NIR Spectroscopy for Material Classification: Advanced Applications in Pharmaceutical and Biomedical Research

This article explores the transformative power of Near-Infrared (NIR) spectroscopy as a rapid, non-destructive analytical tool for material classification and identification.

NIR Spectroscopy for Material Classification: Advanced Applications in Pharmaceutical and Biomedical Research

Abstract

This article explores the transformative power of Near-Infrared (NIR) spectroscopy as a rapid, non-destructive analytical tool for material classification and identification. Tailored for researchers, scientists, and drug development professionals, it covers the foundational principles of NIR, details advanced methodological applications from counterfeit drug detection to personalized medicine, and provides practical troubleshooting for complex samples. By synthesizing recent advancements and comparative studies with other spectroscopic techniques, this review validates NIR's critical role in enhancing analytical precision and accelerating quality control in biomedical and clinical research.

Understanding NIR Spectroscopy: Core Principles and Analytical Strengths

The Fundamental Principles of Near-Infrared Light Interaction with Matter

Near-Infrared (NIR) spectroscopy has established itself as a powerful analytical technique for material classification and identification, finding extensive applications in pharmaceuticals, food science, agriculture, and polymer research. This analytical method operates on the fundamental principles of how light in the near-infrared region (approximately 780–2500 nm) interacts with molecular bonds in matter [1] [2]. The technique is characterized by its non-destructive nature, minimal sample preparation, and ability to provide rapid analytical results, making it particularly valuable for quality control and research applications where sample preservation is crucial [3] [2]. The interaction between NIR light and matter provides a unique molecular fingerprint that enables both qualitative identification and quantitative analysis of various chemical constituents [4].

Core Principles of NIR Spectroscopy

Electromagnetic Interactions

NIR spectroscopy utilizes the portion of the electromagnetic spectrum ranging from approximately 780 to 2500 nanometers, situated adjacent to the visible light region [1] [5]. When NIR radiation interacts with a sample, the photons can be absorbed, transmitted, reflected, or transflected depending on the molecular composition and physical properties of the material [4]. The amount of light absorbed at specific wavelengths follows the Beer-Lambert Law, which establishes the relationship between absorption and the concentration of chemical components in the sample [5] [4].

Molecular Vibration Fundamentals

Unlike UV-Vis spectroscopy that measures electronic transitions, NIR spectroscopy primarily probes molecular vibrations, specifically overtones and combination bands of fundamental molecular vibrations that occur in the mid-infrared region [1] [5] [4]. These vibrational transitions involve bonds with hydrogen atoms, such as:

The energy required to excite these molecular vibrations corresponds to the NIR region of the electromagnetic spectrum. When a molecule absorbs NIR energy, it undergoes vibrational transitions including stretching, bending, and rocking motions that create a unique spectral signature for different chemical compounds [5].

Table 1: Fundamental Molecular Vibrations Detected in NIR Spectroscopy

| Molecular Bond | Vibration Type | Characteristic Wavelength Range | Application Examples |

|---|---|---|---|

| O-H | Stretching (1st overtone) | 1400–1450 nm | Moisture content analysis [2] |

| C-H | Stretching (1st overtone) | 1600–1800 nm | Hydrocarbon analysis [5] |

| N-H | Stretching (1st overtone) | 1450–1550 nm | Protein quantification [6] |

| C-H | Combination bands | 2000–2500 nm | Polymer identification [7] |

Experimental Protocols

Sample Presentation Methods

The selection of appropriate sampling technique is critical for obtaining high-quality NIR spectra. The choice depends on the physical state and optical properties of the sample.

Transmission Method

Principle: NIR light passes through the sample, and the transmitted light is measured [2] [4]. Protocol:

- Place transparent liquid samples in NIR-transparent cuvettes with fixed pathlength (typically 1-10 mm)

- Ensure sample homogeneity to prevent light scattering artifacts

- Measure intensity of light transmitted through the sample relative to blank reference

- Calculate absorbance using the formula: A = -logâ‚â‚€(I/Iâ‚€), where I is transmitted intensity and Iâ‚€ is incident intensity [5]

Applications: Clear liquids, oils, fuels, and solutions [5] [4]

Transflectance Method

Principle: Combines transmission and reflectance measurements using a reflective background [2] [4]. Protocol:

- Place semi-transparent samples against a reflective surface (gold, aluminum, or specialized reflective materials)

- NIR light passes through the sample, reflects off the background, and passes through the sample again

- Use fixed pathlength cells with reflective backing

- Particularly useful for enhancing signal from thin films [7]

Applications: Gels, suspensions, thin films, and semi-transparent materials [2] [7]

Diffuse Reflectance Method

Principle: NIR light penetrates the sample surface, and the diffusely reflected light is collected and measured [2]. Protocol:

- Place solid samples in appropriate containers with transparent window

- Ensure consistent packing density for powdered materials

- Use rotational or movement techniques for heterogeneous samples to improve representativeness [4]

- Measure reflected light using integrating spheres or fiber optic probes

Applications: Powders, granules, tablets, soils, and opaque solid materials [6] [2]

Instrumentation and Spectral Acquisition

Protocol for Spectral Measurement: [6]

Instrument Calibration:

- Warm up spectrometer for 30 minutes to stabilize system

- Collect background spectrum using appropriate reference (Spectralon for reflectance, empty cell for transmission)

- Perform wavelength calibration using certified standards

Spectral Acquisition Parameters:

- Spectral range: 1000–1650 nm (typical for portable instruments) or 780–2500 nm (laboratory instruments)

- Resolution: 1–16 cmâ»Â¹ depending on application requirements

- Scans per spectrum: 32–64 scans to improve signal-to-noise ratio

- Temperature control: Maintain constant temperature (±1°C) during measurement

Quality Control:

- Monitor instrument performance using certified reference materials

- Check photometric accuracy and wavelength reproducibility regularly

- Document environmental conditions (temperature, humidity)

Table 2: Typical Instrument Parameters for NIR Spectroscopy

| Parameter | Benchtop Systems | Portable/Handheld Systems | Application Considerations |

|---|---|---|---|

| Wavelength Range | 780–2500 nm [1] | 900–1700 nm [6] | Wider range provides more molecular information |

| Spectral Resolution | 1–8 cmâ»Â¹ [8] | 4–16 cmâ»Â¹ [6] | Higher resolution needed for complex mixtures |

| Detector Type | InGaAs, PbS [5] | InGaAs array [6] | InGaAs offers better sensitivity for portable use |

| Light Source | Tungsten halogen [5] | Tungsten halogen LED [6] | Long-life sources reduce maintenance |

| Measurement Time | 10–60 seconds [2] | 5–30 seconds [7] | Balance between signal quality and throughput |

Data Analysis and Chemometrics

Spectral Preprocessing

Raw NIR spectra contain both chemical and physical information, requiring preprocessing to enhance chemical information while minimizing physical light scattering effects.

Standard Preprocessing Protocol: [6] [9]

Noise Reduction:

- Apply Savitzky-Golay smoothing (5–11 point window)

- Use moving average filters for high-frequency noise reduction

Scatter Correction:

- Standard Normal Variate (SNV) transformation to remove multiplicative interference

- Multiplicative Scatter Correction (MSC) to compensate for additive and multiplicative effects

Spectral Derivatives:

- Calculate first or second derivatives using Savitzky-Golay algorithm

- Second derivatives particularly effective for resolving overlapping peaks

- Typical parameters: 5–15 point window, 2nd–3rd order polynomial [9]

Multivariate Analysis for Material Classification

NIR spectroscopy relies on chemometrics for material classification and identification. The following workflow illustrates the standard analytical process:

Quantitative Analysis Protocol (PLSR)

Partial Least Squares Regression (PLSR) is the most widely used method for developing quantitative models in NIR spectroscopy [6] [4].

Experimental Protocol: [6] [9]

Reference Method Alignment:

- Analyze samples using reference analytical methods (e.g., Kjeldahl for protein [6], HPLC for APIs)

- Ensure representative sample selection covering expected concentration ranges

- Maintain consistent sample handling between NIR and reference analyses

Calibration Model Development:

- Split data into calibration (∼70%) and validation (∼30%) sets

- Use cross-validation (leave-one-out or k-fold) to optimize number of latent variables

- Evaluate model performance using R², RMSEP (Root Mean Square Error of Prediction), and RPD (Ratio of Performance to Deviation)

Model Validation:

- Test model with independent validation set not used in calibration

- Monitor model performance over time with control charts

- Update model when process or raw materials change

Qualitative Analysis Protocol

Material Classification and Identification utilizes pattern recognition methods to categorize samples based on spectral similarities.

Experimental Protocol: [7] [8]

Spectral Library Development:

- Collect spectra from verified reference materials

- Include expected variability (batch-to-batch, supplier variations)

- Apply standard preprocessing to all spectra

Classification Model Development:

- Principal Component Analysis (PCA) for exploratory analysis and outlier detection [8]

- Soft Independent Modeling of Class Analogy (SIMCA) for class modeling

- K-Nearest Neighbors (KNN) or Support Vector Machines (SVM) for discriminant analysis [8]

- Convolutional Neural Networks (CNN) for complex classification tasks [9]

Model Performance Metrics:

- Classification accuracy (>95% typically required)

- Sensitivity and specificity for each class

- Robustness to instrumental and environmental variations

Research Reagent Solutions

Table 3: Essential Materials and Reagents for NIR Spectroscopy Research

| Item | Specification/Function | Application Examples |

|---|---|---|

| NIR Spectrometer | Wavelength range: 780–2500 nm; Detector: InGaAs or PbS; Resolution: <16 cmâ»Â¹ [5] | All NIR applications |

| Reference Materials | Certified wavelength and reflectance standards (e.g., Polytetrafluoroethylene) [8] | Instrument calibration and validation |

| Sample Containers | NIR-transparent cuvettes (quartz, glass); Diffuse reflectance cups; Fiber optic probes | Sample presentation based on physical state |

| Chemometrics Software | Multivariate analysis packages (e.g., MATLAB, R, Python with scikit-learn) | Data preprocessing, model development, and validation |

| Reflective Backgrounds | Gold, aluminum, Teflon, Spectralon [7] | Signal enhancement for transflectance measurements of thin films |

| Sample Preparation Tools | Mortar and pestle, sieves (50–100 mesh), temperature control units [6] | Standardization of solid samples |

Application Examples in Material Classification

Pharmaceutical Raw Material Identification

Protocol for API and Excipient Verification: [3]

Spectral Library Development:

- Collect 30–50 spectra from each certified reference material

- Include multiple batches and suppliers where applicable

- Store spectra in validated database with metadata

Identification Model:

- Apply SNV preprocessing followed by second derivative transformation

- Develop PCA model using 3–6 principal components

- Establish classification boundaries using Mahalanobis distance or SIMCA

- Achieve >99% classification accuracy for GMP applications

Validation:

- Challenge model with blinded samples including known outliers

- Verify identification accuracy against orthogonal methods (HPLC, NMR)

- Document model performance for regulatory submissions

Polymer Classification for Recycling

Protocol for Plastic Waste Sorting: [7]

Sample Presentation:

- Use metallic reflective background (copper or aluminum) to enhance signal from thin films

- Standardize sample orientation and distance from probe

- Ensure clean sample surface to avoid contamination

Classification Model:

- Collect spectra from pure polyolefins and common contaminants

- Apply scatter correction (SNV) and spectral derivatives

- Develop KNN or SVM classifier with 5–10 nearest neighbors

- Achieve 95–98% accuracy for polyolefin vs. non-polyolefin classification

Field Deployment:

- Transfer model to handheld NIR instruments

- Train operators on standardized measurement protocol

- Implement regular performance verification with control samples

Food and Agricultural Products Analysis

Protocol for Protein Quantification in Nuts: [6]

Reference Analysis:

- Determine protein content using Kjeldahl method (N × 6.25)

- Analyze 100–200 representative samples covering expected range

- Ensure homogeneous sample preparation (grinding to <300 μm)

Model Development:

- Compare different sample states (whole, shelled, granulated)

- Apply outlier detection (PCA-Mahalanobis distance)

- Develop PLSR model with optimal latent variables (typically 5–8)

- Target R² > 0.85 and RPD > 2.0 for practical applications

Implementation:

- Validate with independent sample set

- Establish control limits for routine quality control

- Document method for regulatory compliance

Core Analytical Principles

Near-infrared (NIR) spectroscopy operates in the spectral region of 780 to 2500 nm, measuring molecular overtone and combination vibrations primarily associated with C-H, O-H, and N-H bonds [1] [10]. This foundational principle enables the technique's key strengths: rapid analysis, non-destructive measurement, and minimal sample preparation requirements.

The technique is classified as a secondary technology, requiring calibration against primary reference methods to build prediction models. Once calibrated, it delivers rapid, non-destructive analysis for routine use [11]. The non-destructive nature preserves sample integrity, allowing valuable materials to be reused in subsequent analyses or production processes [1] [12].

Quantitative Performance Data

Table 1: Quantitative Performance of NIR Spectroscopy Across Applications

| Application Area | Sample Matrix | Analytical Parameter | Performance Metrics | Reference Method |

|---|---|---|---|---|

| Pharmaceutical Analysis [13] | Bromobutyl Rubber | Mooney Viscosity, Bromine Number, Volatile Content | Analysis within 1 minute (multiple parameters) | Multiple Traditional QC Methods |

| Food Authentication [10] | Honey | Sugar Content (Glucose, Fructose) | R² > 0.95 | HPLC |

| Food Authentication [10] | Honey | Adulteration (Syrups, 5-10% levels) | >90% Classification Accuracy | Chemical Assays |

| Agricultural Products [14] | Grains (Barley, Chickpea, Sorghum) | Variety Classification | 89.72% - 96.14% Accuracy | DNA Analysis / Visual Inspection |

| Fuel Analysis [9] | Diesel | Cetane Number | Significant R² Improvement (vs. traditional models) | Primary Reference Methods |

| Polymer Recycling [13] | Polypropylene | Polyethylene Content | Fast measurement for recycled plastic feedstock | Traditional Chemical Analysis |

Table 2: Comparison of Analysis Speed: NIR vs. Traditional Methods

| Analytical Task | NIR Spectroscopy | Traditional Methods |

|---|---|---|

| Quality Control in Rubber [13] | ~1 minute for multiple parameters (Mooney viscosity, bromine, volatile content) | Hours to days for individual tests |

| Moisture Analysis [13] | Near-real-time (e.g., in ETFE) | Minutes to hours (e.g., Karl Fischer titration) |

| Honey Adulteration Screening [10] | Seconds to minutes | Days (HPLC, GC-MS) |

| Grain Variety Classification [14] | Rapid, in-field via portable spectrometers | Labor-intensive, subjective visual inspection |

Experimental Protocols

Protocol 1: Qualitative Analysis for Material Classification and Adulteration Detection

This protocol is adapted from methodologies for honey authentication [10] and grain classification [14], applicable for material identification research.

- Sample Preparation: For liquid samples, ensure homogeneity by mixing to eliminate air bubbles or crystals. For solid materials, present a uniform surface to the spectrometer. Minimal preparation is required; samples are typically analyzed directly [10].

- Spectral Acquisition:

- Utilize a benchtop or portable NIR spectrometer with an InGaAs detector for the 1100-2500 nm range.

- Equilibrate samples to a consistent temperature (e.g., 25°C) to minimize spectral variance.

- Acquire spectra in the NIR region (e.g., 1000-2500 nm) at a resolution of 4-16 cmâ»Â¹.

- Data Preprocessing:

- Apply preprocessing algorithms to minimize scattering effects and enhance features.

- Use Standard Normal Variate (SNV) or Multiplicative Scatter Correction (MSC).

- Employ Savitzky-Golay derivatives (e.g., first or second order) to resolve overlapping peaks.

- Chemometric Modeling & Validation:

- For classification (e.g., material type, origin), use Principal Component Analysis (PCA) for exploratory data analysis and to identify natural clustering.

- Develop a classification model using Linear Discriminant Analysis (LDA) or Soft Independent Modeling of Class Analogies (SIMCA).

- Validate the model using cross-validation and an external validation set. Report classification accuracy and use residual analysis to detect outliers.

Protocol 2: Quantitative Analysis Using Chemometrics

This protocol for quantifying component concentrations (e.g., moisture, active ingredients) is based on established practices in pharmaceutical and food analysis [11] [10].

- Calibration Model Development:

- Collect a calibration set of 40-60 samples that represent the expected chemical and physical variability of the material. For complex matrices, larger sets may be needed [11].

- Analyze all samples using both the NIR spectrometer and the primary reference method (e.g., HPLC, titration).

- Acquire and preprocess NIR spectra as detailed in Protocol 1.

- Model Building & Deployment:

- Use Partial Least Squares Regression (PLSR) to correlate the spectral data (X-matrix) with the reference analytical values (Y-matrix).

- Carefully select the number of latent variables to avoid overfitting. Validate the model using cross-validation, reporting Root Mean Square Error of Cross-Validation (RMSECV) and coefficient of determination (R²) [10].

- For routine analysis, new sample spectra are collected, preprocessed, and then applied to the validated PLSR model to predict the parameter of interest.

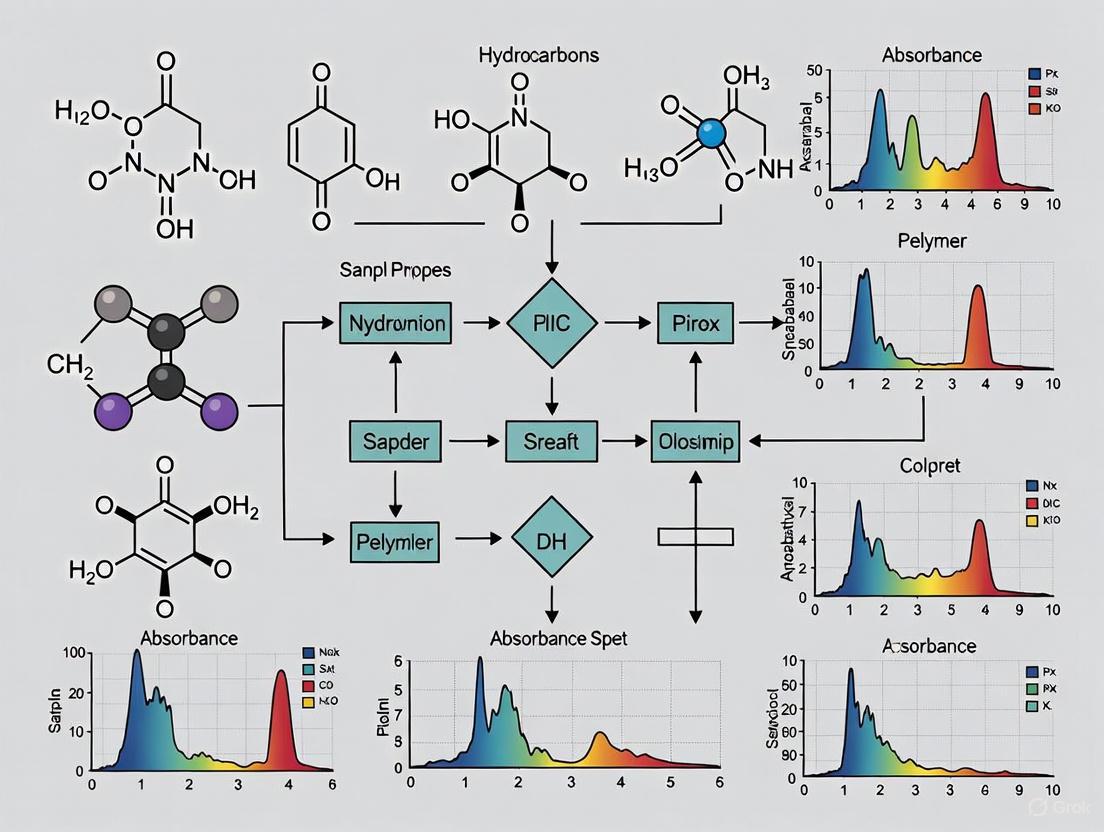

Diagram 1: NIR Analysis Workflow

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions and Materials

| Item | Function / Application |

|---|---|

| Portable NIR Spectrometer (e.g., SCIO Consumer Edition) [14] | Enables in-field, rapid spectral data collection (740-1070 nm range). Ideal for grain, polymer, or raw material analysis. |

| FT-NIR Spectrometer (Benchtop, e.g., Antaris II) [9] | Provides high-resolution spectral data in laboratory settings for method development and validation. |

| Fiber Optic Probes (Transmission, Reflectance, Transflectance) [11] | Allows for remote, non-destructive measurements of solid and liquid samples directly in containers or process streams. |

| Quartz Cuvettes / Flow-Through Cells [10] | Holds liquid samples (e.g., honey, oils, pharmaceutical solutions) for transmission analysis. |

| Chemometrics Software | Essential for data preprocessing (SNV, MSC, Derivatives), model building (PCA, PLSR), and classification (LDA, SIMCA). |

| Reference Materials & Calibration Sets | A representative set of samples with known properties, analyzed by primary methods, is critical for building accurate NIR calibration models [11]. |

| 8-Bromo-2-butylquinoline | 8-Bromo-2-butylquinoline|High-Purity Research Chemical |

| 4,4-Diethoxythian-3-amine | 4,4-Diethoxythian-3-amine|High-Purity|For Research Use |

Advanced Data Analysis & Methodological Considerations

Modern NIR analysis leverages advanced machine learning to overcome challenges. Convolutional Neural Networks (CNNs), such as the BEST-1DConvNet model, demonstrate superior predictive accuracy for quantitative analysis of diesel, gasoline, and milk compared to traditional support vector machine (SVM) approaches [9]. For complex classification tasks like grain variety identification, deep learning models like SpecFuseNet integrate attention mechanisms and residual learning to achieve high accuracy, outperforming PCA-based machine learning models [14].

Diagram 2: Data Analysis Pathways

Methodological choices significantly impact results. A 2025 reproducibility study involving 38 research teams found that while consensus is high for group-level analyses, data quality and analysis pipeline selection are critical for reliable individual-level results [15]. Key sources of variability include handling of poor-quality data, hemodynamic response modeling, and statistical inference techniques. This underscores the need for standardized protocols and transparent reporting to leverage NIR's analytical strengths fully [15].

Near-Infrared (NIR) spectroscopy has emerged as a powerful analytical technique spanning numerous scientific and industrial domains. Operating in the electromagnetic spectrum region of approximately 750 to 2500 nanometers, NIR spectroscopy utilizes the absorption properties of molecular bonds, particularly hydrogen-containing groups like C-H, O-H, and N-H, to generate unique spectral fingerprints for virtually any material [3]. The technique's foundation lies in measuring overtones and combinations of fundamental molecular vibrations, producing complex spectral data that requires sophisticated chemometric tools for interpretation [3] [16].

The non-destructive nature of NIR analysis, combined with its minimal sample preparation requirements, rapid analysis capabilities, and potential for real-time monitoring, has propelled its adoption across diverse fields [3] [12]. From its initial applications in agricultural and food science, NIR spectroscopy has expanded into pharmaceutical manufacturing, biomedical diagnostics, material science, and clinical medicine, demonstrating remarkable versatility and continuous technological evolution [3]. This expansion has been accelerated by advancements in spectrometer miniaturization, portable device development, and the integration of artificial intelligence and machine learning for enhanced data analysis [3] [17].

The following sections provide a comprehensive overview of NIR spectroscopy applications in pharmaceutical analysis and biomedical detection, detailing specific methodologies, experimental protocols, and key findings that demonstrate its transformative potential in material classification and identification research.

Pharmaceutical Analysis Applications

Current Applications in Drug Development and Quality Control

NIR spectroscopy has become indispensable in pharmaceutical analysis, fulfilling critical roles in quality control, process monitoring, and product development. Its applications span the entire pharmaceutical manufacturing continuum, from raw material identification to final product release testing [18] [16]. The technique's non-destructive character allows for analysis without complex sample preparation, enabling rapid decision-making in industrial settings while preserving sample integrity for additional testing if required [16].

Table 1: Pharmaceutical Applications of NIR Spectroscopy

| Application Domain | Specific Use Cases | Key Benefits | References |

|---|---|---|---|

| Raw Material Identification | Verification of active pharmaceutical ingredients (APIs) and excipients | Non-destructive, rapid screening against spectral libraries | [18] [16] |

| Process Monitoring | Real-time monitoring of blending, granulation, drying, and coating | Enables real-time release testing (RTRT) and Quality by Design (QbD) | [18] |

| Quality Control | Determination of content uniformity, moisture content, and solid forms | Reduced analysis time compared to traditional methods | [18] [16] |

| Counterfeit Detection | Identification of substandard and falsified pharmaceutical products | Rapid screening without destroying packaging | [19] |

A particularly significant advancement is the integration of NIR spectroscopy into Process Analytical Technology (PAT) frameworks, where it serves as a robust tool for real-time monitoring and control of critical process parameters [18]. In continuous manufacturing processes, NIR systems provide immediate feedback on granulation endpoints, blend uniformity, and tablet coating thickness, ensuring consistent product quality while reducing manufacturing losses and optimizing resource utilization [18]. The recent development of portable NIR instruments has further expanded these applications, allowing for decentralized testing and on-site quality verification in warehouse and distribution settings [18].

Experimental Protocol: Content Uniformity Analysis in Tablets

Principle: This method utilizes diffuse reflectance NIR spectroscopy to non-destructively quantify API concentration in individual tablets, ensuring uniform drug distribution throughout the batch.

Materials and Equipment:

- FT-NIR or dispersive NIR spectrometer with reflectance probe

- Representative tablet samples from different locations in the batch

- Certified reference standards with known API concentrations

- Chemometric software for model development and validation

Procedure:

- Instrument Calibration: Ensure the NIR spectrometer is warmed up and wavelength accuracy verified using NIST-traceable standards (e.g., SRM 2035 or SRM 2065) [16].

Reference Method Analysis: Determine API concentration in a representative subset of tablets (n=20-30) using a validated reference method (typically HPLC).

Spectral Acquisition: Collect NIR spectra from both sides of each tablet in the calibration set using a reflectance probe. Average multiple scans (typically 32-64) to improve signal-to-noise ratio.

Data Preprocessing: Apply appropriate preprocessing techniques to minimize physical and spectral variations:

- Standard Normal Variate (SNV) or Multiplicative Scatter Correction (MSC) to reduce light scattering effects

- Savitzky-Golay derivatives (1st or 2nd) to enhance spectral features and remove baseline offsets

- Vector normalization to standardize spectral intensity [16]

Calibration Model Development:

- Use Partial Least Squares (PLS) regression to correlate preprocessed spectra with reference API values

- Divide data into training (70%), validation (15%), and test (15%) sets

- Optimize the number of latent variables to prevent overfitting

- Validate model performance using cross-validation and external test sets

Model Validation: Assess model performance using statistical parameters:

- Coefficient of determination (R²) > 0.90

- Root Mean Square Error of Calibration (RMSEC)

- Root Mean Square Error of Prediction (RMSEP)

- Ratio of Performance to Deviation (RPD) > 3 for robust models [16]

Routine Analysis: Implement the validated model for rapid screening of production samples. Monitor model performance periodically with control charts and recalibrate when process changes occur.

Biomedical Detection Applications

Emerging Applications in Disease Diagnosis and Monitoring

The application of NIR spectroscopy in biomedical detection represents a rapidly advancing frontier, particularly with the development of specialized techniques like broadband NIRS (bNIRS) for monitoring metabolic activity and innovative approaches for disease biomarker detection [20]. Biomedical applications leverage the technique's non-invasive character and sensitivity to molecular composition changes in biological samples, including tissues, biofluids, and cellular systems.

Table 2: Biomedical Applications of NIR Spectroscopy

| Application Domain | Specific Use Cases | Key Findings/Performance | References |

|---|---|---|---|

| Cerebral Metabolism Monitoring | Measuring cytochrome c-oxidase (CCO) for oxidative metabolism | bNIRS systems cataloged with spectral range 600-1000 nm; enables monitoring of metabolic impairments | [20] |

| Viral Infection Detection | Hepatitis C virus (HCV) detection in serum samples | Combined with machine learning, achieved 72.2% accuracy and AUC-ROC of 0.850 | [21] |

| Neurotransmitter Detection | Substance P quantification in saliva of COPD patients | Strong agreement with ELISA (p>0.05); enables non-invasive monitoring | [22] |

| Tissue Analysis | Cancer detection and tissue characterization | Identification of disease biomarkers through spectral analysis | [23] [17] |

Broadband NIRS (bNIRS) has shown particular promise in clinical neuroscience for monitoring cytochrome c-oxidase (CCO), a key enzyme in the mitochondrial respiratory chain that serves as a direct marker of cellular metabolic activity [20]. Unlike conventional NIRS systems that measure hemoglobin oxygenation as an indirect metabolic indicator, bNIRS utilizes a broader spectral range (typically 600-1000 nm) with hundreds of wavelengths to specifically resolve the oxidation state of CCO, providing a more direct assessment of tissue energy metabolism [20]. This approach has significant potential for monitoring cerebral metabolism in vulnerable populations, including neonates and patients with neurological disorders, where traditional neuroimaging methods like PET and MRS present limitations due to ionizing radiation, cost, or logistical constraints [20].

Experimental Protocol: HCV Detection in Serum Using NIRS and Machine Learning

Principle: This protocol combines NIR spectroscopy with machine learning to detect Hepatitis C virus (HCV) in serum samples based on their global molecular fingerprint, offering a rapid alternative to PCR-based methods.

Materials and Equipment:

- NIR spectrometer covering 1000-2500 nm range

- Sterile borosilicate glass vials

- Serum samples from patients and controls

- Centrifuge and refrigeration equipment

- Computational resources for machine learning implementation

Procedure:

- Sample Preparation:

- Thaw frozen serum aliquots at room temperature

- Transfer 70 μL to sterile borosilicate glass vials under biosafety hood

- Maintain samples on ice or at <4°C until spectral acquisition [21]

Spectral Acquisition:

- Collect spectra in the 1000-2500 nm range (or instrument-specific range)

- Use a sufficient number of scans (e.g., 64) to ensure adequate signal-to-noise ratio

- Include background and reference measurements regularly

Data Preprocessing:

Feature Selection:

- Implement L1-regularized Logistic Regression (L1-LR) to identify most informative wavelengths

- Focus on biologically relevant regions (e.g., 1150 nm, 1410 nm, 1927 nm associated with water molecular states) [21]

- Validate selected features through permutation importance tests

Model Development and Integration with Clinical Data:

- Combine selected spectral features with routine clinical markers (GPT, GOT, GGT, etc.)

- Train Random Forest classifier on integrated dataset

- Optimize hyperparameters using cross-validation

- Evaluate performance using accuracy, AUC-ROC, sensitivity, and specificity [21]

Model Validation:

- Employ stratified k-fold cross-validation (typically k=10)

- Use independent test set not exposed during model development

- Assess clinical utility through decision curve analysis

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of NIR spectroscopy applications requires specific materials and computational tools tailored to each domain. The following table summarizes essential components for pharmaceutical and biomedical research applications.

Table 3: Essential Research Materials and Reagents for NIR Spectroscopy Applications

| Category | Specific Items | Function/Application | Examples/Specifications | |

|---|---|---|---|---|

| Spectrometer Systems | Benchtop FT-NIR systems | High-resolution laboratory analysis | Fourier-transform systems for pharmaceutical QA/QC | [23] |

| Portable/miniaturized NIR | Field analysis and point-of-care testing | MEMS-based systems for on-site material identification | [3] [23] | |

| Calibration Standards | NIST-traceable wavelength standards | Instrument calibration and validation | SRM 2035 and SRM 2065 for wavelength accuracy | [16] |

| Chemical reference materials | Quantitative model development | Certified API standards for pharmaceutical applications | [16] | |

| Sample Handling | Reflectance probes | Non-contact measurements of solids and tablets | Fiber-optic probes for process monitoring | [18] |

| Quartz cuvettes | Liquid sample analysis | Required for transmission measurements of biofluids | [22] | |

| Computational Tools | Chemometric software | Data preprocessing and model development | PLS, PCA, SVM algorithms for spectral analysis | [12] [16] |

| Machine learning libraries | Advanced pattern recognition | Random Forest, CNN for classification tasks | [21] [22] | |

| Biological Reagents | ELISA kits | Reference method for biomarker validation | Human Substance P kit MBS3800193 | [22] |

| Protease inhibitors | Sample preservation for biofluid analysis | Added to saliva samples before NIR analysis | [22] | |

| 1h-Oxepino[4,5-d]imidazole | 1h-Oxepino[4,5-d]imidazole|CAS 873917-84-1 | 1h-Oxepino[4,5-d]imidazole (CAS 873917-84-1) is a fused heterocycle for pharmaceutical and materials research. This product is For Research Use Only (RUO). Not for human or personal use. | Bench Chemicals | |

| Gold;yttrium | Gold;yttrium, CAS:921765-27-7, MF:Au5Y, MW:1073.7387 g/mol | Chemical Reagent | Bench Chemicals |

Workflow Visualization

The following diagram illustrates the generalized workflow for developing and implementing NIR spectroscopy methods in pharmaceutical and biomedical applications, highlighting critical decision points and validation requirements.

The integration of machine learning with NIR spectroscopy has created powerful analytical pipelines for complex biomedical classification tasks, as illustrated in the following computational workflow.

Future Perspectives and Challenges

The future development of NIR spectroscopy in pharmaceutical and biomedical applications is shaped by several converging trends. Miniaturization of spectrometer components continues to advance, with microelectromechanical systems (MEMS) and compact charge-coupled device (CCD) based sensors enabling truly portable and eventually wearable NIR devices [20] [23]. This evolution facilitates the transition of NIR analysis from centralized laboratories to point-of-care settings, field applications, and even home-use medical devices. The global NIR spectroscopy market reflects this expansion, projected to grow by USD 862 million during 2025-2029, representing a compound annual growth rate of 14.7% [23].

The integration of artificial intelligence and machine learning with NIR spectroscopy represents another significant frontier [3] [17]. Advanced algorithms including convolutional neural networks (CNNs), random forests, and support vector machines (SVMs) are increasingly employed to extract subtle patterns from complex spectral data that might escape conventional chemometric approaches [21] [22]. These techniques are particularly valuable in biomedical applications where disease-specific spectral signatures may be obscured by dominant biological background signals. The emerging field of aquaphotomics, which focuses on water molecular structures and their interactions with solutes, further enhances these capabilities by providing a framework for understanding how water spectral patterns reflect the composition of biological samples [21] [17].

Despite these promising developments, challenges remain in the widespread adoption of NIR spectroscopy, particularly in regulated environments. The high cost of high-performance instruments continues to present barriers for some organizations, though this is gradually changing with technological advancements and increased competition [23]. Method transfer between instruments remains challenging due to instrumental differences, requiring sophisticated standardization approaches and robust calibration protocols [16]. Additionally, the implementation of NIR methods in clinical diagnostics requires extensive validation against gold standard methods and demonstration of clinical utility beyond analytical performance [22]. As these challenges are systematically addressed through technological innovation and methodological refinements, NIR spectroscopy is poised to expand its transformative impact across pharmaceutical, biomedical, and clinical domains.

Molecular Information and Spectral Fingerprints for Material Identification

Near-Infrared (NIR) spectroscopy has emerged as a powerful analytical technique for material identification and classification, offering rapid, non-destructive analysis across diverse scientific and industrial fields. This vibrational spectroscopy method operates in the electromagnetic spectrum region of 780 to 2500 nanometers (12,820 to 4000 cmâ»Â¹), bridging the gap between visible and mid-infrared light [12] [24]. The foundation of NIR spectroscopy lies in probing molecular vibrations, specifically the overtones and combinations of fundamental vibrations involving hydrogen-containing bonds such as C-H, O-H, and N-H [3] [24]. These complex vibrational patterns create unique spectral fingerprints that provide detailed information about the molecular composition and structure of analyzed materials.

The application of NIR spectroscopy has expanded significantly since its emergence as a practical analytical tool in the 1960s, driven by advancements in instrumentation, detector technology, and computational methods [3]. Today, it serves as an indispensable tool for researchers and drug development professionals seeking to characterize materials without altering or destroying samples, making it particularly valuable for quality control, raw material verification, and process monitoring in pharmaceutical development and manufacturing.

Fundamental Principles of NIR Spectroscopy

Molecular Origins of Spectral Fingerprints

NIR spectroscopy probes the anharmonic nature of molecular vibrations, specifically measuring overtone and combination bands that arise from fundamental molecular vibrations. When NIR radiation interacts with a material, chemical bonds absorb specific wavelengths characteristic of their molecular structure and environment. The most informative signals originate from functional groups containing hydrogen atoms due to their relatively large anharmonicity [24]. These include:

- C-H bonds in carbohydrates, lipids, and organic compounds

- O-H bonds in water, alcohols, and carbohydrates

- N-H bonds in proteins and amines [12]

The resulting NIR spectrum represents a highly specific molecular fingerprint that reflects the complete chemical composition of the sample. Table 1 summarizes the primary vibrational modes and their corresponding spectral regions that contribute to these identifying fingerprints.

Table 1: Characteristic NIR Absorption Bands for Biological and Pharmaceutical Materials

| Wavenumber (cmâ»Â¹) | Wavelength (nm) | Vibrational Mode Assignment | Characteristic Compounds |

|---|---|---|---|

| 8250 | 1210 | 3ν C–H str. | C-H rich compounds (carbohydrates, lipids) |

| 6980 | 1435 | 2ν N–H str. | Proteins |

| 6750 | 1480 | 2ν O–H str. | Carbohydrates, alcohols, polyphenols |

| 6200-5800 | 1610-1725 | 2ν C–H str. | Carbohydrates, lipids |

| 4880 | 2050 | ν N–H sym. str. + amide II | Proteins |

| 4645 | 2155 | Amide I + amide III | Proteins |

| 4440 | 2255 | ν O–H str. + O–H def. | Carbohydrates, alcohols, polyphenols |

Abbreviations: str. - stretching; def. - deformation; sym. - symmetric; ν - fundamental vibration [24]

Comparative Advantages for Material Identification

NIR spectroscopy offers several distinct advantages that make it particularly suitable for material identification in research and quality control environments:

- Non-destructive analysis: Samples remain unaltered and can be reused for further testing [3] [12]

- Minimal sample preparation: Eliminates complex extraction or derivatization procedures [3]

- Rapid analysis: Provides results in seconds to minutes [3]

- Versatile sampling: Analyzes solids, liquids, and gases through various measurement modes (reflectance, transmission, transflectance) [3] [25]

- Suitable for aqueous samples: Water signals, while present, do not dominate the spectrum as severely as in mid-IR spectroscopy [24]

However, the technique also presents challenges, including complex spectral interpretation due to overlapping bands and the necessity for robust chemometric models for accurate analysis [3] [12]. The initial setup and method development require significant expertise, though these investments are offset by the rapid analysis capabilities and minimal consumable requirements in the long term [3].

Applications in Material Identification and Classification

Pharmaceutical Analysis and Drug Development

NIR spectroscopy has become an established tool for pharmaceutical analysis, particularly for the identification of active pharmaceutical ingredients (APIs) and excipients. The technique can successfully distinguish between APIs and excipients based on their distinct spectral signatures in specific regions. Notably, the 1550–1900 cmâ»Â¹ spectral region has been identified as particularly valuable for API identity testing, as common excipients typically show no Raman signals in this region, while APIs display unique vibrations [26]. This specific "fingerprint within a fingerprint" enables unambiguous identification of pharmaceutical compounds even in complex formulations.

Applications in pharmaceutical development include:

- Raw material identification and verification [3]

- Active pharmaceutical ingredient (API) quantification [26]

- Content uniformity assessment [26]

- Counterfeit drug detection [26] [19]

- Process Analytical Technology (PAT) for manufacturing monitoring [3]

Food and Agricultural Products

NIR spectroscopy has demonstrated significant utility in the classification and authentication of food and agricultural products. The technique enables rapid differentiation of products based on geographical origin, processing methods, and authenticity. Recent research has combined NIR spectroscopy with artificial intelligence to achieve exceptional classification accuracy. For instance, a study on tea classification utilizing a fine-tuned 1DResNet model demonstrated a 4.32% improvement in accuracy over traditional machine learning methods, achieving high classification rates for different tea varieties [27].

Additional applications in food science include:

- Geographical origin verification: NIR spectroscopy combined with support vector machine (SVM) models achieved 97.08% prediction accuracy for tracing tea oil origins [12]

- Adulteration detection: Identification of adulterated edible oils with R² values exceeding 0.9311 [12]

- Quality parameter assessment: Measurement of moisture, protein, fat, and carbohydrate content [12] [25]

- Genetically Modified Organism (GMO) identification: Discrimination of genetically modified crops without destructive sampling [25]

Industrial and Specialty Materials

The application of NIR spectroscopy extends to various industrial sectors, where it provides rapid material identification and process monitoring capabilities. In the leather industry, NIR spectroscopy combined with principal component analysis (PCA) successfully differentiated between traditional and innovative tanning processes, demonstrating its utility for quality control in complex manufacturing environments [28]. The technique has also been applied in polymer science, biotechnology, and environmental monitoring [3].

Table 2: Quantitative Performance of NIR Spectroscopy in Various Application Domains

| Application Domain | Analytical Task | Methodology | Performance Metrics |

|---|---|---|---|

| Pharmaceutical | API Identity Testing | Raman Spectral Fingerprinting (1550-1900 cmâ»Â¹) | Unique identifiers for all 15 APIs tested with no excipient interference [26] |

| Food Authentication | Tea Classification | NIRS + 1DResNet AI Model | >4.32% improvement in accuracy vs. traditional ML methods [27] |

| Food Adulteration | Peanut Oil Adulteration | NIRS + PLS Modeling | R² > 0.9311, RMSECV < 4.43 [12] |

| Agricultural | Geographical Tracing of Tea Oil | NIRS + Convolutional Neural Network | 97.92% prediction accuracy [12] |

| Industrial | Leather Tanning Process Control | NIRS + Principal Component Analysis | Successful differentiation of traditional and innovative tanning methods [28] |

Experimental Protocols for Material Identification

Protocol 1: Raw Material Identification of Pharmaceutical Ingredients

Principle: This protocol describes the identification and verification of pharmaceutical raw materials using NIR spectroscopy, focusing on the distinctive spectral fingerprints of APIs and excipients in the 1550-1900 cmâ»Â¹ region [26].

Materials and Equipment:

- FT-NIR spectrometer equipped with diffuse reflectance probe

- Reference standards of APIs and excipients

- Chemometric software (e.g., Unscrambler, SIMCA)

- Sample cups or holders appropriate for powder analysis

Procedure:

- Instrument Calibration: Verify spectrometer performance using predefined calibration standards according to manufacturer specifications. Ensure wavelength accuracy and photometric linearity [26].

- Spectral Library Development:

- Collect NIR spectra of verified reference materials (APIs and excipients)

- For each material, acquire triplicate spectra from different lots when possible

- Apply standard normal variate (SNV) transformation to reduce scattering effects

- Develop a principal component analysis (PCA) model to define material clusters [26]

- Unknown Sample Analysis:

- Present unknown sample to the spectrometer using consistent packing density

- Acquire triplicate spectra using the same parameters as library development

- Preprocess spectra using the same methods applied to the reference library

- Data Analysis and Identification:

- Project unknown spectrum into the established PCA model

- Calculate Mahalanobis distance to defined material clusters

- Identify material based on closest spectral match and similarity metrics

- Report match quality with confidence indicators

Validation: Regularly challenge the method with known verification standards to ensure ongoing accuracy. Maintain records of all identifications for quality assurance.

Protocol 2: Non-Destructive Classification of Agricultural Products

Principle: This protocol utilizes NIR spectroscopy combined with chemometric analysis for rapid, non-destructive classification of tea varieties, demonstrating the application of advanced AI methods to spectral fingerprinting [27].

Materials and Equipment:

- Portable NIR spectrometer (908-1676 nm range)

- Integration sphere or diffuse reflectance accessory

- Fine-tuned 1DResNet model implementation

- Data preprocessing software (Python, MATLAB, or proprietary solutions)

Procedure:

- Sample Preparation:

- Present intact tea leaves without grinding or processing

- Ensure consistent presentation geometry for all samples

- Maintain constant environmental conditions (temperature, humidity)

- Spectral Acquisition:

- Acquire spectra in diffuse reflectance mode

- Set scan count to 600 accumulations to improve signal-to-noise ratio

- Collect triplicate spectra from different positions on each sample

- Include background reference scans regularly [27]

- Data Preprocessing:

- Apply Standard Normal Variate (SNV) transformation to minimize scattering effects

- Implement Savitzky-Golay smoothing (2nd order polynomial, 9-point window)

- Perform multiplicative scatter correction (MSC) if necessary

- Employ first or second derivatives to enhance spectral features [27]

- Model Application and Classification:

- Input preprocessed spectra into the fine-tuned 1DResNet model

- Utilize transfer learning capabilities for adapting to new varieties

- Generate classification predictions with confidence scores

- Apply k-nearest neighbor (KNN) verification for ambiguous results [27]

Validation: Validate model performance with independent test sets not used in training. Establish confidence thresholds for classification acceptance and implement routine model updating protocols.

Visualization of Experimental Workflows

NIR-Based Material Identification Workflow

The following diagram illustrates the comprehensive workflow for material identification using NIR spectroscopy, from sample preparation through final identification:

Chemometric Data Processing Pathway

The following diagram details the chemometric data processing pathway essential for transforming raw spectral data into meaningful material identifications:

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for NIR Spectral Analysis

| Item | Function/Application | Technical Specifications | Application Notes |

|---|---|---|---|

| NIR Spectrometer | Spectral data acquisition | Range: 780-2500 nm; Resolution: 4-16 cmâ»Â¹; Detector: InGaAs, Si | Portable units available for field use; Benchtop systems offer higher resolution [27] [28] |

| Reference Materials | Method calibration & validation | Certified reference materials with documented purity | Essential for building spectral libraries; should represent expected sample variability [26] |

| Chemometric Software | Data processing & modeling | PCA, PLS, SVM, machine learning algorithms | Open-source (Python, R) or commercial (Unscrambler, SIMCA) options available [12] [27] |

| Sample Presentation Accessories | Consistent spectral acquisition | Diffuse reflectance cups, transmission cells, fiber optic probes | Selection depends on sample form (solid, liquid, powder) and measurement mode [26] [29] |

| Spectral Preprocessing Tools | Data quality enhancement | SNV, MSC, derivative filters, smoothing algorithms | Critical for removing physical light scattering effects and enhancing chemical information [12] [25] |

| C13H8N4Se | C13H8N4Se, MF:C13H7N4Se, MW:298.19 g/mol | Chemical Reagent | Bench Chemicals |

| C14H25N5O5S | C14H25N5O5S | High-purity C14H25N5O5S for research applications. This product is For Research Use Only. Not for human or veterinary diagnostic or therapeutic use. | Bench Chemicals |

NIR spectroscopy represents a powerful analytical technique that provides detailed molecular information through unique spectral fingerprints, enabling accurate material identification across diverse applications. The combination of NIR spectroscopy with advanced chemometric methods and artificial intelligence creates a robust framework for material classification that balances analytical performance with practical considerations of speed, cost, and non-destructive operation. As instrumentation continues to advance toward miniaturization and improved accessibility, and data analysis methods become increasingly sophisticated through machine learning integration, the application of NIR spectroscopy for material identification is poised for continued expansion across research and industrial sectors. For drug development professionals specifically, the technique offers compelling advantages for raw material verification, process monitoring, and quality control that align with the implementation of Quality by Design (QbD) principles and Process Analytical Technology (PAT) initiatives in pharmaceutical manufacturing.

Advanced NIR Applications: From Drug Analysis to Food Authentication

Counterfeit Drug Identification and Pharmaceutical Quality Control

Near-infrared (NIR) spectroscopy has emerged as a powerful analytical technique for pharmaceutical quality control and counterfeit drug identification. This non-destructive method provides rapid chemical and physical characterization of materials without sample preparation, making it ideal for both laboratory and field applications [30] [31]. The technique measures molecular overtone and combination vibrations, primarily from C-H, N-H, and O-H bonds, which are present in most active pharmaceutical ingredients (APIs) and excipients [32].

The threat of substandard and falsified (SF) medicines represents a significant global health challenge, with an estimated 10.5% of medicines in low- and middle-income countries being SF, contributing to approximately 1 million deaths annually [33]. Counterfeit drugs range from products containing no API to those with incorrect ingredients, wrong dosages, or improper excipients [31] [34]. NIR spectroscopy addresses this problem through rapid spectral fingerprinting that can detect deviations from genuine pharmaceutical products across the entire supply chain.

Principles of NIR Spectroscopy in Pharmaceutical Analysis

NIR spectroscopy operates in the spectral range of 12500–4000 cmâ»Â¹ (833–1330 nm), where molecular overtone and combination vibrations occur [31]. This region provides distinct advantages for pharmaceutical analysis including minimal sample preparation, non-destructive testing, and the ability to analyze samples through packaging [35]. The technique can be deployed in various modes including diffuse reflectance for solids and transmission for liquids, with specialized approaches like diffuse transmission providing information about the inner composition of intact tablets [30].

The application of chemometrics is essential for interpreting NIR spectral data. Multivariate analysis techniques including Principal Component Analysis (PCA), Partial Least Squares (PLS) regression, and various classification algorithms enable the extraction of meaningful information from complex spectral data [36] [37] [31]. These mathematical approaches facilitate both qualitative identification (verifying material identity) and quantitative analysis (determining component concentrations) of pharmaceutical products.

Table 1: Key NIR Spectroscopy Advantages for Pharmaceutical Quality Control

| Advantage | Impact on Pharmaceutical Analysis | Application Examples |

|---|---|---|

| Non-destructive | Preserves sample integrity; allows further testing | Analysis of high-value products like lyophilizates [30] |

| Rapid analysis | Results in seconds versus hours for HPLC | Raw material identification (100% testing requirement) [30] |

| No sample preparation | Reduces analysis time and potential errors | Direct measurement of intact tablets [30] [31] |

| Through-package analysis | Enables supply chain verification without compromising packaging | Counterfeit detection in blister packs [35] [34] |

| Multi-parameter determination | Simultaneous measurement of multiple quality attributes | API content, moisture, content uniformity in single measurement [30] |

Experimental Validation and Performance Data

Counterfeit Detection Capabilities

Multiple studies have demonstrated the effectiveness of NIR spectroscopy for detecting counterfeit pharmaceutical products. A comprehensive evaluation of handheld NIR spectrometers for counterfeit tablet detection achieved 100% identification of challenging samples (counterfeits and generics) when using Support Vector Machine (SVM) classifiers combined with class name check and correlation distance [36]. The study utilized a large database containing nearly all tablets produced by a pharmaceutical firm to develop robust classification models.

Recent research compared NIR spectrometer performance with High-Performance Liquid Chromatography (HPLC) for detecting substandard and falsified medicines in Nigeria. The study analyzed 246 drug samples across multiple therapeutic categories, finding that 25% of samples failed HPLC testing [33]. While the NIR device showed variable performance across drug classes, it demonstrated particular utility for screening applications where rapid results are prioritized.

Table 2: Performance Metrics of NIR Spectroscopy in Pharmaceutical Applications

| Application | Performance Metrics | Reference Method Comparison |

|---|---|---|

| Counterfeit tablet detection | 100% correct identification of counterfeits and generics with SVM classifier [36] | Visual inspection and chromatography |

| API quantification in fixed-dose combination | Accuracy profiles with β-expectation tolerance limits within ±5% acceptance limits [37] | Requires two separate HPLC methods for artesunate and azithromycin |

| Handheld spectrometer performance | 96.0% correct identification in validation (swNIR); 91.1% (cNIR) [36] | Laboratory spectrometer methods |

| Lyophilized product moisture analysis | Suitable for moisture range 0.5-3.0%; meets industry requirement of <2.0% [30] | Karl Fischer titration and loss on drying |

| Blend homogeneity monitoring | Determines optimal blending endpoint through spectral standard deviation [30] | Traditional end-point testing and HPLC |

Quantitative Analysis of APIs

NIR spectroscopy has been successfully applied to quantitative analysis of active pharmaceutical ingredients in various dosage forms. A specific study developing a method for artesunate and azithromycin in hard gelatin capsules demonstrated that NIRS could replace two different HPLC methods typically required for this fixed-dose combination [37]. The method utilized Partial Least Squares (PLS) regression models with spectral pre-processing including Standard Normal Variate (SNV) and first Savitzky-Golay derivative, achieving results compliant with accuracy profile requirements (±5% acceptance limits) [37].

The technique is particularly valuable for formulations where traditional chromatographic methods face challenges, such as compounds with poor UV chromophores or incompatible stability properties with mobile phases. The non-destructive nature also allows the same sample to be used for additional testing, preserving valuable reference materials and clinical trial samples.

Detailed Experimental Protocols

Raw Material Identification Protocol

Scope: This protocol describes the procedure for identity testing of incoming raw materials using NIR spectroscopy, compliant with USP <1119> and European Pharmacopoeia guidelines [30] [35].

Materials and Equipment:

- FT-NIR spectrometer with diffuse reflectance accessory

- Quartz sample vials or glass vials with minimal NIR absorption

- Reference standards for all materials to be tested

- Validated chemometric software for spectral library management

Procedure:

- Instrument Qualification: Verify wavelength accuracy, photometric noise, and reproducibility using manufacturer-specified standards prior to analysis [30].

- Spectral Library Development:

- Collect spectra of authenticated reference materials (minimum 3 batches from different lots)

- For each material, acquire 32 scans at 8 cmâ»Â¹ resolution over 4000-9999 cmâ»Â¹ range

- Apply standard normal variate (SNV) and detrending to minimize physical variability effects

- Develop PCA or SIMCA models for material classification

- Sample Analysis:

- Present sample in appropriate container with consistent packing density

- Acquire triplicate spectra with sample repositioning between measurements

- Pre-process unknown spectra identically to library spectra

- Compare against spectral library using correlation algorithms or Mahalanobis distance

- Acceptance Criteria: Unknown material spectrum must match library reference with correlation coefficient ≥0.95 and pass statistical confidence thresholds established during validation.

Troubleshooting:

- If poor spectral match occurs, verify sample presentation consistency and instrument performance

- For hydrated materials, ensure library includes appropriate hydration state variants

- When new suppliers are qualified, add representative samples to spectral library

Counterfeit Tablet Detection Protocol

Scope: This protocol details the procedure for detecting counterfeit pharmaceutical tablets using handheld NIR spectrometers, suitable for field use and supply chain monitoring [36] [31] [34].

Materials and Equipment:

- Handheld NIR spectrometer (short wavelength or classical NIR range)

- Customized nest for consistent tablet positioning

- Authentic reference tablets from verified sources (multiple batches)

- Computer with multivariate analysis software (SVM, LDA, or PLS-DA capability)

Procedure:

- Database Development:

- Collect spectra from genuine products covering all available batch variations

- Include intentional variants (different production sites, slight formulation changes)

- Acquire spectra from known counterfeits when available

- For each product, minimum of 30 tablets from at least 3 different batches

- Classifier Training:

- Evaluate multiple classification algorithms (SVM, LDA, PCA)

- Select optimal spectral pre-treatment (derivative, SNV, normalization)

- Validate model using cross-validation and external test set

- Establish class boundaries with appropriate confidence levels

- Field Testing:

- Position tablet consistently in measurement nest

- Acquire spectrum using established parameters (typically 16-32 scans)

- Process spectrum through validated classification model

- Record identification result with confidence metric

- Result Interpretation:

- Genuine products must match expected identity with high confidence

- Suspect samples flagged for further laboratory testing

- Regular model updates with new genuine batches and detected counterfeits

Validation Parameters:

- Sensitivity: >90% for counterfeit detection

- Specificity: >95% for genuine product recognition

- Robustness to environmental conditions (temperature, humidity)

Blend Homogeneity Monitoring Protocol

Scope: This protocol describes the real-time monitoring of powder blend homogeneity in pharmaceutical manufacturing using NIR spectroscopy, supporting Process Analytical Technology (PAT) initiatives [30] [38].

Materials and Equipment:

- Process NIR spectrometer with fiber optic probe

- Reflection probe appropriate for powder blending

- Chemometric software for real-time trend analysis

- Calibration samples representing homogeneous and heterogeneous blends

Procedure:

- Calibration Development:

- Prepare calibration samples with varying homogeneity levels

- Establish spectral criteria for homogeneous blend (minimum standard deviation between consecutive spectra)

- Correlate spectral homogeneity with traditional thief sampling results

- In-line Monitoring:

- Install NIR probe in blender at optimal location(s)

- Collect spectra at regular intervals (e.g., every 30 seconds)

- Calculate moving standard deviation of spectral features

- Monitor trend of homogeneity index

- Endpoint Determination:

- Establish acceptance criteria for blend homogeneity

- Define endpoint as when homogeneity index stabilizes within specified limits

- Automate notification system for blend endpoint achievement

- Data Documentation:

- Record all spectra with timestamp and blending parameters

- Generate non-editable reports for regulatory compliance

- Store data with audit trail functionality

Validation Approach:

- Correlation with HPLC results from thief samples

- Demonstration of robustness across multiple batches

- Evaluation of probe positioning effects on measurement reliability

Research Reagent Solutions and Essential Materials

Table 3: Essential Research Materials for NIR Pharmaceutical Analysis

| Category | Specific Items | Function and Application Notes |

|---|---|---|

| Reference Standards | USP/EP API reference standards; Excipient reference materials | Spectral library development; method validation [30] [35] |

| Sample Presentation Accessories | Quartz vials; Glass vials with minimal NIR absorption; Customized tablet nests | Consistent sample presentation; reduced spectral variance [37] |

| Validation Materials | Wavelength verification standards; Photometric stability standards; System suitability standards | Instrument qualification; ongoing performance verification [30] |

| Chemometric Software | PCA, PLS, SVM, LDA algorithms; Spectral preprocessing tools; Classification models | Data processing; method development; sample classification [36] [31] |

| Portable Instrumentation | Handheld NIR spectrometers (swNIR and cNIR); Portable sample accessories; Field calibration kits | Field-based counterfeit detection; supply chain verification [36] [35] |

Implementation Considerations

Regulatory Compliance

NIR spectroscopy is recognized in all major pharmacopeias including European (Ph. Eur. 2.2.40), United States (USP <856> and <1856>), and Japanese pharmacopeias [30]. Regulatory guidelines from the European Medicines Agency outline data requirements for new submissions and variations involving NIRS procedures [39]. Successful implementation requires demonstrated method validity, robustness, and transferability across instruments when applicable.

For compliance with 21 CFR Part 11, NIR systems must include features such as secure user authentication, audit trails, electronic signature capability, and data protection. Pharmaceutical versions of NIR software typically include these functionalities, with appropriate validation documentation [30].

Method Development and Validation

NIR method development follows established chemometric protocols including ASTM E1655 for quantitative methods and ASTM E1790 for qualitative methods [30]. Critical validation parameters for quantitative NIR methods include:

- Accuracy: Demonstrated through comparison to reference methods or standard addition techniques

- Precision: Repeatability and intermediate precision assessed through multiple measurements

- Specificity: Ability to detect analyte in presence of potential interferents

- Robustness: Performance under variation of method parameters

For qualitative methods, focus shifts to discrimination capability, sensitivity, and specificity in correctly classifying samples [31].

NIR spectroscopy represents a versatile, rapid, and non-destructive approach to pharmaceutical quality control and counterfeit drug identification. The technique provides clear advantages over traditional analytical methods through minimal sample preparation, multi-parameter assessment capability, and suitability for both laboratory and field applications. When properly validated with appropriate chemometric models, NIR methods can achieve performance comparable to reference methods like HPLC while significantly reducing analysis time and cost.

The continued development of handheld NIR instruments and advanced classification algorithms will further enhance capabilities for supply chain monitoring and counterfeit detection. Implementation of NIR spectroscopy within quality-by-design and real-time release testing frameworks represents the future of pharmaceutical quality assurance, enabling more efficient manufacturing while ensuring product safety and efficacy.

The advent of personalized medicine necessitates the development of small-batch, patient-tailored drug products, moving away from traditional large-scale batch production [40]. This shift demands alternative quantification techniques that are rapid, non-invasive, and capable of handling the inherent structural variability of customized formulations [40]. Near-infrared (NIR) spectroscopy has emerged as a powerful analytical tool in this domain, offering non-destructive analysis crucial for quality control in the manufacturing of porous, patient-specific drug products [19] [40].

Quantifying the active pharmaceutical ingredient (API) in these complex, often highly porous structures presents significant challenges. Traditional chemical analysis methods are destructive and ill-suited for real-time monitoring [40]. Structural variability, residual solvents, and fluctuating material density can adversely affect spectral readings, complicating accurate API quantification [40]. This application note details advanced protocols combining NIR spectroscopy with machine learning to overcome these hurdles, enabling precise, non-destructive quantification of APIs in porous, patient-specific formulations.

Experimental Protocols

Sample Preparation and System Configuration

Porous Formulation Preparation: This protocol utilizes porous, inkjet-printed antidepressant drug formulations as a model system for patient-specific medications [40]. The tunable modular design (TMD) approach is recommended, which integrates freeze-dried polymeric modules with inkjet printing technology to create customized antidepressant doses [40]. This method is particularly suitable for antidepressant tapering, which requires precise, often sub-milligram dosage adjustments [40].

- Calibration Samples: Prepare calibration samples by mixing pure drug, excipients, and batch samples to span a concentration range of 75–120 mg/g active ingredient [41]. For tablet formulations, use milled production tablets to create underdosed and overdosed samples by adding precisely weighed amounts of excipients or API, respectively [41].

- Post-Print Processing: Implement a post-print drying step to mitigate the effects of residual solvents on spectral readings and ensure sample consistency [40].

NIR Measurement Configuration: Proper instrument setup is critical for obtaining high-quality spectral data from porous formulations.

- Instrument Type: Use a spinning NIR measurement setup to mitigate inconsistencies in quantification caused by structural variability in porous drug products [40].

- Spectral Acquisition: For reflectance measurements, utilize a Foss NIRSystems spectrophotometer or equivalent, averaging 32 scans performed at 2-nm intervals over the range 1,100–2,498 nm [41]. For intact tablets, obtain spectra from both sides and average for subsequent processing [41].

- Real-Time Monitoring: For process monitoring, implement MicroNIR PAT-W sensors (VIAVI) positioned on the loading system pipe of industrial rotary tablet presses for continuous, on-line spectral acquisition during manufacturing [42].

Data Acquisition and Machine Learning Analysis

Spectral Preprocessing: Proper preprocessing of raw spectral data is essential before model development.

- Apply mathematical transformations including Standard Normal Variate (SNV) and derivative processing to remove physical phenomena and reduce random noise [42].

- Calculate derivative spectra using the Savitzky-Golay algorithm with an 11-point moving window and a second-order polynomial [41].

- Employ first derivative preprocessing to correct baseline offset and SNV to reduce physical variability between samples due to scatter [42].

Machine Learning Implementation: Implement machine learning algorithms to handle the complex spectral data from porous formulations.

- Develop Partial Least Squares (PLS) calibration models using second-derivative mode in the wavelength range 1,134–1,798 nm [41]. Determine the optimum number of factors based on the minimum PRESS value [41].

- Apply Support Vector Regression (SVR) to improve predictive accuracy, particularly for handling non-linear relationships in complex porous structures [40].

- For qualitative analysis and process monitoring, utilize Principal Component Analysis (PCA) to identify groupings or trends in the acquired data and recognize product categories [28] [42].

Table 1: Quantitative Performance Comparison of Machine Learning Models for API Quantification

| Model Type | Sample Characteristics | Prediction Error | Key Advantages |

|---|---|---|---|

| Support Vector Regression (SVR) | Highly porous formulations with structural variability | 19% reduction in error compared to PLS [40] | Superior for non-linear relationships in complex structures |

| Partial Least Squares (PLS) | Categorized sample subtypes based on structural properties | Performance equal to or better than non-linear models [40] | Optimal for targeted modeling of specific sample characteristics |

| Principal Component Analysis (PCA) | Process monitoring and qualitative analysis | N/A (qualitative technique) | Identifies process shifts and formulation differences in real-time [42] |

Model Validation: Validate quantification methods according to ICH and EMEA guidelines [41]. Use cross-validation techniques to assess model performance and prevent overfitting. For PLS models, calculate relative standard errors of calibration (% RSEC) and prediction (% RSEP) to evaluate model quality [41].

Results and Data Analysis

API Quantification Performance

The integration of NIR spectroscopy with machine learning has demonstrated exceptional performance in quantifying APIs in complex, porous formulations. Research on highly porous, inkjet-printed drug products shows that combining NIR with advanced machine learning algorithms significantly enhances quantification accuracy [40].

- Error Reduction: Implementation of Support Vector Regression (SVR) reduced prediction errors by 19% compared to traditional linear Partial Least Squares (PLS) regression when analyzing structurally variable porous formulations [40].

- Model Selection: When drug samples were categorized into subtypes based on their structural properties, linear PLS models performed equally or better than non-linear models, underscoring the importance of tailoring analytical models to specific sample characteristics [40].

- Granulation Monitoring: In granulation process monitoring, PLS calibration models have achieved errors of prediction as low as 1.01% for granulated samples and 1.63% for coated tablets, demonstrating the effectiveness of NIR for API quantification across different manufacturing stages [41].

Table 2: Validation Parameters for NIR Spectroscopy Methods in Pharmaceutical Analysis

| Validation Parameter | Granulated Samples | Coated Tablets | Recommended Guidelines |

|---|---|---|---|

| Error of Prediction | 1.01% [41] | 1.63% [41] | ICH Q2(R1) [41] |

| Spectral Range | 1,134–1,798 nm [41] | 1,134–1,798 nm [41] | Method-dependent |

| Scan Replicates | 32 scans [41] | 32 scans [41] | Sufficient for signal-to-noise ratio |

| Sample Presentation | Spinning measurement [40] | Both sides measured [41] | Representative sampling |

Structural Validation with Complementary Techniques

The structural complexity of porous formulations necessitates validation using advanced imaging techniques to corroborate NIR findings.

- Stimulated Raman Scattering (SRS) Microscopy: Utilize SRS microscopy to visualize the distribution of the active pharmaceutical ingredient within the porous matrix [40]. This technique offers faster imaging speeds and improved signal strength compared to conventional Raman imaging [40].

- Structural Analysis: SRS microscopy confirms that structural differences among sample subtypes significantly influence NIR performance, validating the need for targeted modeling strategies [40].

- Process Control: Implement Moving Block (MB) algorithms for real-time process monitoring. MB analysis calculates the area below each spectrum and compares resulting values within the same block, effectively detecting process shifts and formulation changes during manufacturing [42].

The following workflow diagram illustrates the complete experimental procedure from sample preparation to final analysis:

Advanced Data Analysis and Technical Workflow

The data analysis pathway for NIR spectroscopy in pharmaceutical analysis involves sophisticated processing and modeling techniques to ensure accurate API quantification:

The Scientist's Toolkit: Essential Research Reagents and Equipment

Table 3: Essential Materials and Equipment for NIR Analysis of Porous Formulations

| Item | Function/Application | Specifications/Examples |

|---|---|---|

| MicroNIR Spectrophotometer | Spectral acquisition of porous formulations | OnSite-W microNIR instrument (VIAVI Solutions); range 908-1676 nm [28] |