UV-Vis Spectroscopy in Tablet Dissolution: From Foundational Principles to Advanced Imaging and Real-Time Release

This article provides a comprehensive overview of the application of UV-Vis spectroscopy in the dissolution testing of solid oral dosage forms, tailored for researchers, scientists, and drug development professionals.

UV-Vis Spectroscopy in Tablet Dissolution: From Foundational Principles to Advanced Imaging and Real-Time Release

Abstract

This article provides a comprehensive overview of the application of UV-Vis spectroscopy in the dissolution testing of solid oral dosage forms, tailored for researchers, scientists, and drug development professionals. It explores the foundational principles of UV-Vis spectroscopy and its intrinsic link to dissolution testing, detailing traditional and advanced methodological approaches, including fiber-optic probes and cutting-edge UV surface dissolution imaging (SDI). The content further addresses common troubleshooting and optimization strategies for both instrumental and sample-related challenges, and concludes with a rigorous examination of method validation as per ICH guidelines and a comparative analysis with other spectroscopic techniques. This scope ensures a holistic understanding, from fundamental theory to the implementation of real-time release testing (RTRT) in modern pharmaceutical development.

The Principles and Evolution of UV-Vis Spectroscopy in Dissolution Testing

Ultraviolet-Visible (UV-Vis) spectroscopy serves as a cornerstone analytical technique in pharmaceutical development, particularly for the quantitative analysis of drug release and dissolution. The quantification capability of this technique fundamentally relies on the Beer-Lambert Law (also known as Beer's Law), which provides the theoretical foundation relating light absorption to analyte concentration [1] [2]. This principle is indispensable for researchers and scientists engaged in formulating robust and predictive dissolution tests, which are critical for ensuring drug product quality and performance.

Within the context of drug development, the application of the Beer-Lambert Law allows for the real-time monitoring of active pharmaceutical ingredients (APIs) as they dissolve from solid dosage forms, such as tablets, into solution [3] [4]. A precise understanding of this law, its operational parameters, and its limitations is therefore essential for accurately determining key kinetic parameters like dissolution rates and diffusion coefficients, which ultimately inform product development and regulatory submissions.

Core Principles of the Beer-Lambert Law

The Beer-Lambert Law establishes a linear relationship between the absorbance of light by a solution and the concentration of the absorbing species within it [5]. It is a combination of Beer's law, which states that absorbance is proportional to concentration, and Lambert's law, which states that absorbance is proportional to the path length of the light through the sample [6].

Mathematical Formulation

The law is mathematically expressed as:

A = ε * c * l

Where:

- A is the Absorbance (also known as optical density), a dimensionless quantity [5] [1].

- ε is the Molar Absorptivity (or molar extinction coefficient), with units of L·mol⁻¹·cm⁻¹. This is a compound-specific constant that indicates how strongly a chemical species absorbs light at a particular wavelength [5] [1].

- c is the Concentration of the absorbing solute, typically expressed in mol·L⁻¹ (M) [5].

- l is the Path Length, which is the distance the light travels through the sample, usually measured in centimeters (cm) [5].

The absorbance, A, is defined by the ratio of the incident light intensity ((I_0)) to the transmitted light intensity ((I)) [5] [1]:

A = log₁₀ (I₀ / I)

This logarithmic relationship means that absorbance increases as the transmittance (T = I / I₀) decreases. The table below illustrates this inverse correlation.

Table 1: Relationship between Absorbance, Transmittance, and Light Transmission

| Absorbance (A) | Transmittance (T) | % Transmittance (%T) | Light Transmitted |

|---|---|---|---|

| 0 | 1 | 100% | All light passes through |

| 1 | 0.1 | 10% | 10% of light passes through |

| 2 | 0.01 | 1% | 1% of light passes through |

| 3 | 0.001 | 0.1% | 0.1% of light passes through [1] |

Electronic Transitions and Chromophores

The physical basis for light absorption in the UV-Vis range involves the promotion of electrons from a ground state to an excited state within molecules [7] [8]. These electronic transitions require a specific quantum of energy, which is provided by photons of a particular wavelength. Molecules that contain chromophores, which are functional groups capable of absorbing UV or visible light (e.g., C=C, C=O, aromatic rings), undergo these transitions [7]. The specific wavelength of maximum absorbance (λ_max) is a characteristic property of a given chromophore and its molecular environment.

Practical Application in Drug Release Quantification

In dissolution testing, the goal is to measure the concentration of a dissolved API in a dissolution medium over time. The Beer-Lambert Law facilitates this by enabling the construction of a calibration curve.

Establishing a Calibration Curve

A series of standard solutions with known concentrations of the API are prepared. The absorbance of each standard is measured at the API's λ_max, and a plot of Absorbance versus Concentration is generated [1]. For a system obeying the Beer-Lambert Law, this plot will be a straight line passing through the origin, with a slope of ε*l [5]. The concentration of an unknown sample from a dissolution test can then be accurately determined by measuring its absorbance and interpolating from this calibration curve [1] [2].

Table 2: Example Calibration Data for a Hypothetical API

| Standard Solution | Concentration (μg/mL) | Absorbance at λ_max |

|---|---|---|

| Blank | 0.00 | 0.000 |

| 1 | 5.00 | 0.125 |

| 2 | 10.00 | 0.249 |

| 3 | 15.00 | 0.381 |

| 4 | 20.00 | 0.503 |

| 5 | 25.00 | 0.620 |

Experimental Protocol: Quantifying Drug Release from a Tablet

The following protocol details the steps for using UV-Vis spectroscopy to monitor the dissolution profile of a drug tablet.

Protocol Title: Determination of Drug Release Kinetics using UV-Vis Spectroscopy.

Principle: As a tablet dissolves in a dissolution apparatus, the concentration of the API in the medium increases. Sequentially withdrawn samples are analyzed via UV-Vis spectroscopy to construct a release profile [3] [4].

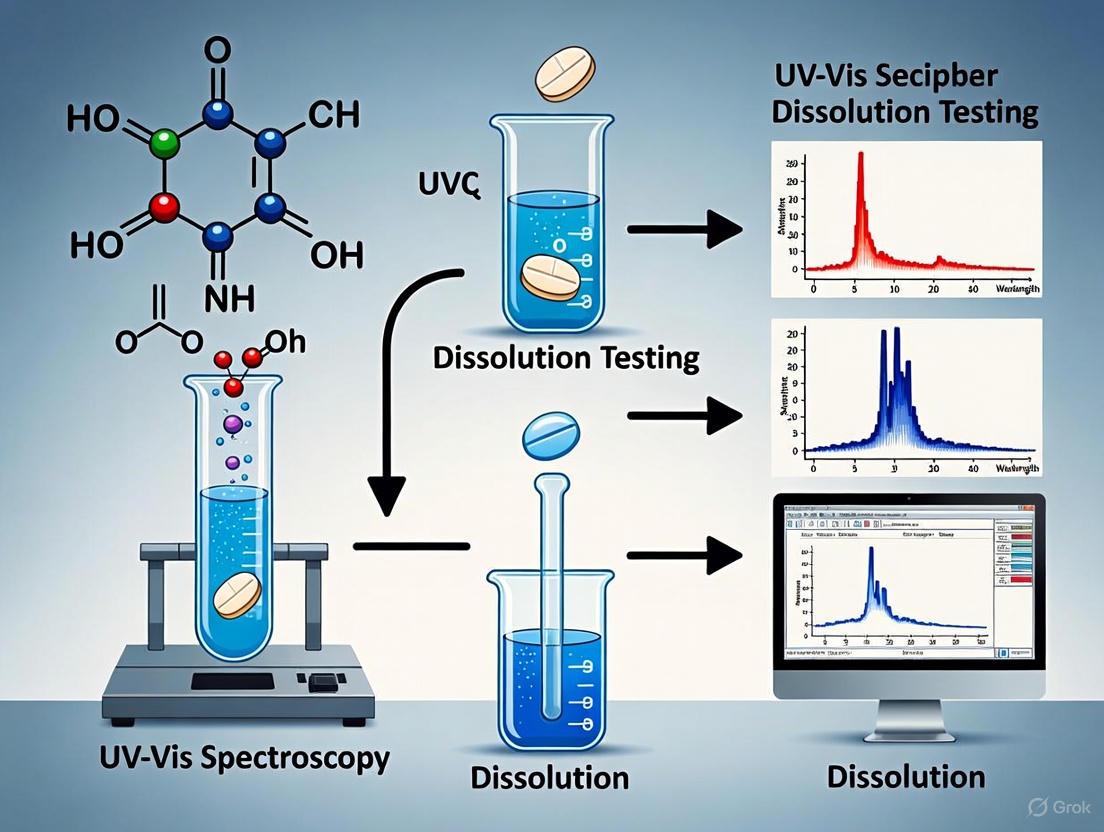

Diagram 1: Drug release quantification workflow.

Materials and Equipment:

- Dissolution apparatus (e.g., USP Type I or II)

- UV-Vis spectrophotometer

- Cuvettes (e.g., quartz with 1 cm path length)

- Volumetric flasks, pipettes

- Membrane filters (e.g., 0.45 μm)

- Dissolution medium (e.g., buffer at pH 1.2, 4.5, or 6.8)

- Standard reference of the API

Procedure:

- Calibration Curve Generation:

- Prepare a stock solution of the API with a known, high concentration.

- Dilute the stock solution serially to create at least five standard solutions covering a concentration range expected during dissolution.

- Measure the absorbance of each standard and the blank (dissolution medium) at the predetermined λ_max.

- Plot absorbance versus concentration and perform linear regression. The R² value should be >0.995.

Dissolution Testing:

- Place the dissolution medium into the apparatus and allow it to equilibrate to 37.0±0.5 °C.

- Introduce the tablet into the vessel and start the agitation (e.g., 50 rpm for paddles).

- Sampling: At predetermined time intervals (e.g., 5, 10, 15, 30, 45, 60 minutes), withdraw a small aliquot (e.g., 2-5 mL) from the vessel.

- Filtration: Immediately pass the sample through a syringe filter to remove any undissolved particles, which can scatter light and cause analytical errors [4].

- Analysis: Transfer the filtered sample to a cuvette and measure its absorbance at λ_max against a blank of fresh dissolution medium.

Data Analysis:

- Use the equation from the calibration curve to calculate the concentration of the API in each sample.

- Calculate the cumulative amount of drug released per volume, and then as a percentage of the tablet's label claim.

- Plot the cumulative drug release (%) versus time to generate the dissolution profile.

Advanced Application: Measuring Diffusion Coefficients

Understanding drug diffusion is critical for predicting in vivo performance. UV-Vis spectroscopy, coupled with the Beer-Lambert Law, can be adapted to measure the diffusion coefficients of small molecules and proteins [3].

Experimental Protocol: Diffusion Cell Method

Protocol Title: UV-Vis Based Measurement of Diffusion Coefficient.

Principle: A custom diffusion cell is created, often by modifying a standard cuvette with a physical barrier or a 3D-printed cover with a slit [3]. The drug diffuses from a high-concentration zone to a low-concentration zone. The changing concentration in the diffusion path is monitored via UV-Vis, and Fick's laws of diffusion are applied to calculate the diffusion coefficient.

Diagram 2: Diffusion coefficient measurement workflow.

Procedure:

- Cell Preparation: A cover with a defined horizontal slit is attached to a cuvette, restricting the light path to a specific height [3].

- Experiment Initiation: The cuvette is filled with a clear dissolution medium or polymer solution. A concentrated drug solution is carefully introduced at the bottom.

- Data Collection: The absorbance at the slit height is measured continuously or at frequent intervals as drug molecules diffuse upwards.

- Calculation: The resulting concentration-time data is fitted to mathematical models derived from Fick's second law of diffusion, using either analytical or numerical approaches, to determine the diffusion coefficient (D) [3]. This method has been shown to produce results with high reproducibility [3].

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagents and Materials for UV-Vis Based Dissolution Studies

| Item | Function / Purpose | Key Considerations |

|---|---|---|

| API Standard | Serves as the reference material for calibration curve generation. | Must be of high and known purity (e.g., pharmacopeial grade). |

| Dissolution Media Buffers | Mimic physiological pH conditions (e.g., gastric pH 1.2, intestinal pH 6.8). | Buffer concentration and ionic strength can affect diffusivity [3] [9]. |

| Quartz Cuvettes | Hold the sample for absorbance measurement. | Quartz is transparent to UV light; plastic cuvettes are not suitable for UV analysis [2]. |

| Membrane Filters | Remove undissolved particles from withdrawn samples to prevent light scattering [4]. | Pore size (e.g., 0.45 μm) must not adsorb the API. Material compatibility should be verified. |

| Polymer Solutions (e.g., HPMC, PVP) | Used to simulate viscous biological fluids or as formulation components in diffusion studies. | Viscosity can significantly impact diffusion coefficients [3]. |

Critical Considerations and Troubleshooting

While the Beer-Lambert Law is foundational, spectroscopists must be aware of its limitations to avoid analytical inaccuracies. Deviations from linearity can be categorized as follows:

Real Deviations (Fundamental Limitations)

- High Concentration: At high concentrations (>10 mM), electrostatic interactions between solute molecules can alter the molar absorptivity (ε). Additionally, high analyte levels can change the refractive index of the solution, leading to non-linearity [9].

- Optical Effects: The classical derivation of the Beer-Lambert law does not fully account for electromagnetic effects, such as changes in the local field, which can become significant, particularly in condensed phases or at high absorbances [10].

Chemical Deviations

- Equilibria: The analyte may undergo concentration-dependent chemical changes such as association, dissociation, dimerization, or reaction with the solvent, leading to species with different absorption spectra [9]. For example, the absorption spectrum of a molecule like phenol red is highly dependent on the pH of the solvent [9].

- Stray Light: Stray radiation outside the nominal wavelength band reaching the detector can cause deviations, especially at high absorbances where the signal-to-noise ratio is low [9].

- Instrumental Deviations

- Polychromatic Light: The law assumes a monochromatic light source. In practice, spectrophotometers use a band of wavelengths. If the molar absorptivity (ε) changes significantly across this bandwidth, non-linearity will result. This is a primary reason for performing measurements at λ_max, where the absorptivity is relatively flat [9].

- Mismatched Cuvettes: Using sample and reference cells with different path lengths or optical properties will introduce a constant systematic error [9].

Best Practices to Mitigate Deviations

- Ensure absorbance readings for quantification fall within the validated linear range of the instrument, typically below 1.0 [2].

- Always use high-quality, matched quartz cuvettes.

- Confirm the monochromaticity of the light and perform measurements at λ_max.

- Use appropriate blank solutions and ensure the sample is free of undissolved particles or air bubbles.

In the pharmaceutical sciences, dissolution testing stands as a critical analytical procedure for assessing drug release from solid oral dosage forms. Throughout the development of this essential quality control test, a natural bond has been established between dissolution and UV spectroscopy for the quantification of active pharmaceutical ingredients (APIs) [11]. This partnership remains fundamental to modern pharmaceutical analysis due to its practical advantages and analytical robustness.

UV spectroscopy has long been the pharmaceutical chemist's traditional method and first option for analyzing dissolution testing results [12]. The technique's fundamental principle—measuring the absorbance of ultraviolet light by dissolved API molecules at specific wavelengths—provides a direct means of quantifying concentration in dissolution media. This simple yet powerful relationship, governed by the Beer-Lambert law, enables researchers to accurately determine API release profiles under physiologically relevant conditions [13] [11].

This application note explores the technical foundations of this synergistic relationship, presents detailed experimental protocols for various dissolution testing scenarios, and examines emerging technologies that build upon this fundamental analytical bond.

Fundamental Advantages of UV Spectroscopy in Dissolution Testing

Practical and Economic Benefits

The enduring partnership between dissolution testing and UV spectroscopy is underpinned by significant practical and economic advantages that make it particularly suitable for pharmaceutical quality control and research settings.

Table 1: Comparative Analysis of UV Spectroscopy vs. HPLC for Dissolution Testing

| Parameter | UV Spectroscopy | HPLC with UV Detection |

|---|---|---|

| Cost per analysis | Low | High (nicknamed "high priced liquid chromatography") |

| Solvent consumption | Aqueous dissolution media only | Organic solvents for mobile phase + disposal costs |

| Equipment maintenance | Minimal | Columns, pumps, and detectors requiring maintenance |

| Sample preparation | Minimal, often just filtration | Transfer to vials, sometimes dilution |

| Analysis time | Seconds to minutes | Minutes to per sample |

| Method validation | Simpler parameters | Additional system suitability parameters (peak symmetry, column plate counts) |

| Data trending | Immediate | Requires data processing |

The economic argument for UV spectroscopy is compelling. As noted by industry experts, HPLC has earned the nickname "high priced liquid chromatography" in some circles due to costs associated with organic solvents, disposal, equipment acquisition, maintenance, and depreciation [12]. UV spectroscopy eliminates many of these expenses, providing significant cost savings for pharmaceutical manufacturers, particularly for routine quality control testing where large numbers of samples are analyzed daily [12].

The speed of analysis represents another significant advantage. A single absorbance value is used to determine concentration, unlike HPLC which requires separation time for each sample [12]. When coupled with sipper systems, UV spectroscopy allows for rapid analysis of samples immediately following dissolution experiments, increasing laboratory throughput and efficiency [12].

Technical and Workflow Advantages

Beyond economic considerations, UV spectroscopy offers substantial technical benefits that strengthen its position in dissolution testing protocols:

- Reduced Complexity: UV methods eliminate HPLC mobile phase preparation, reduce system suitability requirements, and minimize potential analyst errors associated with multiple transfer steps [12].

- Immediate Data Interpretation: Understanding data for trending or investigating potential sources of laboratory errors can be immediate, allowing issues to be resolved quickly under supervision [12].

- Real-time Monitoring Capability: Fiber-optic UV systems enable continuous in-situ measurement of the dissolution process, generating more frequent data points (up to 1/second) for more accurate real-time dissolution profiles [11].

- Regulatory Acceptance: Well-established UV methods are widely accepted by regulatory agencies with clearly defined validation pathways according to ICH Q2 guidelines [14].

Despite these advantages, situations exist where HPLC offers necessary capabilities beyond UV spectroscopy, particularly when dealing with complex formulations where excipients or degradation products absorb at similar wavelengths as the API, requiring chromatographic separation for accurate quantification [12].

Experimental Protocols

Standard UV Spectroscopy for Dissolution Testing

This protocol outlines the standard procedure for quantifying API release using offline UV spectroscopy analysis of dissolution samples.

Table 2: Research Reagent Solutions for Standard UV Dissolution Testing

| Reagent/Material | Specification | Function in Protocol |

|---|---|---|

| Dissolution Medium | USP-specified buffer (e.g., pH 1.2, 4.5, 6.8) | Simulates gastrointestinal conditions for drug release |

| API Reference Standard | Certified purity (>98%) | Calibration curve generation and method validation |

| Filter Membranes | 0.45 μm porosity, compatible with API | Clarification of withdrawn samples by removing particulate matter |

| UV Cuvettes | Quartz, pathlength 1 cm | Holder for liquid samples during spectrophotometric measurement |

| Degassing System | In-line or vacuum filtration | Removal of dissolved gases from dissolution medium to prevent bubble formation |

Workflow Overview

Step-by-Step Procedure

Dissolution Apparatus Setup

- Fill dissolution vessels with 500-900 mL of appropriately selected and degassed medium per USP requirements

- Equilibrate medium to 37.0°C ± 0.5°C

- Place one dosage unit in each vessel following USP Apparatus 1 (basket) or 2 (paddle) specifications

Sample Collection

- Withdraw appropriate aliquot (typically 5-10 mL) from each vessel at predetermined time points using automated sampler or manual syringe

- Immediately replace with equal volume of fresh medium maintained at 37°C to maintain constant volume

- Filter samples through 0.45 μm membrane filters to remove insoluble particulates

UV Spectrophotometric Analysis

- Measure absorbance of filtered samples at predetermined λmax for API using UV spectrophotometer

- Use appropriate blank (dissolution medium) to zero instrument

- Ensure absorbance values fall within linear range of calibration curve (typically 0.2-1.0 AU)

Data Analysis

- Calculate API concentration using pre-established calibration curve (A = εbc)

- Determine cumulative drug release at each time point, correcting for sample removal

- Plot dissolution profile (percentage released vs. time)

Method Validation Parameters

- Linearity: R² > 0.995 over specified concentration range

- Precision: RSD < 2% for repeatability

- Accuracy: 98-102% recovery of spiked samples

- Specificity: No interference from excipients or degradation products

Fiber-Optic UV Dissolution Testing

Fiber-optic dissolution testing (FODT) represents an advanced approach that enables real-time, in-situ monitoring of the dissolution process without manual sampling [14] [11].

Workflow Overview

Step-by-Step Procedure

System Configuration

- Install fiber-optic probes in each dissolution vessel positioned to monitor representative fluid region

- Connect probes to UV spectrophotometer with photodiode array (PDA) or charge-coupled device (CCD) detector

- Configure software for continuous spectral acquisition (e.g., every 10-30 seconds)

Calibration

- Develop multivariate calibration model using standard solutions covering expected concentration range

- Include potential interferents in model development for complex formulations

- Validate model with independent standard set (accuracy 98-102%)

Dissolution Testing

- Initiate dissolution test following standard USP procedures

- Begin continuous spectral acquisition throughout test duration

- Monitor system performance for consistent light transmission

Data Processing

- Process spectral data using appropriate algorithms to convert absorbance to concentration

- Apply background correction and pathlength normalization as needed

- Generate complete dissolution profile with high temporal resolution

Advantages of FODT

- Eliminates manual sampling and associated errors [14]

- Provides high-density data points for accurate profile generation [11]

- Enables real-time release testing with immediate results [14]

- Redances labor requirements and consumable costs [11]

UV Surface Dissolution Imaging

UV dissolution imaging is an emerging technology that provides visualization of dissolution phenomena at the solid-liquid interface with high spatial and temporal resolution [13].

Step-by-Step Procedure

Sample Preparation

- Compact API powder or formulation into pellet using sample cup

- Apply consistent compression force (e.g., 40 cNm torque) for reproducible surface characteristics

- For formulated products, core sample from tablet using appropriate tooling

Instrument Setup

- Mount sample cup at bottom of quartz flow cell with sample surface facing upward

- Set flow rate of dissolution medium using programmable syringe pump (typically 0.01-0.5 mL/min)

- Select appropriate UV wavelength using band pass filter based on API absorbance characteristics

- Focus UV imaging system on sample surface interface

Image Acquisition

- Initiate flow of dissolution medium across sample surface

- Begin time-resolved image acquisition using CMOS array detector

- Continue acquisition throughout dissolution experiment (typically 30-120 minutes)

Data Analysis

- Analyze sequence of UV images to determine drug concentration gradients near interface

- Calculate flux and intrinsic dissolution rate using appropriate mathematical models

- Correlate dissolution behavior with physical changes observed at surface

Application Notes

- Particularly valuable for studying API behavior including single crystal dissolution and intrinsic dissolution of different crystal forms [11]

- Useful for examining drug-excipient interactions and release mechanisms [13]

- Enables visualization of concentration gradients not apparent in bulk solution measurements [13]

Advanced Applications and Emerging Approaches

UV Spectroscopy in Quality by Design and Real-Time Release

The integration of UV spectroscopy with Quality by Design (QbD) principles and real-time release testing (RTRT) represents the cutting edge of pharmaceutical analysis [15] [14]. Implementation of Analytical Quality by Design (AQbD) approaches for UV-based methods involves establishing an Analytical Target Profile (ATP) that defines method performance requirements [15].

For continuous manufacturing platforms, UV spectroscopy serves as a vital process analytical technology (PAT) tool. The methodology has been successfully applied to monitor API content during hot melt extrusion processes, demonstrating that in-line UV-Vis spectroscopy is a robust and practical PAT tool for monitoring critical quality attributes [15]. These applications highlight the expanding role of UV spectroscopy beyond traditional quality control toward integrated process understanding and control.

Addressing Technical Challenges

Despite its widespread utility, UV spectroscopy faces challenges in complex analytical scenarios:

Multicomponent Formulations For formulations containing multiple APIs with overlapping UV spectra, several approaches can maintain methodology effectiveness:

- Fiber-optic systems with multivariate calibration capable of deconvoluting spectral signals [14]

- Mathematical modeling using partial least squares and peak area models [14]

- Implementation of multi-wavelength monitoring and derivative spectroscopy

Interfering Excipients When excipients interfere with API quantification:

- Employ chromatographic separation (HPLC) when specificity cannot be achieved [12]

- Utilize advanced spectral processing algorithms to account for background interference [14]

- Implement standard addition methods to verify accuracy in complex matrices

Table 3: Troubleshooting Guide for UV Dissolution Methods

| Issue | Potential Causes | Recommended Solutions |

|---|---|---|

| Poor reproducibility between vessels | Inadequate degassing, temperature gradients | Implement strict degassing protocols, verify temperature uniformity |

| Deviation from reference method | Spectral interferences, improper wavelength selection | Verify method specificity, confirm λmax with standard solutions |

| Non-linear calibration | Stray light effects, incorrect dilution scheme | Verify linear range, check instrument performance, prepare fresh standards |

| Fiber-optic signal drift | Probe fouling, source intensity variation | Implement reference channel, clean probes regularly |

The natural bond between dissolution testing and UV spectroscopy remains as relevant today as in the early development of pharmaceutical analysis. The technique's fundamental advantages of cost-effectiveness, speed, simplicity, and reliability ensure its continued prominence in pharmaceutical laboratories worldwide [12]. While HPLC remains necessary for specific applications requiring separation, UV spectroscopy provides an optimal balance of performance and practicality for the majority of dissolution testing scenarios.

Emerging technologies including fiber-optic UV systems, UV dissolution imaging, and advanced spectral processing are strengthening this natural bond by extending applications to more complex formulations and enabling real-time release testing [13] [14] [11]. These advancements, coupled with the established regulatory acceptance and straightforward validation pathways, position UV spectroscopy as the cornerstone technique for dissolution testing now and into the foreseeable future.

As the pharmaceutical industry continues to evolve with increased emphasis on continuous manufacturing and real-time quality assurance, the flexibility and adaptability of UV spectroscopic methods will ensure this natural bond grows even stronger, continuing to serve as the foundation for understanding and controlling drug product performance.

Traditional drug dissolution testing has predominantly relied on methods that measure the active pharmaceutical ingredient (API) in the bulk solution, offering limited insight into the underlying release mechanisms [13]. There is now a significant drive within pharmaceutical research and development towards real-time analysis and continuous monitoring methods that can provide a more profound understanding of drug release phenomena [13]. This shift is crucial for enhancing product quality, optimizing formulations, and accelerating drug development processes.

Advanced techniques such as UV dissolution imaging and UV-Vis spectroscopy with CIELAB color space transformation are emerging as powerful tools that transcend conventional bulk concentration measurements [16] [13]. These methodologies enable researchers to visualize dissolution events at the solid-liquid interface, monitor physical and chemical changes in dosage forms in real-time, and establish correlations between critical quality attributes and process parameters, ultimately providing unprecedented insights into drug release mechanisms.

Advanced UV-Vis Methodologies for Comprehensive Dissolution Analysis

UV Dissolution Imaging

UV dissolution imaging represents a significant advancement in dissolution testing technology, providing both visualization of dissolution phenomena at the solid-liquid interface and quantitative concentration measurements [13]. This technique utilizes light in the wavelength range of 190-800 nm, leveraging the inherent ability of drug substances to absorb light, where the absorption occurs when an electron is promoted to a higher energy state by the energy of an incident photon [13].

The technology has proven particularly valuable for intrinsic dissolution rate (IDR) determinations, form selection, and drug-excipient compatibility studies during early development phases [13]. More recently, with the advent of larger area imaging systems such as the USP type IV-like whole dose cell, UV imaging applications have expanded to include whole dosage forms like tablets and capsules, providing insights into dissolution phenomena not captured by offline measurements [13].

Table 1: Key Applications of UV Dissolution Imaging in Pharmaceutical Development

| Application Area | Specific Uses | Key Benefits |

|---|---|---|

| Form Selection | Comparison of different API solid forms | Enables visualization of dissolution behavior linked to crystal form |

| IDR Determination | Measurement of intrinsic dissolution rates from small quantities of material | Compound-sparing approach; requires as little as 14 μg of material [13] |

| Drug-Excipient Compatibility | Assessment of interactions between API and excipients | Provides real-time visualization of incompatibilities |

| Whole Dose Imaging | Study of tablets and capsules using larger imaging cells | Reveals heterogeneity in dissolution behavior within a dosage form |

| Non-Oral Formulations | Transdermal patches, implants, and other delivery systems | Enables monitoring of release mechanisms for non-oral routes |

CIELAB Color Space Transformation with UV/Vis Spectroscopy

The CIELAB color space, developed by the International Commission on Illumination (CIE), provides an innovative approach for simultaneous monitoring of chemical and physical tablet properties during compression [16]. This method transforms raw UV/Vis spectra (380-780 nm) into a three-dimensional Cartesian coordinate system defined by parameters L, a, and b, where L represents lightness (0-black to 100-white), a* represents the green-red ratio, and b* represents the yellow-blue ratio [16]. These parameters can be further converted to polar coordinates C* (chroma, color saturation) and h° (hue) [16].

The fundamental principle underlying this technique involves the relationship between tablet surface properties and light reflection behavior. On smooth surfaces, specular reflection predominates, where the angle of incidence equals the angle of reflection. In contrast, rough surfaces produce diffuse reflection, scattering radiation in all directions [16]. Additional factors such as volume scattering through fine particles and the cavity effect in surface cavities further influence reflection patterns [16]. These phenomena enable the correlation between color parameters and critical tablet properties such as porosity and tensile strength.

Table 2: CIELAB Color Space Parameters and Their Pharmaceutical Significance

| Parameter | Definition | Pharmaceutical Significance |

|---|---|---|

| L* | Lightness (0 = black, 100 = white) | Related to surface reflectance and overall appearance |

| a* | Green (-) to Red (+) ratio | Color characterization of formulation components |

| b* | Blue (-) to Yellow (+) ratio | Color characterization of formulation components |

| C* | Chroma (color saturation) | Correlates with porosity and tensile strength [16] |

| h° | Hue angle | Overall color characterization |

Experimental Protocols

Protocol: In-line Monitoring of Tablet Porosity and Tensile Strength Using CIELAB Color Space

Objective: To demonstrate the feasibility of UV/Vis diffuse reflectance spectroscopy combined with CIELAB color space transformation for real-time monitoring of tablet porosity and tensile strength during continuous direct compression.

Materials and Equipment:

- Rotary tablet press (e.g., Fette 102i) [16]

- UV/Vis probe with diffuse reflectance capability

- Powder blends with varied particle sizes and deformation properties

- Magnesium stearate as lubricant

- Data acquisition system for continuous monitoring

Methodology:

- Formulation Preparation: Prepare five different formulations varying in particle size and deformation behavior according to Table 3. Use α-lactose monohydrate (Foremost 310 and Tablettose 80) for particle size variations and microcrystalline cellulose (Emcocel 90M) for different deformation characteristics. Include theophylline monohydrate as a model API for absorption studies [16].

Blending Procedure: Blend all formulation components except lubricant for 12 minutes in a 3D shaker mixer at 32 rpm. Add magnesium stearate (0.5 wt%) and blend for an additional 1.5 minutes [16].

Tableting Parameters: Set the rotary tablet press turret speed to 13.9 rpm. Implement the UV/Vis probe at the ejection position of the tablet machine. Process powders at six different main compression forces (3, 6, 9, 12, 15, and 18 kN) to systematically alter physical properties [16].

In-line Measurement: Continuously collect UV/Vis diffuse reflectance spectra during tablet ejection. Transform the raw spectra into CIELAB color space parameters (L, a, b, C) using appropriate software algorithms.

Reference Measurements: Measure tablet porosity using established methods (e.g., terahertz spectroscopy) [16]. Determine tensile strength through diametrical compression testing.

Data Analysis: Establish correlation models between chroma value (C*) and both porosity and tensile strength using linear regression analysis. Validate models with verification runs.

Table 3: Example Formulations for CIELAB Color Space Monitoring [16]

| Formulation Name | API | Major Excipient | Lubricant | Deformation Behavior |

|---|---|---|---|---|

| Lfine | None | Foremost 310 (99.5%) | MgSt (0.5%) | Fragmentation |

| Lcoarse | None | Tablettose 80 (99.5%) | MgSt (0.5%) | Fragmentation |

| LT | Theophylline (10%) | Foremost 310 (89.5%) | MgSt (0.5%) | Plastic deformation |

| M | None | Emcocel 90M (99.5%) | MgSt (0.5%) | Plastic deformation |

| MT | Theophylline (10%) | Emcocel 90M (89.5%) | MgSt (0.5%) | Plastic deformation |

Protocol: Degassing Cyclic Flow UV-Vis Spectroscopy for Bilayer Tablet Dissolution

Objective: To evaluate the dissolution kinetics of bilayer tablets using degassing cyclic flow UV-Vis spectroscopy with chemometrics for simultaneous API quantification.

Materials and Equipment:

- Automatic tablet dissolution tester (e.g., NTR-VS6P) with paddle apparatus [17]

- Degassing tube (Poreflon TB-0201, 1 mm i.d.) [17]

- Peristaltic pump with PharMed tubing (0.5 mm i.d.)

- UV-Vis spectrophotometer with flow cell

- Nicotinamide (NA) and Pyridoxine Hydrochloride (PH) as model APIs

- Carnauba wax as sustained-release matrix

Methodology:

- Tablet Preparation: Prepare bilayer tablets using the dual compression method. For the slow-release layer, compress mixture containing API (e.g., pyridoxine HCl) and carnauba wax at 10 kg/cm². For the fast-diffusion layer, add mixture containing second API (e.g., nicotinamide), microcrystalline cellulose, lactose, and croscarmellose sodium, then compress at 30 kg/cm² [17].

Dissolution Test Setup: Assemble the degassing cyclic flow system as illustrated in Figure 1. Set dissolution parameters to 900 mL water, 37°C, and paddle rotation at 50 rpm. Implement a metal filter at the suction port to prevent clogging [17].

Degassing System: Connect a 5 cm Poreflon degassing tube after the metal filter to prevent air bubble formation in the flow cell, which can interfere with optical path consistency [17].

Spectral Acquisition: Circulate dissolution medium through the flow system at 1.25 mL/min. Acquire UV-Vis spectra in the range of 240-380 nm at 1-minute intervals for 60 minutes [17].

Multivariate Calibration: Develop Partial Least Squares (PLS) regression models using standard solutions of individual APIs. Use baseline optimization to prevent baseline shift of spectra. Validate models using root mean square error (RMSE) calculations [17].

Concentration Prediction: Apply PLS regression models to the collected spectral data to predict individual API concentrations throughout the dissolution process, enabling simultaneous quantification of both APIs despite spectral overlap.

Figure 1: Workflow for real-time monitoring of tablet properties using UV-Vis spectroscopy with CIELAB color space transformation.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Research Reagent Solutions for Advanced UV-Vis Dissolution Studies

| Category | Specific Materials | Function & Application |

|---|---|---|

| Model APIs | Theophylline monohydrate [16], Nicotinamide (NA), Pyridoxine hydrochloride (PH) [17] | Model compounds with known UV absorption characteristics for method development |

| Excipients for Release Modulation | Carnauba wax [17], Microcrystalline cellulose (MCC) [16] [17], Lactose [16] [17], Croscarmellose sodium (CCS) [17] | Control drug release rates; MCC and lactose for fast release, carnauba wax for sustained release |

| Tableting Lubricants | Magnesium stearate (Ligamed MF-2-V) [16] | Prevent adhesion to tooling; critical for continuous manufacturing processes |

| Spectroscopic Accessories | Quartz cuvettes/cells [2], Flow cells with degassing systems [17], UV-Vis probes for in-line implementation [16] | Enable accurate UV measurements; quartz transparent to UV light, degassing prevents bubble interference |

| Chemometric Tools | Partial Least Squares (PLS) regression algorithms [17], CIELAB color space transformation algorithms [16] | Resolve overlapping spectral signals; extract physical property information from spectral data |

Data Analysis and Interpretation

Correlation of CIELAB Parameters with Tablet Properties

Research demonstrates that increasing the main compression force during tableting decreases tablet surface roughness and porosity while increasing tensile strength [16]. These physical changes significantly affect the radiation reflection behavior on the tablet surface, resulting in measurable changes in the chroma value (C) in the CIELAB color space [16]. Linear relationships between C values and both porosity and tensile strength have been observed across multiple formulations, enabling the development of predictive models for real-time quality monitoring [16].

The sensitivity of this technique depends on the formulation characteristics, with different excipients and API combinations exhibiting varying response patterns. For instance, formulations containing theophylline as a model API demonstrated distinct absorption characteristics that could be correlated with physical properties while simultaneously monitoring API content [16].

Chemometric Analysis of Dissolution Data

For bilayer tablet dissolution, PLS regression effectively resolves overlapping UV-Vis spectral peaks of multiple APIs, enabling accurate concentration prediction without traditional chromatographic separation [17]. The degassing flow system proves critical for maintaining measurement accuracy by preventing air bubble accumulation in the flow cell over extended measurement periods (up to 1800 minutes) [17].

The dissolution kinetics obtained through this methodology reveal distinctive release profiles for different layers of bilayer tablets, with the wax matrix layer exhibiting sustained release characteristics compared to the fast-diffusion layer [17]. This approach provides a comprehensive understanding of the dissolution mechanism, including the influence of matrix ingredients on release kinetics.

Figure 2: Schematic representation of the degassing cyclic flow UV-Vis spectroscopy system for dissolution testing.

The integration of advanced UV-Vis methodologies, including UV dissolution imaging and CIELAB color space transformation, represents a paradigm shift in dissolution testing that moves beyond simple bulk concentration measurements. These techniques provide comprehensive insights into drug release mechanisms, enable real-time monitoring of critical quality attributes, and facilitate the development of robust pharmaceutical products with enhanced therapeutic performance.

The protocols and applications detailed in this document demonstrate how these advanced spectroscopic methods can be implemented throughout drug development, from early formulation screening to final product quality control. By adopting these innovative approaches, pharmaceutical scientists can gain deeper understanding of product performance, accelerate development timelines, and ultimately deliver higher quality drug products to patients.

{ article }

Key Parameters: Defining critical measurements including λmax, linearity range, and correlation coefficient

Within the framework of research on UV-Vis spectroscopy for dissolution testing of tablets, the reliability of the analytical data is paramount. The accuracy of in vitro dissolution profiles, which are critical for predicting in vivo performance, hinges on the rigorous validation of the spectroscopic method used. This protocol details the application of UV-Vis spectroscopy for drug release studies, focusing on the definition and determination of three fundamental parameters: the wavelength of maximum absorption (λmax), the linearity range, and the correlation coefficient. These parameters form the cornerstone of a robust analytical method, ensuring that the generated dissolution data is accurate, precise, and fit for purpose in pharmaceutical development and quality control.

Theoretical Background and Key Parameter Definitions

The foundation of a reliable UV-Vis spectroscopic method for dissolution testing rests on a clear understanding of its critical parameters. These parameters are not isolated figures but are interconnected characteristics that collectively define the method's capability to produce accurate and precise concentration data from absorbance measurements.

λmax (Wavelength of Maximum Absorption): This is the specific wavelength at which a drug substance exhibits its highest absorbance. Selecting λmax for analysis is crucial as it provides the greatest sensitivity and minimizes the impact of minor instrumental fluctuations. For instance, in dissolution testing, where drug concentration in the medium increases over time, measuring at λmax ensures the highest signal-to-noise ratio throughout the experiment. As evidenced by studies on terbinafine hydrochloride, its λmax can vary with the solvent, such as 283 nm in water and 223 nm in 0.1 M HCl, underscoring the need for empirical determination in the chosen dissolution medium [18] [19].

Linearity Range: This defines the concentration interval over which a direct proportional relationship exists between the analyte's concentration and the instrument's absorbance response. It is empirically established by preparing and measuring a series of standard solutions across an anticipated concentration range. The range must adequately cover the expected concentrations encountered during the entire dissolution process, from the early time points to the final plateau, typically from 5% to 120% of the expected maximum release [20]. For example, a validated method for terbinafine hydrochloride demonstrated a linear range of 5–30 μg/mL [19], while another study confirmed linearity from 0.2–4.0 μg/mL [18].

Correlation Coefficient (r): The correlation coefficient is a statistical measure that quantifies the strength of the linear relationship between concentration and absorbance. A value close to 1.0 indicates a strong linear relationship. According to ICH guidelines, a correlation coefficient of >0.999 is typically required to demonstrate acceptable linearity for analytical methods [21] [19]. This high value confirms that the calibration curve is reliable for interpolating the concentration of unknown samples from their absorbance.

The following workflow outlines the logical process of method development and validation discussed in this article:

Experimental Protocols

Determination of λmax

Principle: This procedure aims to empirically identify the wavelength at which the drug substance shows maximum absorbance in a specific dissolution medium. This ensures optimal analytical sensitivity.

Materials:

- Drug standard (e.g., Terbinafine hydrochloride)

- Dissolution medium or appropriate solvent (e.g., distilled water, 0.1 M HCl)

- Volumetric flasks (10 mL, 100 mL)

- UV-Vis Spectrophotometer (e.g., Shimadzu 2450) with scanning software

Procedure:

- Standard Stock Solution: Accurately weigh approximately 10 mg of the drug standard. Transfer it to a 100 mL volumetric flask, dissolve, and dilute to volume with the dissolution medium to obtain a stock solution of 100 μg/mL [19].

- Working Solution: Pipette 0.5 mL of the standard stock solution into a 10 mL volumetric flask. Dilute to the mark with the dissolution medium to achieve a concentration of 5 μg/mL [19].

- Spectrum Scanning: Fill a cuvette with the dissolution medium to serve as the blank. Place the working solution in another cuvette. Scan both the blank and the sample solution across the UV range, typically from 200 nm to 400 nm [19].

- Identification of λmax: From the resulting spectrum, identify the wavelength corresponding to the highest peak of absorbance. Record this value as the λmax for all subsequent measurements. An example is shown in the visualization of the analytical workflow.

Establishment of Linearity Range and Correlation Coefficient

Principle: This protocol establishes the concentration range over which the Beer-Lambert law holds and quantifies the linearity of the response. This calibration curve is used to determine unknown sample concentrations.

Materials:

- Standard stock solution (100 μg/mL)

- Series of volumetric flasks (e.g., 10 mL)

- UV-Vis Spectrophotometer

Procedure:

- Preparation of Calibration Standards: Into a series of 10 mL volumetric flasks, pipette varying volumes of the standard stock solution. For example, aliquots of 0.5, 1.0, 1.5, 2.0, 2.5, and 3.0 mL can be used. Dilute each to the mark with the dissolution medium to create a calibration series (e.g., 5, 10, 15, 20, 25, and 30 μg/mL) [19].

- Absorbance Measurement: At the predetermined λmax, measure the absorbance of each standard solution against a blank of the dissolution medium.

- Calibration Curve: Plot the measured absorbance against the corresponding concentration for each standard.

- Linear Regression Analysis: Perform a linear regression analysis on the data. The output will provide the equation of the line (y = mx + c, where y is absorbance, m is the slope, x is concentration, and c is the intercept) and the correlation coefficient (r). The method is considered linear if r > 0.999 [21] [19].

- Range Verification: Confirm that the entire range of concentrations expected in dissolution samples (from 5% to 120% of the label claim) falls within the established linear range [20].

The following diagram illustrates the logical steps involved in the calibration and analysis process:

Data Analysis and Acceptance Criteria

The data collected from the experimental protocols must be evaluated against pre-defined acceptance criteria to ensure the method is suitable for dissolution testing. The following table summarizes key validation parameters and their typical targets based on research data.

Table 1: Summary of Key Analytical Parameters from Literature with Acceptance Criteria

| Drug Substance | λmax (Solvent) | Linearity Range (μg/mL) | Correlation Coefficient (r) | LOD/LOQ (μg/mL) | Application |

|---|---|---|---|---|---|

| Terbinafine HCl | 283 nm (Water) [19] | 5–30 [19] | 0.999 [19] | LOD: 0.42, LOQ: 1.30 [19] | Bulk & Formulation |

| Terbinafine HCl | 222 nm (0.1 M HCl) [18] | 0.2–4.0 [18] | - | - | Bulk & Tablets (SIAM*) |

| Terbinafine HCl | 282 nm (0.1 M Acetic Acid) [18] | 2.0–50 [18] | - | - | Bulk & Tablets (SIAM*) |

| Olmesartan Medoxomil | 248.6 nm (0.1 N NaOH) [22] | 10–30 [22] | 0.9999 [22] | LOD: 0.41, LOQ: 1.25 [22] | Combined Tablet |

| Hydrochlorothiazide | 272.8 nm (0.1 N NaOH) [22] | 10–30 [22] | 0.9991 [22] | LOD: 0.44, LOQ: 1.33 [22] | Combined Tablet |

| *SIAM: Stability-Indicating Analytical Method |

Acceptance Criteria:

- Linearity and Correlation: The correlation coefficient (r) for the calibration curve should be greater than 0.999 [21] [19]. The calibration curve is typically constructed from a minimum of six concentration levels [20].

- Precision: The precision of the method, expressed as the percentage relative standard deviation (%RSD) of replicate measurements, should generally be less than 2% [19].

- Accuracy: Recovery studies, where a known amount of standard is added to a pre-analyzed sample, should yield results in the range of 98–102% [19] [22]. This confirms that the method does not suffer from significant interference from the matrix.

The Scientist's Toolkit: Essential Research Reagents and Materials

The development and application of a UV-Vis method for dissolution testing require specific high-quality materials. The following table lists key reagent solutions and their critical functions in the analytical process.

Table 2: Essential Research Reagent Solutions for UV-Vis Dissolution Analysis

| Reagent/Material | Function in Analysis | Exemplary Specification |

|---|---|---|

| Drug Standard | Serves as the primary reference for preparing calibration standards and determining key parameters like λmax. | High-purity certified reference material (CRM) or pharmacopoeial grade [19]. |

| Dissolution Medium | The liquid environment simulating physiological conditions in which tablet dissolution occurs. Acts as the solvent for standards and samples. | Appropriately buffered solutions (e.g., pH 1.2 HCl, pH 6.8 phosphate) as per pharmacopoeia or biorelevant media [23]. |

| HPLC Grade Solvents | Used for preparing mobile phases (in supportive HPLC methods) or for dissolving drugs insoluble in aqueous media. | Low UV absorbance, high purity to prevent interference [21]. |

| Buffer Salts | Used to prepare the dissolution medium and mobile phases to maintain a constant pH, which is critical for drug stability and method robustness. | Analytical Reagent (AR) grade, e.g., Potassium dihydrogen phosphate, disodium hydrogen phosphate [21] [23]. |

The rigorous definition and determination of λmax, linearity range, and correlation coefficient are non-negotiable prerequisites for employing UV-Vis spectroscopy in dissolution testing. As demonstrated through the experimental protocols and literature data, these parameters are interdependent and form the basis of a validated analytical method. Adherence to strict acceptance criteria—such as a correlation coefficient >0.999, a linear range covering 5-120% of the expected release, and precision with an RSD <2%—ensures that the dissolution profile generated is accurate, reliable, and meaningful. This rigorous approach provides drug development professionals and scientists with the confidence needed to make critical decisions regarding formulation performance and quality, ultimately supporting the development of safe and effective pharmaceutical products.

{ /article }

Modern Methodologies: From Fiber Optics to UV Dissolution Imaging

Within pharmaceutical development, dissolution testing serves as a critical analytical procedure to determine the rate and extent of drug release from solid oral dosage forms, such as tablets. This testing provides a vital link between in-vitro product performance and in-vivo bioavailability [24] [25]. UV-Vis spectroscopy is a cornerstone technique for quantifying dissolved analytes in these tests due to its reliability, ease of use, and high precision [26] [2]. The implementation of this spectroscopy primarily follows two distinct pathways: traditional offline (manual) sampling using cuvettes and online (automated) sampling utilizing flow cells.

This application note details the protocols, equipment, and data handling procedures for both methods, providing a structured framework for their application in dissolution testing for drug development.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table catalogues the essential materials and reagents required for conducting UV-Vis spectroscopy in the context of dissolution testing.

Table 1: Key Research Reagent Solutions for UV-Vis Dissolution Testing

| Item | Function & Application in Dissolution Testing |

|---|---|

| UV-Vis Spectrophotometer | The core instrument for measuring light absorbance by analytes; used for concentration quantification in dissolution samples [26] [2]. |

| Quartz Cuvettes | Sample holders for offline analysis; quartz is essential for UV light transmission, unlike plastic or glass which absorb UV wavelengths [2]. |

| Flow Cell | An in-line cell, typically with quartz windows, connected to the HPLC column or dissolution vessel outlet; enables real-time, online monitoring of the eluent [26]. |

| Deuterium & Tungsten Lamps | Standard light sources in UV-Vis instruments; a deuterium lamp provides UV light, while a tungsten/halogen lamp covers the visible range [2]. |

| Dissolution Media | Aqueous buffers (e.g., pH 1.2, 4.5, 6.8) or other physiologically relevant fluids that simulate the gastrointestinal environment for the dissolution test [27]. |

| Reference Standards (USP RS) | Certified materials, such as USP Prednisone RS Tablets, used for performance verification (PVT) of the dissolution apparatus and method [24]. |

| Syringe Filters | Used for clarifying manually drawn dissolution samples by removing undissolved particles prior to analysis, preventing interference and instrument damage [24]. |

| Degassed Solvents | Dissolution media from which dissolved gases have been removed (e.g., via vacuum filtration) to prevent bubble formation that can interfere with dissolution or detection [24] [25]. |

Offline (Manual) Sampling with Cuvettes

Principle and Workflow

The offline method involves manually withdrawing aliquots from the dissolution vessel at predetermined time points. These samples are then filtered, often diluted, and transferred to a cuvette for subsequent absorbance measurement in a UV-Vis spectrophotometer [24] [28]. This approach is characterized by its flexibility and the use of standard, widely available laboratory equipment.

The step-by-step workflow for the offline manual sampling method is summarized in the diagram below:

Detailed Experimental Protocol

Materials and Equipment:

- Dissolution apparatus (USP Apparatus 1 or 2) [24]

- Thermostated bath maintaining 37.0 ± 0.5 °C [27]

- UV-Vis spectrophotometer with deuterium and/or tungsten lamps [2]

- Quartz cuvettes (e.g., 1 cm path length) [2]

- Syringe filters (e.g., 0.45 µm pore size, validated for non-adsorption) [24]

- Volumetric flasks and pipettes for dilution

- Dissolution media (e.g., deaerated water or buffer) [24]

Step-by-Step Procedure:

- Apparatus Preparation: Calibrate the dissolution apparatus mechanically and with USP Performance Verification Test (PVT) tablets, such as Prednisone RS, to ensure proper operation [24] [25]. Fill each vessel with the specified volume of dissolution medium, typically 500-1000 mL, and equilibrate to 37.0 ± 0.5 °C [24] [27].

- Test Initiation: Begin the test by placing one dosage unit (e.g., tablet) into each vessel and starting the agitation (e.g., paddle at 50 rpm) simultaneously. Consider this time point as t=0.

- Sample Withdrawal: At predetermined intervals (e.g., 5, 10, 15, 30, 45, 60 minutes), manually withdraw a specified volume (e.g., 10-20 mL) from each vessel. The sampling probe should be positioned at a defined location away from the dissolving tablet to avoid interference [24] [27].

- Sample Filtration: Immediately filter the withdrawn samples using a suitable syringe filter. It is standard practice to discard the first 5 mL of the filtrate to account for adsorption losses on the filter membrane [24].

- Sample Preparation: If necessary, dilute the filtrate with fresh dissolution medium to ensure the absorbance reading falls within the ideal range of the spectrophotometer (typically 0.2-1.0 AU) to maintain linearity according to the Beer-Lambert law [2].

- UV-Vis Analysis: a. Blank Measurement: Use the dissolution medium as the blank reference to zero the instrument [2]. b. Sample Measurement: Transfer the prepared sample to a clean quartz cuvette and measure its absorbance at the validated wavelength (e.g., 242 nm for prednisone) [24] [26].

- Data Recording: Record the absorbance value for each sample at each time point.

Data Processing and Analysis

- Concentration Calculation: Convert absorbance values to concentration using a pre-established calibration curve or the analyte's known molar absorptivity (ε) based on the Beer-Lambert law (A = ε * b * c) [2].

- Cumulative Release: Calculate the cumulative percentage of drug dissolved at each time point, accounting for volume replacements and dilutions [29].

- Profile Generation: Plot the mean percentage dissolved versus time to generate the dissolution profile for the batch. Include error bars (e.g., ±SD) from multiple vessel measurements (n=6-12) to indicate variability [24] [27].

Online (Automated) Sampling with Flow Cells

Principle and Workflow

Online methods employ flow-through cells integrated directly into the fluidic path after the dissolution vessel or HPLC column. This setup allows for real-time, in-situ monitoring of the drug concentration without the need for manual sample handling [25] [26]. This approach is highly advantageous for extended-release formulations and supports Process Analytical Technology (PAT) initiatives for real-time release testing (RTRT) [16] [25].

The following diagram illustrates the logical flow and components of an online system with a flow cell:

Detailed Experimental Protocol

Materials and Equipment:

- Dissolution apparatus with integrated fluidics

- UV-Vis spectrophotometer equipped with a flow cell (e.g., Diode Array Detector - DAD) [26]

- Peristaltic pump or automated sampling system

- In-line filters

- Tubing (chemically inert, e.g., PTFE)

Step-by-Step Procedure:

- System Setup and Prime: Connect the flow cell to the fluidic path. Prime the entire system with the dissolution medium to remove air bubbles, which can cause significant signal noise and erroneous absorbance readings [25] [2].

- Baseline Establishment: With the dissolution medium circulating through the flow cell, establish a stable baseline on the UV-Vis detector. This baseline signal will serve as the reference (I₀) for all subsequent measurements [2].

- Test Initiation: Begin the dissolution test as described in the offline protocol (Step 3.2, point 2).

- Continuous Monitoring: Initiate continuous pumping of the medium from the dissolution vessel through the in-line filter and into the flow cell. The detector records the absorbance at set intervals (e.g., every few seconds), building a real-time profile of the drug concentration in the vessel [25].

- System Suitability: Prior to critical tests, validate the online system's performance by circulating a standard solution of known concentration and verifying that the measured absorbance aligns with the expected value.

Data Processing and Analysis

- Real-Time Data Stream: The data system directly collects a continuous stream of absorbance data.

- Conversion to Profile: Software automatically converts the absorbance values to concentration and percentage dissolved, using pre-defined parameters, and generates the dissolution profile in real-time [16]. This facilitates immediate data interpretation and decision-making.

Comparative Analysis: Offline vs. Online Methods

Table 2: Quantitative and Qualitative Comparison of Offline and Online Sampling Methods

| Parameter | Offline (Cuvette) Sampling | Online (Flow Cell) Sampling |

|---|---|---|

| Automation Level | Manual or semi-automated [24] | Fully automated [25] |

| Sampling Frequency | Discrete time points [27] | Continuous, real-time [25] |

| Typical Flow Cell Volume | N/A (Cuvette-based) | 8–18 µL (HPLC), 0.5–1 µL (UHPLC) [26] |

| Risk of Sample Alteration | Higher (filtration, dilution, handling) [24] | Lower (closed system, minimal handling) |

| Suitability for Extended Release | Possible, but labor-intensive for long durations | Ideal for prolonged tests (e.g., 24 hours) [25] |

| PAT / RTRT Suitability | Low | High, enables real-time release testing [16] [25] |

| Key Advantage | Flexibility, uses standard equipment [28] | Real-time data, minimal manual intervention [25] |

| Primary Limitation | Labor-intensive; potential for high variability [24] | Higher initial setup cost and complexity [25] |

Both traditional offline sampling with cuvettes and modern online sampling with flow cells are indispensable methods within the pharmaceutical laboratory. The choice between them depends on the specific application requirements, such as the need for high-throughput quality control, real-time process monitoring, or testing of complex modified-release formulations. Offline methods offer a robust, accessible, and flexible approach, while online flow cell techniques provide the automation, speed, and continuous data acquisition essential for advanced PAT and RTRT strategies. A thorough understanding of both protocols ensures the selection of the most appropriate and informative methodology for dissolution testing in drug development.

Within pharmaceutical development, the dissolution test is a cornerstone for assessing the performance of solid oral dosage forms. Traditional methods, which rely on manual sampling and offline analysis, are labor-intensive and provide only limited data points. This application note details the implementation of real-time dissolution profiling using in-situ fiber-optic UV-Vis spectroscopy, a methodology that aligns with the principles of Process Analytical Technology (PAT) [30] [11]. By enabling continuous, in-situ measurement, this technique provides a rich, detailed dataset that is invaluable for formulation development, troubleshooting, and quality control, ultimately supporting a more efficient and science-based drug development process [31] [12].

Theoretical Background and Principles

Fiber-optic dissolution testing is grounded in the Beer-Lambert Law, which states that the absorbance of light by a solution is directly proportional to the concentration of the absorbing species and the pathlength of the light through the solution [31]. A typical system consists of a UV-Vis light source, a spectrometer, and fiber-optic cables connected to probes immersed directly in the dissolution vessels.

The key innovation is the probe design, which allows for the transmission of light to and from the vessel without the need for fluid removal. Different probe geometries (e.g., with overlapping or non-overlapping illumination and collection areas) can be optimized to be sensitive to specific measurement depths or to minimize hydrodynamic interference [32]. The signal captured by the probe is transmitted back to the spectrometer, where the resulting spectra are processed to quantify the concentration of the dissolved Active Pharmaceutical Ingredient (API) in real-time [33].

Key Advantages Over Traditional Methods

The adoption of fiber-optic probes for dissolution testing offers several distinct advantages that enhance both operational efficiency and data quality.

Table 1: Comparison of Dissolution Testing Methods

| Feature | Traditional Manual Sampling & HPLC | In-Situ Fiber-Optic UV |

|---|---|---|

| Data Density | Limited data points (e.g., 5-7 time points) | High-density, continuous data (points as frequent as every 5 seconds) [33] |

| Analysis Speed | Slow; includes sampling, filtration, and often lengthy HPLC run times | Real-time; immediate data and trending [12] |

| Labor & Cost | High labor; cost of solvents, HPLC vials, and disposal [12] | Reduced labor; eliminates consumables like filters, tubing, and syringes [33] |

| Process Understanding | Provides a basic release profile | Enables observation of complex release dynamics as they occur [11] [33] |

| Automation Potential | Complex, often requiring automated sampling systems | Truly automated from start of test to final report [33] |

Furthermore, with the application of multicomponent analysis (MCA) algorithms, fiber-optic UV systems can simultaneously quantify two APIs in a combination product or account for spectral interference from excipients, coatings, or capsules without the need for chromatographic separation [33].

Experimental Protocols

Protocol 1: Establishing a Real-Time Dissolution Profile for an Immediate-Release Tablet

This protocol describes the steps to monitor the dissolution of a single-API immediate-release tablet using a fiber-optic dissolution system.

Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Fiber-Optic Dissolution Testing

| Item | Function | Example/Note |

|---|---|---|

| Fiber-Optic Dissolution System | Performs in-situ UV measurement. | E.g., Opt-Diss 410 or equivalent [33]. |

| Dissolution Apparatus | Provides controlled test environment. | USP Apparatus 1 (baskets) or 2 (paddles). |

| Dissolution Medium | Simulates the gastrointestinal environment. | e.g., 0.1N HCl or pH-buffered solutions, degassed [34]. |

| Fiber-Optic Probe | Transmits and collects light in the vessel. | ARCH probe or adjustable pathlength dip probe (e.g., 2-20 mm) [33]. |

| API Reference Standard | For system calibration and validation. | High-purity material for preparing standard solutions. |

Procedure:

- Instrument Setup: Power on the dissolution bath and allow it to reach the specified temperature (typically 37°C ± 0.5°C). Ensure the fiber-optic probes are clean and securely connected to the spectrometer.

- Pathlength Selection: Select an appropriate optical pathlength for the probe based on the expected API concentration and its absorptivity to ensure absorbance values remain within the instrument's linear range (e.g., 0.2-1.0 AU) [33].

- System Calibration:

- Prepare a series of standard solutions of the API in the dissolution medium across a range of known concentrations.

- Immerse the probe in each standard and collect the UV spectrum.

- Using the instrument's software, build a univariate calibration model (absorbance at λmax vs. concentration) or a multivariate model using full-spectrum data.

- Baseline Measurement: Fill the dissolution vessel with the specified volume of dissolution medium. With the paddles rotating at the specified speed (e.g., 50 rpm), immerse the probe and collect a baseline spectrum.

- Initiate Test: Introduce one tablet into each vessel and start the data acquisition software simultaneously.

- Data Acquisition: The system will automatically collect spectra at pre-defined intervals (e.g., every 5-10 seconds initially) [33]. The software will convert the spectral data into concentration values in real-time using the established calibration model.

- Profile Generation: The software plots the cumulative percentage of drug released versus time, generating a continuous dissolution profile.

Protocol 2: Multicomponent Analysis for a Fixed-Dose Combination Product

This protocol extends the capability to products containing two APIs with overlapping UV spectra.

Procedure:

- Follow Steps 1-2 from Protocol 1.

- Multicomponent Calibration:

- Prepare a calibration set of standard solutions that contains varying concentrations of both API A and API B, designed to span the expected concentration ranges.

- Collect full UV spectra for all standard mixtures.

- Use the instrument's software to build a multivariate calibration model (e.g., Partial Least Squares, or PLS) that correlates the spectral features with the known concentrations of both APIs [35] [33].

- Validation: Validate the model using an independent set of standard solutions not used in the calibration.

- Dissolution Test: Perform the dissolution test as described in Steps 4-6 of Protocol 1.

- Concentration Deconvolution: The software will apply the multicomponent model to each collected spectrum, simultaneously calculating the concentrations of both API A and API B, and generating two individual dissolution profiles from a single test [33].

Data Analysis and Chemometrics

The large volume of spectral data generated requires robust chemometric tools for interpretation.

- Univariate Analysis: For single-component analysis, the absorbance at the wavelength of maximum absorption (λmax) is plotted against time. This data can be directly converted to a dissolution profile using the Beer-Lambert law [34].

- Multivariate Analysis: For complex systems, techniques such as Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression are employed. These methods use the entire spectral region to build models that can predict API concentration even in the presence of interfering species or for multi-API products [31] [35].

- Self-Modeling Curve Resolution (SMCR): In some cases, advanced algorithms like SMCR can resolve the concentration profiles of reacting components without the need for pre-defined standards, which is particularly useful for monitoring chemical reactions or complex release mechanisms [31].

Table 3: Quantitative Data from a Representative Study (Drotaverine Extended-Release Tablets)

| Formulation Variable | Level 1 | Level 2 | Level 3 | Key Finding from Dissolution Prediction |

|---|---|---|---|---|

| DR Content (w/w %) | 6% | 8% | 10% | Prediction models using NIR/Raman spectra and compression force accurately predicted dissolution profiles (f2 > 50) [35]. |

| HPMC Content (w/w %) | 10% | 20% | 30% | HPMC content was a critical factor controlling release rate, successfully captured by the model [35]. |

| Compression Force (MPa) | 63.8 | 95.7 | 127.6 | Higher compression force slightly slowed drug release, and the model accounted for this effect [35]. |

Application in Pharmaceutical Development

The rich, real-time data provided by fiber-optic dissolution is instrumental in several key areas of drug development:

- Formulation Screening and Optimization: The ability to capture detailed release dynamics, especially at early time points, allows formulators to quickly discriminate between different prototype formulations [11]. For instance, the technology has been used to screen co-processed API formulations to identify carriers that provide the desired drug release profile [11].

- Troubleshooting and Root Cause Analysis: Continuous profiles can reveal subtle anomalies in drug release that might be missed by traditional sampling. This is critical for investigating batch-to-batch variability or issues observed in stability studies, such as identifying the cross-linking effect on the dissolution of gelatin capsules [11].

- Support for Real-Time Release Testing (RTRT): As a robust PAT tool, fiber-optic dissolution can form the basis of an RTRT strategy, where the dissolution profile is predicted based on in-process data, eliminating the need for end-product testing and reducing batch release times [30] [35].

Fiber-optic UV probes represent a significant advancement in dissolution testing methodology. By enabling continuous, in-situ monitoring, they provide a comprehensive and accurate view of the drug release process, far surpassing the detail offered by traditional methods. The integration of this technology with advanced chemometric analysis empowers researchers and scientists to develop better formulations more efficiently, resolve complex manufacturing issues, and move toward modern, risk-based quality control paradigms like RTRT. Adopting this technology is a decisive step toward deepening the understanding of drug product performance throughout the development lifecycle.

UV Surface Dissolution Imaging (SDI) represents a technological breakthrough in dissolution testing, enabling researchers to directly observe the solid-liquid interface in real-time as a drug substance dissolves [36]. This advanced analytical technique provides a two-dimensional movie of UV absorbance, offering a detailed view of dissolution processes that occur microns from the drug surface [37]. Unlike traditional dissolution methods that only measure bulk concentration, UV SDI captures spatially resolved concentration data, allowing for visualization of the concentration gradient that forms near the surface of a dissolving substance—a central element in dissolution theory that has been difficult to verify experimentally until now [37].

The technology is particularly valuable in pharmaceutical development because most drug substances contain UV chromophores, making UV absorbance a sensitive and robust measurement approach [37]. By combining an imaging detector with specialized flow cells and analysis software, UV SDI provides unique insights into the kinetics and mechanisms of drug release, helping to shift the dissolution paradigm from a data-driven approach toward a knowledge-driven perspective [37]. This mechanistic performance knowledge contributes to a deeper understanding of critical product quality attributes and process parameters, aligning perfectly with Quality by Design (QbD) initiatives in pharmaceutical development [37].

Core Components of UV SDI Systems

The UV SDI system comprises several integrated components designed to provide controlled hydrodynamic conditions and high-resolution imaging:

- Sample Flow Cell: A specially designed cell that provides laminar flow across the surface of compacted drug material. The quartz flow cell is pressed against the imager face, providing a complete side view of the powder surface including areas upstream and downstream [37].

- UV Light Source and Detection: A broad-spectrum pulsed xenon lamp provides flashes of light that are synchronized with a complementary metal oxide semiconductor (CMOS) image sensor (7 mm × 9 mm made up of 1.3 million 7 × 7 μm pixels) for recording light transmission through the flow cell [37].

- Fluid Delivery System: An accurate, stable syringe pump typically using a 20-mL syringe enables controlled volumetric flow across the sample. Multiple flow rate steps can be programmed and synchronized with UV image acquisition [37].

- Data Analysis Software: Proprietary software tools allow extraction and analysis of dissolution data from the captured image sequences, including calculation of intrinsic dissolution rates and visualization of concentration gradients [37].

Fundamental Operating Principles

UV SDI operates on the principle that most pharmaceutical substances absorb UV light, and this absorbance follows the Beer-Lambert law, which relates absorption to concentration [37]. The system converts intensity measurements at each pixel into absolute absorbance values by first subtracting dark values and then applying the standard logarithmic equation comparing initial transmission (I0) and sample transmission (I) [37]. The resulting absorbance values for each pixel in the selected viewing area create a 2-D image, and sequences of these images form a movie that visually represents the dissolution process [37].

The flow cell creates laminar parabolic flow parallel to the image sensor, with flow passing across the drug compact with a surface velocity near zero [37]. This creates steady-state conditions that enable reliable imaging at each moment of flow, with the parabolic flow profile accounting for faster flow at the center of the flow stream compared to the surface wall [37]. The viewing area and binning level can be selected by the operator, with imaging rates typically around 2 Hz for dissolution experiments [37].

Figure 1: UV SDI Technology Workflow - This diagram illustrates the core process of UV Surface Dissolution Imaging, from illumination to data analysis.

Key Research Applications

Intrinsic Dissolution Rate (IDR) Determination