolution: 4 cm⁻¹

- Scans: 16 per spectrum

- Data Collection: Record transmittance spectra for all standards and samples.

- Data Conversion: Convert transmittance spectra to absorbance using instrument software.

Data Analysis

- Peak Selection: Identify characteristic peaks for each API - AML at 1206 cm⁻¹ (R-O-R stretching) and TEL at 863 cm⁻¹ (C-H out-of-plane bending) [4].

- Area Calculation: Measure area under curve (AUC) for selected peaks using Origin Pro software or equivalent.

- Calibration Curve: Plot AUC against concentration (%w/w) for each drug in the range of 0.2-1.2% w/w.

- Quantification: Determine sample concentrations using linear regression equations from calibration curves.

Method Validation

The method should be validated according to ICH guidelines including [4]:

- Specificity: Verify no interference from excipients at selected wave numbers.

- Linearity: Establish linear range with correlation coefficient (r²) >0.999.

- Precision: Evaluate repeatability (intra-day) and intermediate precision (inter-day) with RSD <2%.

- Accuracy: Conduct recovery studies at 80%, 100%, 120% levels with acceptable recovery of 98-102%.

- LOD/LOQ: Determine limits of detection and quantification demonstrating method sensitivity.

Greenness Evaluation and Comparative Analysis

Application of Greenness Metrics

The green FT-IR method for simultaneous quantification of AML and TEL was evaluated using multiple assessment tools, demonstrating its superior environmental profile compared to conventional HPLC methods [4].

Table 4: Comparative Greenness Assessment of FT-IR vs. HPLC Method

| Assessment Metric | FT-IR Method Score | HPLC Method Score | Key Advantages of FT-IR Method |

|---|---|---|---|

| MoGAPI | 89/100 | 45/100 | Higher scores in solvent usage, waste generation, energy consumption |

| AGREEprep | 0.8/1.0 | 0.4/1.0 | Superior sample preparation profile with minimal reagents |

| RGB Model | 87.2/100 | 52.5/100 | Balanced performance across all greenness dimensions |

| NEMI Pictogram | 4/4 green fields | 1/4 green fields | Meets all criteria for green solvents, low waste, and safety |

| Carbon Footprint | ~60% reduction | Baseline | Lower energy and solvent-related emissions |

Environmental Impact Analysis

The green FT-IR method demonstrates significant environmental advantages across multiple impact categories:

Solvent Elimination: Complete avoidance of organic solvents represents the most substantial green achievement, eliminating procurement, handling, storage, and disposal concerns associated with toxic solvents like acetonitrile and methanol typically used in HPLC methods [4].

Waste Minimization: The method generates minimal solid waste (primarily KBr, which can be recycled), contrasting sharply with HPLC methods that produce hundreds of milliliters of solvent waste per day of operation [4].

Energy Efficiency: FT-IR spectroscopy typically requires less energy than HPLC systems, which need significant power for pump operation, column heating, and detector systems. The elimination of lengthy separation steps further reduces energy consumption per analysis [1].

Operator Safety: The method eliminates exposure risks associated with organic solvent handling and reduces potential for accidents due to the simple procedural steps and benign materials [1].

Implementation in Pharmaceutical Research

Strategic Adoption Framework

Successful implementation of Green Spectrometry in pharmaceutical research requires a systematic approach:

Method Selection Criteria: Prioritize spectroscopic techniques based on their inherent green characteristics. FT-IR, NIR, and Raman spectroscopy typically offer greener profiles than methods requiring extensive sample preparation or hazardous solvents [1].

Technology Integration: Incorporate portable spectrometers for at-line analysis to reduce sample transport and enable real-time decision making [1]. Modern compact instruments provide analytical performance comparable to benchtop systems with significantly reduced footprint and energy requirements.

Workflow Optimization: Re-engineer analytical procedures to maximize green principles while maintaining data quality. This includes implementing direct analysis approaches, reducing procedural steps, and selecting benign reagents [4].

Green Spectrometry Applications in API Analysis

ATR-FTIR for Solid Dosage Forms: Attenuated Total Reflectance FT-IR enables direct analysis of tablets and powders without sample preparation, completely eliminating solvent use [1]. This approach has been successfully applied to quantification of APIs in various pharmaceutical formulations with minimal method development time.

Raman Spectroscopy for Process Monitoring: The minimal sample preparation requirements and ability to use fiber optic probes for in-situ analysis make Raman spectroscopy particularly suitable for green monitoring of pharmaceutical processes and reactions [1].

NIR for Raw Material Identification: Near-infrared spectroscopy provides rapid, non-destructive identification and quantification of APIs and excipients with minimal or no sample preparation, significantly reducing analytical time and resource consumption compared to traditional methods [1].

The implementation of Green Spectrometry principles through the specific methodologies and assessment frameworks detailed in this document enables pharmaceutical researchers to significantly reduce the environmental impact of analytical operations while maintaining the rigorous data quality required for drug development and quality control.

The Twelve Principles of Green Analytical Chemistry (GAC) and Their Practical Implications

Green Analytical Chemistry (GAC) has emerged as a fundamental discipline that integrates the principles of green chemistry into analytical methodologies, aiming to minimize the environmental impact of chemical analysis while maintaining high standards of accuracy and precision [6]. Originating in 2000 as an extension of green chemistry, GAC specifically addresses analytical chemistry techniques and procedures to decrease or eliminate dangerous solvents, reagents, and other materials while providing rapid and energy-saving methodologies that maintain essential validation parameters [3]. This approach represents a significant shift in how analytical challenges are approached, striving for environmental benignity without compromising analytical performance.

The foundation of GAC lies in the 12 principles of green chemistry established by Paul Anastas and John Warner, which provide a comprehensive framework for designing environmentally benign chemical processes [7] [8]. These principles emphasize waste prevention, atom economy, reducing hazardous chemicals, and using renewable raw materials, all of which are highly relevant to analytical chemistry practices [9]. The pharmaceutical industry, in particular, has embraced GAC to foster environmentally safer analytical methods, driven by both regulatory requirements and corporate sustainability goals [7] [10]. As environmental regulations tighten and industries shift towards greener practices, GAC equips chemists with the knowledge to create methods that are not only efficient but also environmentally responsible [6].

The Twelve Principles of Green Analytical Chemistry

The Twelve Principles of Green Chemistry provide a foundational framework for designing chemical processes and products that prioritize environmental and human health [9]. When applied to analytical techniques, these principles drive the development of methodologies that are safer, more efficient, and environmentally benign. The table below summarizes these principles and their specific implications for analytical chemistry.

Table 1: The Twelve Principles of Green Chemistry and Their Analytical Implications

| Principle | Core Concept | Analytical Chemistry Implications |

|---|---|---|

| 1. Prevention | Prevent waste rather than treat or clean up after formation | Design analytical methods that minimize or eliminate waste generation from sample preparation to final analysis [11] [8] |

| 2. Atom Economy | Maximize incorporation of all materials into final product | Optimize synthetic methods used in analytical chemistry to maximize product incorporation; though less directly applicable, it informs reaction choices in derivatization [11] [7] |

| 3. Less Hazardous Chemical Syntheses | Design synthetic methods using/generating substances with minimal toxicity | Select reagents and derivatizing agents with lower toxicity for sample preparation and analysis [11] [8] |

| 4. Designing Safer Chemicals | Design chemical products to preserve efficacy while reducing toxicity | Develop new reagents, derivatizing agents, and solvents that maintain analytical performance with reduced toxicity [11] |

| 5. Safer Solvents and Auxiliaries | Minimize use of auxiliary substances or use innocuous ones | Replace hazardous solvents with safer alternatives like water, ionic liquids, or bio-based solvents [9] [8] |

| 6. Design for Energy Efficiency | Recognize and minimize energy requirements of chemical processes | Employ energy-efficient techniques like ultrasound-assisted extraction and microwave-assisted processes [9] [8] |

| 7. Use of Renewable Feedstocks | Use renewable rather than depleting feedstocks | Utilize solvents and reagents derived from renewable resources in analytical procedures [9] [8] |

| 8. Reduce Derivatives | Minimize or avoid unnecessary derivatization | Avoid derivatization steps in analytical procedures unless absolutely necessary for detection or separation [8] |

| 9. Catalysis | Prefer catalytic reagents over stoichiometric reagents | Use catalytic rather than stoichiometric reagents in sample preparation and analytical reactions [9] [8] |

| 10. Design for Degradation | Design chemical products to break down into innocuous degradation products | Use reagents and solvents that biodegrade into non-hazardous substances after disposal [8] |

| 11. Real-time Analysis for Pollution Prevention | Develop analytical methodologies for real-time, in-process monitoring | Implement process analytical technology (PAT) for real-time monitoring to prevent hazardous substance formation [8] |

| 12. Inherently Safer Chemistry for Accident Prevention | Choose substances and forms to minimize accident potential | Select reagents and solvents with higher safety margins to minimize risks of explosions, fires, or releases [8] |

Greenness Assessment Tools and Metrics

The evaluation of analytical methods' environmental impact is crucial for implementing GAC principles effectively. Several assessment tools have been developed to quantify and compare the greenness of analytical procedures, enabling researchers to make informed decisions about method selection and optimization [3].

Evolution of Greenness Assessment Metrics

The field of GAC has witnessed significant evolution in assessment tools, progressing from basic binary indicators to comprehensive multi-criteria evaluation systems. The National Environmental Methods Index (NEMI) was an early tool that used a simple pictogram indicating whether a method complied with four basic environmental criteria [3]. While user-friendly, its binary structure limited its ability to distinguish degrees of greenness. Subsequent tools like the Analytical Method Volume Intensity (AMVI) focused specifically on solvent and reagent consumption in HPLC methods but overlooked other important factors like toxicity and energy usage [3].

The development of the Analytical Eco-Scale introduced a scoring system that assigns penalty points to non-green attributes, which are subtracted from a base score of 100, allowing for direct comparison between methods [3]. This was followed by the Green Analytical Procedure Index (GAPI), which offers a more comprehensive and visually intuitive approach by assessing the entire analytical process from sample collection through preparation to final detection using a five-part, color-coded pictogram [6] [3].

A significant advancement came with the Analytical Greenness (AGREE) metric, which is based on all 12 principles of GAC and provides both a unified circular pictogram and a numerical score between 0 and 1 [12] [3]. More recently, specialized tools have emerged, including AGREEprep for evaluating sample preparation procedures, Carbon Footprint Reduction Index (CaFRI) for estimating carbon emissions, and Analytical Green Star Analysis (AGSA) that uses a star-shaped diagram for multi-criteria assessment [12] [3].

Table 2: Comparison of Major Greenness Assessment Tools for Analytical Methods

| Assessment Tool | Type of Output | Key Parameters Evaluated | Strengths | Limitations |

|---|---|---|---|---|

| NEMI | Binary pictogram | Persistence, bioaccumulation, toxicity, waste generation | Simple, user-friendly | Limited discrimination, lacks comprehensiveness [3] |

| Analytical Eco-Scale | Numerical score (0-100) | Reagent amount and hazard, energy consumption, waste | Facilitates direct comparison | Relies on expert judgment, lacks visual component [3] |

| GAPI | Color-coded pictogram | Entire analytical process from sampling to detection | Comprehensive, visually intuitive | No overall score, somewhat subjective [3] |

| AGREE | Pictogram + numerical score (0-1) | All 12 GAC principles | Comprehensive, user-friendly interface | Doesn't fully account for pre-analytical processes [12] [3] |

| AGREEprep | Pictogram + numerical score | Sample preparation-specific parameters | Specialized for sample preparation | Must be used with broader tools for full method evaluation [12] |

| AGSA | Star diagram + numerical score | Reagent toxicity, waste, energy, solvent consumption | Intuitive visualization, integrated scoring | Newer tool with less established track record [3] |

White Analytical Chemistry: An Integrated Approach

A significant development in the field is the concept of White Analytical Chemistry (WAC), which presents a holistic approach that balances environmental, practical, and analytical considerations [12] [5]. WAC integrates three color-coded dimensions: the green component (environmental sustainability), the red component (analytical performance and functionality), and the blue component (methodological practicality) [12] [3]. This model acknowledges that a truly excellent analytical method must excel in all three dimensions simultaneously, creating a "white" combination of sustainability, analytical quality, and practical utility [5].

Diagram 1: White Analytical Chemistry (WAC) Integrated Model

Practical Implementation in Pharmaceutical Analysis

Green Spectroscopic Methods for API Analysis

The application of GAC principles to spectroscopic analysis of active pharmaceutical ingredients (APIs) has yielded significant advancements in sustainability without compromising analytical performance. UV spectrophotometric methods have been particularly successful in implementing green principles for pharmaceutical analysis [13]. Recent research has demonstrated the development of green UV spectrophotometric techniques for the simultaneous determination of ternary drug combinations containing Aceclofenac, Paracetamol, and Tramadol in pain reliever formulations [13].

These methods utilize advanced mathematical approaches such as the double divisor ratio spectra method (DDRSM) and area under the curve (AUC) calculations to accurately determine component concentrations without requiring extensive sample preparation or hazardous solvents [13]. The greenness assessment of these methodologies using metric tools confirmed their environmental sustainability while maintaining accuracy, precision, and reliability for pharmaceutical quality control [13].

Green Sample Preparation Techniques

Sample preparation is often the most resource-intensive and waste-generating step in analytical procedures, making it a primary target for green improvements. Ultrasound-assisted extraction (UAE) has emerged as a powerful green technique that significantly reduces extraction times, solvent consumption, and energy requirements compared to conventional methods [12]. A case study evaluating the determination of Mn and Fe in beef samples using UAE demonstrated that the method required only 10 minutes without harsh extractants or external heating, using only diluted acids [12].

Other innovative green sample preparation approaches include:

- Microwave-assisted extraction: Reduces extraction time and solvent volume through efficient energy transfer

- Solid-phase microextraction (SPME): Eliminates solvents entirely in some applications

- Switchable solvents: Allow for recycling and reuse of extraction solvents

- Miniaturized techniques: Dramatically reduce reagent consumption and waste generation

Table 3: Green Sample Preparation Techniques for Pharmaceutical Analysis

| Technique | Mechanism | Green Benefits | Pharmaceutical Applications |

|---|---|---|---|

| Ultrasound-Assisted Extraction (UAE) | Cavitation disrupts sample matrix | Reduced time (e.g., 10 min), minimal solvent, no heating [12] | Herbal medicines, solid dosage forms [12] |

| Microwave-Assisted Extraction | Efficient dielectric heating | Faster extraction, reduced solvent volume | Natural products, APIs from matrices [9] |

| Solid-Phase Microextraction | Sorption onto coated fiber | Solvent-free, minimal waste | Volatile impurities, residual solvents [9] |

| Switchable Solvents | CO₂-triggered polarity changes | Recyclable, reduced consumption | Extraction of acidic/basic pharmaceuticals [6] |

| Miniaturized LED | Reduced scale of operations | 90% less solvent, minimal waste [3] | All sample types, limited sample availability |

Experimental Protocol: Green Ultrasound-Assisted Extraction for Metal Analysis in Biological Samples

The following protocol outlines a specific green analytical method for metal determination in biological samples, demonstrating the practical application of GAC principles:

Objective: To determine manganese (Mn) and iron (Fe) in beef samples using ultrasound-assisted extraction followed by microwave-induced plasma atomic emission spectroscopy (MP AES) [12].

Principles Applied: Waste prevention (minimal waste generation), safer solvents (diluted acids), design for energy efficiency (ultrasound assistance) [12].

Materials and Equipment:

- Ultrasound bath with temperature control

- Microwave-induced plasma atomic emission spectrometer (MP AES)

- Nitric acid (trace metal grade)

- Hydrogen peroxide (30%, analytical grade)

- Deionized water

- Certified reference materials for quality control

Procedure:

- Sample Preparation: Homogenize 0.5 g of beef sample accurately weighed into a 50 mL extraction vessel.

- Green Extraction: Add 5 mL of diluted nitric acid (2% v/v) and 1 mL of hydrogen peroxide to the sample.

- Ultrasound-Assisted Extraction: Place the vessel in an ultrasound bath maintained at room temperature. Extract for 10 minutes at 40 kHz frequency.

- Separation: Centrifuge the extract at 4000 rpm for 5 minutes to separate particulate matter.

- Dilution: Transfer the supernatant to a 10 mL volumetric flask and dilute to volume with deionized water.

- Analysis: Introduce the sample to the MP AES system for simultaneous determination of Mn and Fe.

- Quantification: Use matrix-matched calibration standards for accurate quantification.

Method Validation:

- Linear calibration curves for Mn and Fe in the range of 0.01-1.0 mg/L

- Recovery studies using certified reference materials (85-105%)

- Precision expressed as RSD < 5%

- Limit of detection: 0.005 mg/L for both elements

Greenness Assessment: Evaluation using AGREEprep demonstrated a high greenness score for the sample preparation procedure, primarily due to minimal reagent consumption, avoidance of harsh chemicals, short extraction time, and energy efficiency [12].

Successful implementation of GAC requires access to appropriate tools, reagents, and methodologies. The following toolkit provides essential resources for researchers developing green spectroscopic methods for API analysis.

Table 4: Essential Research Reagent Solutions for Green Analytical Chemistry

| Tool/Resource | Function | Green Alternative | Application Context |

|---|---|---|---|

| AGREE Software | Comprehensive greenness assessment | Free downloadable tool evaluating all 12 GAC principles [6] | Method development and optimization [12] [6] |

| Green Solvent Selection Guide | Solvent replacement | Ranks solvents based on health, safety, environment [11] | HPLC mobile phase, extraction solvents [11] |

| Ionic Liquids | Alternative solvents | Low volatility, tunable properties, recyclable | Extraction, separation, analytical reactions [9] |

| Bio-Based Solvents | Renewable solvents | Derived from biomass (e.g., 2-methyltetrahydrofuran) [11] | Sample preparation, chromatography [9] |

| Switchable Solvents | Smart solvents | CO₂-triggered polarity switching for recycling [6] | Extraction and purification processes [6] |

| Water as Solvent | Benign replacement | Non-toxic, non-flammable, readily available | Suitable for many extraction and analytical processes [9] |

| Supercritical CO₂ | Alternative solvent | Non-toxic, easily removed, tunable solvation | Extraction, chromatography (SFC) [9] |

The adoption of Green Analytical Chemistry principles represents a paradigm shift in pharmaceutical analysis, moving toward sustainable practices that reduce environmental impact while maintaining analytical excellence. The twelve principles of GAC provide a comprehensive framework for developing spectroscopic and other analytical methods that minimize waste, reduce energy consumption, and prioritize safety [8]. The emergence of assessment tools like AGREE, GAPI, and AGREEprep enables quantitative evaluation of method greenness, while the White Analytical Chemistry model offers a holistic approach balancing environmental, analytical, and practical considerations [12] [5] [3].

Future developments in GAC are likely to focus on several key areas. The integration of artificial intelligence and machine learning will enable more efficient optimization of green methods and prediction of method environmental impact [9] [7]. The continued development of green solvent alternatives and their application in pharmaceutical analysis will further reduce the environmental footprint of analytical methods [9]. Additionally, the harmonization of greenness assessment metrics will facilitate more consistent evaluation and comparison of analytical methods across different laboratories and sectors [3].

For researchers working on spectroscopic analysis of APIs, embracing GAC principles not only contributes to environmental sustainability but also often results in more efficient, cost-effective, and safer analytical procedures. The practical protocols and tools outlined in this article provide a foundation for implementing these principles in both research and quality control settings, supporting the pharmaceutical industry's transition toward more sustainable practices.

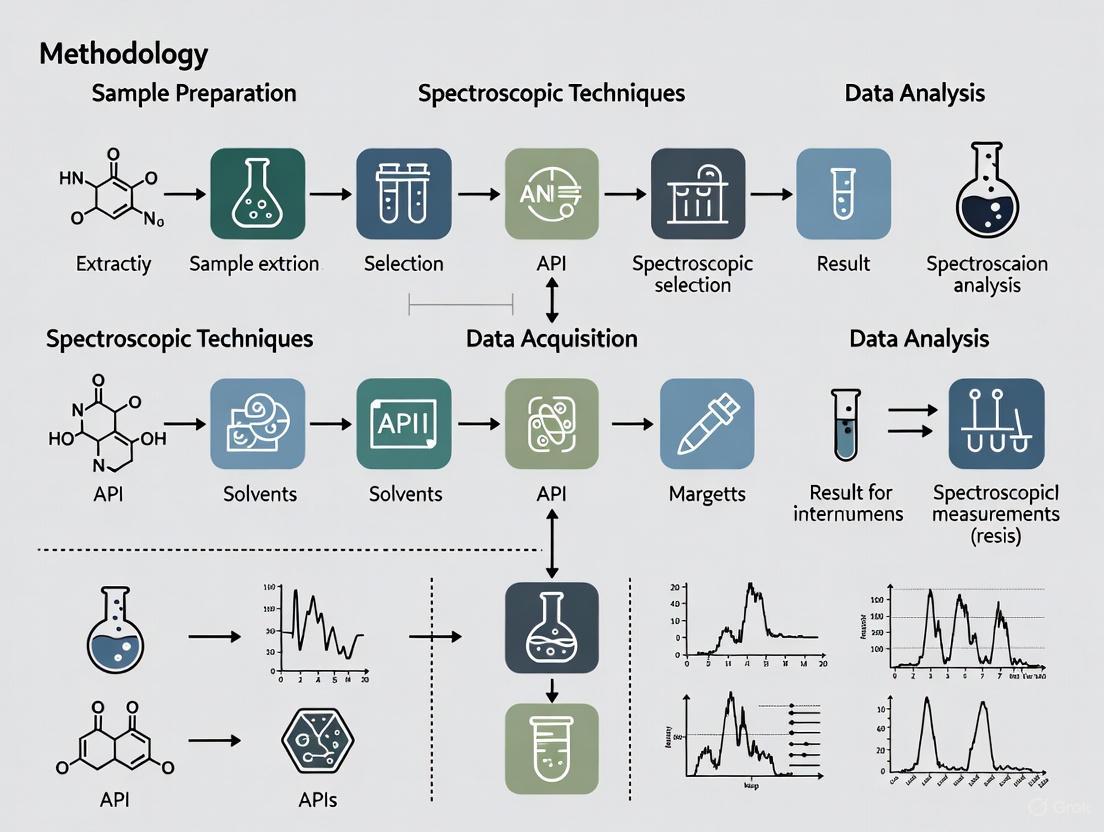

The principles of Green Analytical Chemistry (GAC) are transforming pharmaceutical analysis by promoting environmentally sustainable laboratory practices. This application note provides a comprehensive overview of green spectroscopic techniques—UV-Vis, NIR, MIR, and FT-IR—framed within a broader thesis on methodological approaches for green spectroscopic analysis of active pharmaceutical ingredients (APIs). These non-destructive, solvent-free techniques minimize waste generation, reduce energy consumption, and eliminate toxic reagents while maintaining high analytical precision and accuracy. We detail experimental protocols, application-specific case studies, and greenness assessment metrics to guide researchers and drug development professionals in implementing these sustainable methodologies for API identification, quantification, and process monitoring in alignment with regulatory initiatives such as Process Analytical Technology (PAT).

The pharmaceutical industry is increasingly adopting Green Analytical Chemistry (GAC) principles to reduce the environmental impact of analytical methods while maintaining rigorous performance standards [5]. Traditional chromatographic methods for API analysis often require substantial quantities of organic solvents, lengthy analysis times, and complex sample preparation, generating significant chemical waste [4] [14]. Vibrational spectroscopic techniques offer compelling green alternatives by typically requiring minimal or no sample preparation, eliminating solvent consumption, and providing rapid, non-destructive analysis capabilities [5].

The transition to green spectroscopy supports the Process Analytical Technology (PAT) framework initiated by the US Food and Drug Administration, which encourages innovative approaches to enhance pharmaceutical manufacturing understanding and control [15]. This application note explores four key spectroscopic techniques—UV-Vis, NIR, MIR, and FT-IR—within the context of green API analysis, providing detailed protocols, application examples, and comparative assessment to facilitate their adoption in research and quality control environments.

Technique Principles and Green Characteristics

Fundamental Principles

UV-Vis Spectroscopy measures electronic transitions in molecules when exposed to ultraviolet (200-400 nm) and visible (400-800 nm) light, resulting in characteristic absorption spectra [16]. The technique is widely used for quantitative analysis of APIs due to its simplicity, robustness, and compliance with pharmacopeial standards [16].

Near-Infrared (NIR) Spectroscopy utilizes the spectral range from 800 to 2500 nm (12,500-4,000 cm⁻¹) to measure overtone and combination bands of fundamental molecular vibrations [17]. These weak absorption characteristics enable direct analysis of solid and liquid samples without dilution or preparation [18].

Mid-Infrared (MIR) Spectroscopy probes the fundamental vibrational modes of molecules in the 4000-400 cm⁻¹ range (2.5-25 μm), providing unique molecular "fingerprints" for precise identification and quantification [19] [15]. Fourier Transform Infrared (FT-IR) spectroscopy enhances MIR capabilities through interferometric measurement and Fourier transformation, yielding superior spectral resolution and signal-to-noise ratios [19] [17].

Greenness Assessment

The greenness of these spectroscopic techniques can be evaluated using multiple metric systems:

- AGREEprep and MoGAPI tools provide comprehensive assessment of environmental impact [4]

- White Analytical Chemistry (WAC) framework balances ecological factors with analytical performance and practical utility [5]

- RGB model offers simplified greenness scoring on a 0-100 scale [4]

These assessment tools consistently demonstrate the superior greenness profiles of spectroscopic methods compared to traditional chromatographic approaches due to their minimal solvent consumption, reduced waste generation, and lower energy requirements [4] [5].

Table 1: Greenness Assessment of Spectroscopic Techniques

| Technique | Solvent Consumption | Waste Generation | Energy Requirements | Sample Preparation |

|---|---|---|---|---|

| UV-Vis | Low to moderate | Low to moderate | Low | Minimal |

| NIR | None | None | Low | None |

| MIR | None | None | Low to moderate | Minimal |

| FT-IR | None | None | Moderate | Minimal |

Application Notes

UV-Vis Spectroscopy in Pharmaceutical Analysis

UV-Vis spectroscopy serves as a well-established technique for pharmaceutical quality control, particularly for dissolution testing, impurity quantification, and content uniformity assessment [16]. Its compliance with United States Pharmacopeia (USP) and European Pharmacopoeia (EP) monographs makes it particularly valuable for regulated environments.

Representative Case Study: Ibuprofen analysis according to USP and EP monographs demonstrates UV-Vis application for chemical identity confirmation and purity assessment using validated methodologies [16]. The technique provides rapid results with minimal method development, though it typically requires sample dissolution, which moderately reduces its greenness profile compared to solvent-free techniques.

NIR Spectroscopy for Process Monitoring

NIR spectroscopy excels as a PAT tool for real-time monitoring of pharmaceutical manufacturing processes, including blend uniformity, drying, and granulation [14] [18]. The technique's ability to analyze samples through glass and packaging materials enables non-destructive testing of final products.

Representative Case Study: Quantitative analysis of dexketoprofen in powder blends and coated tablets demonstrates NIR's capability for API determination across multiple production steps [14]. The method achieved prediction errors of 1.01% for granulated samples and 1.63% for tablets, comparable to reference chromatographic methods but with significantly reduced analysis time and no solvent consumption [14].

MIR and FT-IR for API Identification

MIR spectroscopy provides definitive structural elucidation through fingerprint region analysis (4000-400 cm⁻¹), enabling unambiguous API identification [19] [20]. FT-IR enhances these capabilities with improved sensitivity and resolution.

Representative Case Study: API identification in commercial antihistamine tablets using FT-IR with Attenuated Total Reflection (ATR) accessory successfully identified fexofenadine hydrochloride in Allevia, cetirizine dihydrochloride in Piriteze, and loratadine in Tesco Health products [20]. Characteristic carbonyl stretching vibrations in the 1600-1800 cm⁻¹ region provided distinct identification markers for each API [20].

Advanced MIR Techniques

Quantum Cascade Laser (QCL) technology represents an advanced MIR approach with enhanced sensitivity and specificity for pharmaceutical analysis [15]. The high brightness of QCL sources enables diffuse reflectance measurements with superior signal-to-noise ratios compared to conventional FT-IR.

Representative Case Study: Ibuprofen quantification in powder blends and tablets using QCL spectroscopy demonstrated accurate analysis across a concentration range of 0-21% (w/w) with high sensitivity (0.05% w/w) and repeatability (2.7% w/w) [15]. This approach shows particular promise for content uniformity and blend uniformity assessment in PAT applications.

Table 2: Comparative Analysis of Green Spectroscopic Techniques for API Analysis

| Technique | Primary Applications | Green Advantages | Limitations | Greenness Score (RGB) |

|---|---|---|---|---|

| UV-Vis | Quantitative analysis, dissolution testing, impurity profiling | Rapid analysis, compliance with pharmacopeial standards | Often requires solvents for dissolution | 75.2 [5] |

| NIR | Process monitoring, raw material ID, content uniformity | Non-destructive, no sample preparation, through-package analysis | Weak absorption signals require chemometrics | 87.2 [4] |

| FT-IR | API identification, polymorph screening, quality control | Specific molecular fingerprints, minimal sample preparation | Sample thickness limitations for transmission | 89.0 [4] |

| MIR (QCL) | High-sensitivity quantification, blend uniformity | High specificity, low detection limits, minimal sample preparation | Higher instrument cost, specialized equipment | Information missing |

Experimental Protocols

Green FT-IR Protocol for API Identification in Antihistamine Tablets

This protocol outlines a solvent-free method for identifying APIs in solid dosage forms using FT-IR spectroscopy with ATR accessory [20].

4.1.1 Research Reagent Solutions

Table 3: Essential Materials for FT-IR API Identification

| Material/Equipment | Specifications | Function/Purpose |

|---|---|---|

| FT-IR Spectrometer | Edinburgh Instruments IA30 or equivalent | Spectral acquisition |

| ATR Accessory | Diamond crystal | Sample presentation without preparation |

| Analytical Balance | 0.1 mg precision | Sample weighing (if needed) |

| Solid Dosage Forms | Tablets, capsules | Analysis samples |

| Spectral Library | KnowItAll or equivalent | API identification reference |

4.1.2 Procedure

Sample Preparation:

- Gently grind a representative portion of the tablet into a fine powder using an agate mortar and pestle.

- Apply minimal pressure to avoid altering crystal morphology.

Spectrum Acquisition:

- Place a small amount of powder directly onto the ATR crystal.

- Apply consistent pressure using the instrument's anvil to ensure proper crystal contact.

- Collect spectra using the following parameters:

- Spectral range: 4000-400 cm⁻¹

- Resolution: 4 cm⁻¹

- Scans: 32

- Apodization: Happ-Genzel

Data Analysis:

- Process spectra using atmospheric suppression and baseline correction algorithms.

- Compare sample spectrum against reference spectral library.

- Identify characteristic absorption bands for API confirmation (e.g., C=O stretch ~1700 cm⁻¹, C-N stretch ~1300 cm⁻¹) [20].

Figure 1: FT-IR API Identification Workflow

Green NIR Protocol for API Quantification in Powder Blends

This protocol describes a non-destructive method for quantifying API content in pharmaceutical powder blends using NIR spectroscopy and multivariate calibration [14].

4.2.1 Research Reagent Solutions

Table 4: Essential Materials for NIR API Quantification

| Material/Equipment | Specifications | Function/Purpose |

|---|---|---|

| FT-NIR Spectrometer | Antaris II or equivalent | Spectral acquisition in reflectance mode |

| Powder Blends | Varying API concentrations (75-120 mg/g) | Calibration and validation samples |

| Quartz Sample Cup | Standard size for spectrometer | Consistent sample presentation |

| Multivariate Software | Unscrambler v. 9.2 or equivalent | Chemometric modeling |

4.2.2 Procedure

Calibration Set Preparation:

- Prepare laboratory samples with API concentrations spanning the expected range (75-120 mg/g).

- Include production samples to incorporate process variability.

- Mix samples thoroughly using a Turbula shaker until spectral stabilization.

Spectrum Acquisition:

- Place powder samples in a quartz cell under consistent packing pressure.

- Collect reflectance spectra using the following parameters:

- Wavenumber range: 1100-2498 nm

- Scans: 32 per spectrum

- Resolution: 2 nm

- Record triplicate spectra with sample turnover between measurements.

Multivariate Model Development:

- Apply spectral pretreatments: Standard Normal Variate (SNV) and second derivatives (Savitzky-Golay, 11-point window).

- Develop Partial Least Squares (PLS) calibration models using cross-validation.

- Select optimal factors based on minimum Prediction Residual Error Sum of Squares (PRESS).

- Validate models using external validation sets.

Figure 2: NIR API Quantification Workflow

Green UV-Vis Protocol for Simultaneous API Quantification

This protocol describes an environmentally friendly UV-Vis method for simultaneous quantification of multiple APIs in pharmaceutical formulations [4].

4.3.1 Research Reagent Solutions

Table 5: Essential Materials for UV-Vis API Quantification

| Material/Equipment | Specifications | Function/Purpose |

|---|---|---|

| UV-Vis Spectrophotometer | GENESYS or Evolution series | Absorbance measurement |

| Potassium Bromide | FT-IR grade | Pellet preparation (solid samples) |

| Quartz Cuvettes | 1 cm path length | Sample containment for liquids |

| Analytical Software | Origin Pro or equivalent | Data processing and calibration |

4.3.2 Procedure

Sample Preparation (Solid Dosage Forms):

- For solid samples, prepare pellets using potassium bromide pressed pellet technique.

- For liquid samples, direct analysis without dilution is possible.

Spectrum Acquisition:

- Collect transmission spectra of standards and samples.

- Convert transmittance to absorbance spectra.

- Identify characteristic absorption peaks for each API.

Quantitative Analysis:

- Measure area under curve (AUC) for selected characteristic peaks.

- Construct calibration curves plotting AUC against concentration (%w/w).

- Validate method following ICH guidelines for specificity, linearity, precision, and accuracy.

Greenness Assessment Protocol

Comprehensive Methodology Evaluation

Assess the environmental impact of spectroscopic methods using multiple greenness assessment tools [4] [5]:

MoGAPI (Modified Green Analytical Procedure Index) Evaluation:

- Assess 10 parameters including sample preparation, reagents, and waste.

- Calculate total score (higher values indicate greener methods).

AGREEprep (Analytical Greenness for Sample Preparation) Assessment:

- Evaluate sample preparation environmental impact across multiple criteria.

- Generate score on 0-1 scale (closer to 1 indicates greener method).

RGB (Red-Green-Blue) Model Application:

- Calculate overall greenness score (0-100 scale).

- Compare with reference methods (e.g., HPLC).

White Analytical Chemistry (WAC) Implementation:

- Balance analytical criteria (red), ecological criteria (green), and practical criteria (blue).

- Achieve whiteness when all three aspects are optimized.

Greenness Comparison Data

Table 6: Greenness Assessment Scores for Spectroscopic Methods

| Analytical Method | MoGAPI Score | AGREEprep Score | RGB Score | Overall Greenness |

|---|---|---|---|---|

| FT-IR Spectroscopy | 89 [4] | 0.8 [4] | 87.2 [4] | Excellent |

| NIR Spectroscopy | Information missing | Information missing | Information missing | Excellent |

| UV-Vis Spectroscopy | Information missing | Information missing | 75.2 [5] | Very Good |

| Reference HPLC Method | Information missing | Information missing | 62.5 [4] | Moderate |

Green spectroscopic techniques—UV-Vis, NIR, MIR, and FT-IR—offer environmentally sustainable alternatives to traditional chromatographic methods for API analysis while maintaining rigorous analytical performance. These approaches align with GAC principles by minimizing solvent consumption, reducing waste generation, and enabling non-destructive analysis. The detailed protocols and case studies presented in this application note demonstrate practical implementation strategies for pharmaceutical research and quality control environments. As spectroscopic technologies continue to advance with innovations such as QCL and hyperspectral imaging, their application in green pharmaceutical analysis will expand, further enhancing sustainability in drug development and manufacturing processes.

In the field of analytical chemistry, particularly in the green spectroscopic analysis of active pharmaceutical ingredients (APIs), the adoption of standardized greenness assessment tools is crucial for evaluating the environmental impact of methodologies. The principles of Green Analytical Chemistry (GAC) have driven the development of several metric tools designed to quantify the sustainability, safety, and eco-friendliness of analytical procedures [21]. Among these, the National Environmental Methods Index (NEMI), Analytical Eco-Scale (AES), and the Analytical GREEnness (AGREE) metric have emerged as foundational tools. These metrics help researchers and drug development professionals make informed decisions by providing standardized, quantitative, and visual assessments of method greenness, aligning analytical practices with the 12 principles of GAC [22]. Their application ensures that the development of new spectroscopic methods for API analysis not only maintains analytical rigor but also minimizes environmental impact by reducing hazardous waste, energy consumption, and the use of toxic solvents [4] [23].

The following table summarizes the core attributes of the three key greenness assessment tools, providing a baseline for their comparison and application.

Table 1: Comparison of Key Greenness Assessment Tools

| Metric Tool | Primary Focus | Assessment Output | Number of Criteria | Key Strengths | Reported Limitations |

|---|---|---|---|---|---|

| NEMI [21] | Environmental impact & safety | Pictogram (4 quadrants) | 4 | Simple, quick visualization | Binary assessment; limited criteria |

| Analytical Eco-Scale (AES) [22] | Overall environmental impact | Quantitative score | Not specified in results | Provides a total score for easy comparison | Lacks visual representation |

| AGREE [21] [22] | Alignment with 12 GAC Principles | Score (0-1) & colored pictogram | 10 | Comprehensive, user-friendly software, visual and numerical output | Less resistant to user bias |

Detailed Tool Protocols and Applications

AGREE (Analytical GREEnness Metric) Protocol

The AGREE metric is a modern, comprehensive tool explicitly structured around the 12 principles of Green Analytical Chemistry [22]. It is designed to provide a holistic greenness assessment.

Experimental Protocol for AGREE:

- Software Access: Utilize the open-source AGREE software, typically available online.

- Data Input: For each of the 12 principles, input the required methodological data. This includes, but is not limited to:

- Amount and toxicity of solvents/reagents used.

- Energy consumption of the instrumentation.

- Waste generation and its management.

- Health and safety hazards for the operator.

- Throughput and degree of automation.

- Weight Assignment (Optional): Assign relative weights to each criterion based on the assessment's goal. Default weights can be used if no specific priority is required [21].

- Calculation and Visualization: The software automatically calculates an overall score between 0 and 1 and generates a circular pictogram. The pictogram is divided into 12 sections, each corresponding to one GAC principle, with colors ranging from red (poor) to green (excellent) to represent the performance in each category [22].

Application Example: A green FT-IR method for quantifying antihypertensive drugs in tablets was evaluated using AGREEprep (a derivative for sample preparation). The method, which used a solventless pressed pellet technique, achieved a high score of 0.8, visually confirming its excellent greenness profile [4].

NEMI (National Environmental Methods Index) Protocol

NEMI is one of the earlier and simpler green assessment tools. Its evaluation is based on four primary environmental and safety criteria [21].

Experimental Protocol for NEMI:

- Data Collection: Gather the following information from the analytical method:

- Persistence: Whether any chemical used is "persistent" (P) and/or "bioaccumulative" (B) as listed in the US Environmental Protection Agency's Toxic Release Inventory (TRI).

- Hazardousness: Whether any reagent is listed on the TRI as "hazardous".

- Corrosivity: Whether the pH of the waste solution is ≤2 or ≥12.

- Waste Amount: Whether the total waste generated per sample is >50 g.

- Pictogram Generation: A pictogram with four quadrants is used. A quadrant is filled with green only if the method meets the green criterion for that category (i.e., it is not persistent, not hazardous, not corrosive, and generates ≤50 g of waste) [21].

Application Example: A method that uses a small volume of a mildly acidic, non-hazardous solvent and generates 30 g of waste would have all four quadrants colored green. If the same method used a TRI-listed hazardous solvent, the "hazardous" quadrant would be left blank.

Analytical Eco-Scale (AES) Protocol

The Analytical Eco-Scale is a semi-quantitative tool that calculates a total score by penalizing an ideal baseline of 100 points for each element of the method that is not environmentally ideal [22].

Experimental Protocol for Analytical Eco-Scale:

- Establish Baseline: Start with a perfect score of 100.

- Assign Penalty Points: Subtract points for each parameter based on its environmental impact. Penalties are assigned for:

- Reagents: Amount, toxicity (e.g., based on GHS hazard statements), and disposal cost.

- Energy Consumption: The type and amount of energy used by the instrument.

- Occupational Hazards: The required personal protective equipment (PPE) indicates a higher hazard and incurs a penalty.

- Waste: The quantity and treatment requirements.

- Calculate Final Score: The final score is calculated as:

AES Score = 100 - Total Penalty Points. - Interpret Results: An AES score >75 is considered excellent green analysis, a score >50 is acceptable, and a score <50 is inadequate [22].

Advanced Considerations and Emerging Tools

While NEMI, AES, and AGREE are foundational, the field of green metrics is continuously evolving. Key considerations for advanced application include:

- Weighting of Criteria: The overall result of an assessment can be critically dependent on the weights applied to each criterion. Some tools like AGREE allow users to adjust weights, offering flexibility to reflect specific analytical goals, though default weights are often used [21].

- Tool Limitations: Simpler tools like NEMI provide a quick visual but lack granularity due to their binary (yes/no) assessment for each criterion [21]. AES provides a quantitative score but lacks a visual component [22].

- Emerging Tools: Newer metrics have been developed to address the limitations of earlier ones. The Analytical Green Star Area (AGSA), for example, integrates built-in scoring, method classification, and a visual star-shaped diagram while being explicitly aligned with the 12 principles of GAC [22]. Other models like the Multi-color Assessment (MA) tool and the Need–Quality–Sustainability (NQS) index offer unified evaluation of a method's greenness, practicality, performance, and innovation [23].

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagents and Materials for Green Spectroscopic Analysis

| Item | Function in Green Analysis | Example & Green Rationale |

|---|---|---|

| Potassium Bromide (KBr) | Matrix for preparing solid pellets in FT-IR spectroscopy [4]. | Enables solventless analysis of solid APIs, eliminating hazardous solvent waste. |

| Ethanol-Water Mixtures | Green solvent for UV-spectrophotometric analysis [23]. | Replaces toxic organic solvents like acetonitrile or methanol; biodegradable and less hazardous. |

| Chemometric Software | For multivariate calibration and data resolution (e.g., PLS, MCR-ALS) [23]. | Resolves overlapping spectra without requiring complex, resource-intensive separation steps. |

| Fourier Transform Infrared (FT-IR) Spectrometer | Instrument for vibrational spectroscopic analysis [4]. | Requires minimal energy, no solvents, and allows for rapid, precise quantification of APIs. |

Workflow for Green Method Development and Assessment

The following diagram illustrates a logical workflow for developing and assessing a green spectroscopic method, integrating the discussed metric tools.

Green Method Assessment Workflow

The AGREE, AES, and NEMI metrics provide a structured and multi-faceted approach for quantifying the environmental friendliness of analytical methods, which is indispensable for modern research on the spectroscopic analysis of APIs. While each tool has its strengths—from the simplicity of NEMI to the comprehensiveness of AGREE—their combined or selective application empowers scientists to make informed, sustainable choices. The ongoing development of more refined tools like AGSA and NQS ensures that the field of analytical chemistry continues to advance towards greater sustainability without compromising the quality and reliability of scientific data.

The Role of Green Spectroscopy in Regulatory Frameworks and PAT Initiatives

Process Analytical Technology (PAT) has emerged as a fundamental pillar in the pharmaceutical industry, helping industrial processes become more efficient, sustainable, safer, and reliable for more than two decades [24]. The framework, as outlined by regulatory bodies, encompasses tools for design, analysis, and control of manufacturing processes through timely measurements of critical quality attributes [25]. Simultaneously, the principles of Green Analytical Chemistry (GAC) have gained significant traction, focusing on reducing the environmental impact of analytical methods by minimizing hazardous waste, energy consumption, and the use of toxic solvents [26].

Green spectroscopy represents the convergence of these two domains, utilizing vibrational and fluorescence spectroscopic techniques that align with GAC principles while supporting PAT initiatives for real-time monitoring and control. This integration is particularly crucial given that many official standard methods still rely on resource-intensive, outdated techniques, with 67% of evaluated methods scoring below 0.2 on the AGREEprep scale (where 1 represents the highest possible score) [27]. The pharmaceutical industry is now actively seeking greener alternatives to reduce its environmental footprint, with over 60 known instances of pharmaceutical entities implementing green chemistry in research and manufacturing [28].

Theoretical Framework and Synergies

The Twelve Principles of Green Analytical Chemistry

The foundation of green spectroscopy lies in the adaptation of Warner and Anastas's twelve principles of green chemistry to analytical practices [26]. These principles have been specifically tailored to analytical chemistry, emphasizing the need for direct analytical techniques that eliminate or significantly reduce sample preparation stages, thus minimizing solvent consumption and waste generation. The principles prioritize methods that are inherently safer, more energy-efficient, and capable of providing real-time data for process control [26] [28].

PAT Initiatives and Regulatory Drivers

The PAT framework, as promoted by regulatory agencies including the FDA and embodied in initiatives like Quality by Design (QbD), encourages real-time monitoring of critical process parameters to ensure final product quality [24] [25]. This alignment with green spectroscopy is natural, as many spectroscopic techniques used in PAT (e.g., NIR, MIR, Raman) are inherently greener than traditional chromatographic methods, requiring little to no solvent consumption and enabling non-invasive measurements [24] [4].

European regulations, particularly the European Green Deal and REACH, are creating additional drivers for adopting green spectroscopy within PAT frameworks. These regulations push for carbon neutrality by 2050 and impose stricter controls on hazardous substances, making the environmental profile of analytical methods a regulatory consideration alongside traditional performance metrics [28] [29].

Complementary Relationship

The relationship between green spectroscopy and PAT is fundamentally synergistic, as illustrated below:

This synergy creates a powerful framework for developing analytical methods that simultaneously address regulatory requirements for process understanding and control while advancing sustainability goals in pharmaceutical manufacturing.

Green Spectroscopic Techniques in PAT

Comparative Analysis of Techniques

Various spectroscopic techniques offer distinct advantages and limitations for pharmaceutical analysis within PAT frameworks. The table below provides a comparative assessment of the most commonly employed green spectroscopic methods:

Table 1: Comparison of Green Spectroscopic Techniques in PAT Applications

| Technique | Greenness Advantages | PAT Applications | Limitations | Regulatory Acceptance |

|---|---|---|---|---|

| FT-IR [4] | Solvent-free analysis (KBr pellets); Minimal waste generation; Low energy requirements | API quantification in formulations; Polymorph identification; Reaction monitoring | Limited sensitivity for low-concentration analytes; Spectral overlap in complex mixtures | Well-established in pharmacopoeias; Suitable for real-time release |

| NIR [24] [25] | Non-invasive measurements; No sample preparation; Through-container analysis possible | Content uniformity; Blend homogeneity; Moisture analysis; Solvent recovery monitoring | Complex chemometrics required; Limited to bulk analysis; Lower specificity than MIR | Widely referenced in PAT guidance; Extensive pharmacopoeia references |

| Raman [25] [30] | Minimal sample preparation; Water-compatible; Fiber optic probe capability | Crystallization monitoring; Bioprocess monitoring; Polymorph characterization | Fluorescence interference; Potential sample damage at high laser power | Growing regulatory acceptance; Included in modern pharmacopoeias |

| Fluorescence [30] | High sensitivity; Low sample volume; Minimal waste generation | Bioprocess monitoring; Protein quantification; Cell culture monitoring | Limited to fluorescent compounds; Background interference | Emerging in PAT applications; Particularly for biologics |

Greenness Assessment Metrics for Spectroscopic Methods

The evaluation of analytical method greenness has been standardized through several metric tools, enabling objective comparison between conventional and green spectroscopic methods:

Table 2: Greenness Assessment Metrics for Analytical Methods [26] [31]

| Metric Tool | Scoring System | Assessment Criteria | Output Type | Application in Spectroscopy |

|---|---|---|---|---|

| AGREE [31] | 0-1 (1 = greenest) | 12 principles of GAC; Weighted calculation | Pictorial with overall score | Comprehensive method evaluation |

| AGREEprep [27] | 0-1 (1 = greenest) | 10 sample preparation criteria | Pictorial with overall score | Sample preparation steps in spectroscopy |

| NEMI [31] | 4-quadrant pictogram | Persistence, bioaccumulation, toxicity, waste | Qualitative pictogram | Quick visual assessment |

| GAPI [26] | 5-step pictogram | Entire method lifecycle from sampling to waste | Semi-quantitative pictogram | Detailed environmental impact |

| Analytical Eco-Scale [31] | Numerical score (ideal = 100) | Penalty points for hazardous reagents/energy | Quantitative score | Direct comparison between methods |

Application Note: Green FT-IR Spectroscopy for API Quantification

Experimental Protocol

Scope and Application

This protocol describes a green FT-IR spectroscopic method for simultaneous quantification of amlodipine besylate (AML) and telmisartan (TEL) in pharmaceutical tablet formulations, eliminating the use of hazardous solvents while maintaining compliance with PAT requirements for real-time analysis [4].

Principle

The method follows the pressed pellet technique using potassium bromide (KBr). Quantitative analysis is based on the Beer-Lambert law, where the area under the absorption curve in specific infrared regions correlates with API concentration [4].

Materials and Equipment

Table 3: Research Reagent Solutions and Essential Materials

| Item | Specification | Function | Greenness Consideration |

|---|---|---|---|

| FT-IR Spectrometer | Fourier-transform type with DLATGS detector | Spectral acquisition | Energy-efficient modern instruments preferred |

| Hydraulic Press | Capable of 10-15 tons pressure | KBr pellet preparation | Reusable equipment minimizes waste |

| Potassium Bromide (KBr) | FT-IR grade, 99.9% purity | Matrix for pellet preparation | Minimal waste generation; recyclable |

| Standard API | USP/EP reference standards | Calibration curve construction | Minimal quantities required |

| Tablet Formulations | Marketed combination products | Sample analysis | Direct analysis without destructive pretreatment |

Detailed Methodology

Step 1: Instrument Calibration and Setup

- Configure FT-IR spectrometer with the following parameters: resolution of 4 cm⁻¹, scanning range of 4000-400 cm⁻¹, and 32 scans per measurement [4].

- Ensure environmental controls (humidity <40%) as KBr is hygroscopic.

Step 2: Preparation of Standard Calibration Curve

- Prepare standard mixtures of AML and TEL in the range of 0.2-1.2% w/w in KBr matrix [4].

- For each standard, accurately weigh 200 mg KBr and appropriate API quantities, mix geometrically, and grind to uniform particle size.

- Transfer approximately 150 mg of the mixture to a 13 mm die set and compress at 10 tons for 2 minutes to form transparent pellets.

- Acquire spectra and convert transmittance to absorbance. Measure area under curve (AUC) for AML at 1206 cm⁻¹ (R-O-R stretching) and TEL at 863 cm⁻¹ (C-H out-of-plane bending) [4].

- Construct calibration curves plotting AUC against concentration for both APIs.

Step 3: Sample Preparation and Analysis

- Grind representative tablet samples to fine powder using a mortar and pestle.

- Weigh powder equivalent to average tablet weight and mix with KBr (1:100 ratio).

- Prepare pellets following the same procedure as standards.

- Acquire spectra and measure AUC at characteristic wavelengths.

- Calculate API concentrations using the established calibration equations.

Step 4: Method Validation

- Validate the method according to ICH Q2(R2) guidelines for specificity, linearity, accuracy, precision, LOD, LOQ, and robustness [4].

- Assess specificity by comparing sample spectra with placebo formulations to confirm absence of interference.

Step 5: Greenness Assessment

- Evaluate method greenness using AGREEprep, Analytical Eco-Scale, and GAPI metrics [4] [31].

- Compare results with conventional HPLC methods to demonstrate environmental advantages.

Workflow Visualization

The complete experimental workflow for green FT-IR analysis within a PAT framework is illustrated below:

Results and Discussion

The developed green FT-IR method demonstrates excellent analytical performance while significantly reducing environmental impact compared to conventional chromatographic methods. Validation results show linearity in the range of 0.2-1.2% w/w for both APIs, with LOD values of 0.009359% w/w for AML and 0.008241% w/w for TEL [4]. The method achieved AGREEprep and Analytical Eco-Scale scores significantly higher than reported HPLC methods, confirming its superior greenness profile [4].

When implemented within a PAT framework, this method enables real-time release of pharmaceutical products with minimal solvent consumption and waste generation. The elimination of hazardous solvents like acetonitrile and methanol commonly used in HPLC analysis reduces environmental impact while maintaining regulatory compliance [4] [31].

Implementation Strategies in Regulatory Frameworks

Integration with Quality by Design (QbD)

The successful implementation of green spectroscopy within PAT initiatives requires alignment with QbD principles. This involves identifying critical quality attributes (CQAs) measurable by spectroscopic methods and establishing design spaces for method operation [25]. For instance, in the FT-IR method described, critical parameters include pellet thickness, compression force, and grinding time, which must be controlled to ensure method robustness.

Regulatory Submission Considerations

When proposing green spectroscopic methods for regulatory submissions, the following elements should be addressed:

- Method Validation Data: Comprehensive validation following ICH Q2(R2) guidelines, demonstrating equivalence or superiority to compendial methods [4] [31].

- Greenness Assessment: Quantitative evaluation using standardized metrics (AGREE, GAPI, NEMI) to objectively demonstrate environmental benefits [26] [31].

- PAT Integration Strategy: Description of how the method will be implemented for real-time monitoring and control, including data management systems and control strategies [24] [25].

- Comparative Analysis: Statistical comparison (t-test, F-test) with reference methods to demonstrate equivalent or superior performance [4] [32].

Overcoming Implementation Barriers

The transition to green spectroscopic methods faces several challenges, including regulatory inertia and the conservative nature of pharmaceutical analysis. A recent study revealed that 86% of standard methods for environmental analysis of organic compounds scored below 0.2 on the AGREEprep scale, highlighting the urgent need for modernizing official methods [27]. To address this:

- Engage regulatory agencies early in method development through pre-submission meetings

- Develop comprehensive comparability protocols demonstrating equivalence to compendial methods

- Implement phased validation strategies starting with in-process controls before expanding to final product testing

- Provide training on green chemistry principles and spectroscopic applications for regulatory reviewers

Green spectroscopy represents a paradigm shift in pharmaceutical analysis, offering a sustainable alternative to traditional methods while aligning perfectly with PAT initiatives for real-time monitoring and control. The integration of solvent-free spectroscopic techniques like FT-IR, NIR, and Raman into regulatory frameworks addresses the growing demand for environmentally conscious pharmaceutical manufacturing without compromising product quality or patient safety.

The future of green spectroscopy in PAT will likely be shaped by several key developments, including the increased adoption of multi-analyze spectroscopic sensors, the integration of artificial intelligence for advanced data processing, and the development of standardized greenness assessment protocols specifically tailored to spectroscopic methods [24] [30]. Furthermore, regulatory harmonization of green chemistry principles, particularly through initiatives like the European Green Deal, will accelerate the adoption of these sustainable technologies across the global pharmaceutical industry [28] [29].

As the pharmaceutical industry continues its transition toward greener manufacturing practices, the synergy between green spectroscopy and PAT will play an increasingly vital role in achieving sustainability targets while maintaining regulatory compliance and product quality. The methodologies and protocols outlined in this application note provide a framework for researchers and pharmaceutical developers to implement these principles in both development and manufacturing settings.

Developing and Implementing Green Spectroscopic Methods