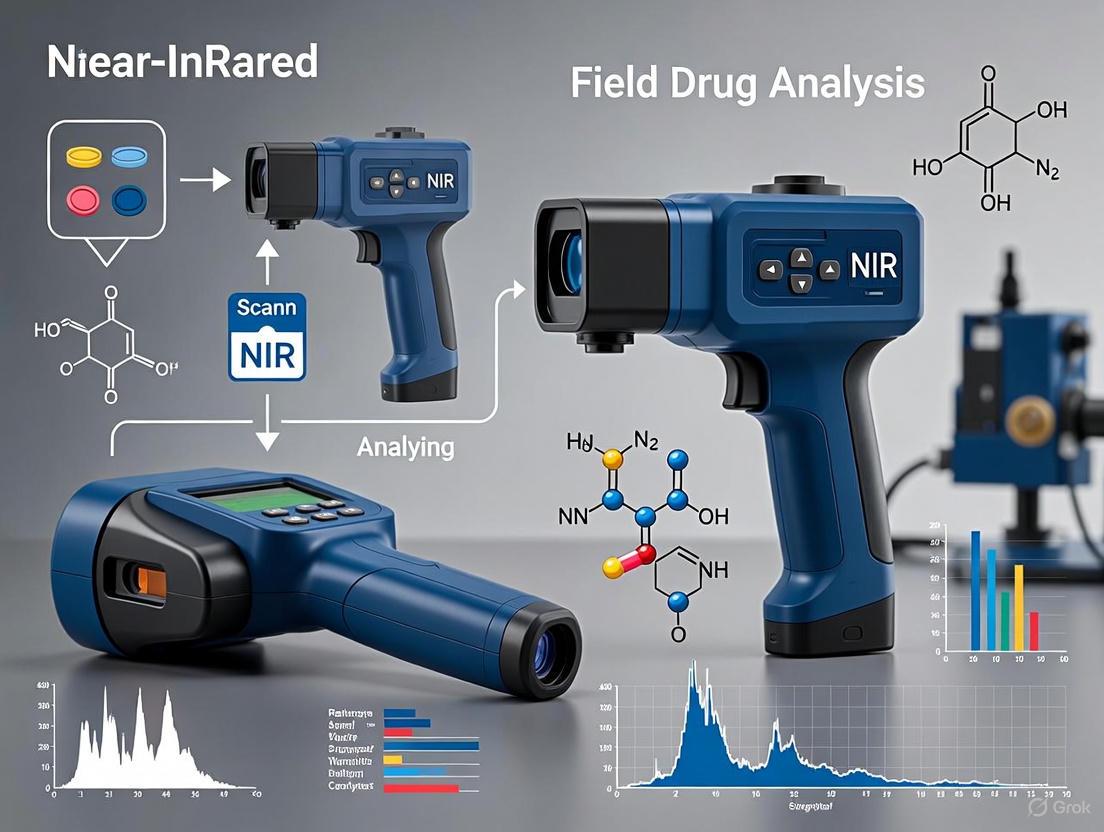

Handheld NIR Spectrometers for Field Drug Analysis: A Guide to On-Site Identification, Quantification, and Operational Workflows

This article provides a comprehensive overview of the application of handheld Near-Infrared (NIR) spectroscopy for the rapid, non-destructive analysis of illicit drugs and pharmaceuticals in field settings.

Handheld NIR Spectrometers for Field Drug Analysis: A Guide to On-Site Identification, Quantification, and Operational Workflows

Abstract

This article provides a comprehensive overview of the application of handheld Near-Infrared (NIR) spectroscopy for the rapid, non-destructive analysis of illicit drugs and pharmaceuticals in field settings. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of ultra-portable NIR technology, details methodological workflows integrating machine learning for identification and quantification, addresses key challenges in model optimization and calibration transfer, and validates performance against traditional laboratory techniques. The scope covers practical implementation, from device operation to data interpretation, empowering professionals to leverage this technology for decentralized forensic capabilities and quality control.

The Principles and Rise of Portable NIR Technology in Decentralized Drug Analysis

The deployment of near-infrared (NIR) spectroscopy for field-based drug analysis relies on the successful miniaturization of three core technological components: Micro-Electro-Mechanical Systems (MEMS), specific detector materials like InGaAs, and the strategic selection of operational spectral ranges. These elements collectively enable the transition of NIR technology from laboratory benchtops to portable, handheld devices capable of providing rapid, non-destructive chemical analysis in the field. For forensic and pharmaceutical researchers, understanding these components is critical for method development, instrument selection, and the valid interpretation of spectral data acquired outside controlled laboratory settings [1] [2].

MEMS technology allows for the fabrication of microscopic mechanical elements on silicon chips, which can replace bulky optical components in traditional spectrometers. Concurrently, the choice of detector material, such as Indium Gallium Arsenide (InGaAs), dictates the wavelength range and sensitivity of the device. The 950-1650 nm spectral range is particularly valuable as it captures meaningful molecular overtone and combination bands while being accessible to compact, cost-effective detector systems [2] [3]. This combination of technologies has made handheld NIR spectrometers a practical tool for on-site identification of counterfeit drugs, quality control of pharmaceutical ingredients, and forensic evidence analysis [1] [4].

Detailed Technology Breakdown

Micro-Electro-Mechanical Systems (MEMS)

MEMS are miniature integrated devices that combine mechanical elements, sensors, actuators, and electronics on a common silicon substrate. In handheld NIR spectrometers, MEMS are primarily used to create two types of miniaturized spectral engines: scanning grating mirrors and Fourier Transform (FT) interferometers.

A prominent approach involves using a simple single-axis MEMS scanning mirror to replace traditional optical components. In this design, a deflectable mirror illuminates a fixed grating, creating an optical path similar to the classic Czerny-Turner spectrometer design. As the mirror plate rotates, the angle of incidence on the grating varies, allowing different wavelengths to pass through an exit slit and reach a single-pixel detector. This scanning action builds a full spectrum sequentially, enabling a spectrometer footprint as small as 10 × 10 × 6 mm³ while maintaining a spectral resolution of approximately 10 nm FWHM across the 950-1900 nm range [2].

Alternative MEMS implementations include MEMS-based FT-NIR spectrometers, such as the NeoSpectra by Si-Ware, which utilize micro-scale interferometers to collect spectral data through Fourier transformation. These MEMS-FT systems can cover an extended spectral range from 1300 nm to 2600 nm, accessing the combination spectral region which provides richer chemical information for complex analyses [1] [3]. The primary advantages of MEMS technology in field instruments include dramatically reduced size and weight, lower power consumption suitable for battery operation, reduced production costs at scale, and enhanced robustness against mechanical shock—a critical feature for field deployment [1] [2].

InGaAs Detectors and Spectral Ranges

The detector material is a decisive factor in defining the performance characteristics of a handheld NIR spectrometer. While silicon detectors are cost-effective, their operational range is limited to approximately 1050 nm. For field drug analysis, which often requires broader spectral information, Indium Gallium Arsenide (InGaAs) detectors have become the preferred solution, offering sensitivity across the 950-1650 nm range and beyond [2] [3].

InGaAs detectors provide high sensitivity to weak NIR signals, which is essential for analyzing diffuse reflectance from solid dosage forms like tablets and capsules. Their ability to operate at room temperature, without requiring cryogenic cooling, makes them ideally suited for portable instrumentation. The spectral range of 950-1650 nm is particularly informative for pharmaceutical analysis because it captures the first and second overtone regions of fundamental molecular vibrations, especially those of C-H, O-H, and N-H bonds [5] [2]. These functional groups are ubiquitous in active pharmaceutical ingredients (APIs) and excipients, enabling the distinction between different chemical compounds based on their unique spectral fingerprints.

Table 1: Common Detector Technologies in Handheld NIR Spectrometers

| Detector Material | Typical Spectral Range | Advantages | Common Applications |

|---|---|---|---|

| InGaAs | 950-1650 nm (extended to 1700-2100 nm) | High sensitivity, room-temperature operation, broad range | Primary choice for drug analysis; identifies APIs & excipients [2] [3] |

| Silicon (Si) | 400-1050 nm | Low cost, widely available | Limited to very short-wave NIR (vis-SWNIR); basic material ID [2] |

The photodetectors themselves, such as the FPD310 series, are engineered for high performance with features including ultrafast response (rise times below 0.5 ns), broad spectral sensitivity covering 950–1650 nm, and wide bandwidth for high-speed data acquisition. These characteristics ensure that handheld instruments can capture clean, high-fidelity spectra even from weakly scattering samples, which is paramount for building robust chemometric models [5].

Application in Field Drug Analysis

Research Context and Significance

The application of handheld NIR spectrometers equipped with MEMS and InGaAs detectors is transforming the landscape of drug analysis, particularly in combating the global threat of substandard and falsified (SF) medicines. It is estimated that 10.5% of medicines in low- and middle-income countries are SF, contributing to approximately 1 million deaths annually [4]. Traditional laboratory analysis using techniques like High-Performance Liquid Chromatography (HPLC), while highly accurate, is costly, time-consuming, and requires sample destruction, making it impractical for widespread field screening [4] [3].

Handheld NIR devices address these limitations by enabling real-time, non-destructive analysis at the point of inspection, such as pharmacies, border crossings, or crime scenes. They function by illuminating a sample and capturing its spectral signature in the NIR range. This signature, which represents the unique chemical composition of both the API and excipients, is then compared against a reference library of authentic products using chemometric algorithms. A mismatch indicates a potentially falsified product, while a deviation in spectral intensity can suggest a substandard product with incorrect API concentration [4].

A 2025 comparative study in Nigeria, which tested 246 drug samples from retail pharmacies, highlighted both the promise and current challenges of the technology. While the study found that 25% of samples failed HPLC analysis, the handheld NIR spectrometer showed a sensitivity of 37% for analgesics, indicating a need for further refinement in detection algorithms for certain drug formulations [4]. Despite this, the advantages of speed, portability, and non-destructive testing make these instruments an invaluable screening tool for regulators and law enforcement.

Experimental Protocol for Drug Verification

This protocol outlines the standard operating procedure for using a handheld NIR spectrometer to verify the authenticity and quality of solid oral dosage forms (e.g., tablets) in a field setting.

Title: Field Verification of Pharmaceutical Tablets Using Handheld NIR Spectroscopy Objective: To non-destructively identify counterfeit or substandard pharmaceutical tablets by comparing their NIR spectral signature to a validated reference library. Principle: The method is based on the differential absorption of NIR radiation by organic functional groups (C-H, O-H, N-H) in the 950-1650 nm range, providing a unique molecular "fingerprint" for the tablet's composition [1] [3].

Materials and Equipment:

- Handheld NIR Spectrometer (e.g., based on MEMS scanning grating or MEMS-FT technology with an InGaAs detector).

- Tablet samples for testing.

- Device charger or spare batteries.

- Smartphone or tablet with proprietary data analysis software (if required).

- Reference spectral library for target drug products, pre-loaded on the device or accessible via cloud.

- Soft, lint-free cloth for cleaning the measurement window.

Procedure:

- Instrument Preparation:

- Power on the handheld spectrometer.

- Allow the instrument to initialize and perform a self-check. Ensure the battery level is sufficient.

- If applicable, allow the instrument to warm up for the time specified by the manufacturer to ensure signal stability.

System Calibration (if performed daily):

- Follow the manufacturer's instructions for a background or reference measurement. This typically involves placing a certified reflectance standard (e.g., a ceramic tile) over the measurement window and acquiring a reference spectrum.

Sample Measurement:

- Wipe the instrument's measurement window with a soft, lint-free cloth to remove any dust or debris.

- Place the tablet sample directly against the measurement window, ensuring full and firm contact.

- Initiate the spectral acquisition using the device's trigger or touchscreen. Keep the instrument steady during the measurement, which typically takes 10-20 seconds [4].

- Repeat the measurement on different spots/faces of the same tablet if heterogeneity is suspected (e.g., for a layered tablet). A minimum of three measurements per tablet is recommended for representative sampling.

Data Analysis and Interpretation:

- The instrument's software will automatically pre-process the spectrum (e.g., using Standard Normal Variate (SNV) or derivative filtering) and compare it to the reference library using built-in chemometric models (e.g., Principal Component Analysis (PCA) or Spectral Angle Mapper (SAM)).

- Review the result provided by the device, which is typically a "Match" or "Non-Match" for authenticity, and may include a quantitative estimate of API concentration.

- For "Non-Match" results, the software may provide a measure of spectral similarity (e.g., a score or distance metric) to aid in decision-making.

Reporting:

- Document the result, including sample ID, date, time, and operator name. If the device is equipped with GPS and a camera, this metadata should be automatically linked to the result.

- Samples flagged as "Non-Match" should be secured and sent to a qualified laboratory for confirmatory analysis using a reference method (e.g., HPLC).

Quality Control:

- Periodically test a verified authentic standard to confirm the system is functioning correctly.

- Keep the reference spectral library updated with new products and formulations.

Limitations:

- The method is a screening tool. Results are not definitive proof of falsification and require confirmatory testing.

- Performance can be affected by variations in tablet coating, color, and excipient composition not accounted for in the model.

- The reference library must be representative of the genuine product for accurate results [1] [4].

Diagram 1: Drug verification workflow using a handheld NIR spectrometer.

Essential Research Reagent Solutions

The following table details key materials and software solutions essential for conducting reliable field drug analysis with handheld NIR spectrometers.

Table 2: Key Research Reagents and Materials for Handheld NIR Drug Analysis

| Item | Function / Role | Specification Notes |

|---|---|---|

| Handheld NIR Spectrometer | Core device for spectral acquisition in the field. | Must feature an InGaAs detector and cover at least the 950-1650 nm range. MEMS-based systems (e.g., NeoSpectra, Texas NanoNIR) are preferred for portability [1] [2]. |

| Certified Reflectance Standard | For daily instrumental calibration and validation (background measurement). | A stable, high-reflectance material (e.g., ceramic or Spectralon) with a known and stable spectral response [3]. |

| Reference Spectral Library | Database of authentic drug spectra for comparison. | Must be built with authentic, verified samples and updated regularly to account for formulation changes. Often cloud-based and powered by proprietary AI [4]. |

| Chemometric Software | Transforms spectral data into actionable results (qualitative and quantitative). | Software packages (often proprietary) that perform preprocessing (SNV, derivatives) and multivariate analysis (PCA, PLS) [1] [3]. |

| Power Supply | Ensures uninterrupted operation in the field. | Rechargeable lithium-ion battery packs and portable power banks suitable for all-day use. |

The integration of MEMS technology, high-sensitivity InGaAs detectors, and the strategically selected 950-1650 nm spectral range has successfully enabled the development of powerful handheld NIR spectrometers. These instruments have moved NIR analysis from the laboratory directly into the hands of researchers and regulators in the field. While challenges remain—such as the need for robust, representative spectral libraries and ongoing improvements in the sensitivity of detection algorithms—this core technology provides a rapid, non-destructive, and practical first line of defense in the critical global effort to ensure drug safety and authenticity [1] [4]. The continued evolution of these technologies promises even greater analytical capabilities in future generations of portable spectroscopic devices.

Near-infrared (NIR) spectroscopy has emerged as a powerful analytical technique, with its miniaturization into handheld and portable devices revolutionizing field-based analysis. This application note details the core advantages—non-destructive analysis, rapid results in approximately five seconds, and minimal sample preparation—that make handheld NIR spectrometers indispensable for field drug analysis. Framed within broader research on decentralized forensic capabilities, we provide validated experimental protocols, quantitative performance data, and a detailed toolkit for researchers and scientists deploying this technology. The evidence underscores handheld NIR's role in enhancing operational efficiency, supporting rapid decision-making, and preserving evidence integrity.

The analysis of illicit drugs traditionally relies on laboratory-based techniques such as gas chromatography-mass spectrometry (GC-MS) and high-performance liquid chromatography (HPLC). While these are considered gold standards for accuracy, they have significant limitations for field deployment: they are time-consuming, require destructive sample preparation, and demand specialized laboratory environments [6].

Driven by the need for rapid, on-the-spot results, handheld Near-Infrared (NIR) spectrometers have filled this critical gap. NIR spectroscopy operates by measuring the absorption of light in the 780 to 2500 nm wavelength range, corresponding to overtone and combination vibrations of molecular bonds like C-H, O-H, and N-H [7] [8]. This interaction provides a molecular "fingerprint" that can be used for both identification and quantification. Advances in micro-electro-mechanical systems (MEMS) and linear variable filter (LVF) technologies have enabled the miniaturization of these spectrometers into devices weighing less than 100 grams, making them truly portable and field-deployable [9] [8].

Core Advantages and Quantitative Performance

The value proposition of handheld NIR spectrometers for field drug analysis rests on three pillars, each supported by robust experimental data.

Non-Destructive Analysis

The technique is fundamentally non-destructive, as NIR radiation causes no physical or chemical degradation to the sample.

- Evidence Preservation: The original sample remains intact for subsequent confirmatory analysis in a laboratory, preserving the chain of custody for legal proceedings [6] [10].

- Material Reusability: The same sample can be analyzed multiple times, facilitating method development and verification directly in the field.

High-Speed Results (~5 Seconds)

The time from measurement to result is exceptionally fast, enabling real-time decision-making.

- Rapid Screening: A study on illicit drug analysis demonstrated that an ultra-portable NIR detector connected to a mobile application could provide results to end-users within 5 seconds [6].

- Operational Efficiency: This speed allows law enforcement and researchers to screen a large number of samples quickly in fast-paced environments, drastically reducing the backlog in central laboratories [10].

Minimal Sample Preparation

Handheld NIR spectrometers require no complex sample preparation, which is a significant advantage over traditional methods.

- Direct Measurement: Analysis is typically performed by bringing the spectrometer window into direct contact with the sample in its native state (e.g., a powder, pill, or plant material), requiring no solvents, reagents, or extraction steps [8].

- Ease of Use: This simplicity allows the technology to be operated effectively by personnel without extensive analytical training, broadening its applicability for field use [8].

Table 1: Quantitative Performance of Handheld NIR in Forensic Drug Analysis

| Analyte | Sensitivity | Number of Samples | Analysis Time | Reference |

|---|---|---|---|---|

| Cocaine | 0.994 | 2047 | ~5 seconds | [6] |

| Heroin | High (Precise value not stated) | Not Specified | ~5 seconds | [6] |

| Cannabis (CBD vs. THC-type) | Effective classification confirmed vs. UHPLC | >250 | Real-time | [10] |

Experimental Protocols for Field Drug Analysis

The following protocols are adapted from validated methodologies used in forensic research for the analysis of seized drugs.

Protocol 1: Qualitative Identification of Illicit Substances

This protocol is designed for the rapid identification of substances like cocaine, heroin, and cannabis.

Research Reagent Solutions & Materials: Table 2: Essential Materials for Field Drug Analysis with Handheld NIR

| Item | Function/Description |

|---|---|

| Handheld NIR Spectrometer (e.g., Viavi MicroNIR Onsite W 1700) | Ultra-compact device (e.g., 250g) operating in the 950-1650 nm range with Bluetooth connectivity. |

| Reference Standards (e.g., pure cocaine HCl, heroin) | Required for building and validating chemometric models. |

| Calibration Model | Pre-loaded model for target analytes, developed using techniques like PCA or PLS-DA. |

| Mobile Application & Cloud Platform | For instrument control, data transmission, and real-time result display. |

| Sample Containers (e.g., glass vials) | For presenting samples to the spectrometer in a consistent manner. |

Procedure:

- Instrument Preparation: Power on the handheld NIR spectrometer and establish a connection to the mobile application via Bluetooth. Ensure the battery has sufficient charge for the intended number of measurements.

- System Check: Perform a quick validation check using a built-in reference standard or a provided calibration tile to ensure instrument performance.

- Sample Presentation: For a solid powder, place a small, representative amount in a glass vial. Ensure the sample is homogeneous. Bring the spectrometer's measurement window into direct contact with the bottom of the vial or hold it at a consistent short distance from the sample.

- Spectral Acquisition: Initiate the measurement from the mobile application. A typical spectrum is acquired in 1-3 seconds. For heterogeneous samples, collect multiple spectra from different spots.

- Data Processing & Result: The acquired spectrum is automatically transmitted to a cloud-based platform via the mobile app. The system compares the sample's spectrum against the pre-loaded qualitative model.

- Result Interpretation: The application displays the result (e.g., "Cocaine identified" or "No match") within approximately 5 seconds of measurement initiation. The sample is preserved for further analysis.

The following workflow diagram illustrates the streamlined process from sample to result:

Protocol 2: Quantitative Analysis of Purity

This protocol outlines the steps for estimating the concentration of an active compound in a street sample, such as cocaine purity.

Procedure:

- Calibration Model Verification: Ensure the instrument is loaded with a validated quantitative model, typically developed using Partial Least Squares (PLS) regression against reference data (e.g., from GC-MS).

- Sample Handling: Follow the same sample presentation steps as in Protocol 1. For quantitative analysis, ensuring sample homogeneity is critical for an accurate result.

- Measurement: Acquire the NIR spectrum. It is recommended to take at least three replicate measurements from different spots on the sample to account for heterogeneity.

- Quantitative Prediction: The transmitted spectrum is analyzed by the quantitative model in the cloud, which predicts the concentration of the target analyte.

- Result: The estimated purity or concentration (e.g., "Cocaine: 78% purity") is displayed on the mobile application. This result can be used for rapid triage, such as categorizing a case as personal consumption or trafficking based on the amount of pure substance [6].

The quantitative analysis process involves a pre-established calibration model, as shown below:

Discussion and Implementation Framework

The decentralization of forensic capabilities is a significant trend, and handheld NIR technology is at its forefront [6]. The non-destructive nature of the analysis ensures that valuable evidence is preserved, while the speed and lack of required preparation make it an ideal triage tool for law enforcement and field researchers. A "toolkit" approach, where handheld NIR is used alongside other portable technologies like handheld Raman or GC-MS, is recommended for the most robust field identification of a wide range of illicit substances and new psychoactive substances (NPS) [11].

Successful deployment relies on:

- Robust Calibration Models: Models must be built using a large and diverse set of samples that represent the variability encountered in street products.

- Cloud-Based Data Management: This facilitates real-time analysis, continuous model improvement, and intelligence-led policing by aggregating data from multiple field devices [6].

- User Training: While operation is simple, users must be trained in basic instrument handling, sample presentation, and result interpretation to ensure data quality.

The field of analytical spectroscopy is undergoing a profound transformation, marked by a significant migration from traditional benchtop instruments toward miniature, portable systems. This evolution is particularly impactful in forensic science, where handheld near-infrared (NIR) spectrometers are revolutionizing field-based drug analysis. These portable tools enable researchers and law enforcement professionals to perform rapid, on-site identification and quantification of illicit substances with laboratory-grade accuracy, directly at the point of need [12]. This shift is driven by advancements in micro-electro-mechanical systems (MEMS), sophisticated chemometrics, and growing demand for real-time analytical data across multiple sectors [13] [9].

The global market data underscores this technological transition. The miniaturized spectrometer market, valued at $1.04 billion in 2024, is projected to grow at a robust compound annual growth rate (CAGR) of 12.8%, reaching $1.91 billion by 2029 [13]. This growth is largely propelled by the critical need for portable diagnostic instruments and point-of-care solutions in fields ranging from law enforcement to pharmaceutical development [13].

Market Evolution and Quantitative Landscape

The quantitative data on the miniaturized spectrometer market reveals a consistent and accelerating expansion, reflecting the increasing adoption of these portable technologies across diverse applications.

Table 1: Miniaturized Spectrometer Global Market Size and Forecast

| Year | Market Size (USD Billion) | Compound Annual Growth Rate (CAGR) |

|---|---|---|

| 2024 | 1.04 | |

| 2025 | 1.18 | 13.2% |

| 2029 | 1.91 | 12.8% |

This historic growth is attributed to increased demand for field-based chemical analysis, government-led initiatives, and expanded use in industrial applications like textiles and printing [13]. The forecast period growth will be fueled by trends such as smartphone-based spectroscopy, wearable spectrometer devices, and progress in AI-enhanced spectral data interpretation [13].

The market segmentation further illustrates the diverse technological approaches and application areas driving this sector.

Table 2: Miniaturized Spectrometer Market Segmentation and Key Players

| Segment Type | Categories | Representative Companies |

|---|---|---|

| Product Type | Portable, Handheld, Benchtop | Thermo Fisher Scientific Inc., Viavi Solutions Inc. |

| Technology | MEMS, Micro-Optical, Fabry-Perot, Filter-Based | Si-Ware Systems, InnoSpectra, Hamamatsu Photonics |

| Application | Pharmaceuticals, Food & Beverage, Environmental Testing, Chemical Analysis, Life Sciences | Bruker Corporation, HORIBA Ltd. |

| End User | Healthcare, Industrial, Research Institutes, Environmental Monitoring | Ocean Insight Inc., B&W Tek LLC |

North America dominated the market in 2024, but the Asia-Pacific region is predicted to exhibit the most rapid growth in the coming years [13].

Technological Drivers and Miniaturization Trends

The miniaturization of spectrometers has been made possible by several key technological advancements that have redefined instrument design and capability.

Core Miniaturization Technologies

Modern portable NIR spectrometers primarily leverage one of several optical designs, each with distinct advantages. These include Linear-Variable Filter (LVF) instruments, MEMS-based Fourier Transform-NIR (FT-NIR) spectrometers, devices using a Digital Micro-mirror Device (DMD), Fabry-Perot tunable filters, and miniaturized NIR grating systems [12]. These technologies have enabled the replacement of bulky optical components with micro-scale equivalents, drastically reducing the size, weight, and power consumption of the instruments without sacrificing analytical performance.

Performance and Form Factor Evolution

The evolution in form factor is dramatic. Where earlier portable instruments were often heavy and limited in capability, current handheld devices can weigh less than 100 grams [12]. For instance, the Viavi MicroNIR 1700ES weighs approximately 64 grams, while the Spectral Engines NIRONE sensor is a mere 15 grams [9]. This reduction in size and complexity has been matched by improvements in performance. A 2025 prototype demonstrated a spectrometer "orders of magnitude smaller than current technologies" that could accurately measure light from ultraviolet to the near-infrared, small enough to "fit on your phone" or even be made "as small as a pixel" [14].

Application Focus: Handheld NIR Spectrometers for Field Drug Analysis

The deployment of handheld NIR spectrometers for the analysis of narcotics and illicit substances represents a paradigm shift in forensic science, enabling decentralized testing and real-time decision-making.

Experimental Protocol for Illicit Drug Identification and Quantification

The following protocol is adapted from a study that optimized and assessed the implementation of NIR spectroscopy for illicit drug analysis in an Australian context [15].

1. Objective: To rapidly identify and quantify the composition of seized illicit drug specimens in a field setting using a handheld NIR spectrometer.

2. Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for Field Drug Analysis with NIR Spectroscopy

| Item | Function & Specification |

|---|---|

| Handheld NIR Spectrometer (e.g., Viavi MicroNIR) | The core analytical instrument; must be portable, robust, and capable of collecting spectra in the 1100-1650 nm or 1600-2400 nm ranges. |

| Chemometric Software Suite (e.g., NIRLAB Pro) | Software for developing, validating, and deploying quantitative and qualitative (classification) models based on spectral data. |

| Calibrated Reference Dataset | A library of NIR spectra from chemically validated drug specimens (e.g., methamphetamine HCl, cocaine HCl, heroin HCl) and common adulterants. |

| Seized Drug Specimens | The unknown samples to be tested. Requires minimal preparation (e.g., placed directly in a glass vial or a specialized sample holder). |

| Laboratory Reference Method (e.g., GC-MS) | A standard laboratory technique used to provide the definitive identity and purity values for building the initial calibration model. |

3. Procedure:

- Step 1: Instrument Preparation. Power on the handheld NIR spectrometer and allow it to warm up as per the manufacturer's instructions. Perform a background or reference scan to calibrate the instrument for the current environmental conditions.

- Step 2: Spectral Acquisition. Present the seized drug specimen to the spectrometer's measurement window. For solids, this may involve placing the substance in a consistent manner against the window. Acquire the NIR spectrum. Each measurement is typically completed within seconds.

- Step 3: Data Preprocessing. The acquired raw spectrum is automatically preprocessed by the instrument's software. Common preprocessing steps include Standard Normal Variate (SNV), Multiplicative Scatter Correction (MSC), and derivative treatments (e.g., Savitzky-Golay) to remove light-scattering effects and enhance spectral features [16].

- Step 4: Chemometric Analysis. The preprocessed spectrum is analyzed against pre-loaded chemometric models.

- Identification: A classification model, such as Partial Least Squares-Discriminant Analysis (PLS-DA), compares the unknown spectrum to the reference database to identify the primary substance (e.g., methamphetamine vs. cocaine) [16].

- Quantification: A regression model, typically Partial Least Squares (PLS) Regression, predicts the concentration or purity percentage of the primary component based on the spectral features [15] [16].

- Step 5: Result Interpretation. The software displays the results, typically showing the identified substance and its predicted purity or concentration with an associated confidence metric. The entire process, from measurement to result, is designed to be completed in less than 30 seconds.

4. Performance Metrics: In a validation study using 608 real-world specimens, this methodology demonstrated exceptional accuracy. Identification accuracy rates for crystalline methamphetamine HCl, cocaine HCl, and heroin HCl were 98.4%, 97.5%, and 99.2%, respectively. Quantification was also highly accurate, with 99% of predicted values falling within ±15% of the reference laboratory values [15].

The workflow for this analytical protocol is outlined in the diagram below.

Broader Applications and Future Directions

The utility of miniature NIR systems extends far beyond drug analysis, demonstrating their versatility as a general-purpose analytical tool.

Diverse Industry Applications

In the dairy industry, portable NIR devices are used for the rapid, non-destructive determination of fat, protein, and moisture content in products like liquid milk, cheese, and dairy powders, enabling quality control from the farm to the production line [9]. In pharmaceuticals, they are deployed to combat counterfeit medicines by allowing regulators to verify the authenticity of medical products within seconds [17]. Harm reduction organizations use portable analyzers like the NIRLAB to screen for more than 150 illicit and psychoactive substances, providing critical data for public health interventions [17]. Furthermore, these devices are used in polymer identification for plastic sorting and recycling, highlighting their role in supporting circular economies [17].

Emerging Trends and Future Outlook

The future trajectory of miniature spectrometers points toward even deeper integration into daily professional and consumer life. Key trends include:

- Ultra-Miniaturization and Integration: Research continues to push size boundaries, with developments like single-pixel spectrometers small enough for integration into smartphone cameras, promising a future where spectroscopic analysis is truly ubiquitous [14] [18].

- Wearable Spectrometers: The emergence of flexible organic photodetectors (OPDs) is paving the way for wearable NIR sensors for real-time health monitoring, such as measuring muscle oxygenation in athletes or enabling neuroimaging with wearable fNIRS headbands [18].

- AI-Enhanced Data Interpretation: The reliance on advanced chemometrics will intensify, with artificial intelligence and machine learning algorithms becoming central to extracting more complex information from spectral data with greater speed and accuracy [13] [16].

- The Route to Green Analytical Chemistry: Portable NIR spectroscopy is recognized as a "true green analytical chemistry" method, as it eliminates the need for solvents, extensive sample preparation, and transportation of samples to a lab, thereby reducing the environmental impact of chemical analysis [12].

The convergence of these technologies and trends is summarized in the following evolution pathway.

Addressing the Need for Decentralization in Forensic and Pharmaceutical Workflows

The analysis of pharmaceutical and illicit drug substances faces persistent challenges regarding the production of timely and reliable results. Traditional laboratory techniques, while highly accurate, are centralized, time-consuming, destructive, and difficult to deploy outside a controlled laboratory environment [6]. There is a growing trend toward the decentralization of analytical capabilities, allowing critical data to be acted upon more efficiently at the point of need—be it a crime scene, customs checkpoint, or pharmacy [19] [15]. Handheld Near-Infrared (NIR) spectroscopy, combined with robust chemometric modeling, has emerged as a powerful technology to meet this need. This document outlines application notes and detailed protocols for implementing handheld NIR spectrometers to decentralize workflows in forensic and pharmaceutical analysis, enabling rapid, non-destructive, and reliable identification and quantification of materials directly in the field.

Application Notes

Handheld NIR spectrometers have been rigorously validated across multiple studies for various applications. The following tables summarize key quantitative performance data.

Table 1: Performance in Illicit Drug Analysis (Laboratory Validation)

| Drug Substance | Identification Accuracy | Sensitivity | Quantitative Performance | Citation |

|---|---|---|---|---|

| Crystalline Methamphetamine HCl | 98.4% | 96.6% | 99% of values within ±15% uncertainty | [15] |

| Cocaine HCl | 97.5% | 93.5% | 99% of values within ±15% uncertainty | [15] |

| Heroin HCl | 99.2% | 91.3% | 99% of values within ±15% uncertainty | [15] |

| Cocaine (Street Samples) | N/A | 99.4% (Specificity) | N/A | [6] |

Table 2: Performance in Pharmaceutical Analysis

| Application | Drug Classes | Model Performance | Citation |

|---|---|---|---|

| Counterfeit Tablet Detection | Various Pharmaceutical Tablets | swNIR+SVM: 100% (Cal), 96.0% (Val)cNIR+LDA: 99.9% (Cal), 91.1% (Val) | [20] |

| Detection of Substandard and Falsified (SF) Medicines | Analgesics, Antimalarials, Antibiotics, Antihypertensives | Overall Sensitivity: 11%; Specificity: 74%Analgesics Sensitivity: 37%; Specificity: 47% | [4] |

Table 3: Operational Advantages of Portable NIR vs. Traditional Methods

| Parameter | Handheld NIR | GC-MS / HPLC |

|---|---|---|

| Analysis Time | ~5 to 20 seconds | Minutes to hours [6] |

| Sample Preparation | Non-destructive; no preparation required | Extensive; destructive [21] [6] |

| Deployment | Fully portable for field use | Laboratory-bound |

| Chemical Reagents | Not required | Often required |

| Data Integration | Real-time results with cloud connectivity | Offline analysis |

Key Technological Workflow

The power of decentralized NIR analysis lies in the integration of hardware, software, and cloud-based data management. The following diagram illustrates the end-to-end workflow for on-site analysis.

On-Site NIR Analysis Workflow

Experimental Protocols

Protocol 1: Rapid Identification and Quantification of Illicit Street Drugs

This protocol is adapted from studies demonstrating the accurate identification and quantification of heroin, cocaine, and methamphetamine in five seconds using ultra-portable NIR technology [19] [6].

Research Reagent Solutions & Essential Materials

Table 4: Essential Materials for Illicit Drug Analysis

| Item | Function | Specification / Notes |

|---|---|---|

| Portable NIR Spectrometer | Acquires spectral data from samples. | E.g., MicroNIR Onsite W 1700; Spectral range: 950–1650 nm; Weight: ~250g [6]. |

| Mobile Application & Cloud Database | Controls the spectrometer, hosts chemometric models, and displays results. | Must provide secure, real-time communication with the spectrometer and cloud [19]. |

| Chemometric Prediction Models | For qualitative ID and quantitative purity. | Pre-trained and validated models for target drugs (e.g., heroin, cocaine, cannabis) [15] [6]. |

| Reference Drug Samples | For model calibration and validation. | Chemically characterized specimens representative of the local drug market [15]. |

| Gloves & Personal Protective Equipment (PPE) | Ensures analyst safety during handling of unknown substances. | Disposable nitrile gloves are recommended. |

Step-by-Step Procedure

- Instrument Preparation: Power on the handheld NIR spectrometer and ensure it connects via Bluetooth to the dedicated mobile application. Verify that the instrument has undergone a successful background/reference scan.

- Sample Presentation: Place a small, representative amount of the street drug sample directly onto the spectrometer's sampling window. For crystalline or powdered samples, ensure a consistent and even layer.

- Spectral Acquisition: Initiate the scan from the mobile application. The acquisition time is typically 5 seconds. The spectrum is automatically transmitted to the cloud database.

- Real-Time Analysis: The cloud-based chemometric model instantly analyzes the spectral data.

- Qualitative Identification: The model compares the sample's spectrum against the spectral library of known substances and provides an identification result (e.g., "Cocaine HCl").

- Quantification: The model simultaneously predicts the concentration or purity of the identified active substance (e.g., "78% Cocaine HCl").

- Result Reporting: The identification and quantification results are displayed on the mobile application within seconds of scan completion. The result can be geo-tagged and time-stamped for intelligence purposes.

- Data Management: Results are logged securely in the cloud database, accessible for later review, reporting, or intelligence analysis.

Protocol 2: Authentication of Pharmaceutical Tablets and Detection of Counterfeits

This protocol is based on methods developed for creating large spectral databases of legitimate pharmaceutical products and using supervised classification models to identify counterfeit tablets with high accuracy [20].

Research Reagent Solutions & Essential Materials

Table 5: Essential Materials for Pharmaceutical Authentication

| Item | Function | Specification / Notes |

|---|---|---|

| Handheld NIR Spectrometer | Acquires spectral data from solid dosage forms. | May offer dual functionality (handheld/benchtop). High signal-to-noise ratio (e.g., 4500:1) for precision [22]. |

| Spectral Database & Software | Stores reference spectra and runs classification models. | Contains spectra of all authentic products. Software like Visum Master can automate model building [22]. |

| Chemometric Classification Model | Differentiates authentic from counterfeit products. | Support Vector Machine (SVM) or Linear Discriminant Analysis (LDA) models have proven effective [20]. |

| Authentic Pharmaceutical Tablets | For building and validating the reference database. | Should encompass all products, batches, and dosages to be screened. |

| Suspect/Counterfeit Tablets | Test samples for model validation and routine screening. | May include generics and outright fakes. |

Step-by-Step Procedure

- Database Creation (One-time Calibration):

- Collect a comprehensive set of authentic tablet samples from the manufacturer.

- Using the handheld NIR spectrometer, acquire multiple spectra for each authentic product to account for natural batch-to-batch variability.

- Use software (e.g., Visum Master) to compile these spectra into a reference database and train a supervised classification model (e.g., SVM or LDA). Validate the model's performance using an independent set of validation samples [20] [22].

- Routine Screening of Unknown Tablets:

- Power on the handheld NIR spectrometer and load the pre-trained classification model.

- Place the unknown tablet on a clean, stable surface or directly onto the spectrometer's sampling window.

- Initiate the scan. The acquisition time is typically 3-10 seconds.

- The instrument's software automatically compares the unknown tablet's spectrum against the model.

- Result Interpretation: The output is a straightforward classification, such as "Authentic - Matches Product X" or "Non-Authentic - Does Not Match Database," often accompanied by a correlation distance metric for confidence assessment [20].

Protocol 3: Field Classification of Cannabis Types

This protocol supports law enforcement in making rapid decisions in the field by distinguishing between legal (e.g., high-CBD) and illegal (e.g., high-THC) cannabis types, as demonstrated in Swiss deployments [19] [6].

Step-by-Step Procedure

- Instrument Preparation: Ensure the handheld NIR spectrometer and mobile application are powered on and connected.

- Sample Presentation: Place a small, representative floral sample of the cannabis in contact with the spectrometer's sampling window.

- Spectral Acquisition: Initiate a scan. The process is non-destructive and takes only a few seconds.

- Model Prediction: The dedicated classification model for cannabis analyzes the spectral signature, which differs between THC- and CBD-dominant strains.

- Result Reporting: The application displays the classification, for example, "THC-type (Illicit)" or "CBD-type (Legal)," providing immediate actionable intelligence to the officer.

The logical decision-making process supported by this protocol is summarized below.

Cannabis Field Decision Logic

Operational Workflows: From Spectral Acquisition to Machine Learning-Driven Results

This Standard Operating Procedure (SOP) outlines the protocols for using handheld Near-Infrared (NIR) spectrometers for the analysis of suspected narcotic substances in field settings. The procedures are designed to ensure the generation of reliable, consistent, and accurate quantitative data for research on substance composition and heterogeneity, directly supporting harm reduction initiatives and forensic science. Adherence to this SOP is critical for maintaining personal safety, sample integrity, and data validity in non-laboratory environments [23].

Safety Precautions

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including nitrile gloves and safety glasses, when handling unknown substances.

- Non-Contact Principle: Utilize the non-contact scanning capability of the spectrometer whenever possible to minimize exposure and cross-contamination [23].

- Decontamination: Clean the device's sapphire glass with ethanol and a lint-free tissue before and after analyzing each sample [23].

Experimental Protocols and Workflows

Sample Presentation and Preparation

Proper sample presentation is fundamental for obtaining high-quality spectra. The chosen method depends on the sample's physical form and the required analytical precision [23].

Table 1: Sample Presentation Methods for Field-Based NIR Analysis

| Sample Type | Presentation Method | Key Considerations |

|---|---|---|

| Intact Tablets (e.g., XTC) | Scan the pill in its original state. | Do not crush or alter the pill. Take multiple measurements from different angles if the initial result is "unknown substance" [23]. |

| Powders | Place powder in a small, neutral aluminum cup. | The aluminum cup provides a spectrally neutral background. For high-quantity or non-homogeneous powders, use the Sample Scan mode to assess homogeneity [23]. |

| Small Samples | Contain within a small aluminum cup. | Prevents sample loss and ensures a consistent, minimal gap between the device and the sample [23]. |

| Samples in Bags | Scan through thin, clear plastic. | A minimal gap of 1-2 mm is acceptable, though direct contact yields the best accuracy for quantification [23]. |

The following workflow outlines the decision process for sample preparation in the field:

Spectrometer Setup and Scanning Protocol

This section details the operational steps for the handheld NIR spectrometer from startup to data acquisition.

3.2.1 Device Setup and Calibration

- Power and Connect: Power up the handheld spectrometer. Launch the dedicated application on the mobile device and establish a connection via Bluetooth pairing [23].

- Calibrate: Perform a calibration using the provided white reference mirror. Follow the in-app instructions to ensure spectral accuracy before commencing sample analysis [23].

3.2.2 Scanning Mode Selection Two primary scanning modes are available. The choice depends on the balance required between speed and analytical depth [23].

Table 2: Scanning Mode Selection for Field Analysis

| Scanning Mode | Use Case | Protocol |

|---|---|---|

| Quick Scan | Rapid identification during outreach; initial assessment. | Provides immediate substance profiles. Position the device in direct contact or at a 1-2 mm gap from the sample. Point the device downwards during measurement [23]. |

| Sample Scan | Detailed analysis of heterogeneous powders; research-grade quantification. | Averages multiple scans to provide a thorough substance breakdown and homogeneity assessment. Requires the sample to be presented in an aluminum cup [23]. |

The following diagram illustrates the core operational workflow for field scanning:

Data Collection and Presentation

For research purposes, quantitative data on sample heterogeneity can be systematically collected and presented. The following table summarizes a methodology for assessing the effect of sample preparation based on established principles of NIR analysis [24].

Table 3: Quantitative Assessment of Sample Homogeneity via NIR

| Sample Group | Preparation Method | Number of Scans per Sample (n) | Observed Statistical Error | Key Finding |

|---|---|---|---|---|

| Ground Wheat | Homogenized using a mill (e.g., TWISTER) | 10 | No significant statistical error | Reliable and meaningful analytical results [24]. |

| Unground Wheat | No preparation (whole grains) | 10 | Significant deviations and considerable statistical error | Results show systematic inaccuracies due to poor light scattering and heterogeneity [24]. |

The Scientist's Toolkit: Research Reagent Solutions

The following table details essential materials and their functions for field-based NIR analysis of narcotic substances.

Table 4: Essential Materials for Field-Based NIR Analysis

| Item | Function / Rationale |

|---|---|

| Handheld NIR Spectrometer | Mobile analytical device for non-destructive, non-contact quantitative analysis of substances [23]. |

| Neutral Aluminum Cups | Provides a spectrally inert background for measuring powders and small samples, minimizing spectral interference [23]. |

| White Reference Mirror | Essential calibration standard for ensuring the spectral accuracy and repeatability of the spectrometer [23]. |

| Ethanol (≥70%) & Lint-Free Tissues | For cleaning the sapphire glass window of the spectrometer to prevent cross-contamination between samples [23]. |

| Laboratory Mill (e.g., TWISTER) | Although not for field use, this is critical for R&D to homogenize samples for method development and validation, ensuring reliable results by achieving analytical fineness [24]. |

| Isononyl isooctyl phthalate | Isononyl Isooctyl Phthalate|High-Purity Plasticizer |

| 3-Chloro-3-ethylheptane | 3-Chloro-3-ethylheptane, CAS:28320-89-0, MF:C9H19Cl, MW:162.70 g/mol |

The Role of Cloud Databases and Mobile Applications for Real-Time Analysis and Reporting

The proliferation of handheld Near-Infrared (NIR) spectrometers has revolutionized field-based drug analysis, enabling rapid, non-destructive identification and quantification of illicit substances and falsified pharmaceuticals outside traditional laboratory settings. These portable analytical capabilities have created a paradigm shift in forensic science and harm reduction strategies [6] [25]. However, the full potential of this technology is only realized through its integration with cloud databases and mobile applications, which together transform standalone devices into networked intelligence systems. This integration enables real-time analysis, continuous model improvement, and immediate reporting that is critical for public health interventions and law enforcement operations [26] [27].

The convergence of miniature NIR spectrophotometers weighing as little as 100-200 grams with advanced data management architectures represents a significant milestone in decentralized forensic capabilities [25]. This technological synergy allows field operators to bypass the traditional bottlenecks of laboratory analysis while maintaining analytical rigor through cloud-accessible calibration models and substance libraries. For researchers and drug development professionals, this ecosystem provides unprecedented access to distributed intelligence gathering capabilities, enabling more responsive and data-driven public health strategies [26] [6].

System Architecture & Workflow

The operational framework for handheld NIR spectroscopy in drug analysis combines hardware, software, and connectivity components into a seamless workflow from sample acquisition to result reporting. The system architecture ensures that complex computational tasks are handled efficiently while maintaining the portability and speed required for field deployment.

Integrated System Components

The typical ecosystem consists of multiple interoperating elements, each serving a distinct function in the analytical chain:

Handheld NIR Spectrometer: Portable devices such as the NIRLIGHT (250g weight) or Visum Palm (1.8kg) operate in the 900-1700nm or 950-1650nm spectral ranges, featuring Bluetooth connectivity and battery lives exceeding 5 hours [26] [22] [6]. These instruments capture spectral data through diffuse reflectance measurements with acquisition times as short as 3-5 seconds [22] [6].

Mobile Application: Native Android and iOS applications (e.g., NIRLAB's platform) provide the user interface for instrument control, results visualization, and data management [28] [26]. These apps display scanning results within seconds, showing identified substances, quantification values, and detected cutting agents in an easily interpretable format.

Cloud Infrastructure: Cloud platforms host spectral databases, machine learning models, and processing algorithms that would be too computationally intensive for the handheld devices themselves [28] [27]. This architecture enables continuous model updates and expansion of substance libraries without requiring device replacement.

Reference Databases: Centralized spectral libraries containing 300+ substances including narcotics, cutting agents, and precursors form the core identification resource [26]. These databases are continuously expanded with new substances, with updates immediately available to all users through cloud synchronization.

The following diagram illustrates the integrated workflow from sample analysis to result reporting:

Data Processing Workflow

The analytical pathway from spectral acquisition to result generation involves multiple validation and processing stages:

Spectral Acquisition: The handheld spectrometer illuminates the sample with NIR light and captures the reflected spectra across its operational wavelength range. Modern devices complete this process within 3-5 seconds while operating through various packaging materials including blister packs [27].

Data Preprocessing: Raw spectral data undergoes preprocessing algorithms including Standard Normal Variate (SNV) and Multiplicative Signal Correction (MSC) to reduce noise and correct for baseline variations caused by environmental factors or sample presentation [25].

Cloud-Based Analysis: Processed spectra are transmitted to cloud services where machine learning models perform substance identification and quantification. These models employ Principal Component Analysis (PCA), Support Vector Machines (SVM), and neural networks to compare unknown spectra against reference libraries [27].

Result Generation: Identification results show the detected primary substance along with cutting agents and purity estimates. Quantification models can determine active pharmaceutical ingredient (API) concentrations, such as sildenafil in falsified Viagra, with accuracy comparable to reference chromatographic methods [27].

Data Synchronization: Results are stored locally on the mobile device while simultaneously synchronizing with cloud databases to contribute to continuous model improvement and population-level trend analysis.

Performance Metrics & Validation

The analytical performance of cloud-enhanced handheld NIR systems has been rigorously validated against established laboratory techniques across multiple substance categories. The integration with cloud databases has significantly improved reliability compared to early standalone devices that suffered from limited spectral libraries and calibration drift.

Quantitative Analytical Performance

Extensive validation studies have demonstrated the capability of these systems to accurately identify and quantify substances across diverse forensic samples:

Table 1: Performance Metrics of Handheld NIR Systems for Drug Analysis

| Parameter | Cocaine Analysis | Heroin Analysis | Pharmaceutical Analysis | Cannabis Analysis |

|---|---|---|---|---|

| Sensitivity | 0.994 (2047 specimens) [6] | High (matrix-dependent) [6] | 100% authentication (PCA/Euclidean) [27] | Type differentiation [6] |

| Quantification Accuracy | Purity determination [26] | Purity determination [26] | RMSEP 0.52% (sildenafil) [27] | THC/CBD content [26] |

| Analysis Time | <5 seconds [26] [6] | <5 seconds [26] [6] | <30 seconds [29] | <5 seconds [26] |

| Cutting Agent ID | Lidocaine, benzocaine, levamisole, caffeine, etc. [26] | Common diluents [26] | Excipient profiling [27] | N/A |

The validation of these systems extends beyond laboratory settings to real-world operational environments. For cocaine analysis, models demonstrated exceptional sensitivity (0.994) when testing 2047 specimens, with only 12 samples not correctly identified [6]. For pharmaceutical applications, portable NIR devices coupled with cloud processing achieved 100% accuracy in distinguishing authentic from falsified Viagra tablets using PCA and Euclidean distance measurements [27].

Operational Advantages in Field Deployments

The integration of handheld NIR devices with cloud databases provides significant operational benefits for field-based drug analysis:

Non-Destructive Testing: Samples remain intact after analysis, preserving evidence for subsequent confirmatory testing or legal proceedings [25].

Through-Package Analysis: Capability to analyze substances through translucent packaging materials, reducing contamination risk and handling hazards [27].

Continuous Improvement: Cloud-connected systems benefit from expanding substance libraries, with new compounds added regularly and immediately available to all devices [26].

Operational Efficiency: Significant reduction in analysis backlog by enabling preliminary testing at point of need rather than relying exclusively on central laboratories [6].

The implementation of these systems follows a structured deployment pathway that includes feasibility assessment, data acquisition, model development, and field validation phases to ensure reliability in operational environments.

Experimental Protocols

To ensure reproducible and reliable results, researchers should follow standardized protocols for field-based NIR analysis of drugs and pharmaceuticals. The following section outlines comprehensive methodologies for both qualitative screening and quantitative analysis.

Protocol 1: Qualitative Identification of Illicit Substances

This protocol describes the procedure for rapid identification of unknown substances in field conditions, particularly suited for harm reduction services and law enforcement operations.

Research Reagent Solutions & Materials

Table 2: Essential Materials for Field Drug Analysis Using Handheld NIR

| Item | Specification | Function/Purpose |

|---|---|---|

| Handheld NIR Spectrometer | NIRLIGHT (250g) or Visum Palm (1.8kg); 900-1700nm range [26] [22] | Spectral acquisition from samples |

| Mobile Device | Android or iOS tablet/smartphone with dedicated application [28] | Instrument control, data visualization, cloud connectivity |

| Reference Standards | Certified reference materials for validation [6] | System performance verification, quality control |

| Sampling Accessories | Disposable cups, spatulas, weighing boats [22] | Safe sample handling without cross-contamination |

| Calibration Reference | Spectralon or white ceramic reference tile [25] | Instrument calibration before measurements |

Step-by-Step Methodology

Instrument Preparation:

- Power on the handheld NIR spectrometer and ensure battery charge exceeds 50%

- Establish Bluetooth connection between spectrometer and mobile device

- Launch the dedicated mobile application (e.g., NIRLAB drug checking application)

- Allow 5-10 minutes for instrument warm-up if previously stored in cold conditions [25]

System Calibration:

- Obtain reference spectrum using certified reflectance standard (Spectralon or equivalent)

- Perform calibration validation using a known reference standard from the system library

- Confirm calibration acceptance criteria are met before proceeding with unknown samples

Sample Preparation:

- For homogeneous powders: Present in a clean, disposable container with minimal headspace

- For tablets: Analyze intact tablet surface, preferably through original packaging when possible

- For plant material: Gently compress to create uniform surface for analysis

- Ensure sample completely covers the instrument's measurement aperture

Spectral Acquisition:

- Position spectrometer probe in direct contact with sample or at specified standoff distance

- Initiate measurement via mobile application interface or device trigger

- Maintain stable position during the 3-5 second acquisition period

- Acquire triplicate spectra from different sample positions if sufficient material available

Data Analysis:

- Transmit acquired spectra to cloud processing service via mobile data or WiFi connection

- Await results from cloud-based pattern matching algorithms (typically 5-10 seconds)

- Review identification report showing primary substance, cutting agents, and match confidence

Quality Assurance:

- Reanalyze reference standard after every 10 samples to monitor instrumental drift

- Document any environmental factors that may affect results (temperature, humidity)

- For inconclusive results, collect sample for confirmatory laboratory analysis when possible

The following workflow diagram illustrates the qualitative identification process:

Protocol 2: Quantitative Analysis of Pharmaceutical Formulations

This protocol describes the procedure for quantifying active pharmaceutical ingredients (APIs) in formulations, with particular application to falsified medicine detection.

Materials and Calibration Standards

- Handheld NIR Spectrometer with spectral range covering 900-1700nm

- Reference API Standards of known purity for model development

- Placebo Formulations without API for matrix-specific calibration

- Chromatographic Reference Method (HPLC/GC-MS) for validation [27]

- Controlled Environment for model development to minimize temperature/humidity variation

Methodology for Quantitative Model Development

Calibration Set Preparation:

- Prepare 50-100 samples with API concentrations spanning expected range (e.g., 0-120% of label claim)

- For tablet analysis, create uniform mixtures of API and excipients at varying concentrations

- For liquid formulations, prepare standard solutions across concentration range

- Document exact composition of each calibration standard

Reference Method Analysis:

- Analyze all calibration samples using reference chromatographic method (HPLC or GC-MS)

- Establish reference values for API concentration in each sample

- Ensure reference methods follow validated protocols with documented accuracy and precision

Spectral Database Creation:

- Acquire NIR spectra for all calibration samples using standardized procedure

- For each sample, collect multiple spectra from different positions to account for heterogeneity

- Associate each spectrum with reference API concentration value

- Upload spectral database with reference values to cloud platform

Chemometric Model Development:

- Utilize cloud-based processing to develop quantitative models using algorithms such as:

- Partial Least Squares (PLS) regression

- Support Vector Machine (SVM) regression

- Artificial Neural Networks (ANN)

- Employ cross-validation techniques to optimize model parameters

- Validate model performance using independent test set not included in calibration

- Utilize cloud-based processing to develop quantitative models using algorithms such as:

Model Deployment:

- Deploy validated quantification model to field devices through cloud synchronization

- Establish ongoing performance monitoring with control charts tracking prediction accuracy

- Update models periodically as new formulations or API forms are encountered

For sildenafil quantification in falsified Viagra tablets, this approach has demonstrated the ability to achieve a Root Mean Square Error of Prediction (RMSEP) of 0.52% using neural network models, providing accuracy comparable to reference chromatographic methods [27].

Advanced Applications & Future Directions

The integration of cloud databases with handheld NIR spectrometers has enabled several advanced applications in drug analysis and forensic science while pointing toward promising future developments.

Intelligence-Led Harm Reduction

Cloud-connected handheld NIR systems have transformed harm reduction services by providing real-time drug composition data at the point of consumption. This capability allows service providers to:

- Issue immediate alerts when substances with unexpected potency or dangerous adulterants are detected

- Monitor trends in drug composition across geographical regions and time periods

- Provide data-driven education to users about the actual composition of substances in circulation

- Support public health responses to emerging drug threats through early warning systems [26]

The implementation of these systems in Switzerland has demonstrated practical utility in differentiating between personal use and trafficking quantities through rapid purity assessment, directly informing legal proceedings [6].

Federated Learning for Privacy-Preserving Collaboration

Emerging approaches in decentralized federated learning (DFL) address the challenge of collaborative model improvement while maintaining data privacy across institutions. This innovative framework:

- Enables multiple organizations to collaboratively enhance spectral models without sharing raw data

- Maintains data sovereignty for law enforcement agencies and forensic laboratories

- Uses peer-to-peer model updates instead of central data aggregation

- Achieves performance within 5-8% of centralized models while preserving privacy [30]

The DFL approach is particularly valuable in regulated environments where data sharing restrictions might otherwise limit model development, creating opportunities for cross-jurisdictional collaboration without compromising legal or privacy requirements.

Emerging Technological Capabilities

Future developments in cloud-connected handheld spectrometry are focusing on several key areas:

Expanded Substance Libraries: Continuous growth of reference databases, particularly for new psychoactive substances (NPS) that frequently emerge in drug markets [26]

Advanced Algorithms: Implementation of deep learning approaches for improved quantification and mixture analysis [30] [27]

Integration with Complementary Technologies: Combination of NIR with other portable analytical techniques to address limitations of individual methods [25]

Automated Reporting Systems: Direct integration with public health surveillance systems and law enforcement databases for real-time trend monitoring [6]

These advancements will further enhance the role of cloud databases and mobile applications in transforming handheld NIR spectrometers from simple identification tools into comprehensive chemical intelligence systems for field-based drug analysis.

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Field NIR Drug Analysis

| Item | Function/Purpose | Specification/Notes |

|---|---|---|

| NIR Spectrometer | Field-based spectral acquisition | 900-1700nm range; Bluetooth connectivity; battery operation [26] [22] |

| Mobile Application Platform | User interface and result display | Android/iOS compatibility; offline functionality [28] |

| Cloud Processing Service | Data analysis and model hosting | Machine learning capabilities; expandable libraries [28] [27] |

| Certified Reference Materials | System validation and calibration | Purity-certified drug standards; excipient mixtures [6] |

| Sampling Kits | Safe sample handling | Disposable containers; spatulas; personal protective equipment [22] |

| Reference Standards | Instrument calibration | Spectralon tiles; white ceramic references [25] |

| ddT-HP | ddT-HP, CAS:140132-19-0, MF:C10H14N2O6P+, MW:289.20 g/mol | Chemical Reagent |

| 1-Hydroxy-2-hexadecen-4-one | 1-Hydroxy-2-hexadecen-4-one|High-Purity Reference Standard |

The proliferation of illicit drugs and the increasing complexity of street samples, often adulterated with cutting agents, present significant challenges for law enforcement and public health agencies worldwide. In this context, the decentralization of forensic capabilities through handheld Near-Infrared (NIR) spectroscopy has emerged as a transformative approach for rapid, on-scene drug analysis. This technology enables the deployment of analytical capabilities directly to frontline personnel, providing results within seconds rather than days while minimizing operator exposure to potentially hazardous substances. The efficacy of handheld NIR technology hinges on the development of robust chemometric models that can accurately identify and quantify illicit substances such as cocaine, heroin, and methamphetamine in field conditions. These models must account for the considerable chemical variability in street samples, which are frequently mixed with various adulterants including levamisole, lidocaine, caffeine, and sugars [31]. The integration of machine learning algorithms with portable NIR spectroscopy represents a significant advancement over traditional colorimetric tests, which are prone to false positives and require physical handling of unknown substances [31]. This application note details the methodologies, validation protocols, and implementation frameworks for building reliable chemometric models tailored to the identification of illicit substances within the operational constraints of field deployment.

Handheld NIR spectrometers have undergone significant miniaturization while maintaining analytical performance comparable to benchtop instruments. Modern ultra-portable devices, such as the MicroNIR (Viavi Solutions Inc.) and NIRLAB's systems, typically weigh between 100-250 grams, operate in the 740-1650 nm wavelength range, and connect via Bluetooth to mobile applications for real-time analysis [19] [8]. These instruments utilize various wavelength selection technologies, including linear-variable filters with array detectors, MEMS-based FT-NIR systems, and Fabry-Perot etalons, with indium gallium arsenide (InGaAs) being the preferred detector material [8]. The primary advantages of handheld NIR systems for field drug analysis include non-invasive measurement through packaging materials, minimal sample preparation, rapid analysis (results in approximately 5 seconds), and reduced safety risks for operators [19] [31]. Unlike Raman spectroscopy, NIR is not affected by fluorescence interference, and the instruments are generally more affordable, facilitating wider deployment among law enforcement agencies [31]. The operational principle relies on measuring overtone and combination vibrations of characteristic molecular bonds (C-H, O-H, N-H, C=O, and C=C) present in illicit substances, though these signals occur at 10-100 times lower intensity compared to fundamental vibrations in the mid-infrared region [8].

Table 1: Performance Summary of Handheld NIR for Illicit Substance Identification

| Substance | Identification Accuracy | Sensitivity | Quantification Performance | Sample Size |

|---|---|---|---|---|

| Methamphetamine HCl | 98.4% | 96.6% | 99% of values within ±15% uncertainty | 608 specimens |

| Cocaine HCl | 97.5% | 93.5% | 99% of values within ±15% uncertainty | 2047 specimens |

| Heroin HCl | 99.2% | 91.3% | 99% of values within ±15% uncertainty | 608 specimens |

| Cocaine (Limited Range NIR) | 97% True Positive | 98% True Negative | Concentration and composition prediction | >10,000 spectra |

Critical Components of Chemometric Modeling

Spectral Database Development

The foundation of any robust chemometric model is a comprehensive spectral database containing chemically relevant specimens representative of the illicit drug market. This database must encompass not only pure substances but also common adulterants and mixtures encountered in street samples. Studies have demonstrated that chemical differences between drugs from different geographical regions must be incorporated into the database to ensure accurate model prediction [15]. A study utilizing the MicroNIR system compiled 608 illicit drug specimens seized by the Australian Federal Police, comprising primarily crystalline methamphetamine HCl, cocaine HCl, and heroin HCl, along with traditional drugs, new psychoactive substances, and adulterants, resulting in 3673 NIR scans for model development [15]. For cocaine detection specifically, research has shown that models based on more than 10,000 spectra from case samples can achieve 97% true-positive and 98% true-negative results [31]. The database should be continuously updated to adapt to changes in the illicit drug market, with metadata enriched by results from subsequent confirmatory laboratory analyses [31].

Data Preprocessing Techniques

Raw NIR spectra contain physical artifacts and noise that must be addressed through appropriate preprocessing to extract meaningful chemical information. The most widely used preprocessing techniques can be classified into scatter-correction methods and spectral derivatives [32]. Standard Normal Variate (SNV) is commonly employed to remove undesired spectral variations due to light scatter effects and variations in effective path length by normalizing each spectrum to zero mean and unit variance [32]. Multiplicative Scatter Correction (MSC) is another prevalent technique for compensating for scattering effects. For spectral derivatives, Savitzky-Golay (SG) polynomial derivative filters are frequently applied to enhance spectral features by reducing baseline offsets and isolating overlapping peaks [32]. The optimal selection and sequencing of these preprocessing methods are determined through iterative testing, with parameters such as polynomial order, window size, and derivative order carefully optimized for each specific application. The interactive preprocessing workflow in platforms like KNIME allows researchers to compare the effects of different methods and parameter settings before applying the transformations to the entire dataset [32].

Machine Learning Algorithms for Identification and Quantification

Chemometric modeling employs both unsupervised and supervised machine learning algorithms to extract meaningful patterns from spectral data. Principal Component Analysis (PCA) is commonly used for exploratory data analysis, outlier detection, and dimensionality reduction, transforming the original variables into a smaller set of principal components that capture the maximum variance in the data [32]. For qualitative identification (classification), algorithms such as Soft Independent Modeling of Class Analogy (SIMCA), Partial Least Squares-Discriminant Analysis (PLS-DA), k-Nearest Neighbors (kNN), Support Vector Machines (SVM), and Random Forest have demonstrated excellent performance [31]. For quantitative analysis, Partial Least Squares (PLS) regression is the most widely used algorithm for establishing relationships between spectral data and substance concentrations [15] [31]. More advanced approaches include multi-stage machine learning strategies that combine classification and regression models, such as using SIMCA for initial substance classification followed by dedicated PLS models for quantification of identified substances [31]. The integration of artificial intelligence, particularly convolutional neural networks (CNN), has shown promising results for complex pattern recognition in spectral data, with one study achieving 97.92% prediction accuracy for geographical identification of camelina oil using NIR spectra-based CNN models [33].

Experimental Protocol for Model Development

Sample Collection and Preparation

A representative set of drug specimens should be obtained from relevant law enforcement agencies, covering the expected variability in the target market. The protocol should include:

Sample Acquisition: Collect seized drug specimens with appropriate legal documentation and safety protocols. The study should include primarily target substances (methamphetamine HCl, cocaine HCl, heroin HCl) along with common adulterants and new psychoactive substances to assess selectivity [15].

Reference Analysis: All specimens must be analyzed using reference laboratory methods (typically GC-MS or LC-MS) to establish ground truth for identity and quantification values [15]. This reference data serves as the benchmark for training and validating the chemometric models.

Spectral Acquisition: Using the handheld NIR device (e.g., MicroNIR with NIRLAB infrastructure), scan each specimen according to manufacturer guidelines. Typical parameters include: spectral range of 950-1650 nm, 128-pixel linear InGaAs array detector, with multiple scans per sample to account for heterogeneity [15] [19].

Data Annotation: Each spectrum should be meticulously annotated with metadata including substance identity, concentration, sample origin, date of seizure, and identified adulterants. This metadata is crucial for assessing model performance across different sample characteristics.

Data Preprocessing Workflow

Implement a systematic preprocessing pipeline to enhance spectral quality and remove artifacts: