Why Is My Spectrometer Inaccurate After Cleaning? A Scientist's Guide to Diagnosis and Repair

This article addresses a critical yet often overlooked challenge in biomedical and clinical research: the sudden onset of inaccurate spectrophotometer readings following routine cleaning.

Why Is My Spectrometer Inaccurate After Cleaning? A Scientist's Guide to Diagnosis and Repair

Abstract

This article addresses a critical yet often overlooked challenge in biomedical and clinical research: the sudden onset of inaccurate spectrophotometer readings following routine cleaning. We explore the foundational reasons behind this phenomenon, from misalignment and residual contaminants to calibration drift. A systematic methodological guide for correct cleaning and handling is provided, alongside a detailed troubleshooting framework to diagnose and rectify post-cleaning errors. Finally, we cover validation protocols and comparative analysis techniques to ensure data integrity, empowering researchers to maintain the high instrument performance essential for reliable drug development and analytical results.

Understanding the Link Between Cleaning and Spectrometer Inaccuracy

How Improper Cleaning Introduces Instrumental Errors

For researchers and scientists in drug development, the integrity of spectrometer data is paramount. A common, yet often overlooked, source of inaccurate analysis results is the improper cleaning of the instrument. Contaminants introduced during cleaning can directly interfere with optical components, light paths, and samples, leading to skewed data, failed calibrations, and unreliable experimental outcomes. This guide addresses the specific instrumental errors caused by improper cleaning and provides protocols to correct and prevent them.

How does improper cleaning cause wavelength accuracy errors?

Answer: Improper cleaning can lead to contamination or physical damage to critical optical components, which directly impacts the instrument's wavelength accuracy.

- Contamination of Optical Lenses: Dust, oils, or lint on the monochromator's lenses or the entrance/exit slits can scatter light and cause a shift in the perceived wavelength [1] [2]. This means the wavelength reaching the detector is not the same as the one selected, leading to incorrect readings.

- Damaged Calibration Standards: If the white calibration tile or holmium oxide filter used for wavelength verification is scratched or contaminated during cleaning, it cannot provide a reliable reference point. A scratched tile may no longer reflect light uniformly, while a smudged filter can alter its characteristic absorption peaks, causing the wavelength calibration to fail [3].

What photometric errors result from contaminated surfaces?

Answer: Photometric accuracy, which concerns the intensity of the measured light, is highly susceptible to errors from dirty surfaces.

- Reduced Light Intensity: Dust and debris on the instrument's measurement port, optical windows, or the fiber optic cable can block or scatter light [4]. This reduces the total light intensity reaching the detector, leading to inconsistent and unreliable analysis readings [4].

- Increased Stray Light: Contamination on optical components, such as the monochromator's mirrors and lenses, is a primary source of stray light—light of wavelengths outside the intended bandpass [5] [1]. Stray light causes a positive deviation from Beer's Law, particularly at high absorbance levels, making measured absorbances lower than the true values [1]. This can severely compromise quantitative analysis.

Why does my instrument need recalibration more frequently after cleaning?

Answer: Frequent need for recalibration is a classic symptom of residual contamination from improper cleaning.

- Drifting Analysis: Dirty windows in front of the fiber optic or in the direct light pipe cause instrument analysis to drift more often, necessitating more frequent recalibration [4]. A poorly maintained optical path will result in poor reproducibility and incorrect analysis results [6].

- Unstable Baseline: Contamination on the sample compartment or the cuvette itself can cause an unstable or drifting baseline reading [3]. This "noise" makes it difficult for the instrument to establish a stable zero point, forcing repeated calibration attempts.

Validated Cleaning and Maintenance Protocols

To prevent the errors described above, follow these detailed cleaning methodologies.

Routine Cleaning of External Optical Components

Objective: To safely remove contaminants from accessible optical surfaces without causing damage. Materials: Lint-free wipes, powder-free gloves, and high-purity solvents like methanol or ethanol [3] [7]. Protocol:

- Power Down: Turn off the instrument to ensure safety.

- Wear Gloves: Always wear powder-free gloves to prevent transferring oils from your skin [3].

- Inspect: Visually inspect the surface to be cleaned (e.g., measurement port, sample window) under light.

- Clean: Gently wipe the surface with a lint-free wipe. For stubborn contaminants, moisten the wipe with a small amount of high-purity solvent and wipe gently. Avoid abrasive motions [3] [7].

- Air Dry: Allow the surface to air dry completely before powering the instrument back on.

Handling and Cleaning of Cuvettes

Objective: To ensure sample holders do not introduce contamination or scattering. Materials: Matched quartz or glass cuvettes, lint-free wipes, and a suitable solvent. Protocol:

- Handle with Care: Always hold cuvettes by the frosted sides to avoid placing fingerprints on the clear optical surfaces.

- Rinse: Rinse the cuvette thoroughly with a pure solvent or the blank solution to be used.

- Clean: Use a lint-free wipe to gently dry the exterior optical surfaces. For interior cleaning, repeatedly rinse with solvent.

- Inspect: Hold the clean cuvette up to the light to check for watermarks, dust, or scratches. A scratched cuvette must be replaced [7].

Verification of Cleaning Efficacy Post-Maintenance

Objective: To confirm that cleaning has not introduced errors and the instrument is performing within specification. Materials: Certified reference materials (e.g., holmium oxide filter for wavelength, neutral density filters for photometric accuracy) [3] [2]. Protocol:

- Warm-up: Turn on the instrument and allow it to warm up for 15-30 minutes to ensure stability [7].

- Perform Baseline Calibration: Establish a baseline using a blank reference material appropriate for your instrument [3].

- Wavelength Accuracy Check: Measure a holmium oxide filter, which has sharp, known absorption peaks (e.g., at 536.5 nm). Compare the measured peak positions to the certified values. The instrument should read within a defined tolerance (e.g., ±0.5 nm) [3].

- Photometric Accuracy Check: Measure a sealed neutral density filter with a known absorbance value (e.g., 0.500 AU). The instrument reading should be within the manufacturer's specified tolerance [3].

The logical relationship between improper cleaning practices and the resulting instrumental errors is summarized below.

Quantitative Impact of Cleaning-Related Errors

The following table summarizes how specific cleaning-related issues translate into measurable analytical errors.

| Cleaning-Related Issue | Direct Consequence | Impact on Measurement Data |

|---|---|---|

| Scratched/Dirty White Calibration Tile [3] | Incorrect 100%T (Reflectance) baseline | Photometric accuracy failure; e.g., reading 0.515 AU vs. certified 0.500 AU [3] |

| Dust on Monochromator Optics [1] | Increased Stray Light | Negative deviation from Beer's Law, especially at high absorbance [1] |

| Contaminated Sample Window [4] | Reduced Light Intensity & Drift | High variability (e.g., >5% RSD) in replicate sample analyses [4] |

| Oils on Cuvette Surface [2] | Light Scattering & Absorption | Unstable baseline and inflated noise, masking smaller measurement signals [1] |

Essential Research Reagent Solutions

The table below lists key materials required for proper instrument maintenance and calibration.

| Material / Reagent | Function in Maintenance & Calibration |

|---|---|

| Lint-Free Wipes [3] | Safely remove contaminants from optical surfaces without leaving fibers. |

| Powder-Free Gloves [3] | Prevent contamination of standards, cuvettes, and optical surfaces with skin oils. |

| High-Purity Solvents (e.g., Methanol) [7] | Dissolve and remove organic contaminants from optical components and cuvettes. |

| NIST-Traceable Calibration Standards [3] | Provide an unbroken chain of documentation to national standards for audit-proof calibration. |

| Sealed Neutral Density Filters [3] | Certified reference materials for verifying photometric accuracy. |

| Holmium Oxide Filter [3] | Certified reference material with sharp absorption peaks for verifying wavelength accuracy. |

| Matched Quartz/Glass Cuvettes [7] | Provide a precise and reproducible path length for sample measurement in UV-Vis regions. |

Frequently Asked Questions (FAQs)

Q1: I just cleaned the instrument's sample window, but my readings are now more unstable. What happened? This is often due to residues from the cleaning agent or lint from the cloth used. Ensure you use high-purity solvents and lint-free wipes. Always allow the surface to dry completely before use, as moisture can also cause signal instability [3] [7].

Q2: Can I use laboratory tissue to clean the quartz cuvette? It is not recommended. Laboratory tissues can scratch soft optical surfaces like quartz and often contain binders that can leave a residue. Always use certified lint-free wipes designed for precision optics [3].

Q3: How often should I perform a full wavelength and photometric accuracy check? This depends on usage and criticality. For high-precision work, a daily check with a blank is advised. A full verification with certified standards should be part of a regular maintenance schedule, at least quarterly, or as recommended by the manufacturer. Always recalibrate after any major cleaning or maintenance [3] [7].

Q4: The wavelength check failed after I cleaned the holmium oxide filter. What is the most likely cause? The most likely cause is that the filter was damaged during cleaning. Holmium oxide filters are solid-state standards; if scratched, their certified values are no longer valid. Before assuming an instrument fault, inspect the standard for damage and check its certification date [3].

Troubleshooting Guide: Common Issues After Cleaning

1. How can I tell if the spectrometer's optics were damaged during cleaning? Inspect the optics under a bright light, using magnification if possible. Look across reflective surfaces (nearly parallel to your line of sight) to see contaminants and not just reflections. For polished surfaces like lenses, look through the optic (perpendicular to your line of sight). Compare any scratches or digs (pits) to a scratch-dig paddle; if defects exceed the manufacturer's specification, the optic may need replacement to restore performance [8] [9].

2. Why are my analysis results for carbon, phosphorus, and sulfur consistently low after I cleaned the instrument? This often indicates a problem with the vacuum pump, not the cleaning itself. The vacuum pump purges the optical chamber to allow low-wavelength light (used for measuring elements like Carbon, P, and S) to pass through. A malfunctioning pump introduces atmosphere, causing a loss of intensity for these elements. Symptoms include a pump that is hot, loud, gurgling, leaking oil, or smoking, requiring immediate service [4].

3. My instrument now requires more frequent recalibration. Could this be related to recent cleaning? Yes. Dirty windows on the spectrometer, particularly the one in front of the fiber optic cable and in the direct light pipe, can cause analysis drift and poor results. If these windows were not cleaned properly or were left dirty, it would necessitate more frequent recalibration. Ensure these windows are cleaned as part of your maintenance routine [4].

4. After cleaning, the instrument's readings are inconsistent and unstable. What should I check? This could be a sign of contaminated argon or a contaminated sample. Check if the burn appears white or milky, which suggests contaminated argon. Also, ensure samples are properly prepared using a new grinding pad to remove coatings and that they are not touched with bare hands or quenched in water or oil, which can re-contaminate them [4].

5. The light intensity is low after cleaning the optical path. What is the most likely cause? This is frequently caused by misalignment during reassembly. If the lens is not properly aligned and focused on the light source, the collected light will not be intense enough for accurate readings. This is similar to a camera flash aimed away from the subject. Trained operators can often perform simple lens alignment fixes [4]. Also, check for debris left in the light path or a misaligned sample cuvette [10].

Routine Inspection & Cleaning Procedures

Inspection Protocol: Before and after any cleaning, optics should be inspected [9]. Use a magnifier, loupe, or microscope with suitable illumination to identify dust, fingerprints, or other contaminants [11] [8]. Distinguishing contamination from physical damage like scratches or pits is critical, as cleaning cannot repair physical damage [11].

Cleaning Methodology: A Stepwise Approach

Step 1: Blow Off Loose Contaminants

- Tool: Use a canister of inert dusting gas or a blower bulb. Do not use your mouth, as saliva can contaminate the surface [11] [8] [9].

- Method: Hold the gas can upright about 6 inches (15 cm) away. Start the gas flow away from the optic, then wave the nozzle at a grazing angle in a figure-eight pattern over the surface [8] [9]. This is the only safe cleaning method for extremely sensitive components like ruled diffraction gratings and unprotected metallic mirrors [11] [9].

Step 2: Solvent Cleaning for Persistent Contamination

- If blowing is insufficient, use solvents with appropriate wipes (e.g., lens tissue, pure cotton Webril wipes) [8] [9]. Wipes should always be moistened with solvent and never used dry [9].

- Drop and Drag Method (for flat optics): Hold a clean sheet of lens tissue above the optic. Place 1-2 drops of a quick-drying solvent (e.g., acetone, methanol, isopropyl alcohol) on the tissue. The solvent's weight will bring the tissue into contact with the surface. Slowly and steadily drag the tissue across the optic to lift off contaminants [8] [9].

- Lens Tissue with Forceps Method (for mounted or curved optics): Fold a lens tissue so a clean portion contacts the optic, and hold it with forceps. Dampen the tissue with solvent, then wipe the optical surface in a smooth motion, slowly rotating the tissue to present a clean surface [8] [9].

The table below summarizes critical risks and precautions for handling key spectrometer components.

| Component | Primary Risk During Cleaning | Correct Handling & Cleaning Procedure | Key Precautions |

|---|---|---|---|

| Optics (Lenses, Windows) | Scratching, damaging coatings, leaving streaks [11] [9] | Use compressed air first. Use solvent with lens tissue or cotton wipes. Use the "drop and drag" or "wipe with rotation" method [8] [9]. | Never use dry wipes. Avoid excessive solvent that can pool. Do not wipe back and forth [11] [9]. |

| Sensitive Optics (Gratings, Unprotected Metal Mirrors) | Permanent damage from physical contact; rippled or soft surfaces are easily damaged [11] [9] | Blowing with compressed air is the ONLY approved method. No physical contact with the optical surface is permitted [11] [8] [9]. | Never attempt to wipe these surfaces. Be gentle with air pressure on fragile components like pellicle beamsplitters [9]. |

| Lamps | Contamination from skin oils, physical damage leading to hot spots or failure [9] [12] | Handle with gloves. Avoid touching the glass envelope directly. Ensure the lamp is cool before removal or cleaning. | Contaminants can absorb radiation, creating hot spots and causing permanent damage [9]. |

| General Instrument | Misalignment of optical components after disassembly [4] | Follow manufacturer guidelines for any disassembly. Keep the operating environment stable and clean [12]. | Temperature fluctuations can cause components to expand/contract, affecting the light path [2]. |

The Scientist's Toolkit: Essential Cleaning Materials

Proper tools are essential for safe and effective cleaning. The table below lists key items for your cleaning kit.

| Tool/Reagent | Function | Usage Notes |

|---|---|---|

| Nitrile/Latex Gloves | Prevents skin oils from contaminating optical surfaces [11] [8]. | Use powder-free gloves to avoid contamination [13]. |

| Compressed Air / Inert Dusting Gas | Removes loose dust and particles without physical contact [11] [8] [9]. | Do not shake the can; hold upright to prevent propellant discharge [8]. |

| Lens Tissue | Soft, disposable wipes for cleaning robust optics with solvent [11] [8] [9]. | Use each sheet only once. Fold to ensure a clean surface contacts the optic [9]. |

| Webril Wipes (Pure Cotton) | Soft, absorbent wipers for cleaning most optics [8] [9]. | Fold the wipe to use a folded edge and avoid lint from the outer edges [8]. |

| Optical Grade Solvents | Dissolves and removes contaminants like fingerprints and grease. | Acetone, Methanol, Isopropyl Alcohol. All are toxic and flammable; use with caution [11] [8] [9]. |

| Optical Tweezers | Handles small optical components without touching surfaces [8] [9]. | Prevents scratches and contamination from handling. |

| Magnifier / Microscope | Inspects optical surfaces for contaminants and damage before/after cleaning [11] [8] [9]. | Essential for identifying small particles and defects. |

| Scratch-Dig Paddle | Calibrated gauge to categorize the size of surface scratches and digs [8] [9]. | Helps determine if an optic is still within specification. |

Post-Cleaning Performance Verification Workflow

After cleaning critical components, follow this logical workflow to verify your spectrometer's performance is restored. This process helps you systematically diagnose any remaining issues.

The Impact of Residual Contaminants and Cleaning Agents on Optical Paths

Troubleshooting Guide: Common Symptoms and Solutions

The table below outlines common symptoms, their potential impact on data, and immediate corrective actions related to contaminants in optical systems.

| Observed Symptom | Potential Cause | Impact on Data | Corrective Action |

|---|---|---|---|

| Unstable readings, poor reproducibility [6] | Dirty optical path lenses or entrance slit [6] | Incorrect analysis results and poor reproducibility [6] | Clean optical path lenses and re-calibrate the instrument [6]. |

| Increased scatter, "hot spots" on optic [8] [9] | Dust, water, or skin oils on optical surface [8] [9] | Increased scattering and absorption of radiation, leading to permanent damage [8] [9]. | Clean optic using approved methods (e.g., blowing off surface, solvent cleaning) [8] [9]. |

| Low light intensity value [6] | Dirty lens or polluted entrance slit [6] | Erroneous concentration calculations due to reduced transmitted light. | Clean the lens and entrance slit [6]. |

| Drifting calibration, poor analysis [4] | Dirty windows in front of fiber optic or in direct light pipe [4] | Frequent need for recalibration and highly inaccurate readings [4]. | Clean the specified windows regularly as part of maintenance [4]. |

| Low intensity/loss of low wavelengths (C, P, S) [4] | Malfunctioning vacuum pump [4] | Incorrect values for elements measured in the lower wavelength spectrum [4]. | Service or replace the vacuum pump [4]. |

| Inaccurate analysis, high photometric error [1] | Stray light from dust on optical components [1] | Measured absorbance lower than true absorbance, serious quantitative errors [1]. | Ensure optics are clean; check and service monochromator [1]. |

| White or milky burn appearance [4] | Contaminated argon gas [4] | Inconsistent and unstable analytical results [4]. | Regrind samples to remove contaminants; ensure argon supply is pure [4]. |

| High, erratic blanks during trace metal analysis [13] | Contaminated reagents (water, acids) or labware [13] | False positive results, elevated baselines, inaccurate quantitation at ppb/ppt levels [13]. | Use high-purity reagents (ICP-MS grade) and dedicated, clean labware [13]. |

Frequently Asked Questions (FAQs)

How do contaminants physically affect light in an optical path?

Contaminants like dust, particulates, and dried residues cause light scattering, deflecting photons from their intended path. Thin films, such as residual solvents or skin oils, can create interference patterns and absorb specific wavelengths, reducing light throughput. This directly violates the assumptions of the Beer-Lambert law, leading to inaccurate absorbance measurements and concentration calculations [8] [1] [9].

What is the only cleaning method approved for extremely delicate optics?

For highly sensitive optics such as holographic gratings, ruled gratings, and first-surface metallic mirrors, the only approved cleaning method is blowing off the surface with inert dusting gas or a blower bulb. Physical contact with a wipe or solvent is likely to cause permanent damage [8] [9].

How can I scientifically justify that my optical path is clean enough?

For critical quantitative applications, performance verification is essential. Use National Institute of Standards and Technology (NIST)-traceable standards to verify photometric accuracy and wavelength accuracy. Regularly running these checks after cleaning provides objective data that the optical path is functioning within specified parameters and that residues are not causing significant analytical error [5] [1].

Can the solvents I use for cleaning cause their own residue problems?

Yes. Low-purity solvents can leave behind inorganic residues upon evaporation. Always use optical-grade or high-purity solvents (e.g., HPLC or spectroscopic grade) for cleaning optical components. Furthermore, pooling and slow drying of any cleaning solvent, even high-purity ones, can leave streaks [8] [13] [9].

What is the proper way to inspect an optic for cleanliness?

First, work in a clean environment and wear gloves to avoid introducing new contaminants. Use a bright light shone at an angle across the optical surface to reveal dust and smudges via specular reflection. For small components, a magnifier or microscope is essential for inspecting for micro-scratches or tiny particles. Compare any defects against a scratch-dig paddle to determine if they fall within the manufacturer's specifications [8] [9].

The Scientist's Toolkit: Essential Cleaning Materials

| Tool / Material | Function | Application Notes |

|---|---|---|

| Powder-Free Gloves | Prevents transfer of skin oils and particles to optical surfaces [8] [13]. | Powdered gloves often contain zinc and should be avoided [13]. |

| Inert Dusting Gas / Blower Bulb | Removes loose, particulate contamination without physical contact [8] [9]. | First line of cleaning. Do not use breath from your mouth [8]. |

| Lens Tissue | Provides a soft, lint-minimizing material for wiping optical surfaces with solvents [8] [9]. | Use fresh sheets for each wipe. Fold to present a clean surface [8]. |

| Webril Wipes (Pure Cotton) | Soft, absorbent wipers for solvent cleaning [8] [9]. | Fold edges inward to avoid lint from the cut edges [8]. |

| Optical Tweezers | Allows for safe handling of small optical components without touching surfaces [8] [9]. | Prevents scratches and oil contamination during handling and cleaning [8]. |

| High-Purity Solvents | Dissolves and removes organic films and contaminants [8] [13]. | Acetone, Methanol, Isopropyl Alcohol. Use optical or HPLC grade. Most are toxic and flammable [8] [13]. |

Experimental Protocol: Validating Cleaning Efficacy for an Optical Path

This protocol provides a detailed methodology to verify that a cleaning procedure effectively removes contaminants without damaging optical components or leaving interfering residues.

Scope and Application

This procedure is designed for flat, reflective optical surfaces (e.g., mirrors, beamsplitters) accessible for direct measurement. It may require modification for complex internal optical paths, where indirect verification via system performance checks is necessary.

- Visual Inspection: Under bright, angled light, visually inspect and document the condition of the optic, noting the location and type of contaminants (dust, fingerprints, etc.).

- Performance Baseline: Before cleaning, collect a baseline transmittance or reflectance spectrum of the optic across its working wavelength range.

Controlled Contamination (Optional)

For a rigorous validation, a controlled contamination study may be performed.

- Procedure: Apply a defined contaminant (e.g., 5 µL of synthetic sebum or a known dust particulate) to a non-critical area of the optic.

- Incubation: Allow the contaminant to reside on the surface for a specified time (e.g., 1 hour) under controlled conditions.

- Step 1: Dry Gas Blowing. Using a canister of inert dusting gas held upright and 6 inches away, blow the entire surface at a grazing angle using a figure-eight pattern. This removes loose particles.

- Step 2: Solvent Cleaning (Drag and Drop Method).

- Inspection: Re-inspect to locate remaining contaminants.

- Drag: Hold a clean sheet of lens tissue above the optic. Apply 1-2 drops of optical-grade acetone to the tissue. Slowly and steadily drag the damp tissue across the optical surface, ensuring it does not lift off.

- Drying: The surface should air-dry quickly without streaks.

Post-Cleaning Verification

- Visual Inspection: Re-inspect the optic as in Step 2. The surface should be free of visible streaks, residues, and particulates.

- Performance Verification: Measure the transmittance/reflectance spectrum again under identical conditions. The post-cleaning spectrum should match the baseline or show improved performance.

- Stray Light Test: Use a suitable cutoff filter (e.g., for a UV-Vis spectrometer, a potassium iodide or sodium nitrite solution) to measure stray light at a critical wavelength (e.g., 220 nm). Compare the stray light value before and after cleaning; an effective clean should not increase stray light [5] [1].

Acceptance Criteria

- Visual: No visible contamination under bright, angled light.

- Performance: Post-cleaning spectrum is within ±1% of the baseline spectrum or manufacturer's specification across the working range.

- Stray Light: Stray light measurement after cleaning is below the instrument's specification and is not elevated compared to the pre-cleaning baseline.

Inter-laboratory comparisons (ILCs) are systematic exercises carried out by a group of laboratories to compare their measurement performance or assess a measurement standard [14]. Within quality assurance frameworks, these comparisons serve as a vital tool for laboratories to confirm the accuracy and reliability of their data, especially following instrument maintenance procedures like cleaning [14] [15].

This case study explores how ILCs reveal measurement variances, providing a structured troubleshooting guide and FAQs. This resource is designed to help researchers, particularly those working with spectrometers, diagnose and resolve issues where analytical results become inaccurate after routine instrument cleaning, a challenge directly relevant to thesis research on this topic.

Key Concepts and Definitions

To effectively troubleshoot, a clear understanding of core measurement concepts is essential. The table below defines key terms frequently encountered in ILC reports and instrument qualification protocols.

| Concept | Definition & Purpose |

|---|---|

| Inter-laboratory Comparison (ILC) | An exercise performed by multiple laboratories to determine laboratory performance or validate a measurement standard [14]. |

| Consensus Mean | An assigned value derived from the results of the participating laboratories in a comparison [14]. |

| Measurement Variance | The observed variation in results for the same measurand across different laboratories or instruments. |

| Stray Light | Unwanted light, outside the intended spectral band, that reaches the detector and can cause significant photometric errors, especially at high absorbances [5] [1]. |

| Photometric Accuracy | The correctness of the instrument's absorbance or transmittance scale, verified using certified reference materials [16]. |

| Wavelength Accuracy | The correctness of the instrument's wavelength scale, typically checked using materials with sharp, known absorption peaks like holmium oxide [16]. |

Essential Research Reagent Solutions for Accurate Spectrophotometry

Proper calibration and operation of spectrophotometers rely on specific, high-quality reagents and materials. The following table details essential items for ensuring data integrity.

| Item | Function & Importance |

|---|---|

| NIST-Traceable Calibration Standards | Certified reference materials (e.g., neutral density filters, holmium oxide) with a documented chain of calibration to national standards. They are non-negotiable for verifying photometric and wavelength accuracy [16]. |

| High-Purity Solvents | Spectroscopic-grade solvents are critical for preparing samples and blanks. Impurities can lead to significant background absorption and erroneous results [1]. |

| Internal Standards (e.g., Maleic Acid, Benzyl Benzoate) | Substances of known, high purity added in a known amount to the sample in quantitative NMR and other analyses. They correct for variations in sample preparation and instrument response [17]. |

| Certified Cuvettes & Sample Holders | Precision-matched cuvettes ensure consistent optical path length. Inconsistencies here are a direct source of measurement error [2]. |

| Lint-Free Wipes & Powder-Free Gloves | Essential for handling optics and standards without introducing contamination or scratches, which can scatter light and affect readings [16]. |

Experimental Protocols for Diagnosing Spectrometer Inaccuracy

Adhering to standardized protocols is fundamental for identifying the root cause of measurement drift. The workflows below are adapted from established methodologies in spectroscopic analysis [17] [16] [2].

Protocol 1: Systematic Post-Cleaning Verification

Objective: To confirm the spectrometer's basic performance is restored after a cleaning procedure. Materials: NIST-traceable wavelength and photometric standards, appropriate solvents, lint-free wipes, instrument manual.

- Instrument Warm-up: Ensure the instrument has been powered on for the manufacturer's specified time to stabilize, typically 30-60 minutes.

- Baseline/Blank Measurement: Using a clean cuvette, measure the pure solvent that will be used for sample analysis to establish a baseline.

- Wavelength Accuracy Check:

- Measure a holmium oxide or other certified wavelength standard.

- Record the peak locations and compare them to the certified values.

- Acceptance Criterion: The measured peaks should typically be within ±1 nm of the certified values [16].

- Photometric Accuracy Check:

- Measure a certified neutral density filter or standard solution with a known absorbance value (e.g., 0.5 AU).

- Record the measured absorbance.

- Acceptance Criterion: The reading should be within the tolerance specified on the standard's certificate (e.g., ±0.005 AU) [16].

- Stray Light Check (if applicable):

- Use a solution or filter that is opaque at a specific wavelength (e.g., a potassium chloride solution for 200 nm).

- Measure the transmittance at that wavelength.

- Acceptance Criterion: The measured transmittance should be below the instrument's specification (often <0.1% T) [5].

Protocol 2: Quantitative NMR (qNMR) Method Verification

Objective: To verify the accuracy of quantitative analysis on a spectrometer, such as after maintenance, by comparison to a known standard. Materials: Active Pharmaceutical Ingredient (API), certified internal standard (e.g., maleic acid, benzyl benzoate), deuterated solvent, NMR spectrometer.

- Sample Preparation: Precisely weigh approximately 30-50 mg of API and 20-30 mg of internal standard. Dissolve them in 1-2 mL of an appropriate deuterated solvent [17].

- Parameter Optimization:

- Determine the longitudinal relaxation time (T1) for the signals of interest using an inversion-recovery experiment.

- Set the repetition time (RT) to be greater than 5*T1 to ensure complete relaxation between scans and accurate integration [17].

- Set the acquisition parameters (number of scans, acquisition time) to achieve a signal-to-noise ratio (SNR) of at least 300 for high accuracy [17].

- Data Acquisition and Processing: Acquire the spectrum and integrate the selected peaks for both the analyte and the internal standard.

- Recovery Rate Calculation: Calculate the amount of API using the known amount of internal standard. The recovery rate should ideally be between 97% and 103% when using deuterated solvents and proper SNR [17].

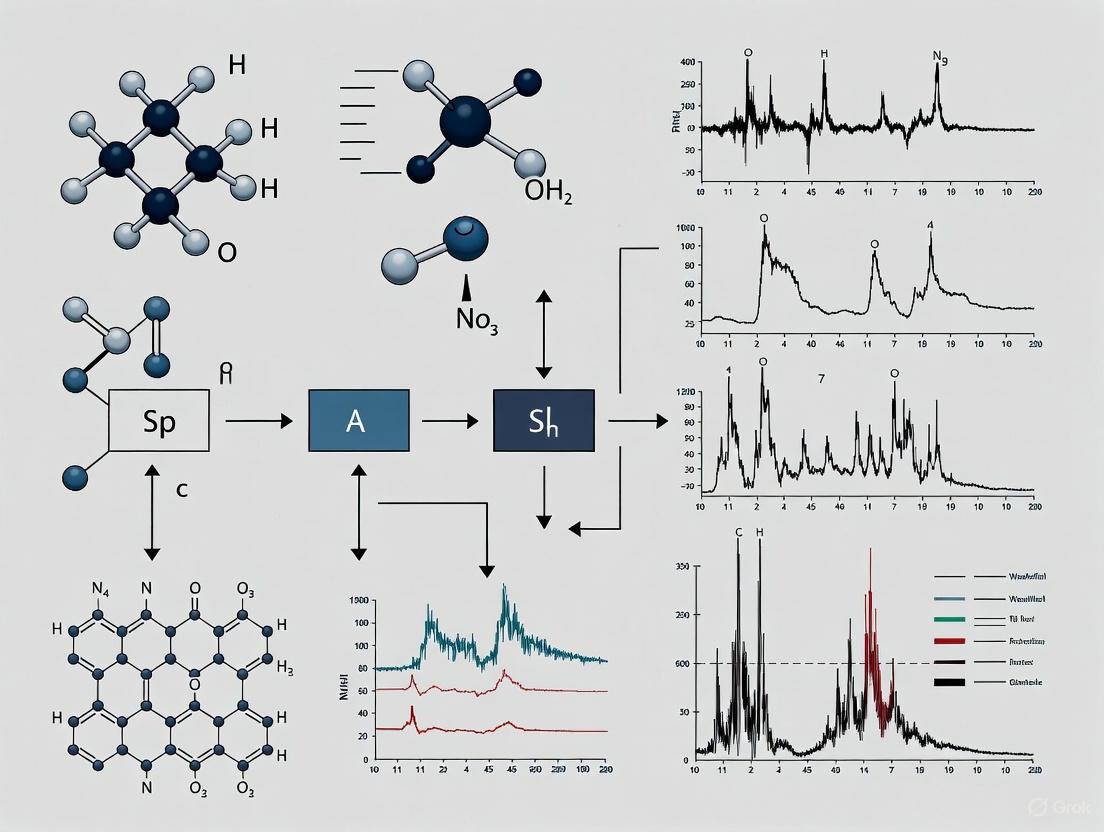

Diagram 1: Diagnostic Workflow for Post-Cleaning Inaccuracies

Troubleshooting Guides & FAQs

Frequently Asked Questions (FAQs)

Q1: Our lab just cleaned our spectrophotometer's optical windows, and now the absorbance readings for our standard samples are consistently low. What is the most likely cause? A: The most probable cause is that the optical windows were not reassembled correctly or were left misaligned after cleaning [2] [4]. Even a slight misalignment can cause a significant loss of light intensity reaching the detector, leading to lower-than-expected absorbance readings. Follow the diagnostic workflow in Diagram 1, starting with a visual inspection and proceeding to a photometric accuracy check.

Q2: After routine maintenance, our quantitative NMR results for pharmaceutical products are showing high variance and a positive bias. Where should we start investigating? A: Begin by verifying your sample preparation protocol, specifically the critical acquisition parameters. Ensure your repetition time (RT) is sufficiently long ( > 5*T1) to allow for complete spin-lattice relaxation, as insufficient relaxation is a common source of quantitative error [17]. Furthermore, confirm that the signal-to-noise ratio (SNR) is adequate (e.g., ≥300) for the required accuracy [17].

Q3: Why would cleaning the spectrometer cause wavelength accuracy errors? A: While cleaning itself shouldn't directly affect the wavelength calibration, physical disturbance of the instrument during the cleaning process can occur. Knocking or vibrating the monochromator can cause misalignment of the grating or other optical components, leading to a shift in the wavelength scale [2]. This underscores the importance of performing a wavelength accuracy check with a holmium oxide filter after any major maintenance [16].

Troubleshooting Guide Table

The following table outlines common symptoms, their potential causes, and recommended actions based on findings from interlaboratory studies and instrument manuals.

| Symptom | Potential Cause | Mitigation Strategy |

|---|---|---|

| Unstable or drifting readings | Instrument not fully warmed up; contaminated calibration standard; dirty optics post-cleaning [16] [4]. | Allow instrument to warm up for manufacturer's specified time. Thoroughly re-clean calibration standards and optical windows with lint-free wipes and appropriate solvent [16]. |

| Wavelength accuracy check fails | Physical misalignment of monochromator from instrument disturbance; use of an expired or degraded wavelength standard [16] [2]. | Verify the certification of your wavelength standard. If the standard is valid, the instrument likely requires realignment by a qualified service technician [16]. |

| Photometric accuracy check fails | Contaminated or scratched calibration standard; misaligned optics or sample holder after reassembly [16] [2]. | Meticulously clean the calibration standard. If it is scratched, it must be replaced. Check the alignment of the sample compartment and optics [16]. |

| High background noise | Contaminated light path (windows, lenses); aging light source; faulty detector [4] [1]. | Re-clean all accessible optical windows in the light path. If the problem persists, the lamp or detector may need replacement [4]. |

| Inconsistent results on the same sample | Poor sample preparation; incorrect probe contact; unstable environmental conditions [2] [4]. | Ensure consistent sample presentation (e.g., flat, clean surface). Control laboratory temperature and humidity. Check that the probe is making secure contact [2] [4]. |

Inter-laboratory comparisons provide the foundational evidence that measurement variance is a real and managed risk in analytical science [14] [15]. For researchers investigating why spectrometer results become inaccurate after cleaning, a structured approach is vital. This involves using certified reference materials for verification, adhering to standardized experimental protocols with particular attention to acquisition parameters, and following a systematic diagnostic workflow. By integrating these rigorous practices, laboratories can quickly differentiate between instrument malfunctions, methodological errors, and sample-related issues, thereby ensuring the return to generating precise and accurate data essential for drug development and scientific research.

Best Practices for Safe and Effective Spectrometer Maintenance

Step-by-Step Guide to Manufacturer-Recommended Cleaning Procedures

FAQs on Spectrometer Cleaning

Q1: Why is cleaning my spectrometer so important, and how can improper cleaning affect my analysis? Proper cleaning is crucial for maintaining the accuracy and reliability of your spectrometer. Inaccurate analysis results are a common symptom of an instrument that is not properly maintained [4]. Specific issues arising from improper cleaning include:

- Analysis Drift and Poor Results: Dirty optical windows can cause instrument analysis to drift more frequently, necessitating more frequent recalibration and resulting in poor analysis readings [4].

- Contamination Introduction: Touching samples with bare hands or cleaning optical components improperly can transfer oils and grease, leading to contaminated samples and unstable or inconsistent results [4].

- Permanent Damage: Using harsh detergents, solvents, or abrasives on the instrument's finish or optical windows can cause permanent damage. Liquid contacting windows or optics can degrade performance, and fingerprints can permanently damage mirrors [18].

Q2: What materials and reagents should I use for cleaning? Using the correct materials is essential to avoid damaging sensitive components. The table below lists key solutions and their functions.

Table 1: Research Reagent Solutions for Spectrometer Cleaning

| Item | Function | Usage Notes |

|---|---|---|

| Lint-free, soft cloth | Gently wipes surfaces without leaving residue; used on white calibration disks and instrument exteriors [19] [18]. | Ensure the cloth is clean. Do not use abrasive wipes. |

| Denatured / Isopropyl Alcohol | Cleans excessive dirt and contaminants from external surfaces and white calibration disks [19] [20]. | Dampen the cloth lightly; never apply directly to the instrument [18]. |

| Canned Air | Removes dust from the instrument's aperture and electronics enclosure without introducing moisture or oil [19] [18]. | Do not use compressed air from a compressor. Do not shake the can or turn it upside down [19]. |

| Mild Soap Solution | Cleans the general exterior of the instrument [18]. | Use a soft cloth lightly dampened with the solution. |

Q3: What should I NEVER do when cleaning my spectrometer? To prevent irreversible damage, always avoid the following:

- Do not use harsh detergents, solvents, or abrasives on any part of the instrument [18].

- Do not allow any liquid to come into contact with optical windows, mirrors, or components inside the sample compartment [18].

- Do not touch optical windows or the white calibration disk with your fingers, as fingerprints can severely degrade performance [18].

- Do not use compressed air from a compressor to clean the interior, as it can contain moisture or oil that will contaminate the instrument [19].

Troubleshooting Guide: Inaccurate Results After Cleaning

A common and critical issue is discovering that your spectrometer's analysis results have become inaccurate following a cleaning procedure. The workflow below outlines a logical diagnostic path to identify and resolve the root cause.

Symptom: Results greatly vary between tests on the same sample, or readings are consistently off [4].

Protocol 1: Inspection and Corrective Cleaning

- Objective: To identify and remove any residual contamination introduced during cleaning.

- Materials: Lint-free gloves, canned air, a lint-free cloth, isopropyl alcohol [4] [19] [20].

- Methodology:

- Inspect the White Calibration Disk: Check for shininess and absence of fingerprints or particles. If dirty, gently wipe with a clean, lint-free cloth in circular motions. For excessive dirt, use a cloth lightly dampened with denatured alcohol [19].

- Inspect Internal Optical Windows: Visually check the windows in front of the fiber optic and in the direct light pipe for dust or smudges [4]. To remove dust, use canned air with short bursts. Critical: Do not touch or wipe these windows, as they scratch easily [18].

- Inspect and Clean the Cuvette:

Protocol 2: System Recalibration

- Objective: To restore photometric accuracy after cleaning and inspection.

- Materials: NIST spectrophotometer calibration standards, certificate of calibration, powder-free gloves, software for the spectrophotometer [22].

- Methodology:

- Warm up the spectrophotometer for at least 45 minutes [22].

- Wearing powder-free gloves, handle the NIST calibration standard.

- Follow the manufacturer's software procedure for a photometric accuracy scan.

- Insert the blank (if provided) and zero the instrument.

- Insert the NIST calibration standard and record the reading.

- Compare the reading to the data on the certificate of calibration. If the data matches within the stated tolerances, the calibration is complete [22].

If Inaccuracy Persists: If the problem continues after following these protocols, the issue may be a damaged component (like a scratched window) or internal misalignment caused during cleaning. At this point, you should contact the manufacturer's technical support for professional service [4] [18].

Selecting the Right Tools and Solvents for Different Component Types

Why Proper Cleaning is Critical for Accurate Results

In the context of spectrometer analysis, inaccurate results following a cleaning procedure are a significant and common challenge. The precision of these instruments is paramount in research and drug development, and their optical components are particularly sensitive. Using an incorrect solvent or an abrasive tool can leave residues, cause scratches, or induce fluorescence, which in turn scatters light, creates spectral interference, and leads to significant photometric errors. This guide provides specific, actionable protocols to ensure your cleaning practices restore, rather than degrade, instrument performance.

FAQ: Troubleshooting Post-Cleaning Spectrometer Issues

Q1: After cleaning the mass spectrometer source, my instrument's sensitivity is still poor. What could be wrong? A1: Poor sensitivity after cleaning often points to incomplete contamination removal or improper reassembly.

- Troubleshooting Steps:

- Re-inspect Metal Parts: Ensure all metal components have been polished to a mirror finish, free of microscopic scratches that can harbor contamination. A second pass with a finer abrasive may be necessary [23].

- Check Insulator Cleaning: Verify that ceramic insulators were properly cleaned. If sandblasted, ensure no abrasive media remains. Alternatively, a high-temperature bake-out might be required to remove stubborn volatile deposits [23].

- Verify Filament Alignment: An incorrectly aligned filament after reassembly will drastically reduce sensitivity. Consult manufacturer guidelines to check the filament's position relative to the source aperture [23].

Q2: The absorbance readings on my UV-Vis spectrophotometer are unstable and drift after I cleaned the sample compartment. What is the cause? A2: Drifting readings are frequently caused by solvent residues that were not allowed to fully evaporate or by contaminants introduced during the cleaning process.

- Troubleshooting Steps:

- Inspect for Residues: Check all surfaces, especially windows and the cuvette holder, for streaks or haze from cleaning solvents. Re-clean with a high-purity solvent and a fresh, lint-free cloth [18] [24].

- Allow for Proper Drying: After using any solvent, allow the compartment to ventilate and dry completely with the lid open before initiating measurements. This prevents solvent vapors from interfering with the light path [24].

- Check the Cuvette: Ensure the cuvette itself was not contaminated during cleaning and is free of fingerprints and lint [24].

Q3: I followed a cleaning procedure, but now my optical emission spectrometer shows low intensity for carbon and phosphorus. What should I check? A3: This symptom strongly indicates a problem with the vacuum system, which may have been disturbed or contaminated during cleaning.

- Troubleshooting Steps:

- Inspect the Vacuum Pump: Check the vacuum pump oil for signs of contamination. If the pump was near the cleaning activity, it may have ingested solvents or dust. Look for pump issues like overheating, unusual noise, or oil leaks [4].

- Check Vacuum Seals and Fittings: Ensure all seals and O-rings in the vacuum path were properly reinstalled and are free from damage. A small leak can significantly impact the analysis of low-wavelength elements like Carbon and Phosphorus [4] [6].

Experimental Protocols for Correct Cleaning

General Workflow for Spectrometer Component Cleaning

The following diagram outlines the universal decision-making process for cleaning spectrometer components, from initial assessment to final testing.

Protocol 1: Cleaning a Mass Spectrometer Ion Source

This detailed methodology is adapted from procedures used by professional service organizations [23].

I. Disassembly

- Tools Required: Jewelers' screwdrivers, small pliers, tweezers, lint-free cloths, and nylon gloves [23].

- Procedure:

- Safety First: Ensure all power and vacuum pumps to the mass spectrometer are turned off and the source has cooled completely [23].

- Vent the System: Bring the vacuum chamber to atmospheric pressure.

- Documentation: Before disconnection, take digital photographs of the source from multiple angles, paying close attention to electrical wire hookups and the orientation of parts and magnets [23].

- Disconnect and Remove: Carefully disconnect electrical leads and remove the source from its mounting assembly.

- Systematic Disassembly: Disassemble the source, placing metal parts for abrasive cleaning in one beaker. Place delicate parts like ceramics, insulators, and polymers in a separate beaker [23].

II. Cleaning by Material Type Table: Cleaning Methods for Mass Spec Source Components

| Component Type | Recommended Cleaning Method | Critical Precautions |

|---|---|---|

| Stainless Steel Parts | Abrasive polishing with motorized tool (e.g., Dremel) using a felt buffing wheel and polishing compound, followed by sequential solvent washing [23]. | Polish thoroughly to remove all carbon residues and microscopic scratches. Avoid forcing parts. |

| Ceramic Insulators | Sandblasting with glass beads, acid washing, or high-temperature bake-out [23]. | Ensure all abrasive media is removed after sandblasting. |

| Vespel Insulators & O-Rings | Gentle solvent wash followed by air drying [23]. | These cannot be abrasively cleaned. Avoid high temperatures. |

| Gold Plated Parts | Solvent wash only, followed by low-temperature bake-out [23]. | Never use abrasive tools, as the gold coating will be damaged. |

| Optical Windows | Use a gentle stream of clean, dry air or nitrogen to remove dust. Do not use liquids or wipe [18] [19]. | Fingerprints and liquid cleaners can permanently damage optical coatings and performance. |

III. Reassembly and Testing

- Reassembly: Using lint-free gloves, reassemble the source precisely by reversing your disassembly steps, referring to the photographs taken initially [23].

- Filament Installation: Carefully install and align the filament according to the manufacturer's specifications, as misalignment is a primary cause of poor sensitivity [23].

- Testing: After reinstalling the source and pumping down the system, perform an auto-tune or sensitivity test to verify performance has been restored [23].

Protocol 2: Routine Cleaning of Spectrometer External Optics & Surfaces

Cleaning Optical Windows (e.g., on FTIR, UV-Vis)

- Objective: Remove dust without damaging fragile coatings.

- Procedure:

- Turn off the instrument [18].

- Use a gentle stream of clean, dry, compressed air or nitrogen. Direct the stream across the window surface to blow dust away [18] [19].

- Critical: Do not touch the window with your fingers. Do not apply any liquid or attempt to wipe the window, as this can permanently damage it [18].

Cleaning the Instrument Exterior and Touchscreen

- Objective: Remove surface dirt and contaminants without damaging finishes or electronics.

- Procedure:

- Turn off and disconnect the power supply to avoid shock hazard [18].

- For the exterior, use a soft, clean cloth lightly dampened with mild soap and water. Gently wipe the surfaces [18].

- For a touchscreen, apply a small amount of glass cleaner to a clean cloth first, then gently wipe the screen. Never apply cleaner directly to the screen [18].

- Avoid: Harsh detergents, solvents, abrasives, and allowing liquid to run into vents or ports on the instrument [18].

The Scientist's Toolkit: Research Reagent Solutions

Table: Essential Solvents and Tools for Spectrometer Maintenance

| Item | Function / Use | Key Considerations |

|---|---|---|

| High-Purity Solvents | ||

| HPLC Grade Methanol | Washing metal and ceramic parts; final rinsing. | Low UV absorbance, high volatility. Store in sealed containers to avoid moisture [25]. |

| HPLC Grade Acetonitrile | Washing parts for LC-MS systems. | Excellent for removing organic residues; low UV cutoff [25]. |

| HPLC Grade Water (Deionized) | Aqueous cleaning and preparing blends. | Must be free of bacteria and particles. Use fresh [25]. |

| Denatured Alcohol | Cleaning white calibration disks (if necessary). | Use sparingly and only for stubborn contaminants on non-optical surfaces [19]. |

| Abrasives & Tools | ||

| Motor Tool (e.g., Dremel) | Polishing metal source parts to a mirror finish. | Use with felt buffing wheels and fine polishing compound at high RPM [23]. |

| Micro Mesh Abrasive Sheets | Hand-polishing complex metal geometries. | Provides a fine, scratch-free finish [23]. |

| Glass Bead Sandblaster | Cleaning ceramic insulators. | Effective for removing stubborn deposits [23]. |

| Consumables | ||

| Lint-Free Wipes | Wiping and handling all cleaned components. | Essential for preventing fiber contamination [23] [19]. |

| Nylon/Latex-Free Gloves | Handling parts during disassembly/assembly. | Prevents fingerprints and skin oils [23]. |

| Canned Air | Dusting off optical windows and apertures. | Prevents introducing oil/moisture vs. compressor air. Do not shake can [19]. |

| Membrane Filters (0.2 µm) | Filtering solvents before use. | Ensures solvents are particle-free [25]. |

The Critical Role of Post-Cleaning Calibration and Standardization

Troubleshooting Guides

Guide 1: Resolving Inaccurate Analysis Results After Cleaning

Problem: After cleaning the spectrometer, subsequent analysis results are inconsistent, drift, or do not match known reference values.

Explanation: Cleaning is essential, but it can subtly shift the instrument's optical system. Contamination or moisture residue from cleaning can create new interference, while the physical act of cleaning might slightly misalign sensitive components. Recalibration restores the instrument's reference points and ensures it measures against a known standard [26].

Check 1: Verify Calibration Status

- Action: Perform a full instrument calibration using NIST-traceable standards [26].

- Why: This is the most direct way to correct for any drift caused by the cleaning process. Do not assume a recently cleaned instrument is still in calibration.

Check 2: Inspect for Contamination or Residue

- Action: Re-inspect all cleaned surfaces, especially optical windows and the sample compartment, for streaks, lint, or residue from cleaning agents. Use a fresh, lint-free wipe and appropriate solvent for a second cleaning if needed [12] [24].

- Why: Cleaning solutions or oils from skin can leave a thin film that scatters or absorbs light, leading to erroneous readings [2].

Check 3: Confirm Component Reassembly

Check 4: Allow for Instrument Re-equilibration

Guide 2: Addressing Persistent Calibration Failures Post-Cleaning

Problem: The spectrometer fails its calibration routine or produces out-of-tolerance errors immediately after cleaning and attempted recalibration.

Explanation: If calibration fails after a proper cleaning, the issue may lie with the calibration standards themselves, a critical component damaged during cleaning, or a deeper instrumental fault that the cleaning process has uncovered [26].

Check 1: Inspect and Clean Calibration Standards

- Action: Examine the calibration standards (e.g., white reference tiles, neutral density filters) for scratches, cracks, or contamination. Clean them meticulously according to manufacturer instructions [26].

- Why: The accuracy of calibration is entirely dependent on the integrity of the standard. A single fingerprint on a white calibration tile is a common cause of photometric calibration failure [26].

Check 2: Troubleshoot Specific Calibration Parameters

- Use the table below to diagnose which aspect of the calibration is failing.

| Calibration Parameter | Symptom of Failure | Common Post-Cleaning Cause & Solution |

|---|---|---|

| Photometric Accuracy [28] | Absorbance/reflectance readings for a known standard are outside acceptable tolerance. | Cause: Contaminated or scratched calibration standard [26].Solution: Thoroughly clean or replace the standard. |

| Wavelength Accuracy [28] | Measured peak positions of a reference material (e.g., Holmium Oxide) are shifted from certified values. | Cause: Misalignment of optics during reassembly; outdated standard [26].Solution: Verify standard is valid. If so, instrument may require professional service. |

| Stray Light [28] | High background signal or inaccurate readings at high absorbance levels. | Cause: Contamination on optical components (lenses, mirrors) inside the sample compartment that were not properly cleaned or were damaged during cleaning [2].Solution: Re-clean internal optics carefully; may require professional service. |

- Check 3: Seek Professional Service

Frequently Asked Questions (FAQs)

Q1: Why is calibration necessary immediately after cleaning the instrument? Calibration is required after cleaning because the process can affect the instrument's baseline state. Residues from cleaning agents can alter the optical path, and handling components can cause minor shifts in alignment. Calibration re-establishes known reference points, ensuring that subsequent sample measurements are accurate and traceable [2] [26].

Q2: What is the difference between calibration and standardization in this context? Standardization (or "blanking") is a routine adjustment performed frequently, often before a series of measurements, to account for short-term drift and define the baseline with a specific solvent or reference tile. Calibration is a more comprehensive procedure that verifies and adjusts the instrument's performance against certified standards to ensure its wavelength, photometric accuracy, and other key parameters are within specified tolerances over the long term [12] [26].

Q3: A colleague cleaned the optics, and now the readings are unstable and drift over time. What is the most likely cause? The most probable cause is that the instrument and its components did not have sufficient time to thermally stabilize after cleaning and before use. Turn the instrument on and allow it to warm up for the manufacturer-recommended time (typically 15-30 minutes) before attempting to standardize or take measurements [24]. Other causes include residual moisture on optical surfaces or a loosely reassembled component.

Q4: Can the wrong type of wipe used for cleaning cause calibration issues? Yes. Using non-lint-free wipes can leave tiny fibers on optical surfaces and calibration standards. These fibers scatter light, which can lead to signal noise, unstable readings, and failed calibration checks. Always use high-quality, lint-free wipes for cleaning any part of the spectrophotometer [26].

Experimental Protocols & Workflows

Post-Cleaning Recalibration and Verification Workflow

The following diagram outlines the critical steps to verify instrument performance after cleaning.

Detailed Calibration Protocol According to USP Guidelines

This protocol details key tests for a comprehensive calibration after instrument maintenance, based on standard pharmacopeia procedures [28].

Photometric Accuracy

- Objective: Verify the instrument correctly measures absorbance/reflectance intensity.

- Method: Measure a certified reference material (e.g., a neutral density filter or potassium dichromate solution) at a specified wavelength. Compare the measured value to the certified value. The deviation must be within the manufacturer's specified tolerance [28] [26].

Wavelength Accuracy

- Objective: Ensure the instrument's wavelength scale is correct.

- Method: Using a standard with sharp, well-defined peaks (e.g., Holmium oxide solution or filter), scan across its characteristic peaks. The recorded peak positions must match the certified wavelengths within a specified tolerance (e.g., ±1 nm) [28] [26].

Stray Light

- Objective: Detect unwanted light that bypasses the sample and reaches the detector.

- Method: Use a solution that acts as a sharp-cut filter (e.g., potassium chloride for UV light). At a wavelength where the solution should block all light, any signal detected by the instrument is classified as stray light and must be below the acceptable threshold [28].

The Scientist's Toolkit: Essential Research Reagents & Materials

The table below lists key materials required for effective post-cleaning calibration.

| Item | Function | Critical Consideration |

|---|---|---|

| NIST-Traceable Standards [26] | Provide an unbroken chain of measurement traceability to national standards for audit compliance and verifying instrument accuracy. | Certificates must be current; store and handle according to manufacturer instructions to prevent degradation. |

| Holmium Oxide Filter/Solution [28] [26] | A primary standard for verifying wavelength accuracy due to its sharp, well-characterized absorption peaks across UV-Vis range. | |

| Neutral Density Filters [28] [26] | Certified filters with known absorbance values used to verify the photometric (absorbance/reflectance) accuracy of the instrument. | Inspect for scratches or delamination before use; clean only with lint-free wipes. |

| Lint-Free Wipes [26] | Remove contaminants from optical surfaces, cuvettes, and calibration standards without introducing fibers that cause light scatter. | Never use laboratory tissues or cloths that shed lint. |

| Potassium Chloride Solution [28] | Used for stray light verification, particularly in the UV range, as it is opaque at specific short wavelengths. | Prepare with high-purity water and chemicals for accurate results. |

| Sealed Cuvette filled with Solvent [24] | Serves as a perfect, stable blank for establishing the baseline and checking for drift or contamination in the optical path. | Ensure the cuvette is impeccably clean and sealed to prevent evaporation. |

Developing a Proactive and Documented Maintenance Schedule

For researchers in drug development, the accuracy of spectrometer analysis is paramount. A clean instrument is fundamental to this accuracy. However, a recurring and frustrating challenge documented in research is the onset of inaccurate analysis results immediately following cleaning procedures. These inaccuracies often manifest as unexpected drift, poor reproducibility, or incorrect values for key elements. This guide provides a structured, proactive maintenance schedule and targeted troubleshooting to directly address this paradox, ensuring that cleaning—a necessary activity—does not compromise data integrity.

Understanding the Impact of Maintenance on Data Accuracy

Regular maintenance is not optional; it is a critical component of quality assurance in analytical chemistry. A well-maintained spectrometer ensures data accuracy, instrument longevity, and operational safety [4] [29]. The precision required for drug development means that even minor deviations in instrument performance can lead to significant errors in research outcomes.

The core thesis problem—inaccurate results after cleaning—typically stems from a few critical areas:

- Residual Contamination: Inadequate cleaning can leave residues that interfere with optical paths.

- Misalignment: Sensitive optical components like lenses or mirrors can be accidentally nudged during cleaning.

- Incorrect Reassembly: Parts not reinstalled correctly post-cleaning can cause operational issues.

- Use of Improper Cleaning Materials: Materials that scratch, lint, or chemically damage components can degrade performance.

A proactive and documented schedule helps isolate the variable introduced during cleaning, making troubleshooting faster and more effective.

Foundational Maintenance Concepts

The Role of Calibration

Calibration is the process of establishing a relationship between the instrument's signal and known reference concentrations. Proper calibration is essential for attaining accurate quantitative results, especially when measuring low-level concentrations [30]. It is important to distinguish between:

- Standardization: A quick check and adjustment performed frequently (e.g., daily or every 8 hours) to correct for short-term drift [12].

- Calibration: A more comprehensive procedure that establishes the instrument's response curve across a concentration range, performed less frequently.

The Criticality of a Controlled Environment

The operating environment directly impacts spectrometer stability. Key factors to control include:

- Temperature and Humidity: Maintain a stable temperature (e.g., 15-25°C) and relative humidity (e.g., below 60-80%) to prevent condensation on optical components and calibration drift [29] [7].

- Vibration and Magnetic Interference: Place the instrument on a stable bench away from equipment that generates vibrations or strong magnetic fields, which can damage delicate optics and cause measurement errors [7].

- Air Quality: A dust-free environment prevents particles from settling on optical components, reducing light transmittance and accuracy [29] [12].

Proactive Maintenance Schedule

A proactive schedule combines daily, weekly, monthly, and annual tasks. Documentation of every action is crucial for tracking performance and identifying trends. The following workflow provides a logical sequence for executing and verifying maintenance activities.

Maintenance Workflow

Detailed Maintenance Task Table

Adherence to the following schedule is the primary defense against analysis drift and post-cleaning inaccuracies.

Table: Proactive and Documented Maintenance Schedule

| Frequency | Task Category | Specific Actions | Documentation Requirements |

|---|---|---|---|

| Daily | Operational Readiness | - Allow proper warm-up (15-30 min) [7].- Perform instrument standardization [12].- Visual inspection for obvious damage or leaks. | Record warm-up time, standardization results, and any observations. |

| Weekly | Preventive Cleaning | - Clean instrument exterior with soft, lint-free cloth [12] [7].- Clean sample handling areas (e.g., cuvette holders).- Check and clean grinding tools for solid samples [4]. | Note cleaning date, materials used, and any pre-existing contamination. |

| Monthly | Optical & System Check | - Inspect and clean external optical windows (fiber optic, light pipe) [4] [6].- Check argon purity and supply.- Verify vacuum pump oil level and color (if applicable). | Record light intensity values, argon pressure, vacuum levels, and pump status. |

| Quarterly | Performance Verification | - Perform wavelength calibration using certified standards [31] [7].- Run certified reference materials (CRMs) to verify analytical accuracy.- Check and clean or replace air filters. | Document calibration results, CRM recovery rates, and any corrective actions taken. |

| Annually | Comprehensive Service | - Full professional calibration and certification [29] [7].- Internal optical inspection and cleaning by trained technician.- Light source output check and replacement if needed [7]. | Archive full service report and certification document. |

Troubleshooting Guide: Inaccurate Results After Cleaning

This section directly addresses the core thesis problem, providing a targeted diagnostic path.

Problem: Data is unstable or drifts after cleaning the optical windows.

- Potential Cause: The windows were cleaned but not thoroughly dried, leaving streaks or a residue that scatters light. Alternatively, the wrong cleaning solvent was used.

- Solution: Re-clean the windows using the manufacturer-recommended solvents and lint-free wipes. Ensure the windows are completely dry before reinstalling them. Perform a recalibration [4] [6].

Problem: Low wavelength elements (C, P, S) show incorrect values after maintenance.

- Potential Cause: Disturbing the vacuum system during cleaning or failing to achieve proper vacuum after reassembly. A malfunctioning pump will cause atmosphere to enter the optic chamber, reducing the intensity of low wavelengths [4].

- Solution: Check the vacuum pump. Ensure it starts automatically and is not leaking oil, hot to the touch, or making unusual noises. Monitor the vacuum value curve for stability [4] [6].

- Potential Cause: The lens was scratched during cleaning, the entrance slit was polluted, or a fiber optic cable was damaged or dislodged [6].

- Solution: Visually inspect the cleaned components for damage. Ensure all connections are secure. If the hardware appears intact, a professional service visit may be required to realign optics or replace components.

Problem: Consistent poor recovery of low-concentration standards after calibration.

- Potential Cause: Contamination introduced during cleaning of the sample introduction system, or a contaminated calibration blank. Contamination can originate from reagents, or deposition in the sample introduction system [30].

- Solution: Use high-purity reagents and ensure all cleaned parts are thoroughly rinsed with appropriate solvents. Re-prepare calibration standards from fresh, certified sources.

Essential Research Reagent Solutions

The quality of materials used in maintenance and calibration is as important as the procedures themselves.

Table: Key Reagents and Materials for Spectrometer Maintenance

| Item | Function | Critical Specification |

|---|---|---|

| Certified Reference Materials (CRMs) | For quarterly and annual performance verification to ensure analytical accuracy. | NIST-traceable, matrix-matched to your samples where possible. |

| Wavelength Calibration Standards | To validate and correct the wavelength accuracy of the spectrometer [31]. | Stable absorption spectra with sharp, known peaks (e.g., rare earth oxides). |

| High-Purity Solvents | For cleaning optical windows and sample components without leaving residues. | Spectroscopic or HPLC grade, supplied in clean, sealed containers. |

| Lint-Free Wipes | To clean optics and sensitive surfaces without introducing fibers or scratches. | Non-abrasive, low-lint material recommended by the instrument manufacturer. |

| High-Purity Argon Gas | To create an inert atmosphere for spark or plasma excitation, preventing unwanted reactions. | Typically 99.998% purity or higher to avoid contamination from oxygen or moisture [4]. |

| Vacuum Pump Oil | To maintain the proper vacuum in the optical chamber for low-wavelength analysis. | The specific grade recommended by the spectrometer or pump manufacturer. |

Frequently Asked Questions (FAQs)

Q1: We just cleaned our spectrometer's lenses, but now the results for carbon are consistently low. What is the most likely cause? This is a classic symptom of a vacuum system issue, potentially disturbed during cleaning. The vacuum pump purges the optic chamber to allow low wavelengths (like carbon's) to pass through. Check that the vacuum pump is operating normally, not leaking oil, and that the vacuum value is stable and within specification [4] [6].

Q2: How often should we really standardize our instrument? The manual says every 4 hours, but this seems excessive. Standardization frequency depends on required precision and environmental stability. While every 8 hours is a common rule of thumb, follow the manufacturer's guidance, especially for high-precision work. More frequent standardization is recommended if the internal sensor temperature changes significantly (e.g., >5°C) [12]. When in doubt, standardize more frequently.

Q3: After cleaning the ATR crystal, our baseline shows negative peaks. What does this mean? Negative peaks strongly indicate that the ATR element was not perfectly clean when the background spectrum was collected. The system is subtracting the "dirt signature" that was in the background from your sample spectrum. Wipe the crystal again with a suitable solvent, collect a new background, and the problem should resolve [32].

Q4: What is the biggest mistake people make when calibrating for low-concentration samples? The most common mistake is using a calibration curve that includes standards at very high concentrations. The error from the high-concentration standards dominates the curve fit, leading to massive inaccuracies at the low end. For accurate low-level results, construct your calibration curve using only low-level standards close to your expected sample concentrations [30].

A proactive and meticulously documented maintenance schedule is the cornerstone of reliable spectrometer performance. It transforms maintenance from a reactive, problem-solving burden into a predictable, quality-driven process. By understanding the intricate relationship between cleaning, calibration, and component care—and by rigorously documenting every step—researchers and drug development professionals can definitively resolve the challenge of inaccurate results post-cleaning, ensuring their data remains unimpeachable and their research progresses with confidence.

Diagnosing and Correcting Post-Cleaning Performance Issues

A Systematic Troubleshooting Checklist for Sudden Inaccuracy

Troubleshooting Guide: Key Questions and Answers

This guide addresses common issues that can lead to sudden inaccuracy in spectrometer analysis, particularly after cleaning procedures.

Q1: My spectrometer's analysis results for Carbon, Phosphorus, and Sulfur are consistently low. What should I check?

- Potential Cause: A malfunctioning vacuum pump. The vacuum pump purges the optic chamber to allow low wavelengths to pass through. If it fails, the atmosphere enters the chamber, causing low-wavelength elements like C, P, and S to lose intensity or disappear [4].

- Troubleshooting Steps:

- Monitor Performance: Check for constant readings below normal levels for carbon, phosphorus, and sulfur [4].

- Physical Inspection: Check if the pump is smoking, hot to the touch, extremely loud, or making gurgling noises. If the pump is leaking oil, it requires immediate replacement [4].

- Check Vacuum Value: A vacuum value that drops quickly can indicate an air leak. Check the tightness of the vacuum cover and the sealing ring [6].

Q2: After cleaning, my data is unstable and the instrument requires frequent recalibration. What is the likely cause?

- Potential Cause: Dirty optical windows. Contamination on the windows in front of the fiber optic or in the direct light pipe can cause instrumental drift and poor analysis readings [4].

- Troubleshooting Steps:

- Clean the Windows: Clean the two primary windows (in front of the fiber optic and in the direct light pipe) according to the manufacturer's instructions [4].

- Regular Maintenance: Implement a scheduled maintenance plan for cleaning optical components. Contamination on the instrument's lens or entrance slit can also cause poor reproducibility and unstable data [6].

Q3: The burn during analysis looks white or milky, and the results are inconsistent. What does this indicate?

- Potential Cause: Contaminated argon or a contaminated sample [4].

- Troubleshooting Steps:

- Re-grind Samples: Use a new grinding pad to remove plating, carbonization, or protective coatings before analysis [4].

- Avoid Re-contamination: Do not quench samples in water or oil. Avoid touching the sample with bare hands, as skin oils can cause contamination [4].

- Check Argon Supply: Ensure you are using high-purity argon and that the supply lines are not contaminated.

Q4: The light intensity value has dropped, and the excitation spark is louder than usual. What should I investigate?

- Potential Cause: Improper probe contact or a dirty excitation table [4] [6].

- Troubleshooting Steps:

- Inspect the Spark: If the sound is louder and there is a bright light escaping from the pistol face, the probe may not be contacting the surface correctly. This can cause incorrect results or even dangerous high-voltage discharge [4].

- Increase Argon Flow: Temporarily increase the argon flow from the standard 43 psi to 60 psi to improve the analysis environment [4].

- Clean the Spark Chamber: Over time, the excitation table can accumulate debris, leading to leakage and irregular discharge. Clean the excitation table and spark chamber regularly [6].

Q5: I am seeing unexpected peaks in my UV-Vis spectrum. How can I resolve this?

- Potential Cause: Sample contamination or issues with the cuvette [33].

- Troubleshooting Steps:

- Clean Cuvettes/Substrates: Thoroughly wash cuvettes or substrates before measurement. Handle them only with gloved hands to avoid fingerprints [33].

- Verify Sample Purity: Check that your sample has not been contaminated during preparation, decanting, or dissolution [33].

- Ensure Correct Cuvette Type: Use quartz glass cuvettes for measurements in the UV range, as they have high transmission in UV and visible light. Ensure plastic disposable cuvettes are compatible with your solvents [33].

The table below summarizes other common problems and their solutions for quick reference.

| Symptom | Possible Cause | Troubleshooting Action |

|---|---|---|

| No peaks in data [34] | Column cracks, detector issue, auto-sampler failure | Check column for cracks, verify detector flame/gas flow, ensure auto-sampler and syringe function [34] |

| High background/noise [13] | Contaminated labware, acids, or water | Use high-purity acids/water; use FEP or quartz labware; avoid borosilicate glass for trace analysis [13] |

| Data instability, poor reproducibility [6] | Dirty optical path, poor vacuum, aging components | Clean lenses and entrance slit; check vacuum pump function; inspect fiber optic for aging [6] |

| Low signal intensity in UV-Vis [33] | Misaligned setup, damaged optical fibers, high sample concentration | Ensure proper alignment of components; replace damaged fibers; dilute sample or use cuvette with shorter pathlength [33] |

| Results vary greatly on the same sample [4] | Need for recalibration | Recalibrate using a properly prepared, flat sample. Follow software sequence and analyze the first standard five times in a row on the same burn spot [4] |

The Scientist's Toolkit: Essential Research Reagent Solutions

Using high-purity reagents and proper materials is critical for avoiding contamination and ensuring accurate results.

| Item | Function | Importance in Preventing Error |

|---|---|---|

| High-Purity Water (Type I) [13] | Diluting standards and samples, rinsing labware | Low elemental contamination is essential for parts-per-billion/trillion analysis to avoid false positives. |

| High-Purity Acids (e.g., HNO₃) [13] | Sample digestion, dilution, and preservation | High-purity acids with known low elemental backgrounds prevent the introduction of contaminants. |

| Fluorinated Ethylene Propylene (FEP) Labware [13] | Storing and preparing samples and standards | Leaches fewer contaminants compared to glass (e.g., boron, silicon, sodium) and minimizes sample adsorption. |