Strategies to Optimize Ionization Efficiency and Overcome Ion Suppression in LC-MS/MS Bioanalysis

Ion suppression remains a critical challenge in liquid chromatography-tandem mass spectrometry (LC-MS/MS), adversely affecting sensitivity, accuracy, and precision in bioanalytical applications.

Strategies to Optimize Ionization Efficiency and Overcome Ion Suppression in LC-MS/MS Bioanalysis

Abstract

Ion suppression remains a critical challenge in liquid chromatography-tandem mass spectrometry (LC-MS/MS), adversely affecting sensitivity, accuracy, and precision in bioanalytical applications. This article provides a comprehensive guide for researchers and drug development professionals, detailing the foundational mechanisms of ion suppression and exploring advanced strategies for its mitigation. We cover methodological optimizations in sample preparation and chromatography, systematic troubleshooting protocols, and the latest validation techniques, including the use of stable isotope-labeled internal standards. By synthesizing current research and practical applications, this resource aims to empower scientists to enhance data quality, improve robustness, and ensure regulatory compliance in pharmacokinetic, metabolomic, and biomarker studies.

Understanding Ion Suppression: Mechanisms, Sources, and Impact on Bioanalytical Data

What is Ion Suppression and Why is it a Critical Concern in LC-MS/MS?

Ion suppression is a matrix effect in Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) where the ionization efficiency of target analytes is reduced due to the presence of co-eluting compounds that compete for charge or inhibit efficient ion formation in the ion source [1] [2]. This phenomenon manifests as reduced detector response (signal intensity) or degraded signal-to-noise ratio, directly impacting key analytical figures of merit [1].

The core issue occurs in the early stages of ionization before mass analysis, making even highly selective MS/MS methods vulnerable [2]. When interfering compounds co-elute with your analyte, the effects on precision, accuracy, and limits of detection can be extensive, potentially invalidating assay results [1]. In practical terms, this can lead to false negatives, false positives when internal standards are affected, or generally unreliable quantification due to variable suppression across samples [2].

Ion suppression originates from both endogenous materials (proteins, lipids, salts, metabolites from biological samples) and exogenous sources (plasticizers from tubes, mobile phase additives, or sample preparation reagents) [1] [3]. The severity of suppression depends heavily on the concentration and physicochemical properties of both analytes and interfering compounds, with electrospray ionization (ESI) typically more susceptible than atmospheric pressure chemical ionization (APCI) [1] [2].

What Mechanisms Cause Ion Suppression?

The specific mechanisms vary by ionization technique, but all involve competition during the critical ionization process.

Table: Ion Suppression Mechanisms by Ionization Technique

| Ionization Technique | Primary Mechanisms | Key Contributing Factors |

|---|---|---|

| Electrospray Ionization (ESI) | - Competition for limited charge on electrospray droplets [1] [2]- Increased droplet surface tension/viscosity reducing desolvation [1] [2]- Co-precipitation with non-volatile salts or prevention of droplet contraction [1] | - High concentration of interfering compounds (>10⁻⁵ M) [2]- High surface activity or basicity of matrix components [1] [2]- Presence of non-volatile materials [1] |

| Atmospheric Pressure Chemical Ionization (APCI) | - Change in colligative properties affecting evaporation [1]- Competition for charge transfer from corona discharge needle [2]- Solid formation or co-precipitation with non-volatile components [2] | - Sample composition effects on charge transfer efficiency [2]- Presence of non-volatile sample components [2] |

The following diagram illustrates the key mechanisms that lead to ion suppression in the ESI process.

How Can I Detect and Quantify Ion Suppression in My Methods?

Regulatory guidance emphasizes evaluating ion suppression during method validation [2]. Two established experimental protocols are used to assess its presence and impact.

Post-Extraction Spiked Sample Comparison

This approach quantifies the extent of ion suppression by comparing responses between different sample preparations [1] [2].

- Procedure:

- Prepare a calibration standard in pure mobile phase or solvent (A).

- Take a blank sample matrix, extract it using your normal protocol, and then spike it with an identical concentration of analyte (B).

- Take a blank sample matrix, spike it with the analyte, and then perform the complete extraction (C).

- Calculation:

- Compare the detector response (peak area/height) of B to A. A lower signal in B indicates ion suppression from residual matrix components.

- Compare the response of C to B. A lower signal in C indicates losses during the sample preparation process (recovery issues), distinguishing them from true ion suppression [1].

Post-Column Infusion Experiment

This method provides a chromatographic profile of ion suppression, identifying specific retention times where suppression occurs [1] [2] [3].

- Experimental Setup:

- Configure your LC-MS/MS with a 'tee' union connecting the column effluent to a syringe pump infusing a solution of your analyte at constant concentration.

- With the syringe pump running, inject a blank, prepared sample matrix (e.g., extracted plasma) onto the LC column.

- Monitor the MRM signal for your infused analyte throughout the chromatographic run.

- Interpretation:

- A stable signal indicates no suppression.

- A drop in the baseline signal indicates the elution of ion-suppressing compounds.

- This creates a "suppression profile" that helps you adjust chromatographic conditions to move your analyte's retention time away from suppression zones [3].

Table: Interpretation of Post-Column Infusion Results

| Observation During Infusion | Indicated Cause | Common Retention Time |

|---|---|---|

| Signal dip at void volume (t₀) | Salts and very polar matrix components [3] | Early (0-2 min) |

| Broad signal depression in first few minutes | Soluble proteins and peptides [3] | Early to mid (1-5 min) |

| Pronounced dips in mid-late gradient | Phospholipids (e.g., lyso-phosphatidylcholines, phosphatidylcholines) [3] | Varies (e.g., 4-8 min for LPC, later for PC) |

| Signal dips in high organic wash | Highly retained lipophilic compounds [1] | Late in run/window |

The workflow for performing this critical diagnostic experiment is outlined below.

What Are the Most Effective Strategies to Overcome Ion Suppression?

A multi-pronged approach is often necessary to mitigate ion suppression. The optimal strategy depends on your analyte, matrix, and required sensitivity.

Sample Preparation Optimization

Enhanced sample clean-up is the most effective way to remove ion-suppressing compounds at the source [1] [3].

- Solid-Phase Extraction (SPE): Selectively retains analytes or interferences. One study optimizing SPE for water analysis reduced the matrix effect (ME) to just 8% while achieving 73% absolute recovery [4] [5].

- Liquid-Liquid Extraction (LLE): Effectively removes phospholipids, a major cause of suppression in biological samples [3].

- Protein Precipitation (PPT): Simple but often inadequate alone, as it leaves many soluble proteins, peptides, and phospholipids in the sample [3]. Use in combination with other techniques.

Chromatographic Separation

Modifying the separation to prevent co-elution of your analyte with suppressing species is highly effective [1].

- Retention Time Shift: Adjust the gradient, change the stationary phase, or modify mobile phase pH to move your analyte's peak away from suppression zones identified by the post-column infusion experiment [1] [3].

- Increased Resolution: Use longer columns, smaller particles, or different selectivity columns to achieve better separation from matrix interferences.

Internal Standardization

Stable isotope-labeled internal standards (SIL-IS) are considered the gold standard for compensating for ion suppression in quantitative assays [1].

- Mechanism: The SIL-IS co-elutes with the native analyte, experiences identical ion suppression, and is used to normalize the response [1].

- Critical Requirement: The internal standard must be physicochemically identical to the analyte. Stable isotopes (e.g., ¹³C, ²H) are ideal because they mimic the analyte's behavior perfectly during both sample preparation and ionization [1].

- Advanced Application: In non-targeted metabolomics, the IROA (Isotopic Ratio Outlier Analysis) workflow uses a ¹³C-labeled internal standard library to systematically correct for ion suppression across all detected metabolites [6].

Instrumental and Parameter Adjustments

- Ionization Source Selection: If possible, switch from ESI to APCI, as APCI generally exhibits less severe ion suppression [1] [2].

- Source Maintenance: Regularly clean the ion source and lenses to prevent contamination buildup that exacerbates suppression [7] [3].

- Flow Rate Reduction: Employing microflow or nanoflow LC can significantly reduce ion suppression. Smaller droplets formed at lower flow rates are more tolerant to non-volatile species and improve desolvation, with reports of up to a 6-fold sensitivity improvement [1] [7].

- Mobile Phase Optimization: Use volatile buffers (ammonium formate/acetate) instead of non-volatile buffers (e.g., phosphate). Avoid ion-pairing reagents like TFA [8].

Table: Comprehensive Mitigation Strategy Checklist

| Strategy Category | Specific Action | Primary Benefit |

|---|---|---|

| Sample Preparation | Implement SPE or LLE [1] [3] | Removes interfering matrix components at source |

| Replace protein precipitation with more selective methods [3] | More effectively removes phospholipids and proteins | |

| Chromatography | Shift analyte retention time [1] | Avoids co-elution with suppressing zones |

| Increase chromatographic resolution [1] | Separates analyte from isobaric interferences | |

| Calibration & Standards | Use stable isotope-labeled internal standards [1] | Normalizes for suppression, improves accuracy/precision |

| Employ matrix-matched calibration or standard addition [1] | Compensates for consistent matrix effects | |

| Instrumentation | Switch from ESI to APCI source if feasible [1] [2] | Uses less suppression-prone ionization mechanism |

| Reduce LC flow rate (micro/nanoflow) [1] [7] | Improves desolvation, reduces suppression | |

| Optimize source parameters and maintain cleanliness [7] | Ensures stable and efficient ionization |

The Scientist's Toolkit: Key Research Reagent Solutions

Table: Essential Materials for Ion Suppression Investigation and Mitigation

| Reagent/Material | Function | Application Example |

|---|---|---|

| Stable Isotope-Labeled Internal Standard (SIL-IS) | Normalizes for analyte recovery and ionization efficiency; corrects for ion suppression [1] [6] | Quantification of small molecules in pharmacokinetic studies |

| IROA Internal Standard (IROA-IS) Library | A library of ¹³C-labeled metabolites for system-wide correction of ion suppression in non-targeted metabolomics [6] | Profiling of cell metabolome response to drug treatment |

| Phospholipid Removal Plates (e.g., HybridSPE-PPT) | Solid-phase extraction sorbent specifically designed to selectively bind and remove phospholipids from biological samples [3] | Sample prep for plasma/serum analysis to eliminate major suppression source |

| Volatile Buffers (Ammonium Formate, Ammonium Acetate) | Provide pH control without introducing non-volatile salts that cause ion suppression and source contamination [8] [7] | Mobile phase additive for LC-MS/MS compatible separation |

| Liquid-Liquid Extraction Solvents (e.g., MTBE) | Effectively extract a wide range of analytes while leaving phospholipids and highly polar matrix components in the aqueous phase [3] | Broad-spectrum clean-up of plasma, serum, and tissue samples |

Frequently Asked Questions (FAQs)

Q: My method was working fine, but now I see sensitivity drops and unstable results. Is this ion suppression? A: Yes, this is a common symptom. Accumulation of matrix components (especially phospholipids) in the LC system and ion source over many injections can gradually increase ion suppression [3]. This manifests as reduced peak area counts, increased %RSD, and variable retention times. Regular system cleaning and enhanced sample clean-up are required to restore performance.

Q: Can I just dilute my sample to reduce ion suppression? A: Dilution reduces the concentration of both the analyte and the interfering compounds, which can lessen ion suppression. However, it also reduces the absolute amount of your analyte, which is often not a viable strategy for trace analysis where high sensitivity is required [1]. It is better to remove the interferents via sample preparation.

Q: Does using MS/MS instead of single MS make me immune to ion suppression? A: No. A common misconception is that the high selectivity of MS/MS eliminates matrix effects. Ion suppression occurs during ionization in the source, before the mass filtering stages of MS or MS/MS. Therefore, both single MS and MS/MS methods are equally susceptible [2].

Q: What is the most advanced method for correcting ion suppression in complex analyses like metabolomics? A: For non-targeted applications, the IROA TruQuant Workflow represents a cutting-edge solution. It uses a 95% ¹³C-labeled internal standard library spiked into every sample. By comparing the signals of the native (¹²C) analyte to its ¹³C counterpart (which experiences identical suppression), the workflow can algorithmically calculate and correct for the degree of ion suppression for nearly every detected metabolite [6].

Q: My analyte is in a very "dirty" matrix. Should I choose ESI or APCI? A: If your analyte is amenable to both, APCI is generally less prone to pronounced ion suppression than ESI due to its different ionization mechanism, which involves vaporization of the LC effluent prior to gas-phase chemical ionization [1] [2]. Screening both sources during method development is recommended.

Frequently Asked Questions

1. Which ionization source, ESI or APCI, is more susceptible to ion suppression? Answer: Electrospray Ionization (ESI) is generally more susceptible to ion suppression than Atmospheric Pressure Chemical Ionization (APCI) [2] [9]. This is because ionization in ESI occurs in the liquid phase before droplets enter the gas phase, making it highly sensitive to the presence of other compounds that can compete for charge. APCI, where ionization happens in the gas phase after vaporization, is typically less affected by these matrix components [2].

2. Can switching from ESI to APCI completely eliminate matrix effects? Answer: No, switching to APCI reduces but does not completely eliminate matrix effects [9]. APCI can still experience ion suppression or, in some cases, signal enhancement due to matrix components [9]. The best approach is to use effective sample cleanup, good chromatographic separation, and appropriate internal standards to compensate for any remaining effects [2].

3. For what types of analytes is APCI the preferred ionization technique? Answer: APCI is preferred for analyzing non-polar to medium-polarity, thermally stable, and low to medium molecular weight compounds [10] [11] [12]. It is not suited for large, thermally labile biomolecules (like proteins), as the high heat required for vaporization can cause their decomposition [11].

4. When should I choose ESI over APCI? Answer: ESI is the preferred technique for analyzing large, polar, and thermally labile molecules, such as proteins, peptides, and many pharmaceuticals [10] [13]. It is a "softer" ionization method that produces ions directly from solution, making it ideal for compounds that would be destroyed by the heat of the APCI source [12].

Troubleshooting Guides

Problem: Suspected Ion Suppression in Analysis Ion suppression is observed as an unexpected drop in analyte signal when analyzing complex samples, leading to reduced sensitivity, poor precision, and inaccurate quantification [2].

Solution: A step-by-step guide to diagnose and mitigate ion suppression.

Step 1: Detect and Locate the Suppression Use the post-column infusion experiment to identify where in the chromatogram ion suppression is occurring [2].

- Procedure:

- Prepare a standard solution of your analyte.

- Infuse this solution directly into the MS detector via a syringe pump at a constant rate to establish a stable baseline signal.

- Inject a blank, processed sample extract (one that has gone through your entire sample preparation protocol) into the LC system and run the chromatographic method.

- Observe the MS signal during the run. A dip in the otherwise stable baseline indicates the retention time window where co-eluting matrix components are causing ion suppression [2].

- Procedure:

Step 2: Evaluate the Extent of Suppression Use the post-extraction spike experiment to quantify the degree of ion suppression or enhancement [2].

- Procedure:

- Prepare two sets of samples:

- Set A (Neat Standard): Dilute your analyte in pure mobile phase.

- Set B (Matrix Spike): Spike your analyte into a blank, processed sample extract after it has been through the extraction and preparation steps.

- Analyze both sets and compare the peak areas (or heights).

- Calculation: Calculate the Matrix Effect (ME) as follows:

ME (%) = (Peak Area of Set B / Peak Area of Set A) × 100- A value of 100% indicates no matrix effect.

- A value <100% indicates ion suppression.

- A value >100% indicates ion enhancement [2].

- Prepare two sets of samples:

- Procedure:

Step 3: Apply Corrective Strategies Based on your findings, apply one or more of the following strategies.

| Strategy | Description & Implementation |

|---|---|

| Improve Sample Cleanup | Modify or add a clean-up step (e.g., liquid-liquid extraction, solid-phase extraction) to remove more matrix components before LC-MS analysis [2]. |

| Optimize Chromatography | Adjust the LC method (mobile phase, gradient, column) to improve separation and shift the analyte's retention time away from the suppression zone identified in Step 1 [2]. |

| Switch Ionization Source | If your analyte is suitable (thermally stable, low-medium polarity), switch from ESI to APCI, which is generally less prone to ion suppression [2] [9]. |

| Use Isotope-Labeled IS | Employ a stable isotope-labeled internal standard (SIL-IS) for each analyte. The SIL-IS experiences nearly identical ion suppression, allowing for accurate correction [9]. |

Comparative Data: ESI vs. APCI

The following tables summarize key comparative data from published studies to aid in source selection.

Table 1. Performance Comparison in Pharmaceutical & Food Analysis

| Study Matrix / Analyte | ESI Performance | APCI Performance | Key Finding & Reference |

|---|---|---|---|

| Levonorgestrel (Human Plasma) | LLOQ: 0.25 ng/mL; Matrix effects observed [14]. | LLOQ: 1 ng/mL; Less liable to matrix effects [14]. | ESI was selected for its superior sensitivity despite matrix effects, which were managed with a good sample preparation method [14]. |

| 22 Pesticides (Cabbage) | LOQs: 0.5-1.0 μg/kg; Less intense matrix effect [15]. | LOQs: 1.0-2.0 μg/kg; Matrix effect was more intense [15]. | ESI was more efficient for this multiresidue analysis, showing better sensitivity and less pronounced matrix effects [15]. |

| 36 Emerging Pollutants (Wastewater, Sludge) | Strong ion suppression for most analytes [9]. | Less susceptible to ion suppression, but some ion enhancement occurred [9]. | Matrix effects were present in both, but could be compensated using stable isotope-labeled surrogate standards [9]. |

Table 2. Characteristics and Typical Applications

| Parameter | Electrospray Ionization (ESI) | Atmospheric Pressure Chemical Ionization (APCI) |

|---|---|---|

| Ionization Mechanism | Ion formation in liquid phase, followed by desolvation and ion emission [10]. | Nebulization and thermal vaporization, followed by gas-phase chemical ionization [11]. |

| Ionization Location | Charged droplets at capillary tip [10]. | Hot vaporizer and corona discharge region [10]. |

| Analyte Polarity | Polar and ionic compounds [10] [12]. | Non-polar to medium-polarity compounds [10] [12]. |

| Thermal Stability | Ideal for thermally labile molecules (proteins, peptides) [13]. | Requires thermally stable compounds [11]. |

| Flow Rate Compatibility | Optimal at lower flow rates (e.g., 0.2-0.8 mL/min) [10]. | Tolerates higher flow rates (e.g., 1.0 mL/min) [14]. |

| Susceptibility to Matrix Effects | High [2] [9]. | Moderate (less than ESI) [2] [9]. |

Experimental Protocols

Protocol 1: The Post-Column Infusion Method for Diagnosing Ion Suppression This protocol is used to map the regions of ion suppression throughout a chromatographic run [2].

- Materials:

- LC-MS/MS system

- Syringe pump

- Analyte standard solution

- Blank matrix sample extract

- Procedure:

- Connect the syringe pump, loaded with the analyte standard, to the system via a T-connector after the LC column and before the ion source.

- Start the infusion of the standard at a constant rate to establish a stable baseline signal in the mass spectrometer.

- Using the autosampler, inject the blank matrix sample extract and run the standard LC method.

- The mass spectrometer will record a continuous signal from the infused analyte. A depression in this baseline indicates the elution of matrix components that cause ion suppression.

- Expected Outcome: A chromatogram that visually displays the retention time windows where ion suppression occurs, guiding further method optimization [2].

Protocol 2: The Post-Extraction Spike Method for Quantifying Matrix Effects This protocol quantifies the absolute magnitude of the matrix effect for a specific analyte [2].

- Materials:

- LC-MS/MS system

- Analyte standard solution

- Blank matrix from at least 6 different sources

- Solvents for preparing neat standards

- Procedure:

- Prepare Set A (Neat Standards): Dilute the analyte in mobile phase at low, medium, and high concentrations (at least 3 levels each in replicate).

- Prepare Set B (Post-Extraction Spikes): Take blank matrix samples from multiple sources, process them through your entire extraction protocol, and then spike the same amounts of analyte as in Set A into the final extracts.

- Analyze all samples in the same batch.

- For each concentration, calculate the matrix effect (ME) using the formula:

ME (%) = (Mean Peak Area of Set B / Mean Peak Area of Set A) × 100.

- Expected Outcome: A numerical value representing the percentage of ion suppression (ME < 100%) or enhancement (ME > 100%). This validates whether your method is robust against matrix effects [2].

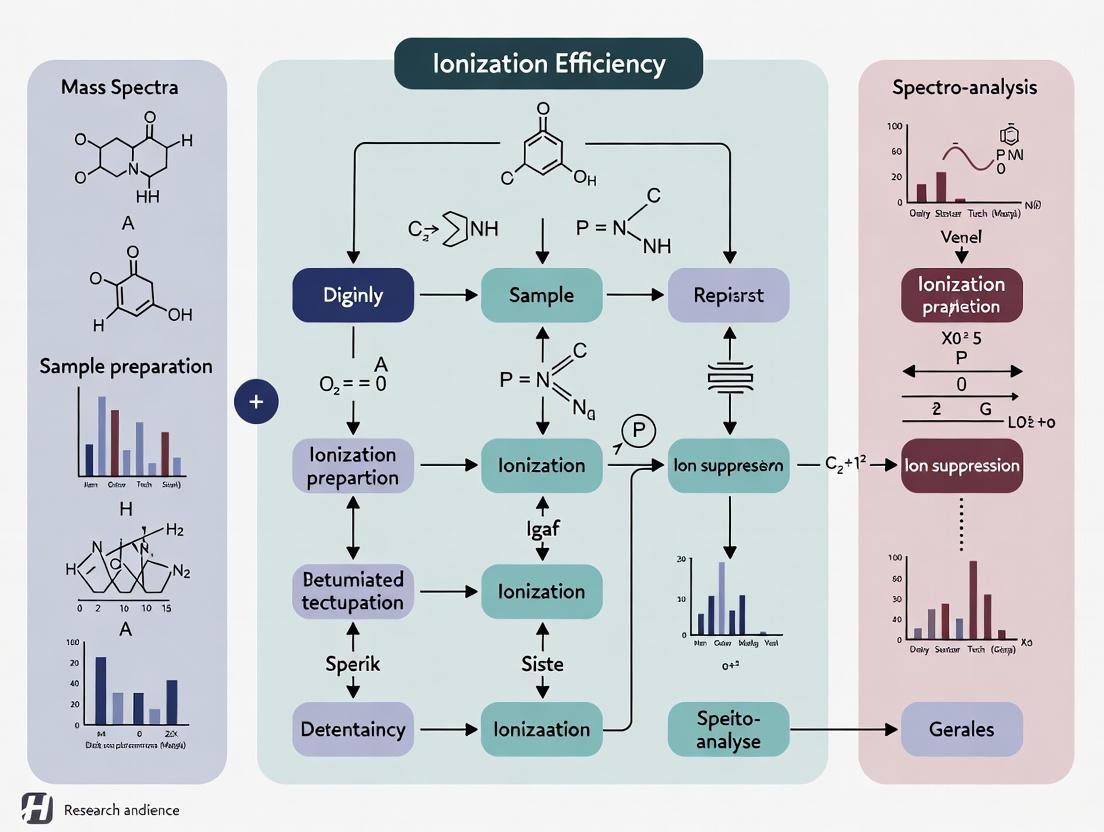

Visualization of Ionization Mechanisms and Suppression

Understanding the fundamental differences in how ESI and APCI work is key to understanding their susceptibility to suppression.

Diagram: Ionization Pathways and Suppression Points. The diagram illustrates the distinct mechanisms of ESI and APCI, highlighting the stages where co-eluting matrix components (yellow) cause interference. ESI is vulnerable in the early liquid-phase droplet formation, while APCI experiences interference later in the gas phase, where it is generally less affected.

The Scientist's Toolkit: Essential Research Reagents

The following table lists key reagents and materials frequently used in experiments to study, mitigate, and correct for ion suppression.

| Reagent / Material | Function in Ion Suppression Research |

|---|---|

| Stable Isotope-Labeled Internal Standards (SIL-IS) | The gold standard for compensating for matrix effects. The SIL-IS co-elutes with the analyte and experiences identical suppression, allowing for accurate quantification [9]. |

| Blank Matrix Samples | Used to prepare calibration standards and QC samples for post-extraction spiking experiments. Crucial for evaluating and validating method selectivity and matrix effects [2]. |

| Formic Acid / Ammonium Acetate | Common volatile mobile phase additives. Formic acid aids protonation in positive ion mode, while ammonium acetate can facilitate adduct formation. They are MS-compatible and do not cause source contamination [10] [13]. |

| HeLa Protein Digest Standard | A complex, well-characterized standard used as a quality control material to test LC-MS system performance, sample preparation protocols, and the presence of matrix effects in proteomic analyses [16]. |

| Solid-Phase Extraction (SPE) Cartridges (e.g., Oasis HLB) | Used for sample clean-up and enrichment to remove matrix components that cause ion suppression, thereby improving sensitivity and accuracy [9]. |

Frequently Asked Questions (FAQs)

Q1: What is ion suppression and why is it a critical issue in LC-MS/MS bioanalysis? Ion suppression is a matrix effect specific to mass spectrometry where less volatile compounds in a sample reduce the ionization efficiency of your target analytes in the ESI source. This leads to reduced peak areas, split peaks, or even peak disappearance. It is critical because it can compromise data accuracy and precision, leading to poor method validation, questionable results, and increased instrument downtime due to contamination and maintenance [3] [17] [18].

Q2: Which competing compounds are the most common causes of ion suppression? The most common interfering compounds originate from the biological sample itself and can be categorized as follows:

- Phospholipids: Particularly lyso-phosphatidylcholines (LPC) and phosphatidylcholines (PC), which are major contributors and cause significant, protracted ion suppression in the middle of a chromatographic run [3].

- Salts and Ionic Species: These cause ion suppression typically observed very early in the chromatogram, near the void volume (t0) [3].

- Proteins and Peptides: Soluble proteins and peptides can cause ion suppression even after sample preparation techniques like protein precipitation [3].

- Other Endogenous Materials: This includes lipids, carbohydrates, and urea [17] [18].

Q3: My chromatogram looks fine. How can I be sure I'm not experiencing ion suppression? A well-shaped chromatogram does not guarantee the absence of ion suppression. The effect can be latent and may not be visible initially. Symptoms often appear later as a project progresses, showing up as a gradual loss of sensitivity, increased %RSD, and shifts in retention times. The only reliable way to visualize ion suppression is to perform a post-column infusion experiment [3].

Q4: What are the long-term consequences of unaddressed ion suppression? Beyond immediate data inaccuracy, long-term effects include:

- Accumulation of endogenous materials in your HPLC column and system, leading to increased backpressure [3].

- Severe contamination of the ionization source and lenses, requiring frequent cleaning and replacement, which shortens the instrument's lifespan and increases operational costs [3].

- Carryover and cross-talk between analyses [3].

Troubleshooting Guides

Problem: Suspected Ion Suppression Causing Reduced or Erratic Analyte Signal

Step 1: Confirm and Locate Ion Suppression with a Post-Column Infusion Experiment This is the definitive method to diagnose ion suppression [3].

- Experimental Protocol:

- Setup: Modify your standard LC-MS/MS setup by adding a tee-connector post-column. Use a syringe pump to continuously infuse a standard of your analyte into the mobile phase flow path just before it enters the MS interface.

- Run 1 (Baseline): Inject a blank mobile phase sample while the syringe pump is running. This will produce a stable MS signal for your analyte (aside from changes due to the mobile phase gradient), establishing a baseline without matrix interference [3].

- Run 2 (Visualization): Inject a processed blank biological sample (e.g., blank plasma extract) prepared using your current sample preparation method, while the post-column infusion continues. The regions where the MS signal of your infused analyte drops indicate the presence and location of ion-suppressing compounds from the matrix [3].

- Run 3 (Identify Phospholipids): In a separate run, inject the same blank matrix sample without the post-column infusion. Monitor the multiple reaction monitoring (MRM) transition 184 → 184 m/z, which is a characteristic fragment of common phospholipids (LPC and PC). Overlaying this trace with the signal from Run 2 will confirm if signal drops align with the elution of phospholipids [3].

The following diagram illustrates the experimental setup and a typical outcome.

Problem: Ineffective Sample Cleanup Leading to Phospholipid Accumulation

Step 1: Evaluate and Enhance Your Sample Preparation Technique Sample preparation is the most effective way to remove interfering compounds. The choice of technique directly impacts the level of ion suppression.

Effectiveness of Common Sample Prep Methods for Removing Ion Suppressors:

| Sample Preparation Technique | Removal of Proteins/Peptides | Removal of Phospholipids | Removal of Salts | Risk of Ion Suppression | Key Limitations |

|---|---|---|---|---|---|

| Dilute-and-Shoot | None | None | None | Very High | Merely dilutes interferents; leads to rapid instrument contamination [3]. |

| Protein Precipitation (PPT) | Moderate (not all) | Poor | Poor | High | Ineffective against phospholipids; soluble proteins may remain [3]. |

| Solid-Phase Extraction (SPE) | Good | Good to Excellent | Good | Low | Can be optimized with selective sorbents to remove specific phospholipids [3]. |

| Liquid-Liquid Extraction (LLE) | Good | Good | Good | Low | Effectiveness depends on the choice of organic solvent [17]. |

- Protocol for Optimization: Compare your current sample prep method against more robust techniques using the post-column infusion experiment described above. Process a blank matrix sample using SPE or LLE and inject it during the experiment. The absence of signal drops, particularly in the phospholipid region (~7-8 minutes and beyond for LPC and PC, respectively), indicates effective cleanup [3].

Step 2: Monitor Phospholipid Buildup in the Column

- Protocol: As a quality control measure, periodically monitor the MRM transition 184 → 184 m/z during a blank injection with a long, high-organic washing step. A large peak eluting during the wash indicates significant phospholipid buildup in the column that was not cleared from previous injections, signaling the need for column cleaning or replacement and a review of the sample cleanup process [3].

Problem: Optimizing the LC-MS/MS System to Minimize Effects

Step 1: Improve Chromatographic Separation The most effective instrumental way to overcome ion suppression is to separate your analyte from the region where ion suppression occurs.

- Protocol: Modify your chromatographic method (e.g., gradient profile, mobile phase composition, or column chemistry) to shift the retention time of your analyte away from the ion suppression zones identified in the post-column infusion experiment [17].

Step 2: Consider Alternative Ionization Techniques

- Protocol: If available, compare the performance of Electrospray Ionization (ESI) with Atmospheric Pressure Chemical Ionization (APCI) or Atmospheric Pressure Photoionization (APPI). ESI is particularly susceptible to ion suppression, while APCI and APPI can be less affected by certain matrix components, potentially improving ionization efficiency for your analyte [17].

Step 3: Use an Effective Internal Standard

- Protocol: Always use a stable isotope-labeled internal standard (SIL-IS) for quantification. Since it has nearly identical chemical and chromatographic properties to the analyte, it will experience the same degree of ion suppression, thereby correcting for the signal loss and improving the accuracy and precision of the method [18].

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent / Material | Function / Application | Example Use-Case |

|---|---|---|

| HeLa Protein Digest Standard | A complex sample standard used to verify overall LC-MS system performance and troubleshoot issues related to sample preparation or the instrument itself [16]. | System suitability testing; diagnosing whether a problem originates from the sample or the LC-MS platform. |

| Peptide Retention Time Calibration Mixture | A mixture of synthetic peptides used to diagnose and troubleshoot the liquid chromatography system, ensuring gradient and column performance are consistent [16]. | Monitoring LC performance and detecting drift in retention times over time. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Analytically identical versions of the target compound with heavy isotopes (e.g., ^13C, ^15N); they correct for variability in sample prep, ionization, and ion suppression [18]. | Essential for accurate quantification in bioanalysis, as they co-elute with the analyte and compensate for matrix effects. |

| Phospholipid MRM Monitor (184→184) | Not a reagent, but a critical MS method parameter. This specific transition is a proxy for tracking phospholipids, the primary cause of ion suppression in plasma samples [3]. | Used in post-column infusion experiments and routine monitoring to identify phospholipid-related ion suppression zones. |

Ion suppression is a prevalent matrix effect in mass spectrometry that occurs when co-eluting compounds interfere with the ionization of target analytes. This phenomenon directly undermines data quality by reducing sensitivity, impairing accuracy, and compromising precision. For researchers and drug development professionals, understanding and mitigating ion suppression is critical for generating reliable, reproducible data in applications from metabolomics to pharmaceutical analysis. This guide provides practical troubleshooting and FAQs to help you identify, address, and prevent the detrimental effects of ion suppression in your experiments.

Understanding Ion Suppression and Its Impact on Data Quality

Ion suppression originates in the ion source and negatively affects key analytical figures of merit. The core problem is competition for charge and space within the ionization source, often exacerbated by complex sample matrices. The consequences manifest across three primary dimensions of data quality.

- Reduced Sensitivity: Ion suppression decreases ionization efficiency, leading to a loss of signal intensity for your target analytes. This can cause you to miss low-abundance compounds entirely, leading to false negatives and a failure to detect critical components in your sample [2].

- Impaired Accuracy: The extent of ion suppression can vary from sample to sample due to differences in matrix composition. This variability means the measured concentration of an analyte no longer consistently reflects its true concentration in the original sample, resulting in inaccurate quantitation [6] [2].

- Poor Precision: When the degree of ion suppression is not consistent across all sample runs, it introduces additional, uncontrolled variability. This leads to high relative standard deviations and an inability to obtain reproducible results, even for replicate injections of the same sample [6].

The table below summarizes how these consequences correlate with specific data quality failures.

Table 1: Consequences of Ion Suppression on Data Quality

| Consequence | Impact on Data Quality | Potential Outcome |

|---|---|---|

| Reduced Sensitivity | Lower signal-to-noise ratio; increased limits of detection [19] | Failure to detect low-abundance analytes (false negatives) |

| Impaired Accuracy | Measured values deviate from the true value due to variable ionization suppression [6] | Incorrect quantitative results and erroneous conclusions |

| Poor Precision | High coefficient of variation (CV) in replicate measurements [6] | Poor reproducibility and lack of confidence in results |

Troubleshooting Guides & FAQs

Frequently Asked Questions

What is the fundamental mechanism behind ion suppression in electrospray ionization (ESI)? In ESI, ion suppression is primarily caused by competition for limited charge available on the surface of the electrospray droplets and for access to the droplet surface itself. Co-eluting matrix components with high concentration, surface activity, or gas-phase basicity can out-compete your target analytes for this charge, suppressing their ionization efficiency. The presence of non-volatile materials can also impair droplet formation and solvent evaporation [2].

How can I quickly check if my experiment is suffering from ion suppression? A common and effective protocol is the post-column infusion experiment [2].

- Continuously infuse a standard solution of your analyte into the mass spectrometer via a syringe pump, introduced post-column.

- Inject a blank, prepared sample matrix into the LC system.

- As matrix components elute from the column, they will mix with the infused analyte. A drop in the baseline signal of the analyte indicates the presence of ion-suppressing compounds at that specific retention time [2].

Are some ionization techniques less prone to ion suppression than others? Yes. Atmospheric Pressure Chemical Ionization (APCI) often experiences less ion suppression than ESI [19] [2]. This is because in APCI, the analyte is vaporized before ionization, reducing the condensed-phase competition that characterizes ESI. However, APCI is not immune to ion suppression, which can occur through different mechanisms, such as interference with charge transfer in the gas phase [2].

Step-by-Step Troubleshooting Guide

Problem: A gradual loss of sensitivity and increased background noise in my analyses.

Step 1: Check the Ion Source and Instrument. Before assuming a sample-specific issue, rule out common instrument problems.

- Action: Perform routine instrument maintenance and calibration. Clean the ion source and ESI probe to remove accumulated contaminants that can contribute to chemical noise and suppression [6]. Recalibrate the mass spectrometer using recommended calibration solutions to ensure optimal performance [16].

- Verification: Run a standard of known concentration and check if signal intensity and mass accuracy are restored to expected levels [16].

Step 2: Evaluate Sample Cleanup and Chromatography.

- Action: Improve sample preparation. Dilute the sample, use a more selective extraction technique (e.g., solid-phase extraction), or employ a Pierce HeLa Protein Digest Standard to test your clean-up method for peptide loss [16] [2].

- Action: Optimize the chromatographic method. The primary defense against ion suppression is to separate your analytes from the matrix components that cause it. Increase chromatographic resolution by adjusting the gradient, mobile phase, or column to shift the retention time of your analyte away from the region of suppression identified in the infusion experiment [2].

Step 3: Consider Alternative Quantification Strategies.

- Action: Use a stable isotope-labeled internal standard (SIL-IS). A SIL-IS is chemically identical to the analyte but isotopically distinct. It co-elutes with the analyte and experiences the same ion suppression, allowing you to correct for the suppression by using the IS response as a calibrant [6] [2]. For non-targeted workflows, advanced methods like the IROA (Isotopic Ratio Outlier Analysis) workflow use a library of internal standards to measure and correct for ion suppression across all detected metabolites [6].

Experimental Protocols

Protocol 1: Validating the Presence of Ion Suppression via Post-Column Infusion

This method visually maps the regions of ion suppression across your chromatographic run [2].

Materials:

- LC-MS system

- Syringe pump

- Standard solution of the target analyte

- Blank prepared matrix (e.g., protein-precipitated plasma, blank solvent extract)

Method:

- Set up your LC method with the typical column and mobile phase.

- Connect the syringe pump containing your analyte standard to the system via a T-connector between the column outlet and the MS inlet.

- Start the LC flow and the syringe pump infusion to establish a stable, constant signal for the analyte.

- Inject the blank matrix sample and start the LC gradient.

- Monitor the signal of the infused analyte. A dip in the signal corresponds to the retention time of matrix components that cause ion suppression.

Protocol 2: Correcting for Ion Suppression Using the IROA Workflow

This non-targeted metabolomics protocol uses a stable isotope-labeled internal standard (IROA-IS) to correct for ion suppression [6].

Materials:

- IROA Internal Standard (IROA-IS) library

- IROA Long-Term Reference Standard (IROA-LTRS)

- ClusterFinder software (IROA Technologies) or equivalent

Method:

- Sample Preparation: Spike all your experimental samples with a constant amount of the IROA-IS. The IROA-IS contains metabolites with a specific isotopolog pattern (e.g., 95% ¹³C).

- Data Acquisition: Run your samples on the LC-MS system. The software will identify true metabolites based on their characteristic IROA isotopolog ladder.

- Ion Suppression Calculation: For each metabolite, the software calculates ion suppression using the signal loss observed in the ¹³C channel (from the IROA-IS) to correct the signal in the ¹²C channel (endogenous metabolite). The core calculation is based on the principle that both channels experience equal suppression.

- Data Normalization: Apply the Dual MSTUS (MS Total Useful Signal) normalization algorithm included in the workflow to generate suppression-corrected, normalized data for robust quantitative analysis [6].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Troubleshooting Ion Suppression

| Reagent / Kit | Function | Application Example |

|---|---|---|

| Pierce HeLa Protein Digest Standard | System suitability test to check LC-MS performance and sample preparation efficacy [16]. | Use it directly or as a control co-treated with your sample to check for peptide loss during clean-up [16]. |

| Pierce Calibration Solutions | To recalibrate the mass spectrometer, ensuring mass accuracy and optimal instrument performance [16]. | Recalibrate when experiencing sensitivity loss or poor mass accuracy before investigating sample-specific suppression [16]. |

| Pierce Peptide Retention Time Calibration Mixture | Diagnose and troubleshoot the LC system and gradient performance [16]. | Use synthetic heavy peptides to verify LC consistency, which is critical for maintaining separation and avoiding suppression regions. |

| IROA Internal Standard (IROA-IS) | A library of stable isotope-labeled metabolites used to measure and correct for ion suppression in non-targeted metabolomics [6]. | Spike into samples to correct for metabolite-specific ion suppression and perform robust normalization. |

| Stable Isotope-Labeled Internal Standard (SIL-IS) | A chemically identical, isotopically heavy version of a specific analyte used for targeted quantitation [6]. | Spike into every sample to correct for analyte-specific ion suppression and losses during sample preparation. |

Workflow Visualization

The following diagram illustrates the logical workflow for diagnosing and addressing ion suppression, integrating the concepts and protocols detailed in this guide.

Diagram 1: A systematic workflow for troubleshooting ion suppression in mass spectrometry.

Post-column infusion is a powerful analytical technique used to visually identify and characterize ion suppression or enhancement in liquid chromatography-mass spectrometry (LC-MS) methods. By continuously introducing a standard compound into the LC effluent after chromatographic separation but before mass spectrometric detection, researchers can create a real-time "map" of ionization interference caused by co-eluting matrix components [20] [21]. This technique has gained importance in bioanalysis, metabolomics, and pharmaceutical development where matrix effects can significantly compromise quantitative accuracy [22] [23]. When properly implemented within a systematic troubleshooting framework, post-column infusion serves as a critical diagnostic tool for optimizing ionization efficiency and improving the reliability of LC-MS methods.

Frequently Asked Questions

Implementation Questions

What is the fundamental principle behind post-column infusion for detecting matrix effects? Matrix effects occur when compounds co-eluting with your analyte alter its ionization efficiency in the MS source, leading to suppression or enhancement of the signal [21]. Post-column infusion works by continuously introducing a standard compound into the mobile phase flow after the column. When a blank matrix extract is injected, any deviation from a stable signal indicates regions in the chromatogram where matrix components are causing ionization interference [20] [22]. This provides a visual profile of suppression/enhancement zones that helps in method development and troubleshooting.

What type of compounds make suitable standards for post-column infusion? Ideal standards cover a broad polarity range and exhibit different MS ionization behaviors [20]. Isotopically labeled analogues of your target analytes are excellent choices because they have similar physicochemical properties but are easily distinguishable mass spectromatically [20] [22]. When isotopically labeled standards are unavailable or cost-prohibitive, structural analogues with similar retention times and ionization characteristics can be used [22].

How do I set up a post-column infusion experiment on my LC-MS system? A basic post-column infusion setup requires a secondary pumping system (such as an syringe pump or auxiliary LC pump) connected via a low-dead-volume T-fitting between the column outlet and MS ion source [20] [21]. The infusion flow rate is typically much lower than the LC flow rate (e.g., 5-20 μL/min versus hundreds of μL/min) [20] [24]. The standard is dissolved in a compatible solvent and infused at a constant rate throughout the chromatographic run while blank matrix samples are injected.

Troubleshooting Questions

Why is my post-column infusion signal unstable even when injecting pure solvent? An unstable baseline in post-column infusion experiments can result from several factors:

- Air bubbles in infusion line: Purge the infusion line thoroughly before connection

- Insufficient mixing: Ensure the T-connector provides adequate mixing of column effluent and infused standard

- Incompatible solvents: Verify the infusion solvent is miscible with mobile phase

- ESI source instability: Check for contamination on MS source components

- Pulsation from infusion pump: Use a pulse-dampener or adjust pump settings [24]

What constitutes significant ion suppression in a post-column infusion chromatogram? Significant suppression is typically indicated by a clear, reproducible dip of ≥20% from baseline signal [24]. Minor fluctuations or single-occurrence dips may not be analytically relevant. To assess significance, perform multiple replicate injections to distinguish consistent matrix effects from random noise [24]. The impact also depends on your analytical requirements - even minor suppression may be problematic for trace analysis.

How can I distinguish between MS source issues and genuine matrix effects? Compare your post-column infusion results with system suitability tests (SST) using neat standards [25]. If SST performance is normal but suppression persists in matrix samples, the issue is likely genuine matrix effects. If both show signal instability, the problem may be MS-related. Additionally, infusing standards directly (bypassing the LC column) can isolate MS source performance from chromatographic effects [25].

My post-column infusion shows severe suppression throughout the chromatogram. What should I optimize first? Widespread suppression suggests inadequate sample clean-up or chromatography. Priority improvements include:

- Enhanced sample preparation: Incorporate phospholipid removal cartridges for plasma samples [20] or optimize extraction selectivity

- Improved chromatographic separation: Adjust gradient profile to shift analyte retention away from major suppression zones [20] [23]

- Column selection: Different stationary phases (especially in HILIC) significantly impact matrix effect profiles [23]

Experimental Protocols

Standard Post-Column Infusion Protocol for Matrix Effect Assessment

Purpose: To identify regions of ion suppression/enhancement in an LC-MS method and evaluate sample preparation efficiency [20].

Materials:

- LC-MS system with auxiliary infusion pump or capable of post-column infusion

- Suitable post-column infusion standards (see Reagent Table)

- Blank matrix (e.g., plasma, urine, tissue homogenate)

- Mobile phase components (LC-MS grade)

- Low-dead-volume T-connector

Procedure:

- Prepare post-column infusion solution: Dissolve selected standards in appropriate solvent at optimized concentrations (typically 0.025-0.25 mg/L for isotopically labeled compounds) [20].

- Set up infusion system: Connect infusion pump to T-connector placed between column outlet and MS source. Use minimal length of narrow-bore tubing to reduce dead volume.

- Establish stable infusion: Start infusion at constant flow rate (typically 5-20 μL/min) and verify stable signal before sample injections.

- Perform chromatographic separation: Inject blank matrix extracts using your LC method while continuously infusing standards.

- Data analysis: Extract ion chromatograms for each infused standard. Compare against solvent blank injection to identify suppression/enhancement regions.

Optimization Tips:

- Adjust infusion standard concentrations to achieve clear signal without detector saturation [20]

- Use multiple standards covering different polarity ranges for comprehensive assessment [20]

- Perform replicate injections to confirm reproducibility of observed effects [24]

Protocol for Evaluating Sample Preparation Efficiency Using Post-Column Infusion

Purpose: To compare different sample clean-up methods by their ability to remove matrix components causing ion suppression [20].

Procedure:

- Prepare samples using different clean-up techniques (e.g., protein precipitation only vs. phospholipid removal cartridges for plasma) [20].

- Inject each sample type while performing post-column infusion of appropriate standards.

- Compare matrix effect profiles between different preparation methods, focusing on:

- Overall reduction in suppression areas

- Specific removal of late-eluting phospholipids in reversed-phase LC (typically 2.5-3.5 minutes) [20]

- Signal stability for your analytes' retention windows

- Confirm phospholipid removal by extracting the characteristic phosphocholine fragment (m/z 184.075) in high collision energy scans [20].

Data Interpretation Guidelines

Quantitative Assessment of Matrix Effects

Table: Matrix Effect Severity Classification Based on Post-Column Infusion Data

| Signal Deviation | Classification | Recommended Action |

|---|---|---|

| <±20% | Minimal | No action required for most applications |

| ±20-50% | Moderate | Consider isotopically labeled internal standards; evaluate impact on quantification |

| >±50% | Severe | Modify sample preparation; optimize chromatography; use matrix-matched calibration |

| Complete suppression | Critical | Major method revision required; consider alternative sample clean-up or chromatography |

Common Matrix Effect Patterns and Interpretations

- Early elution suppression (reversed-phase LC): Often caused by polar matrix components; improve sample clean-up or adjust gradient [20]

- Late elution suppression (2.5-3.5 min in reversed-phase): Characteristic of phospholipids; implement phospholipid removal cartridges [20]

- Specific retention time suppression: Likely from specific matrix interferents; shift analyte retention away from these regions

- Widespread suppression: Indicates inadequate sample clean-up; optimize extraction protocol [20]

Research Reagent Solutions

Table: Essential Materials for Post-Column Infusion Experiments

| Reagent/Equipment | Function/Purpose | Selection Criteria |

|---|---|---|

| Isotopically labeled standards (e.g., atenolol-d7, caffeine-d3, diclofenac-13C6) [20] | Primary infusion standards; mimic analyte behavior without interference | Similar physicochemical properties to target analytes; cover broad polarity range |

| Structural analogues (e.g., arachidonoyl-2'-fluoroethylamide for endocannabinoids) [22] | Alternative when isotopically labeled standards unavailable | Similar retention and ionization characteristics; commercially available |

| Phospholipid removal cartridges (e.g., Ostro) [20] | Reduce late-eluting matrix effects in biological samples | Compatibility with sample matrix; recovery for target analytes |

| Low-dead-volume T-connector | Combine column effluent with infusion stream | Minimal internal volume; pressure compatibility with LC system |

| Auxiliary infusion pump | Deliver constant flow of standard solution | Precise flow control (μL/min range); compatibility with MS solvent requirements |

| LC-MS grade solvents and additives | Mobile phase preparation | High purity to minimize background noise and contamination |

Proactive Strategies: Sample Preparation and Chromatographic Solutions to Minimize Suppression

In mass spectrometry, particularly in Liquid Chromatography-Mass Spectrometry (LC-MS), the sample preparation technique you choose is a critical determinant of the success and reliability of your analysis. The presence of matrix effects, especially ion suppression, can severely compromise data quality by reducing analyte signal, impacting precision, and increasing detection limits [2] [26]. Solid-Phase Extraction (SPE) and Liquid-Liquid Extraction (LLE) are two foundational techniques used to clean up samples and concentrate analytes. This guide provides a detailed comparison and troubleshooting resource to help you select and optimize your extraction protocol to maximize ionization efficiency and minimize ion suppression.

Technical Comparison: SPE vs. LLE

The choice between SPE and LLE involves balancing factors such as selectivity, solvent use, and automation potential. The following table summarizes their core characteristics.

| Parameter | Solid-Phase Extraction (SPE) | Liquid-Liquid Extraction (LLE) |

|---|---|---|

| Fundamental Principle | Physical/chemical adsorption of analytes onto a solid sorbent [27] | Partitioning of analytes between two immiscible liquid phases based on solubility [28] |

| Primary Mechanism | Reversible interactions (hydrophobic, ionic, polar) with a solid stationary phase [29] [27] | Distribution of an analyte according to its partition coefficient (Log P) between organic and aqueous solvents [30] |

| Typical Steps | Conditioning, loading, washing, eluting [28] | Mixing, phase separation, collection (often repeated) [28] |

| Selectivity | High; can be finely tuned by selecting sorbent chemistry (e.g., reversed-phase, ion-exchange, mixed-mode) [27] [28] | Low to moderate; primarily based on solubility and pH, less effective for polar molecules [28] [30] |

| Solvent Consumption | Relatively low [27] | High; requires large volumes of organic solvents [27] [30] |

| Automation & Throughput | High; easily automated with cartridges, plates, and online systems [27] [28] | Low; difficult to automate, labor-intensive, and prone to emulsion formation [28] [30] |

| Risk of Ion Suppression | Lower when optimized; effective removal of matrix interferences [29] | Can be higher due to co-extraction of matrix components [29] |

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: How does my choice of extraction method directly impact ion suppression in LC-MS? Ion suppression occurs when co-eluting matrix components interfere with the ionization of your target analyte in the MS source, leading to reduced and unpredictable signal response [2] [26]. A more selective and efficient sample cleanup method directly removes these interfering substances before they enter the LC-MS system. SPE often provides a cleaner extract than LLE due to its multiple washing steps and highly selective sorbents, leading to lower matrix effects [29].

Q2: For a method targeting a wide range of analytes with different polarities (e.g., in forensic toxicology), which technique is more suitable? SPE is generally more suitable for multi-analyte methods. A single Oasis PRiME HLB SPE method successfully extracted 22 diverse pharmaceuticals, steroids, and drugs of abuse from plasma and 23 drugs of abuse from urine without requiring method re-development for different analyte classes [29]. In contrast, LLE and Supported-Liquid Extraction (SLE) often require multiple, optimized protocols to achieve comparable recoveries for all analytes in a mixture, particularly for polar bases and acidic compounds [29].

Q3: What is the most significant practical disadvantage of LLE? The formation of emulsions is one of the most common and disruptive problems in LLE [30]. Emulsions, which appear as a persistent cloudy mixture between the two liquid layers, are often caused by surfactant-like compounds in the sample. They prevent clean phase separation, are time-consuming to resolve, and can lead to significant analyte loss and poor reproducibility.

Q4: My SPE recoveries are low and inconsistent. What are the key steps to investigate? Low recovery in SPE can stem from several points in the protocol. Key areas to troubleshoot include:

- Sorbent Conditioning: Ensure the sorbent is fully wetted and activated with a solvent that matches the initial mobile phase conditions. An improperly conditioned sorbent will not retain analytes effectively.

- Sample Load pH and Solvent Strength: The sample should be in a solvent that is weak enough (e.g., aqueous) to ensure strong retention of the analytes on the sorbent. For ionizable analytes, adjusting the sample pH to ensure the analyte is in its neutral form is critical for retention on reversed-phase sorbents [30].

- Elution Solvent Strength and Volume: The elution solvent must be strong enough to disrupt the analyte-sorbent interaction (e.g., a high-percentage organic solvent for reversed-phase). Using an insufficiently strong solvent or too little volume will lead to incomplete elution and low recovery.

Troubleshooting Common Problems

Problem: Persistent Emulsion in LLE

- Potential Cause: The sample matrix contains compounds that act as surfactants or stabilizers (e.g., proteins, lipids, detergents).

- Solutions:

- Gentle Manipulation: Avoid vigorous shaking or vortexing; instead, use gentle swirling or inversion for mixing.

- Centrifugation: Use high-speed centrifugation to break the emulsion.

- Salt Addition: Adding a small amount of a neutral salt (e.g., sodium chloride) can help by salting out the organic phase.

- Filtration: Drain the emulsion layer and re-extract it with fresh solvent [30].

- Solvent Change: Switch to a different organic solvent with different physical properties (e.g., from ethyl acetate to hexane).

Problem: Low Analyte Recovery in SPE

- Potential Causes: Incorrect sorbent selection, poor conditioning, inadequate elution solvent, or channeling in the sorbent bed.

- Solutions:

- Verify Sorbent Chemistry: Ensure the sorbent (e.g., C18 for non-polar, SCX for bases, SAX for acids) is appropriate for your analyte's properties [27].

- Check Conditioning: Make sure the sorbent is never allowed to run dry after conditioning and before loading the sample.

- Optimize Elution: Use a stronger elution solvent or a larger volume. Perform two sequential elutions to ensure completeness.

- Prevent Channeling: Ensure the vacuum or pressure applied during the sample load and wash steps is not too high, which can create channels in the sorbent bed and reduce binding efficiency.

Problem: High Matrix Effects (Ion Suppression) Post-Extraction

- Potential Cause: Incomplete cleanup, leaving behind endogenous phospholipids, salts, or other ionizable matrix components.

- Solutions:

- Strengthen Wash Step: Introduce or optimize an intermediate wash step with a solvent strong enough to remove impurities but weak enough to not elute your analyte.

- Change Sorbents: Switch to a more selective sorbent, such as a mixed-mode sorbent that combines reversed-phase and ion-exchange mechanisms for a cleaner extract [27].

- Chromatographic Separation: Improve the LC method to separate the analyte from the remaining matrix interferences, as even the best sample prep may not remove all interferents [2].

The Scientist's Toolkit: Key Research Reagent Solutions

The following table lists essential materials used in SPE and LLE to achieve effective sample cleanup.

| Item | Function & Importance |

|---|---|

| Oasis PRiME HLB Sorbent | A polymeric reversed-phase sorbent known for simplifying SPE protocols. It requires no conditioning or equilibration and provides high, consistent recoveries for a broad range of acidic, basic, and neutral compounds, helping to minimize matrix effects [29]. |

| C18 Bonded Silica Sorbent | A classic reversed-phase sorbent for retaining hydrophobic analytes from aqueous samples. It is widely used but may require pH control for ionizable compounds [27]. |

| Mixed-Mode Sorbents (e.g., MCX, MAX) | Sorbents combining reversed-phase retention with strong ion-exchange (cation for MCX, anion for MAX). They offer superior selectivity and cleaner extracts for ionizable analytes, which is highly effective in reducing ion suppression [27]. |

| Methyl tert-butyl ether (MTBE) | A common, relatively non-polar organic solvent used in LLE and SLE for extracting a wide range of analytes from aqueous matrices like plasma and urine [29]. |

| Diatomaceous Earth (for SLE) | An inert, porous support material used in Supported-Liquid Extraction. The aqueous sample is absorbed onto it, and an organic solvent is passed through to extract the analytes, mimicking LLE without emulsion issues [29] [28]. |

Experimental Protocols and Workflows

To visualize the core procedures and their impact on your mass spectrometry results, refer to the following workflows.

Solid-Phase Extraction (SPE) Workflow

Liquid-Liquid Extraction (LLE) Workflow

Impact of Sample Cleanup on Ionization Efficiency

This diagram conceptualizes how effective sample cleanup mitigates ion suppression in the ESI source.

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: Why is protein precipitation alone insufficient for removing phospholipids, and how does this affect my LC-MS results?

Protein precipitation effectively removes proteins but leaves behind most phospholipids, which are highly soluble in the organic solvents used (e.g., acetonitrile or methanol). These residual phospholipids co-elute with your analytes during LC-MS analysis and cause significant ion suppression, reducing the signal intensity of your target compounds. This happens because phospholipids compete for charge and space in the electrospray droplet, impairing the ionization efficiency of your analytes [31] [32] [26]. The consequences include reduced sensitivity, poor precision, inaccurate quantification, and potential source contamination leading to downtime [32] [7].

Q2: What are the most effective sample preparation techniques specifically for phospholipid removal?

Several sample preparation techniques go beyond protein precipitation to effectively remove phospholipids. The optimal choice depends on your required throughput, need for automation, and the specific phospholipids of concern.

- Phospholipid Removal Plates (e.g., Ostro Plates): These specialized solid-phase extraction plates are designed for a rapid "pass-through" preparation. The sorbent retains phospholipids and proteins while allowing your analyte to pass through with minimal loss. This method is known for its simplicity and minimal method development needs [32].

- Optimized Solid-Phase Extraction (SPE) with Cartridges: Using cartridges like HybridSPE-Phospholipid, with an optimized protocol, is highly effective. This involves a citric acid-assisted protein precipitation followed by loading the supernatant onto the cartridge. The phospholipids are retained, and your analytes are collected in the eluent [31].

- Liquid-Liquid Extraction (LLE): While less common for highly polar analytes, LLE can separate analytes from phospholipids based on their differential solubility in two immiscible solvents. It requires careful optimization of the solvent system [26].

Q3: My research involves quantifying trace-level environmental contaminants in plasma. The sample has a 1000-fold concentration gap between the matrix and my analytes. What is the best strategy?

Your challenge is a classic problem in exposomics. The recommended strategy is an optimized phospholipid removal protocol that allows for a larger injection volume without introducing matrix effects [31]. By removing the bulk of phospholipids, you can concentrate your sample and inject more on-column, effectively improving the sensitivity for your trace contaminants. One validated protocol involves:

- Using 100-200 µL of plasma.

- Protein precipitation with ACN containing 0.5% citric acid.

- Phospholipid removal using a commercial cartridge.

- A larger volume injection of the cleaned extract for LC-HRMS analysis. This approach has been shown to enhance the signal for non-phospholipid compounds by up to 28-fold in positive mode and 58-fold in negative mode, enabling the detection of thousands of additional molecular features [31].

Q4: How can I experimentally detect and quantify the ion suppression caused by phospholipids in my method?

Two common experimental protocols are used to evaluate ion suppression:

- Post-extraction Spike-In Method: Compare the LC-MS/MS response (peak area) of your analyte spiked into a blank sample extract (e.g., after phospholipid removal) to its response in a pure solvent. A lower signal in the matrix indicates ion suppression. This quantifies the overall effect [2] [26].

- Post-column Infusion Experiment: Continuously infuse a standard of your analyte into the MS while injecting a blank, prepared sample extract onto the LC column. A drop in the baseline signal in regions where matrix components elute pinpoints the chromatographic regions affected by ion suppression. This helps identify where phospholipids are eluting and causing interference [2] [26].

Experimental Protocols

Protocol 1: Optimized Phospholipid Removal for Chemical Exposomics in Plasma [31]

This protocol is designed for enhanced sensitivity in targeted and non-targeted analysis.

- Sample Volume: 100–200 µL of plasma.

- Internal Standards: Fortify sample with isotopically labelled internal standards.

- Protein Precipitation: Add 800 µL of ice-cold ACN containing 0.5% Citric Acid (CA) to 200 µL of plasma. Vortex and centrifuge.

- Phospholipid Removal:

- Condition a HybridSPE-Phospholipid cartridge (500 mg/6 mL) with 12 mL MeOH and 12 mL ACN with 0.5% CA.

- Load the supernatant onto the cartridge.

- Elute with 1 mL ACN with 0.5% CA, followed by 2 mL MeOH with 1% ammonium formate.

- Post-processing: Adjust the eluent's pH to ~6.5 with ammonia solution. Evaporate under nitrogen and reconstitute in a suitable solvent for LC-MS analysis.

Protocol 2: Rapid Phospholipid and Protein Removal using a Pass-Through Plate [32]

This is a high-throughput, simplified protocol for quantitative bioanalysis.

- Sample Volume: 10 µL of plasma.

- Procedure:

- Add plasma to an Ostro Pass-through Sample Preparation Plate.

- Add 40 µL of methanol containing your internal standard and 200 µL of methanol with 1% formic acid.

- Mix by aspiration.

- Draw the sample through the plate under vacuum.

- Post-processing: Collect the eluent. Dilute if necessary and inject into the LC-MS/MS system.

Quantitative Data Comparison

The table below summarizes the performance of different phospholipid removal strategies as reported in the literature.

Table 1: Comparison of Phospholipid Removal Techniques

| Technique | Key Modification / Feature | Quantitative Improvement | Effect on Analysis |

|---|---|---|---|

| Optimized SPE [31] | Citric acid-assisted precipitation & phospholipid removal cartridge | - Mean signal intensity of non-phospholipids: +6x (ESI+), +4x (ESI-)- Max signal intensity: +28x (ESI+), +58x (ESI-)- 109% more non-phospholipid features detected in ESI+ | Enables exposomics-scale detection; overcomes 1000-fold concentration gap in plasma. |

| Pass-Through Plate (Ostro) [32] | Sorbent designed to retain phospholipids in a 96-well plate format | - Near-total removal of LPCs, PCs, and sphingomyelins observed.- No loss of analyte response (Gefitinib) reported.- Linear quantitation from 15–7500 ng/mL. | Simple, fast preparation; improves assay robustness and reduces source contamination. |

| Standard Protein Precipitation [31] | Protein precipitation only (control, 4:1 ACN:plasma) | - Serves as a baseline.- Significant signal for phospholipids (LPCs, PCs) remains. | Higher matrix effects, limits injection volume and sensitivity for trace analytes. |

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Advanced Sample Preparation

| Item | Function | Example Use Case |

|---|---|---|

| HybridSPE-Phospholipid Cartridges/Plates | Selective retention of phospholipids from biological extracts following protein precipitation. | Removal of phosphatidylcholines (PCs) and lysophosphatidylcholines (LPCs) from plasma for exposomics studies [31]. |

| Ostro Pass-Through Sample Preparation Plates | Integrated 96-well plate for simultaneous protein and phospholipid removal via a simple "pass-through" workflow. | High-throughput quantitative bioanalysis of drugs in plasma [32]. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Corrects for variability in ionization efficiency and ion suppression during MS analysis by mirroring analyte behavior. | Essential for accurate quantification when 100% removal of matrix effects is not possible [33]. |

| Citric Acid (CA) / Acidified Solvents | Added to precipitation solvent (ACN) to improve protein precipitation efficiency and enhance phospholipid retention on specialized sorbents. | Optimized sample preparation for chemical exposomics [31]. |

| Ammonium Formate / Formic Acid | Common volatile additives for mobile phases in LC-MS. Help stabilize spray formation and influence analyte ionization. | Standard additive in LC-MS mobile phases to improve chromatography and ionization [32]. |

Workflow Visualization

The following diagram illustrates the logical decision process for selecting a sample preparation method based on analytical goals.

Decision Workflow for Sample Preparation

FAQs: Addressing Core Challenges in Ion Suppression

This section provides concise answers to common technical questions about ion suppression, helping researchers quickly identify and resolve issues in their LC-MS workflows.

Q1: What is ion suppression and why is it a critical problem in LC-MS? A1: Ion suppression is a matrix effect in mass spectrometry where co-eluting sample components reduce the ionization efficiency of target analytes, leading to decreased signal intensity and compromised quantification accuracy [7] [34]. It occurs because matrix components compete with analytes for the limited charge available during ionization [34]. This is particularly problematic in complex samples like plasma, urine, and tissue homogenates, where it can dramatically decrease measurement accuracy, precision, and sensitivity, sometimes reducing signals by over 90% [6].

Q2: How can I quickly diagnose ion suppression in my chromatographic runs? A2: Key indicators in your chromatogram include a broad or noisy baseline, unexpected decreases in peak intensity, and inconsistent internal standard responses [7]. To quantify the effect, you can use post-column infusion or post-extraction spike-in experiments [34]. A shift in the calibration curve slope or intercept when comparing analyte response in a matrix versus pure solvent also indicates significant matrix effects [34].

Q3: What are the most effective chromatographic strategies to minimize ion suppression? A3: The most effective approaches include:

- Improved Separation: Optimizing chromatographic conditions to achieve better separation of analytes from matrix components reduces co-elution [7] [34]. This can involve adjusting mobile phase composition, gradient, and flow rate [34].

- Two-Dimensional Chromatography: Comprehensive two-dimensional liquid chromatography (LC×LC) significantly improves separation power by utilizing different stationary phase chemistries in each dimension, effectively resolving more analytes from interferences [35].

- Specialized Phases: Using multi-2D LC×LC, which can switch between HILIC or RP phases as the second dimension based on analysis time, has shown significantly improved separation performance [35].

Q4: How can I correct for ion suppression in non-targeted metabolomics studies? A4: For non-targeted studies where removing all suppression isn't feasible, the IROA TruQuant Workflow uses a stable isotope-labeled internal standard (IROA-IS) library and algorithms to measure and correct for ion suppression across all detected metabolites [6]. This method works across different chromatographic systems (IC, HILIC, RPLC) and both ionization modes, effectively nulling out suppression and its associated error [6].

Q5: What emerging technologies show promise for reducing ion suppression? A5: Recent innovations include:

- Nanobubble-Enhanced ESI: Introducing CO₂ or N₂ nanobubbles into electrospray solvents can substantially improve ionization efficiency and reduce ion suppression, with studies showing signal improvements of 2 to 18.7-fold for various analytes [36].

- AI-Driven Optimization: Machine learning and multi-task Bayesian optimization are now being used to streamline method development for complex setups like LC×LC, reducing the experimental burden while enhancing predictive power for optimal separation conditions [35] [37].

- Low-Adsorption Hardware: New systems with hybrid surface technologies and inert materials in the LC flow path minimize non-specific adsorption and analyte loss, improving signal stability [7] [38].

Troubleshooting Guides: Step-by-Step Protocols

Guide 1: Diagnosing and Quantifying Matrix Effects

This protocol helps you systematically identify and measure ion suppression in your LC-MS method.

Problem: Suspected ion suppression causing inconsistent quantification and reduced sensitivity.

Materials Needed:

- Post-column infusion pump (if using post-column infusion method)

- Pure analyte standards

- Blank matrix samples (e.g., drug-free plasma)

- Internal standards (preferably stable isotope-labeled)

Step-by-Step Procedure:

Step 1: Perform Post-Extraction Spike-In Experiment

- Prepare at least six different blank matrix samples using your standard extraction protocol.

- Spike your target analyte into the processed samples at known concentrations covering your calibration range.

- Prepare equivalent standards in pure solvent at the same concentrations.

- Analyze all samples using your current LC-MS method.

Step 2: Calculate Matrix Effects

- For each concentration, calculate the matrix factor (MF):

MF = Peak area in matrix / Peak area in solvent - Calculate the internal standard-normalized matrix factor:

IS-normalized MF = MF(analyte) / MF(IS) - Interpretation:

- MF ≈ 1.0: No significant matrix effects

- MF < 1.0: Ion suppression

- MF > 1.0: Ion enhancement

- Significant matrix effects are typically indicated by IS-normalized MF values outside 0.8-1.2 [34].

Step 3: Identify Problematic Chromatographic Regions

- If using post-column infusion: Infuse a constant amount of analyte into the mobile phase while running a blank matrix extract.

- Monitor the signal throughout the chromatographic run.

- Note regions where the signal decreases significantly - these indicate co-eluting matrix components causing suppression [34].

Corrective Actions:

- If suppression is detected, optimize chromatography to move analyte peaks away from suppression regions.

- Consider improving sample cleanup or implementing the IROA workflow for non-targeted studies [6] [34].

Guide 2: Implementing the IROA Workflow for Ion Suppression Correction

This protocol outlines how to implement the novel IROA method for systematic correction of ion suppression in non-targeted metabolomics.