Single-Beam vs. Double-Beam UV-Vis Spectrophotometers in Pharmaceutical Analysis: A Comprehensive Guide for Scientists

This article provides a detailed comparison of single-beam and double-beam UV-Vis spectrophotometers, specifically tailored for pharmaceutical researchers and drug development professionals. It explores the foundational principles, distinct advantages, and limitations of each instrument type. The scope extends to methodological applications in drug quantification, impurity profiling, and dissolution testing, alongside practical guidance for troubleshooting common issues and ensuring regulatory compliance. By synthesizing validation protocols and comparative performance metrics, this guide aims to equip scientists with the knowledge to select the optimal spectrophotometer for their specific pharmaceutical QA/QC and research needs, ultimately enhancing analytical accuracy and efficiency in drug development.

Single-Beam vs. Double-Beam UV-Vis Spectrophotometers in Pharmaceutical Analysis: A Comprehensive Guide for Scientists

Abstract

This article provides a detailed comparison of single-beam and double-beam UV-Vis spectrophotometers, specifically tailored for pharmaceutical researchers and drug development professionals. It explores the foundational principles, distinct advantages, and limitations of each instrument type. The scope extends to methodological applications in drug quantification, impurity profiling, and dissolution testing, alongside practical guidance for troubleshooting common issues and ensuring regulatory compliance. By synthesizing validation protocols and comparative performance metrics, this guide aims to equip scientists with the knowledge to select the optimal spectrophotometer for their specific pharmaceutical QA/QC and research needs, ultimately enhancing analytical accuracy and efficiency in drug development.

UV-Vis Spectroscopy Fundamentals: Core Principles for Pharma Analysis

The Principle of UV-Vis Spectroscopy and Beer-Lambert Law

Ultraviolet-Visible (UV-Vis) spectroscopy is a fundamental analytical technique in pharmaceutical research, measuring the absorption of light in the ultraviolet (200–400 nm) and visible (400–800 nm) regions of the electromagnetic spectrum [1]. This method provides valuable information for identifying substances, determining their concentration, and studying molecular interactions based on how light interacts with matter. The technique operates on the principle that molecules contain chromophores—functional groups that absorb light at specific wavelengths—leading to electronic transitions from ground state to excited state [1] [2]. The resulting absorption spectrum serves as a molecular fingerprint, providing critical data for drug discovery, quality control, and analytical research in pharmaceutical settings.

The global UV-Vis spectroscopy market reflects its indispensable role, projected to grow from USD 21.52 billion in 2025 to USD 27.62 billion by 2030 at a 5.12% compound annual growth rate (CAGR) [3]. This growth is particularly driven by pharmaceutical and biotechnology applications, which accounted for 48.54% of the market share in 2024 [3]. Within this sector, the technique is crucial for drug quality control, release testing (46.43% market share in 2024), and the rapidly expanding field of bioprocess monitoring (projected 8.56% CAGR through 2030) [3]. The technology continues to evolve with advancements in portability, automation, and integration with computational methods, maintaining its status as an essential tool for modern drug development professionals.

Fundamental Principles and Instrumentation

The Beer-Lambert Law

The quantitative foundation of UV-Vis spectroscopy is the Beer-Lambert Law (also referred to as the Bouguer-Beer-Lambert Law), which establishes the relationship between light absorption and analyte concentration [2] [4]. This principle states that the absorbance (A) of a solution is directly proportional to the concentration (c) of the absorbing species and the path length (l) of the light through the sample:

A = εcl

Where:

- A is the measured absorbance (unitless)

- ε is the molar absorptivity or extinction coefficient (L·molâ»Â¹Â·cmâ»Â¹)

- c is the concentration of the analyte (mol/L)

- l is the path length of the sample cell (cm) [2] [4]

The absorbance is calculated from the ratio of incident light intensity (Iâ‚€) to transmitted light intensity (I), expressed as A = -logâ‚â‚€(I/Iâ‚€) [1] [4]. This logarithmic relationship means that each unit of absorbance corresponds to a tenfold reduction in light intensity passing through the sample.

The Beer-Lambert Law has specific limitations that pharmaceutical researchers must consider. It assumes a linear relationship between absorbance and concentration, which holds true only for dilute solutions [5]. At higher concentrations (typically >0.01M), electrostatic interactions between molecules can alter absorptivity, deviating from linearity [5]. Other factors including light scattering in turbid samples, fluorescence, chemical reactions during measurement, and stray light can also violate the law's assumptions [5]. For accurate quantitative analysis, absorbance values should generally be kept below 1.0 AU, as higher values can exceed the dynamic range of instruments where detectors struggle to measure small differences in high light attenuation [1].

Instrument Components and Operation

All UV-Vis spectrophotometers share fundamental components despite design variations between models:

- Light Source: Provides stable broadband illumination, typically using deuterium lamps for UV (190–400 nm) and tungsten-halogen lamps for visible regions (320–1100 nm) [1] [6]. Some instruments employ single xenon lamps covering both ranges [1].

- Monochromator: Isolates specific wavelengths using diffraction gratings (typically 1200+ grooves/mm) or filters [1] [6]. This component determines the instrument's spectral bandwidth and resolution.

- Sample Holder: Secures cuvettes (usually with 1 cm path length) or other sample containers in the light path [4]. Quartz cuvettes are essential for UV work as glass and plastic absorb UV light [1].

- Detector: Converts transmitted light intensity into electrical signals. Modern instruments use photodiodes, charge-coupled devices (CCDs), or photomultiplier tubes (PMT) for enhanced sensitivity [1] [6].

- Signal Processor: Calculates and displays absorbance, transmittance, or concentration values, with modern instruments featuring digital interfaces and connectivity [4].

The basic operational workflow involves measuring a blank/reference sample first to establish baseline, followed by the sample measurement where the instrument compares transmitted light intensities to calculate absorbance [4].

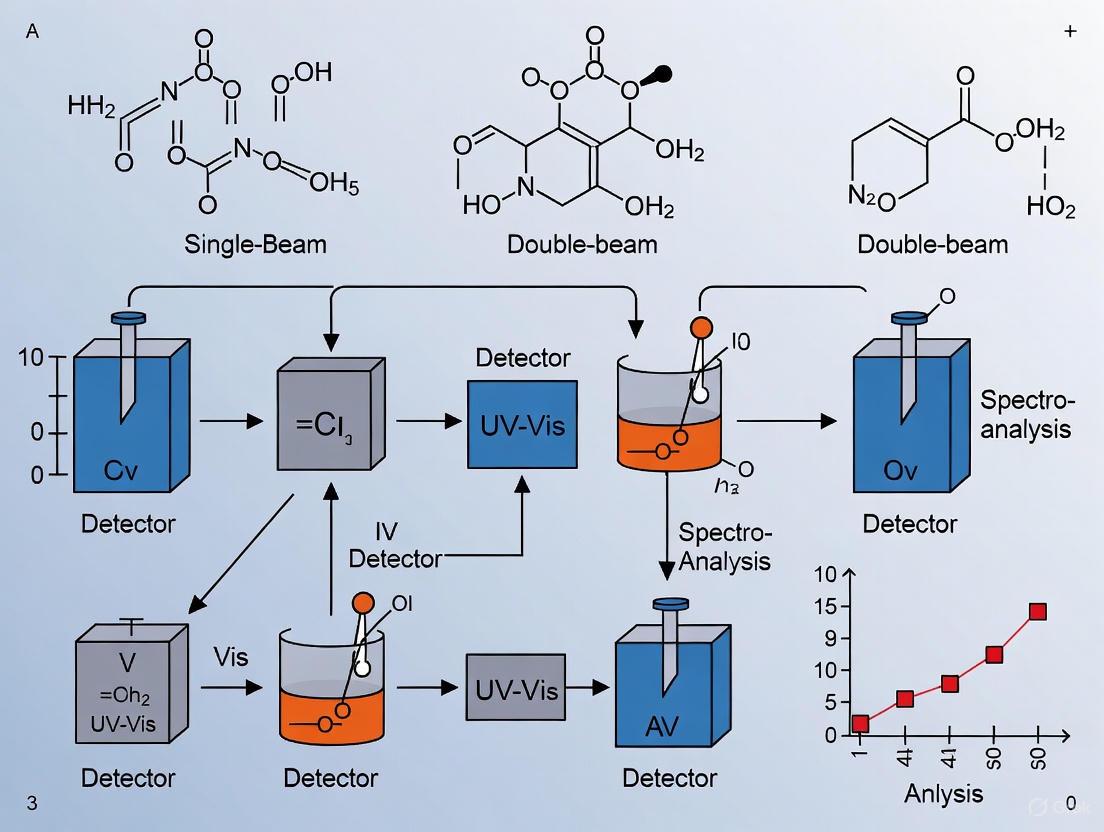

Figure 1: UV-Vis Spectrophotometer Component Workflow. The diagram illustrates the sequential path of light through essential components, with the dashed line indicating the initial blank measurement crucial for accurate absorbance calculation.

Single-Beam vs. Double-Beam Configurations

Optical Design and Operating Principles

The fundamental distinction in UV-Vis spectrophotometers for pharmaceutical applications lies in their optical configurations: single-beam and double-beam designs, each with unique advantages and limitations.

Single-Beam Systems utilize a straightforward optical path where light passes sequentially through the monochromator, sample, and detector [6] [4]. Measurement requires a two-step process: first, a blank reference is measured to establish baseline; then, the sample is measured and compared to the stored reference [4]. This simpler design provides higher light throughput due to fewer optical components, potentially offering better signal-to-noise ratio for specific applications [6]. Modern single-beam instruments have addressed historical stability concerns through improved electronics and correction algorithms [6].

Double-Beam Systems employ an optical chopper (typically a rotating mirror or beam splitter) to divide the light beam into two separate paths: one passing through the sample and the other through a reference blank [6]. Both beams are directed to a single detector, rapidly alternating between sample and reference measurements [6]. This real-time comparison compensates for instrumental drift, lamp instability, and environmental fluctuations, providing superior long-term stability [6]. The design inherently corrects for source and detector instabilities, making it particularly valuable for lengthy analyses and unstable samples [6].

Figure 2: Single-Beam vs. Double-Beam Optical Designs. Single-beam systems use a single light path requiring sequential measurement, while double-beam systems simultaneously measure sample and reference via split optical paths.

Performance Comparison and Pharmaceutical Applications

Table 1: Comprehensive Comparison of Single-Beam and Double-Beam UV-Vis Spectrophotometers

| Parameter | Single-Beam Systems | Double-Beam Systems |

|---|---|---|

| Optical Design | Single light path; sequential reference & sample measurement [4] | Simultaneous sample and reference measurement via beam splitting [6] |

| Cost Considerations | Lower initial investment; cost-effective for budget-limited labs [6] [4] | Higher initial cost; justified by analytical performance in regulated environments [6] |

| Photometric Accuracy | Adequate for routine analysis (±0.005-0.01 AU); susceptible to drift [4] | Superior accuracy (±0.002 AU); real-time reference compensation [6] |

| Signal Stability | Requires stable conditions; modern electronics improve performance [6] | Excellent long-term stability; ideal for kinetic studies and lengthy analyses [6] |

| Pharmaceutical Application Fit | Routine QC checks, educational use, field testing [4] | Regulatory-compliant analysis, bioprocess monitoring, research [3] [6] |

| Sample Throughput | Lower for reference-intensive methods | Higher for methods requiring frequent blanking |

| Stray Light Performance | Dependent on monochromator quality | Typically <0.01%T at 220 nm [6] |

| Maintenance Requirements | Simpler optical alignment | More complex optical system |

The double-beam UV-VIS spectrophotometer market is projected to reach $498 million in 2025, growing at a 4.4% CAGR through 2033, reflecting its essential role in pharmaceutical and biological analysis [7]. The pharmaceutical industry dominates this segment, accounting for approximately 40% of the double-beam market due to stringent quality control requirements [7].

For single-beam systems, key advantages include simplified optics, compact footprint, and lower cost, making them suitable for teaching laboratories, routine quality control checks with stable samples, and field applications where portability is prioritized [4]. Their main limitations stem from potential measurement drift due to source intensity fluctuations, requiring more frequent recalibration.

Double-beam systems excel in applications demanding high precision and stability, particularly in regulated pharmaceutical environments where compliance with FDA 21 CFR Part 11 and pharmacopeial standards is essential [3] [6]. Their ability to maintain baseline stability during lengthy kinetic studies, temperature-controlled experiments, and automated multi-sample measurements makes them indispensable for modern drug development workflows, particularly in bioprocess monitoring which is projected to grow at 8.56% CAGR [3].

Experimental Protocols and Data Analysis

Standardized Measurement Protocols

Protocol 1: Quantitative Analysis of Active Pharmaceutical Ingredients (APIs)

- Instrument Calibration: Verify wavelength accuracy using holmium oxide filter (characteristic peaks at 241.5, 287.5, 361.0, 453.0, 536.5 nm) [6]. Check photometric accuracy with potassium dichromate standards [4].

- Preparation of Standard Solutions: Create minimum five standard solutions of reference standard API covering concentration range from 20% to 150% of target concentration. Use appropriate solvent matching formulation matrix.

- Blank Measurement: Fill quartz cuvette with solvent/vehicle and measure baseline across required wavelength range (typically 200-400 nm for UV-active compounds).

- Standard Curve Acquisition: Measure each standard solution in triplicate at predetermined λmax. Record average absorbance values.

- Sample Analysis: Measure unknown samples following identical procedure. For single-beam instruments, recheck blank every 5-6 samples; double-beam systems automatically reference blank.

- Data Analysis: Plot absorbance vs. concentration, apply linear regression. Acceptable correlation coefficient (R²) ≥ 0.995 for validated methods.

Protocol 2: Kinetic Studies for Reaction Monitoring

- Initial Setup: Select fixed wavelength(s) based on reactant or product absorption characteristics. Set temperature control if available.

- Baseline Establishment: For single-beam: measure blank containing solvent/reaction matrix. For double-beam: place reference cell containing initial reaction mixture.

- Reaction Initiation: Mix reactants directly in cuvette or use stopped-flow accessory for fast kinetics.

- Data Acquisition: Monitor absorbance change at fixed time intervals (milliseconds to minutes depending on reaction rate). Double-beam systems provide superior stability for extended measurements.

- Data Processing: Convert absorbance to concentration using extinction coefficient. Plot concentration vs. time to determine reaction order and rate constants.

Advanced Applications with Chemometrics

Modern UV-Vis spectroscopy increasingly incorporates chemometric approaches to overcome traditional limitations with complex samples. Spectralprint analysis utilizes entire spectral data rather than single wavelengths, enabling simultaneous quantification of multiple components in mixtures through multivariate calibration methods [8]. This approach is particularly valuable for pharmaceutical formulations containing multiple active ingredients with overlapping absorption bands.

Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression can extract relevant information from broad, overlapping UV-Vis spectra of complex mixtures, allowing quantification without physical separation [8]. These methods have revived UV-Vis applications in direct analysis of herbal medicines, polycomponent formulations, and process analytical technology (PAT) in biomanufacturing [8].

Table 2: Research Reagent Solutions for Pharmaceutical UV-Vis Spectroscopy

| Reagent/Material | Function/Application | Specification Considerations |

|---|---|---|

| Quartz Cuvettes | Sample holder for UV range | High transparency down to 190 nm; matched pairs for double-beam [1] |

| Holmium Oxide Filter | Wavelength calibration | Certified reference material with characteristic sharp peaks [6] |

| Potassium Dichromate | Photometric accuracy verification | ACS grade in perchloric acid for precise absorbance at 257 nm [4] |

| Buffer Solutions | Sample dissolution medium | UV-transparent; appropriate pH control without interfering absorptions |

| Neutral Density Filters | Stray light verification | Certified attenuation values across spectral range [6] |

| Protein A Standards | Biologics quantification | High purity for monoclonal antibody concentration curves [3] |

The selection between single-beam and double-beam UV-Vis spectrophotometers represents a critical decision point for pharmaceutical research and development operations. Single-beam systems offer cost-effective solutions for routine measurements, educational purposes, and applications where portability and simplicity are prioritized [4]. Their streamlined optical path provides higher light throughput advantageous for specific low-light applications. However, they require more meticulous calibration routines and stable environmental conditions to maintain measurement integrity.

Double-beam instruments deliver superior analytical performance through real-time reference compensation, making them indispensable for regulated pharmaceutical environments, lengthy kinetic studies, and high-precision quantification required in modern drug development [6]. The double-beam design's ability to correct for instrumental and environmental fluctuations ensures data integrity compliant with stringent regulatory standards like FDA 21 CFR Part 11 and pharmacopeial chapters <857> [3] [6].

The continuing evolution of UV-Vis spectroscopy, including integration with chemometrics [8], miniaturization for point-of-care testing [3], and enhanced data integrity features [3], ensures its ongoing relevance in pharmaceutical sciences. As the market continues to grow at 5.12% CAGR [3], both single-beam and double-beam technologies will maintain their complementary roles in the analytical toolkit of drug development professionals, with selection dependent on the specific application requirements, regulatory context, and operational constraints of each pharmaceutical research setting.

In the pharmaceutical industry, the accuracy and reliability of Ultraviolet-Visible (UV-Vis) spectroscopy are paramount for critical analyses ranging from drug quantification to nucleic acid purity assessment. The fundamental components of these instruments—their light sources, monochromators, and detectors—along with the choice between single-beam and double-beam optical design, directly dictate their performance in a regulated research environment. This guide provides an objective comparison of single-beam and double-beam UV-Vis spectrophotometers, detailing their operational principles, performance characteristics, and suitability for pharmaceutical applications, supported by experimental data and standardized protocols.

Instrument Fundamentals and Design Comparison

Core Optical Components

The performance of any UV-Vis spectrophotometer is governed by the integrated function of its three core subsystems.

- Light Sources: These provide the broad-spectrum electromagnetic radiation necessary for analysis. Typical sources include deuterium lamps for the ultraviolet region and tungsten or tungsten-halogen lamps for the visible region. Some instruments employ xenon flash lamps that cover both UV and visible spectra, enabling rapid measurements without the need to switch between sources [9].

- Monochromators: This component is responsible for isolating a specific, narrow band of wavelength from the broad output of the light source. At its heart is a diffraction grating—a surface with many parallel grooves that disperses light, sending different wavelengths in different directions [9]. Key components include an entrance slit, the dispersive element (grating or prism), and an exit slit. By precisely rotating the grating, specific wavelengths are passed through the exit slit. Instruments utilizing a double monochromator (two dispersion stages in sequence) offer superior resolution and significantly reduce stray light, which is a critical source of error, especially at high absorbances [9] [10].

- Detectors: These devices convert the transmitted light intensity into an electrical signal. Common detectors include photomultiplier tubes (PMTs), which offer high sensitivity, and solid-state devices like photodiode arrays (PDAs) or charge-coupled devices (CCDs). A distinct advantage of a PDA is its ability to measure all wavelengths simultaneously, enabling instantaneous capture of full spectra without the need for scanning [9].

Single-Beam vs. Double-Beam Optical Design

The configuration of the light path after the monochromator defines the two primary instrument categories, each with distinct advantages and limitations [11].

- Single-Beam Design: A single light beam passes through the monochromator, then the sample cuvette, and finally to the detector. To perform a measurement, the instrument first records a baseline (100% transmittance or 0 absorbance) with a blank solvent. The blank is then replaced with the sample to measure its absorbance [11].

- Double-Beam Design: The light beam is split into two parallel paths: one passes through the sample cuvette and the other through a reference cuvette containing the blank solvent. The intensities of both beams are then measured by the detector(s) and compared in real-time [11].

The table below summarizes the fundamental differences in their design and operational principles.

Table 1: Fundamental Design and Operational Principles

| Feature | Single-Beam Spectrophotometer | Double-Beam Spectrophotometer |

|---|---|---|

| Light Path | A single beam passes through the sample only [11]. | The beam is split into reference and sample beams [11]. |

| Absorbance Measurement | Direct measurement of sample transmittance (A = log10(Iâ‚€/I)) [11]. | Ratiometric measurement (A = log10(Iáµ£/Iâ‚›)) [11]. |

| Key Components | Monochromator, sample cuvette, detector, source [11]. | Monochromator, beam splitter, reference & sample cuvettes, dual detector [11]. |

Performance Comparison and Experimental Data

The design differences between single-beam and double-beam instruments translate directly into measurable differences in performance, which are critical for pharmaceutical research.

Quantitative Performance Metrics

The following table consolidates key performance indicators based on instrumental design, highlighting factors that impact data quality in quantitative analysis.

Table 2: Performance Comparison for Pharmaceutical Analysis

| Performance Metric | Single-Beam Spectrophotometer | Double-Beam Spectrophotometer |

|---|---|---|

| Accuracy | Limited; susceptible to error from source fluctuation and baseline drift, especially at high/low absorbance [11]. | Superior; self-compensating for source fluctuations, leading to higher accuracy across a wider absorbance range [11]. |

| Precision | Lower; degraded by baseline drift and source noise over time [11]. | Significantly higher; reduced drift and noise ensure reliable reproducibility [11]. |

| Dynamic Range | Limited; prone to saturation or detector limitations at high absorbance [11]. | Wider; ratiometric measurement allows accurate analysis of samples with very high or low absorbance [11]. |

| Analysis Speed | Faster for single-point measurements due to simpler operational steps [11]. | Slower per measurement due to reference path, but often mitigated by automation; ideal for spectral scanning [9]. |

| Cost & Complexity | Simpler design and lower cost [11]. | More expensive and complex design [11]. |

Experimental Data and Protocol

To illustrate the performance difference in a pharma-relevant context, consider the following experimental simulation for protein quantification, a routine yet critical application.

Experiment: Protein Quantification via the Bradford Assay

- Objective: To determine the concentration of an unknown protein sample and compare the precision and drift of single-beam versus double-beam instruments.

- Principle: The Bradford reagent binds to protein, causing a shift in its absorption maximum from 470 nm to 595 nm. The absorbance at 595 nm is proportional to protein concentration [9].

Research Reagent Solutions:

- Bradford Reagent: Contains Coomassie Brilliant Blue G-250 dye, which undergoes a colorimetric shift upon protein binding [9].

- Protein Standard: Bovine Serum Albumin (BSA) at a known concentration (e.g., 2 mg/mL) for generating a calibration curve.

- Assay Buffer: A phosphate-buffered saline (PBS) solution, used to dilute the standard and unknown samples, and as the blank.

Methodology:

- Preparation: Prepare a series of BSA standard solutions in assay buffer across a concentration range (e.g., 0 to 2000 µg/mL).

- Reaction: Mix a fixed volume of each standard and the unknown sample(s) with the Bradford reagent. Incubate for a specified time (e.g., 10 minutes).

- Measurement: Measure the absorbance of each solution at 595 nm.

Simulated Data and Analysis: The following data table and subsequent diagram model the expected instrumental behavior.

Table 3: Simulated Absorbance Readings for BSA Standards

BSA Concentration (µg/mL) Single-Beam Absorbance (T=0 min) Single-Beam Absorbance (T=30 min) Double-Beam Absorbance (T=0 min) Double-Beam Absorbance (T=30 min) 0 (Blank) 0.000 0.015 0.000 0.000 250 0.125 0.143 0.125 0.125 500 0.245 0.266 0.245 0.245 1000 0.480 0.505 0.480 0.480 1500 0.710 0.738 0.710 0.710 2000 0.935 0.966 0.935 0.935

Instrument Workflow for Protein Quantification

Selection Guide for Pharmaceutical Applications

Choosing between a single-beam and double-beam instrument depends on the specific application requirements, regulatory needs, and budgetary constraints.

Application-Specific Recommendations

- Routine Quality Control (QC) and Single-Point Assays: For high-throughput, dedicated assays where speed and cost are prioritized, and conditions are well-controlled, a single-beam instrument may be sufficient [11]. Examples include fixed-wavelength concentration checks in a production environment.

- Research and Method Development: For applications requiring high accuracy, precision, and full spectral data, a double-beam instrument is the unequivocal choice [11]. This is critical for method validation, characterizing new compounds, kinetic studies, and any analysis where baseline stability is a concern.

- Quantitative Analysis with High Regulatory Scrutiny: The superior stability and self-validation of the double-beam design make it more suitable for environments adhering to strict pharmacopeial standards (e.g., USP, Ph. Eur.), which mandate performance verification for factors like stray light and wavelength accuracy [10].

Decision Framework

- Define Analytical Needs: Identify required accuracy, precision, types of measurements (kinetics vs. endpoint), and sample throughput [11].

- Evaluate Performance Specifications: Prioritize instruments with specifications that meet the needs of the most demanding routine application. Consider dynamic range, spectral bandwidth (for resolution), and stray light performance [11] [10].

- Consider Compliance: Ensure the instrument and its data output meet regulatory requirements for data integrity and can be properly validated [10].

- Assess Total Cost of Ownership: While single-beam instruments have a lower initial cost, the long-term benefits of a double-beam instrument in data reliability and reduced need for re-analysis can offer a better return on investment in a research setting [11].

In pharmaceutical research, the choice between a single-beam and double-beam UV-Vis spectrophotometer is a strategic decision that impacts data quality and operational efficiency. Single-beam designs offer simplicity and cost-effectiveness for routine, dedicated tasks. However, for the rigorous demands of drug development, research, and quality control requiring high accuracy, precision, and stability, the double-beam spectrophotometer, with its robust, self-compensating optical design, remains the indispensable and recommended tool for ensuring reliable and defensible analytical results.

Strengths and Limitations of UV-Vis as a Primary Analytical Technique

Ultraviolet-Visible (UV-Vis) spectroscopy is an analytical technique that measures the amount of discrete wavelengths of UV or visible light that are absorbed by or transmitted through a sample in comparison to a reference or blank sample [1]. This property is influenced by the sample composition, providing information on what is in the sample and at what concentration [1]. The technique operates in the wavelength range of approximately 190 nm to 800 nm, with the UV region from 190 nm to 400 nm and the visible region from 400 nm to 800 nm [12].

When specific wavelengths of light hit molecules, electrons excite from lower energy states to higher energy states. The energy absorbed by the electrons equals the energy difference between the two levels, causing measurable absorption [12]. The fundamental relationship between absorption and sample concentration is governed by the Beer-Lambert Law (A = εcl), where A is absorbance, ε is the molar absorptivity, c is concentration, and l is the path length [1] [12]. This forms the quantitative foundation for most UV-Vis applications in pharmaceutical research and other scientific fields.

Core Strengths of UV-Vis Spectroscopy

UV-Vis spectroscopy offers numerous advantages that make it a staple in analytical laboratories, particularly in pharmaceutical research and quality control.

Practical Operational Advantages

- Fast and Efficient Analysis: UV-Vis provides almost immediate results, making it ideal for time-sensitive applications in quality control and research [13]. Modern instruments can deliver sample-to-data results in under three seconds [14].

- Easy-to-Use Nature: The technique is relatively straightforward, with modern spectrophotometers featuring user-friendly software interfaces accessible to non-experts [14].

- Non-Destructive Testing: UV-Vis allows for repeated measurements on the same sample without degradation, which is particularly valuable for precious or limited samples [13] [14].

- Cost-Effectiveness: UV-Vis spectrophotometers are generally more affordable than other analytical instruments like HPLC, FTIR, or GC systems [13].

Analytical Performance Strengths

- High Sensitivity and Accuracy: These instruments can detect minute changes in absorbance, allowing accurate quantification of analytes even at low concentrations [13] [15].

- Versatility Across Applications: UV-Vis finds applications across numerous fields including pharmaceutical analysis, nucleic acid quantification, food and beverage quality control, environmental testing, and material science [12] [13] [15].

The technique is particularly valuable in pharmaceutical research for drug identification, quantification of active ingredients, dissolution testing, and impurity detection [12]. Its non-destructive nature allows continuous monitoring of reactions over time without compromising sample integrity [15].

Key Limitations of UV-Vis Spectroscopy

Despite its widespread utility, UV-Vis spectroscopy presents several important limitations that researchers must consider when selecting analytical methods.

Technical and Analytical Limitations

- Limited Selectivity for Complex Mixtures: UV-Vis can struggle with complex mixtures where multiple absorbing components lead to overlapping absorption bands, making it difficult to discern individual substances [13]. This limitation often necessitates supplementary techniques like HPLC for high-resolution separation [13].

- Stray Light Interference: Stray light reaching the detector without passing through the sample can distort spectra, leading to inaccurate measurements, particularly at low absorbance levels [13]. This can decrease instrument linearity and reduce accuracy for low-concentration samples [13].

- Dependence on Sample Preparation: Proper sample preparation is crucial, often requiring dissolution in specific solvents or dilution to achieve correct absorbance levels [13]. Turbidity or particulate matter can scatter light, further affecting accuracy [13].

- Limited Structural Information: Unlike techniques such as NMR or IR spectroscopy, UV-Vis provides limited information about molecular structure or chemical reactions [13].

- Inability to Detect Non-Absorbing Compounds: The technique cannot detect compounds that do not absorb in the UV-Vis region, restricting its applicability to chromophore-containing molecules [16].

Sample-Related Constraints

The accuracy of UV-Vis measurements can be compromised by various sample characteristics. Samples with multiple chromophores often exhibit spectral overlap, while turbid samples cause light scattering that distorts absorbance readings [13]. The technique typically requires samples to be in solution, with the solvent itself needing to be transparent in the measured wavelength range [1].

Single-Beam vs. Double-Beam UV-Vis Spectrophotometers

A critical distinction in UV-Vis instrumentation lies between single-beam and double-beam configurations, each with distinct performance characteristics particularly relevant to pharmaceutical research.

Technical Comparison

Table 1: Performance comparison of single-beam and double-beam UV-Vis spectrophotometers

| Feature | Single-Beam Instruments | Double-Beam Instruments |

|---|---|---|

| Light Path Design | Single beam passes through sample to detector [11] | Beam splits into reference and sample paths [11] [17] |

| Accuracy | Limited; affected by source fluctuations and drift [11] | Superior; self-compensating for intensity changes [11] |

| Precision | Lower due to baseline drift and source noise [11] | Significantly higher; reduced drift and noise [11] |

| Dynamic Range | Limited, particularly at absorbance extremes [11] | Wider; maintains accuracy across high/low absorbance [11] |

| Stability | Sensitive to external factors like energy fluctuations [11] | High stability; minimal impact from external factors [17] |

| Analysis Speed | Typically faster for individual measurements [11] | Faster for series measurements; no recalibration needed [17] |

| Cost | Lower initial investment [11] | Higher initial cost [11] [17] |

| Operational Complexity | Simpler operation [17] | More complex operation [17] |

| Warm-up Time | Requires significant lamp warm-up time [17] | Minimal warm-up time [17] |

Application-Specific Considerations for Pharmaceutical Research

For pharmaceutical applications requiring high precision and accuracy—such as drug purity assessment, quality control, and regulatory compliance—double-beam instruments offer significant advantages despite their higher cost [11]. Their ability to provide reliable, reproducible data across a wide dynamic range makes them particularly valuable for drug development and validation studies [17].

Single-beam instruments may suffice for educational purposes, routine checks, or applications where cost and simplicity are prioritized [11]. Their simpler design can be advantageous for dedicated, high-throughput screening where individual measurements are needed rapidly [11].

Experimental Data and Validation in Pharmaceutical Applications

Robust experimental data validates UV-Vis spectroscopy as a reliable technique for pharmaceutical analysis, particularly when appropriate validation protocols are followed.

Comparative Study: UV-Vis vs. HPLC for Drug Quantification

A methodological comparison study developed and validated both UV-Vis and reversed-phase high performance liquid chromatography (RP-HPLC) methods for determining repaglinide, a miglitinide class antidiabetic drug, in tablet dosage forms [18].

Table 2: Experimental validation data comparing UV-Vis and HPLC methods for repaglinide analysis

| Validation Parameter | UV-Vis Spectrophotometry | RP-HPLC Method |

|---|---|---|

| Linearity Range | 5-30 μg/mL [18] | 5-50 μg/mL [18] |

| Regression Coefficient (r²) | >0.999 [18] | >0.999 [18] |

| Precision (% R.S.D.) | <1.50 [18] | <1.50 [18] |

| Mean Recovery | 99.63-100.45% [18] | 99.71-100.25% [18] |

| Detection Wavelength | 241 nm [18] | 241 nm [18] |

Both methods demonstrated excellent linearity, precision, and accuracy according to International Conference on Harmonization (ICH) guidelines [18]. The UV-Vis method provided a simpler, faster, and more economical alternative while maintaining reliability for routine quality control analysis of repaglinide in pharmaceutical formulations [18].

Standard Experimental Protocol for Pharmaceutical Analysis

A typical protocol for drug analysis using UV-Vis spectroscopy involves:

- Standard Solution Preparation: A standard stock solution of the drug (e.g., 1000 μg/mL) is prepared in an appropriate solvent like methanol [18].

- Sample Preparation: Tablets are weighed, finely powdered, and a portion equivalent to the target drug weight is dissolved in solvent, sonicated, filtered, and diluted to volume [18].

- Spectroscopic Measurement: The absorbance of sample solutions is measured at the predetermined maximum absorbance wavelength (e.g., 241 nm for repaglinide) against a blank solvent reference [18].

- Quantification: Drug concentration is calculated using a pre-established calibration curve based on the Beer-Lambert Law [18].

UV-Vis Pharmaceutical Analysis Workflow

Essential Research Reagent Solutions

Successful UV-Vis analysis in pharmaceutical research requires specific materials and reagents tailored to the analytical requirements.

Table 3: Essential reagents and materials for UV-Vis spectroscopy in pharmaceutical analysis

| Item | Function/Application | Technical Specifications |

|---|---|---|

| Quartz Cuvettes | Sample holder for UV range measurements [1] | Transparent to UV light (below 350 nm); standard path length of 1 cm [1] |

| Methanol/Solvents | Dissolving samples and preparing standards [18] | High purity, UV-transparent; appropriate for pharmaceutical compounds [18] |

| Reference Standards | Method validation and calibration [18] | Certified drug reference materials of known purity and concentration [18] |

| Buffer Systems | Maintain consistent pH for ionizable drugs [1] | Aqueous buffered solutions without interfering absorbance [1] |

| Filters/Syringe Filters | Clarify sample solutions by removing particulates [18] | 0.45 μm or 0.22 μm pore sizes to prevent light scattering [18] |

Proper cuvette selection is particularly critical. Quartz or fused silica is essential for UV measurements below 350 nm, as glass and plastic cuvettes absorb significantly in the UV region [1] [12]. Cuvettes must have clear, scratch-free optical surfaces to prevent measurement errors [19].

UV-Vis spectroscopy remains a powerful, versatile, and cost-effective analytical technique with significant utility in pharmaceutical research. Its strengths of speed, simplicity, non-destructive nature, and quantitative accuracy make it invaluable for drug quantification, purity assessment, and quality control. However, researchers must also acknowledge its limitations regarding selectivity for complex mixtures, susceptibility to matrix effects, and restricted structural elucidation capabilities.

The choice between single-beam and double-beam instrumentation involves important trade-offs between cost, simplicity, precision, and stability. Double-beam systems generally offer superior performance for demanding pharmaceutical applications requiring high accuracy and reproducibility, while single-beam instruments provide practical solutions for routine analyses where cost considerations are paramount.

When applied with appropriate validation and understanding of its capabilities and constraints, UV-Vis spectroscopy serves as a reliable primary analytical technique that continues to play a crucial role in pharmaceutical research and drug development.

Pharmaceutical Applications in Practice: From API Quantification to Dissolution Testing

Quantification of Active Pharmaceutical Ingredients (APIs) and Drug Potency

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a fundamental analytical technique in pharmaceutical research for quantifying Active Pharmaceutical Ingredients (APIs) and determining drug potency. This method measures the amount of discrete wavelengths of UV or visible light absorbed by or transmitted through a sample, providing critical information about sample composition and concentration [1]. The selection between single-beam and double-beam spectrophotometer configurations significantly impacts the reliability, accuracy, and efficiency of these analyses, making the choice instrumental for compliance with stringent quality control standards and regulatory requirements in drug development.

The technique operates on the principle that light has a specific amount of energy inversely proportional to its wavelength. When this energy corresponds to the exact amount needed to promote electrons in a substance to a higher energy state, absorption occurs. The unique electronic structure of each compound means this absorption happens at different, characteristic wavelengths, allowing for identification and quantification [1]. In the context of a broader thesis comparing single-beam versus double-beam UV-Vis spectrophotometers for pharmaceutical research, this guide provides an objective comparison of their performance in quantifying APIs, supported by experimental data and detailed protocols.

Single-Beam vs. Double-Beam Spectrophotometers: A Technical Comparison

Understanding the fundamental operational differences between single-beam and double-beam spectrophotometers is crucial for selecting the appropriate instrument for pharmaceutical applications.

Instrument Design and Operation

A single-beam spectrophotometer operates by passing a single light beam through a sample. The instrument must be standardized by first taking a baseline reading with a reference or blank solution, after which the blank is manually replaced with the sample for measurement [20] [21]. This sequential measurement mode means the sample and reference are not measured simultaneously, which can introduce error and requires recalibration between readings if multiple samples are analyzed.

In contrast, a double-beam spectrophotometer splits the light from the source into two beams using a half-mirrored device or mechanical chopper. One beam, the sample beam, passes through the cuvette containing the compound of interest, while the other beam, the reference beam, passes through an identical cuvette containing only the solvent [20] [17]. This design allows for simultaneous measurement of the sample and reference, enabling automatic, real-time correction and compensation [17].

Performance Comparison and Key Differentiators

The core operational differences lead to distinct performance characteristics, which are summarized in the table below.

Table 1: Performance Comparison Between Single-Beam and Double-Beam Spectrophotometers

| Feature | Single-Beam Spectrophotometer | Double-Beam Spectrophotometer |

|---|---|---|

| Measurement Mode | Sequential (blank then sample) [21] | Simultaneous (sample & reference) [20] [21] |

| Reference Handling | Manual, prone to user error [21] | Automatic and continuous [21] [17] |

| Stability & Drift Compensation | Lower stability; sensitive to drift from voltage fluctuations, lamp drift, and temperature [20] [21] | High stability; automatically compensates for source power fluctuations and electronic drift [20] [17] |

| Signal-to-Noise Ratio | Lower, due to inability to correct for fluctuations in real-time [20] | Higher, as noise is minimized via real-time reference comparison [20] |

| Measurement Speed & Throughput | Slower, due to manual reference handling and required recalibration [21] | Faster and higher throughput; no need for recalibration between readings [17] |

| Operational Complexity | Simpler operation and design [21] | More complex optical setup and operation [17] |

| Initial Instrument Cost | Lower, due to simpler design with fewer components [20] [21] | Higher, due to more complex optics and advanced features [20] [17] |

| Ideal Application Scope | Teaching labs, basic quality checks, applications where cost is a primary concern [20] [21] | Research, quality control/assurance (QA/QC), kinetic studies, and high-precision analysis [20] [17] |

The following diagram illustrates the logical decision-making process for selecting between single-beam and double-beam instrumentation based on project requirements and constraints.

Experimental Data in API Quantification

The practical implications of the theoretical differences between single-beam and double-beam instruments are evident in experimental data from pharmaceutical analysis.

Case Study: Quantification of Favipiravir

A 2021 study directly compared a double-beam UV-Vis spectrophotometer with an HPLC method for quantifying Favipiravir in pharmaceutical formulations. The UV method utilized a Shimadzu UV-1800 double-beam spectrophotometer at a wavelength of 227 nm [22].

Table 2: Validation Data for Favipiravir Quantification Using a Double-Beam UV Method [22]

| Validation Parameter | Result |

|---|---|

| Linearity Range | 10 - 60 μg/mL |

| Correlation Coefficient (r²) | > 0.999 |

| Intra-day Precision (% R.S.D.) | Low R.S.D. values (specific value not provided) |

| Inter-day Precision (% R.S.D.) | Low R.S.D. values (specific value not provided) |

| Accuracy (% Recovery) | 99.83 - 100.45% |

The study concluded that the double-beam UV method provided reliable outcomes for the determination of Favipiravir in pharmaceutical formulations, demonstrating excellent linearity, precision, and accuracy [22]. The high correlation coefficient indicates a robust linear relationship, which is essential for confident concentration determination. The high percentage recovery confirms that the method is accurate and not significantly affected by interference from tablet excipients.

Case Study: Quantification of Repaglinide

Further supporting evidence comes from a study on the antidiabetic drug Repaglinide. The research utilized a Shimadzu 1700 Double beam UV-Vis spectrophotometer for analysis at 241 nm [18].

Table 3: Validation Data for Repaglinide Quantification Using a Double-Beam UV Method [18]

| Validation Parameter | Result |

|---|---|

| Linearity Range | 5 - 30 μg/mL |

| Correlation Coefficient (r²) | > 0.999 |

| Precision (% R.S.D.) | < 1.50% |

| Accuracy (% Recovery) | 99.63 - 100.45% |

The authors highlighted that the double-beam spectrophotometric method was "reliable, simple, fast, [and] accurate" for the quality control of repaglinide, making it suitable for routine analysis in quality control laboratories [18]. The low R.S.D. value (<1.5%) demonstrates high precision, a critical factor for ensuring consistency in results across repeated measurements. This level of precision is more challenging to achieve consistently with a single-beam instrument due to its higher susceptibility to drift.

Detailed Experimental Protocols

To ensure reproducibility and clarity in method implementation, the following section outlines a generalized standard operating procedure (SOP) for API quantification using a double-beam UV-Vis spectrophotometer, synthesized from the cited studies.

Standard Operating Procedure for API Quantification

1. Instrument and Materials Preparation

- Instrument: Double-beam UV-Vis spectrophotometer (e.g., Shimadzu UV-1800 or equivalent) [22].

- Cuvettes: Use 1.0 cm path length quartz cuvettes for UV analysis (e.g., measurements at 227 nm or 241 nm). Quartz is transparent across UV and visible wavelengths, unlike glass or plastic [20] [1].

- Solvent: Use an appropriate transparent solvent such as deionized water, methanol, or aqueous buffer, ensuring it does not absorb significantly at the wavelength of interest [22] [18].

- Reference Standard: High-purity API reference standard.

2. Sample and Standard Preparation

- Stock Standard Solution: Accurately weigh the API reference standard and dissolve it in the chosen solvent to prepare a stock solution of known concentration (e.g., 1000 μg/mL) [22] [18].

- Calibration Standards: Perform serial dilutions of the stock solution to prepare a series of standard solutions covering the intended linearity range (e.g., 5-60 μg/mL). Prepare all solutions in triplicate.

- Sample Solution: For tablet analysis, weigh and finely powder not less than 10 tablets. Accurately weigh a portion of the powder equivalent to the target API weight, dissolve in solvent, sonicate, and filter to obtain a clear solution. Dilute this solution to within the calibration range [22] [18].

3. Instrumental Analysis and Quantification

- Wavelength Selection: Based on a preliminary scan (e.g., 200-400 nm), select the wavelength of maximum absorption (λmax) for the API.

- Blank Measurement: Fill a cuvette with the pure solvent and place it in the reference holder. The double-beam instrument will use this for continuous background subtraction [1] [17].

- Calibration Curve: Measure the absorbance of each calibration standard. Plot the average absorbance against concentration and perform linear regression analysis.

- Sample Measurement: Measure the absorbance of the prepared sample solution. The concentration of the API in the sample solution is calculated using the linear regression equation from the calibration curve.

The workflow for this SOP is visualized below.

Essential Research Reagent Solutions

The following table details key materials and reagents required for the successful execution of the API quantification protocol.

Table 4: Essential Research Reagents and Materials for UV-Vis Based API Quantification

| Item | Function / Purpose | Critical Considerations |

|---|---|---|

| API Reference Standard | Serves as the primary standard for constructing the calibration curve, ensuring accuracy and traceability. | Must be of high and documented purity. Handling of HPAPIs requires strict containment protocols [23]. |

| Quartz Cuvettes | Hold the sample and reference solutions in the light path of the spectrophotometer. | Required for UV range analysis due to quartz's transparency down to 190 nm. Path length is typically 1.0 cm [20] [1]. |

| HPLC-Grade Solvents | Used to dissolve the API and prepare standard and sample solutions. | High purity is essential to minimize background absorbance and potential chemical interference [22] [18]. |

| Volumetric Flasks & Pipettes | Used for accurate preparation and dilution of standard and sample solutions. | Accuracy and precision of these tools are directly linked to the accuracy of final results. |

| Filters (0.22 μm or 0.45 μm) | Used to clarify sample solutions derived from solid dosage forms, removing particulate matter that can cause light scattering. | Membrane material should be compatible with the solvent used [22]. |

The choice between single-beam and double-beam UV-Vis spectrophotometers for the quantification of Active Pharmaceutical Ingredients is a balance between analytical requirements and practical constraints. Double-beam spectrophotometers are unequivocally superior for applications demanding high precision, stability, and throughput, such as in rigorous quality control environments, research and development, and kinetic studies. Their ability to perform simultaneous sample and reference measurements provides automatic compensation for instrumental drift, leading to more reliable and reproducible data, as evidenced by the low R.S.D. values and high recovery percentages in the cited studies [22] [18].

Single-beam spectrophotometers offer a cost-effective and simpler alternative that is adequate for educational purposes, basic qualitative checks, or situations with limited budget where the highest level of precision is not critical. However, their susceptibility to drift and manual operation mode make them less suitable for compliance-driven pharmaceutical quality control.

For researchers and drug development professionals, the investment in a double-beam system is justified by the need for data integrity, regulatory compliance, and operational efficiency in the quantification of APIs and the accurate determination of drug potency. The experimental protocols and validation data presented provide a framework for implementing this robust analytical technique in a pharmaceutical context.

Impurity Profiling and Purity Assessment of Drug Substances

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a fundamental analytical technique in pharmaceutical research, providing critical data for identity confirmation, purity assessment, and quantification of active pharmaceutical ingredients (APIs). The technique operates on the principle that molecules absorb light in the ultraviolet (190-400 nm) and visible (400-800 nm) regions of the electromagnetic spectrum, causing electronic transitions that provide characteristic absorption patterns [1] [12]. When applied to impurity profiling and purity assessment, UV-Vis spectroscopy enables researchers to detect unwanted chemical entities that may arise from synthesis, degradation, or storage processes, ensuring drug safety and efficacy [24].

The pharmaceutical industry operates under strict regulatory frameworks requiring comprehensive impurity profiling to identify and quantify potentially harmful substances. According to ICH guidelines, any component of a drug product that is not the drug substance or an excipient qualifies as an impurity, necessitating rigorous analytical control [24]. UV-Vis spectroscopy addresses this need through its ability to measure specific absorbance characteristics of both APIs and their potential impurities, with the Beer-Lambert law (A = εcl) providing the mathematical foundation for concentration determination [12].

The choice between single beam and double beam spectrophotometer configurations represents a critical decision point for pharmaceutical laboratories, with each system offering distinct advantages and limitations for specific applications within drug development and quality control workflows.

Fundamentals of Single and Double Beam Instrumentation

Single Beam Spectrophotometer Design and Operation

Single beam spectrophotometers employ a straightforward optical path where light from the source passes through a monochromator to select specific wavelengths, then travels through the sample before reaching the detector [11] [20]. This design requires sequential measurement, where a reference or blank sample is measured first to establish a baseline, followed by replacement with the actual sample for analysis [25]. The fundamental measurement relies on comparing the intensity of light before (I0) and after (I) passing through the sample, with absorbance calculated as A = log10(I0/I) [11].

The simplicity of the single beam design translates to practical benefits including lower initial cost, reduced instrument footprint, and simplified operation [11] [20]. Additionally, because the entire light beam passes through the sample without splitting, single beam instruments typically achieve higher energy throughput to the detector, potentially enhancing sensitivity for specific applications [26]. These characteristics make single beam systems particularly suitable for educational settings, routine quality checks in non-regulated environments, and applications where budget constraints are paramount [11].

Double Beam Spectrophotometer Design and Operation

Double beam spectrophotometers incorporate a more sophisticated optical system that splits the initial light beam into two separate paths: one passing through the sample and the other through a reference solution [11] [17]. This beam splitting is typically accomplished using a mechanical chopper or half-mirrored device that alternately directs light through both paths, with the beams recombining before reaching the detector [17]. The instrument continuously compares the intensity of the sample beam (Is) with the reference beam (Ir), calculating absorbance as A = log10(Ir/Is) in real time [11].

This simultaneous measurement approach provides inherent compensation for factors that can compromise analytical accuracy, including source lamp fluctuations, voltage variations, and detector sensitivity drift [11] [20]. The continuous referencing capability eliminates the need for frequent recalibration between measurements, reducing analysis time and potential operator error [17]. While double beam instruments command a higher initial investment and require more complex optical components, they deliver superior stability and reliability for demanding pharmaceutical applications [25] [26].

Technical Comparison: Performance Characteristics

The selection between single and double beam configurations significantly impacts analytical performance in pharmaceutical applications. The following table summarizes the key technical differences between these instrument types:

Table 1: Performance Comparison Between Single and Double Beam UV-Vis Spectrophotometers

| Performance Characteristic | Single Beam Spectrophotometer | Double Beam Spectrophotometer |

|---|---|---|

| Optical Path Design | Single path through sample only [11] | Split beam: simultaneous sample and reference measurement [11] [17] |

| Measurement Sequence | Sequential (blank then sample) [25] | Simultaneous [25] |

| Accuracy | Limited by source fluctuations and baseline drift [11] | High due to real-time compensation for instrumental variations [11] [17] |

| Precision | Lower due to drift accumulation over time [11] | Significantly higher with minimal drift [11] |

| Baseline Stability | Subject to environmental and age-related drift [11] | Excellent stability; drift affects both beams proportionally [11] |

| Dynamic Range | Limited, particularly at high/low absorbance [11] | Wider range with accurate measurement across varying absorbances [11] |

| Source Fluctuation Impact | Directly affects measurements, adding noise [11] | Self-compensating; changes affect both beams equally [11] |

| Typical Measurement Speed | Faster for individual samples [11] | Faster for series measurements (no recalibration needed) [17] |

| Cost Considerations | Lower initial investment [20] [25] | Higher initial cost but potentially lower lifetime cost [20] |

For impurity profiling applications, accuracy and precision metrics are particularly crucial as they directly impact the ability to detect and quantify trace-level contaminants. The double beam design's continuous referencing capability provides superior performance in these areas, making it the preferred choice for regulated pharmaceutical environments where data integrity is paramount [11] [27].

Stability and Noise Considerations

Instrument stability represents a critical differentiator between single and double beam systems, especially for lengthy analyses or when measuring multiple samples. Single beam instruments are more susceptible to drift from electronic circuit fluctuations, voltage instability, and lamp energy degradation, all of which can cause anomalous results [20]. Double beam spectrophotometers automatically compensate for these variables, maintaining measurement integrity throughout extended operation [17]. This stability advantage makes double beam instrumentation particularly valuable for kinetic studies, dissolution testing, and high-throughput quality control applications where consistent performance over time is essential.

Application in Pharmaceutical Impurity Profiling

Regulatory Framework and Requirements

Pharmaceutical impurity profiling operates within a strict regulatory framework defined by international guidelines, including those established by the International Conference on Harmonisation (ICH). These guidelines classify impurities into categories including organic impurities (starting materials, by-products, degradation products), inorganic impurities, and residual solvents [24]. According to ICH guidelines, identification of impurities is required at levels of 0.1% or 1 mg per day intake (whichever is lower) for drugs with maximum daily doses below 2 grams [24]. This threshold demands highly sensitive and accurate analytical techniques capable of detecting and quantifying minor components in complex matrices.

Regulatory authorities such as the FDA mandate comprehensive testing of pharmaceutical products to address identity, assay, impurities, and dissolution characteristics [27]. UV-Vis spectroscopy supports multiple aspects of this testing paradigm, with the choice between single and double beam instrumentation directly impacting data quality and regulatory acceptance.

Experimental Protocols for Impurity Assessment

Forced Degradation Studies

Forced degradation studies represent a critical component of impurity profiling, designed to identify potential degradation products that might form under various stress conditions. A typical protocol involves:

Sample Preparation: Prepare solutions of the drug substance at appropriate concentrations (typically yielding absorbances between 0.3-1.0 AU) in suitable solvents [12]. For UV-transparent solvents, quartz cuvettes are required for measurements in the UV range below 350 nm [1].

Stress Conditions Application: Subject drug solutions to stress conditions including acidic and basic hydrolysis (e.g., 0.1M HCl/NaOH at elevated temperatures), oxidative degradation (e.g., 0.3% hydrogen peroxide), thermal degradation, and photolytic cleavage [24].

Spectral Analysis: Collect full UV-Vis spectra (typically 200-400 nm for UV-absorbing compounds) at predetermined time points to monitor degradation progression. Double beam instruments provide superior stability for these extended measurements [11].

Data Interpretation: Identify new absorption peaks or shoulder formations indicating degradation products. Calculate degradation rates based on absorbance changes at API-specific wavelengths.

Quantification of Known Impurities

For quantification of specific impurities with established absorbance characteristics:

Calibration Curve Establishment: Prepare standard solutions of the impurity at minimum five concentrations spanning the expected range. Measure absorbance at the wavelength of maximum absorption (λmax).

Sample Analysis: Measure absorbance of processed samples under identical conditions.

Concentration Calculation: Determine impurity concentration from the linear regression equation of the calibration curve, applying the Beer-Lambert law [12].

The following diagram illustrates the complete workflow for pharmaceutical impurity profiling using UV-Vis spectroscopy:

Diagram 1: Workflow for Impurity Profiling in Pharmaceuticals

Essential Research Reagents and Materials

Successful impurity profiling requires carefully selected materials and reagents to ensure analytical accuracy and reproducibility. The following table outlines essential components for pharmaceutical analysis using UV-Vis spectroscopy:

Table 2: Essential Research Reagents and Materials for Pharmaceutical UV-Vis Analysis

| Material/Reagent | Function/Application | Technical Specifications |

|---|---|---|

| Quartz Cuvettes | Sample holder for UV range measurements | Transmission range: 190-2500 nm [20]; Standard path length: 1 cm [1] |

| High-Purity Solvents | Dissolution medium for drug substances | UV-grade solvents with low absorbance in spectral region of interest [1] |

| Reference Standards | Instrument calibration and method validation | Certified reference materials with known purity [27] |

| Degradation Reagents | Forced degradation studies | ACS grade acids (HCl), bases (NaOH), oxidants (Hâ‚‚Oâ‚‚) [24] |

| Filter Membranes | Sample clarification | 0.45 μm or 0.22 μm pore size, compatible with organic solvents [24] |

| Buffer Salts | pH control for degradation studies | High-purity salts for maintaining specific pH conditions [24] |

Material selection directly impacts measurement quality, particularly for cuvette choice. Quartz or fused silica cuvettes are essential for measurements below 350 nm, as glass and plastic materials absorb significantly in the UV region [1] [20]. Similarly, solvent purity is critical as impurities can introduce interfering absorbance signals, complicating impurity detection and quantification.

Comparative Experimental Data

To objectively evaluate the practical implications of instrument selection for pharmaceutical applications, the following table presents key comparative metrics:

Table 3: Analytical Performance Metrics for Pharmaceutical Applications

| Performance Metric | Single Beam Instrument | Double Beam Instrument |

|---|---|---|

| Typical Analysis Time (10 samples) | 15-20 minutes (with recalibration) [11] | 5-10 minutes (simultaneous reference) [17] |

| Absorbance Accuracy | ±0.010 AU (subject to drift) [11] | ±0.002 AU (stable over time) [11] |

| Photometric Repeatability | 0.5% RSD [11] | 0.1% RSD [11] |

| Wavelength Reproducibility | ±0.5 nm [11] | ±0.2 nm [11] |

| Baseline Stability (over 1 hour) | Significant drift [11] [25] | Minimal drift (<0.001 AU/hour) [11] [17] |

| Suitable Absorbance Range | 0.2-0.8 AU (optimal) [1] | 0.1-2.0 AU (with linear response) [11] |

| Detectable Impurity Level | ~1% of API [11] | ~0.1% of API [11] [24] |

The data demonstrates clear advantages for double beam instrumentation across all metrics relevant to impurity profiling, particularly regarding detection limits that approach the 0.1% threshold specified in ICH guidelines [24]. The extended linear dynamic range of double beam systems additionally facilitates analysis of both concentrated and dilute solutions without requiring sample dilution, streamlining analytical workflows.

Selection Guidelines for Pharmaceutical Applications

The choice between single and double beam spectrophotometers should be guided by specific application requirements, regulatory constraints, and operational considerations:

Recommended Applications for Single Beam Systems

- Educational and Training Laboratories: Where instrument simplicity and cost-effectiveness are prioritized [11] [20]

- Preliminary Method Development: Initial scoping studies preceding validated analytical methods

- Quality Control in Non-Regulated Environments: Routine identity checks where highest precision is not critical [25]

- Limited Budget Situations: Where initial capital investment is a primary concern [26]

Recommended Applications for Double Beam Systems

- Regulated Pharmaceutical Quality Control: Environments requiring compliance with FDA, ICH, or pharmacopeial standards [28] [27]

- Stability Studies and Forced Degradation Studies: Where measurement stability over extended periods is essential [24]

- Dissolution Testing: Monitoring API release from dosage forms over time [28] [27]

- High-Throughput Environments: Where analytical efficiency and minimal recalibration are valuable [11] [17]

- Trace Impurity Detection: Applications requiring maximum sensitivity and detection limit capabilities [11] [24]

The following decision diagram provides a systematic approach to instrument selection based on application requirements:

Diagram 2: Decision Process for Instrument Selection

Impurity profiling and purity assessment of drug substances demand analytical techniques capable of delivering precise, accurate, and reliable data. While both single and double beam UV-Vis spectrophotometers can perform these analyses, their performance characteristics differ significantly for pharmaceutical applications. Single beam systems offer advantages in simplicity and initial cost, making them suitable for educational settings and non-regulated environments. However, double beam spectrophotometers provide superior stability, accuracy, and operational efficiency that align with the rigorous demands of regulated pharmaceutical research and quality control.

The comprehensive data presented in this guide demonstrates that double beam instrumentation delivers the performance metrics necessary for detecting and quantifying impurities at the thresholds specified in international regulatory guidelines. For pharmaceutical scientists engaged in method development, stability testing, and quality assurance, investment in double beam technology provides the analytical robustness required to ensure drug safety, efficacy, and regulatory compliance.

Dissolution Testing and Drug Release Kinetics for Solid Dosage Forms

Dissolution testing is a critical analytical technique in pharmaceutical development and quality control, evaluating how a solid oral dosage form releases its active pharmaceutical ingredient (API) into solution. This process serves as a fundamental determinant of a drug's bioavailability and therapeutic effectiveness. For researchers and drug development professionals, understanding drug release kinetics is essential for ensuring consistent drug performance, guiding formulation development, establishing bioequivalence, and verifying batch-to-batch quality. The data obtained from dissolution testing provides crucial insights into in vivo performance, helping scientists optimize formulations to achieve desired release characteristics while maintaining regulatory compliance.

The selection of appropriate analytical instrumentation, particularly UV-Visible spectrophotometers, is paramount for obtaining accurate and reliable dissolution data. This guide provides an objective comparison between single-beam and double-beam UV-Vis spectrophotometry systems within the context of pharmaceutical dissolution testing, supported by experimental data and protocols relevant to modern drug development workflows.

Fundamentals of UV-Vis Spectrophotometry in Dissolution Testing

Basic Principles and Instrumentation

UV-Visible spectrophotometry measures the absorption of light in the ultraviolet and visible regions of the electromagnetic spectrum, providing quantitative determination of different analytes including APIs, excipients, and biological macromolecules. In pharmaceutical dissolution testing, this technique enables researchers to accurately quantify the concentration of drug substances released from solid oral dosage forms over time, generating the critical data needed to construct drug release profiles and calculate kinetic parameters.

The fundamental principle underlying this analytical method is the Beer-Lambert law, which states that the absorbance of a solution is directly proportional to the concentration of the absorbing species and the path length of the light through the solution. This relationship provides the mathematical foundation for converting absorbance measurements into concentration values essential for dissolution profile generation and release kinetics modeling.

Comparative Instrument Designs: Single-Beam vs. Double-Beam Systems

Single-beam spectrophotometers utilize a single light path that passes sequentially through a reference and then the sample. This design involves measuring the intensity of light first through a reference cell containing only the dissolution medium, followed by measurement through the sample cell containing the dissolved API. The key components include a light source (typically deuterium lamp for UV and tungsten-halogen lamp for visible light), monochromator for wavelength selection, sample holder, and detector [29].

Double-beam spectrophotometers employ a more complex optical system that splits the light from the source into two separate beams: one passing through the sample and the other through a reference. A beam splitter or rotating mirror alternately directs light to both paths, with detectors measuring transmitted intensities simultaneously or in rapid alternation. This design allows for real-time compensation of instrumental variations [29].

Table 1: Technical Comparison of Single-Beam and Double-Beam UV-Vis Spectrophotometers

| Feature | Single-Beam Spectrophotometer | Double-Beam Spectrophotometer |

|---|---|---|

| Optical Design | Sequential measurement (reference then sample) | Simultaneous or alternating measurement of sample and reference |

| Precision & Stability | Susceptible to drift due to light source variations | Compensates for drift, offering higher stability |

| Baseline Correction | Manual measurement required | Automated real-time correction |

| Cost Considerations | Lower initial cost, simpler design | Higher cost due to additional components |

| Maintenance Requirements | Fewer components, simpler maintenance | More complex, requiring skilled maintenance |

| Typical Applications in Pharma | Routine quality control, educational settings | Research and development, kinetic studies, regulatory testing |

Experimental Protocols for Dissolution Testing

Standard Dissolution Test Methodologies

Dissolution testing of solid oral dosage forms follows standardized methodologies outlined in pharmacopeias such as the United States Pharmacopeia (USP). The FDA provides comprehensive guidance for in vitro dissolution testing of immediate release solid oral dosage forms, emphasizing standardized conditions to ensure reproducibility and regulatory compliance [30].

Apparatus Selection: Two USP apparatus types are most commonly used for solid oral dosage forms:

- USP Apparatus I (Basket Method): Employed for capsules and tablets that tend to float, using a wire mesh basket rotated at 50-100 rpm while submerged in dissolution medium [30] [31].

- USP Apparatus II (Paddle Method): Suitable for most immediate-release tablets, utilizing a rotating paddle at 50-75 rpm that agitates the medium above the dosage form placed at the vessel bottom [30] [31].

Test Conditions: Dissolution tests should be conducted at 37±0.5°C to simulate physiological conditions. Typical media volumes are 500, 900, or 1000 mL, selected based on maintaining "sink conditions" - defined as the volume needed to dissolve at least three times the amount of API in the dosage form [30]. Media composition should be carefully selected based on drug substance properties, with options including acidic or basic solutions, buffers, and surfactants when necessary to enhance solubility [30].

Sampling and Analysis: Timepoints should adequately reflect the dissolution profile's shape, including ascending and plateau phases. Samples are typically withdrawn at predetermined intervals, filtered, and analyzed using UV-Vis spectrophotometry to determine API concentration [30].

Advanced Dissolution Monitoring Techniques

Fiber Optic Dissolution Systems (FODS) represent an innovative approach that enables real-time monitoring without sample extraction. This method uses immersion probes with fiber optics to record UV spectral information at regular intervals (e.g., every 5 seconds), providing more detailed dissolution profiles while eliminating issues associated with manual sampling, filtration, and dilution [32].

FODS offers several advantages including full real-time spectra availability, wide pathlength selection (0.25 mm to 10 mm), and elimination of sampling errors. However, limitations include potential UV spectral overlap, API interactions with excipients, signal attenuation from undissolved particles, and UV signal saturation at high concentrations [32]. These challenges can be addressed through multivariate chemometric approaches like Principal Component Regression (PCR) and Partial Least Squares (PLS) regression, which enable accurate quantification despite signal saturation issues [32].

Experimental Workflow for Comprehensive Dissolution Testing

The following diagram illustrates a generalized experimental workflow for dissolution testing of solid oral dosage forms, integrating both traditional and advanced analytical approaches:

Research Reagent Solutions for Dissolution Testing

Table 2: Essential Materials and Reagents for Pharmaceutical Dissolution Testing

| Reagent/Equipment | Function/Application | Specifications/Standards |

|---|---|---|

| Dissolution Apparatus | Provides controlled environment for drug release testing | USP Apparatus I (Basket) or II (Paddle) |

| UV-Vis Spectrophotometer | Quantification of dissolved API concentration | Single-beam for routine QC; Double-beam for research |

| Dissolution Media | Simulates gastrointestinal environment for drug release | Buffers (pH 1.2-7.5), surfactants, fasted/fed state simulants |

| Reference Standards | Calibration and method validation | USP-grade API reference standards |

| Filter Materials | Removal of undissolved particles from samples | 0.45μm or smaller pore size, compatible with API |

| Deaeration Equipment | Removal of dissolved gases that could affect hydrodynamics | Vacuum filtration with heating capability |

Performance Comparison in Pharmaceutical Applications

Analytical Performance in Dissolution Testing

The selection between single-beam and double-beam instrumentation significantly impacts data quality, methodological efficiency, and application suitability in pharmaceutical research and quality control environments.

Analytical Precision and Stability: Double-beam systems demonstrate superior performance for dissolution testing requiring high precision and long-term stability. The simultaneous measurement of sample and reference beams compensates for instrumental drift caused by light source fluctuations, temperature variations, or electronic noise. This capability is particularly valuable in extended-release formulation testing, where dissolution studies may extend to 8-24 hours [29]. Single-beam instruments, while adequate for routine quality control of immediate-release formulations with shorter testing durations, show greater susceptibility to baseline drift that can compromise data accuracy in prolonged experiments.

Kinetic Studies and Method Development: The automated baseline correction and enhanced stability of double-beam spectrophotometers make them ideal for kinetic studies, method development, and dissolution testing of complex formulations. These applications often involve multiple sampling points, varying media conditions, and detailed profile analysis where measurement consistency is paramount. Single-beam systems require manual re-referencing during extended experiments, introducing potential operational inconsistencies [29].

Turbid and Complex Samples: Double-beam systems outperform single-beam instruments when analyzing turbid samples or formulations that generate particulate matter during dissolution. The real-time reference compensation minimizes interference from light scattering, providing more accurate concentration measurements without additional sample preparation [29]. This capability is particularly valuable for suspension formulations or poorly soluble drugs requiring surfactants in dissolution media.