UV-Vis Spectroscopy vs. HPLC for Drug Quantification: A Comprehensive Comparative Analysis for Scientists

This article provides a systematic comparison of Ultraviolet-Visible (UV-Vis) spectroscopy and High-Performance Liquid Chromatography (HPLC) for drug quantification, addressing the critical needs of researchers and drug development professionals.

UV-Vis Spectroscopy vs. HPLC for Drug Quantification: A Comprehensive Comparative Analysis for Scientists

Abstract

This article provides a systematic comparison of Ultraviolet-Visible (UV-Vis) spectroscopy and High-Performance Liquid Chromatography (HPLC) for drug quantification, addressing the critical needs of researchers and drug development professionals. We explore the foundational principles of both techniques, detail methodological applications across diverse pharmaceutical scenarios—from simple APIs to complex formulations and drug delivery systems—and offer practical troubleshooting guidance. The analysis extends to rigorous method validation parameters and a direct performance comparison, supported by recent case studies, to empower informed analytical method selection that balances accuracy, cost, and regulatory compliance.

Core Principles: Understanding the Fundamentals of UV-Vis and HPLC

Ultraviolet-Visible (UV-Vis) Spectroscopy is a fundamental analytical technique in pharmaceutical research, used to identify and quantify compounds based on their light absorption properties. For drug development professionals, the choice between UV-Vis and High-Performance Liquid Chromatography (HPLC) represents a critical decision point, balancing factors of speed, cost, and analytical precision. This guide objectively compares these methodologies within the context of drug quantification, providing experimental data and protocols to inform analytical strategy.

The Fundamental Principle: How UV-Vis Spectroscopy Works

UV-Vis spectroscopy measures the amount of ultraviolet (100-400 nm) or visible (400-800 nm) light absorbed by a chemical substance in solution [1] [2]. The core principle involves passing a beam of light through a sample and measuring the intensity of the transmitted light relative to the initial incident light.

When a molecule absorbs this light energy, electrons are promoted from a ground state to a higher energy excited state [1] [2]. The instrument, a spectrophotometer, consists of a light source, a monochromator to select specific wavelengths, a sample holder (cuvette), and a detector [1]. The resulting absorbance spectrum, a plot of absorbance versus wavelength, provides characteristic information about the electronic structure of the molecule [3].

The Beer-Lambert Law: The Foundation of Quantification

The quantitative power of UV-Vis spectroscopy rests almost entirely on the Beer-Lambert Law (also known as Beer's Law). This law establishes a linear relationship between the absorbance of a solution and the concentration of the absorbing species [4] [1].

The law is expressed by the equation: A = εcl

Where:

- A is the measured Absorbance (unitless) [4] [2].

- ε is the Molar Absorptivity (or extinction coefficient), a constant characteristic of the substance at a specific wavelength (Mâ»Â¹cmâ»Â¹) [4].

- c is the Molar Concentration of the absorbing solute (M) [4] [1].

- l is the Path Length, the distance the light travels through the sample (cm) [4] [1].

This principle allows researchers to determine an unknown concentration by measuring absorbance, provided the molar absorptivity and path length are known [3]. In practice, a calibration curve is first constructed by plotting the absorbance of standard solutions of known concentration, with the slope of the linear curve being (εl) [4] [1].

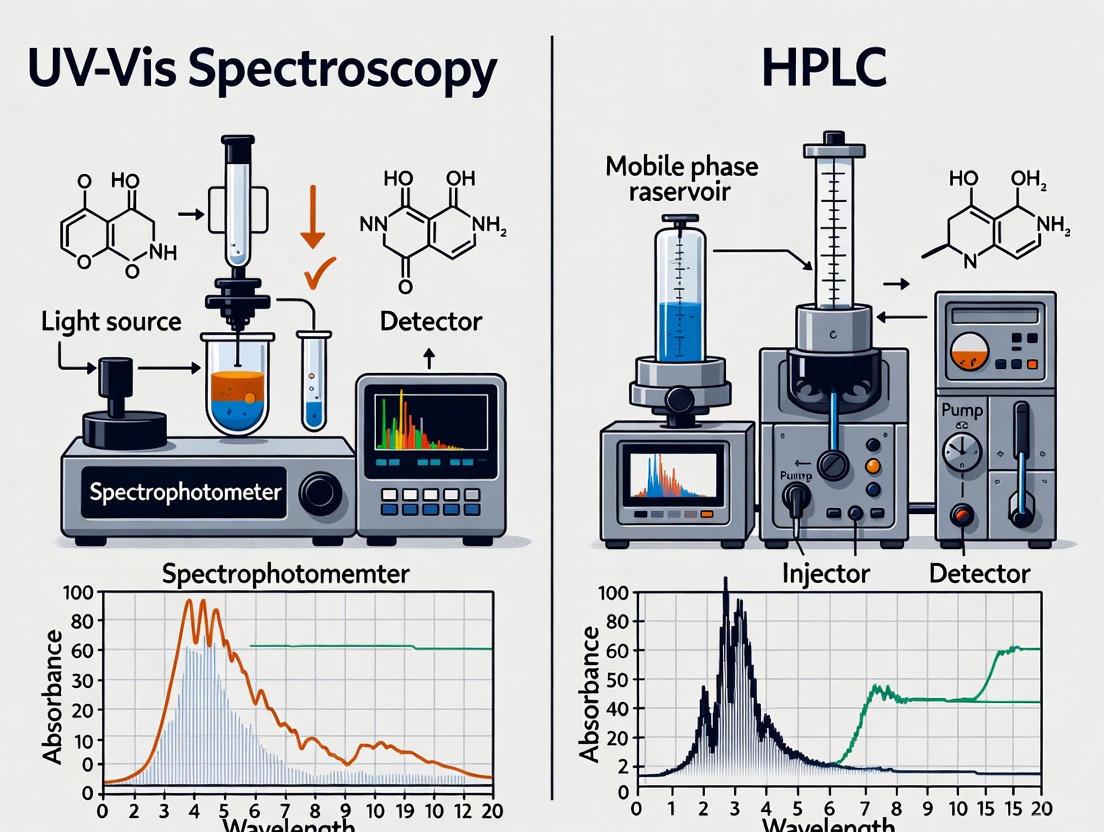

Figure 1: The UV-Vis Spectroscopy Workflow for Quantitative Analysis.

UV-Vis vs. HPLC: A Head-to-Head Comparison for Drug Analysis

While UV-Vis is often used as a stand-alone technique, it also serves as a common detector in HPLC systems. The choice between using a simple UV-Vis spectrophotometer versus a full HPLC system depends heavily on the analytical goals and sample complexity.

Table 1: Technical Comparison of UV-Vis Spectroscopy and HPLC for Drug Quantification

| Feature | UV-Vis Spectroscopy | High-Performance Liquid Chromatography (HPLC) |

|---|---|---|

| Principle of Analysis | Measures light absorption by chromophores [2]. | Separates components via liquid chromatography before detection (often by UV-Vis) [5] [6]. |

| Analytical Selectivity | Low; cannot distinguish multiple absorbers without chemometrics [1] [7]. | High; physically separates analytes, allowing individual quantification [5] [6]. |

| Sample Complexity | Best for simple, pure solutions or single analytes in a matrix [1]. | Ideal for complex mixtures (e.g., drug formulations, biological samples) [5] [8]. |

| Key Instrument Components | Light source, monochromator, cuvette, detector [1]. | Pump, injector, column, detector (e.g., UV-Vis) [5] [6]. |

| Analysis Speed | Very fast (seconds to minutes) [1]. | Slower due to separation step (minutes to tens of minutes) [6]. |

| Cost & Operational Complexity | Relatively inexpensive, simple to operate [1]. | Higher cost, requires more skilled operation and maintenance [7]. |

| Environmental Impact | Lower solvent consumption as a stand-alone technique [1]. | Higher consumption of organic solvents [7]. |

Supporting Experimental Data: Direct Method Comparisons

Independent studies directly comparing the two techniques for specific drug assays highlight the practical implications of their differences.

Table 2: Experimental Recovery Data for Levofloxacin from a Complex Drug-Delivery System [5] [8]

| Method | Spiked Concentration (µg/ml) | Mean Recovery Rate (%) | Standard Deviation |

|---|---|---|---|

| HPLC | 5 (Low) | 96.37 | ± 0.50 |

| 25 (Medium) | 110.96 | ± 0.23 | |

| 50 (High) | 104.79 | ± 0.06 | |

| UV-Vis | 5 (Low) | 96.00 | ± 2.00 |

| 25 (Medium) | 99.50 | ± 0.00 | |

| 50 (High) | 98.67 | ± 0.06 |

Table 3: Validation Parameters for the Analysis of Repaglinide in Tablets [6]

| Validation Parameter | UV-Vis Spectroscopy | HPLC |

|---|---|---|

| Linearity Range | 5 - 30 µg/ml | 5 - 50 µg/ml |

| Correlation Coefficient (R²) | > 0.999 | > 0.999 |

| Precision (% R.S.D.) | < 1.50 | < 1.50 |

| Mean Recovery | 99.63 - 100.45% | 99.71 - 100.25% |

Key Experimental Protocols from Cited Studies

1. Protocol for Levofloxacin Analysis in Composite Scaffolds [5] [8]

- Objective: Compare HPLC and UV-Vis for determining Levofloxacin released from mesoporous silica/nano-hydroxyapatite scaffolds.

- HPLC Method: A Sepax BR-C18 column was used with a mobile phase of 0.01 mol/L KHâ‚‚POâ‚„, methanol, and 0.5 mol/L tetrabutylammonium hydrogen sulphate (75:25:4). The flow rate was 1 ml/min, and detection was at 290 nm.

- UV-Vis Method: The standard solution of Levofloxacin was scanned from 200–400 nm to find the maximum absorption wavelength for quantification.

- Conclusion: For this complex drug-delivery system with potential interfering substances, HPLC was determined to be the preferred and more accurate method.

2. Protocol for Repaglinide Analysis in Tablets [6]

- Objective: Develop and validate simple, fast UV-Vis and HPLC methods for quality control of repaglinide tablets.

- UV-Vis Method: The drug was dissolved in methanol, and absorbance was measured at 241 nm.

- HPLC Method: An Agilent TC-C18 column was used with an isocratic mobile phase of methanol and water (80:20 v/v, pH 3.5). The flow rate was 1.0 ml/min with detection at 241 nm.

- Conclusion: Both methods were found reliable for the quality control of the drug in pharmaceutical formulations, demonstrating that for simpler matrices like tablets, UV-Vis can be sufficient.

Advanced UV-Vis Techniques: Overcoming Limitations

The primary limitation of UV-Vis—poor selectivity in mixtures—can be addressed using chemometric models. A 2025 study on quantifying antibiotics clofazimine (CLZ) and dapsone (DAP) in a combined leprosy therapy used Partial Least Squares (PLS) and Multivariate Curve Resolution with Alternating Least Squares (MCR-ALS) to analyze overlapping UV-Vis spectra [7]. This approach successfully handled the sample matrix effect and interferents, offering a greener and faster alternative to HPLC for this specific application while maintaining reliability.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Reagents and Materials for UV-Vis and HPLC Drug Analysis

| Item | Function/Description | Example Use Case |

|---|---|---|

| Cuvette | A transparent container (typically with 1 cm path length) for holding liquid samples during analysis [1] [3]. | Standard sample holder in UV-Vis spectrophotometry. |

| Methanol & Acetonitrile (HPLC Grade) | High-purity organic solvents used to prepare mobile phases and standard/sample solutions [5] [6] [9]. | Ensures minimal background interference in HPLC and UV-Vis analysis. |

| C18 Chromatography Column | A reverse-phase column packed with octadecylsilane; the stationary phase for separating compounds in HPLC [5] [6]. | Critical for the physical separation of drug components in a mixture during HPLC. |

| Simulated Body Fluid (SBF) | A buffer solution that mimics the ionic composition of human blood plasma [5] [8]. | Used in drug release studies from scaffolds or implants to simulate in-vivo conditions. |

| Standard Reference Compound | A high-purity sample of the analyte drug used for calibration and method validation [5] [6]. | Essential for creating accurate calibration curves in both HPLC and UV-Vis. |

| Einecs 300-803-9 | Einecs 300-803-9|High-Purity Chemical for Research | Research-grade Einecs 300-803-9 for lab use. Explore its specific applications and value. This product is for Research Use Only (RUO). Not for human use. |

| 4a,6-Diene-bactobolin | 4a,6-Diene-bactobolin|High-Purity Research Compound | 4a,6-Diene-bactobolin is a research chemical for studying ribosomal antibiotics. This product is For Research Use Only (RUO). Not for diagnostic, therapeutic, or personal use. |

Figure 2: A Decision Framework for Selecting Between UV-Vis and HPLC.

UV-Vis spectroscopy, grounded in the robust Beer-Lambert Law, is a powerful, simple, and cost-effective tool for drug quantification, particularly for pure samples or simple formulations. However, HPLC provides superior selectivity and accuracy for complex mixtures, such as those found in novel drug-delivery systems or biological matrices. The choice is not a matter of which technique is universally better, but which is more appropriate for the specific analytical challenge, weighing the need for speed and simplicity against the demands of selectivity and precision in pharmaceutical research.

High-Performance Liquid Chromatography (HPLC) is a powerful analytical technique used to separate, identify, and quantify components in a mixture. This separation is achieved by exploiting the differential interactions of sample components with a stationary phase (a solid packing material inside a column) and a mobile phase (a liquid solvent pumped through the system under high pressure) [10] [11]. The fundamental principle is straightforward: components that interact more strongly with the stationary phase are retained longer in the column and thus have longer retention times, while components with greater affinity for the mobile phase elute more quickly [10] [12]. The advent of HPLC revolutionized analytical chemistry by providing high-resolution separations for compounds that are non-volatile, thermally unstable, or have high molecular weights, making it indispensable in pharmaceutical, environmental, and biological research [13] [11].

Core Principles of HPLC Separation

The Separation Mechanism

At its heart, HPLC is a mass transfer process involving adsorption and/or partition [11]. The separation occurs inside a column packed with fine particles of the stationary phase. When a sample mixture is introduced into the flowing mobile phase, its individual components are carried into the column. Each component then partitions between the stationary and mobile phases based on its chemical nature and the affinity it has for each phase [10] [11]. This continuous partitioning process, combined with the high pressure used to force the mobile phase through the tightly packed column, results in highly efficient separation. The high operational pressure (typically 50–1400 bar) is a defining characteristic of HPLC, setting it apart from traditional liquid chromatography and enabling the use of much smaller stationary phase particles for superior resolution [11].

Primary HPLC Separation Modes

The specific chemical interactions governing separation depend on the selected mode of HPLC. The most common modes are summarized in the table below.

Table 1: Common HPLC Separation Modes and Their Principles

| Separation Mode | Primary Interaction | Stationary Phase | Mobile Phase | Typical Applications |

|---|---|---|---|---|

| Reversed-Phase (RP) [10] [13] | Hydrophobicity | Non-polar (e.g., C18) | Polar (e.g., water, methanol, acetonitrile) | Small molecule pharmaceuticals, vitamins [10] |

| Normal-Phase (NP) [10] [12] | Hydrophilicity / Polarity | Polar (e.g., silica, diol) | Non-polar organic solvents | Saccharides, nucleic acids [10] |

| Ion-Exchange (IEX) [10] [13] | Electrostatic / Charge | Charged functional groups | Aqueous buffers with varying pH and ionic strength | Inorganic ions, amino acids, proteins [10] |

| Size-Exclusion (SEC) [10] [13] | Molecular Size | Porous particles | Aqueous or organic solvents | Synthetic polymers, biopolymers [10] |

| Hydrophilic Interaction (HILIC) [14] | Partitioning into water-rich layer | Hydrophilic (e.g., amide, zwitterionic) | High concentration of organic solvent in water | Polar compounds, small organic acids, basic drugs [14] |

Reversed-Phase Chromatography (RPC) is the most widely used mode, particularly for small molecules. It separates compounds based on hydrophobicity, with more non-polar compounds retaining longer on the non-polar stationary phase [10]. In contrast, Normal-Phase Chromatography (NPC) utilizes a polar stationary phase and is better suited for separating polar compounds [10] [12]. Hydrophilic Interaction Liquid Chromatography (HILIC) is a variant that acts as a "reverse normal-phase" mode; it uses a hydrophilic stationary phase with a mobile phase containing a high proportion (e.g., 50-95%) of an organic solvent like acetonitrile. HILIC is particularly valuable for retaining and separating highly polar compounds that elute too quickly in RPC [14].

HPLC in Practice: Instrumentation and Workflow

Key System Components

A standard HPLC system consists of several integrated components designed to deliver precision and reproducibility [13].

- Pump: Delivers the mobile phase at a constant, high pressure and controlled flow rate. Many systems feature gradient pumps that can mix solvents to create a changing mobile phase composition over time [11].

- Injector: Introduces a precise, small volume of the sample mixture into the high-pressure mobile phase stream [13].

- Column: The heart of the separation, typically a stainless-steel tube packed with micron-scale particles coated with the stationary phase. Column chemistry (e.g., C18, silica, ion-exchange) is selected based on the application [10] [13].

- Detector: Monitors the eluting stream from the column, generating a signal when a component is present. Common detectors include UV-Vis (measuring light absorbance), fluorescence, and mass spectrometry (MS) [13] [11].

- Data System: A computer and software that control the instrument, acquire data from the detector, and process the resulting chromatogram for qualitative and quantitative analysis [15].

The following diagram illustrates the logical flow and key components of a generic HPLC system.

The Researcher's Toolkit: Essential Reagents and Materials

Successful HPLC analysis requires careful selection of consumables and reagents. The following table details key items used in a typical HPLC experiment.

Table 2: Essential Research Reagent Solutions and Materials for HPLC

| Item | Function / Description | Example from Literature |

|---|---|---|

| Stationary Phase Columns | The medium where separation occurs; choice dictates separation mechanism (e.g., C18 for reversed-phase). | Sepax BR-C18 column [8]; Atlantis columns for polar compounds [16]. |

| HPLC-Grade Solvents | High-purity solvents (e.g., water, methanol, acetonitrile) used to prepare the mobile phase; minimize background noise. | Methanol (HPLC-grade) used in mobile phase for analysis [8] [17]. |

| Buffer Salts | Added to mobile phase to control pH and ionic strength, critical for separating ionizable compounds. | Potassium dihydrogen phosphate (KHâ‚‚POâ‚„), Tetrabutylammonium hydrogen sulphate [8]. |

| Analytical Standards | Pure reference compounds used to identify analytes by retention time and to create calibration curves for quantitation. | Levofloxacin standard from National Institutes for Food and Drug Control [8]. |

| Internal Standards | A known compound added to the sample to correct for variability during sample preparation and injection. | Ciprofloxacin used as an internal standard in levofloxacin analysis [8]. |

| Enoxolone aluminate | Enoxolone Aluminate|C90H135AlO12|RUO | |

| Tunichrome B-1 | Tunichrome B-1, CAS:97689-87-7, MF:C26H25N3O11, MW:555.5 g/mol | Chemical Reagent |

HPLC vs. UV-Vis Spectroscopy for Drug Quantification: An Experimental Comparison

Fundamental Differences in Principle

While both HPLC and Ultraviolet-Visible (UV-Vis) Spectroscopy can be used for drug quantification, their underlying principles are fundamentally different. UV-Vis spectroscopy measures the absorbance of light by a sample at specific wavelengths, providing a single, collective measurement for all absorbing species in a solution. It cannot distinguish between individual compounds in a mixture without prior separation [8]. In contrast, HPLC is primarily a separation technique that physically resolves the components of a mixture. Each pure component is then quantified as it elutes from the column, typically using a UV-Vis detector itself. This combination of separation and detection is what gives HPLC its superior specificity for complex samples [8] [11].

Quantitative Experimental Comparison: Levofloxacin Analysis

A direct comparison of HPLC and UV-Vis for quantifying Levofloxacin released from a novel drug-delivery system (mesoporous silica microspheres/nano-hydroxyapatite composite scaffolds) highlights the practical performance differences [8].

Table 3: Quantitative Comparison of HPLC and UV-Vis for Levofloxacin Analysis

| Parameter | HPLC Method | UV-Vis Method |

|---|---|---|

| Regression Equation | y = 0.033x + 0.010 [8] | y = 0.065x + 0.017 [8] |

| Coefficient of Determination (R²) | 0.9991 [8] | 0.9999 [8] |

| Recovery Rate (Low Conc.) | 96.37 ± 0.50% [8] | 96.00 ± 2.00% [8] |

| Recovery Rate (Medium Conc.) | 110.96 ± 0.23% [8] | 99.50 ± 0.00% [8] |

| Recovery Rate (High Conc.) | 104.79 ± 0.06% [8] | 98.67 ± 0.06% [8] |

| Key Advantage | Accurate in complex matrices; separates target drug from excipients and impurities. | Simpler and faster for pure solutions. |

The experimental data demonstrates that while UV-Vis can exhibit excellent linearity (R²=0.9999), its accuracy can be compromised in complex sample matrices. The HPLC method provided more consistent and accurate recovery rates across concentrations, especially at the medium level where its recovery was closer to the true value. The study concluded that UV-Vis measurement is not accurate for determining drug concentration loaded on biodegradable composite scaffolds due to impurity interference, and that HPLC is the preferred method for evaluating the sustained release characteristics of Levofloxacin [8].

Detailed Experimental Protocols

- Objective: To accurately determine the concentration of Levofloxacin released from a composite scaffold in simulated body fluid.

- Chromatographic Conditions:

- Column: Sepax BR-C18 (250 × 4.6 mm, 5 µm particle size).

- Mobile Phase: A mixture of 0.01 mol/L KHâ‚‚POâ‚„, methanol, and 0.5 mol/L tetrabutylammonium hydrogen sulphate in a ratio of 75:25:4.

- Flow Rate: 1.0 mL/min.

- Column Temperature: 40°C.

- Detection Wavelength: 290 nm.

- Injection Volume: 10 µL.

- Sample Preparation:

- The sample solution is mixed with an internal standard (Ciprofloxacin).

- The mixture is vortexed for 5 minutes.

- Dichloromethane is added for liquid-liquid extraction, followed by another 5 minutes of vortexing.

- The solution is centrifuged at 7,155 × g for 5 minutes.

- The supernatant is extracted, dried under nitrogen in a 50°C water bath, and reconstituted for injection.

- Quantitation: A calibration curve is constructed using levofloxacin standards, and sample concentrations are calculated based on peak areas.

- Objective: To determine the concentration of Levofloxacin via direct absorbance measurement.

- Instrument Setup:

- Instrument: UV-Vis Spectrophotometer.

- Wavelength Scan: 200–400 nm to identify the maximum absorption wavelength (λmax) for Levofloxacin.

- Procedure:

- Standard solutions of Levofloxacin are prepared at known concentrations (e.g., 5, 25, and 50 µg/mL).

- The absorbance of each standard is measured at the predetermined λmax.

- A calibration curve is plotted (Absorbance vs. Concentration).

- The absorbance of the unknown sample is measured and its concentration is interpolated from the calibration curve.

The decision-making process for selecting the appropriate analytical technique is summarized below.

Advanced HPLC Techniques and Applications

Technological Advancements

HPLC technology continues to evolve, leading to more powerful and efficient techniques.

- Ultra-High-Performance Liquid Chromatography (UHPLC): UHPLC utilizes columns packed with smaller particles (typically less than 2 µm) and operates at significantly higher pressures. This results in faster analysis times, higher resolution, and increased sensitivity compared to conventional HPLC [13] [16].

- Multidimensional HPLC (2D-LC): This technique couples two independent separation mechanisms (e.g., reversed-phase and ion-exchange) to dramatically increase peak capacity for extremely complex mixtures. It is particularly valuable in proteomics and metabolomics research [13].

Representative Applications in Research

HPLC's versatility is demonstrated by its wide range of applications. In pharmaceutical analysis, it is used for purity testing, stability studies, and drug formulation validation [13]. A specific example is the quality control of fermented Cordyceps sinensis products, where HPLC fingerprints combined with quantitative analysis of multiple nucleosides (e.g., uracil, uridine, adenosine) are used to differentiate between samples and ensure consistent quality [17]. In environmental testing, HPLC enables the detection and quantification of pollutants like pesticides and pharmaceuticals in water and soil [13]. Furthermore, specialized software tools like HappyTools have been developed to enable high-throughput, automated processing of HPLC data, facilitating large-scale clinical and biopharmaceutical studies [15].

In pharmaceutical research, the accurate quantification of active pharmaceutical ingredients (APIs) and the assessment of drug delivery systems are fundamental to drug development and quality control. Among the plethora of analytical techniques available, Ultraviolet-Visible (UV-Vis) Spectroscopy and High-Performance Liquid Chromatography (HPLC) stand as two cornerstone methodologies. While both techniques leverage the principle of light absorption by molecules, their instrumental complexity, applications, and performance characteristics differ significantly.

UV-Vis spectroscopy is an analytical technique that measures the amount of discrete wavelengths of UV or visible light absorbed by a sample in comparison to a reference [18] [19]. Its simplicity and speed make it attractive for direct concentration measurements. HPLC, conversely, is a separation technique that resolves complex mixtures before detection, most commonly using a UV-Vis based detector [20] [21]. This fundamental difference—direct analysis versus separation followed by analysis—dictates their respective roles in the laboratory. This guide provides an objective, data-driven comparison of their instrumentation and performance to help researchers select the appropriate tool for drug quantification research.

Core Instrumentation Compared

The architectures of UV-Vis spectrophotometers and HPLC systems with UV detectors reveal their different purposes: one is designed to measure bulk absorption, the other to monitor separated analytes.

UV-Vis Spectrophotometry: A Direct Absorption Measurement

A UV-Vis spectrophotometer functions by passing a beam of light through a sample and measuring the intensity of the transmitted light [18] [19]. Its key components work in sequence as shown in Figure 1 and include:

- Light Source: Typically, a combination of a deuterium lamp (for the UV region, 190-380 nm) and a tungsten or halogen lamp (for the visible region, 380-900 nm) [18] [22]. The instrument switches between sources during a scan.

- Wavelength Selector (Monochromator): This critical component uses a diffraction grating to disperse the broad-spectrum light and select a specific, narrow band of wavelengths to pass through the sample [18] [19]. This ensures that the measured absorption is specific to a chosen wavelength.

- Sample Compartment: The sample, typically dissolved in a suitable solvent, is held in a cuvette with a standard path length of 1 cm. For UV light, quartz cuvettes are essential as they are transparent to UV radiation, unlike glass or plastic [18] [19].

- Detector: The transmitted light is converted into an electrical signal by a detector. Common types include Photomultiplier Tubes (PMTs), which are highly sensitive for low-light detection, and semiconductor-based photodiodes or Charge-Coupled Devices (CCDs) [18] [19].

The following diagram illustrates the streamlined workflow of a UV-Vis spectrophotometer.

HPLC-UV: Separation Followed by Detection

An HPLC system is more complex, as its primary goal is to separate the components of a mixture before they reach the detector. The key modules are [20] [21]:

- Pump: Delivers a constant, high-pressure flow of the mobile phase (solvent).

- Injector: Introduces the sample mixture into the mobile phase stream.

- Chromatography Column: The heart of the system, where the separation of analytes occurs based on their chemical interactions with the stationary phase.

- UV Detector: After separation, the analytes pass through a flow cell, where a UV-Vis detection system measures their absorption. Two main types of UV detectors are prevalent:

- Variable Wavelength Detector (VWD): Uses a monochromator to select a single, specific wavelength to pass through the flow cell. This offers high sensitivity for targeted analysis [20] [21].

- Diode Array Detector (DAD or PDA): Passes a broad spectrum of light through the flow cell, then disperses it onto an array of photodiodes. This allows for the simultaneous collection of all wavelengths, enabling spectral analysis and peak purity assessment for each separated compound [20] [22] [23].

The sequential process of an HPLC system, highlighting the detector's role, is shown in Figure 2.

Performance Comparison in Drug Analysis

The theoretical differences in instrumentation translate directly into practical performance outcomes. A comparison of experimental data from peer-reviewed studies clearly illustrates the strengths and limitations of each technique.

Table 1: Experimental Comparison of UV-Vis and HPLC for Drug Quantification

| Performance Metric | UV-Vis Spectroscopy | HPLC with UV Detection |

|---|---|---|

| Application Context | Direct measurement of Levofloxacin released from composite scaffolds [8] [5] | Direct measurement of Levofloxacin released from composite scaffolds [8] [5] |

| Linear Range | 0.05 - 300 µg/mL [8] [5] | 0.05 - 300 µg/mL [8] [5] |

| Recovery (Low Conc.) | 96.00% ± 2.00 [8] [5] | 96.37% ± 0.50 [8] [5] |

| Recovery (Medium Conc.) | 99.50% ± 0.00 [8] [5] | 110.96% ± 0.23 [8] [5] |

| Recovery (High Conc.) | 98.67% ± 0.06 [8] [5] | 104.79% ± 0.06 [8] [5] |

| Key Limitation | Inaccurate in complex matrices due to impurity interference [8] [5] | Accurate for complex matrices due to separation power [8] [5] |

| Application Context | Repaglinide in tablet dosage form [6] | Repaglinide in tablet dosage form [6] |

| Linearity (R²) | > 0.999 [6] | > 0.999 [6] |

| Precision (% RSD) | < 1.50% [6] | Better than UV method [6] |

| Key Advantage | Simple, fast, and economical [6] | Highly precise and robust for quality control [6] |

Interpretation of Comparative Data

The data in Table 1 reveals a clear trend:

HPLC Offers Superior Specificity and Accuracy in Complex Matrices: The study on Levofloxacin highlights a critical limitation of UV-Vis. While both methods showed good linearity, the recovery rates for HPLC were closer to 100% and more consistent across concentration levels, especially at medium and high concentrations. The study concluded that UV-Vis was inaccurate for measuring drug release from the composite scaffolds because it could not distinguish the Levofloxacin signal from interfering substances in the complex scaffold matrix. HPLC's separation power eliminated this problem [8] [5].

UV-Vis is a Viable Option for Simple Mixtures: The Repaglinide study demonstrates that for a relatively simple matrix like a tablet formulation, UV-Vis can perform well, with excellent linearity and acceptable precision. This makes it a suitable, cost-effective option for routine quality control of raw materials or simple formulations where interference from other components is minimal [6].

Essential Research Toolkit

Selecting the correct materials and reagents is fundamental to the success of any analytical method. The following table details key components and their functions for both techniques.

Table 2: Essential Research Reagents and Materials

| Item | Function / Description | Critical Consideration |

|---|---|---|

| HPLC-Grade Solvents | High-purity solvents (e.g., methanol, acetonitrile, water) used as the mobile phase to dissolve samples and elute the column [8] [6]. | Minimizes UV-absorbing impurities that cause high background noise and baseline drift [24]. |

| UV-Vis Cuvettes | Container for holding liquid samples during analysis in a UV-Vis spectrophotometer. | Must be quartz for UV range analysis (below ~350 nm); glass or plastic can only be used for visible light measurements [18] [19]. |

| HPLC Column | The core component where chemical separation occurs. Typically a reverse-phase C18 column [8] [6]. | Column chemistry, length, and particle size must be selected based on the analytes of interest for optimal separation. |

| Standard Compounds | Highly purified analytes used for calibration and method validation [8] [6]. | Essential for accurate quantification. Purity should be certified and traceable. |

| Buffers & Additives | (e.g., Phosphate buffers, tetrabutylammonium salts) Modify the mobile phase to control pH and ionic strength, improving separation and peak shape [24] [8]. | The UV "cut-off" wavelength of the buffer must be considered to avoid background absorption at the detection wavelength [24]. |

| Indolaprilat | Indolaprilat|ACE Inhibitor | Indolaprilat (CAS 83601-86-9) is a potent angiotensin-converting enzyme (ACE) inhibitor for research use. This product is For Research Use Only and is not intended for diagnostic or therapeutic applications. |

| Einecs 269-968-1 | Einecs 269-968-1, CAS:68392-94-9, MF:C32H42N3O7S4-, MW:709.0 g/mol | Chemical Reagent |

Experimental Protocols for Method Comparison

To empirically compare the performance of UV-Vis and HPLC for a specific drug, a researcher can implement the following protocols, adapted from the literature [8] [6].

Sample Preparation Protocol

- Standard Stock Solution: Accurately weigh the drug reference standard and dissolve it in an appropriate solvent (e.g., methanol or the mobile phase) to prepare a stock solution of known concentration (e.g., 1000 µg/mL).

- Calibration Standards: Dilute the stock solution serially to prepare a series of standard solutions covering the expected concentration range (e.g., 5-50 µg/mL).

- Sample Solution: For a tablet formulation, weigh and powder tablets. Dissolve a portion of the powder equivalent to the drug's label claim in solvent, sonicate, filter, and dilute to the required concentration.

UV-Vis Spectroscopy Method

- Instrument Calibration: Use a blank solvent to zero the spectrophotometer.

- Wavelength Selection: Scan a standard solution to identify the wavelength of maximum absorption (λmax) for the drug.

- Measurement: Measure the absorbance of each calibration standard and the sample solution at the predetermined λmax.

- Quantification: Construct a calibration curve of absorbance versus concentration and use the linear regression equation to determine the concentration in the sample [6].

HPLC-UV Method

- Chromatographic Conditions:

- Column: C18 (250 x 4.6 mm, 5 µm)

- Mobile Phase: Methanol:Water (e.g., 80:20 v/v, pH optionally adjusted with orthophosphoric acid)

- Flow Rate: 1.0 mL/min

- Detection Wavelength: As determined from the drug's UV spectrum (e.g., 241 nm for Repaglinide, 290 nm for Levofloxacin)

- Injection Volume: 20 µL [8] [6]

- Analysis: Inject each calibration standard and the sample solution.

- Quantification: Construct a calibration curve of peak area versus concentration and use the linear regression equation to determine the concentration in the sample.

The choice between UV-Vis spectroscopy and HPLC for drug quantification is not a matter of which instrument is universally superior, but which is fit-for-purpose.

- UV-Vis Spectrophotometry is an excellent tool for rapid, cost-effective analysis of pure substances or simple mixtures where specificity is not a concern. Its simplicity and speed are its greatest assets.

- HPLC with UV detection is the indispensable choice for complex mixtures, such as drug release studies from sophisticated delivery scaffolds, stability-indicating methods, or purity assays. Its power to separate before detection provides unmatched specificity and accuracy, which is non-negotiable in rigorous pharmaceutical research and regulatory quality control.

Researchers must base their selection on the sample complexity, required specificity, and the goals of the analysis. When results from a simple UV-Vis method seem inconsistent, the presence of interfering compounds should be suspected, and the superior separation capability of HPLC should be employed to verify the findings.

Inherent Strengths and Limitations of Each Technique

In the field of pharmaceutical analysis, the selection of an appropriate analytical technique is a critical decision that directly impacts the accuracy, efficiency, and cost-effectiveness of drug quantification research. Ultraviolet-Visible (UV-Vis) spectroscopy and High-Performance Liquid Chromatography (HPLC) represent two foundational methodologies with distinct operational principles and application domains. UV-Vis spectroscopy measures the absorption of ultraviolet or visible light by analytes, providing a straightforward approach to quantification based on the Beer-Lambert law [19]. In contrast, HPLC separates complex mixtures using a pressurized liquid mobile phase and a stationary phase, followed by detection of individual components, typically using UV-Vis detectors among other options [25]. This article provides a systematic comparison of these techniques, examining their inherent strengths and limitations through experimental data and methodological considerations to guide researchers and drug development professionals in selecting the optimal approach for specific analytical challenges.

Fundamental Principles and Instrumentation

UV-Vis Spectroscopy

UV-Vis spectroscopy operates on the principle that molecules absorb specific wavelengths of light in the ultraviolet (100-400 nm) and visible (400-780 nm) regions of the electromagnetic spectrum. When light passes through a sample, the amount of absorption at characteristic wavelengths provides quantitative information about the analyte concentration based on the Beer-Lambert law, which states that absorbance is proportional to concentration, path length, and a compound-specific molar absorptivity coefficient [19]. A typical UV-Vis spectrophotometer consists of a light source (often combining deuterium and tungsten/halogen lamps), a wavelength selection component (monochromator or filters), a sample holder, and a detector (such as a photomultiplier tube or photodiode) [19].

High-Performance Liquid Chromatography

HPLC is a separation technique that resolves complex mixtures into individual components through differential partitioning between a liquid mobile phase and a stationary phase packed into a column. The separated analytes then pass through a detector for identification and quantification. Various detectors are available for HPLC systems, with UV-Vis detectors being among the most common due to their versatility and reliability for many pharmaceutical compounds [25]. Other detector options include photodiode array (PDA) detectors, which capture absorbance across multiple wavelengths simultaneously; fluorescence detectors for compounds with natural fluorescence or those that can be derivatized; refractive index detectors for universal detection; mass spectrometry for structural identification; and conductivity detectors for ionic species [25].

Experimental Comparison in Pharmaceutical Analysis

Method Development and Validation Protocols

To objectively compare the performance of UV-Vis spectroscopy and HPLC for drug quantification, we examine experimental protocols and validation data from studies that applied both techniques to the same pharmaceutical compounds.

For UV-Vis analysis of repaglinide, the methodology involved preparing standard stock solutions in methanol, with further dilutions to achieve concentrations ranging from 5-30 μg/mL. Absorbance was measured at 241 nm using a Shimadzu 1700 Double beam UV-Vis spectrophotometer with 1.0-cm quartz cells [6].

For HPLC analysis of repaglinide, researchers used an Agilent 1120 Compact LC system with a TC-C18 column (250 mm × 4.6 mm, 5 μm particle size). The mobile phase consisted of methanol and water (80:20 v/v, pH adjusted to 3.5 with orthophosphoric acid) at a flow rate of 1.0 mL/min. Detection was performed at 241 nm, with injection volume of 20 μL and a linearity range of 5-50 μg/mL [6].

Both methods were validated according to International Conference on Harmonisation (ICH) guidelines, assessing parameters including linearity, precision, accuracy, specificity, and detection limits [6].

Table 1: Validation Parameters for Repaglinide Analysis Using UV-Vis and HPLC Methods

| Validation Parameter | UV-Vis Method | HPLC Method |

|---|---|---|

| Linearity range | 5-30 μg/mL | 5-50 μg/mL |

| Correlation coefficient (r²) | >0.999 | >0.999 |

| Precision (% RSD) | <1.50% | <1.50% |

| Accuracy (% Recovery) | 99.63-100.45% | 99.71-100.25% |

| Detection Limit | Based on standard deviation of y-intercept and slope | Based on standard deviation of y-intercept and slope |

Comparative Case Study: Levofloxacin Analysis

A direct comparison of HPLC and UV-Vis spectroscopy for determining Levofloxacin released from mesoporous silica microspheres/nano-hydroxyapatite composite scaffolds revealed significant methodological differences. The regression equation for HPLC was y=0.033x+0.010 (R²=0.9991), while for UV-Vis it was y=0.065x+0.017 (R²=0.9999) [8].

Recovery rates at low, medium, and high concentrations (5, 25, and 50 μg/mL) demonstrated notable differences between the techniques:

Table 2: Recovery Rates for Levofloxacin Determination Using HPLC and UV-Vis Methods

| Concentration Level | HPLC Recovery Rate | UV-Vis Recovery Rate |

|---|---|---|

| Low (5 μg/mL) | 96.37 ± 0.50% | 96.00 ± 2.00% |

| Medium (25 μg/mL) | 110.96 ± 0.23% | 99.50 ± 0.00% |

| High (50 μg/mL) | 104.79 ± 0.06% | 98.67 ± 0.06% |

The study concluded that UV-Vis provided less accurate measurements for drugs loaded on biodegradable composite scaffolds, likely due to interference from scaffold components, and recommended HPLC as the preferred method for evaluating sustained release characteristics in such complex systems [8].

Inherent Strengths and Limitations

UV-Vis Spectroscopy

Strengths:

- Simplicity and ease of use: UV-Vis spectrophotometers are generally straightforward to operate with minimal training requirements [19].

- Rapid analysis: Measurements can be performed quickly, often in minutes, making the technique suitable for high-throughput applications [6].

- Cost-effectiveness: Both initial equipment investment and ongoing maintenance costs are typically lower than HPLC systems [26] [19].

- Minimal solvent consumption: The technique requires small sample volumes and generates little waste compared to chromatographic methods [27].

Limitations:

- Limited selectivity for complex mixtures: UV-Vis spectroscopy cannot resolve individual components in mixtures without prior separation, as it provides only a composite spectrum of all absorbing species [19].

- Interference susceptibility: Excipients, impurities, or formulation additives can interfere with absorbance measurements, compromising accuracy [8] [25].

- Structural requirements: Analytes must contain chromophores (aromatic rings, conjugated systems) that absorb in the UV-Vis range [25] [19].

- Dynamic range constraints: For accurate quantification, absorbance values should generally be kept below 1, which may require sample dilution and additional preparation steps [19].

High-Performance Liquid Chromatography

Strengths:

- High selectivity and resolution: HPLC can separate complex mixtures into individual components, enabling precise quantification of specific analytes even in the presence of interfering substances [6] [25].

- Excellent sensitivity: With appropriate detectors, HPLC can achieve very low detection limits, often in the nanogram or picogram range [25].

- Versatility: Various detector options (UV-Vis, PDA, fluorescence, MS) and column chemistries allow method customization for diverse analytical needs [25].

- Robust quantification in complex matrices: HPLC effectively handles samples with multiple components, such as biological fluids or formulated products, with minimal interference [8].

Limitations:

- Higher complexity and cost: HPLC systems require significant financial investment, specialized training, and regular maintenance [25].

- Time-consuming method development: Optimizing separation parameters (mobile phase composition, column type, gradient profile) can be labor-intensive [27].

- Substantial solvent consumption: HPLC methods typically use significant volumes of high-purity solvents, generating waste that requires proper disposal [27].

- Longer analysis times: Chromatographic separations often require more time than direct spectroscopic measurements [6].

Advanced Applications and Hybrid Approaches

Chemometrics-Enhanced UV-Vis Spectroscopy

To address the limitation of spectral overlap in mixtures, advanced chemometric approaches have been successfully applied to UV-Vis spectroscopy. Researchers developed a method for simultaneous determination of propranolol, rosuvastatin, and valsartan in ternary mixtures using UV-Vis spectroscopy coupled with artificial neural networks (ANN) [27]. The firefly algorithm was used as a variable selection procedure to optimize ANN models, resulting in improved predictive performance with lower relative root mean square error of prediction values compared to full-spectrum ANN models [27]. This approach maintained the simplicity and cost advantages of UV-Vis spectroscopy while overcoming its traditional limitation in analyzing multi-component mixtures.

HPLC with Advanced Detection Technologies

The combination of HPLC separation with sophisticated detectors significantly expands analytical capabilities. Photodiode array detectors enable peak purity assessment by capturing complete spectra of eluting compounds [25]. Mass spectrometry detectors provide structural information through mass-to-charge ratios, enabling definitive compound identification [25]. Such hybrid approaches deliver both the separation power of chromatography and the identification capability of spectroscopic techniques, making them invaluable for impurity profiling, metabolite identification, and complex formulation analysis.

Research Reagent Solutions and Essential Materials

Table 3: Key Research Reagents and Materials for UV-Vis and HPLC Analysis

| Item | Function/Purpose | Example Specifications |

|---|---|---|

| HPLC-grade solvents | Mobile phase preparation; sample dissolution | Low UV absorbance; high purity (e.g., methanol, acetonitrile, water) [6] |

| Buffer salts | Mobile phase pH control | Orthophosphoric acid for pH adjustment [6] |

| Stationary phases | Chromatographic separation | C18 columns (250 mm × 4.6 mm, 5 μm) [6] |

| Reference standards | Method calibration and validation | High-purity authenticated compounds [6] |

| Spectroscopic cells | Sample holder for UV-Vis | Quartz cuvettes (1 cm path length) for UV transparency [19] |

| Filters | Sample clarification | 0.45 μm syringe filters for particulate removal [6] |

| Internal standards | Quantification reference | Certified reference materials [8] |

Workflow and Application Decision Framework

The following diagram illustrates the fundamental operational workflows for both techniques and their relationship to application suitability:

Both UV-Vis spectroscopy and HPLC offer distinct advantages for drug quantification research, with their suitability dependent on specific analytical requirements. UV-Vis spectroscopy provides a rapid, cost-effective solution for routine analysis of single components or simple mixtures, particularly when resources are limited or high throughput is essential. In contrast, HPLC delivers superior selectivity and sensitivity for complex mixtures, stability studies, and impurity profiling, despite requiring greater instrumental investment and methodological expertise. The emerging trend of combining HPLC separation with sophisticated detection technologies, alongside chemometrics-enhanced UV-Vis spectroscopy, continues to expand the capabilities of both techniques. Researchers should base their selection on comprehensive consideration of factors including sample complexity, required sensitivity, available resources, and analytical objectives to optimize their pharmaceutical analysis outcomes.

Practical Deployment: Selecting and Applying Methods for Real-World Drug Analysis

For researchers and drug development professionals selecting analytical methods, the choice between Ultraviolet-Visible (UV-Vis) spectroscopy and High-Performance Liquid Chromatography (HPLC) represents a fundamental trade-off between speed, cost, and simplicity versus separation power, specificity, and ability to handle complex mixtures.

The following table summarizes the core characteristics of each technique:

| Feature | UV-Vis Spectroscopy | HPLC |

|---|---|---|

| Core Principle | Measures light absorption by molecules at specific wavelengths [19] | Separates components in a mixture via a column before detection [28] [29] |

| Analysis Speed | Very fast (seconds to minutes) [30] [31] | Slower (minutes to tens of minutes) [32] [28] |

| Cost | Lower instrument and operational costs [31] | Higher initial investment and running costs [32] [28] |

| Sample Preparation | Minimal; often just dissolution or dilution [19] [33] | Can be extensive; may require derivatization, filtration [28] |

| Specificity | Lower; can struggle with spectrally overlapping compounds [31] [33] | High; separates analytes from impurities and excipients [28] [29] |

| Primary Use Case | Quantification of pure analytes or simple mixtures [30] [34] | Complex mixture analysis, impurity profiling, stability studies [28] [29] |

Key Experimental Evidence: Direct Performance Comparisons

Case Study 1: Analysis of Levofloxacin in a Drug Delivery System

A direct comparison of HPLC and UV-Vis for quantifying Levofloxacin released from a mesoporous silica microspheres/nano-hydroxyapatite composite scaffold revealed critical performance differences [8].

Table 1: Method Performance Metrics for Levofloxacin Analysis

| Method | Regression Equation (y=concentration, x=absorbance/peak area) | R² | Recovery Rate at 25 µg/ml |

|---|---|---|---|

| HPLC | y = 0.033x + 0.010 | 0.9991 | 110.96% ± 0.23% |

| UV-Vis | y = 0.065x + 0.017 | 0.9999 | 99.50% ± 0.00% |

While UV-Vis showed a better R² value and excellent recovery in this specific test, the study concluded that HPLC is the preferred method for this complex drug-delivery system. The central finding was that UV-Vis was less accurate for measuring drug concentration loaded onto the biodegradable composite due to potential interference from other scaffold components, which HPLC could separate out [8].

Case Study 2: Monitoring Nucleoside Transformations

Research into enzymatic nucleoside phosphorylation reactions demonstrated how a advanced UV-Vis assay could compete with HPLC for specific applications [32].

Table 2: HPLC vs. Advanced UV-Vis for Reaction Monitoring

| Parameter | HPLC-Based Analysis | UV-Vis with Spectral Unmixing |

|---|---|---|

| Cost | Baseline (1x) | Approximately 5-fold lower [32] |

| Analysis Time | Baseline (1x) | 20-fold faster [32] |

| Precision | High | Comparable [32] |

| Throughput | Low | High (96-well plate format) [32] |

This study highlights that for well-defined reactions involving compounds with distinct UV spectra, modern UV-Vis methods employing algorithms like spectral unmixing can provide high-throughput, cost-effective analysis without sacrificing precision [32].

Detailed Protocols for Key Applications

Protocol 1: High-Throughput Protein and Nucleic Acid Quantification

This is a quintessential UV-Vis application due to its speed and simplicity for pure samples [34].

Workflow Diagram: Protein and DNA Quantification via UV-Vis

Step-by-Step Methodology:

- Sample Preparation: Dissolve or dilute the purified protein or nucleic acid sample in a compatible aqueous buffer (e.g., phosphate-buffered saline) [34] [33].

- Instrument Setup: Use a UV-Vis spectrophotometer, ideally with micro-volume capabilities (e.g., 2 µL pathlength) to conserve precious samples and avoid dilutions [34].

- Measurement: Transfer the sample to a quartz cuvette or a micro-volume platform. Acquire the absorbance spectrum, typically between 230 nm and 350 nm [34].

- Data Analysis:

- For protein concentration, measure absorbance at 280 nm (A280). Apply the Beer-Lambert law: Concentration = (A280 / ε) / pathlength, where ε is the protein's extinction coefficient [34].

- For nucleic acid concentration, measure absorbance at 260 nm (A260). Use the relationship: DNA concentration (ng/µL) = A260 × 50 ng/µL × dilution factor [34].

- Purity Assessment: Check the A260/A280 ratio. Expected values are ~1.8 for pure DNA and ~0.6 for pure protein, indicating minimal contamination [34].

Protocol 2: UV-Vis with Chemometrics for Antibiotic Mixtures

This advanced UV-Vis protocol uses chemometrics to resolve spectral overlaps, encroaching on a traditional HPLC strength [35].

Workflow Diagram: Quantification of Antibiotic Mixtures with Chemometrics

Step-by-Step Methodology:

- Calibration Set Design: Prepare a training set of synthetic mixtures containing the fluoroquinolone antibiotics (e.g., Ciprofloxacin, Lomefloxacin, Enrofloxacin) at varying concentration levels using an experimental design (e.g., fractional factorial design) [35].

- Spectral Acquisition: Record the UV absorption spectra (e.g., from 200-400 nm) for all calibration mixtures [35].

- Chemometric Modeling:

- Variable Selection: Employ the Firefly Algorithm (FA) to identify the most significant wavelengths for quantifying each antibiotic, reducing model complexity and improving predictive power [35].

- Model Calibration: Use the selected wavelengths to build a Partial Least Squares (PLS) regression model, which correlates spectral data with the known concentrations in the calibration set [35].

- Validation: Test the model's predictive performance using an independent validation set of mixtures not used in the calibration step. Figures of merit like Recovery % and Relative Standard Deviation (RSD) are calculated [35].

- Analysis of Unknowns: For an unknown sample, simply acquire its UV spectrum and use the calibrated PLS model to simultaneously predict the concentration of each antibiotic present [35].

Essential Research Reagent Solutions

The following table lists key materials and their functions for implementing the protocols described above.

Table 3: Essential Reagents and Materials for UV-Vis and HPLC Analysis

| Item | Function / Application | Key Considerations |

|---|---|---|

| Quartz Cuvettes / Micro-Volume Plates | Sample holder for UV-Vis measurement [19] [34] | Quartz is transparent to UV light; plastic and glass absorb it. Micro-volume systems (e.g., 2 µL) save sample [19] [34]. |

| High-Purity Solvents & Buffers | Dissolving and diluting samples for both UV-Vis and HPLC [30] [19] | Must be UV-transparent at measured wavelengths; common choices are water, methanol, acetonitrile, and aqueous buffers [19]. |

| Certified Reference Standards | For calibration curve generation in both UV-Vis and HPLC [34] [29] | Essential for accurate quantification. Purity should be certified and traceable (e.g., NIST standards) [34]. |

| Deuterated Solvents (for NMR) | Used in NMR spectroscopy, a powerful technique for structural elucidation [30] | Avoids interference with proton signals in NMR analysis (e.g., D₂O, CDCl₃) [30]. |

| HPLC Columns (C18) | The stationary phase for separating components in reverse-phase HPLC [28] [8] | The workhorse column for many pharmaceutical applications; particle size and column dimensions affect resolution and pressure [28]. |

| Chemometric Software | For developing PLS and other multivariate models for advanced UV-Vis analysis [35] | Required to resolve spectral overlaps in mixtures (e.g., MATLAB, PLS_Toolbox) [35]. |

UV-Vis spectroscopy is the unequivocal choice for high-throughput, cost-effective quantification of pure, well-characterized substances like single-component APIs, proteins, and nucleic acids. Its value is amplified in early-stage development, routine QC of simple formulations, and reaction monitoring where speed is critical.

However, for stability-indicating methods, impurity profiling, and analysis of complex mixtures where specificity is paramount, HPLC remains the gold standard. The emergence of UV-Vis coupled with advanced chemometrics offers a powerful hybrid approach, providing a middle ground for certain multi-analyte determinations without the full cost and complexity of HPLC. The informed scientist strategically deploys each technique based on the specific analytical question at hand.

In the field of drug quantification research, scientists often face a critical decision: when to use High-Performance Liquid Chromatography (HPLC) versus UV-Visible (UV-Vis) spectroscopy. While UV-Vis spectroscopy offers simplicity and cost-effectiveness, HPLC provides superior separation capabilities essential for complex analytical challenges. This guide objectively compares the performance of these techniques, supported by experimental data, to help researchers make informed methodological choices based on their specific analytical needs.

Core Principles and Technical Differences

UV-Vis Spectroscopy operates on the Lambert-Beer Law, where the absorption of light by a sample is directly proportional to the concentration of the absorbing species [36]. This technique provides a simple, rapid means of quantification but lacks inherent separation capabilities, making it susceptible to interference from other absorbing compounds in complex mixtures.

HPLC, in contrast, separates components based on their differential partitioning between a mobile phase and a stationary phase packed within a column [37]. A high-pressure pump forces the mobile phase containing the sample through the column, where different constituents interact with the stationary phase to varying degrees based on physicochemical properties like size, polarity, and charge [37]. This separation mechanism allows HPLC to resolve individual components in complex mixtures before detection.

The following diagram illustrates the fundamental workflow and decision process for selecting between these techniques:

Comparative Performance Data

Experimental studies directly comparing HPLC and UV-Vis spectroscopy demonstrate significant performance differences across key analytical parameters:

Table 1: Method Comparison for Drug Quantification

| Analytical Parameter | HPLC Performance | UV-Vis Performance | Comparative Study Findings |

|---|---|---|---|

| Linearity Range | 0.05-300 µg/mL (Levofloxacin) [8] | 0.05-300 µg/mL (Levofloxacin) [8] | Both techniques demonstrated wide linear ranges |

| Regression Equation | y = 0.033x + 0.010 [8] | y = 0.065x + 0.017 [8] | Both showed excellent correlation (R² > 0.999) |

| Recovery Rates (Low Concentration) | 96.37 ± 0.50% [8] | 96.00 ± 2.00% [8] | Comparable performance at low concentrations |

| Recovery Rates (Medium Concentration) | 110.96 ± 0.23% [8] | 99.50 ± 0.00% [8] | HPLC showed higher deviation at medium concentration |

| Recovery Rates (High Concentration) | 104.79 ± 0.06% [8] | 98.67 ± 0.06% [8] | HPLC showed higher deviation at high concentration |

| Precision (RSD) | <1.50% (Repaglinide) [6] | <1.50% (Repaglinide) [6] | Both demonstrated acceptable precision |

Table 2: Application-Based Method Selection Guide

| Analytical Scenario | Recommended Technique | Experimental Evidence |

|---|---|---|

| Complex Drug Formulations | HPLC | UV-Vis inaccurately measured Levofloxacin in composite scaffolds due to impurity interference [8] |

| Impurity Profiling | HPLC | Effectively separated and quantified multiple Clonidine HCl impurities and degradation products [38] |

| Stability Studies | HPLC | Forced degradation studies under acidic, basic, oxidative, photolytic, and thermal conditions confirmed method specificity [38] |

| Simple Tablet Formulations | UV-Vis or HPLC | Both techniques successfully quantified Lamivudine and Repaglinide in tablets with comparable accuracy [6] [9] |

| Multicomponent Mixtures | HPLC with Advanced Detection | Successfully resolved ternary mixtures of cardiovascular drugs where UV-Vis showed spectral overlap [27] |

| Herbal Medicine Analysis | UV-Vis or HPLC | Strong correlation (R² > 0.99) between techniques for flavonoid quantification in Bauhinia forficata [39] |

HPLC Experimental Protocols

Stability-Indicating Method for Clonidine HCl

Objective: To develop a stability-indicating HPLC method for identification and quantification of Clonidine HCl impurities and degradation products in tablet formulations [38].

Chromatographic Conditions:

- Column: Kromasil C8 (250 × 4.6 mm, 5 µm)

- Mobile Phase: Phosphate buffer (pH 6.9) and acetonitrile (50:50 v/v)

- Flow Rate: 0.8 mL/min

- Injection Volume: 50µL

- Detection: 210 nm (Diode Array Detector)

- Column Temperature: 30°C [38]

Sample Preparation:

- Twenty tablets were crushed and powder equivalent to 1 mg of Clonidine HCl was transferred to a 25 mL volumetric flask

- 15 mL of mobile phase was added and sonicated for 15 minutes with intermittent shaking

- After cooling, volume was made up to mark with mobile phase

- Solution was centrifuged at 4000 RPM for 5 minutes

- Supernatant was filtered through 0.45 µm PVDF membrane filter, discarding first 2 mL of filtrate [38]

Forced Degradation Studies:

- Acidic/Basic Stress: Treatment with HCl/NaOH at room temperature or elevated temperatures

- Oxidative Stress: Treatment with hydrogen peroxide

- Photolytic Stress: Exposure to UV light

- Thermal Stress: Heating solid samples in oven [38]

Comparison Protocol for Levofloxacin Analysis

Objective: To compare HPLC and UV-Vis methods for determining Levofloxacin released from mesoporous silica microspheres/nano-hydroxyapatite composite scaffolds [8].

HPLC Conditions:

- Column: Sepax BR-C18 (250×4.6 mm, 5 µm particle diameter)

- Mobile Phase: 0.01 mol/l KHâ‚‚POâ‚„, methanol and 0.5 mol/l tetrabutylammonium hydrogen sulphate (75:25:4)

- Flow Rate: 1 ml/min

- Detection Wavelength: 290 nm

- Injection Volume: 10 µl for assay determination [8]

UV-Vis Conditions:

- Wavelength Selection: Scanning standard solutions at 200-400 nm

- Quantification Wavelength: Maximum absorption wavelength for Levofloxacin

- Sample Preparation: Direct analysis of samples after appropriate dilution [8]

Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for HPLC Analysis

| Reagent/Material | Function in Analysis | Example Application |

|---|---|---|

| C18 Chromatography Columns | Stationary phase for reverse-phase separation | Levofloxacin separation [8], Repaglinide analysis [6] |

| Methanol and Acetonitrile (HPLC-grade) | Mobile phase components | Organic modifiers in mobile phase [8] [6] |

| Phosphate Buffers | Aqueous mobile phase component | pH control and ion pairing [8] [38] |

| Tetrabutylammonium Salts | Ion-pairing reagents | Improve separation of ionic compounds [8] |

| Internal Standards (e.g., Ciprofloxacin) | Reference for quantification accuracy | Compensation for procedural variations [8] |

| PVDF Membrane Filters | Sample clarification | Removal of particulate matter before injection [38] |

Advanced Applications and Signaling Pathways

HPLC's separation capability is particularly valuable in stability studies and impurity profiling, where it enables the detection and quantification of degradation products that may form under various stress conditions. The following diagram illustrates the degradation pathways and analytical approach for pharmaceutical stability testing:

The choice between HPLC and UV-Vis spectroscopy for drug quantification depends primarily on sample complexity, required specificity, and analytical objectives. UV-Vis spectroscopy serves as an efficient, cost-effective tool for simple formulations where no significant interference exists. However, HPLC emerges as the unequivocal choice for complex mixtures, impurity profiling, and stability studies due to its superior separation capabilities, specificity, and ability to provide comprehensive information about multiple components simultaneously. As demonstrated in comparative studies, while UV-Vis may sometimes show comparable accuracy for specific simple applications, HPLC provides the necessary separation power to ensure accurate results across diverse pharmaceutical analysis scenarios, particularly in regulated environments where comprehensive impurity characterization is mandatory.

The accurate quantification of active pharmaceutical ingredients (APIs) is fundamental to developing effective drug delivery systems. For antibiotics like levofloxacin, a broad-spectrum fluoroquinolone, precise measurement is particularly crucial in controlled-release formulations designed to maintain therapeutic levels while minimizing side effects [8] [5]. Researchers primarily utilize two analytical techniques for this purpose: High-Performance Liquid Chromatography (HPLC) and Ultraviolet-Visible Spectrophotometry (UV-Vis).

While UV-Vis spectroscopy offers simplicity and rapid analysis, HPLC provides separation capabilities that are critical in complex matrices. This case study examines a direct comparison of these methods for quantifying levofloxacin released from an innovative mesoporous silica microspheres/nano-hydroxyapatite (n-HA) composite scaffold, demonstrating HPLC's superior accuracy in this advanced drug delivery context [8].

Methodological Comparison: Experimental Protocols

Drug Delivery System and Sample Preparation

The study utilized a novel biodegradable composite scaffold as a drug-delivery system. The synthesis process involved:

- Synthesis of Mesoporous Silica Nanoparticles (MSNs): MSNs were synthesized using cetyltrimethylammonium bromide (CTAB) as a template and tetraethyl orthosilicate as a silica source, with Fe₃O₄ stabilized by oleic acid to create magnetic nanoparticles [8] [5].

- Drug Loading: Levofloxacin (1,500 µg/ml) was loaded into the MSNs via electrostatic attraction [5].

- Scaffold Fabrication: Nano-hydroxyapatite/polyurethane (n-HA/PU) composite porous scaffolds were synthesized using an in situ foaming method, then immersed in the Levofloxacin-MSN suspension to create the final drug-loaded scaffold [8] [5].

- Sample Collection: The release of levofloxacin was measured in simulated body fluid (SBF), with samples collected at various time points for analysis by both HPLC and UV-Vis methods [8].

HPLC Methodology

The established HPLC protocol provided high specificity for levofloxacin quantification [8]:

- Equipment: Shimadzu liquid chromatograph with LC-2010AHT gradient pump and UV-Visible detector [8].

- Column: Sepax BR-C18 (250 × 4.6 mm, 5 µm particle diameter) maintained at 40°C [8].

- Mobile Phase: 0.01 mol/l KHâ‚‚POâ‚„, methanol, and 0.5 mol/l tetrabutylammonium hydrogen sulphate in proportion (75:25:4), delivered at 1 ml/min flow rate [8].

- Detection: UV detection at 290 nm with injection volumes of 10-20 µl [8].

- Internal Standard: Ciprofloxacin was used to improve quantification accuracy [8].

- Sample Preparation: Samples were mixed with internal standard, vortexed, extracted with dichloromethane, centrifuged, and the supernatant was dried under nitrogen before reconstitution [8].

UV-Vis Methodology

The UV-Vis method provided a simpler alternative but with limitations:

- Equipment: UV-2600 UV-Vis spectrophotometer [8].

- Wavelength Selection: Scanning of standard levofloxacin solutions at 200-400 nm to determine maximum absorption wavelength [8].

- Sample Preparation: Direct measurement of samples without extensive pre-processing [8].

The experimental workflow below illustrates the parallel paths for method comparison:

Critical Comparison: Performance Data and Analytical Outcomes

Quantitative Method Performance

Direct comparison of validation parameters reveals significant differences between the two techniques:

Table 1: Analytical Method Performance Comparison for Levofloxacin Quantification

| Performance Parameter | HPLC Method | UV-Vis Method |

|---|---|---|

| Linear Range | 0.05–300 µg/ml | 0.05–300 µg/ml |

| Regression Equation | y = 0.033x + 0.010 | y = 0.065x + 0.017 |

| Correlation Coefficient (R²) | 0.9991 | 0.9999 |

| Recovery (Low Concentration, 5 µg/ml) | 96.37 ± 0.50% | 96.00 ± 2.00% |

| Recovery (Medium Concentration, 25 µg/ml) | 110.96 ± 0.23% | 99.50 ± 0.00% |

| Recovery (High Concentration, 50 µg/ml) | 104.79 ± 0.06% | 98.67 ± 0.06% |

While both methods demonstrated excellent linearity across the concentration range, the recovery data reveals HPLC's superior consistency, particularly at medium and high concentrations [8]. The precision of HPLC recovery rates (as indicated by smaller standard deviations) highlights its better reproducibility in complex samples.

Accuracy in Complex Drug Delivery Systems

The composite scaffold environment presented particular challenges that differentiated the methods:

- Matrix Interference: The mesoporous silica microspheres/n-HA composite scaffold contained multiple components that could interfere with accurate quantification [8]. HPLC's separation capability effectively isolated levofloxacin from these potential interferents.

- Specificity Challenges: UV-Vis spectroscopy measures total absorbance at a specific wavelength without separation power, making it susceptible to interference from degradation products or scaffold components that co-absorb at similar wavelengths [8] [40].

- Recovery Discrepancies: The consistently higher and more variable recovery rates obtained with HPLC, especially at medium and high concentrations (110.96% and 104.79% respectively), suggest that UV-Vis may underestimate levofloxacin concentration in the presence of scaffold materials [8].

The study concluded that "it is not accurate to measure the concentration of drugs loaded on the biodegradable composite composites by UV-Vis" and identified "HPLC as the preferred method to evaluate sustained release characteristics of Levofloxacin" in such complex drug delivery systems [8].

Essential Research Reagent Solutions

Successful implementation of these analytical methods requires specific high-quality reagents and materials:

Table 2: Essential Research Reagents for Levofloxacin Analysis

| Reagent/Material | Specification | Analytical Function |

|---|---|---|

| Levofloxacin Reference Standard | Pharmaceutical grade (>98% purity) | Primary calibration standard for quantification [8] |

| Ciprofloxacin | Analytical standard grade | Internal standard for HPLC to improve accuracy [8] |

| Methanol | HPLC-grade | Mobile phase component and extraction solvent [8] |

| Tetrabutylammonium Bromide | Analytically pure | Ion-pairing agent in mobile phase to improve separation [8] |

| Potassium Dihydrogen Phosphate (KHâ‚‚POâ‚„) | Analytical grade | Buffer component for mobile phase [8] |

| Simulated Body Fluid (SBF) | Physiological pH and ion composition | Release medium mimicking in vivo conditions [8] |

| Dichloromethane | HPLC-grade | Extraction solvent for sample preparation [8] |

Discussion: Implications for Drug Delivery Research

Method Selection Framework

The comparative data supports a clear decision framework for analytical method selection:

- UV-Vis Applications: Suitable for simple quality control of pure levofloxacin formulations without complex matrices, or for rapid screening when highest accuracy is not critical [40].

- HPLC Applications: Essential for drug release studies from complex delivery systems, stability-indicating assays, impurity profiling, and whenever specific quantification in complex matrices is required [8] [41].

Stability-Indicating Capabilities

Beyond routine quantification, HPLC offers critical stability-indicating properties essential for drug delivery system characterization. A validated stability-indicating RP-HPLC method can separate levofloxacin from its degradation products and process-related impurities, which is crucial for understanding API stability in the delivery system [41] [42]. Forced degradation studies under various stress conditions (acid, base, oxidative, thermal, photolytic) have demonstrated HPLC's ability to monitor levofloxacin stability while detecting degradation products, a capability absent in conventional UV-Vis spectroscopy [42].

Advanced HPLC Configurations

Recent methodological advances further enhance HPLC's applicability for levofloxacin analysis:

- Dual Detection Systems: Simultaneous UV and fluorescence detection provides enhanced sensitivity and confirmation capabilities [43].

- Multi-Component Analysis: HPLC methods can simultaneously quantify levofloxacin alongside other drugs (e.g., amoxicillin, lansoprazole) in combination therapies [44] [45].

- Mass Spectrometry Detection: LC-MS/MS methods offer ultimate specificity and sensitivity for complex biological samples or trace analysis [46] [42].

The following diagram illustrates the decision pathway for method selection based on research objectives:

This case study demonstrates that while UV-Vis spectroscopy offers simplicity and rapid analysis for levofloxacin quantification, HPLC provides definitively superior accuracy and reliability for characterizing drug release from advanced delivery systems like mesoporous silica/n-HA composite scaffolds. The separation capability of HPLC proves essential in complex matrices where scaffold components or degradation products could interfere with accurate quantification.

The experimental evidence shows that HPLC should be the method of choice for precise characterization of levofloxacin release profiles, stability studies, and quality control of complex drug delivery systems. As pharmaceutical formulations grow more sophisticated, the need for specific, stability-indicating analytical methods like HPLC becomes increasingly critical to ensure accurate pharmacokinetic predictions and therapeutic efficacy.

The quantification of active ingredients, such as bakuchiol, in complex cosmetic matrices presents significant challenges for researchers and quality control professionals. Bakuchiol, a meroterpene natural product isolated from Psoralea corylifolia, has gained prominence in cosmetics as a retinoid alternative due to its anti-aging, antioxidant, and anti-inflammatory properties without the associated side effects of retinal derivatives [47] [48]. The complexity of cosmetic formulations, which often include oils, emulsifiers, preservatives, and other functional ingredients, creates a challenging environment for accurate analytical measurement. This case study, framed within a broader thesis comparing UV-Vis spectroscopy with HPLC for drug quantification, examines the limitations of UV-Vis and demonstrates how more sophisticated techniques like HPLC and NMR provide superior analytical solutions for reliable bakuchiol quantification in cosmetic products.

Analytical Methodologies: A Comparative Framework

UV-Vis Spectrophotometry

Experimental Protocol: For bakuchiol analysis via UV-Vis, researchers typically proceed with the following steps [47]:

- Standard Preparation: Prepare a standard solution of pure bakuchiol in ethanol or methanol.

- Sample Preparation: Dissolve or extract the cosmetic product in ethanol. For emulsion-type products, this may involve partial dissolution followed by centrifugation or filtration to obtain a clear supernatant.

- Spectrum Acquisition: Scan the standard and sample solutions across the 200-400 nm range to identify the maximum absorption wavelength (λmax).

- Calibration: Prepare a series of standard solutions at known concentrations and measure their absorbance at λmax (established at 262 nm for bakuchiol) to create a calibration curve.

- Quantification: Measure the absorbance of the sample solution at 262 nm and calculate the bakuchiol concentration using the calibration curve.

The fundamental limitation of this method arises from its lack of separation power; it measures total absorbance at a specific wavelength without distinguishing between the target analyte and other matrix components that may absorb at the same wavelength [5].

High-Performance Liquid Chromatography (HPLC)

Experimental Protocol (HPLC-FLD for Bakuchiol): A developed reversed-phase HPLC method with fluorescence detection offers a more robust approach [49]:

- Extraction: Weigh 0.5 g of cosmetic product accurately. Add tetrahydrofuran (THF) as an extraction solvent in a 1:4 (weight:volume) ratio. Vortex the mixture for 5 minutes.

- Centrifugation: Centrifuge the extract at 14,000 rpm for 10 minutes at 25°C to separate insoluble excipients.

- Chromatographic Separation:

- Column: Zorbax Eclipse Plus C18 (100 × 4.6 mm, 3.5 µm particle size).

- Mobile Phase: Gradient elution with water and acetonitrile.

- Flow Rate: 1.0 mL/min.

- Column Temperature: 25°C.

- Detection: Fluorescence detection with excitation at 264 nm and emission at 338 nm.

- Injection Volume: Typically 10-20 µL.

- Quantification: Identify bakuchiol based on its retention time (approximately 31.8 minutes in some methods [47]) and quantify using a calibration curve constructed from standard solutions.

This method effectively separates bakuchiol from other cosmetic ingredients, mitigating the interference issues plaguing UV-Vis analysis [47] [49].

Quantitative Nuclear Magnetic Resonance (qNMR)

Experimental Protocol (1H qNMR): A protocol for quantifying bakuchiol in cosmetics via 1H qNMR is as follows [47]:

- Sample Preparation: Mix approximately 20-30 mg of the cosmetic product with a deuterated solvent (e.g., CDCl3). For quantitative analysis, add a known amount of an internal standard, such as nicotinamide, which is selected for its stability, lack of reactivity, and suitable solubility.

- Data Acquisition: Acquire 1H NMR spectra on a suitable spectrometer (e.g., 400 MHz). Use specific parameters to ensure quantitative conditions, including a relaxation delay (d1) of at least 5 times the longest T1 relaxation time of the signals of interest.