Overcoming Direct Spectral Overlap in ICP-OES: A Comprehensive Guide for Accurate Analysis

This article provides a detailed guide for researchers and scientists on identifying and correcting direct spectral overlap in ICP-OES, a critical challenge in elemental analysis.

Overcoming Direct Spectral Overlap in ICP-OES: A Comprehensive Guide for Accurate Analysis

Abstract

This article provides a detailed guide for researchers and scientists on identifying and correcting direct spectral overlap in ICP-OES, a critical challenge in elemental analysis. It covers the foundational principles of spectral interferences, explores established correction methodologies including Inter-Element Correction (IEC), offers practical troubleshooting strategies to optimize analytical performance, and outlines validation protocols to ensure data accuracy and regulatory compliance, with specific relevance to biomedical and pharmaceutical applications.

Understanding the Challenge: The Fundamentals of Spectral Interferences in ICP-OES

FAQ: Direct Spectral Overlap in ICP-OES

What is a direct spectral overlap in ICP-OES? A direct spectral overlap occurs when an emission line from an interfering element in the sample is at almost the exact same wavelength as the analytical line of the element you are trying to measure (the analyte) [1]. The separation between these two wavelengths is smaller than the resolution of your ICP-OES spectrometer [2]. This means the instrument cannot physically separate the two signals, leading to a combined measurement that inflates the apparent concentration of the analyte [3] [1].

How is this different from other spectral interferences? Spectral interferences are generally categorized into three types [4]:

- Direct Spectral Overlap: As defined above, this is an exact or near-exact match of wavelengths [2].

- Wing Overlap: This happens when a very intense emission line from an interferent has broad "wings" that extend under the analyte's peak, even if the main peaks are resolved [4] [5].

- Background Shift: A high concentration of matrix elements can cause a general elevation or shift in the background emission around the analyte line, making accurate background correction difficult [4] [5].

What are some classic examples of direct spectral overlaps? Well-documented examples include the interference of Arsenic (As) on the Cadmium (Cd) line at 228.802 nm and the overlap of Iron (Fe) on the Boron (B) line at 208.892 nm [4] [5]. The table below quantifies the impact of an As interference on Cd analysis.

Table 1: Quantifying the Interference of 100 µg/mL Arsenic on Cadmium Measurement at 228.802 nm [4]

| Cadmium Concentration (µg/mL) | Ratio (As:Cd) | Uncorrected Relative Error | Best-Case Corrected Relative Error | Notes |

|---|---|---|---|---|

| 0.1 | 1000:1 | 5100% | 51.0% | Detection limit severely degraded |

| 1.0 | 100:1 | 541% | 5.5% | Lower limit of quantitation is raised |

| 10.0 | 10:1 | 54% | 1.1% | Quantitative analysis becomes feasible |

| 100.0 | 1:1 | 6% | 1.0% | Minor interference |

How can I identify a direct spectral overlap in my data? During method development, a direct overlap may cause the analyte peak to appear asymmetric or show a slight "shoulder" [2]. The most reliable way to identify an overlap is to perform a spectral interference study [5] [6]. This involves:

- Aspirating a high-purity, single-element solution of the suspected interfering element (e.g., at 1000 µg/mL).

- Carefully examining the spectral region around your chosen analyte line for any signal.

- Confirming the signal is from interference and not an impurity in the interferent solution by checking trace metal data or using an alternate analytical technique [5].

Troubleshooting Guide: Resolving Direct Spectral Overlaps

When you encounter a direct spectral overlap, you have several strategies to resolve it. The following workflow outlines the most common and effective approaches.

Strategy 1: Avoidance by Selecting an Alternate Analytical Line The simplest and most highly recommended solution is to avoid the problem entirely by choosing a different, interference-free emission line for your analyte [4] [1]. Modern ICP-OES instruments with echelle spectrometers and solid-state detectors provide great flexibility for simultaneous multi-element analysis at multiple wavelengths [7].

Table 2: Examples of Alternate Analytical Lines for Common Elements [1]

| Analyte | Primary Wavelength (nm) | Alternate Wavelength (nm) | Sensitivity Factor* |

|---|---|---|---|

| Cadmium (Cd) | 214.438 | 228.802 | 1.1 |

| Lead (Pb) | 220.353 | 216.999 | 2.1 |

| Zinc (Zn) | 213.856 | 202.548 | 2.2 |

| Copper (Cu) | 324.754 | 224.700 | 1.4 |

| *Factor by which sensitivity is decreased compared to the primary line. |

Strategy 2: Correction Using Inter-Element Correction (IEC) If no suitable alternate line is available, you can use a mathematical correction known as Inter-Element Correction (IEC). This is an accepted method in many regulated procedures (e.g., US EPA methods) [2]. The IEC workflow is as follows:

Experimental Protocol: Implementing an Inter-Element Correction (IEC)

Determine the Correction Coefficient:

- Prepare a high-purity standard containing a known, high concentration of the interfering element (e.g., 1000 µg/mL).

- Aspirate this solution and measure the apparent signal (intensity) at the analyte's wavelength.

- The correction coefficient (K) is calculated as: K = (Iint / Cint), where

I_intis the measured intensity at the analyte wavelength, andC_intis the concentration of the interfering element [1] [2].

Analyze Your Sample:

- For any unknown sample, simultaneously measure:

- The combined signal (I_total) at the analyte wavelength.

- The concentration of the interfering element (Cintsample) at its own, interference-free wavelength.

- For any unknown sample, simultaneously measure:

Apply the Correction:

Key Consideration: The effectiveness of the IEC must be demonstrated by running an Interference Check Solution (ICS)—a solution containing a high concentration of the interferent but none of the analyte—and confirming it returns a result close to zero [2].

Strategy 3: Sample Preparation to Remove the Interferent In persistent cases, you can use classical sample preparation techniques to physically separate the interfering element from the analyte before analysis. Techniques like solvent extraction, chromatography, or precipitation can be employed for this purpose [1].

The Scientist's Toolkit: Essential Reagents & Materials

Table 3: Key Research Reagents for Spectral Interference Studies and Corrections

| Item | Function in Experiment |

|---|---|

| High-Purity Single-Element Standards | Used in spectral interference studies to map the emission spectrum of potential interferents and to calculate IEC coefficients [5]. |

| Interference Check Solution (ICS) | A solution containing a high concentration of known interferents; used to validate that IEC corrections are working effectively during analysis [2]. |

| Internal Standard Element (e.g., Yttrium, Scandium) | An element added in a constant amount to all samples, blanks, and standards; its signal is monitored to correct for physical matrix effects and signal drift, improving overall accuracy [1] [5]. |

| High-Purity Acid Matrices (e.g., HNO₃) | Used to prepare blanks, standards, and samples to ensure a consistent matrix, which minimizes background shifts and physical interferences [4]. |

| Certified Reference Material (CRM) | A sample with known concentrations of analytes; used to validate the entire analytical method, including the success of spectral interference corrections [8]. |

Frequently Asked Questions (FAQs)

1. What are the main types of spectral interference in ICP-OES? Spectral interferences in ICP-OES are typically categorized into three main types: direct spectral overlap, wing overlap, and background shifts. These occur when the emission signal from an interfering species in the sample affects the accurate measurement of the analyte's emission line [2] [9].

2. What is the most effective way to handle a direct spectral overlap? The most effective strategy is often avoidance by selecting an alternative, interference-free analytical wavelength for your analyte [4] [2]. If that is not possible, an Inter-Element Correction (IEC) can be applied. This mathematical correction subtracts the interfering element's calculated contribution from the analyte's signal [2] [9].

3. My results show negative concentrations. What could be the cause? Negative values can occur due to spectral interferences affecting the background correction points. If a spectral feature from an interferent (like an iron line) coincides with a background correction point, the software may over-correct the analyte signal, leading to a negative value [10].

4. How can I proactively identify potential spectral interferences in my method? Conducting a systematic spectral interference study is recommended. This involves aspirating high-purity, single-element solutions (e.g., 1000 µg/mL) of potential interfering elements and examining the spectral regions around your chosen analyte lines for any unexpected signals [10].

Troubleshooting Guides

Problem: Suspected Direct Spectral Overlap

Symptoms:

- Consistently high or biased results for a specific analyte.

- Poor recovery in quality control samples (e.g., certified reference materials).

- A visible "shoulder" or asymmetrical peak shape in the spectral scan [2].

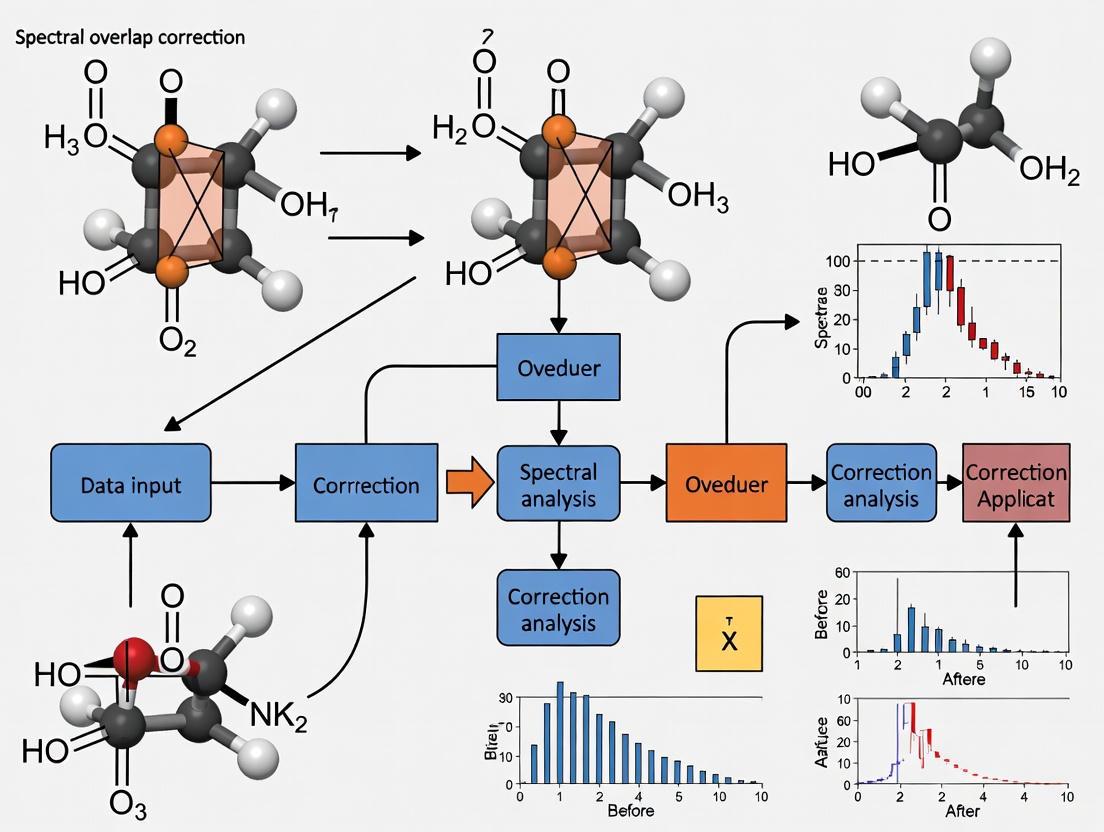

Investigation and Resolution Workflow: The following diagram outlines the systematic process for diagnosing and resolving a direct spectral overlap.

Detailed Steps:

Confirm the Interference:

- Collect a detailed spectral scan (or "Fullframe") of your sample and a solution containing a high concentration of the suspected interfering element [9] [10].

- Visually inspect the scan at your analyte's wavelength. A direct overlap is confirmed if a peak from the interferent is centered at the exact same wavelength as your analyte peak [4] [1].

Apply a Resolution Strategy:

- Avoidance (Preferred): Consult your instrument's wavelength library and select a different, sensitive line for the analyte that is free from interference. Modern software often has tools to assist with this selection [4] [9].

- Correction (if avoidance is not possible): Use an Inter-Element Correction (IEC). This requires:

- Measuring the concentration of the interfering element at another, interference-free wavelength.

- Determining a "correction coefficient" (the apparent concentration of the analyte per unit concentration of the interferent) [4] [1].

- The software then uses this coefficient to subtract the interferent's contribution from the analyte signal [2].

Problem: Suspected Wing or Background Shift Interference

Symptoms:

- Inaccurate results that may be either high or low.

- Curved or sloping background under the analyte peak.

- Problems with background correction fitting.

Investigation and Resolution Workflow: The diagram below illustrates the process for addressing wing overlaps and background shifts.

Detailed Steps:

Identify the Interference Type:

- Wing Overlap: Caused by the broadened spectral wing of an intense emission line from a high-concentration element (e.g., Fe or Ca) located close to the analyte line. The background appears sloping or curved [4] [10].

- Background Shift: A general increase in background intensity across a spectral region due to the overall sample matrix, which can be seen by comparing a sample to a blank [4] [9].

Apply a Resolution Strategy:

- For Wing Overlap: Avoidance is the best strategy. Select an analyte line in a less complex spectral region [4].

- For Background Shifts: Use sophisticated background correction. Instead of a single point, select multiple background correction points on either side of the peak. The instrument software can then fit a linear or curved function to model and subtract the background accurately [4] [9].

The table below summarizes the key characteristics and quantitative impacts of different spectral interferences, using an example from the search results.

Table 1: Characteristics and Impact of Spectral Interference Types

| Interference Type | Description | Example | Impact on Analysis |

|---|---|---|---|

| Direct Spectral Overlap | An interfering element has an emission line at the exact same wavelength as the analyte [2] [1]. | As 228.812 nm line directly overlapping Cd 228.802 nm line [4]. | Can cause severe false positives. In the Cd/As example, 100 µg/mL As can make a 0.1 µg/mL Cd solution appear as 51 µg/mL—a 5100% error [4]. |

| Wing Overlap | The broadened base (wing) of an intense spectral line from an interferent partially overlaps the analyte line [4] [10]. | Wing of a high-concentration Fe line overlapping the Ba 233.527 nm line [10]. | Causes a sloping or curved background, leading to inaccurate background correction and biased results (either high or low) [4]. |

| Background Shift | The sample matrix causes a general increase or shift in the background intensity across a spectral range [4] [9]. | High dissolved solids or high Ca matrix raising background vs. acid blank [4]. | Increases the baseline noise, which can degrade detection limits and cause inaccuracy if not corrected [4]. |

Table 2: Effect of Arsenic (As) Interference on Cadmium (Cd) Detection Limits (Example of Direct Overlap) [4]

| Cd Concentration (µg/mL) | As:Cd Ratio | Uncorrected Relative Error | Best-Case Corrected Relative Error |

|---|---|---|---|

| 0.1 | 1000:1 | 5100% | 51.0% |

| 1.0 | 100:1 | 541% | 5.5% |

| 10.0 | 10:1 | 54% | 1.1% |

Experimental Protocols

Protocol 1: Systematic Interference Check for Method Development

This procedure should be performed during method development and verified annually [10].

- Preparation of Solutions: Prepare high-purity (1000 µg/mL) single-element stock solutions for all potential interfering elements present in your sample matrix (e.g., Na, K, Ca, Fe, Al) [10].

- Spectral Scanning: Aspirate each high-purity interferent solution and acquire a high-resolution spectral scan (or Fullframe) across the spectral regions of your chosen analyte lines [9] [10].

- Inspection and Analysis: Overlay the spectral scan of the interferent with that of a pure analyte standard.

- Look for direct overlaps, wing overlaps, or background shifts.

- Use a trace metals analysis of your interferent stocks to distinguish true spectral overlap from analyte impurity in the interferent solution [10].

- Documentation: Document all observed interferences to justify wavelength selections and any required corrections in your standard operating procedure.

Protocol 2: Implementing an Inter-Element Correction (IEC)

Follow this protocol to set up a correction for a confirmed direct spectral overlap [2] [1].

- Determine the Correction Coefficient:

- Prepare a standard containing a known, high concentration of the interfering element (e.g., 100 µg/mL). The analyte should be absent or present at a negligible level.

- Analyze this solution and measure the apparent concentration (or intensity) it produces at the analyte's wavelength.

- The correction coefficient (K) is calculated as: K = (Apparent Analyte Concentration) / (Interferent Concentration) [1].

- Integrate into the Method:

- In the instrument software, access the IEC settings for the affected analyte.

- Specify the interfering element and input the calculated correction coefficient (K).

- Validate the Correction:

- Analyze an interference check solution containing a known mixture of the analyte and the interferent.

- The results for the analyte should now be accurate, demonstrating that the correction is working effectively [2].

The Scientist's Toolkit: Key Reagents and Materials

Table 3: Essential Research Reagent Solutions for ICP-OES Interference Management

| Item | Function / Purpose |

|---|---|

| High-Purity Single-Element Standards | Used for spectral interference studies to identify and characterize overlaps from specific elements [10]. |

| Ionization Buffer (e.g., Cs, Li salts) | Added to samples and standards to suppress ionization interferences, particularly from Easily Ionized Elements (EIEs) like Na and K [2] [11]. |

| Internal Standards (e.g., Sc, Y, In) | Added in a constant amount to all samples and standards to correct for physical interferences and signal drift [9]. |

| Certified Reference Materials (CRMs) | Used for method validation and verification, ensuring accuracy and confirming that interference corrections are effective [9]. |

| High-Purity Acids and Water | Essential for preparing blanks, standards, and sample dilutions to minimize contamination and baseline noise [8]. |

FAQ 1: What are spectral overlaps and how do they cause false positives in ICP-OES?

A: Spectral overlaps occur when the emission wavelength of an interfering element or molecular species in your sample directly or partially overlaps with the emission wavelength of your target analyte [3]. In ICP-OES, when light from this interference is detected at your analyte's wavelength, it adds to the signal, causing a falsely high reading or a false positive [3] [2]. This degrades accuracy because the reported concentration does not reflect the true amount of the analyte present. Spectral overlaps are considered one of the most challenging types of interference in ICP-OES [3].

FAQ 2: What other types of interferences should I be aware of besides spectral overlaps?

A: Interferences in ICP-OES are typically subdivided into three main types [3] [2]:

- Spectral Interferences: As described above, these are caused by overlapping emission signals [3].

- Physical Interferences: These are caused by differences in physical properties (like viscosity or density) between your samples and calibration standards, which can affect nebulization efficiency and transport to the plasma, leading to signal suppression or variability [3] [2].

- Chemical Interferences: These arise from differences in the way sample and calibration matrices behave in the plasma, which can change atomization and ionization efficiencies. An example is the signal enhancement for elements like arsenic when carbon is present in the sample [3].

The diagram below illustrates the primary types of interferences and their impact on your data.

(Diagram: Data Impact Pathways of ICP-OES Interferences)

FAQ 3: Could you provide a concrete example of a spectral overlap?

A: A classic example is the interference of Arsenic (As) on the Cadmium (Cd) line at 228.802 nm. The As emission line at 228.812 nm is so close to the Cd line that it can contribute significant signal [4]. The table below quantifies this effect, showing how the presence of 100 µg/mL As can lead to massive uncorrected relative errors, especially at low Cd concentrations.

Table 1: Quantifying the Impact of a Spectral Overlap (100 µg/mL As on Cd 228.802 nm)

| Cadmium (Cd) Concentration | Uncorrected Relative Error (%) | Best-Case Corrected Relative Error (%) |

|---|---|---|

| 0.1 ppm | 5100% | 51.0% |

| 1 ppm | 541% | 5.5% |

| 10 ppm | 54% | 1.1% |

| 100 ppm | 6% | 1.0% |

Source: Adapted from [4]

As the table shows, without correction, the result for a 0.1 ppm Cd sample could be over 50 times its true value. Even with a mathematical correction, the error remains significant at low concentrations, dramatically raising the practical limit of quantification [4].

Troubleshooting Guide: Identifying and Correcting for Spectral Overlaps

Experimental Protocol: Interference Check

This procedure is often required by regulated methods like US EPA 200.7 or 6010D to demonstrate your analysis is free from spectral interferences [2].

- Prepare Solutions: Create interference check solutions containing high concentrations of well-documented interfering elements for your target analytes.

- Analyze: Run these solutions on your ICP-OES.

- Interpret Results: The results for your target analytes should be close to zero. A significantly non-zero result indicates a spectral interference is present, and corrective action is required [2].

Experimental Protocol: Resolving Interferences with Inter-Element Correction (IEC)

For unresolvable direct spectral overlaps, an Inter-Element Correction (IEC) is a standard and accepted mathematical correction method [2].

- Identify Interference: Confirm the interfering element and the correction factor (the signal contribution per unit concentration of the interferent at the analyte wavelength).

- Apply IEC Equation: The software uses an equation to subtract the interference's contribution.

Corrected Analyte Signal = Measured Signal at λ - (Interferent Concentration * Correction Factor) - Validate: The effectiveness of the IEC should be demonstrated and updated daily by running an interference check solution as part of your workflow [2].

The Scientist's Toolkit: Research Reagent Solutions

The following table lists key reagents and materials used for managing interferences in ICP-OES.

Table 2: Essential Reagents and Materials for Interference Management

| Item | Function in Experiment |

|---|---|

| Ionization Buffer | Added to samples and standards to minimize chemical interferences by stabilizing ionization conditions in the plasma [2]. |

| Internal Standard Solution | A known concentration of an element not expected in samples (e.g., Yttrium, Scandium) added to all solutions. Used to correct for physical interferences and signal drift by ratioing the analyte signal to the internal standard signal [2] [12]. |

| Interference Check Solutions | Solutions containing high concentrations of potential interferents. Used to identify and quantify spectral interferences during method development and validation [2]. |

| High-Purity Single-Element Standards | Used to characterize the emission spectrum of individual elements, which is essential for identifying spectral overlaps and for setting up multiple linear regression corrections [7]. |

For complex spectral interferences, advanced software techniques like Multiple Linear Regression (MLR) can be used. This method fits the sample spectrum using stored, pure single-element spectra for the analyte and all potential interferents to mathematically separate their contributions [7]. The workflow for this advanced correction is shown below.

(Diagram: Advanced Spectral Unmixing with MLR)

FAQ 4: What is the best first step to avoid spectral interferences?

A: The most straightforward and highly encouraged strategy is avoidance [4]. Modern ICP-OES instruments with simultaneous detection and echelle spectrometers offer high resolution and flexibility. If your primary analytical line suffers from a known or suspected interference, the best approach is often to simply select an alternative, interference-free emission line for your analyte [2] [4]. Always consult wavelength tables and your instrument's database during method development.

For researchers in drug development, achieving accurate elemental analysis via Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is critical. A core challenge is direct spectral overlap, where an interfering element's emission line overlaps the analyte's wavelength, potentially causing false positives or negatives and degrading method accuracy and precision [2]. Instrument resolution is a fundamental property that determines the ability to distinguish between these closely spaced wavelengths. This guide explores the role of high resolution in minimizing interferences and provides protocols for identifying and correcting for them when they occur.

FAQs on Resolution and Spectral Interferences

1. What is instrument resolution in ICP-OES and why is it critical? Instrument resolution, defined as the smallest wavelength separation at which two emission lines can be distinguished, is a key determinant of analytical capability [13]. In ICP-OES, resolution is determined by the optical design, including the grating, focal length, and slit dimensions [13]. High resolution is critical because it allows the spectrometer to separate the analyte's emission line from interfering lines caused by other elements or molecular species in the sample. Modern high-resolution instruments can resolve many spectral interferences down to the baseline, even in complex samples like mixed platinum group metal solutions [2].

2. What is the difference between a direct spectral overlap and a wing overlap? Spectral interferences are typically categorized as follows [4] [14]:

- Direct Spectral Overlap: Occurs when the interference and analyte wavelengths are separated by less than the resolution of the ICP-OES [2]. The spectrum of the peak may appear slightly asymmetric or have a slight "shoulder" [2].

- Wing Overlap: Occurs when the wing (the broadened base) of a high-intensity line from an interfering element overlaps the analyte line [14].

- Background Interference: A shift in the continuous background radiation beneath the analyte peak, which can be flat, sloping, or curved due to the proximity of a high-intensity line [4] [14].

3. When is high instrument resolution not sufficient to overcome an interference? High resolution cannot correct for a "true" direct spectral overlap where two distinct elements emit light at the exact same wavelength. In such cases, the signals are intrinsically combined and cannot be optically separated by the spectrometer. For these unresolvable interferences, mathematical corrections must be applied [2].

4. What are the primary mathematical correction techniques? The two main approaches are:

- Inter-Element Correction (IEC): A robust and accepted method for correcting direct spectral overlaps. It uses a predetermined correction factor to subtract the interfering element's contribution from the measured analyte intensity [2] [13]. The basic equation for one interfering element is:

Corrected Intensity = Uncorrected Intensity – k * Concentration of Interfering Element, where k is the correction factor [13]. - Multiple Linear Regression (MLR): This advanced method uses the entire spectrum around the analyte line. It determines the constants for which the sum of the pure analyte spectrum, the interferent spectrum, and the blank spectrum best fits the measured sample spectrum [7].

Troubleshooting Guide: Identifying and Resolving Interferences

Problem: Suspected Spectral Interference Causing Inaccurate Results

You are observing consistently high (or low) recoveries for a specific analyte, or your results for a certified reference material (CRM) are biased.

Investigation and Resolution Workflow

The following diagram outlines a systematic protocol for diagnosing and addressing spectral interferences.

Detailed Experimental Protocols

Protocol 1: Visual Spectral Examination & Interference Check This initial check helps identify the type and source of interference [2] [14].

- Analyze High-Purity Solutions: Aspirate a high-purity, single-element solution of the suspected interfering element (e.g., 1000 µg/mL). For a comprehensive assessment, perform this for all potential interferents in your sample matrix [14].

- Collect Spectral Data: Examine the spectral region around your analyte's wavelength. Modern software allows you to overlay spectra from the interferent, a blank, and your sample.

- Identify Interference Type:

Protocol 2: Inter-Element Correction (IEC) Factor Determination and Application This protocol details how to establish and validate a correction for a direct spectral overlap [2] [13].

- Prepare Calibration Standards: Prepare a multi-point calibration curve for the analyte.

- Prepare Interference Check Solution: Prepare a solution containing a high concentration of the interfering element but none of the analyte.

- Calculate Correction Factor (k):

- Analyze the interference check solution.

- The software will typically calculate the factor

kautomatically. Manually, it can be derived as:k = (Measured Apparent Analyte Concentration) / (Concentration of Interfering Element).

- Apply the Correction: Input the

kfactor into the ICP-OES software. The instrument will then automatically perform the calculation:Corrected Intensity = Uncorrected Intensity – k * [Interferent][13]. - Validate the Correction: Analyze an interference check solution post-correction. The reported concentration for the analyte should be close to zero. Further validate using a certified reference material (CRM) or a spiked sample with known concentrations of both analyte and interferent [2].

Key Research Reagent Solutions

The following reagents are essential for developing robust, interference-free ICP-OES methods.

| Reagent / Solution | Function & Importance in Interference Management |

|---|---|

| High-Purity Single-Element Standards | Used for interference studies (Protocol 1) and to generate correction factors. High purity is essential to avoid misidentifying impurities as spectral overlaps [14]. |

| Interference Check Solutions | Contains high concentrations of documented interfering elements. Used to confirm the effectiveness of IECs and should be run as part of the quality control workflow [2]. |

| Certified Reference Materials (CRMs) | Critical for method validation. A matrix-matched CRM with certified values for both analytes and potential interferents provides the highest confidence that interferences have been correctly resolved [14]. |

| Internal Standard Solution | While primarily for physical interference correction, a properly chosen internal standard can help monitor and correct for signal instability. It should be an element not present in samples and free from spectral interferences itself [2] [14]. |

Comparison of Interference Types and Resolution Strategies

The table below summarizes the primary interference types and the role of instrument resolution in managing them.

| Interference Type | Key Characteristic | Impact on Results | Primary Resolution Strategy |

|---|---|---|---|

| Direct Spectral Overlap | Emission lines are closer than instrument resolution [2]. | False positives; overestimation of concentration [2]. | 1. High Instrument Resolution (to resolve)2. Inter-Element Correction (IEC) (if unresolvable) [2] [13]. |

| Wing Overlap | Broadened base of a strong line overlaps analyte [14]. | Signal enhancement; overestimation [14]. | 1. High Instrument Resolution2. Careful Background Correction [4]. |

| Background Shift | Change in continuum background under analyte peak [4]. | Under- or over-estimation if background is miscalculated [4]. | Appropriate Background Correction Algorithm (e.g., linear, curved) selected based on the background shape [4]. |

| Physical/Chemical | Affects sample transport/nebulization or ionization in plasma [2] [3]. | Signal suppression/enhancement; drift [3]. | Internal Standardization or matrix-matching [2] [3]. |

Correction Strategies in Action: From Inter-Element Correction to Line Selection

FAQs: Core Concepts of Inter-Element Correction (IEC)

Q1: What is Inter-Element Correction (IEC) in ICP-OES, and when is it used? Inter-Element Correction (IEC) is a mathematical method used in Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) to correct for unresolvable spectral interferences [2]. These are interferences where the emission wavelength of an analyte (the element you want to measure) and an interfering element are so close that they cannot be separated by the spectrometer's resolution [2]. This direct or partial spectral overlap causes the signal from the interfering element to contribute to the measured signal of the analyte, leading to falsely high (or positive) results [13] [3]. IEC is the accepted gold-standard methodology for correcting these specific, well-characterized overlaps and is described in many regulated methods, such as US EPA 6010D [2].

Q2: What is the fundamental difference between a spectral line overlap and a matrix effect? The key difference lies in how the interference affects the calibration curve and the required correction [13].

- Spectral Line Overlap: This always causes a parallel shift of the calibration curve to the right (higher intensity) because you are always measuring too much signal for the analyte [13]. The correction, therefore, always involves subtracting the contribution of the interfering element.

- Matrix Effect: This causes a change in the slope of the calibration curve [13]. The correction can be either positive or negative, as the matrix can either suppress or enhance the analyte signal [13].

Q3: What is the basic mathematical formula for an IEC? For a single interfering element, the corrected analyte intensity is calculated using a simple subtraction [13]:

Corrected Intensityᵢ = Uncorrected Intensityᵢ – (h × Concentrationⱼ)

Where:

Corrected Intensityᵢis the intensity used for the final analyte concentration calculation.Uncorrected Intensityᵢis the raw intensity measured at the analyte's wavelength.his the correction factor (specific to the analyte/interferent pair).Concentrationⱼis the concentration of the interfering element.

This corrected intensity is then used in the calibration function: Concentrationᵢ = A₀ + A₁ × (Corrected Intensityᵢ) [13].

Q4: How do I determine the correction factor (h) for an IEC?

The correction factor, h, is empirically determined and represents the intensity contribution of the interfering element per unit of its concentration at the analyte's wavelength [4]. It is established by analyzing a high-purity standard of the interfering element and measuring the apparent intensity it produces at the analyte wavelength [4]. For example, to correct Cadmium (Cd) for an Arsenic (As) overlap, you would analyze a 100 µg/mL As solution and measure the signal at the Cd wavelength. The correction factor h would be calculated as the measured intensity divided by 100 [4]. This factor should be verified regularly using interference check solutions [2].

Q5: Can I use IEC to correct for multiple interferences on a single analyte line?

Yes, the IEC model can be expanded to correct for multiple interferences. The formula becomes a summation of the contributions from all j interfering elements [13]:

Concentrationᵢ = A₀ + A₁ × (Ii - ΣhᵢⱼCⱼ)

Where ΣhᵢⱼCⱼ is the sum of the intensity contributions from all known interfering elements.

Troubleshooting Guide: Implementing and Validating IEC

Problem 1: IEC correction is ineffective, and results for interference check solutions are still not close to zero.

- Cause A: Incorrect or drifted correction factor. The correction factor

hmay have been calculated incorrectly or may have changed due to instrumental drift. - Solution: Re-measure the correction factor using a fresh, high-purity standard of the interfering element. Ensure the instrument is properly calibrated and stable. Modern software can often help set up and update these factors within the daily workflow [2].

- Cause B: Unaccounted or new spectral interference. There may be another interfering element present in your sample that you have not included in your correction equation.

- Solution: Re-examine the sample spectrum around the analyte wavelength for shoulders or asymmetrical peaks indicating another overlap [2]. Review spectral libraries for other potential interferents at that wavelength.

Problem 2: After applying IEC, the precision of low-level analyte measurements is poor.

- Cause: Propagation of error. The IEC process involves subtracting two measured values (uncorrected intensity and calculated interference), each with its own inherent measurement error. This can lead to an amplification of the relative error, especially when the analyte concentration is low and the interference contribution is high [4].

- Solution: Consider using an alternative, interference-free analytical line for the analyte if available [4]. If no other line is suitable, the best approach is to understand that the method's detection limit and lower limit of quantitation will be higher for that analyte in the presence of the interferent [4].

Problem 3: The plasma is unstable, or sensitivity is drifting, making IEC corrections unreliable.

- Cause: Physical issues with the sample introduction system. A partially clogged nebulizer, worn pump tubing, or contaminated torch can cause signal instability and drift, which undermines the consistency of the mathematically derived IEC factors [15].

- Solution: Perform routine maintenance. Check and replace peristaltic pump tubing if it has lost elasticity. Inspect and clean the nebulizer for blockages and the torch injector for salt deposits [15]. Ensure the spray chamber is clean and not causing beading of the aerosol [15].

Experimental Protocol: Establishing an Inter-Element Correction

Objective: To determine the correction factor h for the spectral interference of Element B on the analytical line of Element A.

Materials:

- ICP-OES instrument with robust, stable plasma

- High-purity, single-element standard solution of interfering Element B (e.g., 100 µg/mL)

- Acid-matched blank solution (e.g., 2% HNO₃)

- Method and software capable of applying IEC equations

Procedure:

- Instrument Stabilization: Ensure the ICP-OES instrument is ignited and has stabilized for at least 30 minutes with the acid blank being aspirated.

- Spectral Analysis: Acquire a spectrum in the vicinity of Element A's analytical wavelength while aspirating the high-purity standard of Element B. Visually confirm the spectral overlap.

- Intensity Measurement: Aspirate the standard of Element B and record the net intensity measured at the exact wavelength of Element A. This is the "apparent" intensity of Element A coming from Element B.

- Calculate Correction Factor: Calculate the correction factor

husing the formula:h = (Measured Apparent Intensity of A from B) / (Concentration of B)The unit ofhis intensity per concentration (e.g., counts per µg/mL). - Software Input: Enter this

hfactor into the ICP-OES software's IEC method for Element A, specifying Element B as the interferent. - Validation: Run an interference check solution containing a high concentration of Element B and a negligible concentration of Element A. The result for Element A should be close to zero, confirming the correction is working.

Research Reagent Solutions

The following table lists key materials required for reliable ICP-OES analysis and the implementation of IECs.

| Item | Function in ICP-OES & IEC | Critical Specification Notes |

|---|---|---|

| High-Purity Single-Element Standards | Used to determine specific IEC correction factors (h) and for wavelength calibration [4] [8]. |

Must be of high purity to avoid contributions from other elements that could skew the correction factor. |

| Interference Check Solutions | Contains high concentrations of documented interferents; used to validate IEC effectiveness during analysis [2]. | Should be matched to the specific application (e.g., following EPA Method 6010D). |

| Matrix-Matched Custom Standards | Custom-made standards in a specific sample matrix (e.g., Mehlich-3, saline); help verify accuracy when interelement effects are complex [8]. | Essential for methods where the sample matrix is difficult to replicate with simple acid diluents. |

| Acid-Matched Blank Solution | Used for instrument calibration, background correction, and as a rinse solution between samples. | Typically 1-2% high-purity nitric acid; must be free of analyte contaminants. |

| Internal Standard Solution | Corrects for physical interferences and instrument drift, improving overall precision [2]. | Added to all samples, standards, and blanks. Common examples are Scandium (Sc), Yttrium (Y), or Indium (In). |

Workflow Diagram: Implementing Inter-Element Correction

The following diagram illustrates the logical workflow for identifying a spectral interference and implementing an IEC, from initial suspicion to final validated analysis.

Frequently Asked Questions (FAQs)

Q1: What is an Inter-Element Correction (IEC) factor, and when should I use it?

An Inter-Element Correction (IEC) factor is a mathematical constant used to correct for unresolvable spectral interferences in ICP-OES analysis, specifically when an interfering element causes a direct or partial spectral overlap on an analyte's emission wavelength [2]. You should use it when a spectral interference has been identified and cannot be resolved by the instrument's optical resolution or by simply selecting an alternative analyte wavelength [2] [4].

Q2: My interference check solution fails for a specific analyte. Does this mean I need an IEC?

Yes, a failed interference check solution is a direct indicator that an interference is present. Regulated methods, such as US EPA 200.7 or 6010D, require you to demonstrate that your analysis is free from spectral interferences [2]. If analyzing an interference check solution containing a high concentration of a known interferent returns a significantly non-zero result for your analyte, corrective action—such as applying an IEC—is required [2].

Q3: How stable are IEC factors over time? Do I need to re-determine them daily?

IEC factors are typically robust and do not change significantly on a daily basis [2]. The effectiveness of your IECs should be demonstrated as part of your daily quality control workflow by running an interference check solution. This verifies that the correction remains valid without needing to re-calculate the factor every day [2].

Q4: Can I use IEC to correct for any type of interference?

No, IEC is specifically designed for spectral interferences [2]. It is not the appropriate tool for correcting physical interferences (e.g., differences in viscosity or nebulization efficiency) or chemical interferences (e.g., ionization effects in the plasma). Physical interferences are often corrected via internal standardization, while chemical interferences may be addressed by adding an ionization buffer [2] [16].

Q5: What is the main risk of using an incorrect IEC factor?

Applying an incorrect IEC factor will lead to degraded accuracy and precision, potentially resulting in either false positive or false negative results [2] [16]. An improperly calibrated correction can systematically add or subtract too much signal, making your quantitative results unreliable.

Troubleshooting Guide

Issue 1: Poor Recovery After Applying IEC

Problem: After implementing an IEC, your quality control standards or certified reference materials (CRMs) still show poor recovery for the corrected analyte.

Investigation and Resolution:

- Verify the Correction Factor: Re-check the calculation of your IEC factor. Ensure it was determined using high-purity single-element solutions and that the intensity measurement for the interferent at the analyte's wavelength is accurate [2] [4].

- Check for Background Correction: A poorly chosen background correction point can interact with the IEC. Examine the spectral background near your analyte line to ensure it is being modeled and subtracted correctly before the IEC is applied [4] [17].

- Look for Additional Interferents: The initial interference might be from more than one element. Use software tools to check for other potential spectral overlaps on your analyte line that your current IEC does not account for [17].

Issue 2: Increased Uncertainty in Corrected Results

Problem: The results for an analyte corrected with IEC show high variability or poor precision.

Investigation and Resolution:

- Review Signal Precision: The precision of the corrected analyte concentration is dependent on the precision of both the analyte signal and the interfering element's signal. The combined standard deviation is calculated as

SD_correction = √( (SD_analyte)² + (SD_interferent)² )[4]. If the interferent is at a very high concentration relative to the analyte, the noise from its signal can dominate and degrade your detection limit [4]. - Assess Concentration Ratio: Evaluate the relative concentration of the interferent to the analyte. The table below, based on a Cd/As interference example, illustrates how the relative error escalates as the interferent concentration increases [4]:

Table: Impact of Interferent-to-Analyte Ratio on Measurement Error

| Concentration of Cd (ppm) | As/Cd Ratio | Uncorrected Relative Error (%) | Best-Case Corrected Relative Error (%) |

|---|---|---|---|

| 0.1 | 1000 | 5100 | 51.0 |

| 1 | 100 | 541 | 5.5 |

| 10 | 10 | 54 | 1.1 |

| 100 | 1 | 6 | 1.0 |

- Consider Alternative Lines: If the corrected results remain unacceptably noisy, the best solution may be to avoid the interference entirely by selecting an alternative, interference-free emission line for your analyte [4].

Issue 3: Calibration Failure on Specific Wavelengths

Problem: Your method calibration fails for specific analytical wavelengths, some of which may be involved in IEC.

Investigation and Resolution:

- Check for Spectral Interferences: The primary cause of calibration failure on specific lines is often an unaccounted-for spectral interference [17]. Use software tools to review the "Possible Interferences" graph for the failing wavelengths.

- Inspect the Blank: Contamination of your calibration blank with the analyte or a high concentration of the interfering element is a common problem that can cause calibration failure [17]. Always prepare a fresh blank to rule this out.

- Verify Standard Values and Stability: Ensure the values entered for your standards are correct and that the elements are chemically compatible and stable in the solution over time [17].

Experimental Protocols

Protocol 1: Determining an IEC Factor

This protocol describes how to empirically determine a correction factor for an interference of Element B on Analyte A.

1. Principle

The intensity measured at Analyte A's wavelength (I_net_A) is a sum of the true intensity from A (I_true_A) and the contribution from Element B (I_B_on_A). The IEC factor (k) is the proportionality constant that relates the concentration of B to I_B_on_A [2] [4].

2. Procedure

- Step 1: Aspirate a high-purity, blank solution and measure the background intensity at the wavelength for Analyte A.

- Step 2: Aspirate a high-purity standard solution of Analyte A at a known concentration and measure the net intensity. This establishes the sensitivity for A.

- Step 3: Aspirate a high-purity standard solution of the Interferent B. Its concentration should be high enough to produce a measurable signal at Analyte A's wavelength.

- Step 4: Calculate the IEC factor

(k). The net intensity measured from the pure B solution at A's wavelength isI_B_on_A. The IEC factorkis calculated as:k = I_B_on_A / Concentration_of_B - Step 5: In your ICP-OES software, enter the IEC equation for Analyte A. The corrected concentration of A will be calculated by the software using a relationship such as:

[A]_corrected = [A]_uncorrected - (k * [B])where[B]is the measured concentration of the interfering element [2].

The following workflow summarizes the key steps for establishing and validating an IEC factor:

Protocol 2: Validating IEC Performance According to Regulatory Guidelines

This protocol ensures your IEC setup meets the requirements of methods like EPA 6010D [2].

1. Principle Demonstrate that the correction successfully reduces the signal from an interferent to an acceptable level, typically a result close to zero for the analyte in a solution containing only the interferent.

2. Procedure

- Step 1: Prepare an interference check solution containing the interfering element(s) at the highest concentration expected in your samples, but containing none of the analyte.

- Step 2: Run this solution as an unknown.

- Step 3: Evaluate the result. The reported concentration for the analyte should be below the method's required limit (e.g., less than the method detection limit or a specified fraction of the regulatory limit).

- Step 4: If the result is not sufficiently low, the IEC factor may need to be re-determined, or a different analytical line for the analyte must be selected [2].

Data Presentation

Table 1: Example Data Set for IEC Factor Determination (As interference on Cd at 228.802 nm)

| Solution Composition | Net Intensity at Cd 228.802 nm | Calculated IEC Factor (k) |

|---|---|---|

| 100 µg/mL As | 672,850 counts | 672,850 / 100 µg/mL = 6728.5 |

| Blank (1% HNO₃) | ~110,000 counts (background) | N/A |

Table 2: Demonstrating IEC Effectiveness with an Interference Check Solution

| Interference Check Solution | Reported Cd Concentration (Uncorrected) | Reported Cd Concentration (After IEC) |

|---|---|---|

| 100 µg/mL As, 0 µg/mL Cd | ~5.4 µg/mL (False Positive) | < 0.1 µg/mL (Acceptable) |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for IEC Development and Validation

| Reagent / Material | Function in IEC Context |

|---|---|

| High-Purity Single-Element Standards | Used to determine the IEC factor without confounding signals from other elements [2] [4]. |

| Interference Check Solutions | Certified or carefully prepared solutions containing known interferents at high concentrations to validate the IEC [2]. |

| Acid-Matched Blank Solutions | High-purity nitric acid or other appropriate acids in water, used to establish baseline background signals [4] [18]. |

| Certified Reference Materials (CRMs) | Materials with known analyte concentrations in a relevant matrix, used for final validation of method accuracy after IEC is applied [19]. |

Spectral Interference Fundamentals: Identifying the Problem

Spectral interferences are a major source of error in ICP-OES analysis, occurring when the emission signal from an interfering element overlaps with the signal of the analyte element at the chosen wavelength. If not corrected, these interferences lead to falsely elevated concentrations and degraded method accuracy and precision [4] [2]. Understanding the types of spectral interference is the first step in avoiding them.

What are the main types of spectral interferences in ICP-OES?

There are three primary types of spectral interferences that analysts encounter:

- Direct Spectral Overlap: This is the most straightforward interference, where an emission line from an interfering element lies at the exact same wavelength as the analyte line. Modern high-resolution instruments can often resolve these overlaps, but if the wavelengths are separated by less than the instrument's resolution, the peaks will appear as a single, asymmetric peak or a peak with a "shoulder" [2].

- Wing Overlap: Also known as line wing overlap, this occurs when the broadened base (the "wings") of an intense emission line from an interfering element overlaps with a nearby analyte line [5].

- Background Interference (Continuum and Structured): The plasma itself produces a continuous background radiation at all wavelengths. High concentrations of matrix elements can elevate or shift this background, causing a sloping or curved baseline under the analyte peak. If not corrected, this leads to an inaccurate measurement of the analyte peak's intensity [4] [5].

The table below summarizes these interference types and their characteristics.

| Type of Interference | Description | Common Causes |

|---|---|---|

| Direct Spectral Overlap [5] [2] | An interfering element's emission line directly coincides with the analyte's wavelength. | Elements with complex emission spectra (e.g., Fe, Al, rare earths) near simpler analytes. |

| Wing Overlap [5] | The broadened base of a strong, nearby emission line overlaps the analyte line. | High concentrations of elements with very intense emission lines. |

| Background Interference [4] [5] | A shift or elevation of the spectral background beneath the analyte peak. | High concentrations of matrix elements (e.g., Ca, Na) contributing to continuum background. |

The Line Selection Strategy: A Proactive Avoidance Methodology

The most effective and highly recommended strategy for dealing with spectral interferences is avoidance through careful analytical line selection [4]. This proactive approach involves choosing an alternative emission line for your analyte that is free from known interferences in your sample matrix, rather than trying to correct for an overlap later.

How do I select the best analytical line to avoid interferences?

A robust line selection process involves the following steps:

- Consult Wavelength Tables: Begin by consulting instrument software libraries or published wavelength tables to identify all potential analytical lines for your analyte. Our Interactive Periodic Table lists the three most popular lines for each element, along with their major interferences [5].

- Prioritize Sensitivity and Freedom from Interference: The first step in line selection is to choose lines that meet the sensitivity requirements for your measurement. However, more than one line may be necessary due to spectral interferences. Always have a backup line selected [5].

- Perform a Spectral Interference Study: Wavelength tables are useful, but they are no replacement for an empirical study on your own instrument. These studies should be performed when the instrument is installed and repeated annually. They involve aspirating a high-purity, high-concentration (e.g., 1000 µg/mL) solution of the potential interfering element and examining the spectral regions around your candidate analyte lines for any unwanted signals [5].

- Verify with a Trace Metals Analysis: To distinguish between a true spectral overlap and the presence of your analyte as an impurity in the interfering element's solution, analyze the high-purity interfering solution for trace levels of your analyte. This requires standards with accurate trace metals impurity data [5].

The following workflow outlines a systematic approach to analytical line selection:

Experimental Protocols for Interference Checking

Protocol 1: Spectral Interference Study

This protocol is used to identify potential spectral overlaps for your selected analyte lines [5].

- Objective: To empirically identify direct, wing, and background interferences on candidate analytical lines.

- Materials:

- ICP-OES with instrument software capable of spectral scanning.

- High-purity (e.g., 1000 µg/mL) single-element standard solutions for all major matrix components in your samples.

- High-purity acid blank (e.g., 1% HNO₃).

- Method:

- Aspirate the acid blank and perform a spectral scan across the wavelength region for each of your candidate analyte lines. This establishes the baseline.

- Aspirate the first high-purity interfering element solution.

- Perform a spectral scan over the same wavelength regions as in step 1.

- Overlay the spectrum from the interferent solution onto the blank spectrum. Any signal above the blank baseline in the region of the analyte peak indicates a potential spectral interference.

- Repeat steps 2-4 for every major matrix component.

- Interpretation: A clean, flat spectrum from the interferent solution that matches the blank indicates the analyte line is free from interference from that specific element.

Protocol 2: Interference Check Solution Analysis

This is a standard requirement in many regulated methods (e.g., US EPA 200.7, 6010D) to demonstrate that an analysis is free from spectral interferences [2].

- Objective: To verify that your final method and line selection are not affected by spectral interferences.

- Materials:

- Prepared interference check solutions (ICS). These are solutions containing high concentrations of well-documented interfering elements but should contain little to none of the analytes of interest.

- Calibrated ICP-OES.

- Method:

- Analyze the interference check solution as an unknown sample.

- Record the measured concentration for each analyte.

- Interpretation: The measured concentration for each analyte should be close to zero (e.g., below the method detection limit). If a significant concentration is reported for an analyte that should not be present, an interference is confirmed, and corrective action (such as selecting a new analytical line) must be taken [2].

Critical Limitations of Common Practices

A critical and often overlooked point is that neither good spike recoveries nor the use of the Method of Standard Additions (MSA) guarantees accurate results if a spectral interference is present [20].

Why don't spike recovery tests or the Method of Standard Additions correct for spectral interferences?

Both techniques add analyte to the sample matrix. If the matrix contains an interferent that contributes to the signal at the analyte wavelength, the interference affects both the original sample and the spiked sample equally. The recovery calculation may appear acceptable (typically 85-115%), but the reported concentration for the original sample will be biased high. The table below demonstrates this phenomenon using the determination of Phosphorus in the presence of high Copper [20].

| Analytical Wavelength (nm) | Known [P] = 10 mg/L | Spike Recovery | Result with MSA |

|---|---|---|---|

| P 213.617 (Interfered by Cu) | ~17 mg/L (Inaccurate) | 100% (Acceptable) | ~17 mg/L (Inaccurate) |

| P 214.914 (Interfered by Cu) | ~16 mg/L (Inaccurate) | 92% (Acceptable) | ~16 mg/L (Inaccurate) |

| P 178.221 (Clean line) | 10 mg/L (Accurate) | 101% (Acceptable) | 10 mg/L (Accurate) |

Data adapted from an experimental example where 10 mg/L P in 200 mg/L Cu was analyzed using different wavelengths [20].

This data clearly shows that while spike recovery and MSA can compensate for physical and matrix-related interferences, they cannot compensate for spectral interferences. The only solution in this case is to use an interference-free line like P 178.221 or to apply a valid inter-element correction.

Research Reagent Solutions

The table below lists key reagents and materials essential for developing and validating interference-free ICP-OES methods.

| Reagent / Material | Function in Interference Avoidance |

|---|---|

| High-Purity Single-Element Standards [5] | Used in spectral interference studies to identify overlaps. High purity is critical to rule out analyte impurity as a cause of signal. |

| Interference Check Solutions (ICS) [2] | Quality control solutions containing high levels of potential interferents. Used to validate that the final method is free from spectral interferences. |

| High-Purity Acids & Water | Used for preparing blanks, standards, and samples. Minimizes background signal and introduction of contaminant elements that could cause interference. |

| Internal Standard Solution [21] | An element not expected in samples (e.g., Sc, Y, In) used to monitor and correct for physical interferences and sample-to-sample variability, isolating spectral effects. |

FAQs

Q1: My instrument has high resolution. Can I ignore spectral interferences? A: No. While high-resolution instruments can resolve many spectral overlaps down to baseline, some interferences, particularly direct overlaps with a separation smaller than the instrument's resolution, will remain and require correction or avoidance [2] [7].

Q2: If I matrix-match my standards and samples, do I still need background correction? A: It can be argued that matrix-matching eliminates the need for background correction, as the background should be similar. However, the problems with perfectly matrix-matching all samples and standards are significant and may offset any advantage gained. Background correction is generally still recommended [4].

Q3: What should I do if I cannot find a completely interference-free line for my analyte? A: If avoidance is not fully possible, you must employ a correction technique. The most common is Inter-Element Correction (IEC), which is a mathematical correction built into most instrument software. It uses a predetermined "correction coefficient" to subtract the interfering element's contribution to the analyte signal [4] [2].

Leveraging Modern Software for Automated Correction and Workflow Integration

FAQs: Spectral Interference and Software Correction

What are the main types of spectral interference in ICP-OES, and how does software help correct them?

Spectral interferences occur when an emission line from an interfering element overlaps with the analyte line you are measuring. Modern ICP-OES software provides tools to manage the three primary interference types [2]:

- Direct Spectral Overlap: When the interference and analyte wavelengths are separated by less than the instrument's resolution. The peak may appear asymmetric or have a "shoulder" [2].

- Wing Overlap: When the wing of a broad or intense spectral line from an interferent overlaps with your analyte line [4].

- Background Interference: Caused by shifts in background radiation due to the sample matrix, which can be flat, sloping, or curved [4].

Software assists by allowing you to select alternative, interference-free analytical lines automatically. When avoidance is not possible, it facilitates Inter-Element Correction (IEC) and sophisticated background correction algorithms to mathematically subtract the interference [2] [4].

My results for cadmium are consistently high when arsenic is present in the sample. What is the likely cause, and how can I fix this?

This is a classic example of a direct spectral overlap. The cadmium line at 228.802 nm can be directly overlapped by the arsenic line at 228.812 nm [4]. The software will measure the combined intensity from both elements, leading to falsely elevated cadmium results.

Solution: Implement an Inter-Element Correction (IEC). Your software will use a pre-determined correction factor to subtract the contribution of arsenic from the total measured intensity at the cadmium wavelength [2] [13].

- Corrected Intensity (Cd) = Uncorrected Intensity (Cd) - (h × Concentration of As)

where

his the correction factor determined from analyzing a high-purity arsenic standard [13]. Modern software allows you to set up and validate these IEC equations as a routine part of your analysis workflow [2].

How can I validate that my software's interference corrections are working correctly?

It is a requirement of many regulated methods (e.g., US EPA 6010D) to demonstrate that an analysis is free from spectral interferences [2]. This is done by running Interference Check Solutions (ICS).

Experimental Protocol:

- Preparation: Create a solution containing a high concentration of the suspected interfering element (e.g., 100 µg/mL Arsenic) but none of your target analyte (e.g., Cadmium).

- Analysis: Run this ICS through your ICP-OES method.

- Validation: The software should report a concentration for the target analyte that is close to zero. A significant positive result indicates the interference is not fully corrected, and your IEC factor may need adjustment [2]. This check can be integrated into your daily workflow for ongoing validation.

The software's background correction seems inaccurate for my samples. What should I check?

Inaccurate background correction often stems from improperly placed background correction points. The location of these points is critical and depends on the background's shape [4].

Troubleshooting Guide:

- Symptom: Consistently high or low results.

- Investigation: Manually inspect the spectral profile for your analyte.

- Solutions:

- For Flat Backgrounds: Ensure background points are placed on both sides of the peak in regions free of other spectral features [4].

- For Sloping Backgrounds: Place background points at equal distances from the peak center to accurately estimate the slope [4].

- For Curved Backgrounds (near a high-intensity line): Use a curved (e.g., parabolic) correction algorithm if your software supports it. If possible, consider switching to an alternate analytical line with a less complex background [4].

What is the difference between concentration-based and intensity-based inter-element corrections?

This distinction defines what value is used to calculate the interference.

- Concentration-Based Correction (Preferred Method): This method uses the calculated concentration of the interfering element to perform the correction. It requires high-quality, well-characterized calibration standards for all interfering elements and is the most common and robust approach used in ICP-OES [13].

Ci = A0 + A1 (Ii - hCj)whereCjis the concentration of the interfering element [13].

- Intensity-Based Correction: This method uses the raw measured intensity of the interfering element's spectral line. It is useful when you lack concentration standards for the interferent but know which spectral line is causing the overlap [13].

Ci = A0 + A1 (Ii - hijIj)whereIjis the intensity of the interfering element [13].

The table below compares the impact of an uncorrected Arsenic interference on Cadmium results, highlighting the necessity of using a correction method [4].

Table 1: Impact of 100 µg/mL Arsenic on Cadmium Detection at 228.802 nm

| Cadmium Concentration | Uncorrected Relative Error | Best-Case Corrected Relative Error | Note |

|---|---|---|---|

| 0.1 ppm | 5100% | 51% | Detection limit severely degraded |

| 1 ppm | 541% | 5.5% | Quantitative analysis impossible without correction |

| 10 ppm | 54% | 1.1% | Significant bias without correction |

| 100 ppm | 6% | 1.0% | Bias is reduced but correction still improves accuracy |

How does automated sample preparation integrate with ICP-OES software to improve data integrity?

Advanced autosamplers and diluters (e.g., ACAROS, Agilent ADS 2) integrate directly with ICP-OES instruments and their software [22] [23]. This creates a seamless, traceable workflow:

- Unified Control: The ICP-OES software controls the automated preparation system, triggering dilutions, calibration, and quality control checks [22] [23].

- Gravimetric Precision: Some systems use high-precision balances for weight-based dilution, minimizing human error and improving reproducibility beyond traditional volumetric methods [22].

- Data Traceability: All dilution factors and preparation steps are automatically recorded within the analytical data file, ensuring full traceability and simplifying compliance with regulatory standards [23].

Troubleshooting Guides

Guide 1: Resolving Poor Accuracy Due to Spectral Interferences

Follow this logical pathway to systematically identify and correct the source of interference in your analysis.

Guide 2: Implementing an Inter-Element Correction (IEC)

This protocol provides a detailed methodology for establishing a concentration-based IEC factor, as referenced in the troubleshooting guide [2] [13].

Objective: To determine the correction factor (h) for the impact of an interfering element (j) on an analyte element (i).

Materials:

- ICP-OES with software capable of IEC (e.g., Thermo Scientific Qtegra ISDS) [2].

- High-purity single-element standard for the interfering element (j).

- Appropriate calibration standards for analyte (i).

Procedure:

- Method Setup: In the software, navigate to the method editor for your analyte and select the option to add an inter-element correction.

- Analyze Interferent Standard: Aspirate a high-purity standard containing a known, significant concentration of the interfering element (Cj) but no analyte (i).

- Record Apparent Intensity: The software will measure the apparent intensity (or concentration) of analyte (i) at its wavelength due to the interference from element (j). Record this value as I_apparent.

- Calculate Correction Factor (h): The software typically calculates the factor (h) automatically using the formula:

- h = I_apparent / Cj This factor, expressed in intensity units per concentration, is saved in the method.

- Validate the Correction: Re-analyze the interference check solution. The corrected result for analyte (i) should now be close to zero. The effectiveness of the IEC should be demonstrated as part of the daily workflow by running an interference check solution [2].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Interference Correction in ICP-OES

| Item | Function | Application Note |

|---|---|---|

| High-Purity Single-Element Standards | Used to characterize spectral interferences and calculate IEC factors [13]. | Essential for creating Interference Check Solutions. |

| Interference Check Solutions (ICS) | Validates that spectral corrections are working effectively [2]. | Should contain high concentrations of documented interferents. |

| Certified Reference Materials (CRMs) | Verifies the accuracy of the overall analytical method, including all corrections. | Matrix-matched CRMs provide the highest level of confidence. |

| Automated Dilution System | Integrates with ICP-OES software to perform precise, traceable dilutions, reducing human error [22] [23]. | Critical for high-throughput labs and generating reproducible calibration curves. |

| Argon Humidifier | Prevents salt crystallization in the nebulizer gas channel, a physical interference that can affect signal stability [8]. | Particularly important for analyzing high-total-dissolved-solids (TDS) samples. |

A step-by-step guide for researchers on identifying and correcting a direct spectral overlap in ICP-OES analysis.

When determining Cadmium (Cd) at its most sensitive 228.802 nm line in the presence of Arsenic (As), a direct spectral overlap occurs because the Arsenic emission line at 228.812 nm is too close to be resolved by the spectrometer [4] [2]. This interference causes falsely high or positive results for Cd [3]. This guide provides a practical, step-by-step example of how to correct for this specific interference.

Understanding the Interference

The following workflow outlines the complete process for identifying and correcting the As-on-Cd interference:

Quantitative Feasibility Assessment

Before applying a correction, you must first determine if it is feasible for your required Cd detection limits and the level of As present. The table below summarizes the impact of 100 µg/mL As on Cd measurements at the 228.802 nm line, assuming a 1% measurement precision for both Cd and As intensities [4].

Table 1: Impact of 100 µg/mL Arsenic on Cd 228.802 nm Line Measurements [4]

| Cd Concentration (µg/mL) | Ratio (As/Cd) | Uncorrected Relative Error (%) | Best-Case Corrected Relative Error (%) | Notes |

|---|---|---|---|---|

| 0.1 | 1000 | 5100 | 51.0 | Detection limit severely degraded; correction is ineffective. |

| 1 | 100 | 541 | 5.5 | Quantitation possible with correction, but with moderate error. |

| 10 | 10 | 54 | 1.1 | Correction is effective and provides good results. |

| 100 | 1 | 6 | 1.0 | Interference impact is minimal; correction works very well. |

Key Interpretation of the Data

- High Ratio (As/Cd > 10): The uncorrected error is massive. While mathematical correction improves the result, the residual error is often unacceptably high, and the detection limit for Cd is significantly degraded [4]. In one assessment, the detection limit for Cd degraded from 0.004 ppm (clean) to approximately 0.5 ppm in the presence of 100 ppm As [4].

- Low Ratio (As/Cd ≤ 10): The interference correction becomes robust and reliable, yielding accurate results with minimal error [4].

Step-by-Step Correction Protocol

Step 1: Collect Spectral Data and Confirm the Overlap

Aspirate high-purity single-element solutions and collect spectral scans around 228.802 nm.

- Aspirate a 100 µg/mL Cd standard: Note the net intensity at the peak center [4].

- Aspirate a 100 µg/mL As standard: Observe the signal intensity it produces at the Cd 228.802 nm wavelength. A significant signal confirms the direct spectral overlap [4].

- Compare spectra: Use your instrument's software to overlay the spectra, as shown in Figure 8.5 of the search results, to visually confirm the overlap [4].

Step 2: Determine the Correction Coefficient (K)

The correction coefficient represents the signal contribution of As per unit concentration at the Cd wavelength.

- Prepare a series of at least three calibration standards containing known concentrations of As (e.g., 50, 100, 150 µg/mL). The solutions should not contain any Cd.

- Aspirate these standards and measure the intensity at the Cd 228.802 nm line.

- Plot the intensity (y-axis) against the As concentration (x-axis). The slope of the resulting line is your correction coefficient (K), in units of Intensity per (µg/mL As) [4].

Step 3: Apply the Inter-Element Correction (IEC)

The core correction is performed using the following equation [4] [2]:

Corrected Cd Intensity = (Measured Intensity at Cd λ) - [ (K) × (Measured As Concentration) ]

- Measured Intensity at Cd λ: The raw intensity measured for your sample at the Cd 228.802 nm line.

- K: The correction coefficient determined in Step 2.

- Measured As Concentration: The concentration of As in your sample, determined by measuring As at its own, interference-free emission line.

This correction is often automated within the ICP-OES instrument's software, where you can define the interfering element (As), the analyte (Cd), and the pre-determined K factor [2].

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents and Materials for Interference Correction [4] [24]

| Item | Function | Critical Considerations |

|---|---|---|

| High-Purity As Standard | To determine the correction coefficient (K). | Use a standard with certified low Cd impurities to avoid overestimating the interference [4] [25]. |

| High-Purity Cd Standard | For analyte calibration and sensitivity checks. | Ensure it is free of As to obtain a clean Cd spectrum for line selection [4]. |

| Internal Standard (e.g., Yttrium) | Corrects for physical matrix effects and signal drift [24]. | Must not be present in samples and must be spectrally free from interferences. The internal standard's behavior in the plasma (ionic or atomic) should match that of your analytes for optimal correction [24]. |

| Interference Check Solution | Validates the correction. Contains a high concentration of As but no Cd [2]. | After applying the correction, the result for Cd in this solution should be close to zero. This is often a requirement of regulated methods like EPA 6010D [2]. |

Method Validation and Quality Control

- Always Use an Interference Check Solution: Analyze a solution containing a high level of As (e.g., 100 µg/mL) but no Cd after applying your correction. A successful correction will yield a Cd concentration report below your method's limit of quantitation [2].

- Monitor Multiple Cd Lines: If your instrument allows, simultaneously monitor a secondary, less-sensitive Cd line that is free from As interference. Agreement between the corrected primary line and the secondary line increases confidence in your results [25].

- Re-establish Detection Limits: As shown in Table 1, the presence of the interference degrades detection limits. You must experimentally determine the new Method Detection Limit (MDL) for Cd in the presence of your expected As matrix [4].

Key Takeaways and Best Practices

- Avoidance is Preferable: The most robust approach is to select an alternative, interference-free Cd emission line if sensitivity requirements permit [4] [2].

- Correction is Concentration-Dependent: Inter-element corrections are most reliable when the concentration of the interferent (As) is not massively greater than that of the analyte (Cd) [4].

- Validate Rigorously: Never rely on a mathematical correction without thorough validation using interference check solutions and, if possible, a second analytical technique or line.

Achieving Precision: Troubleshooting Common Pitfalls and Optimizing Methods

What is the purpose of a spectral interference study in ICP-OES?

A spectral interference study is a systematic process to identify and document unwanted spectral lines from other elements that overlap with your analyte's emission line [26]. The goal is to ensure accurate results by either selecting interference-free analytical lines or setting up appropriate mathematical corrections. Conducting this study is crucial because spectral interferences can lead to false positives or falsely elevated results, compromising data reliability [3] [20].

What are the main types of spectral interferences I need to look for?

Spectral interferences in ICP-OES generally fall into three categories. The table below summarizes them for easy identification.

| Interference Type | Description | Visual Clue |

|---|---|---|

| Direct Spectral Overlap [2] | An interfering element has an emission line at the exact same wavelength as your analyte. | The analyte peak may appear asymmetric or have a slight "shoulder" [2]. |

| Wing Overlap [26] | The wing (broadened base) of a high-intensity line from a concentrated element overlaps with your analyte line. | Elevated background on one or both sides of the analyte peak [26]. |