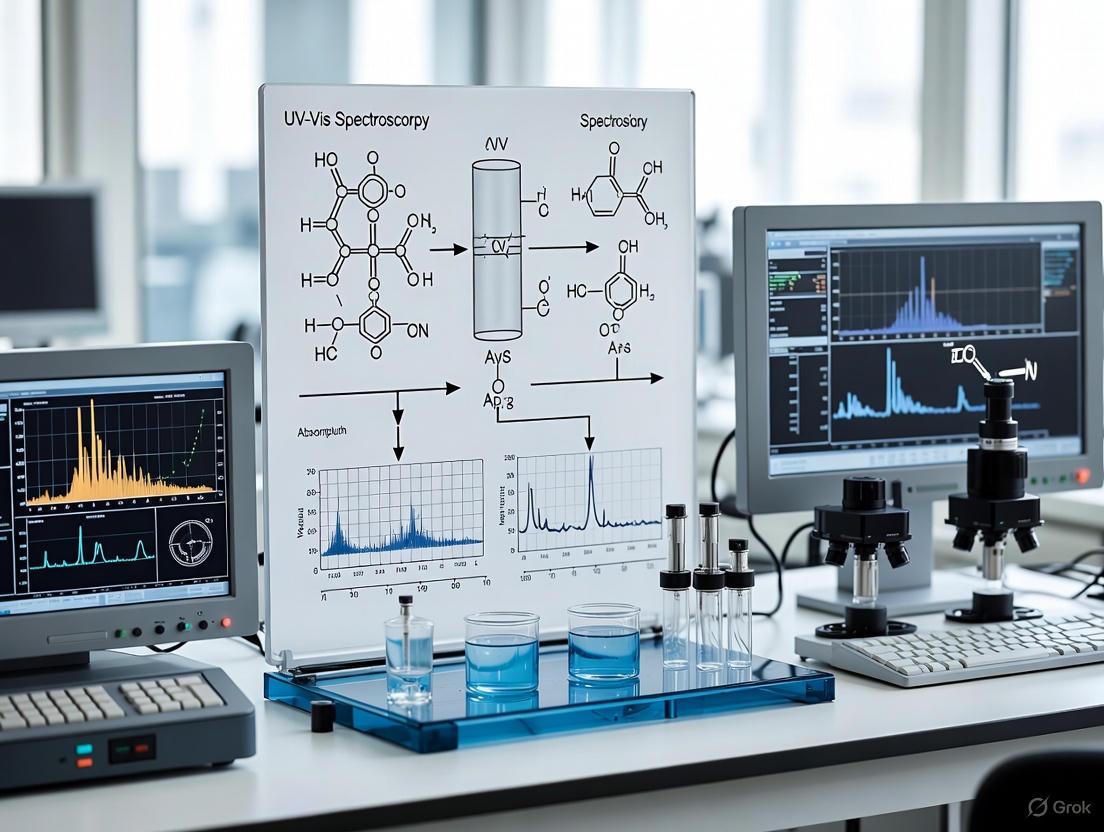

UV-Vis Spectroscopy in Pharmaceutical Quality Control: Principles, Applications, and Regulatory Compliance

This article provides a comprehensive overview of Ultraviolet-Visible (UV-Vis) spectroscopy as a critical analytical technique in pharmaceutical quality control.

UV-Vis Spectroscopy in Pharmaceutical Quality Control: Principles, Applications, and Regulatory Compliance

Abstract

This article provides a comprehensive overview of Ultraviolet-Visible (UV-Vis) spectroscopy as a critical analytical technique in pharmaceutical quality control. Tailored for researchers, scientists, and drug development professionals, it covers foundational principles from light absorption and instrumentation to advanced methodological applications in drug stability testing, dissolution monitoring, and impurity quantification. The content further addresses practical troubleshooting, method optimization strategies, and rigorous validation protocols required for regulatory compliance with USP, EP, and ICH guidelines. By synthesizing current instrumentation trends and validation frameworks, this resource serves as an essential guide for ensuring drug safety, efficacy, and quality throughout the development and manufacturing lifecycle.

The Fundamentals of UV-Vis Spectroscopy: How Light Absorption Powers Pharmaceutical Analysis

Ultraviolet-Visible (UV-Vis) spectroscopy is a fundamental analytical technique in pharmaceutical quality control (QA/QC) that relies on the interaction of light with matter. The core principle involves measuring the absorption of ultraviolet or visible light by a sample, which provides critical data for ensuring the identity, purity, potency, and stability of drug substances and products [1]. When light in the UV-Vis range (approximately 190–800 nm) interacts with a molecule, specific wavelengths are absorbed, promoting electrons to higher energy states [2] [3]. This absorption is quantitatively described by the Beer-Lambert law, forming the basis for concentration determination and other essential QA/QC analyses [4]. The technique is valued for its speed, precision, reproducibility, and non-destructive nature, making it indispensable for compliance with rigorous regulatory standards such as those outlined in ICH Q2(R1), USP Chapter <857>, and Ph. Eur. Chapter 2.2.25 [1] [5].

Core Principles

The Interaction of Light with Matter

The fundamental interaction in UV-Vis spectroscopy occurs when photons of light possess energy that matches the energy required to excite a molecule's electrons from a ground state to an excited state [3]. The energy of the photon is inversely proportional to its wavelength. The key electronic transitions involved for organic molecules are:

- π→π* and n→π* transitions: These are the most common transitions observed in UV-Vis spectroscopy, often associated with unsaturated centers in molecules, such as C=C, C=O, or aromatic rings [2].

- σ→σ* transitions: These require high energy and are typically observed in the far-UV region for saturated compounds [2].

The resulting absorption spectrum is a plot of absorbance versus wavelength, which serves as a fingerprint for qualitative analysis and provides the basis for quantitative measurement [3].

The Beer-Lambert Law

The Beer-Lambert law establishes the quantitative relationship between light absorption and the properties of the absorbing species [4]. It is mathematically expressed as:

A = εlc

Where:

- A is the Absorbance (unitless), defined as log10(Iâ‚€/I), where Iâ‚€ is the intensity of incident light and I is the intensity of transmitted light [4].

- ε is the Molar Absorptivity (L·molâ»Â¹Â·cmâ»Â¹), a constant that is a characteristic of the substance at a specific wavelength [4].

- l is the Path Length (cm), the distance the light travels through the sample [4].

- c is the Concentration (mol·Lâ»Â¹) of the absorbing species in the solution [4].

This law demonstrates that absorbance is directly proportional to concentration for a fixed path length, enabling the determination of unknown concentrations via a calibration curve [4].

Table 1: Key Parameters of the Beer-Lambert Law

| Parameter | Symbol | Units | Description |

|---|---|---|---|

| Absorbance | A | Unitless (Absorbance Units, AU) | Logarithmic measure of the amount of light absorbed by the sample. |

| Molar Absorptivity | ε | L·molâ»Â¹Â·cmâ»Â¹ | A constant indicative of how strongly a chemical species absorbs light at a given wavelength. |

| Path Length | l | cm | The internal width of the cuvette or sample holder that the light beam traverses. |

| Concentration | c | mol·Lâ»Â¹ | The concentration of the absorbing analyte in the solution. |

Applications in Pharmaceutical QA/QC

UV-Vis spectroscopy supports critical QA/QC workflows in the pharmaceutical industry, ensuring drug products meet predefined quality standards [1].

Table 2: Key Applications of UV-Vis Spectroscopy in Pharmaceutical QA/QC

| Application | Objective | Typical Protocol Summary |

|---|---|---|

| Assay and Potency Determination | Quantify the concentration of the Active Pharmaceutical Ingredient (API) in a drug product [1]. | Absorbance of the sample solution is measured at the λmax of the API and concentration is determined using a pre-established calibration curve [1]. |

| Content Uniformity | Ensure each dosage unit (e.g., tablet) contains an API amount within the specified range [1]. | Individual dosage units are dissolved in an appropriate solvent, and the absorbance of each solution is measured to calculate the API content [1]. |

| Dissolution Testing | Monitor the rate and extent of API release from a solid dosage form [1]. | Absorbance of dissolution media samples is measured at predetermined time points to calculate the cumulative percentage of API dissolved [1]. |

| Identity Testing | Confirm the identity of a raw material or finished product. | The UV absorption spectrum of the sample is compared to that of a reference standard for a match in characteristic peaks [1]. |

| Purity and Impurity Assessment | Detect and quantify potential impurities or degradation products [1]. | Absorbance is measured at a wavelength specific to an impurity, or spectral deviations from the reference standard are investigated [1]. |

An emerging application is the use of UV-Vis as a Process Analytical Technology (PAT). For instance, it can be implemented as an in-line monitoring system during continuous manufacturing processes like Hot Melt Extrusion (HME) to monitor critical quality attributes such as API concentration and solubility in a polymer matrix in real-time [6].

Experimental Protocols

Protocol 1: Standard Calibration Curve for API Quantification

This protocol details the steps for developing a calibration curve to determine the unknown concentration of an Active Pharmaceutical Ingredient (API).

1. Objective: To create a calibration curve for [API Name] in [Solvent, e.g., pH 6.8 phosphate buffer] for quantitative analysis.

2. Materials and Reagents:

- The Scientist's Toolkit for this protocol is detailed in Section 6.

3. Instrumentation:

- UV-Vis spectrophotometer (e.g., Agilent Cary Series, Shimadzu UV series) with validated performance (wavelength accuracy, photometric accuracy, stray light) [5] [7].

- Quartz cuvettes (1 cm path length).

4. Procedure:

- Step 1: Preparation of Standard Stock Solution. Accurately weigh approximately 50 mg of API reference standard. Transfer to a 50 mL volumetric flask, dissolve, and dilute to volume with solvent to obtain a stock solution of known concentration (e.g., 1 mg/mL).

- Step 2: Preparation of Working Standard Solutions. Perform serial dilutions of the stock solution to prepare a minimum of five standard solutions covering the concentration range expected for the sample (e.g., 2–20 μg/mL).

- Step 3: Spectral Scan. Scan one of the mid-concentration standards over a relevant wavelength range (e.g., 200–400 nm) to determine the wavelength of maximum absorption (λmax).

- Step 4: Measurement of Absorbance. Using the solvent as the blank, measure the absorbance of each working standard solution at the predetermined λmax.

- Step 5: Preparation of Calibration Curve. Plot the average absorbance (y-axis) against the corresponding concentration (x-axis). Perform linear regression to obtain the equation of the line (y = mx + c) and the correlation coefficient (R²).

5. Data Analysis:

- The slope of the line is related to the molar absorptivity (ε), and the concentration of an unknown sample (cunknown) is calculated as: cunknown = (Aunknown) / (εl), where Aunknown is the absorbance of the sample solution.

Protocol 2: Identity Confirmation of a Raw Material via Spectrum Comparison

1. Objective: To verify the identity of an incoming raw material (e.g., [Excipient Name]) against a qualified reference standard.

2. Procedure:

- Step 1: Sample Preparation. Prepare solutions of the test sample and the reference standard in the same solvent at equivalent concentrations.

- Step 2: Acquisition of Spectra. Scan both solutions over a specified wavelength range (e.g., 220–350 nm) using the solvent as a blank.

- Step 3: Comparison and Evaluation. Overlay the spectrum of the test sample with that of the reference standard. The identity is confirmed if the two spectra are identical in shape and show absorbance maxima and minima at the same wavelengths [1].

Method Validation

According to ICH Q2(R1) guidelines, methods used in pharmaceutical QA/QC must be validated. The following table summarizes key validation parameters for a typical UV-Vis quantitative method [8].

Table 3: Summary of Method Validation Parameters for a UV-Vis Assay

| Validation Parameter | Definition | Acceptance Criteria Example |

|---|---|---|

| Accuracy | The closeness of the measured value to the true value. | Recovery: 98.0–102.0% |

| Precision (Repeatability) | The closeness of agreement between a series of measurements under the same conditions. | %RSD ≤ 2.0% |

| Linearity | The ability of the method to obtain results directly proportional to analyte concentration. | Correlation coefficient (R²) ≥ 0.998 |

| Range | The interval between the upper and lower concentration levels over which linearity, accuracy, and precision are demonstrated. | Typically a defined range around the target concentration (e.g., 80–120%). |

| Specificity | The ability to assess the analyte unequivocally in the presence of potential interferents (e.g., impurities, excipients). | No interference observed. |

| Limit of Detection (LOD) | The lowest concentration of analyte that can be detected. | Signal-to-Noise ratio ≈ 3:1 |

| Limit of Quantitation (LOQ) | The lowest concentration of analyte that can be quantified with acceptable accuracy and precision. | Signal-to-Noise ratio ≈ 10:1 |

The Scientist's Toolkit: Essential Materials and Reagents

Table 4: Key Research Reagent Solutions and Materials

| Item | Function / Role | Critical Considerations |

|---|---|---|

| High-Purity Reference Standards | Serves as the benchmark for identity, purity, and quantity; essential for calibration [8]. | Must be of certified purity and traceable to a pharmacopoeial standard if available. |

| Spectroscopic Grade Solvents | To dissolve the analyte without introducing interference [1] [2]. | Must be transparent in the wavelength region of interest (e.g., HPLC-grade water, methanol, acetonitrile). |

| Quartz Cuvettes | Hold the sample solution for analysis. | Required for UV range analysis as quartz is transparent to UV light; standard path length is 1 cm [3]. |

| Volumetric Flasks and Pipettes | For accurate preparation and dilution of standard and sample solutions. | Class A glassware is recommended to ensure measurement accuracy and precision. |

| Filters (e.g., 0.45 μm membrane filters) | To remove particulate matter from samples, ensuring optically clear solutions and preventing light scattering [1]. | Filter material must be compatible with the solvent and must not adsorb the analyte. |

| Fos-choline-14 | Fos-choline-14, MF:C19H43NO4P+, MW:380.5 g/mol | Chemical Reagent |

| Hexahydroxyplatinumdiuide | Hexahydroxyplatinumdiuide | High-purity Hexahydroxyplatinumdiuide for catalyst and materials research. For Research Use Only (RUO). Not for diagnostic or therapeutic use. |

Troubleshooting and Best Practices

Successful implementation requires awareness of potential pitfalls and adherence to best practices.

- Adherence to Beer-Lambert Law: Ensure measurements are within the linear range of the instrument (typically absorbance < 1–2 AU). High absorbance can lead to deviations due to stray light or polychromatic effects [2] [3].

- Sample Preparation: Samples must be optically clear and free of particulates to prevent light scattering. Use filtration or centrifugation if necessary [1].

- Instrument Performance: Regular instrument validation is critical. Key performance checks include [7]:

- Wavelength Accuracy: Verify using holmium oxide or deuterium lamp emission lines.

- Stray Light: Check using solutions like sodium iodide.

- Photometric Accuracy: Confirm using neutral density filters or standard solutions.

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a cornerstone analytical technique in pharmaceutical quality assurance and quality control (QA/QC) environments, where precision, reproducibility, and non-destructive testing are vital. This technique measures the absorption of ultraviolet or visible light by a compound as it transitions between electronic energy levels, providing a rapid, reliable means to characterize drug substances and products [1]. Within the highly regulated pharmaceutical industry, UV-Vis spectroscopy is indispensable for ensuring the identity, purity, potency, and stability of pharmaceutical compounds—critical factors in regulatory compliance, method validation, and ultimately, patient safety [1].

The fundamental principle governing quantitative UV-Vis analysis is the Beer-Lambert Law, which states that the absorbance of light by a solution is directly proportional to the concentration of the absorbing species and the path length the light takes through the solution [2]. This relationship is mathematically expressed as A = εlc, where A is the measured absorbance, ε is the molar absorptivity (a compound-specific constant), l is the path length (cm), and c is the concentration (mol/L) [2]. This law forms the basis for the quantitative determination of active pharmaceutical ingredients (APIs), impurity monitoring, and content uniformity testing that are routine in pharmaceutical control laboratories.

Core Instrumentation Components

A UV-Vis spectrophotometer is an integrated system of several key components, each playing a critical role in ensuring accurate and reproducible results. Understanding the function and specifications of each part is essential for proper instrument operation, method development, and troubleshooting in a pharmaceutical context.

The light source must provide a steady emission of light across a broad range of wavelengths. Modern instruments often use multiple lamps to cover the entire UV and visible spectrum effectively [3] [9].

| Light Source Type | Spectral Range | Key Characteristics | Pharmaceutical Application Consideration |

|---|---|---|---|

| Deuterium Lamp [3] [9] | 190 – 350 nm [9] | Intense, continuous UV spectrum; limited lifetime. | Essential for API quantification at lower UV wavelengths (e.g., nucleic acid analysis at 260 nm) [10]. |

| Tungsten-Halogen Lamp [3] [9] | 330 – 3200 nm [9] | Robust, inexpensive, stable output in visible/NIR region. | Ideal for colored compounds and dissolution testing in the visible range. |

| Xenon Lamp [3] | UV to Visible | High intensity, continuous spectrum across UV-Vis. | Higher cost and lower stability can be a concern for routine QC; often used in research instruments. |

Wavelength Selection: Monochromators

The monochromator is responsible for selecting a specific, narrow band of wavelengths from the broad output of the light source. Its core components include an entrance slit, a diffraction grating, and an exit slit [9]. The grating, which is rotated to select wavelengths, is characterized by its groove frequency (grooves per mm); a higher frequency (e.g., 1200 grooves/mm or more) provides better optical resolution [3]. The slits control the spectral bandwidth (SBW), defined as the full width at half maximum (FWHM) of the light intensity distribution exiting the monochromator [9]. A narrower SBW provides higher spectral resolution, crucial for distinguishing between closely spaced absorption peaks, while a wider SBW allows more light to pass, improving the signal-to-noise ratio for more sensitive detection [9]. The optimal SBW is typically 1/10th of the narrowest absorption peak's FWHM [9].

Sample Compartment

The sample compartment holds the analyte, typically contained within a cuvette, in the path of the light beam. The choice of cuvette material is critical and depends on the wavelength range of interest. For UV measurements below ~350 nm, quartz or fused silica cuvettes are mandatory as they are transparent to UV light [3]. For visible-only measurements, optical glass or plastic cuvettes may be sufficient and are more cost-effective [3]. Standard path lengths are 1 cm, but varying this length can help keep absorbance readings within the ideal linear range of 0.1 to 1.0 AU [1] [3]. Proper sample preparation is paramount; samples must be optically clear and free of particulate matter to prevent light scattering, which can lead to erroneously high absorbance readings [1].

Detection Systems

The detector converts the transmitted light intensity into an electrical signal, which is then processed to produce the absorbance spectrum. The selection of an appropriate detector balances sensitivity, spectral response, and cost.

| Detector Type | Operating Principle | Spectral Range | Advantages and Limitations |

|---|---|---|---|

| Photomultiplier Tube (PMT) [3] [9] | Photoelectric effect with electron multiplication via dynodes. | UV-Vis | Very high sensitivity and low noise; excellent for low-light applications. |

| Silicon Photodiode [9] | Semiconductor device generating photocurrent from incident light. | UV-Vis | Fast response, robust, and lower cost; less sensitive than PMT. |

| InGaAs Photodiode [9] | Semiconductor photodiode. | NIR | High sensitivity in NIR region; more expensive. |

Optical Configurations: Single vs. Double Beam

Spectrophotometers can have two primary optical configurations, each with distinct advantages for pharmaceutical analysis:

- Single Beam: Uses a single light path that passes through the sample. It requires measuring a blank reference sample immediately before or after the analyte measurement [9]. This design is simpler and more cost-effective but is susceptible to errors from source intensity fluctuations over time [9].

- Double Beam: Splits the monochromatic light into two beams—one passing through the sample and the other through a reference blank. The detector then measures the ratio of the two intensities simultaneously [9]. This configuration automatically compensates for drift in the light source intensity, electronic fluctuations, and stray light, providing superior stability and more reliable data, which is critical for lengthy analyses and regulated QC environments [9].

Detailed Experimental Protocol: API Potency Determination by UV-Vis Spectroscopy

This protocol details a standard procedure for quantifying the concentration of an Active Pharmaceutical Ingredient (API) in a solution using a double-beam UV-Vis spectrophotometer, a common assay in pharmaceutical potency and content uniformity testing.

Research Reagent Solutions

| Reagent/Material | Specification | Function/Purpose |

|---|---|---|

| API Reference Standard | Certified purity (e.g., USP grade) | Primary standard for calibration curve; ensures accuracy and traceability. |

| HPLC-Grade Solvent | Spectrophotometric grade, low UV absorbance | Dissolves analyte and reference; minimizes background absorbance (stray light). |

| Volumetric Flasks | Class A | Precise preparation and dilution of standard and sample solutions. |

| Quartz Cuvettes | 1 cm pathlength, matched pair | Holds sample and reference solutions; quartz is transparent in UV range. |

Step-by-Step Procedure

Instrument Preparation and Qualification:

- Power on the spectrophotometer and the computer. Allow the system to initialize and the lamp to warm up for the time recommended by the manufacturer (typically 15-30 minutes).

- Using the instrument software, set the scanning parameters: Wavelength range: 200-400 nm (or a suitable range encompassing the API's λmax); Scan speed: Medium; Spectral Bandwidth (SBW): As determined during method development (e.g., 1 nm or 2 nm).

- Ensure the sample compartment is clean and place a cuvette filled with the pure solvent (blank) in both the sample and reference holder positions.

Preparation of Standard Solutions:

- Accurately weigh approximately 50 mg of the API reference standard and transfer it quantitatively to a 100 mL volumetric flask. Dissolve and dilute to volume with the solvent to create a stock solution of known concentration (e.g., ~500 µg/mL).

- Using a serial dilution technique, prepare a minimum of five standard solutions covering the concentration range where the Beer-Lambert law is known to be linear (e.g., 5, 10, 20, 30, 40 µg/mL). Ensure all dilutions are performed with precision.

Sample Preparation:

- For a solid dosage form (tablet/capsule), weigh and finely powder not less than 10 units. Accurately weigh a portion of the powder equivalent to the weight of one unit and transfer to a suitable volumetric flask. Extract the API with the solvent, sonicate if necessary, dilute to volume, and filter.

- For a liquid formulation, dilute an accurately measured volume with solvent to obtain a concentration within the linear range of the calibration curve.

Data Acquisition:

- Perform a blank correction with the solvent in both cuvettes.

- Measure the absorbance spectrum of each standard solution, identifying the wavelength of maximum absorption (λmax) for the API.

- Measure the absorbance of the prepared sample solution at the determined λmax.

Data Analysis and Calculation:

- Construct a calibration curve by plotting the average absorbance (y-axis) of each standard against its known concentration (x-axis).

- Perform a linear regression analysis on the data. The coefficient of determination (R²) should be ≥ 0.995 for a valid calibration.

- Use the linear regression equation (y = mx + c) to calculate the concentration of the API in the sample solution based on its measured absorbance.

- Account for all dilution factors from the original sample to report the final API concentration in the drug product.

Critical Performance Parameters and Troubleshooting in Pharmaceutical Analysis

Adherence to strict performance specifications is non-negotiable in a GMP-regulated pharmaceutical laboratory.

- Stray Light: This is any light that reaches the detector without passing through the sample or is outside the selected wavelength band. It is a primary cause of deviation from the Beer-Lambert law, especially at high absorbances (>2 AU), leading to falsely low absorbance readings [2] [9]. It is controlled by using high-purity optical components and can be minimized with double-monochromator instruments [9].

- Spectral Bandwidth (SBW): As previously discussed, an inappropriate SBW can lead to poor resolution or reduced sensitivity. The selected SBW must be validated as part of the analytical method to ensure accurate quantification [9].

- Linearity and Range: The analytical method must demonstrate that the instrument's response is directly proportional to the concentration of the analyte across the specified range. This is established during method validation per ICH Q2(R1) guidelines [1].

- Wavelength Accuracy: The instrument must be regularly calibrated for wavelength accuracy (e.g., using holmium oxide filters) to ensure that the reported λmax is correct, as shifts can lead to misidentification and inaccurate quantification [1].

A thorough understanding of the key components of a UV-Vis spectrophotometer—from the stability of its light sources and the resolution of its monochromator to the sensitivity of its detector—is fundamental for scientists and researchers in drug development. This knowledge empowers them to develop robust and validated analytical methods, operate instruments effectively, troubleshoot issues, and, most importantly, generate reliable data that ensures the quality, safety, and efficacy of pharmaceutical products. As a versatile and quantitative workhorse of the QC laboratory, the proper application of UV-Vis spectroscopy remains a critical skill in the pharmaceutical scientist's toolkit.

Within pharmaceutical quality control (QC), the demand for rapid, reliable, and cost-efficient analytical techniques is paramount. Ultraviolet-Visible (UV-Vis) spectroscopy stands as a cornerstone technology in this field, offering significant advantages that align with the rigorous demands of modern drug development and manufacturing. This application note frames these advantages—speed, cost-effectiveness, and versatility—within a broader thesis on the indispensable role of UV-Vis spectroscopy in pharmaceutical QC. It provides researchers and scientists with structured quantitative data and detailed experimental protocols to facilitate implementation and underscore the technique's value in ensuring drug identity, purity, potency, and safety.

Advantages and Quantitative Data

The utility of UV-Vis spectroscopy in pharmaceutical QC is demonstrated through its performance across multiple applications. The following tables summarize key quantitative data supporting its speed, cost-effectiveness, and versatility.

Table 1: Speed and Performance Metrics of UV-Vis Spectroscopy in Pharma QC

| Application Context | Measured Parameter | Performance Outcome | Reference / Model System |

|---|---|---|---|

| In-line Content Uniformity | Measurement Frequency | ~1,000 spectra acquired in a short time [11] | Hyperspectral Imaging Prototype |

| In-line Potency Monitoring | Integration Time | Measurements in the millisecond-range [6] | Hot Melt Extrusion (HME) |

| API Quantification | Analytical Run Time | Rapid results for routine quantification [1] | General API Analysis |

| Dissolution Testing | Throughput | High-throughput capability [1] | Dissolution Profile Evaluation |

Table 2: Versatility and Analytical Scope in Pharmaceutical Applications

| Application Area | Specific Use Case | Typical Analytical Range / Performance | Reference / Model System |

|---|---|---|---|

| Identity Testing | Raw Material Identification | Spectral fingerprint comparison [1] | IR/UV-Vis for Raw Materials |

| Purity Assessment | Impurity and Degradation Detection | Detects unwanted absorption peaks [1] | General Purity Testing |

| Potency Determination | API Concentration in Tablets | R² ~0.99 for 7-13% API content [12] | In-line Theophylline Tablets |

| Process Control (PAT) | Content Uniformity Monitoring | Validated for ICH Q2(R2); Range: 7-13 wt% [12] | Continuous Manufacturing |

| Hyperspectral Imaging | API Characterization | Complete sample separation via PCA [11] | Ibuprofen, Paracetamol, Aspirin |

Experimental Protocols

Protocol: In-Line Content Uniformity Monitoring for Tablets

This protocol validates UV-Vis spectroscopy for real-time, in-line monitoring of Active Pharmaceutical Ingredient (API) content uniformity during tablet manufacturing, as per ICH Q2(R2) [12].

- 1. Objective: To implement and validate a non-destructive, rapid UV-Vis method for in-line content uniformity determination of tablets on a rotary press.

- 2. Materials:

- API: Theophylline monohydrate

- Excipients: Lactose monohydrate (filler/binder), Magnesium stearate (lubricant)

- Equipment: Rotary tablet press with integrated UV/Vis reflectance probe, data acquisition system

- Software: For data pre-treatment and calculation of relative reflectance

- 3. Methodology:

- Formulation: Prepare a powder blend with a target of 10 wt% theophylline, 0.5 wt% magnesium stearate, and the remainder as lactose monohydrate.

- Instrument Setup: Integrate a UV-Vis reflectance probe directly into the tablet press, positioning it to measure the main side of the tablets during compression.

- Data Acquisition:

- Synchronize spectrum acquisition with the tablet production cycle.

- Calculate reflectance (R) from the intensity of reflected light (I) and emitted light (I0): R = I / Iâ‚€ [12].

- Apply data pre-treatment to filter out spectra not measured from the full tablet surface.

- Calibration & Quantification:

- Use the relative reflectance at a specific, optimized wavelength (e.g., 272 nm for theophylline).

- Establish a univariate calibration model correlating the relative reflectance value to the known API concentration from off-line reference methods.

- 4. Validation:

- Specificity: Confirm the API-specific wavelength is free from excipient interference.

- Linearity: Demonstrate a linear relationship (e.g., R² ~0.99) over a defined range (e.g., 7-13 wt% API).

- Precision: Evaluate repeatability and intermediate precision under different throughputs.

- Accuracy: Compare results with a validated reference method (e.g., HPLC).

Protocol: API Solubility and Oversaturation Monitoring in Hot Melt Extrusion

This protocol uses in-line UV-Vis spectroscopy to monitor API solubility and identify oversaturation thresholds during Hot Melt Extrusion (HME) for forming amorphous solid dispersions [6].

- 1. Objective: To use UV-Vis spectroscopy as a Process Analytical Technology (PAT) tool for real-time monitoring of API-polymer solubility and detection of oversaturation during HME.

- 2. Materials:

- API: Piroxicam (PRX)

- Polymer: Kollidon VA64

- Equipment: Co-rotating twin-screw extruder with in-line UV-Vis fiber-optic probe, HPLC system for off-line validation

- 3. Methodology:

- Sample Preparation: Blend PRX and Kollidon VA64 at varying concentrations (e.g., 10-30% w/w).

- Process Setup: Install the UV-Vis probe in-line within the extruder die.

- Data Acquisition:

- Collect full-range spectra (230-700 nm) in real-time.

- Monitor the absorbance at the API-specific λ-max.

- Simultaneously calculate the lightness value (L) from the visible region of the spectrum.

- Analysis:

- Homogeneous dissolution is indicated by a stable baseline in the visible region and consistent absorbance in the UV region.

- Oversaturation is identified by a sharp increase in absorbance and a sharp decrease in L value, accompanied by baseline scattering in the visible range due to undissolved API particles.

- 4. Data Interpretation:

- Use a sequential Design of Experiments (DoE) to understand the interaction effects of CPPs (e.g., die temperature, screw speed, feed rate, API concentration) on CQAs (absorbance, L*).

- Correlate in-line UV-Vis data with off-line characterization (HPLC, DSC, XRD) to confirm the absence of degradation and the amorphous state of the dispersion.

The following workflow diagram illustrates the sequential stages of this HME monitoring process:

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for UV-Vis-Based Pharmaceutical QC

| Item | Function / Application | Critical Specifications |

|---|---|---|

| High-Purity Solvents | Dissolve samples for analysis; must not absorb in the measured wavelength range. | Spectrophotometric grade (e.g., Methanol, Acetonitrile, Water). Optically clear and free from particulates [1]. |

| Quartz Cuvettes | Hold liquid samples for transmission measurements in UV range. | High-transmission quartz; standard 1 cm path length; matched pairs for accuracy [3]. |

| Deuterated Solvents | For NMR-based confirmation of UV-Vis results in structural elucidation. | D₂O, CDCl₃, DMSO-d₆; high isotopic purity to avoid signal interference [1]. |

| Certified Reference Standards | Calibrate the spectrophotometer; validate analytical methods; quantify API. | USP/EP/JP certified; high purity and known concentration [13]. |

| Hyperspectral Imaging System | Spatially resolve API distribution in solid dosage forms (PAT). | UV wavelength range (e.g., 225-400 nm); pushbroom imager with CCD camera [11]. |

| Reflectance Probe | Enable in-line measurements on solid surfaces (e.g., powder blends, tablets). | Fiber-optic design; robust for integration into process equipment (e.g., tablet press, extruder) [12]. |

| BocNH-PEG9-CH2COOH | BocNH-PEG9-CH2COOH, MF:C25H49NO13, MW:571.7 g/mol | Chemical Reagent |

| Fmoc-Tyr(POMe)-OH | Fmoc-Tyr(POMe)-OH, MF:C26H26NO8P, MW:511.5 g/mol | Chemical Reagent |

Ultraviolet-Visible (UV-Vis) spectroscopy is a fundamental analytical technique in pharmaceutical quality control research, providing a rapid, non-destructive means to verify identity, assess purity, and determine the concentration of active pharmaceutical ingredients (APIs) and finished drug products [3] [1]. The technique measures the absorption of light in the ultraviolet (typically 190-400 nm) and visible (400-700 nm) regions of the electromagnetic spectrum, which corresponds to the excitation of outer electrons in molecules to higher energy states [14] [3]. For pharmaceutical scientists, interpreting the resulting spectra—particularly the absorption maxima (λmax) and molar absorptivity (ε)—is critical for confirming molecular identity and detecting potential impurities [15] [1]. This application note details the principles and protocols for interpreting spectral data within a pharmaceutical development context.

Theoretical Principles of Electronic Transitions

The absorption of UV or visible radiation corresponds to the excitation of outer electrons from their ground state to an excited state [14]. The specific wavelengths absorbed, and the intensity of these absorptions, provide fundamental structural information about the molecule.

Table 1: Primary Electronic Transitions in UV-Vis Spectroscopy

| Transition Type | Electrons Involved | Typical λmax Range | Molar Absorptivity (ε, L·molâ»Â¹Â·cmâ»Â¹) | Chromophore Example |

|---|---|---|---|---|

| π → π* | π electrons in double bonds | 200-700 nm (varies with conjugation) | 1,000 - 10,000 | Alkenes, Conjugated systems [14] [16] |

| n → π* | Non-bonding (lone pair) electrons | 250-500 nm | 10 - 100 | Carbonyl groups [14] [16] |

| n → σ* | Non-bonding electrons | 150-250 nm | ~1,000 | Alcohols, Amines [14] |

| Charge-Transfer | Electron donor to acceptor | 200-800 nm | > 10,000 | Charge-transfer complexes [14] |

The most analytically useful transitions for organic molecules in the conventional UV-Vis range (200-700 nm) involve π → π and n → π transitions [14]. The π → π transitions, typically found in molecules with conjugated double bond systems, are characterized by high molar absorptivities. In contrast, n → π transitions, occurring in molecules with heteroatoms bearing lone pairs (like carbonyl oxygen), have lower probabilities and thus weaker intensities [14] [17] [16].

Conjugation is the single most important factor affecting λmax, causing a bathochromic shift (red shift) to longer wavelengths and often a hyperchromic effect (increased intensity). This occurs because conjugation lowers the energy gap between the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO) [17] [16]. For instance, while ethene absorbs at 165 nm, the conjugated system in 1,3-butadiene absorbs at 217 nm, and beta-carotene, with its extensive 11-conjugated double-bond system, absorbs in the visible region (~450 nm), making it orange [16].

Instrumentation and Data Acquisition Workflow

A UV-Vis spectrophotometer consists of several key components: a light source, a wavelength selector, a sample holder, and a detector [3].

Diagram 1: UV-Vis Instrument Workflow

The light source typically consists of two lamps: a deuterium lamp for the UV region and a tungsten or halogen lamp for the visible region [3]. The monochromator, often containing a diffraction grating with 1200 grooves per mm or more, selects a specific wavelength of light to pass through the sample and reference [3]. For accurate measurements, the sample and a reference blank (typically the solvent used to prepare the sample) are analyzed simultaneously or sequentially. The detector then converts the transmitted light intensity into an electrical signal, and the processor calculates the absorbance at each wavelength to generate the absorption spectrum [3].

Core Quantitative Relationships

Beer-Lambert Law

The fundamental quantitative relationship in UV-Vis spectroscopy is the Beer-Lambert Law, which states that absorbance is directly proportional to the concentration of the absorbing species and the path length through the sample [14] [3].

A = ε * c * l

Where:

- A is the measured Absorbance (unitless)

- ε is the Molar Absorptivity (L·molâ»Â¹Â·cmâ»Â¹)

- c is the concentration of the analyte (mol·Lâ»Â¹)

- l is the path length of the cuvette (cm) [14] [3]

Absorbance values between 0.1 and 1.0 (or up to 2.0 for modern instruments) are generally considered within the ideal quantitative range, corresponding to 10% to 1% light transmission [3]. Values outside this range may require sample dilution or a path length adjustment.

Spectral Parameters

The key parameters extracted from a UV-Vis spectrum are:

- λmax: The wavelength at which maximum absorption occurs. This is a characteristic property of a chromophore and is highly reproducible under identical conditions [16].

- Molar Absorptivity (ε): A measure of how strongly a chromophore absorbs light at a specific wavelength. It is a intrinsic molecular property. The magnitude of ε reflects both the size of the chromophore and the probability of the electronic transition [14] [17].

Experimental Protocols for Pharmaceutical Analysis

Protocol 1: Sample Preparation and Measurement

Table 2: The Scientist's Toolkit: Essential Materials and Reagents

| Item | Function/Description | Key Considerations |

|---|---|---|

| UV-Vis Spectrophotometer | Instrument for measuring light absorption. | Must be qualified (IQ/OQ/PQ) per GMP guidelines. Wavelength accuracy and photometric accuracy should be verified [1]. |

| Quartz Cuvettes | Sample holders for liquid samples. | Quartz is essential for UV detection (<350 nm); must be matched and clean. Standard path length is 1.0 cm [3]. |

| High-Purity Solvents | To dissolve the analyte (e.g., methanol, water, buffer). | Must be optically pure, transparent in the spectral region of interest, and not react with the analyte [1]. |

| Volumetric Flasks | For precise preparation of standard and sample solutions. | Class A glassware ensures accurate volume measurements for quantitative work. |

| Analytical Balance | For accurate weighing of reference standards and samples. | Must be calibrated; critical for preparing standard solutions of known concentration. |

- Solution Preparation: Accurately weigh the API or drug product standard. Dissolve in an appropriate high-purity solvent (e.g., methanol, phosphate buffer) that is transparent in the spectral region of interest. Prepare a series of standard solutions across the expected concentration range [1].

- Blank Measurement: Fill a quartz cuvette with the pure solvent and place it in the reference compartment. This corrects for solvent absorption and reflection losses [3].

- Spectral Acquisition: Place the sample solution in a quartz cuvette and insert it into the sample holder. Scan across the desired wavelength range (e.g., 200-400 nm for UV analysis) to obtain the full absorption spectrum and identify λmax [16].

- Quantitation: Measure the absorbance of standards and samples at the predetermined λmax. Construct a calibration curve of absorbance versus concentration and use it to determine the unknown sample concentration [3] [1].

Protocol 2: Identity Confirmation via Absorbance Ratios (as per USP/EP)

This protocol is exemplified by the identification test for Ibuprofen in the USP and European Pharmacopoeia (EP) [15].

- Standard Preparation: Prepare a solution of the reference standard of Ibuprofen in the specified solvent at the concentration stated in the monograph.

- Test Sample Preparation: Prepare the test sample (ibuprofen API) identically to the standard.

- Spectrum Acquisition: Obtain the UV absorption spectrum of both the standard and test sample solutions over the specified wavelength range.

- Peak and Ratio Comparison:

- USP Test: Confirm that the test sample spectrum exhibits absorbance maxima at the same wavelengths as the standard spectrum [15].

- EP Test: Calculate the ratio of absorbances at designated wavelengths (e.g., Aâ‚/Aâ‚‚) for the test sample. Confirm that this ratio is within the acceptance range specified in the EP monograph [15].

Diagram 2: Identity Confirmation Workflow

Factors Influencing Spectral Data

Solvent Effects

The solvent can significantly influence the absorption spectrum [14]. Polar solvents can cause:

- Blue Shift (Hypsochromic Shift) for n → π* transitions: Increased solvation of lone pair electrons lowers the energy of the n orbital, increasing the transition energy [14].

- Red Shift (Bathochromic Shift) for π → π* transitions: Attractive polarization forces between the solvent and absorber lower the energy levels of both the excited and unexcited states, with a greater effect on the excited state, slightly reducing the energy difference [14].

Table 3: Common Solvents and Their UV Cut-Off Wavelengths

| Solvent | UV Cut-Off (nm) | Notes |

|---|---|---|

| Water | ~190 nm | Suitable for far-UV work. |

| Acetonitrile | ~190 nm | Excellent UV transparency. |

| n-Hexane | ~200 nm | Common for non-polar analytes. |

| Methanol | ~205 nm | Common polar solvent. |

| Chloroform | ~245 nm | Unsuitable for detection below 245 nm. |

pH and Derivatization

The pH of the solution can dramatically alter the spectrum of ionizable compounds. For example, phenols and aromatic acids may show different λmax and ε in their protonated versus deprotonated forms. This property can be exploited to enhance detection sensitivity or selectivity. Sample impurities or turbidity can cause light scattering, leading to erroneously high absorbance readings. Samples must be optically clear and free of particulates, achievable through filtration or centrifugation [1].

Advanced Applications and Computational Predictions

Beyond quantification, UV-Vis spectroscopy is used in pharmaceutical stability studies to track degradation (e.g., by observing the appearance of new absorption peaks) and in dissolution testing to monitor the release of an API from its dosage form [1].

Computational chemistry methods, particularly Time-Dependent Density Functional Theory (TD-DFT), can predict the UV-Vis spectra of molecules from first principles [18] [19]. These calculations simulate the energies and probabilities of electronic transitions, providing a theoretical λmax and oscillator strength (related to ε). While often slightly shifted compared to experimental data (by ~0.1-0.5 eV), these methods are invaluable for assigning spectral bands to specific molecular transitions and for rational molecular design in drug development [18]. Large-scale text-mining and computational efforts are underway to create vast databases of experimental and computed UV/Vis spectral attributes, facilitating data-driven materials discovery [19].

The interpretation of absorption maxima and spectral data is a cornerstone of pharmaceutical analysis. A rigorous understanding of the underlying electronic transitions, coupled with strict adherence to validated experimental protocols, allows researchers and quality control professionals to reliably identify compounds, determine their concentration, and ensure the safety and efficacy of final drug products. Mastery of this technique, supported by robust procedures and an understanding of regulatory requirements, remains essential in the modern pharmaceutical landscape.

Practical Applications in the Pharma Lab: From API Quantification to Dissolution Testing

Active Pharmaceutical Ingredient (API) Identification and Assay

Ultraviolet-Visible (UV-Vis) spectroscopy is a cornerstone analytical technique in pharmaceutical quality control and drug development, providing a reliable means for the identification and quantification of Active Pharmaceutical Ingredients (APIs). The technique operates on the principle that molecules absorb light in the ultraviolet (200-400 nm) and visible (400-780 nm) regions, resulting in electronic transitions. The fundamental relationship between absorbance and concentration is governed by the Beer-Lambert Law (A = εcl), where absorbance (A) is proportional to the concentration (c) of the analyte, its molar absorptivity (ε), and the path length (l) of the light through the sample [3]. This principle, combined with the technique's speed, sensitivity, and relative simplicity, makes it indispensable for ensuring the identity, strength, and quality of pharmaceutical products in various stages of development and manufacturing, from raw material testing to final product release [20] [21].

The application of UV-Vis spectroscopy in pharmaceuticals has evolved significantly. Traditionally used for off-line analysis of single components in solution, it is now increasingly implemented as an in-line Process Analytical Technology (PAT) tool. This shift supports the pharmaceutical industry's movement towards continuous manufacturing and the adoption of Quality by Design (QbD) and Analytical Quality by Design (AQbD) principles, which emphasize building quality into the product and process through scientific understanding and risk management [22] [12] [6]. Furthermore, the challenge of analyzing complex mixtures with overlapping spectra is being addressed through the integration of chemometrics, which uses multivariate statistical methods to extract meaningful information from spectral data [23] [24].

A comprehensive examination of UV-Vis spectrophotometric methods in pharmaceutical analysis published between 2015 and 2023 reveals clear trends in application and methodology [20]. The following tables summarize key statistical findings.

Table 1: Application Distribution of UV-Vis Spectrophotometric Methods (2015-2023)

| Sample Type | Percentage of Studies |

|---|---|

| Pharmaceutical Dosage Forms | 56% |

| Bulk Materials | 27% |

| Pure Substances | 16% |

| Biological Materials | 2% |

| Herbal Materials | 0.4% |

Table 2: Wavelength Range Utilization in UV-Vis Methods (2015-2023)

| Wavelength Range | Percentage of Studies |

|---|---|

| 200 - 240 nm | 28% |

| 240 - 300 nm | 27% |

| > 300 nm | 44% |

The data indicates a strong focus on the analysis of final dosage forms, underscoring the technique's vital role in product quality control. The significant use of wavelengths above 300 nm highlights its applicability not only to the characteristic aromatic and chromophoric group absorptions in the UV range but also to colored compounds in the visible range [20].

Experimental Protocols

This section provides detailed methodologies for two primary applications: the fundamental assay of a single API in a tablet and an advanced in-line PAT method for monitoring API content during a continuous manufacturing process.

Protocol 1: Assay of a Single API in a Tablet Formulation Using a Traditional Off-Line Approach

This protocol describes a standard method for determining the API content in a finished tablet, using theophylline as a model compound [12].

- 1. Objective: To quantify the concentration of theophylline in immediate-release tablets and validate the method according to ICH Q2(R2) guidelines.

- 2. Materials and Reagents:

- API: Theophylline monohydrate standard.

- Tablets: Immediate-release tablets containing theophylline (e.g., 10% w/w target).

- Solvent: A suitable solvent, such as 0.1 M sodium hydroxide or a buffered aqueous solution, in which the API is freely soluble.

- Volumetric Flasks: 100 mL, 250 mL.

- Ultrasonic Bath.

- Syringe Filters: 0.45 µm, nylon or PTFE.

- UV-Vis Spectrophotometer with quartz cuvettes (path length: 1 cm).

- 3. Instrumental Parameters:

- Wavelength: 272 nm (λmax for theophylline).

- Mode: Absorbance.

- Scan Range: 220 - 350 nm (for spectrum identification).

- Slit Width: 1 nm.

- Scan Speed: Medium.

- 4. Procedure:

- Standard Stock Solution: Accurately weigh approximately 25 mg of theophylline standard into a 250 mL volumetric flask. Dissolve and make up to volume with the solvent to obtain a concentration of about 100 µg/mL.

- Calibration Standards: Dilute the stock solution to prepare a series of standard solutions (e.g., 5, 10, 15, 20, 25 µg/mL).

- Sample Preparation: Weigh and finely powder not less than 20 tablets. Accurately weigh a portion of the powder equivalent to about 25 mg of theophylline into a 250 mL volumetric flask. Add approximately 150 mL of solvent, sonicate for 15-30 minutes with intermittent shaking, allow to cool, and dilute to volume. Filter a portion of the solution through a 0.45 µm syringe filter, discarding the first few mL of the filtrate.

- Blank Solution: Prepare the solvent used for extraction as the blank.

- Measurement: Measure the absorbance of the calibration standards and the sample solution against the blank at 272 nm.

- 5. Data Analysis:

- Plot a calibration curve of absorbance versus concentration of the standard solutions.

- Determine the regression equation (y = mx + c) and the coefficient of determination (R²). A value of R² > 0.995 is typically expected.

- Calculate the concentration of theophylline in the sample solution using the regression equation.

- Calculate the % label claim using the following formula:

- % Label Claim = (Calculated Concentration × Dilution Factor × Average Tablet Weight) / (Weight of Sample Taken × Label Claim) × 100%

Protocol 2: In-Line Monitoring of API Content During Hot Melt Extrusion (HME) Using AQbD Principles

This protocol outlines the development and validation of an in-line UV-Vis method for real-time monitoring of piroxicam content in a polymer matrix during HME, following AQbD principles [22] [6].

- 1. Define the Analytical Target Profile (ATP): The ATP states that the method must predict the concentration of piroxicam in Kollidon VA 64 with an accuracy (trueness and precision) within ±5% acceptance limits.

- 2. Materials and Equipment:

- API: Piroxicam (PRX).

- Polymer: Kollidon VA 64.

- Equipment: Co-rotating twin-screw hot melt extruder.

- PAT Tool: In-line UV-Vis spectrophotometer with high-temperature optical probes configured in transmission mode, installed in the extruder die.

- 3. Risk Assessment: Perform a Failure Mode and Effect Analysis (FMEA) to identify and rank risks to the analytical procedure. Critical parameters may include probe window fouling, air bubbles in the melt, and spectral interference from polymer degradation.

- 4. Method Development and Calibration:

- Setup: Install the UV-Vis probes in the extruder die. Collect a reference transmittance spectrum with an empty, clean die at the process temperature (e.g., 140°C).

- Data Collection: Collect transmittance spectra in the range of 230-780 nm with a data collection frequency of 0.5 Hz during extrusion.

- Model Development: Prepare calibration batches with known concentrations of piroxicam (e.g., 10%, 15%, 20% w/w). Use the absorbance values at the API's λmax or develop a multivariate model to correlate the spectral data with the known API concentration.

- 5. Validation Based on Accuracy Profile:

- Perform validation experiments using independent sets at various concentration levels around the target (e.g., 15% w/w).

- Calculate the β-expectation tolerance intervals for each concentration level. The method is considered valid if the 95% tolerance limits fall within the pre-defined ±5% acceptance limits.

- 6. Testing Robustness: Deliberately vary critical process parameters, such as screw speed (150-250 rpm) and feed rate (5-9 g/min), to demonstrate that the piroxicam content prediction remains accurate and precise.

Advanced Applications and Techniques

Chemometrics-Assisted UV-Vis Spectroscopy

For formulations with multiple absorbing components, such as those containing two APIs or an API with impurities, spectral overlapping poses a significant challenge. Chemometrics provides a powerful solution by applying mathematical and statistical models to extract quantitative information from complex, overlapping spectra [24].

- Common Algorithms:

- Principal Component Analysis (PCA): An unsupervised technique used for pattern recognition, classification, and outlier detection.

- Partial Least Squares (PLS) Regression: A supervised technique that builds a model between spectral data and concentration data. It is the most widely used method for quantitative analysis of complex mixtures [23].

- Application Example: Simultaneous assay of Carbetocin (API) and L-Methionine (critical excipient) in a solution for injection. A single PLS model was developed using UV-Vis spectra, allowing for the in-line monitoring of both components' concentrations during continuous liquid flow manufacturing without the need for separation [23].

UV Hyperspectral Imaging

UV hyperspectral imaging is an emerging PAT tool that combines spatial and spectroscopic information. It generates a hypercube of data, allowing for the visualization of API distribution within a solid dosage form, such as a tablet [11].

- Principle: A pushbroom imaging system scans tablets on a conveyor belt, collecting a full spectrum at every pixel of the image, typically in the 225-400 nm range.

- Data Analysis: Principal Component Analysis (PCA) is applied to the hypercube to differentiate and classify tablets based on their API content and to identify heterogeneity or potential counterfeit products.

- Advantage: This non-destructive technique provides a rapid and comprehensive analysis of the chemical composition of solid dosage forms, making it highly suitable for 100% quality control in a production setting [11].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials, Reagents, and Equipment for UV-Vis API Analysis

| Item | Function / Role in Analysis | Example from Literature |

|---|---|---|

| UV-Vis Spectrophotometer | Measures the absorption of light by the sample. Can be benchtop, fiber-optic PAT, or imaging-based. | In-line system with optical probes for HME [22]; Hyperspectral imager for tablets [11]. |

| Quartz Cuvettes / High-Temp PAT Probes | Sample holders. Quartz is essential for UV range analysis. Specialized probes withstand process conditions (e.g., high temp/pressure). | Transmission probes installed in extruder die [22]; 1 mm quartz cuvette for solution analysis [11]. |

| Chemometric Software | For multivariate data analysis, model development (e.g., PLS), and data reduction (e.g., PCA). | PLS for simultaneous API/excipient assay [23]; PCA for hyperspectral image analysis [11]. |

| Chemical Standards (API, Excipients) | High-purity materials for developing and validating analytical methods, creating calibration curves, and specificity testing. | Piroxicam and Kollidon VA64 for HME [22]; Carbetocin and L-Methionine for solution assay [23]. |

| Suitable Solvents | To dissolve the sample without interfering spectrally in the region of interest (e.g., methanol, water, buffered solutions). | 0.1 M HCl:Methanol (1:1) for acetylsalicylic acid [11]; Methanol/Water for paracetamol [11]. |

| N-arachidonoyl-serotonin | N-arachidonoyl-serotonin, MF:C30H42N2O2, MW:462.7 g/mol | Chemical Reagent |

| Dihexyl L-aspartate | Dihexyl L-Aspartate |

Visualized Workflows

Drug Stability and Forced Degradation Studies for Shelf-Life Prediction

Within pharmaceutical quality control research, ensuring drug product stability is paramount for guaranteeing patient safety and therapeutic efficacy. A drug's shelf life, defined as the time period during which it maintains its intended identity, strength, quality, and purity, is directly determined through rigorous stability studies [25]. These studies are a regulatory requirement for all new drug applications. Forced degradation studies, also known as stress testing, are a proactive scientific approach used to intentionally degrade a drug substance or product under severe conditions. This process identifies potential degradation products, elucidates degradation pathways, and, crucially, helps develop stability-indicating analytical methods [25] [26]. UV-Vis spectroscopy serves as a cornerstone analytical technique in these endeavors due to its speed, accuracy, and economic viability for quantifying active pharmaceutical ingredients (APIs) and detecting contaminants that arise from decomposition [27]. This document details the application of UV-Vis spectroscopy within structured forced degradation protocols to accurately predict the shelf life of pharmaceutical products.

Fundamental Principles of Forced Degradation

Forced degradation is a scientific necessity that provides an insight into degradation pathways and the intrinsic stability of a molecule. It is performed under conditions more severe than those used in accelerated stability studies to generate relevant degradation products within a short timeframe [25] [26]. The primary objectives are to establish degradation pathways, elucidate the structure of degradation products, and most importantly, to develop and validate stability-indicating methods that can accurately monitor the quality of a drug product over time [25].

A key consideration in forced degradation is determining the extent of degradation. While regulatory guidelines do not specify exact limits, a degradation of the drug substance between 5% and 20% is generally considered acceptable for validating chromatographic assays, with 10% often viewed as an optimal target [25]. This ensures sufficient degradation products are generated without causing over-stressing, which may lead to secondary degradation products not representative of real-world conditions.

The following diagram illustrates the logical decision-making process and strategic workflow for designing a forced degradation study.

Experimental Protocols for Forced Degradation Studies

A minimal set of stress conditions must be investigated to comprehensively challenge the stability of a drug molecule. These typically include acid and base hydrolysis, thermal degradation, photolysis, and oxidation [25]. The following protocols provide a detailed methodology for conducting these studies, with UV-Vis spectroscopy as a primary analytical tool.

Recommended Stress Conditions

The table below summarizes the standard experimental conditions used for forced degradation studies to simulate various stress factors.

Table 1: Standard Conditions for Forced Degradation Studies [25]

| Degradation Type | Experimental Conditions | Commonly Used Storage Conditions | Sampling Time Points |

|---|---|---|---|

| Acid Hydrolysis | 0.1 M HCl | 40 °C, 60 °C | 1, 3, 5 days |

| Base Hydrolysis | 0.1 M NaOH | 40 °C, 60 °C | 1, 3, 5 days |

| Oxidation | 3% Hydrogen Peroxide (H₂O₂) | 25 °C, 60 °C | 1, 3, 5 days |

| Thermal | Solid or solution in heat chamber | 60 °C, 80 °C (with/without 75% RH) | 1, 3, 5 days |

| Photolytic | Exposure to UV/Visible light per ICH Q1B | 1x and 3x ICH energy levels | 1, 3, 5 days |

Detailed Methodological Workflow

The execution of a forced degradation study follows a systematic workflow from sample preparation to data analysis, as visualized below.

Protocol 1: Hydrolytic Degradation

- Preparation: Prepare a stock solution of the drug substance at a concentration of approximately 1 mg/mL in a suitable solvent [25].

- Stress Application: Aliquot 10 mL of the stock solution into three separate vials. Adjust one vial to 0.1 M HCl with concentrated acid, another to 0.1 M NaOH with concentrated base, and leave the third as a neutral control.

- Incubation: Store all vials at elevated temperatures (e.g., 40°C and 60°C) to accelerate the reaction [25].

- Sampling: Withdraw aliquots from each vial at predetermined time points (e.g., 24, 72, and 120 hours).

- Neutralization: For acid and base stress samples, neutralize the withdrawn aliquot immediately to stop the degradation process.

- Analysis: Dilute the samples as necessary and analyze using a UV-Vis spectrophotometer. Scan the absorption spectrum from 220 nm to 800 nm and note the absorbance at the λ_max of the API. A decrease in the API peak or the appearance of new spectral peaks indicates degradation [27].

Protocol 2: Oxidative Degradation

- Preparation: Prepare the drug solution as in Protocol 1.

- Stress Application: Add 3% (v/v) hydrogen peroxide (Hâ‚‚Oâ‚‚) to the drug solution. A control sample without oxidant must be prepared simultaneously.

- Incubation: Store the solutions at 25°C or 60°C [25].

- Sampling & Analysis: Withdraw aliquots at 24, 72, and 120 hours. Analyze directly via UV-Vis spectroscopy without further treatment, monitoring for changes in the spectral profile.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table lists essential materials and reagents required for executing the forced degradation protocols outlined in this document.

Table 2: Essential Reagents and Materials for Forced Degradation Studies

| Item | Function / Application | Specific Examples / Notes |

|---|---|---|

| Drug Substance/Product | The analyte under investigation for stability. | High-purity active pharmaceutical ingredient (API) or prototype formulation. |

| UV-Vis Spectrophotometer | Primary analytical tool for quantifying API loss and detecting degradants via spectral changes. | Instruments with scanning capability and temperature-controlled cuvette holders are preferred [27]. |

| Hydrochloric Acid (HCl) | Used for acid hydrolysis stress testing to simulate acid-induced degradation. | Typically used at 0.1 M concentration [25]. |

| Sodium Hydroxide (NaOH) | Used for base hydrolysis stress testing to simulate base-induced degradation. | Typically used at 0.1 M concentration [25]. |

| Hydrogen Peroxide (Hâ‚‚Oâ‚‚) | An oxidizing agent used to simulate oxidative degradation pathways. | Commonly used at 3% concentration [25]. |

| Thermostatically-Controlled Oven | Provides elevated temperature conditions for thermal stress testing of solid and liquid samples. | Capable of maintaining temperatures at 60°C and 80°C, with humidity control for solid-state studies [25]. |

| ICH-Q1B Compliant Light Cabinet | Provides controlled UV and visible light exposure for photostability testing. | Must meet the spectral output requirements specified in ICH Q1B guideline [25]. |

| Tafluprost ITS-1 | Tafluprost ITS-1 | Tafluprost ITS-1 is a potent prostaglandin F2α analog for research on intraocular pressure and aqueous humor dynamics. For Research Use Only. Not for human consumption. |

| N-(3-Sulfopropyl)-L-alanine | N-(3-Sulfopropyl)-L-alanine, CAS:819863-37-1, MF:C6H13NO5S, MW:211.24 g/mol | Chemical Reagent |

Data Interpretation and Shelf-Life Prediction

UV-Vis spectroscopy provides critical quantitative data for stability assessment. The fundamental measurement is the change in absorbance at the λ_max of the API. The percentage of API remaining at each time point under stress is calculated using the formula:

% API Remaining = (At / A0) × 100

Where A0 is the initial absorbance and At is the absorbance at time t. A plot of % API remaining versus time under each stress condition provides a visual representation of the drug's susceptibility to different stressors [27].

For shelf-life prediction, the data generated from forced degradation studies at elevated temperatures are used. The degradation rate constants (k) obtained at higher temperatures (e.g., 60°C and 80°C) can be fitted to the Arrhenius equation, which describes the temperature dependence of reaction rates. This model allows for the extrapolation of the degradation rate at intended storage temperatures (e.g., 25°C or 5°C). The time taken for the API to degrade to 90% of its initial concentration (the acceptable limit for many small molecules) at the storage temperature is then estimated as the predicted shelf life [25] [28]. This model-based approach, validated by real-time stability studies, provides a scientifically sound basis for assigning expiration dates to pharmaceutical products.

Forced degradation studies are an integral part of the regulatory submission process for new drugs. Agencies like the FDA and ICH require stress testing data to understand the intrinsic stability of a molecule and to validate that the analytical methods used in stability testing are truly stability-indicating [25] [29]. A well-developed stability-indicating method, often using UV-Vis spectroscopy as a rapid screening tool, ensures that any changes in the quality of the drug product over time can be accurately detected and measured.

In conclusion, forced degradation studies are a vital predictive tool in pharmaceutical development. When combined with robust analytical techniques like UV-Vis spectroscopy, they provide invaluable insights into drug stability, guide the formulation and packaging development, and ultimately ensure that safe and effective medicines with a scientifically justified shelf life reach the patient. The protocols and methodologies detailed in this application note provide a structured framework for researchers to implement these critical studies within a pharmaceutical quality control context.

Dissolution Testing and UV Dissolution Imaging for Release Profiling

This application note provides a detailed examination of dissolution testing and UV dissolution imaging as critical tools for drug release profiling in pharmaceutical development. Intended for researchers and drug development professionals, this document outlines standardized protocols, data interpretation methods, and practical applications of these techniques within quality control frameworks. We present specific case studies and experimental data to illustrate how these methodologies enable precise characterization of drug release kinetics and performance under physiologically relevant conditions.

Dissolution testing serves as a cornerstone of pharmaceutical quality control and drug development, providing critical insights into the release characteristics of active pharmaceutical ingredients (APIs) from dosage forms. When combined with the analytical power of UV-Vis spectroscopy, this technique enables comprehensive drug release profiling essential for predicting in vivo performance, particularly for poorly soluble drugs where dissolution is the rate-limiting step for absorption [30] [31].

UV-Vis spectroscopy offers a cost-effective, simple, versatile, and non-destructive analytical technique suitable for a broad spectrum of organic compounds and some inorganic species [32]. The fundamental principle involves measuring the absorption or transmission of discrete wavelengths of UV or visible light as a function of wavelength, which provides information about sample composition and concentration [3]. When applied to dissolution testing, this enables real-time monitoring of drug release kinetics with high temporal resolution.

The emergence of UV dissolution imaging represents a significant technological advancement, generating spatially and temporally resolved absorbance maps that visualize and quantify dissolution phenomena directly [33]. This technique has expanded applications from determining intrinsic dissolution rates to monitoring drug release from complex dosage forms and profiling drug diffusion and transport processes.

Theoretical Background

Fundamentals of UV-Vis Spectroscopy in Dissolution Testing

UV-Vis spectroscopy measures the amount of discrete wavelengths of UV (100-400 nm) or visible (400-780 nm) light absorbed by or transmitted through a sample relative to a reference blank [3]. The technique operates on the principle that molecules containing π-electrons or non-bonding electrons (n-electrons) can absorb ultraviolet or visible light energy, promoting electrons to higher anti-bonding molecular orbitals [32].

The relationship between light absorption and analyte concentration is governed by the Beer-Lambert Law:

A = ε × c × L

Where:

- A = Absorbance (no units)

- ε = Molar absorptivity (L·molâ»Â¹Â·cmâ»Â¹)

- c = Concentration (mol·Lâ»Â¹)

- L = Path length (cm)

This relationship forms the quantitative foundation for determining drug concentration during dissolution testing [3]. For dissolution imaging, this principle is extended to generate spatially resolved concentration maps, providing unprecedented insight into localized dissolution phenomena at solid-liquid interfaces [33].

Critical Factors Influencing Dissolution

For weakly basic BCS Class II drugs, dissolution exhibits complex dependence on multiple physiological factors:

- pH dependence: Significantly affects solubility, especially for weakly basic drugs with pKa values in the physiological range [31]

- Buffer capacity: Influences the ability to maintain sink conditions during dissolution [31]

- Ionic strength: Impacts solubility through common ion effects and solution thermodynamics [31]

- Buffer species: May form salts with drug molecules of varying solubility, directly affecting dissolution profiles [31]

Equipment and Reagents

Research Reagent Solutions and Essential Materials

Table 1: Essential research reagents and materials for dissolution testing with UV detection

| Item | Function/Application | Specifications |

|---|---|---|

| UV-Vis Spectrophotometer | Quantification of drug concentration in dissolution media | Includes light source, wavelength selector, sample holder, detector [3] |

| Quartz Cuvettes | Sample holder for UV range measurements | Transparent to UV light; path lengths 1 mm to 10 mm [3] |

| Diffraction Grating Monochromator | Wavelength selection | 1200-2000 grooves/mm; blazed holographic for better resolution [3] |

| Phosphate Buffer Salts (NaHâ‚‚POâ‚„, Naâ‚‚HPOâ‚„) | Preparation of physiologically relevant dissolution media | pH range 6.5-7.8; various molarities (6.25-100 mM) [31] |

| Simulated Gastrointestinal Fluids (FaSSGF, FeSSGF, FaSSIF, FeSSIF) | Biorelevant dissolution media | Mimics fasted/fed state conditions [31] |

| Hydrochloric Acid (HCl) | Simulated gastric fluid preparation | 0.7% HCl (pH ~1.5) to 83.7 mM (pH ~1.2) [31] |

| Acetate Buffer Components (CH₃COOH, CH₃COONa·3H₂O) | Acidic dissolution media | pH 4.5-5.0 for duodenal conditions [31] |

UV Dissolution Imaging Systems

Specialized UV imaging systems incorporate UV light sources, high-resolution CCD detectors, and flow-through cells that enable spatial resolution of dissolution phenomena. These systems provide both temporal and spatial information about drug release, allowing researchers to visualize concentration gradients and interfacial processes during dissolution [33].

Experimental Protocols

Protocol 1: pH-Dependent Solubility and Dissolution Profiling

This protocol uses carvedilol, a weakly basic BCS Class II drug (pKa 7.8), as a model compound to demonstrate the effects of physiological pH variations on dissolution behavior [31].

Materials and Preparation

- API: Carvedilol powder

- Media Preparation: Prepare simulated gastrointestinal fluids covering physiological pH range:

- Gastric fluids: 0.7% HCl (pH 1.5), SGFsp (pH 1.2), blank FaSSGF (pH 1.6), blank FeSSGF (pH 5.0)

- Intestinal fluids: Acetate buffer (pH 4.5), blank FeSSIF (pH 5.0), blank FaSSIF (pH 6.5), Phosphate buffer (pH 6.8), Phosphate buffers (pH 7.2, 7.8)

- Instrumentation: USP-compliant dissolution apparatus with UV-Vis spectrophotometer or fiber-optic detection system

Procedure

Equilibrium Solubility Determination:

- Place excess carvedilol in each dissolution medium

- Agitate at constant temperature (37±0.5°C) for 24 hours

- Filter samples through 0.45μm membrane filter

- Dilute filtrate appropriately and measure absorbance at λmax

- Calculate concentration using Beer-Lambert law with established calibration curve

Dissolution Testing:

- Use USP Apparatus I (baskets) or II (paddles) maintained at 37±0.5°C

- Set rotational speed to 50-75 rpm

- For immediate-release tablets, employ 900mL dissolution medium

- Withdraw samples automatically (via perfusion) or manually at predetermined time points

- Filter samples immediately through 0.45μm membrane filter

- Analyze drug concentration using UV-Vis spectrophotometry at λmax=285nm

- Perform measurements in triplicate for statistical significance

Data Analysis:

- Calculate mean cumulative drug release at each time point

- Plot release profiles (percentage released vs. time)

- Compute similarity factors (f2) for profile comparisons

- Determine dissolution efficiency and mean dissolution time

Expected Results

Table 2: Carvedilol solubility and dissolution across physiological pH range

| Medium | pH | Solubility (μg/mL) | % Released at 60 min | Biorelevance |

|---|---|---|---|---|

| 0.7% HCl | 1.5 | 545.1 | 95.8-98.2 | Gastric (fasted) |

| SGFsp | 1.2 | 2591.4 | 95.8-98.2 | Gastric (fasted) |

| Blank FeSSGF | 5.0 | 2591.4 | 95.8-98.2 | Gastric (fed) |

| Acetate Buffer | 4.5 | 2591.4 | 95.8-98.2 | Duodenal |

| Blank FeSSIF | 5.0 | 51.9 | 15.9-86.2 | Proximal Jejunum |

| Blank FaSSIF | 6.5 | 12.6 | 15.9-86.2 | Distal Jejunum |

| Phosphate Buffer | 6.8 | 8.7 | 15.9-86.2 | Ileum |

| Phosphate Buffer | 7.8 | 5.8 | 15.9-86.2 | Colon |

The data demonstrates the dramatic pH-dependent solubility and dissolution behavior characteristic of weakly basic drugs. Complete release occurs in gastric conditions (pH 1.2-5.0), while significantly reduced release is observed in intestinal conditions (pH 6.5-7.8) [31].

Protocol 2: IVRT Kinetic Monitoring of Semisolid Formulations Using UV-Vis Spectrophotometry

This protocol adapts Higuchi's square root approximation for rapid in vitro release testing (IVRT) of semisolid formulations using UV-Vis spectrophotometry, substantially reducing analysis time from hours to minutes [34].

Materials and Preparation

- Formulations: Hydrocortisone creams (0.5% and 1.0%)

- Receptor Solution: Methanol

- Instrumentation: UV-Vis spectrophotometer with quartz cuvette

- Membrane: Appropriate inert membrane (validated via HPLC)

Procedure

Experimental Setup:

- Place receptor solution (methanol) in spectrophotometer cuvette

- Position membrane appropriately in the diffusion cell setup

- Apply semisolid formulation uniformly to membrane

Kinetic Monitoring:

- Initiate release experiment

- Collect absorbance measurements at λ=242nm every 15 seconds for 5 minutes

- Maintain temperature control throughout experiment

- Perform six measurements per formulation over multiple days for precision assessment

Data Analysis:

- Plot absorbance at 242nm versus square root of time (√t)

- Calculate release rates from the slope of the linear region

- Determine correlation coefficient (r²) for linearity assessment

- Perform statistical comparison of release rates between different strength formulations

Method Validation

- Specificity: Demonstrate via HPLC comparison with USP traceable reference standard

- Sensitivity and Selectivity: Show statistically different release rates between 0.5% and 1.0% formulations

- Linearity: Achieve r² value ≥0.97 throughout assay duration

- Precision: Maintain %CV values ≤15% for both intra-run and inter-run experiments

Protocol 3: UV Dissolution Imaging for Intrinsic Dissolution Rate Determination

This protocol utilizes UV dissolution imaging to determine intrinsic dissolution rates (IDR) with spatial and temporal resolution [33].

Materials and Preparation

- API: Drug substance compact (prepared under controlled compression)

- Media: Physiologically relevant dissolution media

- Instrumentation: UV dissolution imaging system with appropriate flow-through cell

Procedure

Sample Preparation:

- Compress drug powder into compact using hydraulic press

- Mount compact in imaging cell ensuring flat surface exposure

Imaging Conditions:

- Set appropriate UV wavelength based on drug chromophore

- Establish flow rate to maintain sink conditions

- Calibrate system with standard solutions

Image Acquisition:

- Initiate dissolution with media flow

- Capture sequential images at predetermined intervals

- Maintain temperature at 37±0.5°C throughout experiment

Data Analysis:

- Convert absorbance maps to concentration profiles

- Determine concentration gradients at solid-liquid interface

- Calculate flux and intrinsic dissolution rates

- Model drug diffusion and transport processes

Data Analysis and Interpretation

Dissolution Profile Comparison