Spectroscopic Analysis of Pharmaceutical Active Components: Techniques, Applications, and 2025 Trends

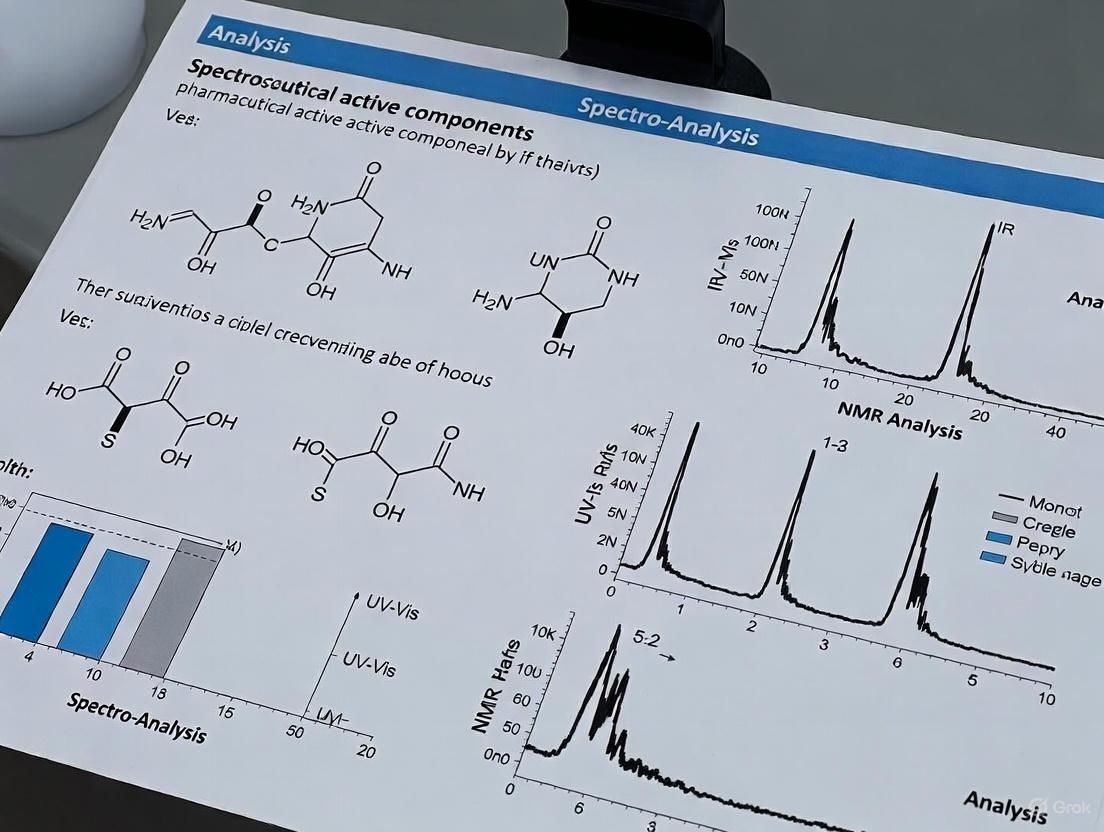

This article provides a comprehensive overview of spectroscopic techniques essential for the analysis of active pharmaceutical ingredients (APIs).

Spectroscopic Analysis of Pharmaceutical Active Components: Techniques, Applications, and 2025 Trends

Abstract

This article provides a comprehensive overview of spectroscopic techniques essential for the analysis of active pharmaceutical ingredients (APIs). Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of UV-Vis, IR, NMR, MS, and Raman spectroscopy. The scope extends to methodological applications in quality control, structure elucidation, and process monitoring, alongside practical troubleshooting guidance and a comparative analysis of techniques to inform method selection and validation in compliance with current regulatory standards.

Core Principles and Modern Instrumentation for API Analysis

The Role of Spectroscopy in Pharmaceutical QA/QC and R&D

Spectroscopic analytical techniques are pivotal in the pharmaceutical and biopharmaceutical industries, providing non-destructive, rapid, and reliable tools for the classification and quantification of processes and products [1]. These methods are essential for ensuring the identity, purity, potency, and stability of pharmaceutical compounds—critical factors in regulatory compliance, method validation, and patient safety [2]. From raw material verification to real-time process monitoring, spectroscopy supports comprehensive analytical workflows across drug development and commercial production. This article explores the key spectroscopic techniques, their applications, and detailed experimental protocols within the context of pharmaceutical quality assurance, quality control (QA/QC), and research and development (R&D).

Key Spectroscopic Techniques and Their Applications

Modern pharmaceutical analysis leverages a suite of spectroscopic techniques, each providing unique insights into drug substance and product characteristics.

Table 1: Key Spectroscopic Techniques in Pharmaceutical QA/QC and R&D

| Technique | Primary Application in Pharma | Key Advantage | Common Use Cases |

|---|---|---|---|

| UV-Vis Spectroscopy [2] | Quantification of concentration | Fast, simple, inexpensive, high throughput | Content uniformity, dissolution testing, impurity monitoring |

| IR & FT-IR Spectroscopy [2] [1] | Structural verification & identification | Provides molecular "fingerprint" | Raw material ID, polymorph screening, contaminant detection |

| NMR Spectroscopy [2] [1] | Structural elucidation & impurity profiling | High specificity and structural detail | Confirm molecular identity, detect trace impurities, stereochemistry |

| NIR Spectroscopy [3] | Quantitative analysis of powders & tablets | Non-destructive, requires no sample prep | Blend uniformity, potency, moisture content in solid dosage forms |

| Raman Spectroscopy [4] | Molecular composition analysis | Unaffected by water, easy to automate | In-line process monitoring, raw material ID, polymorph distinction |

| ICP-MS [5] [1] | Trace elemental analysis & impurity profiling | High sensitivity and precision | Heavy metal detection, quantifying trace elements in biologics |

The applications of these techniques span the entire drug lifecycle. Identity testing confirms the molecular structure of raw materials and finished products, commonly using IR and NMR spectroscopy [2]. Purity assessment evaluates substances for potential contaminants or degradation products, with UV-Vis and NMR playing crucial roles [2]. Potency determination, often performed using UV-Vis spectroscopy, measures the active pharmaceutical ingredient (API) concentration for content uniformity testing and batch release [2]. Furthermore, spectroscopy is integral to Process Analytical Technology (PAT), enabling in-line and at-line monitoring of critical quality attributes during manufacturing for real-time quality control [2] [4].

Detailed Experimental Protocols

Protocol for Content Uniformity of Tablets Using NIR Spectroscopy

This non-destructive method is used for the rapid assessment of content uniformity in solid dosage forms [3].

- 1. Instrumentation: FT-NIR spectrometer (e.g., Bruker Optics MPA) equipped with a fully automated sample wheel and an external transmission head containing an Indium Gallium Arsenide (InGaAs) detector [3].

- 2. Sample Presentation: Place individual tablets into customized tablet nests on the automated sample wheel. Ensure a consistent orientation for each sample [3].

- 3. Spectral Acquisition:

- 4. Data Processing & Analysis:

- Process the collected spectra using integrated software (e.g., OPUS/LAB).

- The software automatically evaluates the spectra against pre-defined, validated calibration models. These models, which correlate spectral data to API concentration, are developed using chemometric methods such as Partial Least Squares (PLS) regression [3].

- The system generates a non-editable report indicating whether the tablet passes or fails the content uniformity specification. All data and actions are recorded in a secure Audit Trail [3].

Protocol for In-Line Process Monitoring Using Raman Spectroscopy

This protocol allows for real-time monitoring of critical process parameters, such as in a bioreactor, without the need for manual sampling [4].

- 1. Instrumentation: Raman process analyzer comprising a stable, narrow-linewidth laser source, a fiber-optic cable, and a robust probe designed for in-line installation [4].

- 2. System Setup: Install the Raman probe directly inside the bioreactor vessel, ensuring it is properly sterilized and integrated to maintain the system's integrity [4].

- 3. Spectral Acquisition & Automation:

- The laser light is delivered to the process stream via the probe. The scattered light (Raman signal) is collected and transmitted back to the detector.

- The system can be configured to take measurements at regular intervals (e.g., every 38 seconds) [1]. This provides a near-continuous stream of data on the chemical environment.

- 4. Real-Time Analysis & Feedback:

- The unique Raman "fingerprint" spectrum is analyzed automatically using machine learning algorithms or pre-calibrated chemometric models [1] [4].

- Key parameters like glucose, lactate, and glutamine levels, as well as protein aggregation, are quantified in real-time [1] [4].

- The data can be fed into an automated control system that triggers notifications or alarms when target concentrations are reached or when a process deviation is detected, enabling immediate corrective action [4].

Workflow for Spectroscopic Analysis in Pharmaceutical Development

The following diagram illustrates a generalized workflow for employing spectroscopy in pharmaceutical development, from raw material analysis to stability testing.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful spectroscopic analysis requires not only advanced instrumentation but also a suite of high-quality reagents and materials to ensure accuracy and reproducibility.

Table 2: Essential Research Reagent Solutions for Spectroscopic Analysis

| Item | Function & Application |

|---|---|

| High-Purity Deuterated Solvents (e.g., D₂O, CDCl₃, DMSO-d₆) [2] | Used in NMR spectroscopy to avoid signal interference with the analyte of interest. The deuterium atoms provide a signal for the spectrometer to lock onto. |

| Potassium Bromide (KBr) [2] | Used for preparing solid samples for traditional IR spectroscopy. The sample is mixed with KBr and pressed into a transparent pellet for analysis. |

| ATR Crystals (e.g., Diamond, ZnSe) [2] | The core component of modern ATR-FTIR accessories. The sample is placed in direct contact with the crystal, enabling analysis with minimal sample preparation. |

| Matched Quartz Cuvettes [2] | Required for holding liquid samples in UV-Vis spectroscopy. Quartz allows transmission of UV light, and using a matched pair ensures pathlength accuracy. |

| Certified Reference Standards [2] | Highly characterized materials used to calibrate instruments and validate analytical methods. They are essential for ensuring the accuracy and traceability of results. |

| Cell Culture Media (for biopharma) [1] | A complex mixture of nutrients used to grow cells for biologic drug production. Its metal content and speciation are critical and can be monitored using SEC-ICP-MS. |

| Size Exclusion Chromatography (SEC) Columns [1] | Used in conjunction with ICP-MS (SEC-ICP-MS) to separate and analyze metal-protein interactions in biopharmaceuticals like monoclonal antibodies. |

| 2,3,6-Trimethylundecane | 2,3,6-Trimethylundecane, CAS:143328-30-7, MF:C14H30, MW:198.39 g/mol |

| 3-(6-Methoxyhexyl)thiophene | 3-(6-Methoxyhexyl)thiophene|Thiophene Monomer |

Advanced Applications and Data Analysis

The integration of chemometrics—the application of multivariate mathematical and statistical techniques—is what transforms complex spectral data into actionable information [6] [7]. Principal Component Analysis (PCA) is a fundamental chemometric tool used for exploratory data analysis. It reduces the dimensionality of spectral data, allowing scientists to visualize trends, identify clusters (e.g., separating different API types), and detect outliers or potential adulterations in a set of samples [6] [7].

Advanced applications are pushing the boundaries of pharmaceutical analysis. Surface-Enhanced Raman Spectroscopy (SERS) and Tip-Enhanced Raman Spectroscopy (TERS) are being used to study protein unfolding and aggregation mechanisms with high sensitivity, offering insights relevant to diseases like Alzheimer's and the stability of biologic drugs [1]. Furthermore, 2D-NMR techniques are employed for detailed characterization of higher-order structures and protein-excipient interactions in complex biologics, providing critical data for formulation development [1]. The ongoing adoption of these sophisticated spectroscopic methods, supported by robust chemometrics, continues to enhance efficiency, compliance, and product quality in the pharmaceutical industry.

Ultraviolet-Visible (UV-Vis) spectroscopy is an analytical technique that measures the amount of discrete wavelengths of ultraviolet (UV) or visible (Vis) light that are absorbed by or transmitted through a sample in comparison to a reference or blank sample [8]. This technique is fundamentally based on the excitation of electrons from the ground state to higher energy states when molecules absorb light in the 190-800 nm range [9] [2]. The UV-vis region of energy for the electromagnetic spectrum covers 1.5 - 6.2 eV, which relates to a wavelength range of 800 - 200 nm [9]. In the pharmaceutical industry, UV-Vis spectroscopy serves as a cornerstone analytical tool for ensuring the identity, purity, potency, and stability of active pharmaceutical ingredients (APIs) and finished drug products throughout development and manufacturing [2].

Theoretical Foundation

Electronic Transitions and Chromophores

When sample molecules are exposed to light with energy that matches a possible electronic transition, some light energy is absorbed as electrons are promoted to higher energy orbitals [10]. The most common electronic transitions in organic chromophores are [10] [11]:

- π–π*: Often occurs in conjugated systems, typically with high molar absorptivity.

- n–π*: Involves excitation of a non-bonding electron, often with lower probability and absorptivity.

- σ–σ*: Requires high energy, generally in the far-UV region.

- n–σ*: Similar to σ-σ* but involving non-bonding electrons.

Light-absorbing groups responsible for these transitions are called chromophores. The presence of conjugation in a molecule shifts absorption maxima to longer wavelengths (lower energy) and typically increases the intensity of absorption [10].

The Beer-Lambert Law

The fundamental principle quantifying absorption is the Beer-Lambert Law [9] [8] [11]. It states that the absorbance of a solution is directly proportional to the concentration of the absorbing species and the path length of light through the sample:

A = εbc

Where:

- A is the measured Absorbance (unitless)

- ε is the molar absorptivity or extinction coefficient (Mâ»Â¹cmâ»Â¹)

- b is the path length of the cuvette or sample holder (cm)

- c is the concentration of the solution (M)

The relationship between the light intensities measured by the instrument and absorbance is given by A = logâ‚â‚€(Iâ‚€/I), where Iâ‚€ is the intensity of incident light and I is the intensity of transmitted light [8]. Absorbance values are optimally kept between 0.1 and 1.0 absorbance units to maintain linearity and avoid instrumental deviations from the Beer-Lambert law [11] [2].

Key Pharmaceutical Applications

UV-Vis spectroscopy is widely embedded in pharmaceutical quality control and research workflows due to its simplicity, speed, and quantitative reliability [12] [2].

Table 1: Key Applications of UV-Vis Spectroscopy in Pharmaceutical Analysis

| Application Area | Specific Use | Typical Analytical Parameters | Regulatory Relevance |

|---|---|---|---|

| Identity Testing | Confirmation of chemical identity via spectral fingerprint [2]. | Comparison of sample spectrum λmax and band shape to a reference standard [11]. | USP, Ph. Eur., ICH Q2(R1) [12] [2]. |

| Assay and Potency | Quantification of Active Pharmaceutical Ingredient (API) concentration [2]. | Absorbance measurement at λmax using a pre-established calibration curve [9]. | USP, Ph. Eur. (e.g., Ibuprofen monograph) [12]. |

| Content Uniformity | Ensuring consistent API dose in individual dosage units (e.g., tablets) [2]. | Absorbance measurement of dissolved unit, compared to specification [2]. | USP ⟨905⟩ [2]. |

| Dissolution Testing | Monitoring drug release profile from solid oral dosage forms [12] [2]. | Absorbance measurement of dissolution media at specific time points [12]. | USP ⟨711⟩ [12]. |

| Impurity Profiling | Detection and quantification of impurities or degradation products [12] [2]. | Detection of unexpected absorbance peaks or shifts; may require HPLC-UV coupling [2]. | ICH Q3A, Q3B [2]. |

Experimental Protocols

Standard Operating Protocol for API Quantification

This protocol outlines the procedure for quantifying the concentration of an Active Pharmaceutical Ingredient (API) in a solution using a double-beam UV-Vis spectrophotometer, compliant with pharmacopeial standards [12] [2].

I. Principle The concentration of the target API in an unknown sample is determined by measuring its absorbance at a wavelength of maximum absorption (λmax) and comparing it to a calibration curve generated from standard solutions of known concentration, based on the Beer-Lambert Law [9] [8].

II. Materials and Equipment

- Double-beam UV-Vis Spectrophotometer: Equipped with deuterium and tungsten/halogen lamps, capable of scanning 190-800 nm [8].

- Quartz Cuvettes: 1 cm pathlength, matched pair [8] [2].

- Analytical Balance (accuracy ±0.1 mg).

- Volumetric Flasks (Class A).

- Digital Pipettes (variable volume).

- Reference Standard of the API (certified purity ≥98%).

- High-Purity Solvent (e.g., HPLC-grade water, buffer, or alcohol as appropriate) [11] [2].

III. Procedure

Step 1: Instrument Preparation and Qualification

- Power on the spectrophotometer and allow the lamps to warm up for at least 15-30 minutes.

- Verify instrument performance according to pharmacopeial requirements (e.g., wavelength accuracy using holmium oxide filter; stray light check with potassium chloride solution) [11] [2].

- Set the desired method parameters in the software: scan range or fixed wavelength (λmax), data interval, and spectral bandwidth (typically 1-2 nm) [11].

Step 2: Blank Measurement

- Fill a quartz cuvette with the pure solvent used for sample preparation.

- Place the cuvette in the reference cell holder.

- Perform a blank measurement to establish the baseline (0% Absorbance or 100% Transmittance) [9] [8].

Step 3: Preparation of Standard Solutions

- Stock Standard Solution: Accurately weigh about 50 mg of the API reference standard into a 50 mL volumetric flask. Dissolve and dilute to volume with solvent to obtain a concentration of approximately 1 mg/mL [9].

- Calibration Standards: Using digital pipettes and volumetric flasks, prepare at least five standard solutions by serial dilution from the stock solution. The concentrations should bracket the expected unknown concentration and cover a range that yields absorbances between 0.1 and 1.0 AU [9] [2]. For example: 5, 10, 15, 20, and 25 μg/mL.

Step 4: Sample Preparation

- Prepare the unknown sample according to the specific monograph or method (e.g., dissolve and extract a powdered tablet in solvent, then dilute to a target concentration within the calibration range) [2].

- Ensure the sample solution is optically clear and free of particulate matter by filtration (e.g., 0.45 μm syringe filter) if necessary [2].

Step 5: Data Acquisition

- Calibration Curve:

- Rinse a cuvette twice with a small portion of the first standard solution.

- Fill the cuvette with the standard, wipe the clear surfaces with a lint-free tissue, and place it in the sample holder.

- Measure the absorbance at λmax. Repeat for each calibration standard [9].

- Unknown Sample:

- Rinse and fill the cuvette with the prepared unknown sample and measure its absorbance at the same λmax.

Step 6: Data Analysis and Calculation

- The instrument software (or external data processing) will plot absorbance versus concentration for the standard solutions and perform a linear regression analysis [9].

- The correlation coefficient (R²) for the calibration curve should be ≥0.995 [9].

- The concentration of the unknown sample (Cunknown) is calculated using the linear equation from the calibration curve: Aunknown = m * C_unknown + b, where m is the slope and b is the y-intercept [9] [8].

Additional Method-Specific Protocols

Table 2: Protocols for Specific Pharmaceutical Applications

| Application | Core Experimental Workflow | Critical Parameters & Considerations |

|---|---|---|

| Dissolution Testing | 1. Place dosage unit in dissolution vessel.2. Withdraw aliquots at specified times (e.g., 10, 20, 30 min).3. Filter aliquot immediately.4. Measure absorbance and calculate % drug released [12] [2]. | - Sink conditions.- Temperature control (37±0.5°C).- Avoid air bubbles during sampling.- Immediate filtration to prevent continued dissolution. |

| Content Uniformity | 1. Accurately weigh 10 individual dosage units.2. Dissolve each unit individually in a specified volume of solvent.3. Filter and dilute the solutions appropriately.4. Measure absorbance of each solution and calculate API content per unit [2]. | - Individual unit preparation.- Complete extraction of API from excipients.- Acceptance criteria per pharmacopeia (e.g., USP ⟨905⟩). |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Materials for UV-Vis Analysis in Pharma

| Item | Function / Purpose | Critical Specifications & Notes |

|---|---|---|

| Reference Standards | Provides the benchmark for identity and quantification; used to create calibration curves [2]. | Certified purity (e.g., USP Reference Standard); stored as per certificate of analysis [2]. |

| Quartz Cuvettes | Holds liquid sample in the light path [8]. | 1 cm pathlength is standard; must be used for UV range (<340 nm); ensure clear, unscratched windows [8] [2]. |

| HPLC-Grade Solvents | Dissolves analyte and fills reference cell; should not absorb significantly at wavelengths of interest [11] [2]. | Low UV cutoff below measurement wavelength (e.g., water, acetonitrile, ethanol). Check solvent transparency [11]. |

| Buffer Salts | Controls pH of the solution, which can critical for stability and absorbance of ionizable analytes [11]. | High purity; must not form complexes with the analyte or absorb light in the measured region [11]. |

| Syringe Filters | Clarifies sample solutions by removing particulate matter that causes light scattering [2]. | 0.45 μm or 0.2 μm pore size; membrane material must be compatible with solvent (e.g., Nylon, PTFE, PVDF) [2]. |

| Volumetric Glassware | Ensures accurate and precise preparation of standard and sample solutions [9]. | Class A certified for highest accuracy; used for all dilutions in quantitative work [9]. |

| Lithium;cyclohex-2-en-1-one | Lithium;cyclohex-2-en-1-one | Lithium;cyclohex-2-en-1-one (C6H8LiO+) is a versatile organolithium reagent for synthesis and neuroscience research. This product is for research use only and not for human or veterinary use. |

| 3-Phenyl-1,4-dithian-2-one | 3-Phenyl-1,4-dithian-2-one, CAS:190251-46-8, MF:C10H10OS2, MW:210.3 g/mol | Chemical Reagent |

Instrumentation and Data Analysis

Spectrophotometer Components

A UV-Vis spectrophotometer consists of several key components [8]:

- Light Source: Typically a combination of a deuterium lamp (for UV region) and a tungsten or halogen lamp (for visible region) [8].

- Wavelength Selector (Monochromator): Uses a diffraction grating (typically with ≥1200 grooves/mm) to disperse light and select a narrow band of wavelengths to pass through the sample [8].

- Sample Compartment: Holds the sample and reference cuvettes.

- Detector: Converts light intensity into an electrical signal. Common types include photomultiplier tubes (PMT), photodiodes, and charge-coupled devices (CCD) [8].

Practical Considerations for Accurate Results

- Stray Light: Light of unwanted wavelengths reaching the detector can cause significant errors, especially at high absorbances (>2 AU). It is a key specification checked during instrument qualification [11].

- Spectral Bandwidth: The range of wavelengths transmitted simultaneously. A narrower bandwidth provides higher resolution but requires more energy and time. It should be less than the natural width of the sample's absorption peak [11].

- Deviations from Beer-Lambert Law: Can occur at high concentrations (>0.01 M) due to electrostatic interactions or chemical effects like association or dissociation. The linear range should always be verified during method development [11].

UV-Vis spectroscopy remains an indispensable technique in the spectroscopic analysis of pharmaceutical active components. Its ability to provide rapid, accurate, and reproducible quantitative data on API concentration, purity, and behavior under various conditions makes it a fundamental tool for both research and quality control. When applied within a well-defined and validated protocol—using qualified instruments, high-quality reagents, and appropriate data analysis—it delivers robust results that are essential for ensuring drug efficacy, safety, and regulatory compliance.

Infrared (IR) Spectroscopy is an analytical technique that deals with the frequencies of bond vibration in a molecule, providing unique insights into molecular structures and compositions. This method measures the absorption of infrared light by molecules, creating a characteristic "fingerprint" based on their functional groups and chemical bonds. In pharmaceutical research and development, IR spectroscopy has emerged as a critical tool for identifying and quantifying molecular structures, driving significant improvements in quality control and drug discovery processes. The technique is particularly valuable due to its non-destructive nature, rapid analysis capabilities, and exceptional specificity for chemical identification [13] [14].

The fundamental principle of IR spectroscopy involves exposing a sample to infrared radiation, where part of the incident radiation is absorbed by the molecules while the remaining radiation is transmitted. The resulting spectrum represents molecular absorption and transmission, creating a plot of absorbance or transmittance percentage against wavenumber (cmâ»Â¹). Different functional groups absorb characteristic frequencies of IR radiation, enabling researchers to identify specific molecular components within complex pharmaceutical formulations. Modern Fourier Transform Infrared (FTIR) spectroscopy has largely replaced older dispersive instruments due to superior accuracy, sensitivity, and speed—all frequencies are measured simultaneously rather than sequentially, significantly enhancing analytical efficiency [13].

In the context of pharmaceutical analysis, IR spectroscopy provides unparalleled advantages for verifying the identity of active pharmaceutical ingredients (APIs), excipients, and potential impurities. The technique supports comprehensive analytical workflows from early drug development through commercial manufacturing, helping ensure compliance with rigorous regulatory standards while maintaining product quality and patient safety. The molecular fingerprint generated by IR spectroscopy is highly sensitive to subtle structural differences, including polymorphic forms, hydration states, and molecular interactions—critical factors influencing drug stability, bioavailability, and therapeutic efficacy [2] [14].

Theoretical Foundations: Molecular Vibrations and Spectral Interpretation

Fundamental Principles of Molecular Vibrations

At the core of IR spectroscopy lies the principle that molecules undergo continuous vibrational motions, and these vibrations occur at specific frequencies corresponding to discrete energy levels. When infrared radiation interacts with a molecule, energy is absorbed if the frequency of radiation matches the natural vibrational frequency of a chemical bond within the molecule. This energy absorption promotes the molecule to a higher vibrational energy state, resulting in characteristic absorption patterns that provide detailed information about the molecular structure. The absorption of IR radiation requires a net change in the dipole moment of the molecule during vibration, making the technique particularly sensitive to polar functional groups [13].

The infrared region of the electromagnetic spectrum is typically divided into three main bands: Near-Infrared (NIR, 0.78-3.0 μm), Mid-Infrared (MIR, 3.0-50.0 μm), and Far-Infrared (FIR, 50.0-1000.0 μm). Most analytical applications in pharmaceutical research utilize the mid-IR region (4000-400 cmâ»Â¹), where the fundamental vibrational modes of organic molecules occur. The unit of measurement most commonly used in IR spectroscopy is wavenumber (cmâ»Â¹), which is inversely proportional to wavelength and directly related to vibrational energy. This relationship enables precise characterization of molecular structures through their unique vibrational signatures [13].

IR Spectrum Interpretation and Correlation Tables

Interpreting IR spectra requires understanding characteristic absorption frequencies for different functional groups and molecular bonds. An IR spectrum can be conceptually divided into two main regions: the functional group region (4000-1200 cmâ»Â¹) and the fingerprint region (1200-400 cmâ»Â¹). The functional group region contains absorptions from specific bond types (e.g., O-H, N-H, C=O), while the fingerprint region provides a unique pattern characteristic of the entire molecule, enabling discrimination between structurally similar compounds [13].

The following correlation table summarizes characteristic IR absorption frequencies for common functional groups encountered in pharmaceutical compounds:

Table 1: Characteristic IR Absorption Frequencies of Common Functional Groups in Pharmaceutical Compounds

| Bond | Type of Bond | Specific Type | Absorption Peak (cmâ»Â¹) | Appearance |

|---|---|---|---|---|

| O─H | alcohols, phenols | low concentration | 3610–3670 | sharp |

| high concentration | 3200–3400 | broad | ||

| carboxylic acids | low concentration | 3500–3560 | sharp | |

| high concentration | 3000 | broad | ||

| N─H | primary amines | any | 3400–3500 | strong |

| 1560–1640 | strong | |||

| secondary amines | any | >3000 | weak to medium | |

| Câ•O | aldehyde/ketone | saturated aliphatic | 1720 | strong |

| α,β-unsaturated | 1685 | strong | ||

| cyclic 5-membered | 1750 | strong | ||

| carboxylic acids | saturated | 1710 | strong | |

| esters | any | 1735 | strong | |

| amides | associated | 1650 | strong | |

| C─H | alkyl | methyl | 2870, 2960 | medium to strong |

| methylene | 2850, 2925 | medium to strong | ||

| aromatic | any | 3070 | weak | |

| Câ•C | alkenes | monosubstituted | 1645 | medium |

| aromatic | any | 1450, 1500, 1580, 1600 | weak to strong | |

| C≡N | nitriles | unconjugated | 2250 | medium |

Source: Adapted from Infrared Spectroscopy Correlation Table [15]

Several factors can influence vibrational frequencies observed in IR spectra, including conjugation, inductive effects, hydrogen bonding, and ring strain. Conjugation typically decreases stretching frequency by reducing bond force constants, while hydrogen bonding can significantly broaden and shift absorption peaks—particularly for O-H and N-H groups. Understanding these factors is essential for accurate spectral interpretation and structural elucidation of pharmaceutical compounds [13].

Experimental Protocols and Methodologies

Sample Preparation Techniques

Proper sample preparation is crucial for obtaining accurate and reproducible IR spectra. The specific methodology varies depending on sample physical state (solid, liquid, or gas) and the selected sampling technique. Consistent sample preparation ensures optimal spectral quality while minimizing artifacts that could interfere with data interpretation [2].

Table 2: Sample Preparation Methods for Different Pharmaceutical Formulations

| Sample Type | Preparation Method | Key Considerations | Typical Accessories |

|---|---|---|---|

| Solid APIs and Excipients | KBr Pellet | Mix 1-2 mg sample with 100-200 mg dry KBr; press under vacuum | Hydraulic Press, Die Set |

| ATR (Attenuated Total Reflectance) | Place sample directly on crystal; apply uniform pressure | Diamond ATR, ZnSe ATR | |

| Diffuse Reflectance (DRIFTS) | Dilute sample in non-absorbing matrix (KBr) | DRIFTS accessory | |

| Liquid Formulations | Transmission Cell | Use sealed cells with precise pathlength (0.01-1 mm) | Fixed-pathlength cells, Demountable cells |

| ATR | Apply liquid directly to crystal; clean thoroughly between samples | Diamond ATR, ZnSe ATR | |

| Semi-Solid Formulations | ATR | Apply thin, uniform layer on crystal | Diamond ATR, Multi-bounce ATR |

| Transmission | Sandwich between salt plates | NaCl, KBr windows | |

| Powder Blends and Tablets | ATR | Press tablet directly onto crystal | Diamond ATR with high-pressure clamp |

| DRIFTS | Dilute with KBr (1-5% concentration) | DRIFTS accessory |

For solid samples, the potassium bromide (KBr) pellet method remains widely used, particularly for transmission measurements. The sample is finely ground and mixed with dry KBr powder, then compressed under high pressure to form a transparent pellet. Alternatively, Attenuated Total Reflectance (ATR) techniques have gained popularity for their minimal sample preparation requirements—solids can be analyzed directly by placing them in contact with the ATR crystal and applying consistent pressure to ensure good contact [2].

Liquid samples, including API solutions, suspensions, and oral formulations, are typically analyzed using transmission cells with controlled pathlengths or ATR accessories. For transmission measurements, appropriate pathlength selection is critical to ensure absorbance values remain within the optimal linear range (0.1-1.0 AU). ATR techniques are particularly advantageous for volatile solvents, viscous solutions, and samples that are difficult to contain in traditional liquid cells [2] [16].

FTIR Instrumentation and Accessory Selection

Modern FTIR spectrometers offer enhanced sensitivity, resolution, and speed compared to traditional dispersive instruments. The core components include an IR source, interferometer, sample compartment, detector, and computer system for Fourier transform processing. Accessory selection should align with specific pharmaceutical applications and sample types:

Transmission Accessories: Ideal for quantitative analysis of liquids and KBr pellets. The Specac Pearl Liquid Transmission Accessory provides precise pathlength control for dissolution testing and concentration verification, with typical pathlengths ranging from 0.025 mm to 1 mm [16].

ATR Accessories: Versatile for solids, liquids, and semi-solids. Diamond ATR accessories (e.g., Specac Golden Gate) offer durability and minimal maintenance, while multi-bounce ATR systems (e.g., Harrick ConcentratIR2) enhance sensitivity for low-concentration analytes. ATR-FTIR is particularly valuable for polymorph screening, raw material identification, and contamination analysis [2] [16].

Diffuse Reflectance (DRIFTS): Effective for powdered samples and tablet formulations without requiring pellet preparation. DRIFTS is commonly applied for blend uniformity analysis, polymorph quantification, and excipient compatibility studies [16].

Specialized Accessories: High-temperature ATR accessories (e.g., Golden Gate High Temperature ATR) enable polymorph screening through temperature-dependent studies, while in-situ reaction cells facilitate real-time monitoring of chemical reactions and degradation processes [16].

Quantitative Analysis Method Development

While often considered primarily qualitative, FTIR spectroscopy offers robust quantitative capabilities when properly validated. Method development for quantitative pharmaceutical analysis involves several critical steps:

Wavelength Selection: Identify specific, well-resolved absorption bands unique to the analyte of interest, avoiding spectral regions with excipient interference.

Baseline Definition: Establish consistent baseline points on either side of the absorption peak to enable reproducible absorbance measurements.

Calibration Model: Prepare standard solutions or calibration mixtures spanning the expected concentration range. Plot absorbance versus concentration to establish a linear relationship (typically following Beer-Lambert Law).

Method Validation: Assess key validation parameters including accuracy, precision, linearity, range, limit of detection (LOD), limit of quantitation (LOQ), and robustness according to ICH Q2(R1) guidelines [2].

For complex formulations, multivariate calibration techniques (e.g., partial least squares regression) may be employed to correlate spectral changes with analyte concentration, particularly in near-IR applications where overlapping bands are common.

Pharmaceutical Applications and Case Studies

API Identity Testing and Raw Material Verification

IR spectroscopy serves as a primary technique for identity testing of active pharmaceutical ingredients and raw materials, as required by major pharmacopeias. The molecular fingerprint region (1200-400 cmâ»Â¹) provides unique patterns that enable unambiguous identification of compounds. In practice, the sample spectrum is compared against a reference standard using validated software algorithms that calculate correlation coefficients or spectral match values [2] [17].

Protocol: Raw Material Identity Confirmation

- Obtain reference spectrum of qualified raw material standard

- Prepare test sample using appropriate technique (typically ATR or KBr pellet)

- Acquire spectrum with 4 cmâ»Â¹ resolution, 32 scans

- Process spectra (baseline correction, vector normalization)

- Compare test spectrum against reference using library search algorithm

- Document correlation value (typically ≥0.95 for confirmation) and spectral overlay

This application is particularly valuable for incoming raw material inspection, where rapid verification of chemical identity ensures only approved materials enter manufacturing processes. Modern FTIR systems with automated sample handling can analyze dozens of samples per hour with minimal operator intervention [2].

Polymorph Characterization and Screening

Different crystalline forms (polymorphs) of pharmaceutical compounds can significantly impact solubility, stability, and bioavailability. IR spectroscopy is exceptionally sensitive to subtle differences in crystal structure and hydrogen bonding patterns, making it indispensable for polymorph screening and form identification [16].

Case Study: Paracetamol Polymorph Monitoring Researchers utilized variable temperature ATR-FTIR with the Golden Gate High Temperature Accessory to unambiguously profile paracetamol polymorphs. Spectral changes monitored during temperature ramping clearly revealed form transitions that were difficult to detect using other techniques due to similar transition temperatures. This approach enabled precise identification of polymorphic forms critical for commercial manufacturing and regulatory filing [16].

Protocol: Polymorph Screening by ATR-FTIR

- Prepare saturated solution of API in appropriate solvent

- Deposit solution on ATR crystal and allow for solvent evaporation

- Acquire initial spectrum (4000-400 cmâ»Â¹, 4 cmâ»Â¹ resolution)

- Apply temperature ramp (e.g., 25-300°C at 5°C/min) while collecting spectra

- Monitor specific spectral regions for form transitions

- Correlate spectral changes with thermal events (e.g., DSC data)

- Create reference library of stable and metastable forms

Drug-Excipient Compatibility Studies

During formulation development, FTIR spectroscopy identifies potential incompatibilities between APIs and excipients through detection of molecular interactions. Spectral shifts, appearance of new bands, or disappearance of characteristic peaks indicate chemical interactions that may compromise product stability [16].

Case Study: Levodopa-Excipient Interactions ATR-FTIR spectroscopy demonstrated incompatibility between levodopa (a Parkinson's disease treatment) and several common excipients. Spectral changes indicated molecular interactions that could potentially affect drug stability and performance. These findings guided rational excipient selection to develop stable dosage forms [16].

Protocol: Drug-Excipient Compatibility Screening

- Prepare binary mixtures of API with individual excipients (1:1 ratio)

- Include appropriate controls (API alone, excipient alone)

- Subject mixtures to stress conditions (e.g., 40°C/75% RH for 4 weeks)

- Acquire FTIR spectra at predetermined timepoints

- Analyze spectral changes indicating interactions:

- Shift in characteristic API peaks (>5 cmâ»Â¹)

- Appearance of new absorption bands

- Changes in band intensity ratios

- Peak broadening suggesting amorphous formation

- Rank excipients based on compatibility results

Counterfeit Drug Detection and Supply Chain Protection

FTIR spectroscopy provides rapid, non-destructive authentication of pharmaceutical products to combat counterfeit drugs. The technique detects composition differences between genuine and falsified products through spectral fingerprint comparison [16].

Case Study: Tadalafil and Sildenafil Authentication A research study employed ATR-FTIR fingerprinting (1800-525 cmâ»Â¹) to accurately distinguish between genuine and counterfeit tadalafil and sildenafil tablets. Multivariate analysis of spectral data revealed significant composition differences despite identical visual appearance between authentic and falsified products, demonstrating FTIR's capability for rapid screening of suspect products [16].

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of IR spectroscopic methods requires appropriate selection of reagents, accessories, and reference materials. The following toolkit outlines essential components for pharmaceutical IR analysis:

Table 3: Essential Research Reagents and Materials for Pharmaceutical IR Analysis

| Category | Specific Items | Function/Application | Key Considerations |

|---|---|---|---|

| Sample Preparation | Potassium Bromide (KBr) | Transmission pellet matrix | Infrared grade, dry (<1% moisture) |

| Deuterated Solvents (CDCl₃, DMSO-d₆) | NMR correlation studies | High isotopic purity, appropriate storage | |

| ATR Cleaning Solvents | Crystal maintenance | HPLC grade methanol, acetone | |

| Reference Standards | USP/EP API Standards | Identity testing | Qualified, traceable to reference standards |

| Polymorphic Form Standards | Form identification | Well-characterized crystalline forms | |

| Excipient Libraries | Compatibility screening | Pharmaceutical grade | |

| Instrument Accessories | Diamond ATR | Solid and liquid analysis | Durability, chemical resistance |

| Transmission Cells | Quantitative liquid analysis | Precise pathlength calibration | |

| High-Temperature ATR | Polymorph screening | Temperature calibration, stability | |

| DRIFTS Accessory | Powder analysis | Non-destructive, minimal preparation | |

| Data Analysis Tools | Spectral Libraries | Compound identification | Industry-specific databases |

| Chemometrics Software | Quantitative modeling | Multivariate analysis capabilities | |

| Validation Protocols | Method qualification | ICH Q2(R1) compliance | |

| Dodec-1-EN-8-yne | Dodec-1-EN-8-yne, CAS:197901-17-0, MF:C12H20, MW:164.29 g/mol | Chemical Reagent | Bench Chemicals |

| 1-Tert-butylchrysene | 1-Tert-butylchrysene | 1-Tert-butylchrysene (C22H20) is a polycyclic aromatic hydrocarbon (PAH) for materials science research. This product is for Research Use Only and not for human or veterinary use. | Bench Chemicals |

Proper maintenance of IR accessories and consistent quality of research reagents are fundamental for obtaining reliable, reproducible results. Diamond ATR crystals should be regularly cleaned with appropriate solvents and inspected for surface damage. Hygroscopic materials like KBr must be stored in controlled humidity environments to prevent moisture absorption that could interfere with spectral acquisition. Reference standards require proper characterization and storage according to supplier specifications to maintain integrity throughout their use lifecycle [2] [16].

Regulatory Considerations and Method Validation

Pharmaceutical applications of IR spectroscopy must adhere to rigorous regulatory standards and validation requirements. Regulatory bodies including FDA, EMA, and ICH recognize properly validated spectroscopic methods as reliable tools for ensuring drug quality, safety, and efficacy [2].

Method Validation Parameters

According to ICH Q2(R1) guidelines, analytical procedures must demonstrate suitability for their intended purpose through validation across multiple parameters:

- Specificity: Ability to unequivocally assess the analyte in the presence of potential interferants (e.g., excipients, impurities)

- Accuracy: Agreement between measured value and true value, typically established through spike recovery studies (98-102%)

- Precision: Degree of agreement among individual measurements, including repeatability (intra-assay) and intermediate precision (inter-day, inter-analyst)

- Detection Limit (LOD) & Quantitation Limit (LOQ): Lowest concentrations that can be detected or quantified with acceptable accuracy and precision

- Linearity & Range: Ability to obtain results proportional to analyte concentration across the specified range

- Robustness: Capacity to remain unaffected by small, deliberate variations in method parameters

For identity testing applications, validation typically focuses on specificity and robustness, while quantitative methods require comprehensive validation across all parameters [2].

Regulatory Documentation Requirements

Implementation of IR methods in regulated environments requires thorough documentation including:

- Standard Operating Procedures (SOPs) for instrument operation, calibration, and maintenance

- Method validation protocols and reports

- System suitability testing procedures

- Change control documentation for method modifications

- Data integrity measures following ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate)

The FDA's Process Analytical Technology (PAT) framework encourages implementation of IR spectroscopy for real-time quality monitoring during pharmaceutical manufacturing. This approach aligns with Quality by Design (QbD) principles, enabling enhanced process understanding and control through continuous quality verification [2] [16].

Emerging Applications and Future Perspectives

IR spectroscopy continues to evolve with technological advancements, expanding its applications in pharmaceutical research and quality control. Several emerging areas show particular promise for enhancing drug development and manufacturing:

Point-of-Care Evaluation of 3D Printed Dosage Forms: As personalized medicine advances, FTIR spectroscopy offers potential for quality control of 3D printed pharmaceuticals. Early research with griseofulvin, indomethacin, and nifedipine formulations demonstrates feasibility for point-of-care verification of printed dosage forms [16].

RNA Therapeutics Characterization: With growing interest in RNA-based therapies, FTIR shows potential for analyzing RNA structure and formulation interactions. While primarily used in basic RNA biology research currently, the technique may provide valuable insights for pharmaceutical RNA formulations as the field advances [16].

Process Analytical Technology (PAT) Integration: Implementation of inline FTIR analysis enables real-time monitoring of critical quality attributes during manufacturing. Particularly valuable for blend homogeneity assessment in powder mixers, this approach provides immediate feedback to manufacturing systems, enhancing compliance while reducing failures and waste [2] [16].

Handheld and Portable IR Devices: Advances in miniaturization have enabled development of portable IR spectrometers for field-based testing. These devices offer potential for supply chain monitoring, counterfeit detection, and at-line manufacturing control, though method transfer from laboratory instruments requires careful validation [16].

As pharmaceutical manufacturing evolves toward continuous processing and real-time release testing, IR spectroscopy is positioned to play an increasingly central role in quality assurance frameworks. The technique's versatility, speed, and molecular specificity make it indispensable for modern pharmaceutical analysis, from early discovery through commercial manufacturing [2] [14] [16].

Nuclear Magnetic Resonance (NMR) spectroscopy stands as a pivotal analytical technique in pharmaceutical research, providing unparalleled insights into the atomic-level structure and dynamics of active pharmaceutical ingredients (APIs) and biomolecules. This capability is fundamental for understanding drug-receptor interactions, characterizing complex formulations, and ensuring product quality. NMR's unique advantage lies in its ability to elucidate molecular structures in solution and solid states, closely mirror physiological conditions and relevant pharmaceutical dosage forms. The integration of advanced NMR protocols and computational tools has significantly accelerated structure-based drug discovery, enabling researchers to resolve complex spectroscopic data into precise three-dimensional models that drive rational drug design.

The application of NMR in pharmaceutical analysis continues to evolve, with recent developments including quantitative solid-state NMR (qSSNMR) for characterizing solid drug formulations [18] and intact NMR methods for analyzing complex dosage forms like nanoemulsions without disruptive sample preparation [19]. These advancements align with regulatory science initiatives, as demonstrated by the FDA's recent adoption of intact NMR for nanoemulsion drug quality assessment [19]. This Application Note details standardized protocols and data analysis methodologies that leverage NMR spectroscopy for high-throughput structure determination of pharmaceutical targets and excipient characterization.

Application Notes

High-Throughput Protein Structure Determination

Structural genomics initiatives have demonstrated the capability of advanced NMR protocols to determine protein structures with atomic resolution in significantly reduced timeframes. A standardized protocol employing G-matrix Fourier Transform (GFT) NMR spectroscopy enables rapid data collection for proteins ranging from 9 to 20 kDa, effectively removing data collection as a bottleneck in high-throughput structural pipelines [20]. This approach capitalizes on high spectrometer sensitivity through joint sampling of several indirect dimensions, solving the "NMR sampling problem" associated with conventional multidimensional NMR.

The methodology was validated through the structure determination of eight target proteins from the Northeast Structural Genomics Consortium, with molecular masses ranging from 9 to 20 kDa (average ≈14 kDa) [20]. The protocol integrated five GFT NMR experiments for resonance assignment based on highly resolved 4D and 5D spectral information, acquired in conjunction with a single simultaneous 3D 15N,13Caliphatic,13Caromatic-resolved [1H,1H]-NOESY spectrum that provided 1H-1H upper distance limit constraints [20]. This comprehensive data collection required only 1-9 days of instrument time per structure, representing less than 10-25% of the measurement time routinely required with conventional approaches [20].

Table 1: Summary of High-Throughput Protein Structure Determinations Using GFT NMR

| Parameter | yqfB (ET99) | PF0470 (PfR14) | BC4709 (BcR68) | yqbG (SR215) | yhgG (ET95) | rps24e (MaR11) | BH1534 (BhR29) | UFC1 (HR41) |

|---|---|---|---|---|---|---|---|---|

| Molecular Mass (kDa) | 15.3/11.9 | 15.7/13.8 | 18.1/16.1 | 16.7/14.7 | 10.3/8.7 | 13.5/11.7 | 18.0/15.9 | 21.7/19.5 |

| Correlation Time τr (ns) | ≈7.7 | ≈8.1 | ≈10 | ≈8.5 | ≈5.1 | ≈6.5 | ≈8.7 | ≈11 |

| Protein Concentration (mM) | ≈1.0 | ≈1.0 | ≈1.5 | ≈0.9 | ≈1.1 | ≈1.0 | ≈0.8 | ≈1.0 |

| Total Measurement Time (days) | 1.1 | 8.5 | 6.9 | 5.3 | 2.0 | 5.0 | 5.7 | 8.9 |

| Completeness BB/SC Assignment (%) | 98/95 | 84/89 | 99/99 | 100/99 | 98/99 | 100/99 | 99/99 | 97/97 |

Nanoemulsion Characterization in Drug Formulations

NMR spectroscopy has emerged as a powerful regulatory science tool for characterizing complex drug formulations, particularly nanoemulsions. The FDA has adopted intact NMR methods for nanoemulsion drug quality assessment, enabling non-invasive characterization of microstructure properties that enhances excipient selection and formulation optimization [19]. This approach provides significant advantages for analyzing complex generics, supporting bioequivalence determinations and post-approval change assessments.

Research focused on difluprednate, an orphan drug approved for post-operative ocular pain and inflammation, demonstrated NMR's capability to characterize oil-in-water nanoemulsion formulations [19]. The method revealed correlated microstructure changes in nanoemulsion formulations for the first time, observing real-time, coordinated changes without disrupting the formulation environment. Different NMR relaxation times and diffusion coefficients served as surrogate indicators for microstructural changes, suggesting possible future development of NMR-based specifications for complex generics and innovator products [19].

Solid-State Analysis of Pharmaceutical Formulations

Quantitative solid-state NMR (qSSNMR) has become a key technique for pharmaceutical analysis, enabling precise quantification and characterization of solid drug formulations [18]. This methodology addresses critical quality attributes including polymorphism, amorphous content, and excipient interactions that directly impact drug stability, solubility, and bioavailability. Technical advancements have improved detection limits, resolution, and high-throughput capabilities for analyzing complex pharmaceutical mixtures [18].

The evolution of qSSNMR provides formulation scientists with robust tools for investigating solid-state transformations during processing and storage, crystallization of amorphous solid dispersions, and impact of different polymers on API stability [18]. These applications align with Quality by Design principles, offering enhanced understanding of critical quality attributes in pharmaceutical development.

Experimental Protocols

High-Throughput Structure Determination Protocol

Sample Preparation: Uniformly 13C,15N-double-labeled protein samples are prepared at ≈1 mM concentration in appropriate buffer systems (e.g., 95% H2O/5% 2H2O, 20 mM Mes, pH 6.5, 100 mM NaCl, 10 mM DTT, 5 mM CaCl2, 0.02% NaN3) [20]. For proteins expressed with purification tags, ensure proper cleavage and confirm protein identity and purity through mass spectrometry and analytical chromatography.

Data Collection:

- HNNCαβCα and CαβCα(CO)NHN experiments: Acquire for backbone and side-chain resonance assignment (10-67 hours depending on protein molecular weight and concentration) [20].

- HACACONHN/HαβCαβ(CO)NHN experiments: Implement for complementary assignment information (17-28 hours measurement time) [20].

- HCCH experiments: Perform separate acquisitions for aliphatic (4-29 hours) and aromatic (1.4-16 hours) regions to complete side-chain assignments [20].

- 3D 15N,13Caliphatic,13Caromatic-resolved [1H,1H]-NOESY: Acquire with mixing times of 60-70 ms (9-103 hours) to obtain 1H-1H upper distance limit constraints for structure calculation [20].

Data Processing and Analysis:

- Process multidimensional NMR data using appropriate software tools (NMRium, NMRProcFlow) [21] [22].

- Apply semiautomated data analysis protocols for resonance assignment and NOE peak integration.

- Calculate structures using distance geometry and restrained molecular dynamics simulated annealing protocols.

- Validate final structures against experimental restraints and check geometric quality using established validation software.

Diagram 1: High-Throughput Protein Structure Determination Workflow. This protocol enables complete structure determination within 1-9 days of instrument time [20].

Nanoemulsion Characterization Protocol

Sample Preparation: Prepare nanoemulsion formulations according to standard manufacturing protocols. For difluprednate ophthalmic emulsion, maintain intact formulation without dilution or manipulation to preserve native microstructure [19].

Data Collection:

- Relaxation Measurements: Acquire NMR relaxation times (T1, T2) to characterize molecular dynamics and microenvironment properties.

- Diffusion Experiments: Perform pulsed-field gradient NMR measurements to determine diffusion coefficients of oil and water phases.

- Intact NMR Analysis: Conduct non-invasive measurements without sample disruption to monitor real-time microstructure changes.

Data Analysis:

- Correlate relaxation parameters and diffusion coefficients with microstructure properties.

- Monitor coordinated changes in multiple NMR parameters as indicators of formulation stability.

- Establish acceptance criteria based on NMR parameter ranges for quality control purposes.

Quantitative Solid-State NMR Protocol

Sample Preparation: Prepare solid formulations with appropriate internal standards for quantification. Ensure uniform packing in NMR rotors for magic-angle spinning (MAS) experiments.

Data Collection:

- Magic-Angle Spinning: Acquire data at sufficient spinning speeds to resolve relevant spectral features.

- Cross-Polarization: Implement CP-MAS for sensitivity enhancement of low-abundance nuclei.

- Relaxation Measurements: Determine relaxation parameters to establish quantitative conditions.

- Spectral Acquisition: Collect sufficient transients for adequate signal-to-noise in quantitative analysis.

Data Processing and Analysis:

- Process spectra with appropriate line broadening and phase correction.

- Integrate relevant peaks for quantitative analysis.

- Apply reference standards for concentration determination.

- Utilize principal component analysis (PCA) for multivariate data analysis when characterizing complex mixtures.

The Scientist's Toolkit

Table 2: Essential Research Reagents and Materials for NMR-Based Structural Analysis

| Category | Item | Function/Application |

|---|---|---|

| Isotope Labeling | Uniformly 13C/15N-labeled compounds | Enables detection of low-abundance nuclei in proteins and pharmaceuticals for structural studies [20]. |

| Buffer Components | Deuterated buffers (e.g., D2O), cryoprotectants | Maintains pH stability and enables lock signal referencing in aqueous solutions [20]. |

| NMR Tubes | High-quality NMR tubes, Shigemi tubes | Provides optimal sample containment with minimal background signal for sensitive measurements. |

| Reference Standards | Chemical shift reference compounds (e.g., TMS, DSS) | Provides precise chemical shift calibration for reproducible results [23]. |

| Software Tools | NMRium, NMRProcFlow, MagresView | Enables processing, visualization, and analysis of multidimensional NMR data [24] [21] [22]. |

| Structure Validation | PDB validation tools, IUPAC standards | Ensures structural quality and adherence to international reporting standards [23]. |

| 1,2-Dihydrotetrazete | 1,2-Dihydrotetrazete|High-Purity Research Chemical | 1,2-Dihydrotetrazete for research. This product is For Research Use Only (RUO). Not for diagnostic, therapeutic, or personal use. |

| D6UF8X4Omb | D6UF8X4Omb, CAS:199734-14-0, MF:C19H24INO2, MW:423.3 g/mol | Chemical Reagent |

Data Analysis and Interpretation

Structural Calculation and Validation

The calculation of NMR structures requires careful interpretation of experimental constraints and iterative refinement. The recommendations from the IUPAC-IUBMB-IUPAB Inter-Union Task Group provide standardized approaches for presenting NMR structures of proteins and nucleic acids, ensuring unified nomenclature and reporting standards across the scientific community [23]. These guidelines cover atomic nomenclature, conformational parameters, and data presentation formats essential for database deposition and publication.

Structure quality is assessed through multiple validation metrics including completeness of resonance assignments (backbone and side-chain), number of NOE-derived distance constraints, and adherence to stereochemical quality standards [20]. As shown in Table 1, successful structure determinations typically achieve >95% completeness for backbone assignments and >89% for side-chain assignments, with sufficient NOE constraints to define the protein fold [20]. The final structures should comply with database deposition requirements for the Protein Data Bank and Biological Magnetic Resonance Data Bank.

Diagram 2: NMR Data Analysis and Structure Validation Pathway. This workflow ensures standardized structure calculation and validation according to IUPAC recommendations [23].

Pharmaceutical Quality Assessment

For pharmaceutical applications, NMR data interpretation focuses on establishing critical quality attributes and comparing against predefined specifications. The FDA's adoption of intact NMR for nanoemulsion characterization demonstrates how NMR parameters serve as surrogate indicators for microstructure properties and formulation stability [19]. Quantitative analysis of solid-state NMR data enables precise determination of polymorph ratios, amorphous content, and excipient interactions in final dosage forms [18].

Advanced software tools facilitate comprehensive data analysis through automated peak picking, spectral processing, and multivariate statistical analysis. Tools like NMRium provide smart peak picking capabilities and generate NMR strings required for publication or patent applications [21], while NMRProcFlow offers specialized processing and visualization of 1D NMR data for metabolomics applications [22]. For solid-state NMR parameters, MagresView and MagresPython enable visualization and processing of computed NMR parameters [24].

NMR spectroscopy provides an indispensable platform for atomic-level structure elucidation in pharmaceutical research, enabling characterization of biomolecular targets, excipient interactions, and final dosage forms. The standardized protocols presented in this Application Note demonstrate how advanced NMR methodologies can accelerate drug discovery and development while ensuring product quality. Integration of high-throughput structure determination approaches with robust validation frameworks and regulatory science initiatives positions NMR as a critical technology for modern pharmaceutical analysis. As NMR instrumentation and methodology continue to evolve, particularly in quantitative solid-state NMR and intact formulation analysis, the technique will play an increasingly vital role in addressing complex challenges in pharmaceutical development and quality assurance.

Mass Spectrometry (MS) is a cornerstone analytical technique in pharmaceutical research, enabling the precise determination of molecular weights and the detailed structural analysis of active pharmaceutical ingredients (APIs), their impurities, and metabolites through fragmentation patterns [25]. The utility of MS stems from its ability to provide both qualitative and quantitative information with high sensitivity and specificity, making it indispensable from drug discovery through to quality control [26] [27]. In the context of spectroscopic analysis of pharmaceutical active components, MS offers unparalleled capabilities for the fast confirmation of parent ions and the identification of unknown compounds [25].

The fundamental principle of MS involves the generation of gaseous ions from the analyte, which are then separated by a mass analyzer based on their mass-to-charge ratio (m/z) and detected [27]. The resulting mass spectrum provides the molecular weight of the analyte, while tandem mass spectrometry (MS/MS) experiments induce fragmentation of a selected parent ion, generating product ions that reveal critical structural information [25]. The following sections detail the core principles, applications, and standardized protocols that underpin these analyses within the pharmaceutical industry.

Core Principles and Instrumentation

Molecular Weight Determination and Resolving Power

The accurate determination of molecular weight relies on the mass analyzer's resolving power (RP) and mass accuracy. Resolving power is defined as the ability of a mass analyzer to distinguish between two ions of slightly different m/z values and is calculated as (m/z)/Δm/z, where Δm/z is the full width of the peak at half its maximum height (FWHM) [26]. Mass accuracy refers to the conformity between the measured m/z value and its theoretical value [26].

Mass spectrometers are categorized based on their resolving power [26]:

- Low-resolution (RP < 10,000): e.g., quadrupole or linear ion trap.

- High-resolution (HRMS, RP > 10,000): e.g., time-of-flight (ToF) analyzers.

- Ultra-high-resolution (UHRMS, RP > 100,000): e.g., Fourier Transform Ion Cyclotron Resonance (FTICR) and Orbitrap instruments.

UHRMS instruments are particularly valuable for pharmaceutical analysis as they allow for the unambiguous assignment of molecular formulas and the detection of trace components in complex mixtures, such as distinguishing between compounds with very close exact masses like DMF and the toxic nitrosamine NDMA [25] [26].

Table 1: Key Mass Analyzer Technologies for Pharmaceutical Analysis

| Analyzer Type | Typical Resolving Power | Mass Accuracy | Common Applications in Pharma |

|---|---|---|---|

| Triple Quadrupole (QqQ) | Low (< 10,000) | Moderate | Targeted quantitation (e.g., MRM), impurity profiling [25] [27] |

| Time-of-Flight (ToF) | High (> 10,000) | < 5 ppm | Untargeted metabolomics, metabolite identification [27] |

| Orbitrap | Ultra-High (up to 1,000,000) | < 2 ppm | Molecular formula assignment, trace analysis in complex mixtures [26] |

| FTICR | Ultra-High (up to 10,000,000) | < 1 ppm | Unambiguous elemental composition, isotopic fine structure analysis [26] |

Fragmentation Analysis

Fragmentation is the process by which a molecular ion (parent ion) breaks down into smaller product (daughter) ions. The pattern of fragmentation is highly informative of the molecule's structure [25]. Fragmentation is typically induced in a controlled manner through Collision-Induced Dissociation (CID) within a tandem mass spectrometer (MS/MS).

The application of optimum collision energy is critical for effective fragmentation of the parent ion into structurally significant product ions [25]. Several factors influence fragmentation patterns and must be optimized [25]:

- MS parameters: Collision energy, entry and exit voltages.

- Environmental factors: Temperature, gas pressure, flow rate, and diluent.

- Ionization mode: Choice between Electrospray Ionisation (ESI) and Atmospheric Pressure Chemical Ionisation (APCI) depends on the chromophoric or non-chromophoric nature of the compound.

Figure 1: Workflow for MS/MS Fragmentation Analysis. The selected parent ion is subjected to collision-induced dissociation, generating product ions that are analyzed to produce a characteristic fragmentation spectrum.

Applications in Pharmaceutical Analysis

Mass spectrometry is a versatile tool applied across the entire pharmaceutical development pipeline.

- API and Impurity Identification: UHRMS is used for the accurate identification of APIs and the structural elucidation of known and unknown impurities and degradation products. This is critical for ensuring drug safety and quality [25] [26].

- Metabolite Profiling and Pharmacokinetics: LC-MS/MS methods are extensively used to detect, quantify, and localize pharmaceuticals and their metabolites in biological samples (e.g., plasma, serum, tissue) [27]. This provides vital information on drug metabolism, distribution, and exposure.

- High-Throughput Screening: Affinity Selection Mass Spectrometry (AS-MS) is a label-free, high-throughput screening technique used to identify ligands from natural product or synthetic libraries that bind to a specific biological target, such as a protein or nucleic acid [28]. The workflow involves incubating the target with a library, separating the target-ligand complexes from unbound molecules (e.g., via ultrafiltration or immobilization), dissociating the ligands, and identifying them by MS [28].

Experimental Protocols

Protocol: LC-MS/MS Analysis of Pharmaceuticals in Biological Matrices

This protocol outlines a standard procedure for the detection and quantitation of a pharmaceutical compound and its metabolites in mouse plasma, based on published methodologies [27].

1. Sample Preparation

- Protein Precipitation: Add a 3:1 volume of ice-cold acetonitrile containing internal standards (e.g., deuterated analogs of the analytes) to the plasma sample.

- Vortex and Centrifuge: Vortex mix for 1 minute and centrifuge at 14,000 × g for 10 minutes at 4°C.

- Collection: Transfer the clear supernatant to a fresh LC-MS vial [27].

2. Liquid Chromatography (LC) Conditions

- Column: Reversed-Phase C18 column (e.g., 2.1 x 100 mm, 1.7 μm).

- Mobile Phase A: Water with 0.1% Formic Acid.

- Mobile Phase B: Acetonitrile with 0.1% Formic Acid.

- Gradient:

- 0-1 min: 5% B

- 1-8 min: 5% B to 95% B

- 8-10 min: 95% B

- 10-11 min: 95% B to 5% B

- 11-15 min: 5% B (re-equilibration)

- Flow Rate: 0.3 mL/min

- Injection Volume: 5 μL [27]

3. Mass Spectrometry (MS) Conditions

- Ionization: Electrospray Ionisation (ESI), positive mode.

- Data Acquisition: Multiple Reaction Monitoring (MRM).

- Source Parameters:

- Capillary Voltage: 3.0 kV

- Desolvation Temperature: 350°C

- Desolvation Gas Flow: 800 L/hr

- Analyzer: Triple Quadrupole (QqQ).

- MRM Transitions: Define specific precursor ion → product ion transitions for the pharmaceutical and each metabolite, with optimized collision energies [27].

Table 2: Example MRM Transitions and Parameters for a Pharmaceutical Analysis

| Analyte | Precursor Ion (m/z) | Product Ion (m/z) | Collision Energy (eV) | Dwell Time (sec) |

|---|---|---|---|---|

| Pharmaceutical X | 357.2 | 195.1 | 22 | 0.05 |

| Metabolite Y | 373.2 | 211.1 | 18 | 0.05 |

| Internal Std (dâ‚„-Pharm X) | 361.2 | 199.1 | 22 | 0.05 |

Protocol: Ultrafiltration AS-MS for Ligand Screening

This protocol describes a solution-based AS-MS method for screening ligands from a natural product library against a soluble protein target [28].

1. Incubation

- Prepare the target protein in a suitable buffer (e.g., phosphate-buffered saline) at a low micromolar concentration.

- Incubate the protein with the natural product extract or compound library for a predetermined equilibrium time (e.g., 30-60 minutes) at room temperature. The target is typically in molar excess over the small molecules [28].

2. Separation of Complexes

- Transfer the incubation mixture to an ultrafiltration device (e.g., a centrifugal filter with a molecular weight cutoff suitable for retaining the protein-ligand complexes).

- Centrifuge the device according to manufacturer's instructions to separate the unbound compounds (in the filtrate) from the protein-ligand complexes (retained on the filter).

3. Dissociation of Ligands

- Wash the retained complex with buffer to remove non-specifically bound compounds.

- Add a denaturing solvent (e.g., 50:50 methanol:acetonitrile with 1% formic acid) to the filter unit to disrupt the non-covalent protein-ligand interactions.

- Centrifuge to collect the dissociated ligands in the filtrate.

4. Ligand Identification

- Analyze the filtrate containing the dissociated ligands using LC-HRMS (e.g., LC-Orbitrap).

- Acquire data in full-scan and data-dependent MS/MS modes.

- Identify the ligands by accurate mass and MS/MS fragmentation, comparing against controls (incubation without protein) to calculate an affinity or index ratio [28].

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions and Materials for MS-Based Pharmaceutical Analysis

| Item | Function / Application |

|---|---|

| Volatile Buffers (e.g., Ammonium Acetate, Formic Acid) | Compatible with ESI-MS; facilitate ionization and maintain pH in LC mobile phases without causing ion suppression [25]. |

| HPLC-grade Solvents (Water, Methanol, Acetonitrile) | Used for sample preparation, dilution, and as LC mobile phases to minimize background interference and ensure chromatographic performance [27]. |

| Deuterated Internal Standards | Added to samples prior to analysis to correct for variability in sample preparation and ionization efficiency, enabling highly accurate quantitation [27]. |

| Solid Phase Extraction (SPE) Cartridges | Used for clean-up and pre-concentration of analytes from complex biological matrices like plasma or urine, reducing matrix effects [27]. |

| Ultrafiltration Devices | Key for AS-MS workflows; separate protein-ligand complexes from unbound molecules based on size exclusion [28]. |

| Reference Standard Compounds | Crucial for confirming the identity of disclosed ligands in screening assays (e.g., AS-MS) and for method development and validation [28]. |

| 1-Aminohex-5-en-3-ol | 1-Aminohex-5-en-3-ol|Alfa Chemistry |

| 1-Pyrenebutanethiol | 1-Pyrenebutanethiol for Carbon Nanotube Research |

Raman spectroscopy is a powerful spectroscopic technique that provides a structural fingerprint for molecules by detecting inelastic scattering of monochromatic light, usually from a laser source. This technique characterizes molecular vibrations to enable unambiguous, highly specific chemical identification of solids, liquids, and gases without extensive sample preparation [29] [30]. Within pharmaceutical research, Raman spectroscopy has emerged as an indispensable analytical tool for drug development and quality control due to its non-destructive nature, minimal interference from water, and ability to analyze samples through containers [31]. The superior spatial resolution of confocal Raman microprobes often provides better content characterization than traditional IR spectroscopy, making it particularly valuable for analyzing complex pharmaceutical formulations and solid-state properties [30].

The complementary relationship between Raman and infrared (IR) spectroscopy arises from their different fundamental mechanisms. IR absorption requires a change in the dipole moment of a molecule and is particularly sensitive to polar bonds (e.g., C-O, N-O, O-H), while Raman activity depends on changes in a molecule's polarizability and is more sensitive to relatively neutral bonds (e.g., C-C, C-H, C=C) and symmetric molecular vibrations [29] [32]. This complementary nature means that molecular vibrations that are weak in IR often produce strong Raman signals, and vice versa, providing researchers with a more comprehensive vibrational profile of pharmaceutical compounds [32].

Table 1: Fundamental Characteristics of Raman and Infrared Spectroscopy

| Characteristic | Raman Spectroscopy | Infrared Spectroscopy |

|---|---|---|

| Physical Basis | Inelastic scattering of light | Absorption of light |

| Molecular Requirement | Change in polarizability | Change in dipole moment |

| Sensitivity to Water | Low | High |

| Spatial Resolution | Superior with confocal microprobes | Limited |

| Sample Preparation | Minimal, non-destructive | Often requires preparation |

| Through-Container Analysis | Possible | Not typically possible |

| Strong Signals From | C-C, C=C, C-H, S-S bonds | C-O, N-O, O-H bonds |

Advanced Raman Imaging Techniques

Raman Chemical Imaging and Mapping

Raman imaging combines spectral information with spatial resolution to create chemical maps showing the distribution of components within a sample. Tablet mapping is a key pharmaceutical application where Raman spectroscopy assesses tablet uniformity and analyzes the grain size and distribution of active pharmaceutical ingredients (APIs) and excipients [30]. Modern Raman imaging systems can acquire information-rich maps ranging from large-area overviews of entire tablets to high-resolution images of individual grains and phase boundaries. SWIFT imaging technology enables acquisition of these detailed maps within practical timeframes of minutes to hours, significantly accelerating pharmaceutical development and quality control processes [30].

In a demonstrated application, researchers acquired three Raman maps from an aspirin-containing painkiller tablet at different spatial scales. The whole-tablet map (7 × 18 mm² area with 50,901 pixels) revealed the distribution of aspirin, paracetamol, caffeine, and the tablet coating. A higher-resolution image identified a fourth component (cellulose) distributed widely across the tablet, while a final image acquired with 2μm step size (90,601 data points) enabled detailed observation of individual cellulose grain size and shape [30]. This multi-scale imaging capability provides unparalleled insight into formulation homogeneity and potential defect identification.

Specialized Raman Imaging Modalities

Several enhanced Raman techniques have been developed to overcome the inherent weakness of spontaneous Raman scattering:

Coherent Anti-Stokes Raman Scattering (CARS) employs multiple photons to address molecular vibrations and produces a coherent signal that is several orders of magnitude stronger than spontaneous Raman scattering [33]. This label-free imaging technique has primarily been used to image molecules abundant in biological tissues, particularly lipids that have high density of CHâ‚‚ groups. The non-linear nature of CARS permits imaging with sub-cellular resolution, making it valuable for studying pharmaceutical interactions at the cellular level [33].

Surface-Enhanced Raman Spectroscopy (SERS) utilizes metal nanoparticles (typically gold or silver) to amplify Raman signals by up to 10¹â´-10¹ⵠfold through plasmonic effects, achieving detection sensitivity comparable to fluorescence [33]. The superb multiplexing capability of SERS-based Raman imaging enables simultaneous interrogation of multiple biological events when different agents are attached to different Raman tags. This extreme sensitivity makes SERS particularly valuable for detecting low-concentration impurities or metabolites in pharmaceutical analysis [33].

Experimental Protocols for Pharmaceutical Analysis

Protocol 1: Tablet Homogeneity and Component Distribution Analysis

This protocol details the procedure for analyzing the spatial distribution of active and inactive components in pharmaceutical tablets using Raman chemical mapping.

Materials and Equipment:

- Confocal Raman microscope (e.g., XploRA Confocal Raman Microscope)

- Pharmaceutical tablet samples

- Microscope slides and mounting materials

- Raman spectral libraries for component identification

Procedure:

- Sample Preparation: Place the intact tablet on a microscope stage. No additional sample preparation is required, preserving the native state of the formulation.

Instrument Setup:

- Select appropriate laser wavelength (typically 532 nm or 785 nm for pharmaceutical applications)

- Set laser power to avoid sample degradation (typically 1.5 mW to 11 mW depending on sample sensitivity)